JEEP CHEROKEE 1994 Service Manual PDF

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 61 of 1784

CAUTION: Never loosen the pinion gear nut to de-

crease the pinion gear bearing preload torque. If the

specified preload torque is exceeded, a new col-

lapsible spacer must be installed. The torque se-

quence will have to be repeated.

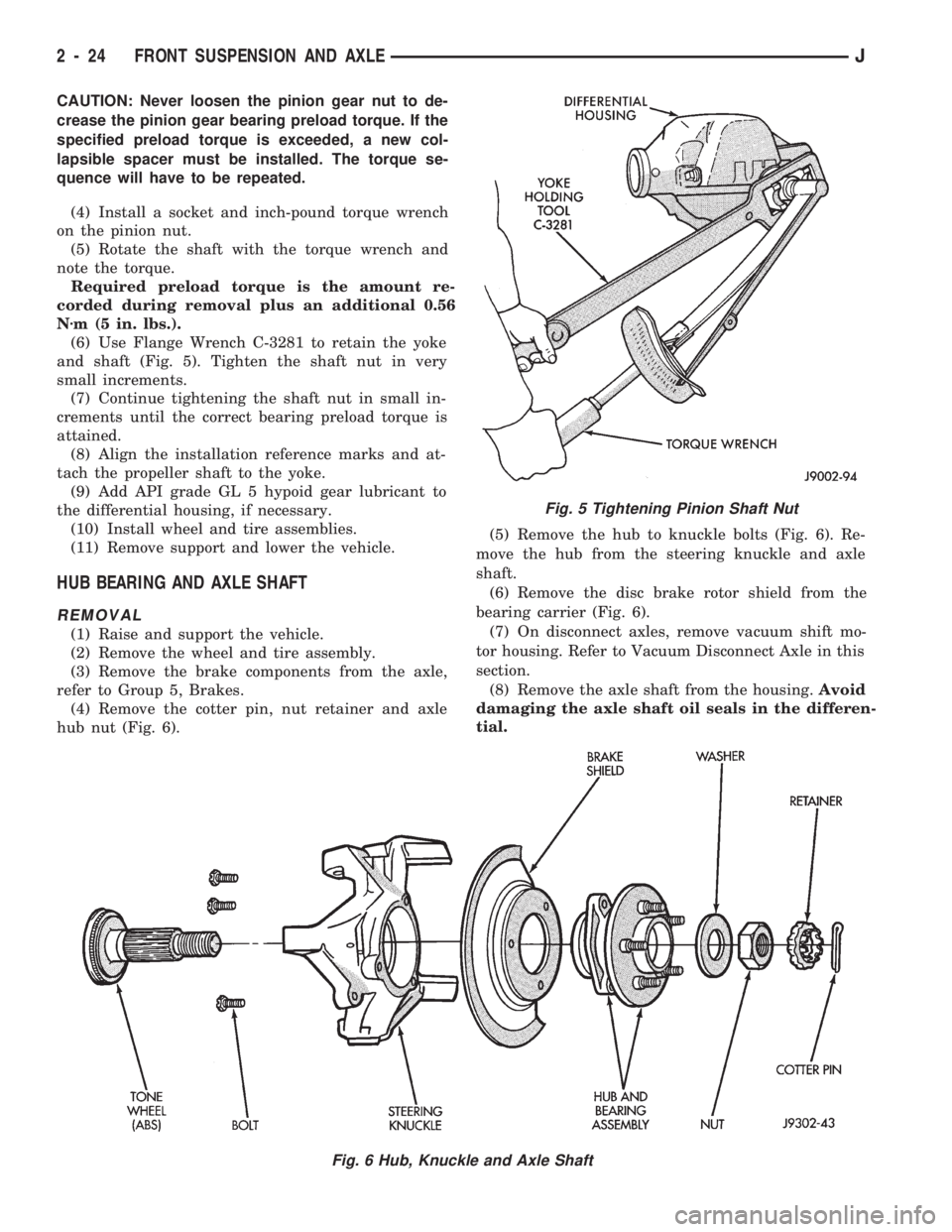

(4) Install a socket and inch-pound torque wrench

on the pinion nut.

(5) Rotate the shaft with the torque wrench and

note the torque.

Required preload torque is the amount re-

corded during removal plus an additional 0.56

Nzm (5 in. lbs.).

(6) Use Flange Wrench C-3281 to retain the yoke

and shaft (Fig. 5). Tighten the shaft nut in very

small increments.

(7) Continue tightening the shaft nut in small in-

crements until the correct bearing preload torque is

attained.

(8) Align the installation reference marks and at-

tach the propeller shaft to the yoke.

(9) Add API grade GL 5 hypoid gear lubricant to

the differential housing, if necessary.

(10) Install wheel and tire assemblies.

(11) Remove support and lower the vehicle.

HUB BEARING AND AXLE SHAFT

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake components from the axle,

refer to Group 5, Brakes.

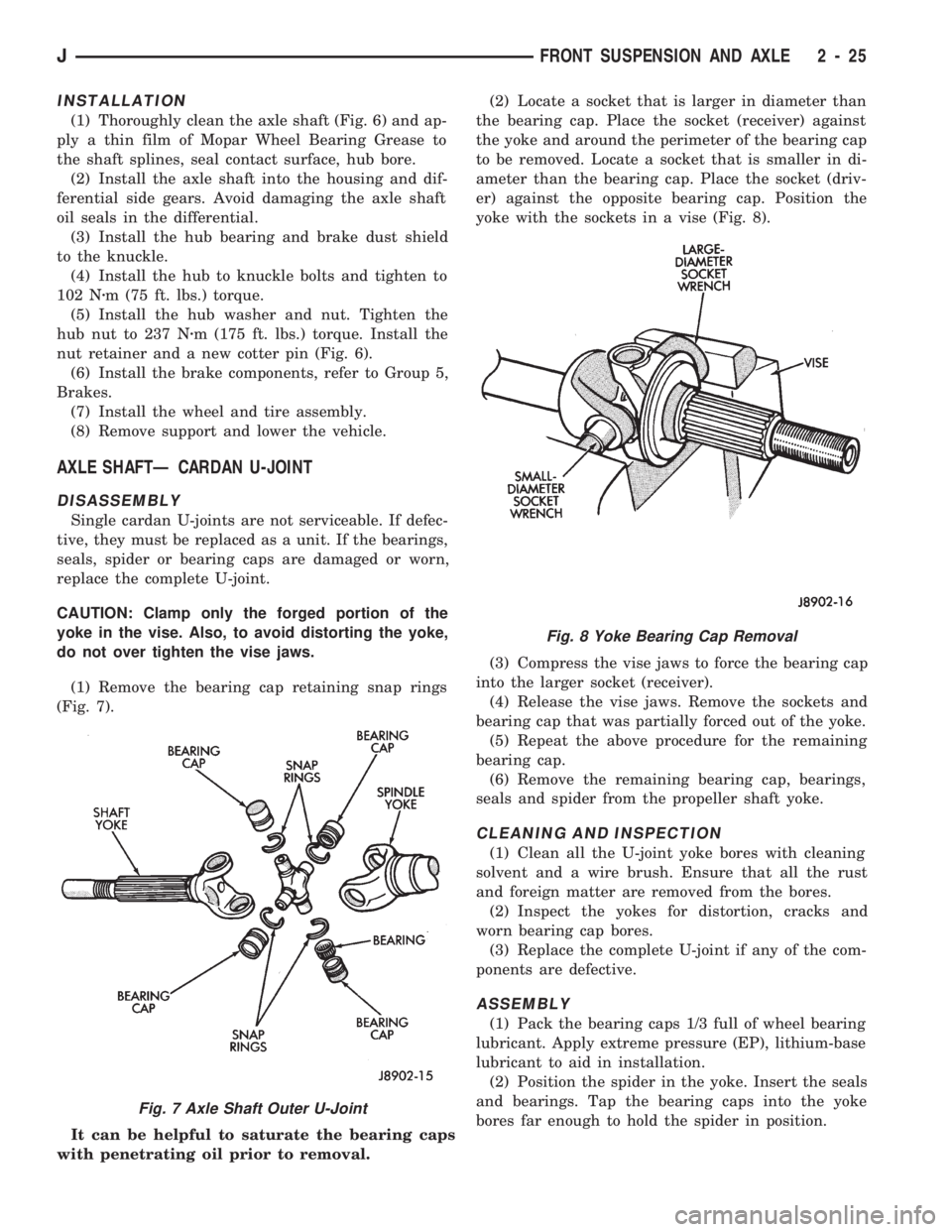

(4) Remove the cotter pin, nut retainer and axle

hub nut (Fig. 6).(5) Remove the hub to knuckle bolts (Fig. 6). Re-

move the hub from the steering knuckle and axle

shaft.

(6) Remove the disc brake rotor shield from the

bearing carrier (Fig. 6).

(7) On disconnect axles, remove vacuum shift mo-

tor housing. Refer to Vacuum Disconnect Axle in this

section.

(8) Remove the axle shaft from the housing.Avoid

damaging the axle shaft oil seals in the differen-

tial.

Fig. 5 Tightening Pinion Shaft Nut

Fig. 6 Hub, Knuckle and Axle Shaft

2 - 24 FRONT SUSPENSION AND AXLEJ

Page 62 of 1784

INSTALLATION

(1) Thoroughly clean the axle shaft (Fig. 6) and ap-

ply a thin film of Mopar Wheel Bearing Grease to

the shaft splines, seal contact surface, hub bore.

(2) Install the axle shaft into the housing and dif-

ferential side gears. Avoid damaging the axle shaft

oil seals in the differential.

(3) Install the hub bearing and brake dust shield

to the knuckle.

(4) Install the hub to knuckle bolts and tighten to

102 Nzm (75 ft. lbs.) torque.

(5) Install the hub washer and nut. Tighten the

hub nut to 237 Nzm (175 ft. lbs.) torque. Install the

nut retainer and a new cotter pin (Fig. 6).

(6) Install the brake components, refer to Group 5,

Brakes.

(7) Install the wheel and tire assembly.

(8) Remove support and lower the vehicle.

AXLE SHAFTÐ CARDAN U-JOINT

DISASSEMBLY

Single cardan U-joints are not serviceable. If defec-

tive, they must be replaced as a unit. If the bearings,

seals, spider or bearing caps are damaged or worn,

replace the complete U-joint.

CAUTION: Clamp only the forged portion of the

yoke in the vise. Also, to avoid distorting the yoke,

do not over tighten the vise jaws.

(1) Remove the bearing cap retaining snap rings

(Fig. 7).

It can be helpful to saturate the bearing caps

with penetrating oil prior to removal.(2) Locate a socket that is larger in diameter than

the bearing cap. Place the socket (receiver) against

the yoke and around the perimeter of the bearing cap

to be removed. Locate a socket that is smaller in di-

ameter than the bearing cap. Place the socket (driv-

er) against the opposite bearing cap. Position the

yoke with the sockets in a vise (Fig. 8).

(3) Compress the vise jaws to force the bearing cap

into the larger socket (receiver).

(4) Release the vise jaws. Remove the sockets and

bearing cap that was partially forced out of the yoke.

(5) Repeat the above procedure for the remaining

bearing cap.

(6) Remove the remaining bearing cap, bearings,

seals and spider from the propeller shaft yoke.

CLEANING AND INSPECTION

(1) Clean all the U-joint yoke bores with cleaning

solvent and a wire brush. Ensure that all the rust

and foreign matter are removed from the bores.

(2) Inspect the yokes for distortion, cracks and

worn bearing cap bores.

(3) Replace the complete U-joint if any of the com-

ponents are defective.

ASSEMBLY

(1) Pack the bearing caps 1/3 full of wheel bearing

lubricant. Apply extreme pressure (EP), lithium-base

lubricant to aid in installation.

(2) Position the spider in the yoke. Insert the seals

and bearings. Tap the bearing caps into the yoke

bores far enough to hold the spider in position.

Fig. 7 Axle Shaft Outer U-Joint

Fig. 8 Yoke Bearing Cap Removal

JFRONT SUSPENSION AND AXLE 2 - 25

Page 63 of 1784

(3) Place the socket (driver) against one bearing

cap. Position the yoke with the socket wrench in a

vise.

(4) Compress the vise to force the bearing caps into

the yoke. Force the caps enough to install the retain-

ing clips.

(5) Install the bearing cap retaining clips.

(6) Install the axle shaft, refer to Hub Bearing and

Axle Shaft installation.

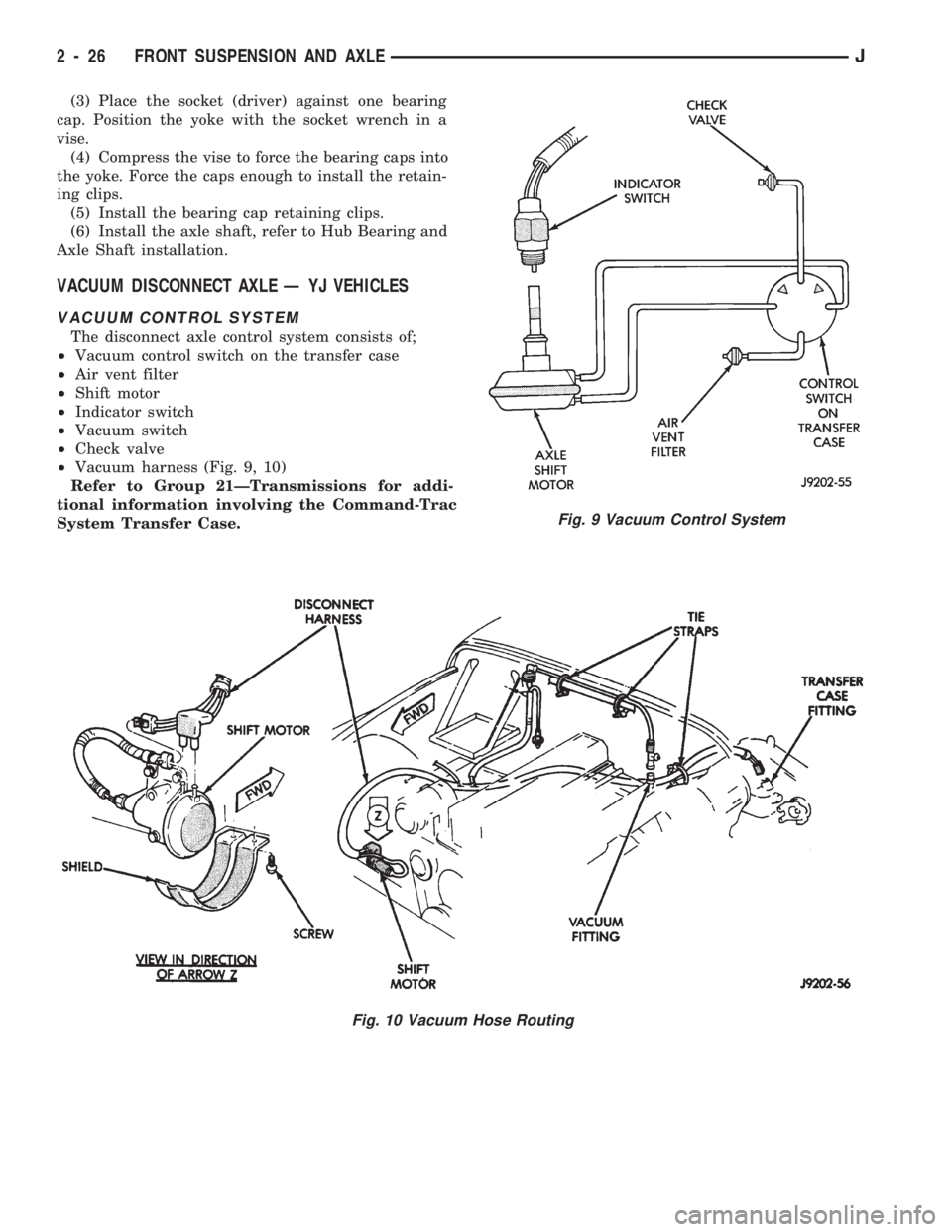

VACUUM DISCONNECT AXLE Ð YJ VEHICLES

VACUUM CONTROL SYSTEM

The disconnect axle control system consists of;

²Vacuum control switch on the transfer case

²Air vent filter

²Shift motor

²Indicator switch

²Vacuum switch

²Check valve

²Vacuum harness (Fig. 9, 10)

Refer to Group 21ÐTransmissions for addi-

tional information involving the Command-Trac

System Transfer Case.

Fig. 9 Vacuum Control System

Fig. 10 Vacuum Hose Routing

2 - 26 FRONT SUSPENSION AND AXLEJ

Page 64 of 1784

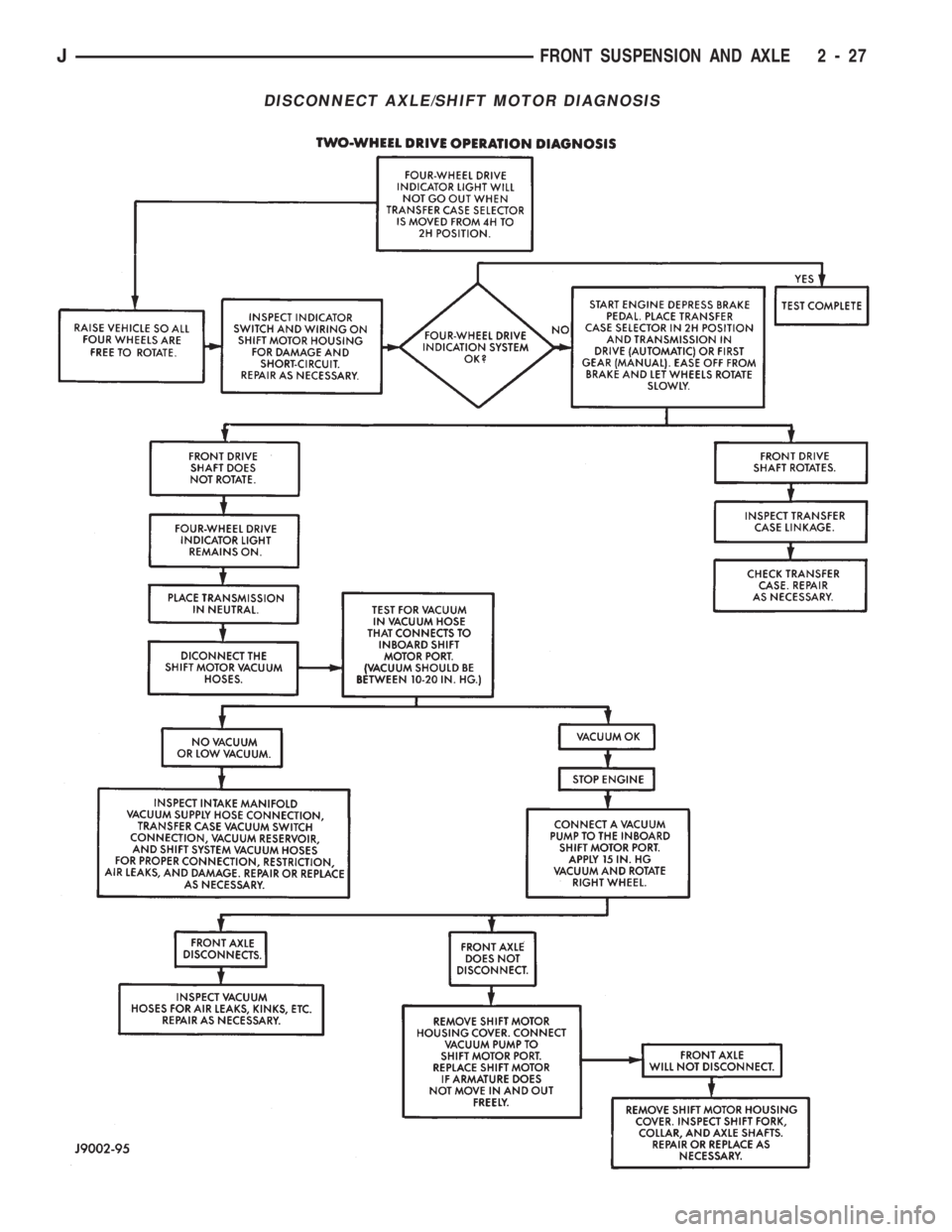

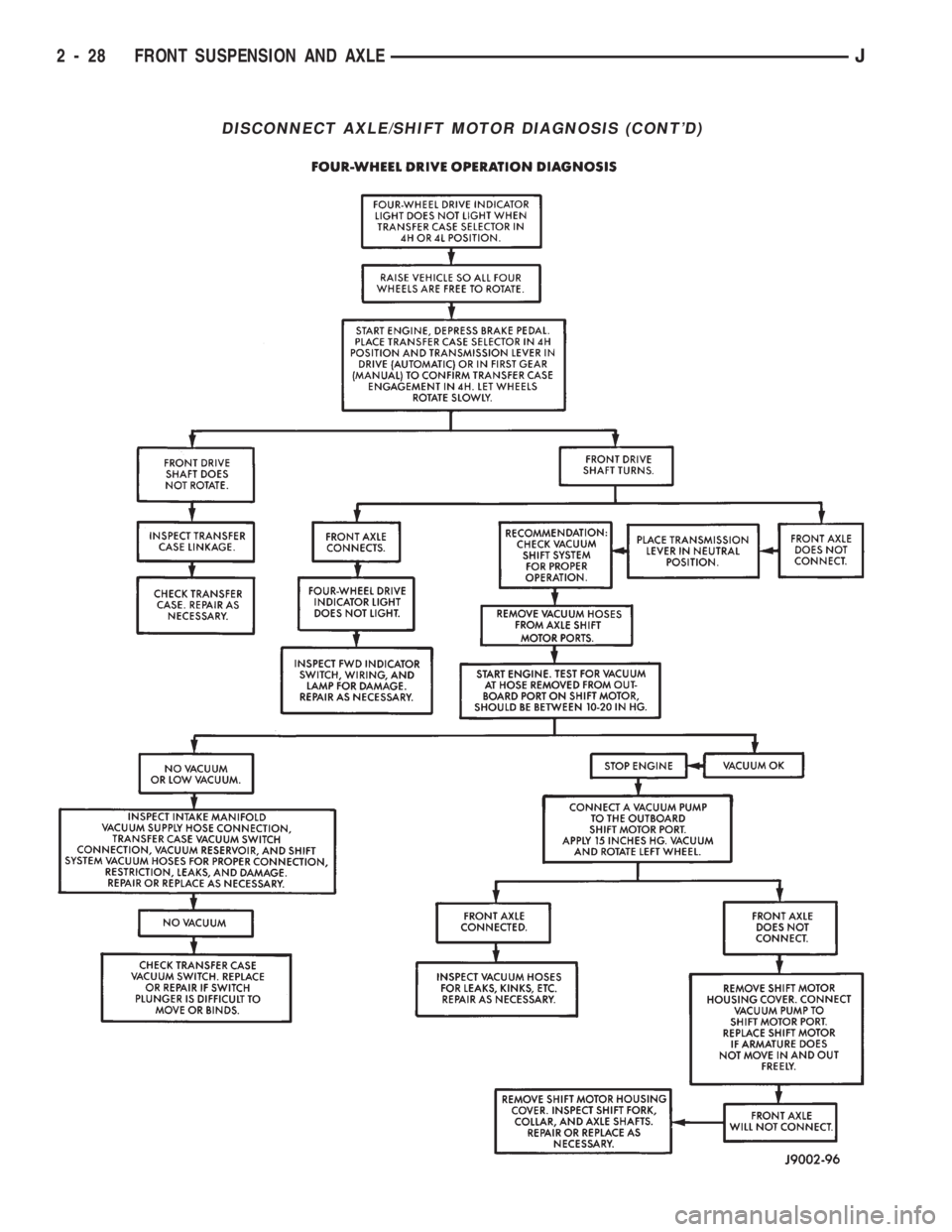

DISCONNECT AXLE/SHIFT MOTOR DIAGNOSIS

JFRONT SUSPENSION AND AXLE 2 - 27

Page 65 of 1784

DISCONNECT AXLE/SHIFT MOTOR DIAGNOSIS (CONT'D)

2 - 28 FRONT SUSPENSION AND AXLEJ

Page 66 of 1784

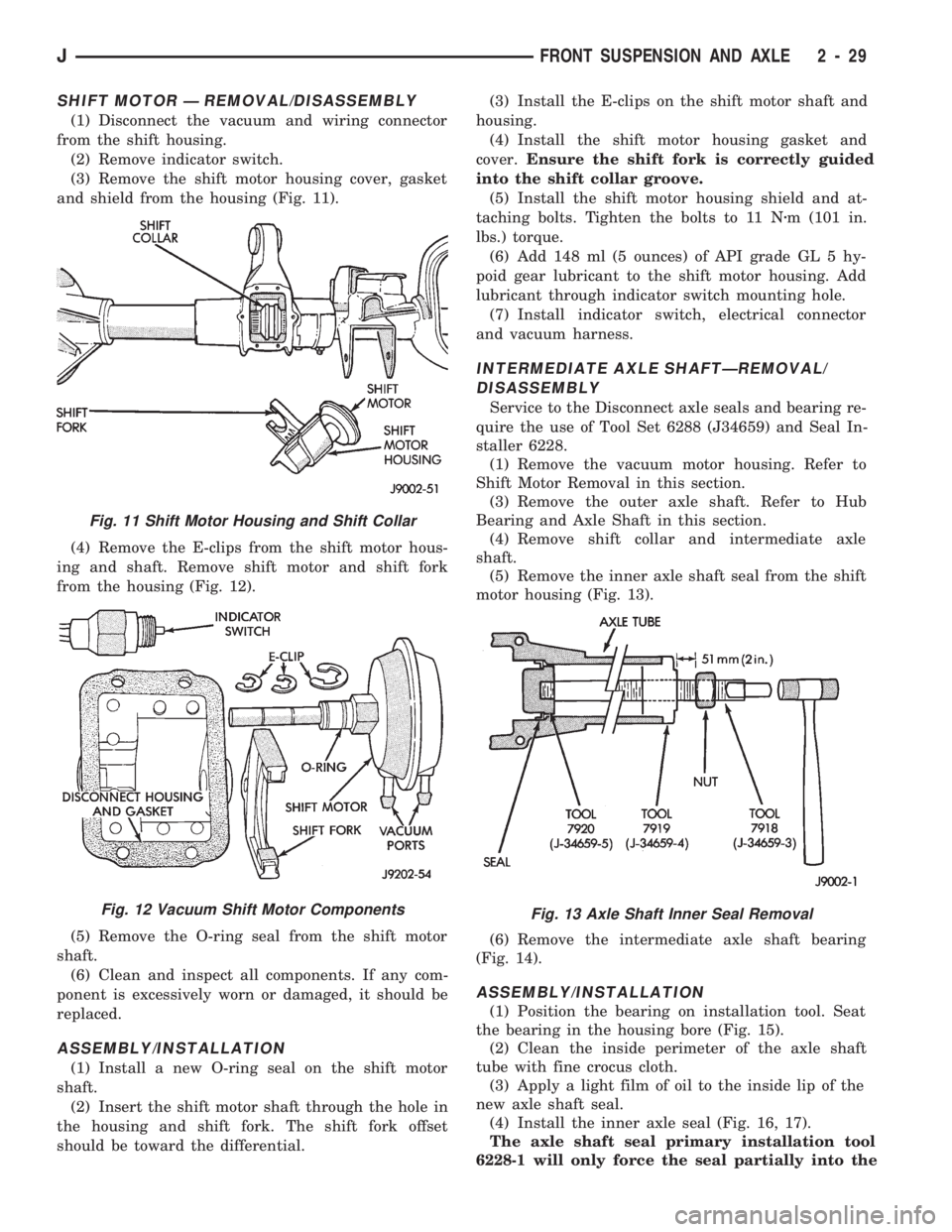

SHIFT MOTOR Ð REMOVAL/DISASSEMBLY

(1) Disconnect the vacuum and wiring connector

from the shift housing.

(2) Remove indicator switch.

(3) Remove the shift motor housing cover, gasket

and shield from the housing (Fig. 11).

(4) Remove the E-clips from the shift motor hous-

ing and shaft. Remove shift motor and shift fork

from the housing (Fig. 12).

(5) Remove the O-ring seal from the shift motor

shaft.

(6) Clean and inspect all components. If any com-

ponent is excessively worn or damaged, it should be

replaced.

ASSEMBLY/INSTALLATION

(1) Install a new O-ring seal on the shift motor

shaft.

(2) Insert the shift motor shaft through the hole in

the housing and shift fork. The shift fork offset

should be toward the differential.(3) Install the E-clips on the shift motor shaft and

housing.

(4) Install the shift motor housing gasket and

cover.Ensure the shift fork is correctly guided

into the shift collar groove.

(5) Install the shift motor housing shield and at-

taching bolts. Tighten the bolts to 11 Nzm (101 in.

lbs.) torque.

(6) Add 148 ml (5 ounces) of API grade GL 5 hy-

poid gear lubricant to the shift motor housing. Add

lubricant through indicator switch mounting hole.

(7) Install indicator switch, electrical connector

and vacuum harness.

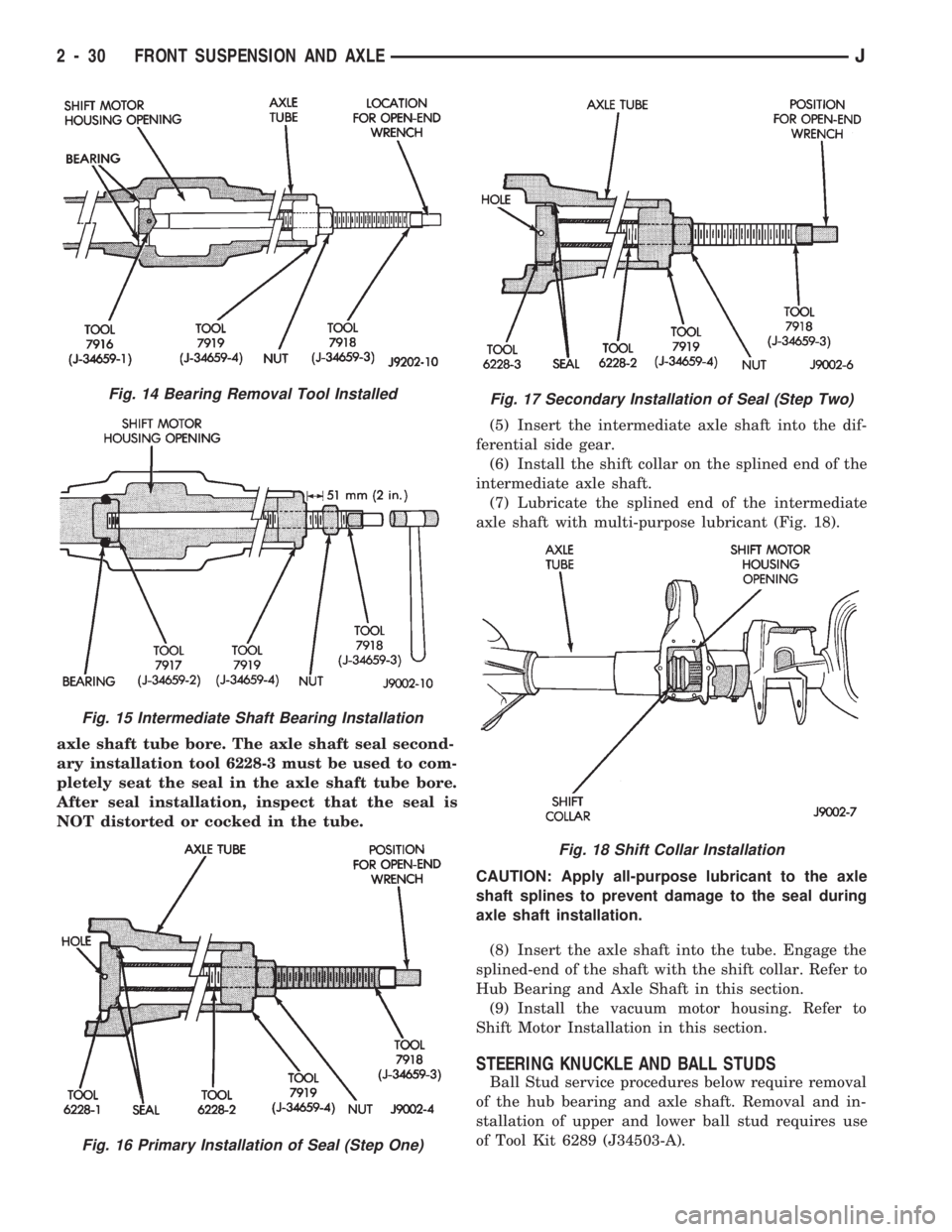

INTERMEDIATE AXLE SHAFTÐREMOVAL/

DISASSEMBLY

Service to the Disconnect axle seals and bearing re-

quire the use of Tool Set 6288 (J34659) and Seal In-

staller 6228.

(1) Remove the vacuum motor housing. Refer to

Shift Motor Removal in this section.

(3) Remove the outer axle shaft. Refer to Hub

Bearing and Axle Shaft in this section.

(4) Remove shift collar and intermediate axle

shaft.

(5) Remove the inner axle shaft seal from the shift

motor housing (Fig. 13).

(6) Remove the intermediate axle shaft bearing

(Fig. 14).

ASSEMBLY/INSTALLATION

(1) Position the bearing on installation tool. Seat

the bearing in the housing bore (Fig. 15).

(2) Clean the inside perimeter of the axle shaft

tube with fine crocus cloth.

(3) Apply a light film of oil to the inside lip of the

new axle shaft seal.

(4) Install the inner axle seal (Fig. 16, 17).

The axle shaft seal primary installation tool

6228-1 will only force the seal partially into the

Fig. 11 Shift Motor Housing and Shift Collar

Fig. 12 Vacuum Shift Motor ComponentsFig. 13 Axle Shaft Inner Seal Removal

JFRONT SUSPENSION AND AXLE 2 - 29

Page 67 of 1784

axle shaft tube bore. The axle shaft seal second-

ary installation tool 6228-3 must be used to com-

pletely seat the seal in the axle shaft tube bore.

After seal installation, inspect that the seal is

NOT distorted or cocked in the tube.(5) Insert the intermediate axle shaft into the dif-

ferential side gear.

(6) Install the shift collar on the splined end of the

intermediate axle shaft.

(7) Lubricate the splined end of the intermediate

axle shaft with multi-purpose lubricant (Fig. 18).

CAUTION: Apply all-purpose lubricant to the axle

shaft splines to prevent damage to the seal during

axle shaft installation.

(8) Insert the axle shaft into the tube. Engage the

splined-end of the shaft with the shift collar. Refer to

Hub Bearing and Axle Shaft in this section.

(9) Install the vacuum motor housing. Refer to

Shift Motor Installation in this section.

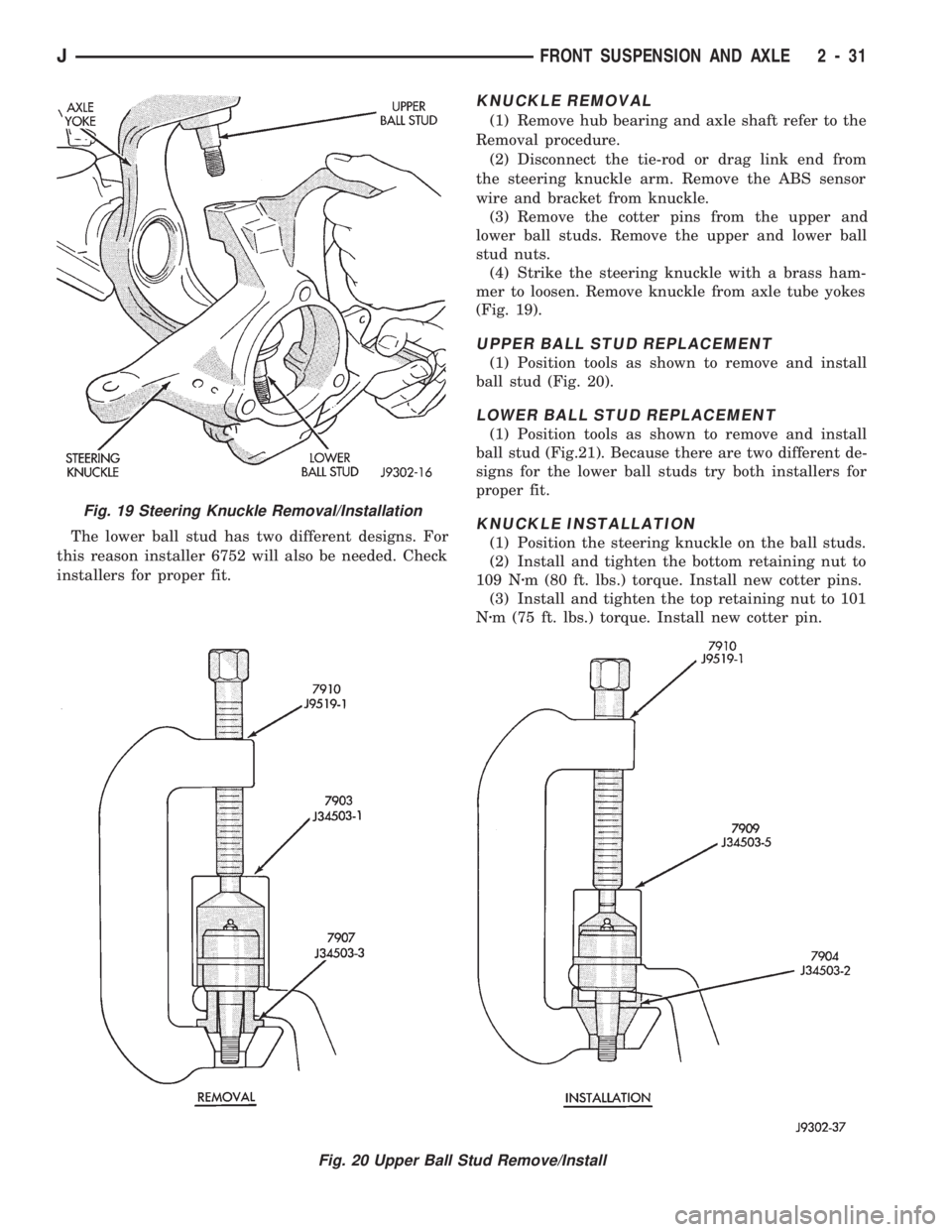

STEERING KNUCKLE AND BALL STUDS

Ball Stud service procedures below require removal

of the hub bearing and axle shaft. Removal and in-

stallation of upper and lower ball stud requires use

of Tool Kit 6289 (J34503-A).

Fig. 14 Bearing Removal Tool Installed

Fig. 15 Intermediate Shaft Bearing Installation

Fig. 16 Primary Installation of Seal (Step One)

Fig. 17 Secondary Installation of Seal (Step Two)

Fig. 18 Shift Collar Installation

2 - 30 FRONT SUSPENSION AND AXLEJ

Page 68 of 1784

The lower ball stud has two different designs. For

this reason installer 6752 will also be needed. Check

installers for proper fit.

KNUCKLE REMOVAL

(1) Remove hub bearing and axle shaft refer to the

Removal procedure.

(2) Disconnect the tie-rod or drag link end from

the steering knuckle arm. Remove the ABS sensor

wire and bracket from knuckle.

(3) Remove the cotter pins from the upper and

lower ball studs. Remove the upper and lower ball

stud nuts.

(4) Strike the steering knuckle with a brass ham-

mer to loosen. Remove knuckle from axle tube yokes

(Fig. 19).

UPPER BALL STUD REPLACEMENT

(1) Position tools as shown to remove and install

ball stud (Fig. 20).

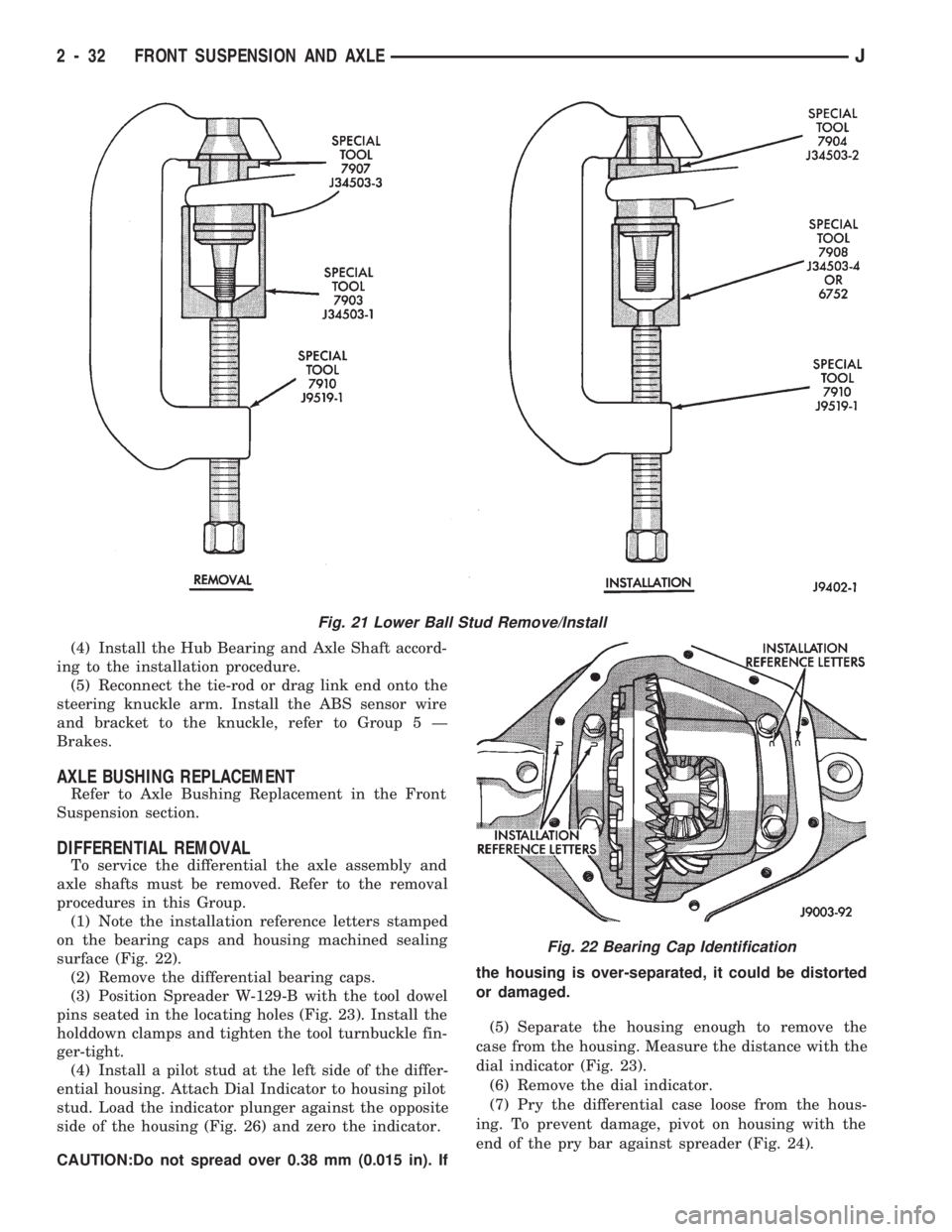

LOWER BALL STUD REPLACEMENT

(1) Position tools as shown to remove and install

ball stud (Fig.21). Because there are two different de-

signs for the lower ball studs try both installers for

proper fit.

KNUCKLE INSTALLATION

(1) Position the steering knuckle on the ball studs.

(2) Install and tighten the bottom retaining nut to

109 Nzm (80 ft. lbs.) torque. Install new cotter pins.

(3) Install and tighten the top retaining nut to 101

Nzm (75 ft. lbs.) torque. Install new cotter pin.

Fig. 19 Steering Knuckle Removal/Installation

Fig. 20 Upper Ball Stud Remove/Install

JFRONT SUSPENSION AND AXLE 2 - 31

Page 69 of 1784

(4) Install the Hub Bearing and Axle Shaft accord-

ing to the installation procedure.

(5) Reconnect the tie-rod or drag link end onto the

steering knuckle arm. Install the ABS sensor wire

and bracket to the knuckle, refer to Group 5 Ð

Brakes.

AXLE BUSHING REPLACEMENT

Refer to Axle Bushing Replacement in the Front

Suspension section.

DIFFERENTIAL REMOVAL

To service the differential the axle assembly and

axle shafts must be removed. Refer to the removal

procedures in this Group.

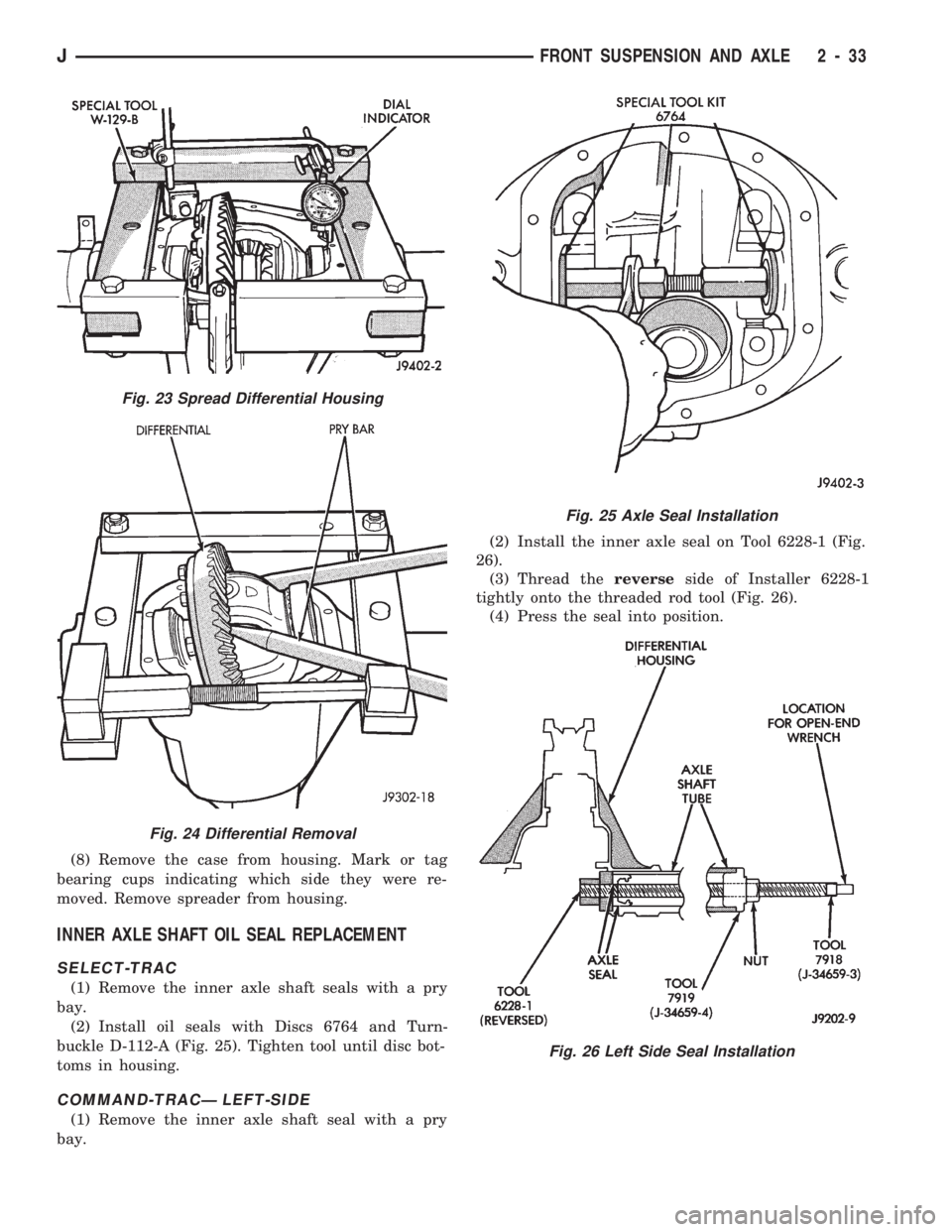

(1) Note the installation reference letters stamped

on the bearing caps and housing machined sealing

surface (Fig. 22).

(2) Remove the differential bearing caps.

(3) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 23). Install the

holddown clamps and tighten the tool turnbuckle fin-

ger-tight.

(4) Install a pilot stud at the left side of the differ-

ential housing. Attach Dial Indicator to housing pilot

stud. Load the indicator plunger against the opposite

side of the housing (Fig. 26) and zero the indicator.

CAUTION:Do not spread over 0.38 mm (0.015 in). Ifthe housing is over-separated, it could be distorted

or damaged.

(5) Separate the housing enough to remove the

case from the housing. Measure the distance with the

dial indicator (Fig. 23).

(6) Remove the dial indicator.

(7) Pry the differential case loose from the hous-

ing. To prevent damage, pivot on housing with the

end of the pry bar against spreader (Fig. 24).

Fig. 21 Lower Ball Stud Remove/Install

Fig. 22 Bearing Cap Identification

2 - 32 FRONT SUSPENSION AND AXLEJ

Page 70 of 1784

(8) Remove the case from housing. Mark or tag

bearing cups indicating which side they were re-

moved. Remove spreader from housing.

INNER AXLE SHAFT OIL SEAL REPLACEMENT

SELECT-TRAC

(1) Remove the inner axle shaft seals with a pry

bay.

(2) Install oil seals with Discs 6764 and Turn-

buckle D-112-A (Fig. 25). Tighten tool until disc bot-

toms in housing.

COMMAND-TRACÐ LEFT-SIDE

(1) Remove the inner axle shaft seal with a pry

bay.(2) Install the inner axle seal on Tool 6228-1 (Fig.

26).

(3) Thread thereverseside of Installer 6228-1

tightly onto the threaded rod tool (Fig. 26).

(4) Press the seal into position.

Fig. 23 Spread Differential Housing

Fig. 24 Differential Removal

Fig. 25 Axle Seal Installation

Fig. 26 Left Side Seal Installation

JFRONT SUSPENSION AND AXLE 2 - 33