air suspension JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 4 of 1784

Above that temperature range the viscosity will de-

crease, and below that range the viscosity will in-

crease.

An engine oil with an SAE 5W-30 viscosity grade

provides good flow capability for fast cold weather

engine starts. The viscosity will then increase with

engine temperature to provide good high-tempera-

ture engine lubrication.

API SERVICE GRADE

The API Service Grade specifies the type of engine/

operating conditions for which the oil is intended.

The API Service Grade specifications also apply to

energy conserving engine oils (Fig. 3). The API cer-

tification mark is also used indicating that the oil is

certified to meet the most critical requirements es-

tablished by the manufacturer (Fig. 4).

For maximum protection, use API Service Grade

SG, SG/CD or SG/CE engine oil in Jeeptengines.

GEAR LUBRICANTS

A dual SAE viscosity grade is also used to specify

the viscosity of multipurpose gear lubricants.

The API lubrication quality grade designation

identifies gear lubricants in terms of recommended

usage.

CHASSIS COMPONENT AND WHEEL BEARING

LUBRICANTS

The chassis component and wheel bearing lubri-

cants are identified by the NLGI Certification Sym-

bol (Fig. 5).

The letterGindicates wheel bearing lubricant and

the letterLindicates chassis lubricant. When the

letters are combined the lubricant can be used for

dual applications. The suffix lettersCandBindi-

cates quality level of the lubricant. Use only lubri-

cants that display the NLGI Certification Symbol.

RECOMMENDED LUBRICANT AND REPLACEMENT

PARTS

Jeeptvehicles are engineered to provide many

years of dependable operation. When necessary,MO-

PAR brand lubricants and genuine replacement

partsare highly recommended.

COMPONENTS REQUIRING NO LUBRICATION

There are many components that should not be lu-

bricated. The components that shouldnotbe lubri-

cated are:

²air pumps;

²generator bearings;

²drive belts;

²drive belt idler pulleys;

²rubber bushings;

²starter motor bearings;

²suspension strut bearings;

²throttle control cables;

²throttle linkage ball joints; and

²water pump bearings.

Fig. 4 The API Engine Oil Certification Mark

Fig. 5 NLGI Lubricant Certification/Identification

Symbol

JLUBRICATION AND MAINTENANCE 0 - 3

Page 43 of 1784

not change except when a spindle or ball stud is

damaged or bent. The angle is not adjustable and the

damaged component(s) must be replaced to correct

mis-alignment.

CAUTION:Do not attempt to modify any suspension

or steering component by heating and bending.

PRE-ALIGNMENT INSPECTION

Before starting a front wheel alignment, the follow-

ing inspection and necessary corrections must be

completed.

(1) Tires with the same recommended air pressure,

size, and thread wear. Refer to Group 22, Tires And

Wheels for diagnosis information.

(2) Front wheel bearings for wear.

(3) Ball studs, steering linkage pivot points and

steering gear for looseness, roughness, binding or

wear. Refer to Group 19, Steering for additional in-

formation.

(4) Front wheels for excessive radial or lateral

runout and unbalance. Refer to Group 22, Tires And

Wheels for diagnosis information.

(5) Suspension components for wear and noise.

Check components for correct torque. Refer to Groups

2 and 3, Suspension and Axle for additional informa-

tion.

ALIGNMENT MEASUREMENTS AND ADJUSTMENTS

Before each alignment reading, the vehicle should

be jounced (rear first, then front). Grasp each bumper

at the center and jounce the vehicle up and down

several times. Always release the bumper in the

down position.Set the front end alignment to

specifications with the vehicle at its NOR-

MALLY RIDE HEIGHT.

CAMBER

The wheel camber angle (Fig. 1) is preset at ZERO

DEGREES (0É). The angle is not adjustable and can-

not be altered.

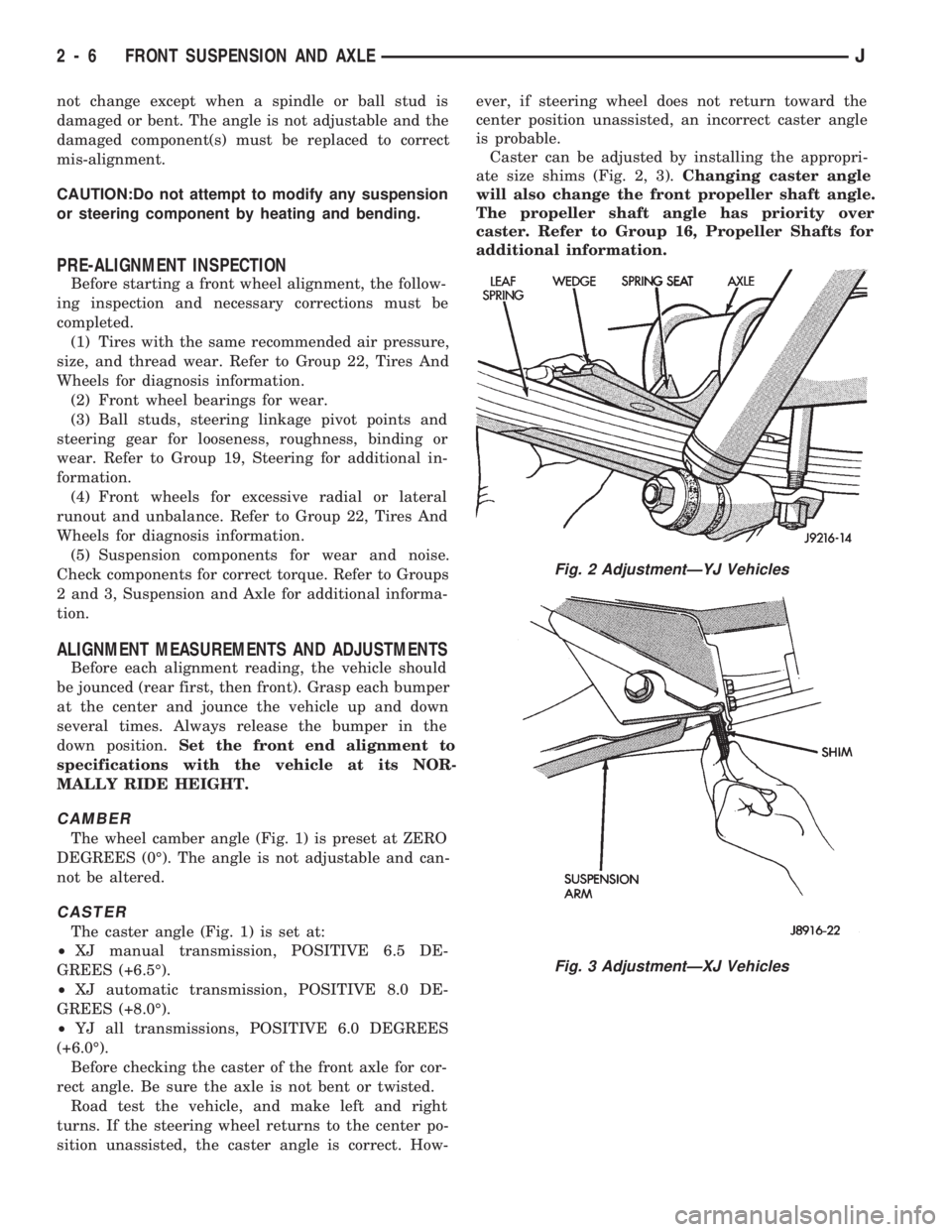

CASTER

The caster angle (Fig. 1) is set at:

²XJ manual transmission, POSITIVE 6.5 DE-

GREES (+6.5É).

²XJ automatic transmission, POSITIVE 8.0 DE-

GREES (+8.0É).

²YJ all transmissions, POSITIVE 6.0 DEGREES

(+6.0É).

Before checking the caster of the front axle for cor-

rect angle. Be sure the axle is not bent or twisted.

Road test the vehicle, and make left and right

turns. If the steering wheel returns to the center po-

sition unassisted, the caster angle is correct. How-ever, if steering wheel does not return toward the

center position unassisted, an incorrect caster angle

is probable.

Caster can be adjusted by installing the appropri-

ate size shims (Fig. 2, 3).Changing caster angle

will also change the front propeller shaft angle.

The propeller shaft angle has priority over

caster. Refer to Group 16, Propeller Shafts for

additional information.

Fig. 2 AdjustmentÐYJ Vehicles

Fig. 3 AdjustmentÐXJ Vehicles

2 - 6 FRONT SUSPENSION AND AXLEJ

Page 49 of 1784

(2) Install the bolts and finger tighten the nuts

(Fig. 3).

(3) Remove support and lower the vehicle.

(4) Tighten the front and rear nuts to 115 Nzm (85

ft. lbs.) torque.

SPRING AND SHOCK DIAGNOSIS

A squeak noise from the shock absorber can be pro-

duced if movement between the rubber bushings and

the metal occurs. This noise can usually be stopped

by tightening the attaching nuts. If the squeak noisepersists, inspect for damaged and worn bushings, and

attaching components. Repair as necessary.

The shock absorber bushings do not require any

type of lubrication. Do not lubricate the bushings to

reduce bushing noise. Grease or mineral oil-base lu-

bricants will deteriorate the bushing rubber.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston into and out

of the cylinder four or five times. The action through-

out each stroke should be smooth and even.

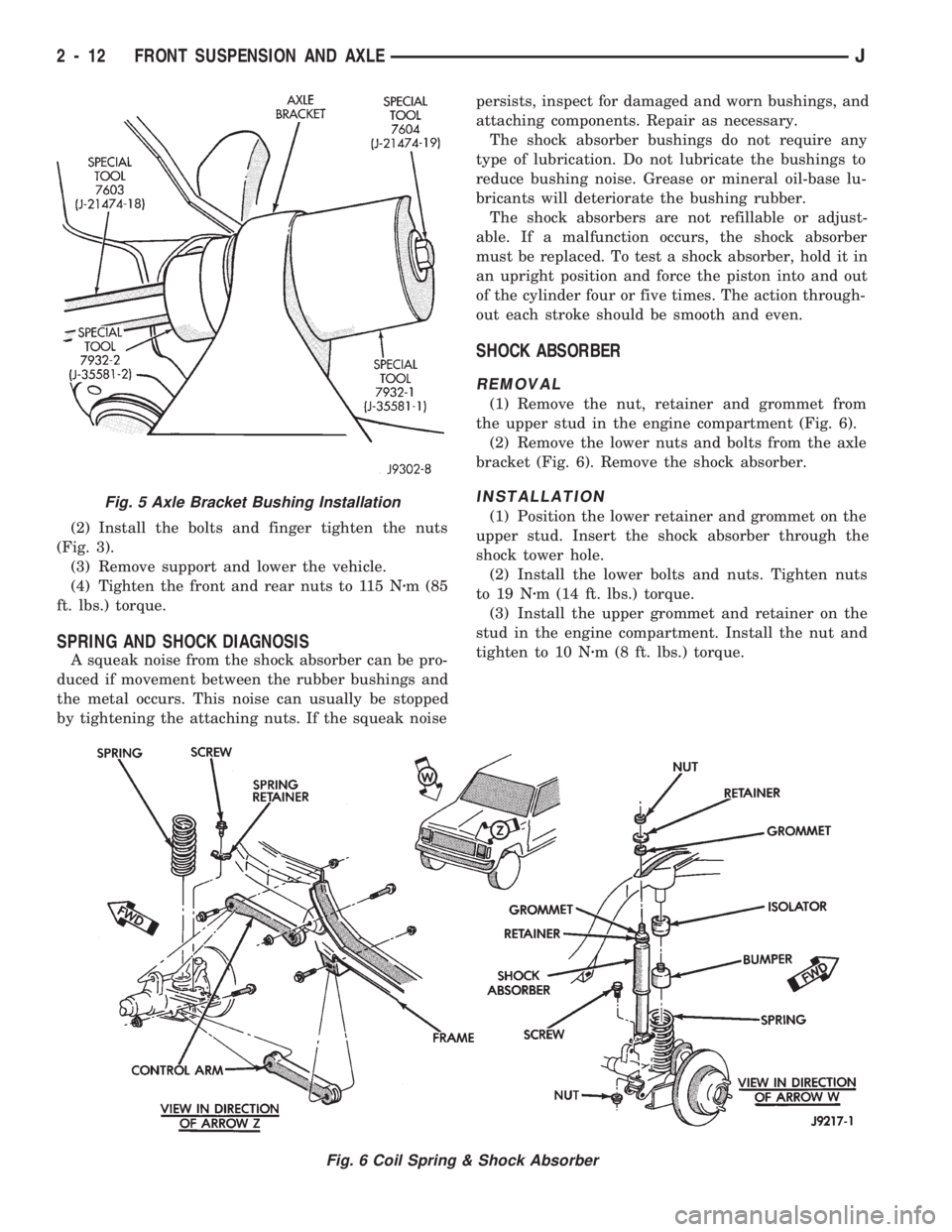

SHOCK ABSORBER

REMOVAL

(1) Remove the nut, retainer and grommet from

the upper stud in the engine compartment (Fig. 6).

(2) Remove the lower nuts and bolts from the axle

bracket (Fig. 6). Remove the shock absorber.

INSTALLATION

(1) Position the lower retainer and grommet on the

upper stud. Insert the shock absorber through the

shock tower hole.

(2) Install the lower bolts and nuts. Tighten nuts

to 19 Nzm (14 ft. lbs.) torque.

(3) Install the upper grommet and retainer on the

stud in the engine compartment. Install the nut and

tighten to 10 Nzm (8 ft. lbs.) torque.

Fig. 6 Coil Spring & Shock Absorber

Fig. 5 Axle Bracket Bushing Installation

2 - 12 FRONT SUSPENSION AND AXLEJ

Page 51 of 1784

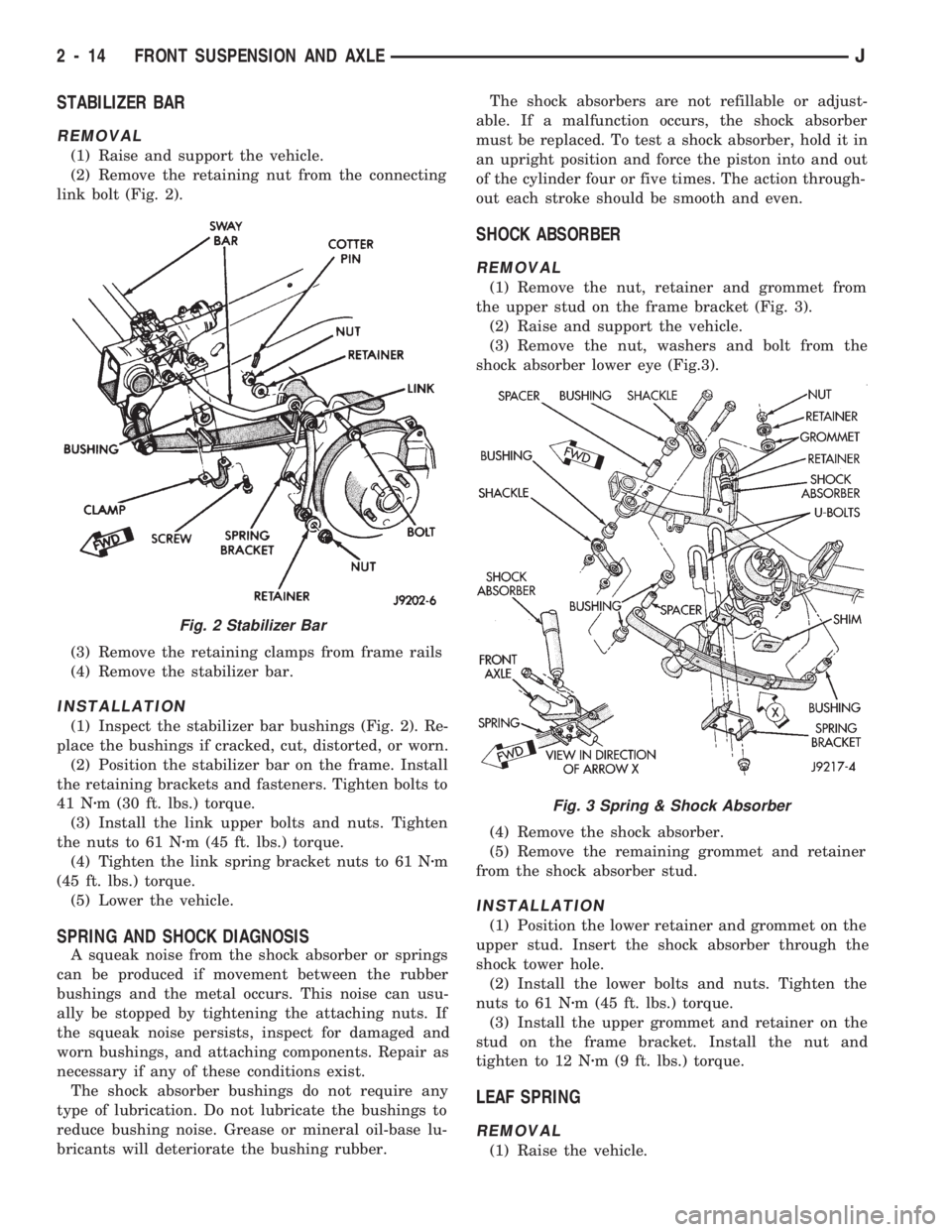

STABILIZER BAR

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the retaining nut from the connecting

link bolt (Fig. 2).

(3) Remove the retaining clamps from frame rails

(4) Remove the stabilizer bar.

INSTALLATION

(1) Inspect the stabilizer bar bushings (Fig. 2). Re-

place the bushings if cracked, cut, distorted, or worn.

(2) Position the stabilizer bar on the frame. Install

the retaining brackets and fasteners. Tighten bolts to

41 Nzm (30 ft. lbs.) torque.

(3) Install the link upper bolts and nuts. Tighten

the nuts to 61 Nzm (45 ft. lbs.) torque.

(4) Tighten the link spring bracket nuts to 61 Nzm

(45 ft. lbs.) torque.

(5) Lower the vehicle.

SPRING AND SHOCK DIAGNOSIS

A squeak noise from the shock absorber or springs

can be produced if movement between the rubber

bushings and the metal occurs. This noise can usu-

ally be stopped by tightening the attaching nuts. If

the squeak noise persists, inspect for damaged and

worn bushings, and attaching components. Repair as

necessary if any of these conditions exist.

The shock absorber bushings do not require any

type of lubrication. Do not lubricate the bushings to

reduce bushing noise. Grease or mineral oil-base lu-

bricants will deteriorate the bushing rubber.The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston into and out

of the cylinder four or five times. The action through-

out each stroke should be smooth and even.

SHOCK ABSORBER

REMOVAL

(1) Remove the nut, retainer and grommet from

the upper stud on the frame bracket (Fig. 3).

(2) Raise and support the vehicle.

(3) Remove the nut, washers and bolt from the

shock absorber lower eye (Fig.3).

(4) Remove the shock absorber.

(5) Remove the remaining grommet and retainer

from the shock absorber stud.

INSTALLATION

(1) Position the lower retainer and grommet on the

upper stud. Insert the shock absorber through the

shock tower hole.

(2) Install the lower bolts and nuts. Tighten the

nuts to 61 Nzm (45 ft. lbs.) torque.

(3) Install the upper grommet and retainer on the

stud on the frame bracket. Install the nut and

tighten to 12 Nzm (9 ft. lbs.) torque.

LEAF SPRING

REMOVAL

(1) Raise the vehicle.

Fig. 2 Stabilizer Bar

Fig. 3 Spring & Shock Absorber

2 - 14 FRONT SUSPENSION AND AXLEJ

Page 53 of 1784

AXLE NOISE/VIBRATION DIAGNOSIS

INDEX

page page

Driveline Snap........................... 17

Gear and Bearing Noise................... 16

General Information....................... 16Low Speed Knock........................ 17

Vibration............................... 17

GENERAL INFORMATION

Axle bearing problem conditions are usually caused

by:

²Insufficient or incorrect lubricant

²Foreign matter/water contamination

²Incorrect bearing preload torque adjustment

²Incorrect backlash (to tight)

When serviced, the bearings must be cleaned thor-

oughly. They should be dried with lint-free shop tow-

els.Never dry bearings with compressed air.

This will overheat them and brinell the bearing

surfaces. This will result in noisy operation after

repair.

Axle gear problem conditions are usually the result

of:

²Insufficient lubrication

²Incorrect or contaminated lubricant

²Overloading (excessive engine torque) or exceeding

vehicle weight capacity

²Incorrect clearance or backlash adjustment

Insufficient lubrication is usually the result of a

housing cover leak. It can also be from worn axle

shaft or pinion gear seals. Check for cracks or porous

areas in the housing or tubes.

Using the wrong lubricant will cause overheating

and gear failure. Gear tooth cracking and bearing

spalling are indicators of this.

Axle component breakage is most often the result

of:

²Severe overloading

²Insufficient lubricant

²Incorrect lubricant

²Improperly tightened components

Overloading occurs when towing heavier than rec-

ommended loads. Component breakage can occur

when the wheels are spun excessively. Incorrect lu-

bricant quantity contributes to breakage. Loose dif-

ferential components can also cause breakage.

Incorrect bearing preload or gear backlash will not

result in component breakage. Mis-adjustment will

produce enough noise to cause service repair before a

failure occurs. If a mis-adjustment condition is not

corrected, component failure can result.

Excessive bearing preload may not be noisy. This

condition will cause high temperature which can re-

sult in bearing failure.

GEAR AND BEARING NOISE

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant. Incorrect backlash, tooth contact, or worn/dam-

aged gears can cause noise.

Gear noise usually happens at a specific speed

range. The range is 30 to 40 mph, or above 50 mph.

The noise can also occur during a specific type of

driving condition. These conditions are acceleration,

deceleration, coast, or constant load.

When road testing, accelerate the vehicle to the

speed range where the noise is the greatest. Shift

out-of-gear and coast through the peak-noise range.

If the noise stops or changes greatly, check for insuf-

ficient lubricant. Incorrect ring gear backlash, or

gear damage can cause noise changes.

Differential side and pinion gears can be checked

by turning the vehicle. They usually do not cause

noise in straight-ahead driving. These gears are

loaded during vehicle turns. If noise does occur dur-

ing vehicle turns, the side or pinion gears could be

worn or damaged. A worn pinion gear mate shaft can

also cause a snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion gear bear-

ings can all produce noise when worn or damaged.

Bearing noise can be either a whining, or a growling

sound.

Pinion gear bearings have a constant-pitch noise.

This noise changes only with vehicle speed. Pinion

bearing noise will be higher because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs the pinion rear bearing is

the source of the noise. If the bearing noise is heard

during a coast, front bearing is the source.

Worn, damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing. The pitch of differential

bearing noise is also constant and varies only with

vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

2 - 16 FRONT SUSPENSION AND AXLEJ

Page 54 of 1784

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion gear shaft bore will also cause low speed

knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft

²Missing drive shaft balance weight

²Worn, out-of-balance wheels

²Loose wheel lug nuts

²Worn U-joint

²Loose spring U-bolts

²Loose/broken springs

²Damaged axle shaft bearings

²Loose pinion gear nut

²Excessive pinion yoke run out

²Bent axle shaft

Check for loose or damaged front-end components

or engine/transmission mounts. These componentscan contribute to what appears to be a rear-end vi-

bration. Do not overlook engine accessories, brackets

and drive belts.

All driveline components should be examined be-

fore starting any repair.

Refer to Group 22ÐTires And Wheels for addi-

tional information involving vibration diagnosis.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed

²Loose engine/transmission/transfer case mounts

²Worn U-joints

²Loose spring mounts

²Loose pinion gear nut and yoke

²Excessive ring gear backlash

²Excessive differential side gear-to-case clearance

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the ve-

hicle on a hoist with the wheels free to rotate.

Instruct the helper to shift the transmission into

gear. Listen for the noise, a mechanics stethoscope is

helpful in isolating the source of a noise.

JFRONT SUSPENSION AND AXLE 2 - 17

Page 63 of 1784

(3) Place the socket (driver) against one bearing

cap. Position the yoke with the socket wrench in a

vise.

(4) Compress the vise to force the bearing caps into

the yoke. Force the caps enough to install the retain-

ing clips.

(5) Install the bearing cap retaining clips.

(6) Install the axle shaft, refer to Hub Bearing and

Axle Shaft installation.

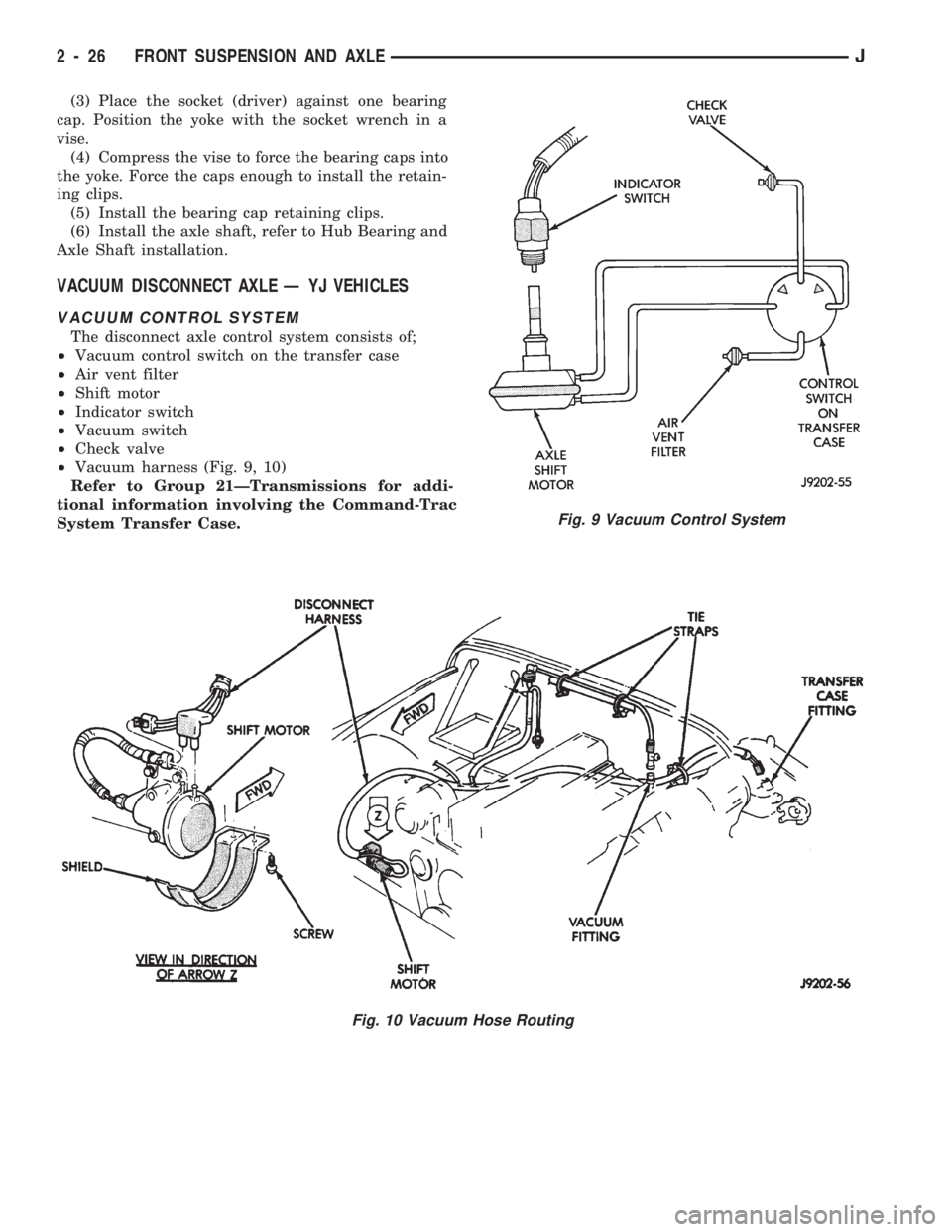

VACUUM DISCONNECT AXLE Ð YJ VEHICLES

VACUUM CONTROL SYSTEM

The disconnect axle control system consists of;

²Vacuum control switch on the transfer case

²Air vent filter

²Shift motor

²Indicator switch

²Vacuum switch

²Check valve

²Vacuum harness (Fig. 9, 10)

Refer to Group 21ÐTransmissions for addi-

tional information involving the Command-Trac

System Transfer Case.

Fig. 9 Vacuum Control System

Fig. 10 Vacuum Hose Routing

2 - 26 FRONT SUSPENSION AND AXLEJ

Page 72 of 1784

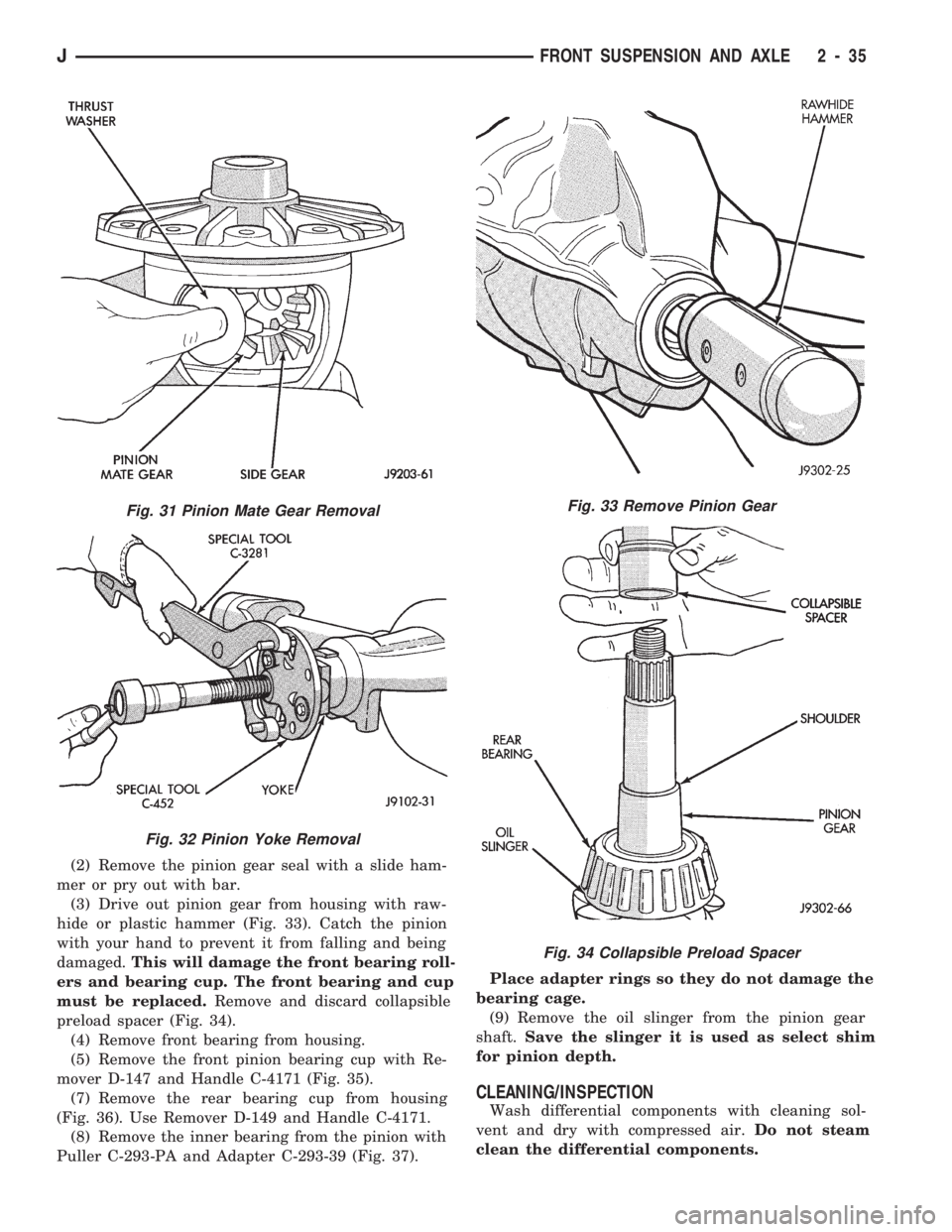

(2) Remove the pinion gear seal with a slide ham-

mer or pry out with bar.

(3) Drive out pinion gear from housing with raw-

hide or plastic hammer (Fig. 33). Catch the pinion

with your hand to prevent it from falling and being

damaged.This will damage the front bearing roll-

ers and bearing cup. The front bearing and cup

must be replaced.Remove and discard collapsible

preload spacer (Fig. 34).

(4) Remove front bearing from housing.

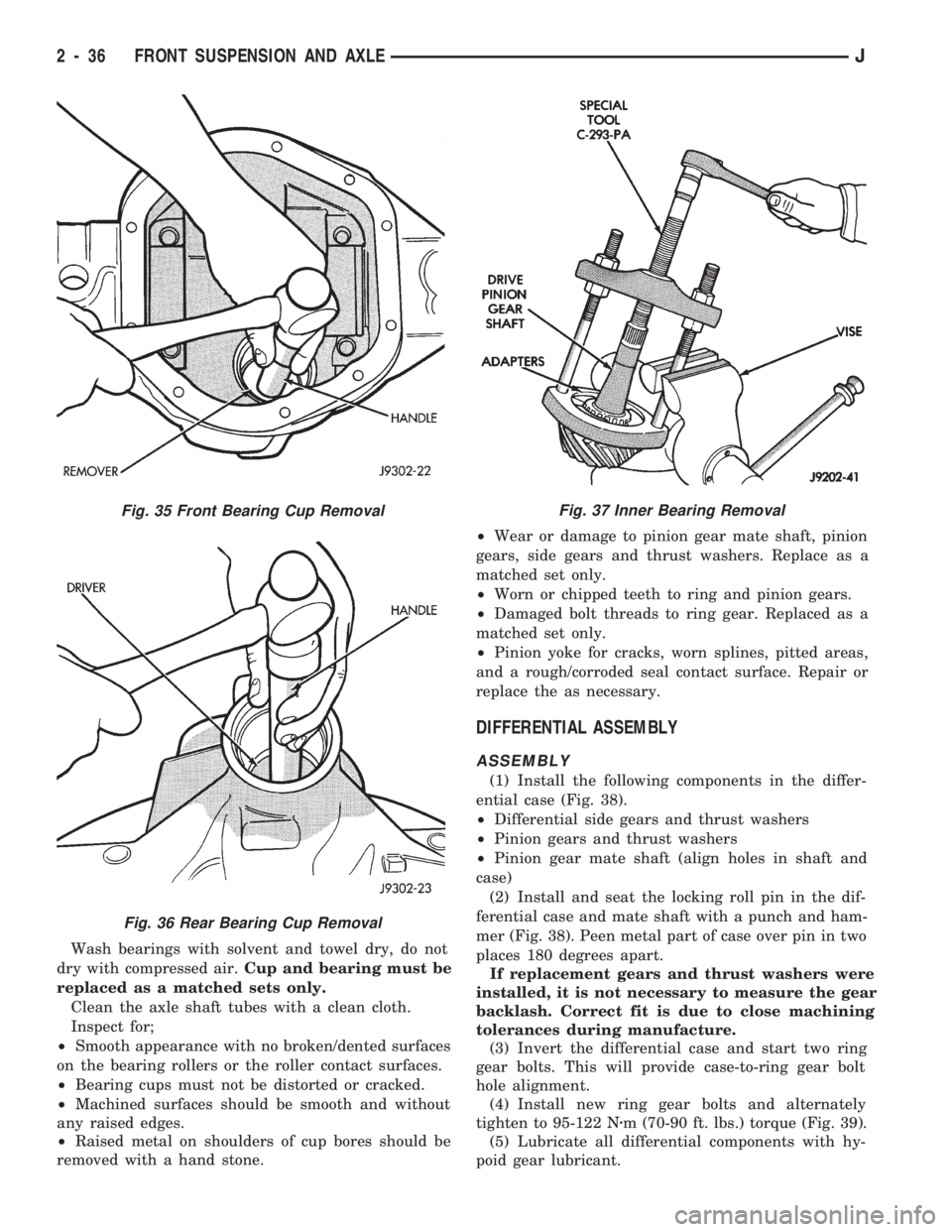

(5) Remove the front pinion bearing cup with Re-

mover D-147 and Handle C-4171 (Fig. 35).

(7) Remove the rear bearing cup from housing

(Fig. 36). Use Remover D-149 and Handle C-4171.

(8) Remove the inner bearing from the pinion with

Puller C-293-PA and Adapter C-293-39 (Fig. 37).Place adapter rings so they do not damage the

bearing cage.

(9) Remove the oil slinger from the pinion gear

shaft.Save the slinger it is used as select shim

for pinion depth.

CLEANING/INSPECTION

Wash differential components with cleaning sol-

vent and dry with compressed air.Do not steam

clean the differential components.

Fig. 31 Pinion Mate Gear Removal

Fig. 32 Pinion Yoke Removal

Fig. 33 Remove Pinion Gear

Fig. 34 Collapsible Preload Spacer

JFRONT SUSPENSION AND AXLE 2 - 35

Page 73 of 1784

Wash bearings with solvent and towel dry, do not

dry with compressed air.Cup and bearing must be

replaced as a matched sets only.

Clean the axle shaft tubes with a clean cloth.

Inspect for;

²Smooth appearance with no broken/dented surfaces

on the bearing rollers or the roller contact surfaces.

²Bearing cups must not be distorted or cracked.

²Machined surfaces should be smooth and without

any raised edges.

²Raised metal on shoulders of cup bores should be

removed with a hand stone.²Wear or damage to pinion gear mate shaft, pinion

gears, side gears and thrust washers. Replace as a

matched set only.

²Worn or chipped teeth to ring and pinion gears.

²Damaged bolt threads to ring gear. Replaced as a

matched set only.

²Pinion yoke for cracks, worn splines, pitted areas,

and a rough/corroded seal contact surface. Repair or

replace the as necessary.

DIFFERENTIAL ASSEMBLY

ASSEMBLY

(1) Install the following components in the differ-

ential case (Fig. 38).

²Differential side gears and thrust washers

²Pinion gears and thrust washers

²Pinion gear mate shaft (align holes in shaft and

case)

(2) Install and seat the locking roll pin in the dif-

ferential case and mate shaft with a punch and ham-

mer (Fig. 38). Peen metal part of case over pin in two

places 180 degrees apart.

If replacement gears and thrust washers were

installed, it is not necessary to measure the gear

backlash. Correct fit is due to close machining

tolerances during manufacture.

(3) Invert the differential case and start two ring

gear bolts. This will provide case-to-ring gear bolt

hole alignment.

(4) Install new ring gear bolts and alternately

tighten to 95-122 Nzm (70-90 ft. lbs.) torque (Fig. 39).

(5) Lubricate all differential components with hy-

poid gear lubricant.

Fig. 35 Front Bearing Cup Removal

Fig. 36 Rear Bearing Cup Removal

Fig. 37 Inner Bearing Removal

2 - 36 FRONT SUSPENSION AND AXLEJ

Page 157 of 1784

when the cover is off. The second involves adding to,

or filling the cylinder reservoirs with a non-recom-

mended fluid.

Brake fluid contaminated with only dirt, or debris

usually retains a normal appearance. In some cases,

the foreign material will remain suspended in the

fluid and be visible. The fluid and foreign material

can be removed from the reservoir with a suction

gun but only if the brakes have not been applied. If

the brakes are applied after contamination, system

flushing will be required. The master cylinder may

also have to be disassembled, cleaned and the piston

seals replaced. Foreign material lodged in the reser-

voir compensator/return ports can cause brake drag

by restricting fluid return after brake application.

Brake fluid contaminated by a non-recommended

fluid will usually be discolored, milky, oily looking,

or foamy. In some cases, it may even appear as if the

fluid contains sludge.However, remember that

brake fluid will darken in time and occasionally

be cloudy in appearance. These are normal con-

ditions and should not be mistaken for contami-

nation.

If some type of oil has been added to the system,

the fluid will separate into distinct layers. To verify

this, drain off a sample with a clean suction gun.

Then pour the sample into a glass container and ob-

serve fluid action. If the fluid separates into distinct

layers, it is definitely contaminated.

The only real correction for contamination by non-

recommended fluid is to flush the entire hydraulic

system and replace all the seals.

BRAKE NOISE

Squeak/Squeal

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or

oil. Glazed linings and rotors with hard spots can

also contribute to squeak. Dirt and foreign material

embedded in the brake lining will also cause squeak/

squeal.

A very loud squeak or squeal is frequently a sign

of severely worn brake lining. If the lining has worn

through to the brakeshoes in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors can become so scored that replacement is nec-

essary.

Thump/Clunk

Thumping or clunk noises during braking are fre-

quentlynotcaused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components. How-

ever, calipers that bind on the slide surfaces can gen-

erate a thump or clunk noise. In addition, worn out,

improperly adjusted, or improperly assembled rear

brakeshoes can also produce a thump noise.Chatter/Shudder

Brake chatter, or shudder is usually caused by

loose or worn components, or glazed/burnt lining. Ro-

tors with hard spots can also contribute to chatter.

Additional causes of chatter are out of tolerance ro-

tors, brake lining not securely attached to the shoes,

loose wheel bearings and contaminated brake lining.

BRAKELINING CONTAMINATION

Brakelining contamination is usually a product of

leaking calipers or wheel cylinders, driving through

deep water puddles, or lining that has become cov-

ered with grease and grit during repair.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a condition similar to grab as the tire loses

and recovers traction.

Flat-spotted tires can cause vibration and wheel

tramp and generate shudder during brake operation.

A tire with internal damage such as a severe

bruise or ply separation can cause pull and vibration.

DIAGNOSING PARKING BRAKE PROBLEMS

Adjustment Mechanism

Parking brake adjustment is controlled by a

cable tensioner mechanism. This applies to 1991

through 1994 YJ models and 1992 and later XJ

models. The cable tensioner, once adjusted at

the factory, will not need further adjustment un-

der normal circumstances. There are only two

instances when adjustment is required. The first

is when a new tensioner, or cables have been in-

stalled. And the second, is when the tensioner

and cables are disconnected for access to other

brake components.

Parking Brake problem Causes

In most cases, the actual cause of an improperly

functioning parking brake (too loose/too tight/wont

hold), can be traced to a drum brake component.

The leading cause of improper parking brake

operation, is excessive clearance between the

brakeshoes and the drum surface. Excessive

clearance is a result of: lining and/or drum wear;

oversize drums; or inoperative shoe adjuster

components.

Excessive parking brake lever travel (sometimes

described as a loose lever or too loose condition), is

the result of worn brakeshoes/drums, improper

brakeshoe adjustment, or mis-assembled brake parts.

A ``too loose'' condition can also be caused by inop-

erative brakeshoe adjusters. If the adjusters are mis-

5 - 10 BRAKESJ