charging JEEP CHEROKEE 1994 Service Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1667 of 1784

In the mid-position the gauge port is open. This po-

sition is used for pressure testing and for recovery of

the system.

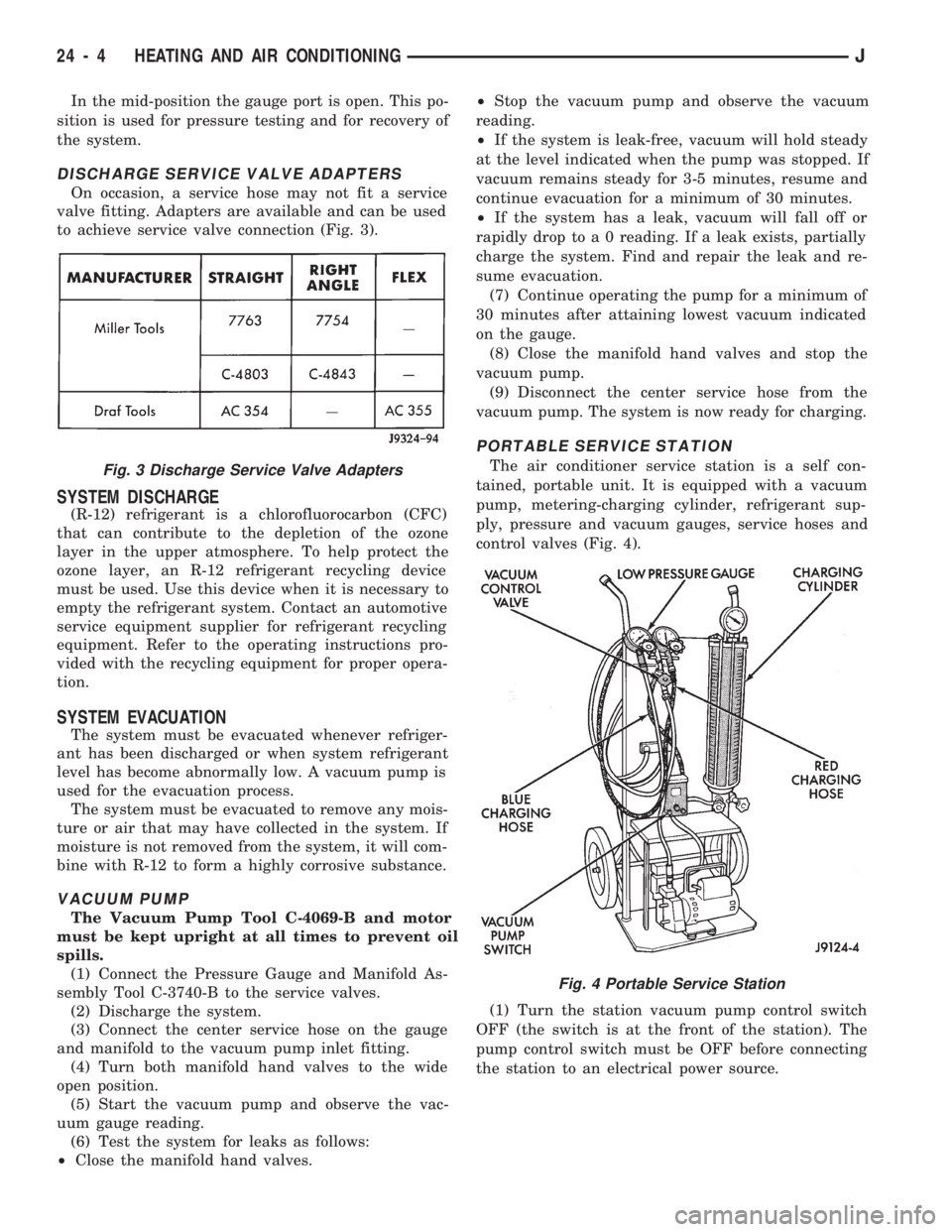

DISCHARGE SERVICE VALVE ADAPTERS

On occasion, a service hose may not fit a service

valve fitting. Adapters are available and can be used

to achieve service valve connection (Fig. 3).

SYSTEM DISCHARGE

(R-12) refrigerant is a chlorofluorocarbon (CFC)

that can contribute to the depletion of the ozone

layer in the upper atmosphere. To help protect the

ozone layer, an R-12 refrigerant recycling device

must be used. Use this device when it is necessary to

empty the refrigerant system. Contact an automotive

service equipment supplier for refrigerant recycling

equipment. Refer to the operating instructions pro-

vided with the recycling equipment for proper opera-

tion.

SYSTEM EVACUATION

The system must be evacuated whenever refriger-

ant has been discharged or when system refrigerant

level has become abnormally low. A vacuum pump is

used for the evacuation process.

The system must be evacuated to remove any mois-

ture or air that may have collected in the system. If

moisture is not removed from the system, it will com-

bine with R-12 to form a highly corrosive substance.

VACUUM PUMP

The Vacuum Pump Tool C-4069-B and motor

must be kept upright at all times to prevent oil

spills.

(1) Connect the Pressure Gauge and Manifold As-

sembly Tool C-3740-B to the service valves.

(2) Discharge the system.

(3) Connect the center service hose on the gauge

and manifold to the vacuum pump inlet fitting.

(4) Turn both manifold hand valves to the wide

open position.

(5) Start the vacuum pump and observe the vac-

uum gauge reading.

(6) Test the system for leaks as follows:

²Close the manifold hand valves.²Stop the vacuum pump and observe the vacuum

reading.

²If the system is leak-free, vacuum will hold steady

at the level indicated when the pump was stopped. If

vacuum remains steady for 3-5 minutes, resume and

continue evacuation for a minimum of 30 minutes.

²If the system has a leak, vacuum will fall off or

rapidly drop to a 0 reading. If a leak exists, partially

charge the system. Find and repair the leak and re-

sume evacuation.

(7) Continue operating the pump for a minimum of

30 minutes after attaining lowest vacuum indicated

on the gauge.

(8) Close the manifold hand valves and stop the

vacuum pump.

(9) Disconnect the center service hose from the

vacuum pump. The system is now ready for charging.

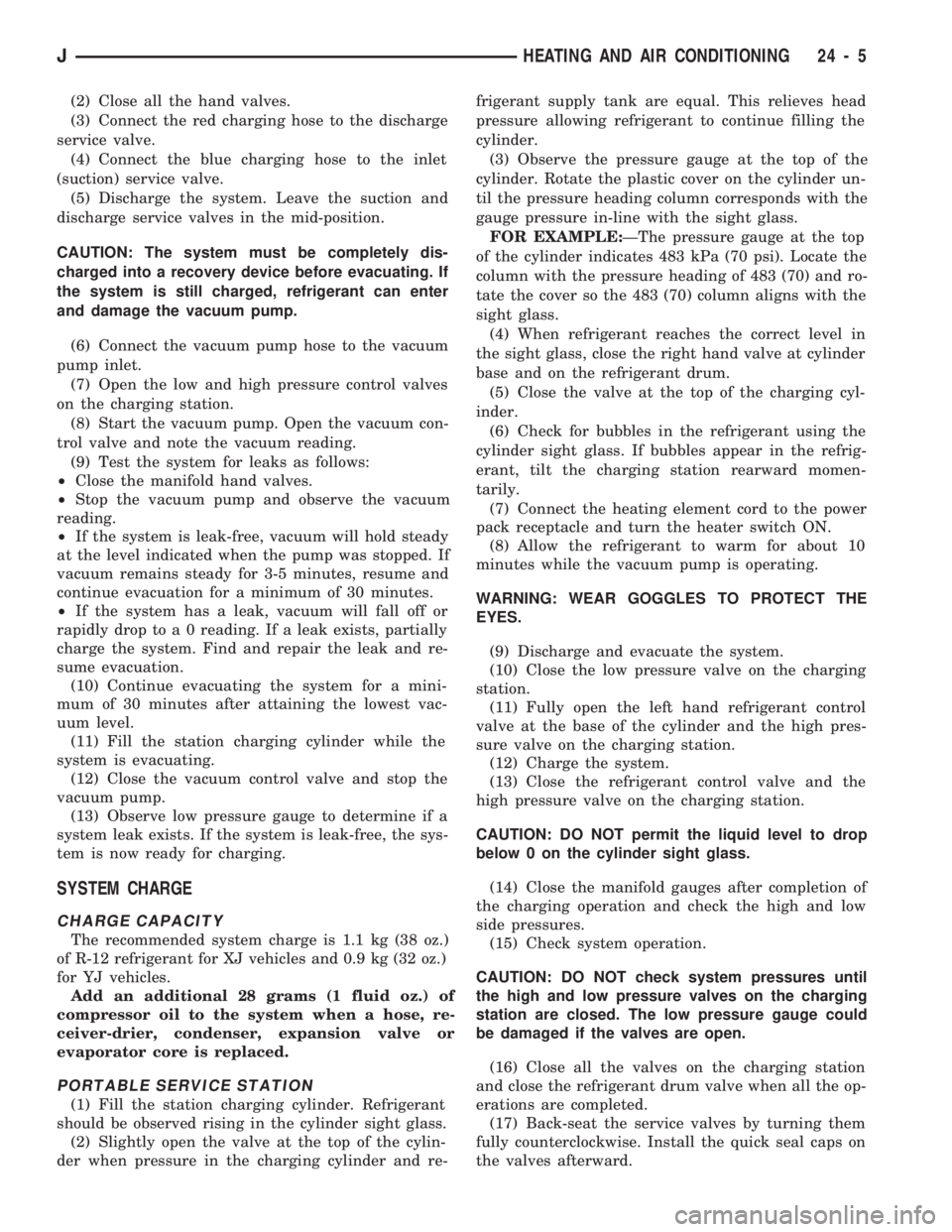

PORTABLE SERVICE STATION

The air conditioner service station is a self con-

tained, portable unit. It is equipped with a vacuum

pump, metering-charging cylinder, refrigerant sup-

ply, pressure and vacuum gauges, service hoses and

control valves (Fig. 4).

(1) Turn the station vacuum pump control switch

OFF (the switch is at the front of the station). The

pump control switch must be OFF before connecting

the station to an electrical power source.Fig. 3 Discharge Service Valve Adapters

Fig. 4 Portable Service Station

24 - 4 HEATING AND AIR CONDITIONINGJ

Page 1668 of 1784

(2) Close all the hand valves.

(3) Connect the red charging hose to the discharge

service valve.

(4) Connect the blue charging hose to the inlet

(suction) service valve.

(5) Discharge the system. Leave the suction and

discharge service valves in the mid-position.

CAUTION: The system must be completely dis-

charged into a recovery device before evacuating. If

the system is still charged, refrigerant can enter

and damage the vacuum pump.

(6) Connect the vacuum pump hose to the vacuum

pump inlet.

(7) Open the low and high pressure control valves

on the charging station.

(8) Start the vacuum pump. Open the vacuum con-

trol valve and note the vacuum reading.

(9) Test the system for leaks as follows:

²Close the manifold hand valves.

²Stop the vacuum pump and observe the vacuum

reading.

²If the system is leak-free, vacuum will hold steady

at the level indicated when the pump was stopped. If

vacuum remains steady for 3-5 minutes, resume and

continue evacuation for a minimum of 30 minutes.

²If the system has a leak, vacuum will fall off or

rapidly drop to a 0 reading. If a leak exists, partially

charge the system. Find and repair the leak and re-

sume evacuation.

(10) Continue evacuating the system for a mini-

mum of 30 minutes after attaining the lowest vac-

uum level.

(11) Fill the station charging cylinder while the

system is evacuating.

(12) Close the vacuum control valve and stop the

vacuum pump.

(13) Observe low pressure gauge to determine if a

system leak exists. If the system is leak-free, the sys-

tem is now ready for charging.

SYSTEM CHARGE

CHARGE CAPACITY

The recommended system charge is 1.1 kg (38 oz.)

of R-12 refrigerant for XJ vehicles and 0.9 kg (32 oz.)

for YJ vehicles.

Add an additional 28 grams (1 fluid oz.) of

compressor oil to the system when a hose, re-

ceiver-drier, condenser, expansion valve or

evaporator core is replaced.

PORTABLE SERVICE STATION

(1) Fill the station charging cylinder. Refrigerant

should be observed rising in the cylinder sight glass.

(2) Slightly open the valve at the top of the cylin-

der when pressure in the charging cylinder and re-frigerant supply tank are equal. This relieves head

pressure allowing refrigerant to continue filling the

cylinder.

(3) Observe the pressure gauge at the top of the

cylinder. Rotate the plastic cover on the cylinder un-

til the pressure heading column corresponds with the

gauge pressure in-line with the sight glass.

FOR EXAMPLE:ÐThe pressure gauge at the top

of the cylinder indicates 483 kPa (70 psi). Locate the

column with the pressure heading of 483 (70) and ro-

tate the cover so the 483 (70) column aligns with the

sight glass.

(4) When refrigerant reaches the correct level in

the sight glass, close the right hand valve at cylinder

base and on the refrigerant drum.

(5) Close the valve at the top of the charging cyl-

inder.

(6) Check for bubbles in the refrigerant using the

cylinder sight glass. If bubbles appear in the refrig-

erant, tilt the charging station rearward momen-

tarily.

(7) Connect the heating element cord to the power

pack receptacle and turn the heater switch ON.

(8) Allow the refrigerant to warm for about 10

minutes while the vacuum pump is operating.

WARNING: WEAR GOGGLES TO PROTECT THE

EYES.

(9) Discharge and evacuate the system.

(10) Close the low pressure valve on the charging

station.

(11) Fully open the left hand refrigerant control

valve at the base of the cylinder and the high pres-

sure valve on the charging station.

(12) Charge the system.

(13) Close the refrigerant control valve and the

high pressure valve on the charging station.

CAUTION: DO NOT permit the liquid level to drop

below 0 on the cylinder sight glass.

(14) Close the manifold gauges after completion of

the charging operation and check the high and low

side pressures.

(15) Check system operation.

CAUTION: DO NOT check system pressures until

the high and low pressure valves on the charging

station are closed. The low pressure gauge could

be damaged if the valves are open.

(16) Close all the valves on the charging station

and close the refrigerant drum valve when all the op-

erations are completed.

(17) Back-seat the service valves by turning them

fully counterclockwise. Install the quick seal caps on

the valves afterward.

JHEATING AND AIR CONDITIONING 24 - 5

Page 1669 of 1784

(18) Disconnect the charging hoses from the ser-

vice valves.

COMPRESSOR OIL LEVEL

The compressor oil level must be checked and ad-

justed if the system has been discharged rapidly, or

when a component has been replaced. If a replace-

ment compressor is being installed, it must be filled

with new compressor oil (Suniso 5GS, or equivalent).

The normal quantity of oil required for the com-

pressor and entire system is 136 ml (4.6 fluid oz.) for

SD 709 compressor. DO NOT overfill the compressor.

Excessive amounts of oil in the system will hinder

compressor operation and reduce A/C performance.

CAUTION: The compressor is a high speed unit.

Satisfactory operation is dependent on sufficient lu-

brication; however, excess oil will hinder A/C per-

formance.

Two oil level checking procedures are necessary.

Use Procedure (A) when the compressor is being re-

placed and the system was discharged properly (no

oil loss). Use Procedure (B) for routine maintenance

or when checking oil level after replacing a system

component.

In cases where rapid loss of refrigerant and oil

occurred, the system must be evacuated and

purged. Then the compressor must be filled with

the necessary amount of oil to fill the entire sys-

tem.

PROCEDURE A

(1) Remove the oil filler plug, discharge cap and

suction port caps from the original and replacement

compressor.

(2) Use a clean container to drain the oil from the

replacement compressor. Drain the oil through the

oil filler plug hole, the discharge and suction. Then

rotate clutch front plate several times to push the oil

on cylinder out to discharge chamber of cylinder

head and drain the oil from discharge port.

(3) Drain the oil from the original compressor into

a measuring cup or graduated beaker in the same

way as Step 2. Note the amount of oil drained.

(4) Fill the replacement compressor with the same

amount of oil drained from the original compressor

plus 30 ml (1 fluid oz.).

FOR EXAMPLE:ÐIf the old compressor contained

103.5 ml (3.5 fluid oz.) of oil, fill the replacement

compressor with a total of 133 ml (4.5 fluid oz.) of oil.

PROCEDURE B

(1) Start the engine and operate the engine at idle.

(2) Operate the air conditioning system for 10 min-

utes to return the maximum amount of oil in the sys-

tem to the compressor.(3) Stop the engine and disconnect the magnetic

clutch feed wire.

(4) Front-seat the discharge and suction service

valves.

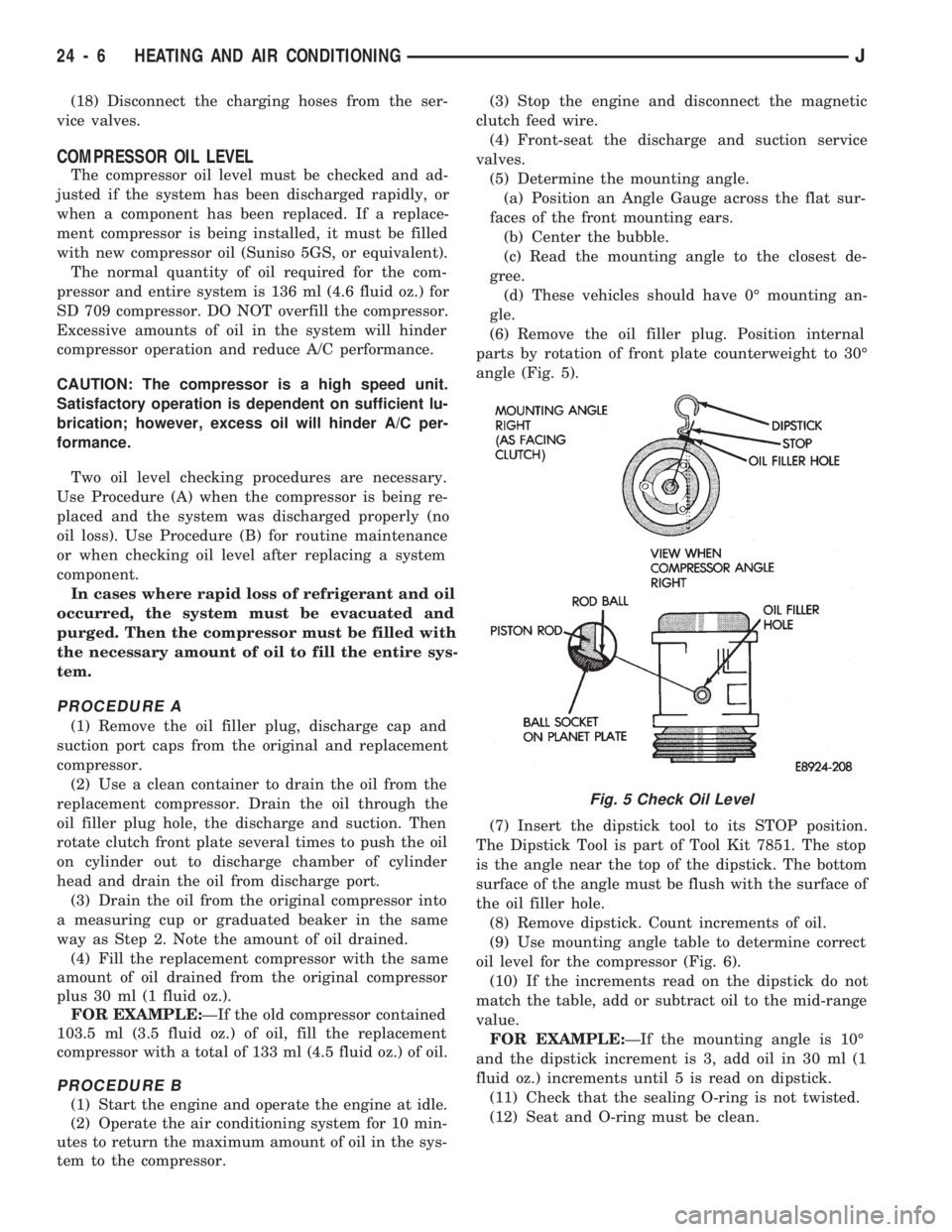

(5) Determine the mounting angle.

(a) Position an Angle Gauge across the flat sur-

faces of the front mounting ears.

(b) Center the bubble.

(c) Read the mounting angle to the closest de-

gree.

(d) These vehicles should have 0É mounting an-

gle.

(6) Remove the oil filler plug. Position internal

parts by rotation of front plate counterweight to 30É

angle (Fig. 5).

(7) Insert the dipstick tool to its STOP position.

The Dipstick Tool is part of Tool Kit 7851. The stop

is the angle near the top of the dipstick. The bottom

surface of the angle must be flush with the surface of

the oil filler hole.

(8) Remove dipstick. Count increments of oil.

(9) Use mounting angle table to determine correct

oil level for the compressor (Fig. 6).

(10) If the increments read on the dipstick do not

match the table, add or subtract oil to the mid-range

value.

FOR EXAMPLE:ÐIf the mounting angle is 10É

and the dipstick increment is 3, add oil in 30 ml (1

fluid oz.) increments until 5 is read on dipstick.

(11) Check that the sealing O-ring is not twisted.

(12) Seat and O-ring must be clean.

Fig. 5 Check Oil Level

24 - 6 HEATING AND AIR CONDITIONINGJ

Page 1680 of 1784

COMPRESSOR OVERHAUL

INDEX

page page

Compressor............................. 17

Compressor Isolation...................... 17

Description............................. 17Magnetic Clutch......................... 18

Purging Compressor of Air................. 17

DESCRIPTION

The A/C system uses a Sanden compressor. This

compressor is a 7 piston design. Designated the SD-

709, the compressor is mounted on the front right

side of the engine and is driven by a serpentine belt.

System lubrication is provided by 135cc615cc (4.6

cu. in.60.5 cu. in.) of 500 viscosity refrigerant oil.

The clutch used on the compressor consists of 3 ba-

sic components: the pulley, front plate and the field

coil. The pulley and field coil are attached to the

front head of the compressor with tapered snap rings.

The hub is keyed to the compressor shaft and is re-

tained on the shaft with a self-locking nut. Special

service tools are required to remove and install the

clutch plate on the compressor shaft.

COMPRESSOR ISOLATION

It is not necessary to discharge the system for com-

pressor removal. The compressor can be isolated from

the remainder of the system and eliminate the need

for recharging when performing compressor service.

(1) Connect pressure gauge and manifold.

(2) Close both gauge hand valves.

(3) Mid-position both service valves.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A DI-

RECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(4) Start the engine and operate the air condition-

ing system.

(5) Turn the suction service valve slowly clockwise

toward the front seated position.

(6) When pressure drops to zero, stop the engine

and compressor and quickly finish front-seating the

suction service valve.

(7) Front-seat the discharge service valve.

(8) Loosen the oil level check plug slowly to re-

lease any internal pressure in the compressor.

The compressor is now isolated from the remainder

of the system.

The service valves can be removed from the com-

pressor.

PURGING COMPRESSOR OF AIR

The compressor must be purged of air whenever it

has been isolated for an oil level check or other ser-

vice procedures without discharging the entire sys-

tem.

(1) Cap the service gauge ports on both of the ser-

vice valves.

(2) Back-seat the suction service valve to allow the

system refrigerant to enter the compressor.

(3) Place the discharge service valve in the mid-po-

sition or cracked-position.

(4) Loosen the discharge service valve gauge port

cap to permit the refrigerant to force any air out of

the compressor.

(5) Back-seat the discharge service valve and

tighten the gauge port cap.

(6) The compressor is now ready for service.

COMPRESSOR

REMOVAL

(1) Isolate the compressor.

(2) Disconnect negative cable from battery.

(3) Disconnect the clutch lead wire.

(4) Remove the discharge and inlet (suction) ser-

vice valves from the compressor. Plug or tape all the

openings.

(5) Remove the serpentine drive belt (refer to

Group 7, Cooling System for the proper procedure).

(6) Remove the bolts and lift the compressor from

the mounting bracket (Figs. 1 and 2).

INSTALLATION

If a replacement compressor is being installed;

check the oil level. Add or subtract oil as neces-

sary and install the magnetic clutch on the com-

pressor.

(1) If the mounting bracket was removed, install

the bracket to the block. Tighten the mounting bolts

to 27 NIm (20 ft. lbs.) torque.

(2) Install the compressor on the mounting

bracket. Tighten the bolts to 27 NIm (20 ft. lbs.)

torque.

(3) Install the serpentine drive belt (refer to Group

7, Cooling System for the proper procedure).

(4) Tighten the serpentine drive belt to the speci-

fied tension.

²New belt tensionÐ800-900 N (180-200 lb-f).

JHEATING AND AIR CONDITIONING 24 - 17

Page 1710 of 1784

AIR CONDITIONING

CONTENTS

page page

AIR CONDITIONING EQUIPMENT........... 4

AIR CONDITIONING PERFORMANCE TESTS . . 5

GENERAL INFORMATION.................. 1

REFRIGERANT LEAK TESTING, DISCHARGING,

EVACUATING AND CHARGING............ 8REFRIGERANT OIL....................... 9

SERVICE PRECAUTIONS.................. 3

WARNINGS AND CAUTIONS FOR R134A

SYSTEM.............................. 3

GENERAL INFORMATION

A/C COMPONENTS

COMPRESSORÐThe SD-709 Compressor is used

on all models. The compressor compresses the low-

pressure refrigerant vapor from the evaporator into a

high pressure, high temperature vapor. The compres-

sor is serviced as an assembly only.

CLUTCH PULLEY AND COILÐThey are

mounted on the compressor and providing a way to

drive the compressor. The compressor clutch and coil

are the only serviced parts on the SD-709 compres-

sor. When the compressor is not in operation, the

pulley free wheels on the clutch hub bearing. When

the coil is energized the clutch plate is magnetically

engaged with the pulley and turns the compressor

shaft.

CONDENSERÐThe condenser is located in front

of the engine radiator. Its function is to cool the hot

high pressure refrigerant gas. This causes it to con-

dense into high pressure liquid refrigerant.

FILTER-DRIERÐThe drier is used to remove con-

taminates and traces of moisture from the refriger-

ant system.

SIGHT-GLASSÐThe sight glass is located on top

of the filter drier. It is used as a diagnostic tool to ob-

serve refrigerant flow.

LOW-PRESSURE HIGH-PRESSURE CUT-OFF

SWITCHÐThe switch is located on the filter drier

and is wired in series with compressor clutch. When

the pressure drops down to 193 kPa (28 psi) the

switch interrupts the power to the compressor clutch.

When the pressure increases above 3100 to 3375 kPa

(450 to 490 psi) the switch interrupts the power to

the compressor clutch.

HIGH PRESSURE RELIEF VALVEÐThe valve

is located on the filter drier. The valve is used to pre-

vent excessive pressure up build of 3445 to 4135

kPag (500 to 600 psi) and above. This will prevent

damage to the compressor and other system compo-

nents.EXPANSION VALVEÐThe expansion valve is lo-

cated in the engine compartment on XJ vehicles. On

YJ vehicles it is located behind the A/C housing. Its

function is to meter refrigerant into the evaporator in

accordance with cooling requirements.

EVAPORATOR COILÐThe coil is located in the

A/C housing. Its function is to remove heat and de-

humidify the air before it enters the vehicle.

FIN SENSING CYCLING CLUTCH SWITCHÐ

The switch is attached to the evaporator coil. This

switch prevents condensate water on the evaporator

coil from freezing. It does this by cycling the com-

pressor clutch on and off. This switch is used onXJ

only

THERMOSTATÐThe thermostat is located in the

evaporator housing. Its function is to cycle the com-

pressor clutch to control temperature. The thermo-

stat is used on theYJonly.

REFRIGERANT LINESÐThe lines are used to

carry the refrigerant between the various system

components.

SERVICE PORTSÐThe high pressure service

port is located on the discharge line near the com-

pressor. The low pressure service port is located on

the suction line near the compressor. The compressor

no longer uses service valves.

After servicing the refrigerant system, always in-

stall service port caps.

REFRIGERANT

The vehicles use a new type of refrigerant called

R-134a. It is a non-toxic, non-flammable, clear color-

less liquified gas.

R-134a refrigerant is not compatible with R-12 re-

frigerant in an air conditioning system. A small

amount of R-12 in a R-134a system will cause com-

pressor failure, refrigerant oil sludge or poor A/C per-

formance.

JAIR CONDITIONING1

Page 1712 of 1784

WARNINGS AND CAUTIONS FOR R134A SYSTEM

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND/OR THROAT. WEAR

EYE PROTECTION WHEN SERVICING THE AIR

CONDITIONING REFRIGERANT SYSTEM. SERIOUS

EYE INJURY CAN RESULT FROM EYE CONTACT

WITH REFRIGERANT. IF EYE CONTACT IS MADE,

SEEK MEDICAL ATTENTION IMMEDIATELY.

WARNING: DO NOT EXPOSE REFRIGERANT TO

OPEN FLAME. POISONOUS GAS IS CREATED

WHEN REFRIGERANT IS BURNED. AN ELEC-

TRONIC LEAK DETECTOR IS RECOMMENDED.

WARNING: IF ACCIDENTAL SYSTEM DISCHARGE

OCCURS, VENTILATE THE WORK AREA BEFORE

RESUMING SERVICE. LARGE AMOUNTS OF RE-

FRIGERANT RELEASED IN A CLOSED WORK AREA

WILL DISPLACE THE OXYGEN AND CAUSE SUFFO-

CATION.

WARNING: THE EVAPORATION RATE OF R-134A

REFRIGERANT AT AVERAGE TEMPERATURE AND

ALTITUDE IS EXTREMELY HIGH. AS A RESULT,

ANYTHING THAT COMES IN CONTACT WITH THE

REFRIGERANT WILL FREEZE. ALWAYS PROTECT

SKIN OR DELICATE OBJECTS FROM DIRECT CON-

TACT WITH REFRIGERANT.WARNING: R-134A SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. SOME MIXTURES OF AIR AND R-134A HAVE

BEEN SHOWN TO BE COMBUSTIBLE AT ELEVATED

PRESSURES. THESE MIXTURES ARE POTENTIALLY

DANGEROUS AND MAY RESULT IN FIRE OR EX-

PLOSION CAUSING INJURY OR PROPERTY DAM-

AGE.

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with equipment being used.

CAUTION: Never add R-12 to a system designed to

use R-134a. Damage to the system will result.

CAUTION: R-12 compressor oil can not be mixed

with the R-134a compressor oil. They ARE NOT

compatible.

CAUTION: DO NOT use R-12 equipment or parts on

the R-134a system. Damage to the system will re-

sult.

SERVICE PRECAUTIONS

Never open or loosen a connection before discharg-

ing the system refrigerant.

The A/C system must always be evacuated before

charging.

DO NOT open a refrigerant system or uncap a re-

placement component unless it is as close as possible

to room temperature. This will prevent condensation

from forming inside of a component which is cooler

than the surrounding air.

Before disconnecting a component from the system,

clean the outside of the fittings thoroughly.

Immediately after disconnecting a component from

the system, seal the open fittings with a cap or plug.

Before connecting an open fitting always insall a

new seal/gasket. Coat the fitting and seal with clean

refrigerant oil before connecting.

DO NOT remove the sealing caps from a replace-

ment component until ready to install.When installing a refrigerant line avoid sharp

bends. Position the line away from the exhaust or

any sharp edges which may chafe the line.

Tighten fittings only to the specified torque. The

aluminum fittings used in the A/C system will not

tolerate over tightening.

When disconnecting a fitting use a wrench on both

halves of the fitting. This will prevent twisting of the

refrigerant lines or tubes.

Refrigerant oil will absorb moisture from the atmo-

sphere if left uncapped. DO NOT open an oil con-

tainer until ready to use and install the cap

immediately after using. Store the oil only in a clean

moisture-free container.

Keep service tools and the work area clean. Con-

tamination of A/C system through careless work hab-

its must be avoided.

JAIR CONDITIONING3

Page 1713 of 1784

AIR CONDITIONING EQUIPMENT

WARNING: EYE PROTECTION MUST BE USED

WHEN SERVICING AN AIR CONDITIONING REFRIG-

ERANT SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED

BEFORE PROCEEDING WITH THIS OPERATION.

PERSONNEL INJURY CAN RESULT.

When servicing an air conditioning system, a

R-134a Charging Station and a Recovery/Recycling

Station is required. These devices must meet SAE

standard J2210. Refer to the operating instructions

provided with the equipment for proper operation.

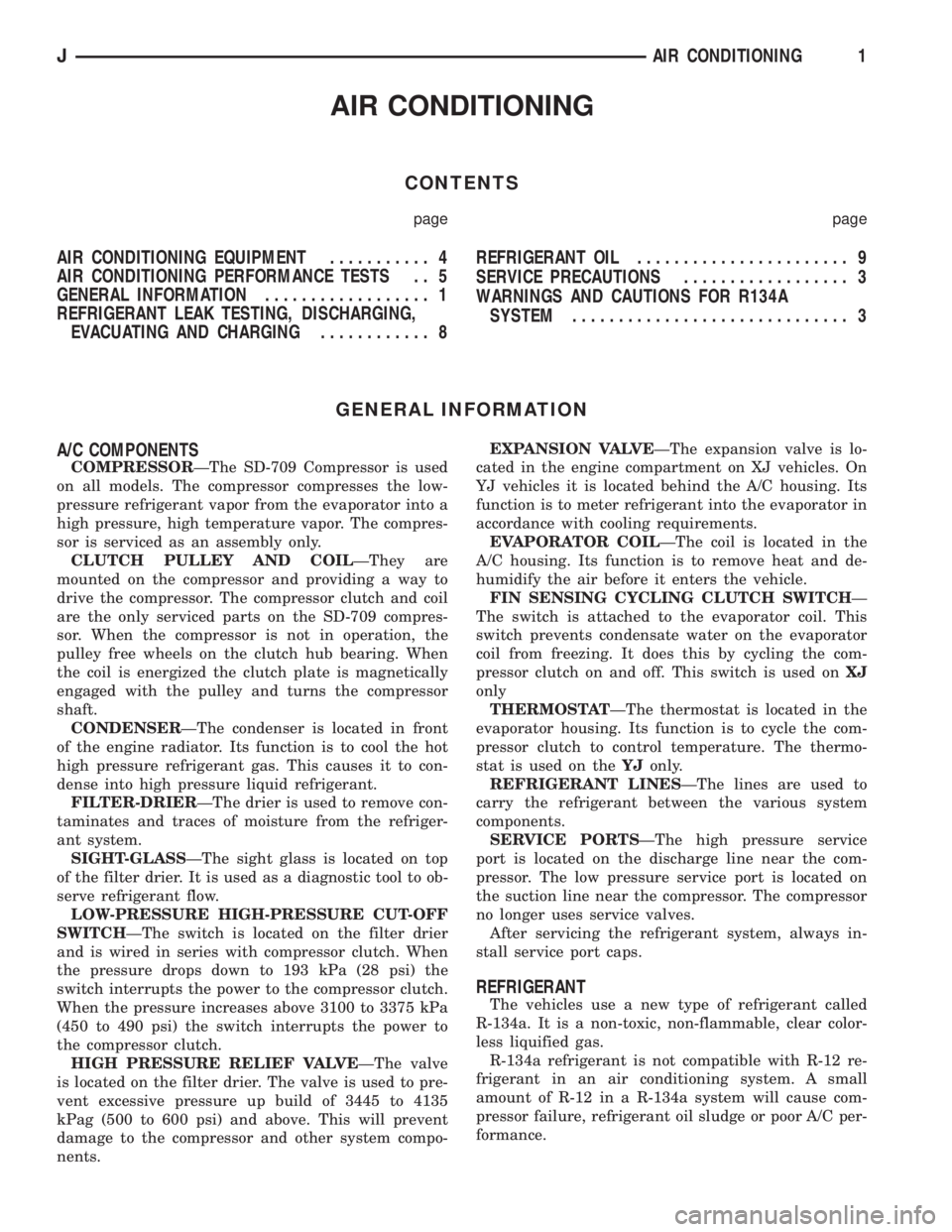

A manifold gauge set (Fig. 1) must also be used

with the Charging and or Recovery/Recycling Station.

The service hoses on the gauge set uses a Quick-Dis-

connect coupler. The coupler has a knob on top which

is used to engage and disengage the sharder valve in

the service port.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: DO NOT use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

CENTER GAUGE HOSE

The center hose is YELLOW or WHITE with

BLACK STRIP. It is used to recover, evacuate and

charge the refrigerant system. When the low or high

pressure gauge valves on the manifold gauge set are

opened, the refrigerant in the system will escape

through this hose.

This hose attaches to the Recovery/Recycling sta-

tion. Refer to the Recovery/Recycling station Opera-

tors Manual for proper procedures.

LOW PRESSURE GAUGE HOSE

The low pressure hose is BLUE with BLACK

STRIP. The low pressure port is located on the suc-

tion line.

HIGH PRESSURE GAUGE HOSE

The high pressure hose is RED with BLACK

STRIP. The high pressure port is located on the dis-

charge line.CONNECTION

(1) Remove the service port cap.

(2) Check all valves on the equipment being used

to verify they are closed.

(3) Attach the Quick-Disconnect coupler to the ser-

vice port and turn knob clockwise to depress sharder

valve.

DISCONNECT

(1) Turn coupler knob counter clockwise to release

sharder valve.

(2) Remove the coupler.

(3) Install the service port cap.

Fig. 1 Manifold Gauge Set

4 AIR CONDITIONINGJ

Page 1717 of 1784

REFRIGERANT LEAK TESTING, DISCHARGING, EVACUATING AND CHARGING

LEAK TESTING REFRIGERANT

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE LEAK TESTING.

If A/C system is not cooling properly, determine if

system is fully charged. Refer to Refrigerant System

Diagnosis Chart. If the system is empty evacuate the

A/C system and charge system with 0.283 kPa (0.6

lbs. or 10 oz.) R-134a refrigerant. Refer to Charging

Refrigerant System for instructions. To detect a leak

in the system, perform the following procedures.

(1) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(2) Bring A/C system up to operating temperature

and pressure. This is done by allowing the engine to

run with the A/C on for 5 to 7 minutes.

(3) Open hood 5 minutes prior to leak test. This

will dissipate any accumulated refrigerant in the en-

gine compartment.

(4) With the engine not running, use an R-134a

Electronic Leak Detector and search for leaks. Move

probe slowly along the bottom side of lines and fit-

tings, because R-134a is heavier than air. Fittings,

lines, or components that appear to be oily usually

indicates a refrigerant leak.

(5) To inspect the evaporator core for leaks. Set the

blower at low speed and the selector in PANEL and

RECIRC mode check for leaks at CENTER panel ou-

lets.

DISCHARGING REFRIGERANT SYSTEM

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE DISCHARGING SYSTEM.

R-134a refrigrant is a hydrofluorocarbon (HFC)

that does not contain chlorine. R-134a refrigerant Re-

covery/Recycling Station that meets SAE standard

J2210 must be used to discharge the refrigerant sys-

tem. Refer to the operating instructions provided

with the equipment for proper operation.

EVACUATING REFRIGERANT SYSTEM

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE EVACUATING SYSTEM.If the A/C system has been open to the atmosphere,

it must be evacuated before the system can be

charged. Moisture and air mixed with refrigerant will

raise the compressor head pressure above acceptable

operating levels. This will reduce the performance of

the air conditioner and damage the compressor. Mois-

ture will boil at near room temperature when ex-

posed to vacuum. To evacuate the refrigerant system

use following procedure:

(1) Connect a suitable charging station and mani-

fold gauge set to the vehicle.

(2) Open the low and high side valves and start

vacuum pump. When suction gauge reads 88 kPag

(26 in. Hg) vacuum or greater, close all valves and

turn off vacuum pump. If system fails to reach spec-

ified vacuum, the system has a leak that must be

corrected. If system maintains the specified vacuum

for 30 minutes, start the vacuum pump. Then open

the suction and discharge valves and evacuate an ad-

ditional 10 minutes.

(3) Close all valves. Turn off and disconnect the

vacuum pump.

The system is now ready to be charged with refrig-

erant.

CHARGING REFRIGERANT SYSTEM

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE CHARGING SYSTEM.

After the system has been tested for leaks and

evacuated, a refrigerant charge can be injected into

the system. Refer to refrigerant capacities for proper

amount of refrigerant charge.

The most accurate method of charging is to com-

pletely evacuate the system. Then charge the system

using a Recovery/Recycling Station approved for

R-134a refrigerant. Refer to the operating instruc-

tions provided with the equipment for proper opera-

tion.

CAUTION: Do not over charge refrigerant system.

This will cause excessive compressor head pres-

sure and can cause noise and system failure.

REFRIGERANT CHARGE CAPACITY

The R-134a system charge capacity is 0.9 kPag (32

oz.) for XJ and YJ vehicles.

8 AIR CONDITIONINGJ

Page 1746 of 1784

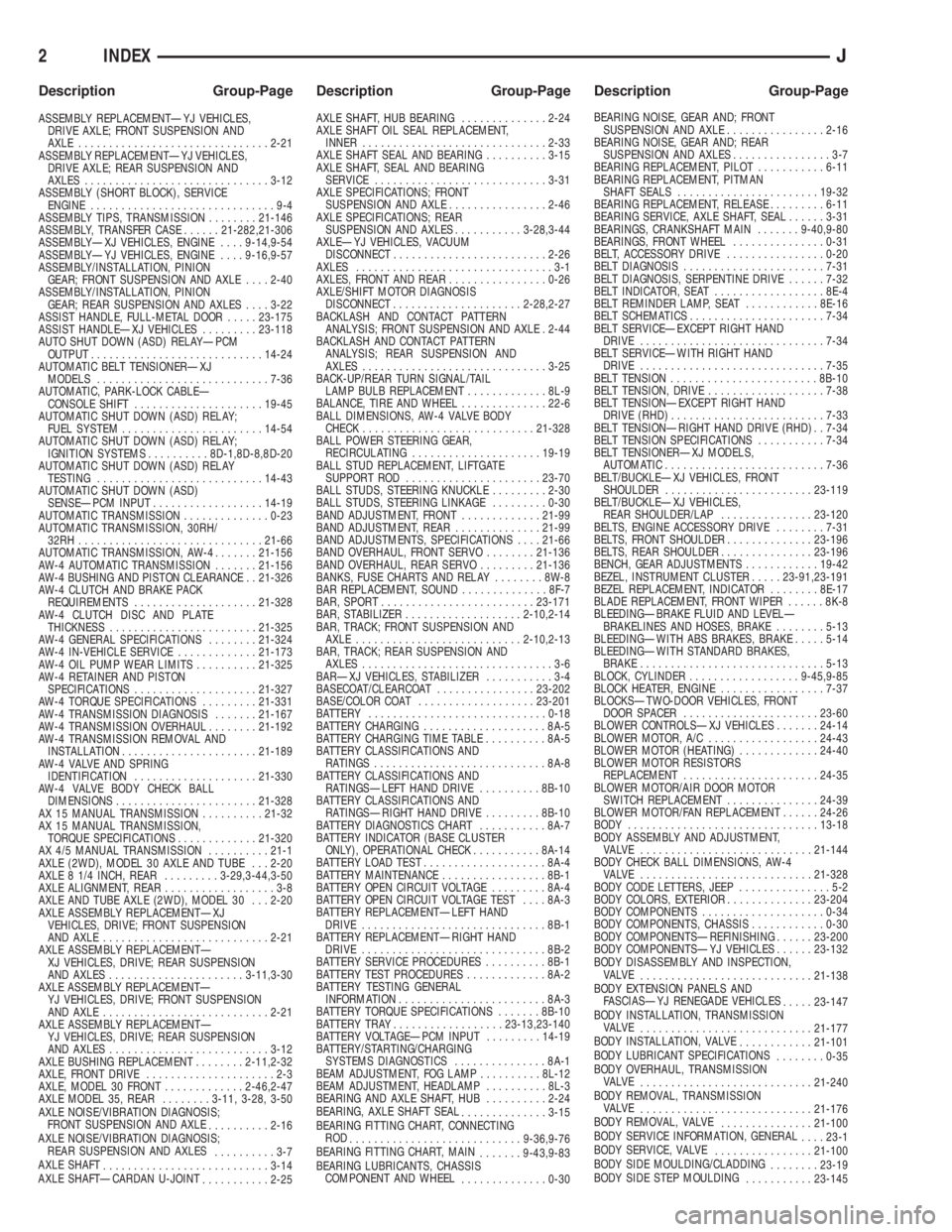

ASSEMBLY REPLACEMENTÐYJ VEHICLES,

DRIVE AXLE; FRONT SUSPENSION AND

AXLE...............................2-21

ASSEMBLY REPLACEMENTÐYJ VEHICLES,

DRIVE AXLE; REAR SUSPENSION AND

AXLES..............................3-12

ASSEMBLY (SHORT BLOCK), SERVICE

ENGINE..............................9-4

ASSEMBLY TIPS, TRANSMISSION........21-146

ASSEMBLY, TRANSFER CASE......21-282,21-306

ASSEMBLYÐXJ VEHICLES, ENGINE....9-14,9-54

ASSEMBLYÐYJ VEHICLES, ENGINE....9-16,9-57

ASSEMBLY/INSTALLATION, PINION

GEAR; FRONT SUSPENSION AND AXLE....2-40

ASSEMBLY/INSTALLATION, PINION

GEAR; REAR SUSPENSION AND AXLES....3-22

ASSIST HANDLE, FULL-METAL DOOR.....23-175

ASSIST HANDLEÐXJ VEHICLES.........23-118

AUTO SHUT DOWN (ASD) RELAYÐPCM

OUTPUT............................14-24

AUTOMATIC BELT TENSIONERÐXJ

MODELS............................7-36

AUTOMATIC, PARK-LOCK CABLEÐ

CONSOLE SHIFT.....................19-45

AUTOMATIC SHUT DOWN (ASD) RELAY;

FUEL SYSTEM.......................14-54

AUTOMATIC SHUT DOWN (ASD) RELAY;

IGNITION SYSTEMS..........8D-1,8D-8,8D-20

AUTOMATIC SHUT DOWN (ASD) RELAY

TESTING...........................14-43

AUTOMATIC SHUT DOWN (ASD)

SENSEÐPCM INPUT..................14-19

AUTOMATIC TRANSMISSION..............0-23

AUTOMATIC TRANSMISSION, 30RH/

32RH..............................21-66

AUTOMATIC TRANSMISSION, AW-4.......21-156

AW-4 AUTOMATIC TRANSMISSION.......21-156

AW-4 BUSHING AND PISTON CLEARANCE . . 21-326

AW-4 CLUTCH AND BRAKE PACK

REQUIREMENTS....................21-328

AW-4 CLUTCH DISC AND PLATE

THICKNESS........................21-325

AW-4 GENERAL SPECIFICATIONS........21-324

AW-4 IN-VEHICLE SERVICE.............21-173

AW-4 OIL PUMP WEAR LIMITS..........21-325

AW-4 RETAINER AND PISTON

SPECIFICATIONS....................21-327

AW-4 TORQUE SPECIFICATIONS.........21-331

AW-4 TRANSMISSION DIAGNOSIS.......21-167

AW-4 TRANSMISSION OVERHAUL........21-192

AW-4 TRANSMISSION REMOVAL AND

INSTALLATION......................21-189

AW-4 VALVE AND SPRING

IDENTIFICATION....................21-330

AW-4 VALVE BODY CHECK BALL

DIMENSIONS.......................21-328

AX 15 MANUAL TRANSMISSION..........21-32

AX 15 MANUAL TRANSMISSION,

TORQUE SPECIFICATIONS.............21-320

AX 4/5 MANUAL TRANSMISSION..........21-1

AXLE (2WD), MODEL 30 AXLE AND TUBE . . . 2-20

AXLE 8 1/4 INCH, REAR.........3-29,3-44,3-50

AXLE ALIGNMENT, REAR..................3-8

AXLE AND TUBE AXLE (2WD), MODEL 30 . . . 2-20

AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES, DRIVE; FRONT SUSPENSION

AND AXLE...........................2-21

AXLE ASSEMBLY REPLACEMENTÐ

XJ VEHICLES, DRIVE; REAR SUSPENSION

AND AXLES......................3-11,3-30

AXLE ASSEMBLY REPLACEMENTÐ

YJ VEHICLES, DRIVE; FRONT SUSPENSION

AND AXLE...........................2-21

AXLE ASSEMBLY REPLACEMENTÐ

YJ VEHICLES, DRIVE; REAR SUSPENSION

AND AXLES..........................3-12

AXLE BUSHING REPLACEMENT........2-11,2-32

AXLE, FRONT DRIVE.....................2-3

AXLE, MODEL 30 FRONT.............2-46,2-47

AXLE MODEL 35, REAR........3-11, 3-28, 3-50

AXLE NOISE/VIBRATION DIAGNOSIS;

FRONT SUSPENSION AND AXLE

..........2-16

AXLE NOISE/VIBRATION DIAGNOSIS;

REAR SUSPENSION AND AXLES

..........3-7

AXLE SHAFT

...........................3-14

AXLE SHAFTÐCARDAN U-JOINT

...........2-25AXLE SHAFT, HUB BEARING..............2-24

AXLE SHAFT OIL SEAL REPLACEMENT,

INNER..............................2-33

AXLE SHAFT SEAL AND BEARING..........3-15

AXLE SHAFT, SEAL AND BEARING

SERVICE............................3-31

AXLE SPECIFICATIONS; FRONT

SUSPENSION AND AXLE................2-46

AXLE SPECIFICATIONS; REAR

SUSPENSION AND AXLES...........3-28,3-44

AXLEÐYJ VEHICLES, VACUUM

DISCONNECT.........................2-26

AXLES................................3-1

AXLES, FRONT AND REAR................0-26

AXLE/SHIFT MOTOR DIAGNOSIS

DISCONNECT.....................2-28,2-27

BACKLASH AND CONTACT PATTERN

ANALYSIS; FRONT SUSPENSION AND AXLE . 2-44

BACKLASH AND CONTACT PATTERN

ANALYSIS; REAR SUSPENSION AND

AXLES..............................3-25

BACK-UP/REAR TURN SIGNAL/TAIL

LAMP BULB REPLACEMENT.............8L-9

BALANCE, TIRE AND WHEEL..............22-6

BALL DIMENSIONS, AW-4 VALVE BODY

CHECK............................21-328

BALL POWER STEERING GEAR,

RECIRCULATING.....................19-19

BALL STUD REPLACEMENT, LIFTGATE

SUPPORT ROD......................23-70

BALL STUDS, STEERING KNUCKLE.........2-30

BALL STUDS, STEERING LINKAGE.........0-30

BAND ADJUSTMENT, FRONT.............21-99

BAND ADJUSTMENT, REAR..............21-99

BAND ADJUSTMENTS, SPECIFICATIONS....21-66

BAND OVERHAUL, FRONT SERVO........21-136

BAND OVERHAUL, REAR SERVO.........21-136

BANKS, FUSE CHARTS AND RELAY........8W-8

BAR REPLACEMENT, SOUND..............8F-7

BAR, SPORT.........................23-171

BAR, STABILIZER...................2-10,2-14

BAR, TRACK; FRONT SUSPENSION AND

AXLE...........................2-10,2-13

BAR, TRACK; REAR SUSPENSION AND

AXLES...............................3-6

BARÐXJ VEHICLES, STABILIZER...........3-4

BASECOAT/CLEARCOAT................23-202

BASE/COLOR COAT...................23-201

BATTERY.............................0-18

BATTERY CHARGING....................8A-5

BATTERY CHARGING TIME TABLE..........8A-5

BATTERY CLASSIFICATIONS AND

RATINGS............................8A-8

BATTERY CLASSIFICATIONS AND

RATINGSÐLEFT HAND DRIVE..........8B-10

BATTERY CLASSIFICATIONS AND

RATINGSÐRIGHT HAND DRIVE.........8B-10

BATTERY DIAGNOSTICS CHART...........8A-7

BATTERY INDICATOR (BASE CLUSTER

ONLY), OPERATIONAL CHECK...........8A-14

BATTERY LOAD TEST....................8A-4

BATTERY MAINTENANCE.................8B-1

BATTERY OPEN CIRCUIT VOLTAGE.........8A-4

BATTERY OPEN CIRCUIT VOLTAGE TEST....8A-3

BATTERY REPLACEMENTÐLEFT HAND

DRIVE..............................8B-1

BATTERY REPLACEMENTÐRIGHT HAND

DRIVE..............................8B-2

BATTERY SERVICE PROCEDURES..........8B-1

BATTERY TEST PROCEDURES.............8A-2

BATTERY TESTING GENERAL

INFORMATION........................8A-3

BATTERY TORQUE SPECIFICATIONS.......8B-10

BATTERY TRAY..................23-13,23-140

BATTERY VOLTAGEÐPCM INPUT.........14-19

BATTERY/STARTING/CHARGING

SYSTEMS DIAGNOSTICS...............8A-1

BEAM ADJUSTMENT, FOG LAMP..........8L-12

BEAM ADJUSTMENT, HEADLAMP..........8L-3

BEARING AND AXLE SHAFT, HUB..........2-24

BEARING, AXLE SHAFT SEAL

..............3-15

BEARING FITTING CHART, CONNECTING

ROD

............................9-36,9-76

BEARING FITTING CHART, MAIN

.......9-43,9-83

BEARING LUBRICANTS, CHASSIS

COMPONENT AND WHEEL

..............0-30BEARING NOISE, GEAR AND; FRONT

SUSPENSION AND AXLE................2-16

BEARING NOISE, GEAR AND; REAR

SUSPENSION AND AXLES................3-7

BEARING REPLACEMENT, PILOT...........6-11

BEARING REPLACEMENT, PITMAN

SHAFT SEALS.......................19-32

BEARING REPLACEMENT, RELEASE.........6-11

BEARING SERVICE, AXLE SHAFT, SEAL......3-31

BEARINGS, CRANKSHAFT MAIN.......9-40,9-80

BEARINGS, FRONT WHEEL...............0-31

BELT, ACCESSORY DRIVE................0-20

BELT DIAGNOSIS.......................7-31

BELT DIAGNOSIS, SERPENTINE DRIVE......7-32

BELT INDICATOR, SEAT..................8E-4

BELT REMINDER LAMP, SEAT............8E-16

BELT SCHEMATICS......................7-34

BELT SERVICEÐEXCEPT RIGHT HAND

DRIVE..............................7-34

BELT SERVICEÐWITH RIGHT HAND

DRIVE..............................7-35

BELT TENSION........................8B-10

BELT TENSION, DRIVE...................7-38

BELT TENSIONÐEXCEPT RIGHT HAND

DRIVE (RHD).........................7-33

BELT TENSIONÐRIGHT HAND DRIVE (RHD) . . 7-34

BELT TENSION SPECIFICATIONS...........7-34

BELT TENSIONERÐXJ MODELS,

AUTOMATIC..........................7-36

BELT/BUCKLEÐXJ VEHICLES, FRONT

SHOULDER........................23-119

BELT/BUCKLEÐXJ VEHICLES,

REAR SHOULDER/LAP...............23-120

BELTS, ENGINE ACCESSORY DRIVE........7-31

BELTS, FRONT SHOULDER..............23-196

BELTS, REAR SHOULDER...............23-196

BENCH, GEAR ADJUSTMENTS............19-42

BEZEL, INSTRUMENT CLUSTER.....23-91,23-191

BEZEL REPLACEMENT, INDICATOR........8E-17

BLADE REPLACEMENT, FRONT WIPER......8K-8

BLEEDINGÐBRAKE FLUID AND LEVELÐ

BRAKELINES AND HOSES, BRAKE........5-13

BLEEDINGÐWITH ABS BRAKES, BRAKE.....5-14

BLEEDINGÐWITH STANDARD BRAKES,

BRAKE..............................5-13

BLOCK, CYLINDER..................9-45,9-85

BLOCK HEATER, ENGINE.................7-37

BLOCKSÐTWO-DOOR VEHICLES, FRONT

DOOR SPACER......................23-60

BLOWER CONTROLSÐXJ VEHICLES.......24-14

BLOWER MOTOR, A/C..................24-43

BLOWER MOTOR (HEATING).............24-40

BLOWER MOTOR RESISTORS

REPLACEMENT......................24-35

BLOWER MOTOR/AIR DOOR MOTOR

SWITCH REPLACEMENT...............24-39

BLOWER MOTOR/FAN REPLACEMENT......24-26

BODY...............................13-18

BODY ASSEMBLY AND ADJUSTMENT,

VALVE ............................21-144

BODY CHECK BALL DIMENSIONS, AW-4

VALVE ............................21-328

BODY CODE LETTERS, JEEP...............5-2

BODY COLORS, EXTERIOR..............23-204

BODY COMPONENTS....................0-34

BODY COMPONENTS, CHASSIS............0-30

BODY COMPONENTSÐREFINISHING......23-200

BODY COMPONENTSÐYJ VEHICLES......23-132

BODY DISASSEMBLY AND INSPECTION,

VALVE

............................21-138

BODY EXTENSION PANELS AND

FASCIASÐYJ RENEGADE VEHICLES

.....23-147

BODY INSTALLATION, TRANSMISSION

VALVE

............................21-177

BODY INSTALLATION, VALVE

............21-101

BODY LUBRICANT SPECIFICATIONS

........0-35

BODY OVERHAUL, TRANSMISSION

VALVE

............................21-240

BODY REMOVAL, TRANSMISSION

VALVE

............................21-176

BODY REMOVAL, VALVE

...............21-100

BODY SERVICE INFORMATION, GENERAL

....23-1

BODY SERVICE, VALVE

................21-100

BODY SIDE MOULDING/CLADDING

........23-19

BODY SIDE STEP MOULDING

...........23-145

2 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1748 of 1784

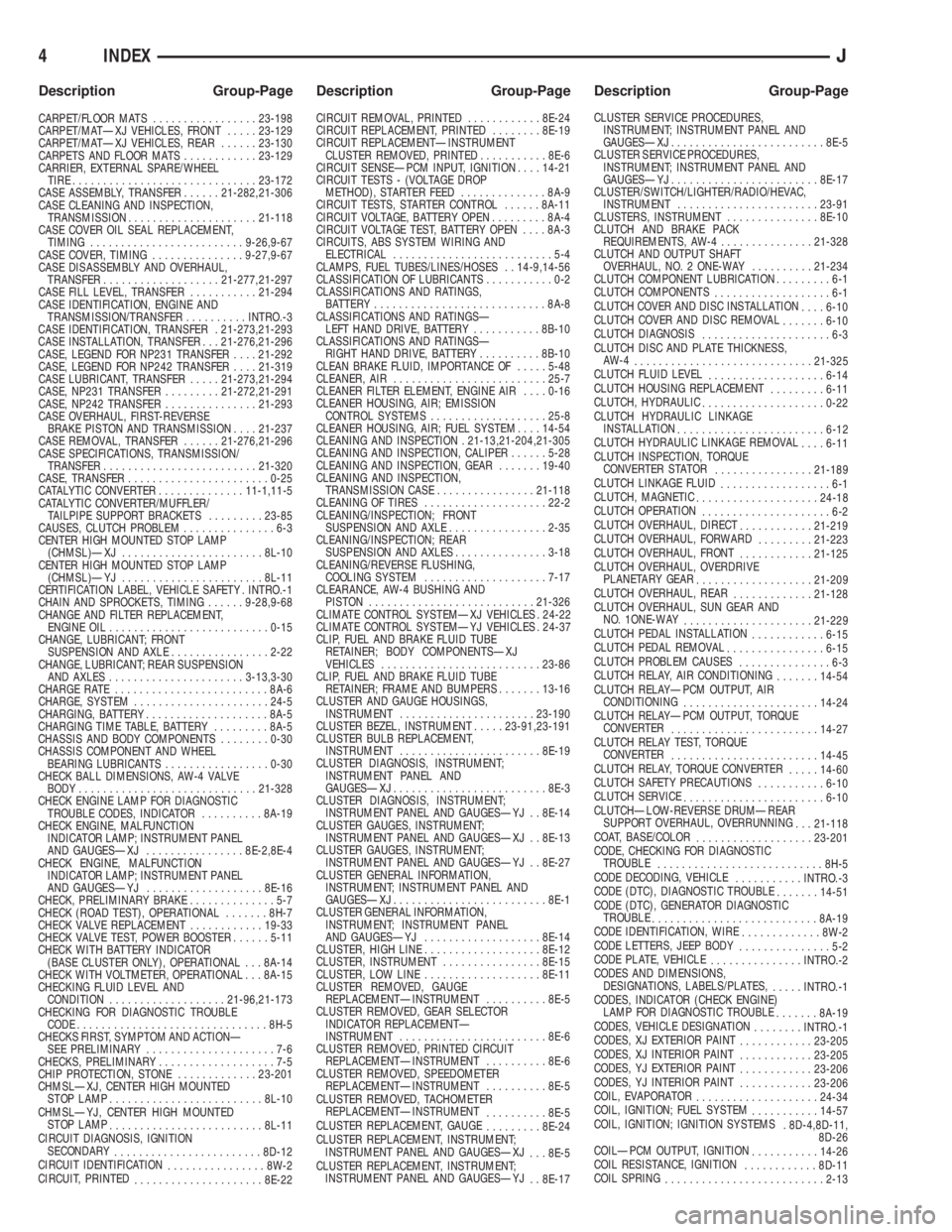

CARPET/FLOOR MATS.................23-198

CARPET/MATÐXJ VEHICLES, FRONT.....23-129

CARPET/MATÐXJ VEHICLES, REAR......23-130

CARPETS AND FLOOR MATS............23-129

CARRIER, EXTERNAL SPARE/WHEEL

TIRE..............................23-172

CASE ASSEMBLY, TRANSFER......21-282,21-306

CASE CLEANING AND INSPECTION,

TRANSMISSION.....................21-118

CASE COVER OIL SEAL REPLACEMENT,

TIMING.........................9-26,9-67

CASE COVER, TIMING...............9-27,9-67

CASE DISASSEMBLY AND OVERHAUL,

TRANSFER...................21-277,21-297

CASE FILL LEVEL, TRANSFER...........21-294

CASE IDENTIFICATION, ENGINE AND

TRANSMISSION/TRANSFER..........INTRO.-3

CASE IDENTIFICATION, TRANSFER . 21-273,21-293

CASE INSTALLATION, TRANSFER . . . 21-276,21-296

CASE, LEGEND FOR NP231 TRANSFER....21-292

CASE, LEGEND FOR NP242 TRANSFER....21-319

CASE LUBRICANT, TRANSFER.....21-273,21-294

CASE, NP231 TRANSFER.........21-272,21-291

CASE, NP242 TRANSFER...............21-293

CASE OVERHAUL, FIRST-REVERSE

BRAKE PISTON AND TRANSMISSION....21-237

CASE REMOVAL, TRANSFER......21-276,21-296

CASE SPECIFICATIONS, TRANSMISSION/

TRANSFER.........................21-320

CASE, TRANSFER.......................0-25

CATALYTIC CONVERTER..............11-1,11-5

CATALYTIC CONVERTER/MUFFLER/

TAILPIPE SUPPORT BRACKETS.........23-85

CAUSES, CLUTCH PROBLEM...............6-3

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐXJ.......................8L-10

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐYJ.......................8L-11

CERTIFICATION LABEL, VEHICLE SAFETY . INTRO.-1

CHAIN AND SPROCKETS, TIMING......9-28,9-68

CHANGE AND FILTER REPLACEMENT,

ENGINE OIL..........................0-15

CHANGE, LUBRICANT; FRONT

SUSPENSION AND AXLE................2-22

CHANGE, LUBRICANT; REAR SUSPENSION

AND AXLES......................3-13,3-30

CHARGE RATE.........................8A-6

CHARGE, SYSTEM......................24-5

CHARGING, BATTERY....................8A-5

CHARGING TIME TABLE, BATTERY.........8A-5

CHASSIS AND BODY COMPONENTS........0-30

CHASSIS COMPONENT AND WHEEL

BEARING LUBRICANTS.................0-30

CHECK BALL DIMENSIONS, AW-4 VALVE

BODY.............................21-328

CHECK ENGINE LAMP FOR DIAGNOSTIC

TROUBLE CODES, INDICATOR..........8A-19

CHECK ENGINE, MALFUNCTION

INDICATOR LAMP; INSTRUMENT PANEL

AND GAUGESÐXJ................8E-2,8E-4

CHECK ENGINE, MALFUNCTION

INDICATOR LAMP; INSTRUMENT PANEL

AND GAUGESÐYJ...................8E-16

CHECK, PRELIMINARY BRAKE..............5-7

CHECK (ROAD TEST), OPERATIONAL.......8H-7

CHECK VALVE REPLACEMENT............19-33

CHECK VALVE TEST, POWER BOOSTER......5-11

CHECK WITH BATTERY INDICATOR

(BASE CLUSTER ONLY), OPERATIONAL . . . 8A-14

CHECK WITH VOLTMETER, OPERATIONAL . . . 8A-15

CHECKING FLUID LEVEL AND

CONDITION...................21-96,21-173

CHECKING FOR DIAGNOSTIC TROUBLE

CODE...............................8H-5

CHECKS FIRST, SYMPTOM AND ACTIONÐ

SEE PRELIMINARY.....................7-6

CHECKS, PRELIMINARY...................7-5

CHIP PROTECTION, STONE.............23-201

CHMSLÐXJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-10

CHMSLÐYJ, CENTER HIGH MOUNTED

STOP LAMP

.........................8L-11

CIRCUIT DIAGNOSIS, IGNITION

SECONDARY

........................8D-12

CIRCUIT IDENTIFICATION

................8W-2

CIRCUIT, PRINTED

.....................8E-22CIRCUIT REMOVAL, PRINTED............8E-24

CIRCUIT REPLACEMENT, PRINTED........8E-19

CIRCUIT REPLACEMENTÐINSTRUMENT

CLUSTER REMOVED, PRINTED...........8E-6

CIRCUIT SENSEÐPCM INPUT, IGNITION....14-21

CIRCUIT TESTS - (VOLTAGE DROP

METHOD), STARTER FEED..............8A-9

CIRCUIT TESTS, STARTER CONTROL......8A-11

CIRCUIT VOLTAGE, BATTERY OPEN.........8A-4

CIRCUIT VOLTAGE TEST, BATTERY OPEN....8A-3

CIRCUITS, ABS SYSTEM WIRING AND

ELECTRICAL..........................5-4

CLAMPS, FUEL TUBES/LINES/HOSES . . 14-9,14-56

CLASSIFICATION OF LUBRICANTS...........0-2

CLASSIFICATIONS AND RATINGS,

BATTERY............................8A-8

CLASSIFICATIONS AND RATINGSÐ

LEFT HAND DRIVE, BATTERY...........8B-10

CLASSIFICATIONS AND RATINGSÐ

RIGHT HAND DRIVE, BATTERY..........8B-10

CLEAN BRAKE FLUID, IMPORTANCE OF.....5-48

CLEANER, AIR.........................25-7

CLEANER FILTER ELEMENT, ENGINE AIR....0-16

CLEANER HOUSING, AIR; EMISSION

CONTROL SYSTEMS...................25-8

CLEANER HOUSING, AIR; FUEL SYSTEM....14-54

CLEANING AND INSPECTION . 21-13,21-204,21-305

CLEANING AND INSPECTION, CALIPER......5-28

CLEANING AND INSPECTION, GEAR.......19-40

CLEANING AND INSPECTION,

TRANSMISSION CASE................21-118

CLEANING OF TIRES....................22-2

CLEANING/INSPECTION; FRONT

SUSPENSION AND AXLE................2-35

CLEANING/INSPECTION; REAR

SUSPENSION AND AXLES...............3-18

CLEANING/REVERSE FLUSHING,

COOLING SYSTEM....................7-17

CLEARANCE, AW-4 BUSHING AND

PISTON...........................21-326

CLIMATE CONTROL SYSTEMÐXJ VEHICLES . 24-22

CLIMATE CONTROL SYSTEMÐYJ VEHICLES . 24-37

CLIP, FUEL AND BRAKE FLUID TUBE

RETAINER; BODY COMPONENTSÐXJ

VEHICLES..........................23-86

CLIP, FUEL AND BRAKE FLUID TUBE

RETAINER; FRAME AND BUMPERS.......13-16

CLUSTER AND GAUGE HOUSINGS,

INSTRUMENT......................23-190

CLUSTER BEZEL, INSTRUMENT.....23-91,23-191

CLUSTER BULB REPLACEMENT,

INSTRUMENT.......................8E-19

CLUSTER DIAGNOSIS, INSTRUMENT;

INSTRUMENT PANEL AND

GAUGESÐXJ.........................8E-3

CLUSTER DIAGNOSIS, INSTRUMENT;

INSTRUMENT PANEL AND GAUGESÐYJ . . 8E-14

CLUSTER GAUGES, INSTRUMENT;

INSTRUMENT PANEL AND GAUGESÐXJ . . 8E-13

CLUSTER GAUGES, INSTRUMENT;

INSTRUMENT PANEL AND GAUGESÐYJ . . 8E-27

CLUSTER GENERAL INFORMATION,

INSTRUMENT; INSTRUMENT PANEL AND

GAUGESÐXJ.........................8E-1

CLUSTER GENERAL INFORMATION,

INSTRUMENT; INSTRUMENT PANEL

AND GAUGESÐYJ...................8E-14

CLUSTER, HIGH LINE...................8E-12

CLUSTER, INSTRUMENT................8E-15

CLUSTER, LOW LINE...................8E-11

CLUSTER REMOVED, GAUGE

REPLACEMENTÐINSTRUMENT..........8E-5

CLUSTER REMOVED, GEAR SELECTOR

INDICATOR REPLACEMENTÐ

INSTRUMENT........................8E-6

CLUSTER REMOVED, PRINTED CIRCUIT

REPLACEMENTÐINSTRUMENT..........8E-6

CLUSTER REMOVED, SPEEDOMETER

REPLACEMENTÐINSTRUMENT..........8E-5

CLUSTER REMOVED, TACHOMETER

REPLACEMENTÐINSTRUMENT

..........8E-5

CLUSTER REPLACEMENT, GAUGE

.........8E-24

CLUSTER REPLACEMENT, INSTRUMENT;

INSTRUMENT PANEL AND GAUGESÐXJ

. . . 8E-5

CLUSTER REPLACEMENT, INSTRUMENT;

INSTRUMENT PANEL AND GAUGESÐYJ

. . 8E-17CLUSTER SERVICE PROCEDURES,

INSTRUMENT; INSTRUMENT PANEL AND

GAUGESÐXJ.........................8E-5

CLUSTER SERVICE PROCEDURES,

INSTRUMENT; INSTRUMENT PANEL AND

GAUGESÐYJ........................8E-17

CLUSTER/SWITCH/LIGHTER/RADIO/HEVAC,

INSTRUMENT.......................23-91

CLUSTERS, INSTRUMENT...............8E-10

CLUTCH AND BRAKE PACK

REQUIREMENTS, AW-4...............21-328

CLUTCH AND OUTPUT SHAFT

OVERHAUL, NO. 2 ONE-WAY..........21-234

CLUTCH COMPONENT LUBRICATION.........6-1

CLUTCH COMPONENTS

...................6-1

CLUTCH COVER AND DISC INSTALLATION

....6-10

CLUTCH COVER AND DISC REMOVAL

.......6-10

CLUTCH DIAGNOSIS

.....................6-3

CLUTCH DISC AND PLATE THICKNESS,

AW-4

.............................21-325

CLUTCH FLUID LEVEL

...................6-14

CLUTCH HOUSING REPLACEMENT

.........6-11

CLUTCH, HYDRAULIC

....................0-22

CLUTCH HYDRAULIC LINKAGE

INSTALLATION

........................6-12

CLUTCH HYDRAULIC LINKAGE REMOVAL

....6-11

CLUTCH INSPECTION, TORQUE

CONVERTER STATOR

................21-189

CLUTCH LINKAGE FLUID

..................6-1

CLUTCH, MAGNETIC

....................24-18

CLUTCH OPERATION

.....................6-2

CLUTCH OVERHAUL, DIRECT

............21-219

CLUTCH OVERHAUL, FORWARD

.........21-223

CLUTCH OVERHAUL, FRONT

............21-125

CLUTCH OVERHAUL, OVERDRIVE

PLANETARY GEAR

...................21-209

CLUTCH OVERHAUL, REAR

.............21-128

CLUTCH OVERHAUL, SUN GEAR AND

NO. 1ONE-WAY

.....................21-229

CLUTCH PEDAL INSTALLATION

............6-15

CLUTCH PEDAL REMOVAL

................6-15

CLUTCH PROBLEM CAUSES

...............6-3

CLUTCH RELAY, AIR CONDITIONING

.......14-54

CLUTCH RELAYÐPCM OUTPUT, AIR

CONDITIONING

......................14-24

CLUTCH RELAYÐPCM OUTPUT, TORQUE

CONVERTER

........................14-27

CLUTCH RELAY TEST, TORQUE

CONVERTER

........................14-45

CLUTCH RELAY, TORQUE CONVERTER

.....14-60

CLUTCH SAFETY PRECAUTIONS

...........6-10

CLUTCH SERVICE

.......................6-10

CLUTCHÐLOW-REVERSE DRUMÐREAR

SUPPORT OVERHAUL, OVERRUNNING

. . . 21-118

COAT, BASE/COLOR

...................23-201

CODE, CHECKING FOR DIAGNOSTIC

TROUBLE

...........................8H-5

CODE DECODING, VEHICLE

...........INTRO.-3

CODE (DTC), DIAGNOSTIC TROUBLE

.......14-51

CODE (DTC), GENERATOR DIAGNOSTIC

TROUBLE

...........................8A-19

CODE IDENTIFICATION, WIRE

.............8W-2

CODE LETTERS, JEEP BODY

...............5-2

CODE PLATE, VEHICLE

...............INTRO.-2

CODES AND DIMENSIONS,

DESIGNATIONS, LABELS/PLATES,

.....INTRO.-1

CODES, INDICATOR (CHECK ENGINE)

LAMP FOR DIAGNOSTIC TROUBLE

.......8A-19

CODES, VEHICLE DESIGNATION

........INTRO.-1

CODES, XJ EXTERIOR PAINT

............23-205

CODES, XJ INTERIOR PAINT

............23-205

CODES, YJ EXTERIOR PAINT

............23-206

CODES, YJ INTERIOR PAINT

............23-206

COIL, EVAPORATOR

....................24-34

COIL, IGNITION; FUEL SYSTEM

...........14-57

COIL, IGNITION; IGNITION SYSTEMS

. 8D-4,8D-11,

8D-26

COILÐPCM OUTPUT, IGNITION

...........14-26

COIL RESISTANCE, IGNITION

............8D-11

COIL SPRING

..........................2-13

4 INDEXJ

Description Group-Page Description Group-Page Description Group-Page