jump cable JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 8 of 1784

JUMP STARTING, HOISTING AND TOWING

JUMP STARTING

WARNING: DO NOT ATTEMPT TO PUSH OR TOW A

VEHICLE TO START THE ENGINE. UNBURNED

FUEL COULD ENTER THE EXHAUST CATALYTIC

CONVERTER AND IGNITE AFTER THE ENGINE IS

STARTED. THIS COULD CAUSE THE CONVERTER

TO OVERHEAT AND RUPTURE.

BOOSTER BATTERY

WARNING: TO PREVENT PERSONAL INJURY OR

CLOTHING DAMAGE, DO NOT ALLOW BATTERY

(ACID) TO CONTACT EYES, SKIN OR CLOTHING.

DO NOT LEAN OVER A BATTERY WHEN CON-

NECTING JUMPER CABLES. DO NOT ALLOW THE

POSITIVE AND NEGATIVE CABLE CONNECTOR

CLAMPS TO CONTACT EACH OTHER. KEEP OPEN

FLAMES AND SPARKS AWAY FROM THE BATTERY

VENT HOLES. ALWAYS WEAR EYE PROTECTION

WHEN INVOLVED WITH BATTERIES.

If it is necessary to use a booster battery and

jumper cables to start an engine use the following

procedure.

(1) Engage the parking brake and shift the auto-

matic transmission to PARK, manual transmission

shift to NEUTRAL.

(2) Turn off all lights, the heater-A/C blower mo-

tor, and all other electrical loads.

WARNING: WHEN THE AIR TEMPERATURE IS BE-

LOW THE FREEZING POINT (0ÉC OR 32ÉF), THE

ACID IN A DISCHARGED VEHICLE BATTERY CAN

FREEZE. DO NOT ATTEMPT TO JUMP START AN

ENGINE BEFORE DETERMINING THE CONDITION

OF THE BATTERY.

(3) Inspect the general condition of the battery.

CAUTION: Do not permit metal surfaces on vehicles

to contact because this could establish ground con-

tinuity between vehicle bodies.

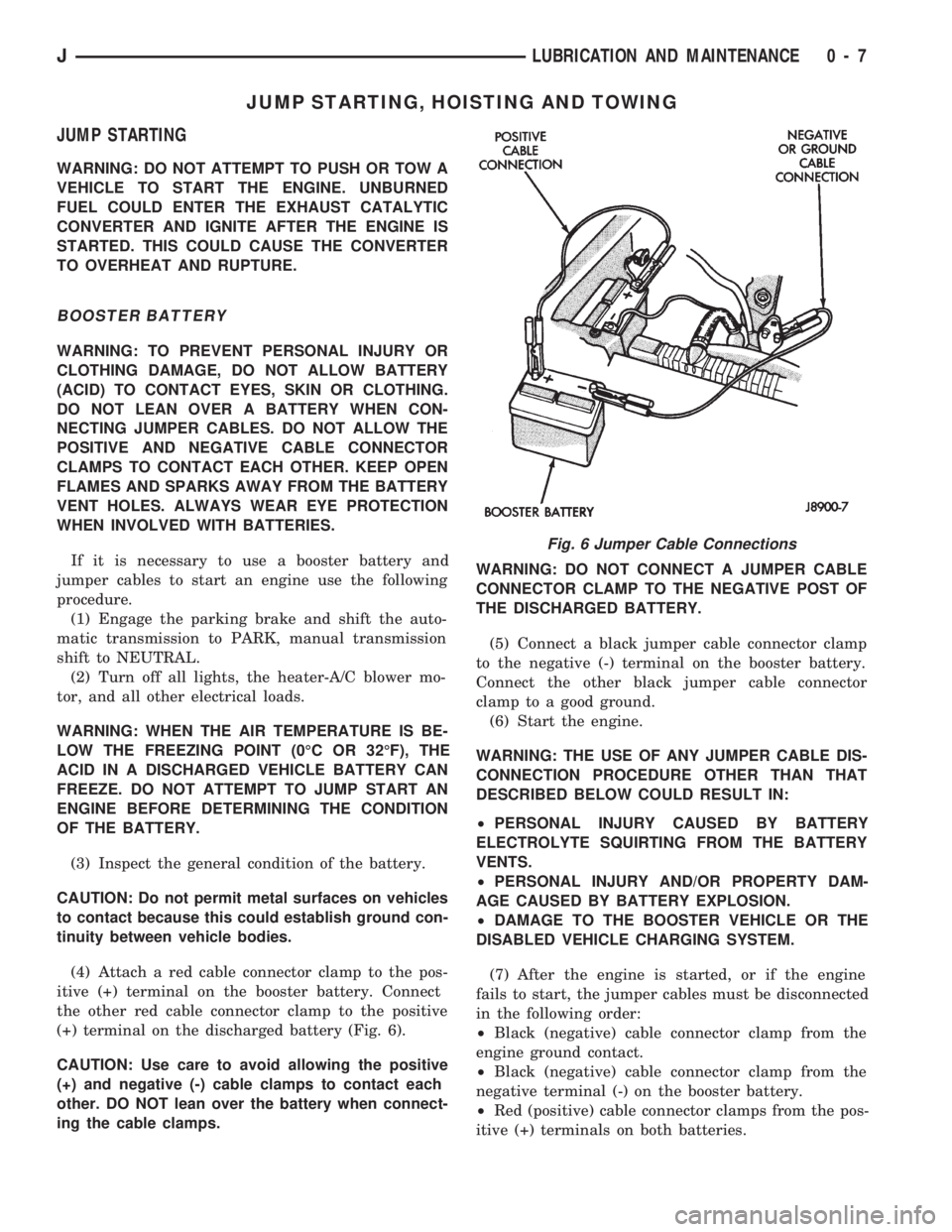

(4) Attach a red cable connector clamp to the pos-

itive (+) terminal on the booster battery. Connect

the other red cable connector clamp to the positive

(+) terminal on the discharged battery (Fig. 6).

CAUTION: Use care to avoid allowing the positive

(+) and negative (-) cable clamps to contact each

other. DO NOT lean over the battery when connect-

ing the cable clamps.WARNING: DO NOT CONNECT A JUMPER CABLE

CONNECTOR CLAMP TO THE NEGATIVE POST OF

THE DISCHARGED BATTERY.

(5) Connect a black jumper cable connector clamp

to the negative (-) terminal on the booster battery.

Connect the other black jumper cable connector

clamp to a good ground.

(6) Start the engine.

WARNING: THE USE OF ANY JUMPER CABLE DIS-

CONNECTION PROCEDURE OTHER THAN THAT

DESCRIBED BELOW COULD RESULT IN:

²PERSONAL INJURY CAUSED BY BATTERY

ELECTROLYTE SQUIRTING FROM THE BATTERY

VENTS.

²PERSONAL INJURY AND/OR PROPERTY DAM-

AGE CAUSED BY BATTERY EXPLOSION.

²DAMAGE TO THE BOOSTER VEHICLE OR THE

DISABLED VEHICLE CHARGING SYSTEM.

(7) After the engine is started, or if the engine

fails to start, the jumper cables must be disconnected

in the following order:

²Black (negative) cable connector clamp from the

engine ground contact.

²Black (negative) cable connector clamp from the

negative terminal (-) on the booster battery.

²Red (positive) cable connector clamps from the pos-

itive (+) terminals on both batteries.

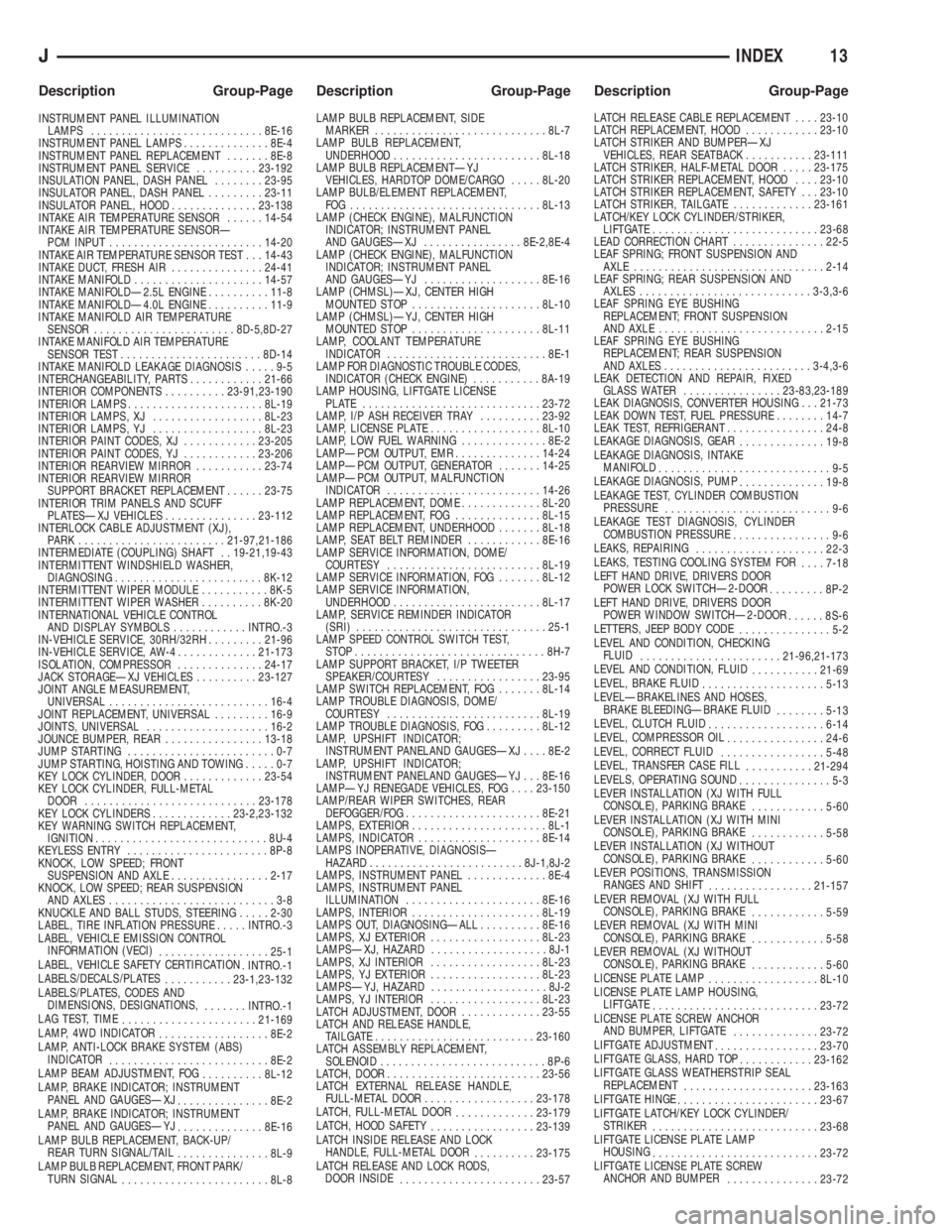

Fig. 6 Jumper Cable Connections

JLUBRICATION AND MAINTENANCE 0 - 7

Page 133 of 1784

87 and 30. Continuity should not be present between

terminals number 87A and 30.

(8) Disconnect jumper wires from relay and 12

Volt power source.

If continuity or resistance tests did not pass, re-

place relay. If tests passed, refer to Group 8W, Wir-

ing Diagrams for additional circuit information. Also

refer to the appropriate Powertrain Diagnostic Proce-

dures manual for operation of the DRB scan tool.

STARTER MOTOR RELAY TEST

Refer to Group 8A, Battery/Starting/Charging/Sys-

tem Diagnostics, for starter motor relay testing.

INJECTOR TEST

Disconnect the injector wire connector from the in-

jector. Place an ohmmeter on the injector terminals.

Resistance reading should be approximately 14.5

ohms61.2 ohms at 20ÉC (68ÉF). Proceed to following

Injector Diagnosis chart.

FUEL SYSTEM PRESSURE TEST

Refer to the Fuel Delivery System section of this

group. See Fuel System Pressure Test.

ON-BOARD DIAGNOSTICS (OBD)

The Powertrain Control Module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed in a

monitored circuit often enough to indicate an actual

problem, a Diagnostic Trouble Code (DTC) is stored.

The DTC will be stored in the PCM memory for

eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a diagnostic trou-

ble code (DTC) to be entered into PCM memory. The

criteria may be a specific range of engine rpm, en-

gine temperature and/or input voltage to the PCM.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. This may happen because one

of the DTC criteria for the circuit has not been met.

Example: assume that one of the criteria for the

MAP sensor circuit is that the engine must be oper-

ating between 750 and 2000 rpm to be monitored for

a DTC. If the MAP sensor output circuit shorts to

ground when the engine rpm is above 2400 rpm, a 0

volt input will be seen by the PCM. A DTC will not

be entered into memory because the condition does

not occur within the specified rpm range.

A DTC indicates that the powertrain control mod-

ule (PCM) has recognized an abnormal signal in a

circuit or the system. A DTC may indicate the result

of a failure, but never identify the failed component

directly.There are several operating conditions that the

PCM does not monitor and set a DTC for. Refer to

the following Monitored Circuits and Non-Monitored

Circuits in this section.

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain problems in the fuel injection system.

Open or Shorted Circuit- The PCM can deter-

mine if sensor output (which is the input to PCM) is

within proper range. It also determines if the circuit

is open or shorted.

Output Device Current Flow- The PCM senses

whether the output devices are hooked up.

If there is a problem with the circuit, the PCM

senses whether the circuit is open, shorted to ground

(-), or shorted to (+) voltage.

Oxygen Sensor- The PCM can determine if the

oxygen sensor is switching between rich and lean.

This is, once the system has entered Closed Loop. Re-

fer to Open Loop/Closed Loop Modes Of Operation in

the Component Description/System Operation section

for an explanation of Closed (or Open) Loop opera-

tion.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems or conditions that could have malfunctions

that result in driveability problems. A Diagnostic

Trouble Code (DTC) may not be displayed for these

conditions.

Fuel Pressure: Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

line. However, these could result in a rich or lean

condition causing an oxygen sensor DTC to be stored

in the PCM.

Secondary Ignition Circuit: The PCM cannot

detect an inoperative ignition coil, fouled or worn

spark plugs, ignition cross firing, or open circuited

spark plug cables.

Engine Timing: The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket or

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor DTC to be stored in the PCM.

Cylinder Compression: The PCM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System: The PCM cannot detect a

plugged, restricted or leaking exhaust system.

Fuel Injector Malfunctions: The PCM cannot de-

termine if the fuel injector is clogged, or the wrong

injector is installed. However, these could result in a

rich or lean condition causing an oxygen sensor DTC

to be stored in the PCM.

14 - 48 FUEL SYSTEMJ

Page 289 of 1784

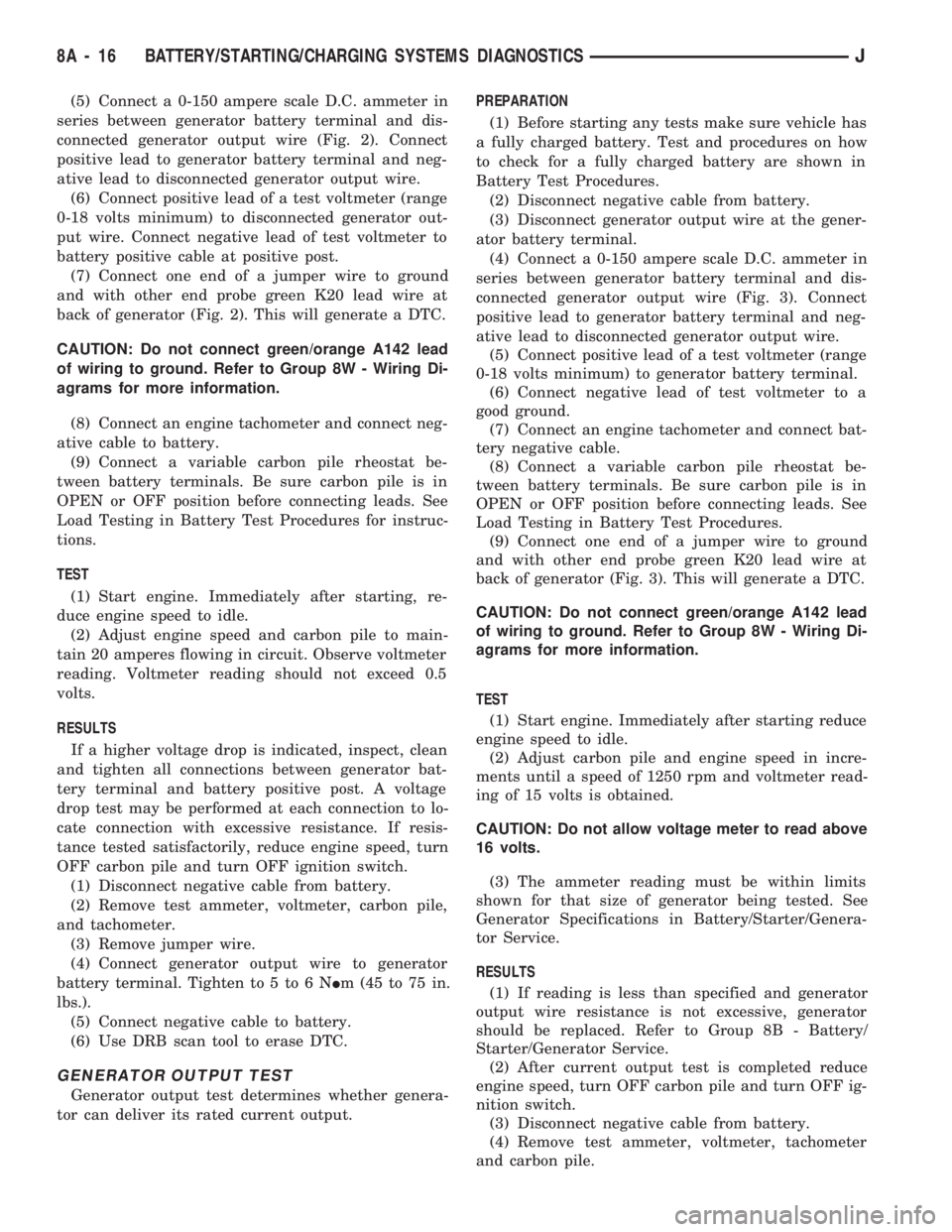

(5) Connect a 0-150 ampere scale D.C. ammeter in

series between generator battery terminal and dis-

connected generator output wire (Fig. 2). Connect

positive lead to generator battery terminal and neg-

ative lead to disconnected generator output wire.

(6) Connect positive lead of a test voltmeter (range

0-18 volts minimum) to disconnected generator out-

put wire. Connect negative lead of test voltmeter to

battery positive cable at positive post.

(7) Connect one end of a jumper wire to ground

and with other end probe green K20 lead wire at

back of generator (Fig. 2). This will generate a DTC.

CAUTION: Do not connect green/orange A142 lead

of wiring to ground. Refer to Group 8W - Wiring Di-

agrams for more information.

(8) Connect an engine tachometer and connect neg-

ative cable to battery.

(9) Connect a variable carbon pile rheostat be-

tween battery terminals. Be sure carbon pile is in

OPEN or OFF position before connecting leads. See

Load Testing in Battery Test Procedures for instruc-

tions.

TEST

(1) Start engine. Immediately after starting, re-

duce engine speed to idle.

(2) Adjust engine speed and carbon pile to main-

tain 20 amperes flowing in circuit. Observe voltmeter

reading. Voltmeter reading should not exceed 0.5

volts.

RESULTS

If a higher voltage drop is indicated, inspect, clean

and tighten all connections between generator bat-

tery terminal and battery positive post. A voltage

drop test may be performed at each connection to lo-

cate connection with excessive resistance. If resis-

tance tested satisfactorily, reduce engine speed, turn

OFF carbon pile and turn OFF ignition switch.

(1) Disconnect negative cable from battery.

(2) Remove test ammeter, voltmeter, carbon pile,

and tachometer.

(3) Remove jumper wire.

(4) Connect generator output wire to generator

battery terminal. Tighten to 5 to 6 NIm (45 to 75 in.

lbs.).

(5) Connect negative cable to battery.

(6) Use DRB scan tool to erase DTC.

GENERATOR OUTPUT TEST

Generator output test determines whether genera-

tor can deliver its rated current output.PREPARATION

(1) Before starting any tests make sure vehicle has

a fully charged battery. Test and procedures on how

to check for a fully charged battery are shown in

Battery Test Procedures.

(2) Disconnect negative cable from battery.

(3) Disconnect generator output wire at the gener-

ator battery terminal.

(4) Connect a 0-150 ampere scale D.C. ammeter in

series between generator battery terminal and dis-

connected generator output wire (Fig. 3). Connect

positive lead to generator battery terminal and neg-

ative lead to disconnected generator output wire.

(5) Connect positive lead of a test voltmeter (range

0-18 volts minimum) to generator battery terminal.

(6) Connect negative lead of test voltmeter to a

good ground.

(7) Connect an engine tachometer and connect bat-

tery negative cable.

(8) Connect a variable carbon pile rheostat be-

tween battery terminals. Be sure carbon pile is in

OPEN or OFF position before connecting leads. See

Load Testing in Battery Test Procedures.

(9) Connect one end of a jumper wire to ground

and with other end probe green K20 lead wire at

back of generator (Fig. 3). This will generate a DTC.

CAUTION: Do not connect green/orange A142 lead

of wiring to ground. Refer to Group 8W - Wiring Di-

agrams for more information.

TEST

(1) Start engine. Immediately after starting reduce

engine speed to idle.

(2) Adjust carbon pile and engine speed in incre-

ments until a speed of 1250 rpm and voltmeter read-

ing of 15 volts is obtained.

CAUTION: Do not allow voltage meter to read above

16 volts.

(3) The ammeter reading must be within limits

shown for that size of generator being tested. See

Generator Specifications in Battery/Starter/Genera-

tor Service.

RESULTS

(1) If reading is less than specified and generator

output wire resistance is not excessive, generator

should be replaced. Refer to Group 8B - Battery/

Starter/Generator Service.

(2) After current output test is completed reduce

engine speed, turn OFF carbon pile and turn OFF ig-

nition switch.

(3) Disconnect negative cable from battery.

(4) Remove test ammeter, voltmeter, tachometer

and carbon pile.

8A - 16 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 290 of 1784

(5) Remove jumper wire (Fig. 3).

(6) Connect generator output wire to generator

battery terminal. Tighten nut to 5-6 NIm (45-75 in.

lbs.).(7) Connect negative cable to battery.

(8) Use DRB scan tool to erase DTC.

Fig. 3 Generator Current Output Test (Typical)

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 17

Page 326 of 1784

(4) Using insulated pliers, hold the cable terminal

approximately 12 mm (1/2 in.) from the engine cylin-

der head or block while rotating the engine with the

starter motor. Observe the spark plug cable terminal

for an arc. If steady arcing occurs, it can be expected

that the ignition secondary system is operating cor-

rectly. If steady arcing occurs at the spark plug ca-

bles, but the engine will not start, connect the DRB

scan tool. Refer to the Powertrain Diagnostic Proce-

dures service manual for DRB operation.

FAILURE TO START TEST

To prevent unnecessary diagnostic time and wrong

test results, the previous Checking For Spark test

should be performed prior to this test.

WARNING: SET PARKING BRAKE OR BLOCK THE

DRIVE WHEELS BEFORE PROCEEDING WITH THIS

TEST.

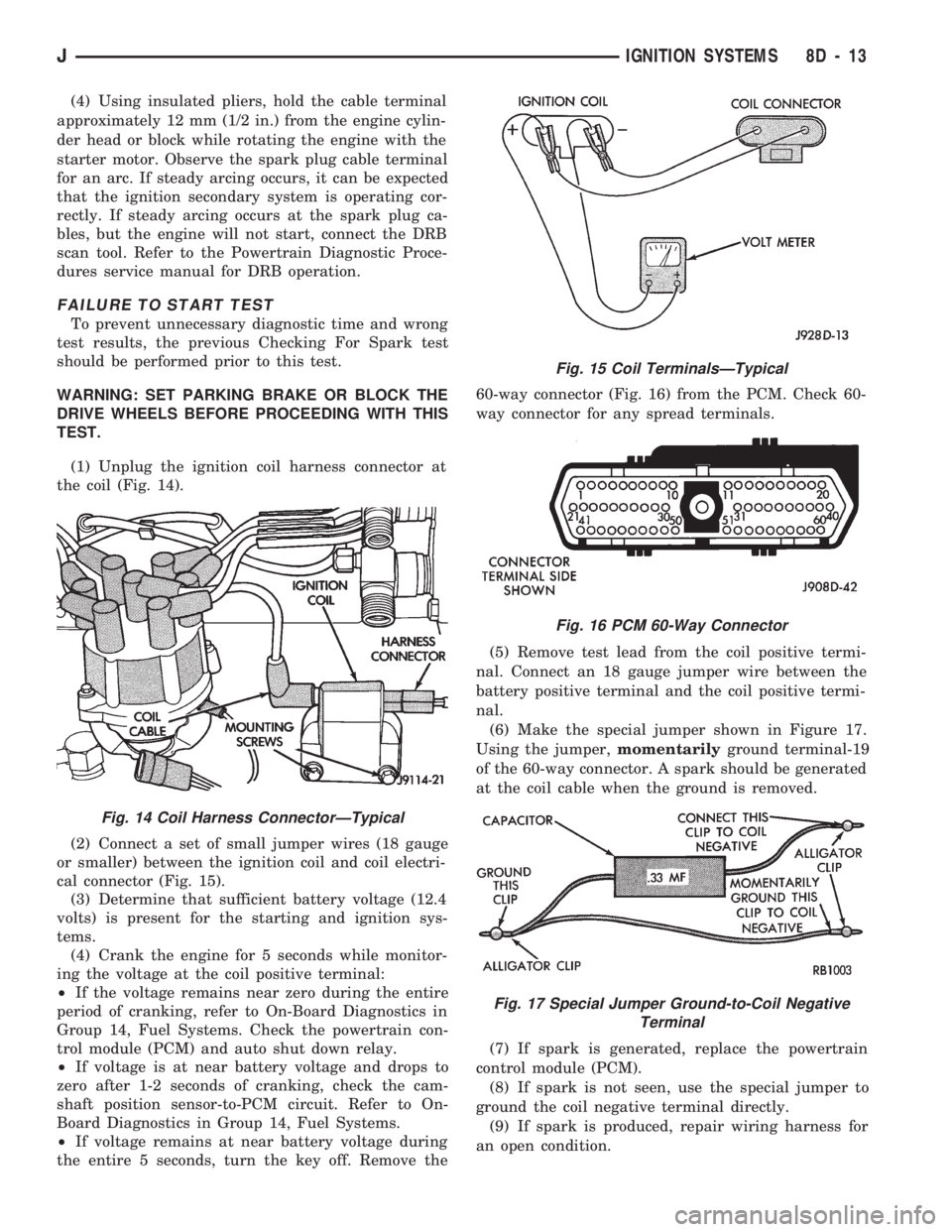

(1) Unplug the ignition coil harness connector at

the coil (Fig. 14).

(2) Connect a set of small jumper wires (18 gauge

or smaller) between the ignition coil and coil electri-

cal connector (Fig. 15).

(3) Determine that sufficient battery voltage (12.4

volts) is present for the starting and ignition sys-

tems.

(4) Crank the engine for 5 seconds while monitor-

ing the voltage at the coil positive terminal:

²If the voltage remains near zero during the entire

period of cranking, refer to On-Board Diagnostics in

Group 14, Fuel Systems. Check the powertrain con-

trol module (PCM) and auto shut down relay.

²If voltage is at near battery voltage and drops to

zero after 1-2 seconds of cranking, check the cam-

shaft position sensor-to-PCM circuit. Refer to On-

Board Diagnostics in Group 14, Fuel Systems.

²If voltage remains at near battery voltage during

the entire 5 seconds, turn the key off. Remove the60-way connector (Fig. 16) from the PCM. Check 60-

way connector for any spread terminals.

(5) Remove test lead from the coil positive termi-

nal. Connect an 18 gauge jumper wire between the

battery positive terminal and the coil positive termi-

nal.

(6) Make the special jumper shown in Figure 17.

Using the jumper,momentarilyground terminal-19

of the 60-way connector. A spark should be generated

at the coil cable when the ground is removed.

(7) If spark is generated, replace the powertrain

control module (PCM).

(8) If spark is not seen, use the special jumper to

ground the coil negative terminal directly.

(9) If spark is produced, repair wiring harness for

an open condition.

Fig. 14 Coil Harness ConnectorÐTypical

Fig. 15 Coil TerminalsÐTypical

Fig. 16 PCM 60-Way Connector

Fig. 17 Special Jumper Ground-to-Coil Negative

Terminal

JIGNITION SYSTEMS 8D - 13

Page 331 of 1784

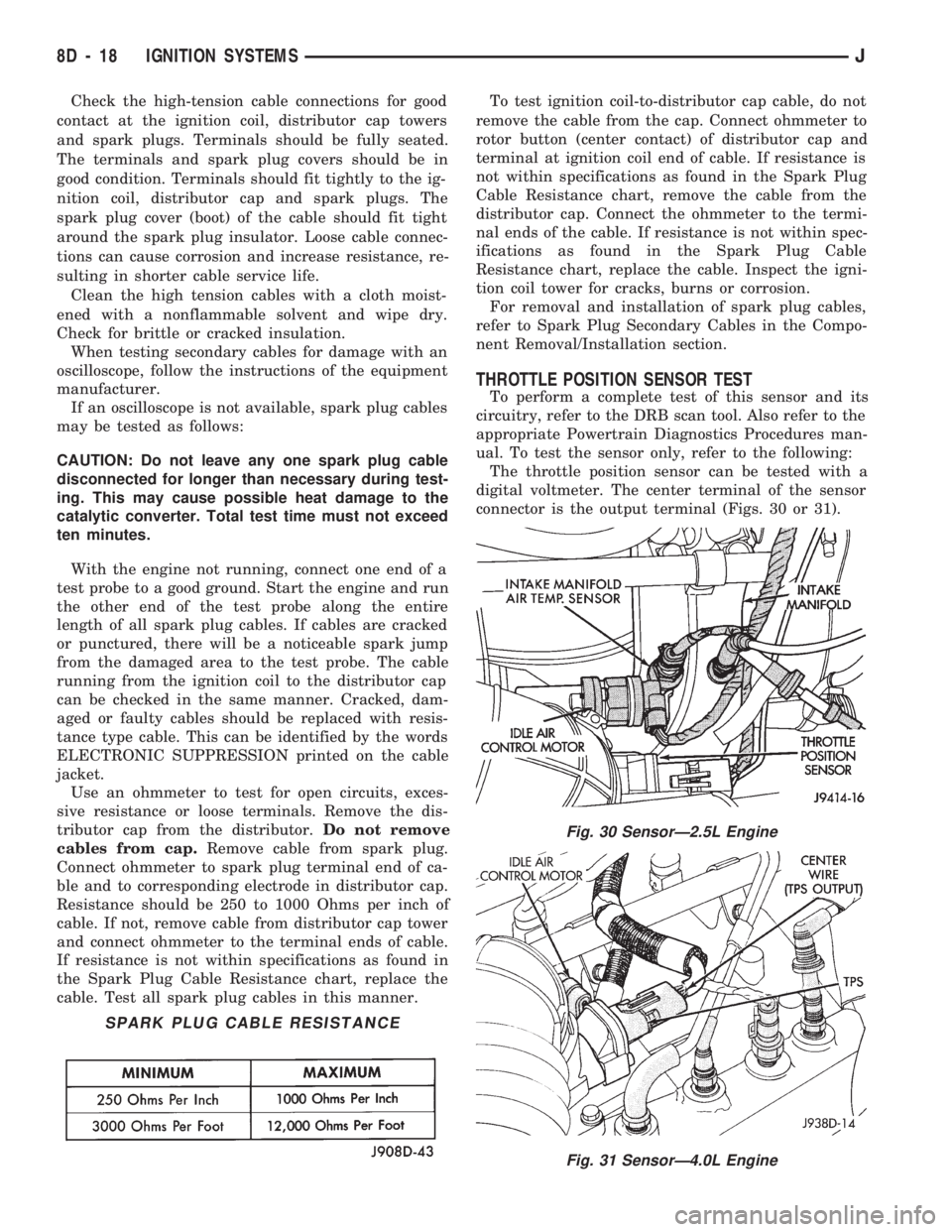

Check the high-tension cable connections for good

contact at the ignition coil, distributor cap towers

and spark plugs. Terminals should be fully seated.

The terminals and spark plug covers should be in

good condition. Terminals should fit tightly to the ig-

nition coil, distributor cap and spark plugs. The

spark plug cover (boot) of the cable should fit tight

around the spark plug insulator. Loose cable connec-

tions can cause corrosion and increase resistance, re-

sulting in shorter cable service life.

Clean the high tension cables with a cloth moist-

ened with a nonflammable solvent and wipe dry.

Check for brittle or cracked insulation.

When testing secondary cables for damage with an

oscilloscope, follow the instructions of the equipment

manufacturer.

If an oscilloscope is not available, spark plug cables

may be tested as follows:

CAUTION: Do not leave any one spark plug cable

disconnected for longer than necessary during test-

ing. This may cause possible heat damage to the

catalytic converter. Total test time must not exceed

ten minutes.

With the engine not running, connect one end of a

test probe to a good ground. Start the engine and run

the other end of the test probe along the entire

length of all spark plug cables. If cables are cracked

or punctured, there will be a noticeable spark jump

from the damaged area to the test probe. The cable

running from the ignition coil to the distributor cap

can be checked in the same manner. Cracked, dam-

aged or faulty cables should be replaced with resis-

tance type cable. This can be identified by the words

ELECTRONIC SUPPRESSION printed on the cable

jacket.

Use an ohmmeter to test for open circuits, exces-

sive resistance or loose terminals. Remove the dis-

tributor cap from the distributor.Do not remove

cables from cap.Remove cable from spark plug.

Connect ohmmeter to spark plug terminal end of ca-

ble and to corresponding electrode in distributor cap.

Resistance should be 250 to 1000 Ohms per inch of

cable. If not, remove cable from distributor cap tower

and connect ohmmeter to the terminal ends of cable.

If resistance is not within specifications as found in

the Spark Plug Cable Resistance chart, replace the

cable. Test all spark plug cables in this manner.To test ignition coil-to-distributor cap cable, do not

remove the cable from the cap. Connect ohmmeter to

rotor button (center contact) of distributor cap and

terminal at ignition coil end of cable. If resistance is

not within specifications as found in the Spark Plug

Cable Resistance chart, remove the cable from the

distributor cap. Connect the ohmmeter to the termi-

nal ends of the cable. If resistance is not within spec-

ifications as found in the Spark Plug Cable

Resistance chart, replace the cable. Inspect the igni-

tion coil tower for cracks, burns or corrosion.

For removal and installation of spark plug cables,

refer to Spark Plug Secondary Cables in the Compo-

nent Removal/Installation section.

THROTTLE POSITION SENSOR TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

The throttle position sensor can be tested with a

digital voltmeter. The center terminal of the sensor

connector is the output terminal (Figs. 30 or 31).

SPARK PLUG CABLE RESISTANCE

Fig. 30 SensorÐ2.5L Engine

Fig. 31 SensorÐ4.0L Engine

8D - 18 IGNITION SYSTEMSJ

Page 394 of 1784

TEST PROCEDURES

INDEX

page page

Checking for Diagnostic Trouble Code......... 5

Electrical Tests at Powertrain Control Module.... 6

Electrical Tests at Servo.................... 5

Inoperative System........................ 5

Operational Check (Road Test)............... 7

Road Test............................... 5Speed Control Switch (Turn Signal Lever) Test . . . 7

Stop Lamp Speed Control Switch Test......... 7

Vacuum Supply Test....................... 7

Vehicle Speed Control System Electrical Tests . . . 5

Vehicle Speed Sensor Test.................. 5

ROAD TEST

Refer to Operational Check (Road Test) section to

verify reports of speed control system malfunction.

INOPERATIVE SYSTEM

Road test vehicle to verify reports of speed control

system malfunction. An inspection should be made

for loose electrical and vacuum connections at the

servo.

Check for correct installation of the vacuum check

valve in the hose from servo to vacuum source. The

word VAC on the valve must point toward the vac-

uum source.

Corrosion should be removed from electrical termi-

nals and a light coating of Mopar MultiPurpose

Grease, or equivalent, applied.

Inspection also should be made to verify that both

ends of the speed control cable are securely attached.

CHECKING FOR DIAGNOSTIC TROUBLE CODE

(1) When trying to verify a speed control system

electronic malfunction use a DRB scan tool to find

the cause (refer to Powertrain Diagnostic Procedures

manual).

If DRB is not available, the Diagnostic Trouble

Code (DTC) may be determined with the following

method:

(a) With key inserted in ignition switch, cycle

switch to ON position 3 times. On third cycle, leave

switch in ON position.

(b) After switch has been cycled 3 times, observe

Malfunction Indicator Lamp (CHECK ENGINE)

on instrument cluster. If a DTC is present, the code

will be displayed in a series of flashes representing

digits. Three flashes in rapid succession, a slight

pause, then 4 flashes in rapid succession would in-

dicate DTC 34.

(2) If a DTC 34 is observed, perform tests in the

sections Electrical Tests at Servo and Electrical Tests

at Powertrain Control Module.

If a DTC 15 is observed, perform test for a faulty

vehicle speed sensor.

(3) Correct any problems found when performing

these tests and recheck for DTC if changes were

made.

VEHICLE SPEED SENSOR TEST

For testing of the vehicle speed sensor and related

components, refer to Powertrain Diagnostic Proce-

dures manual.

VEHICLE SPEED CONTROL SYSTEM ELECTRICAL

TESTS

Vehicle speed control systems may be tested using

two different methods. One involves use of a DRB

scan tool. If this test method is desired, refer to Pow-

ertrain Diagnostic Procedures manual.

The other test method uses a voltmeter. The volt-

meter method is described in the following tests.

If any information is needed concerning wiring, re-

fer to Section 8W - Wiring Diagrams.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

ELECTRICAL TESTS AT SERVO

(1) Turn ignition switch to the ON position. With

speed control switch in the ON position, setup a volt-

meter to read battery voltage and connect negative

lead to a good chassis ground.

(2) Disconnect 4-way connector going to servo

(Figs. 2 and 3). Blue wire with red tracer of main

harness 4-way connector should read approximately

battery voltage. If not, check for loose connections,

brake switch adjustment or, repair main harness as

necessary.

(3) Connect a jumper wire between male and fe-

male terminals of blue wire with red tracer. The

other 3 male terminals from servo should show bat-

tery voltage. If not, replace servo.

(4) Using an ohmmeter, connect one lead to a good

body ground. Touch other lead to black wire terminal

in 4-way connector of main harness. Meter should

show continuity. If not, repair ground circuit as nec-

essary.

JVEHICLE SPEED CONTROL SYSTEM 8H - 5

Page 1009 of 1784

87 and 30. Continuity should not be present between

terminals number 87A and 30.

(8) Disconnect jumper wires from relay and 12

Volt power source.

If continuity or resistance tests did not pass, re-

place relay. If tests passed, refer to Group 8W, Wir-

ing Diagrams for additional circuit information. Also

refer to the appropriate Powertrain Diagnostic Proce-

dures manual for operation of the DRB scan tool.

STARTER MOTOR RELAY TEST

Refer to Group 8A, Battery/Starting/Charging/Sys-

tem Diagnostics, for starter motor relay testing.

INJECTOR TEST

Disconnect the injector wire connector from the in-

jector. Place an ohmmeter on the injector terminals.

Resistance reading should be approximately 14.5

ohms61.2 ohms at 20ÉC (68ÉF). Proceed to following

Injector Diagnosis chart.

FUEL SYSTEM PRESSURE TEST

Refer to the Fuel Delivery System section of this

group. See Fuel System Pressure Test.

ON-BOARD DIAGNOSTICS (OBD)

The Powertrain Control Module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed in a

monitored circuit often enough to indicate an actual

problem, a Diagnostic Trouble Code (DTC) is stored.

The DTC will be stored in the PCM memory for

eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a diagnostic trou-

ble code (DTC) to be entered into PCM memory. The

criteria may be a specific range of engine rpm, en-

gine temperature and/or input voltage to the PCM.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. This may happen because one

of the DTC criteria for the circuit has not been met.

Example: assume that one of the criteria for the

MAP sensor circuit is that the engine must be oper-

ating between 750 and 2000 rpm to be monitored for

a DTC. If the MAP sensor output circuit shorts to

ground when the engine rpm is above 2400 rpm, a 0

volt input will be seen by the PCM. A DTC will not

be entered into memory because the condition does

not occur within the specified rpm range.

A DTC indicates that the powertrain control mod-

ule (PCM) has recognized an abnormal signal in a

circuit or the system. A DTC may indicate the result

of a failure, but never identify the failed component

directly.There are several operating conditions that the

PCM does not monitor and set a DTC for. Refer to

the following Monitored Circuits and Non-Monitored

Circuits in this section.

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain problems in the fuel injection system.

Open or Shorted Circuit- The PCM can deter-

mine if sensor output (which is the input to PCM) is

within proper range. It also determines if the circuit

is open or shorted.

Output Device Current Flow- The PCM senses

whether the output devices are hooked up.

If there is a problem with the circuit, the PCM

senses whether the circuit is open, shorted to ground

(-), or shorted to (+) voltage.

Oxygen Sensor- The PCM can determine if the

oxygen sensor is switching between rich and lean.

This is, once the system has entered Closed Loop. Re-

fer to Open Loop/Closed Loop Modes Of Operation in

the Component Description/System Operation section

for an explanation of Closed (or Open) Loop opera-

tion.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems or conditions that could have malfunctions

that result in driveability problems. A Diagnostic

Trouble Code (DTC) may not be displayed for these

conditions.

Fuel Pressure: Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

line. However, these could result in a rich or lean

condition causing an oxygen sensor DTC to be stored

in the PCM.

Secondary Ignition Circuit: The PCM cannot

detect an inoperative ignition coil, fouled or worn

spark plugs, ignition cross firing, or open circuited

spark plug cables.

Engine Timing: The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket or

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor DTC to be stored in the PCM.

Cylinder Compression: The PCM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System: The PCM cannot detect a

plugged, restricted or leaking exhaust system.

Fuel Injector Malfunctions: The PCM cannot de-

termine if the fuel injector is clogged, or the wrong

injector is installed. However, these could result in a

rich or lean condition causing an oxygen sensor DTC

to be stored in the PCM.

14 - 48 FUEL SYSTEMJ

Page 1755 of 1784

GRILLE OPENING PANEL (GOP), GRILLE.....23-3

GRILLEÐXJ VEHICLES, AIR EXHAUST.....23-30

GROUND, POWER.....................14-22

GROUP INDEX; ELECTRICAL..............8A-1

GUARD, BRUSH........................23-3

GUARD/EDGE PROTECTOR STRIP, DOOR

EDGE..............................23-61

GUIDES AND CHARTS, DIAGNOSIS........21-76

HALF METAL DOOR MIRROR (EXTERNAL) . . 23-158

HALF-METAL DOOR LATCH STRIKER......23-175

HALF-METAL SOFT TOP DOOR..........23-173

HAND DRIVE, BATTERY CLASSIFICATIONS

AND RATINGSÐLEFT.................8B-10

HAND DRIVE, BATTERY CLASSIFICATIONS

AND RATINGSÐRIGHT................8B-10

HAND DRIVE, BATTERY REPLACEMENTÐ

LEFT...............................8B-1

HAND DRIVE, BATTERY REPLACEMENTÐ

RIGHT..............................8B-2

HAND DRIVE, BELT SERVICEÐEXCEPT

RIGHT..............................7-34

HAND DRIVE, BELT SERVICEÐWITH

RIGHT..............................7-35

HAND DRIVE, DRIVERS DOOR POWER

LOCK SWITCHÐ2-DOOR LEFT...........8P-2

HAND DRIVE, DRIVERS DOOR POWER

LOCK SWITCHÐ2-DOOR RIGHT..........8P-3

HAND DRIVE, DRIVERS DOOR POWER

WINDOW SWITCHÐ2-DOOR LEFT........8S-6

HAND DRIVE, DRIVERS DOOR POWER

WINDOW SWITCHÐ2-DOOR RIGHT......8S-7

HAND DRIVE, GENERATOR

REPLACEMENTÐLEFT.................8B-7

HAND DRIVE, GENERATOR

REPLACEMENTÐRIGHT................8B-9

HAND DRIVE (RHD), BELT TENSIONÐ

EXCEPT RIGHT.......................7-33

HAND DRIVE (RHD), BELT TENSIONÐ

RIGHT..............................7-34

HAND DRIVE VEHICLES, RIGHT............23-1

HAND DRIVE, WASHER PUMP

REPLACEMENTÐLEFT.................8K-2

HAND DRIVE, WASHER PUMP

REPLACEMENTÐRIGHT................8K-3

HANDLE, DOOR EXTERNAL..............23-55

HANDLE, FULL-METAL DOOR ASSIST.....23-175

HANDLE, FULL-METAL DOOR LATCH

EXTERNAL RELEASE.................23-178

HANDLE, FULL-METAL DOOR LATCH

INSIDE RELEASE AND LOCK...........23-175

HANDLE, FULL-METAL DOOR WINDOW

GLASS REGULATOR.................23-175

HANDLE, TAILGATE LATCH AND

RELEASE..........................23-160

HANDLEÐXJ VEHICLES, ASSIST.........23-118

HANGER BRACKET, MUFFLER/TAILPIPE.....13-16

HARD TOP DOME/CARGO LAMP BULB

REPLACEMENTÐYJ VEHICLES..........8L-20

HARD TOP LIFTGATE GLASS............23-162

HARD TOP QUARTER WINDOW GLASS....23-188

HARD TOP REPAIR....................23-165

HARD TOP ROOF VENT................23-165

HARD TOP SERVICE...................23-164

HARD TOP SERVICE INFORMATION.......23-164

HAZARD LAMPSÐXJ....................8J-1

HAZARD LAMPSÐYJ....................8J-2

HCU DIAGNOSIS........................5-4

HCU INSTALLATIONÐXJ.................5-54

HCU INSTALLATIONÐYJ.................5-54

HCU PUMP AND PEDAL TRAVEL

SENSOR OPERATION...................5-44

HCU REMOVALÐXJ.....................5-53

HCU REMOVALÐYJ.....................5-54

HCU SOLENOID VALVE OPERATION.........5-43

HEAD COVER, ENGINE CYLINDER......9-18,9-59

HEAD, ENGINE CYLINDER............9-19,9-60

HEAD GASKET FAILURE DIAGNOSIS,

ENGINE CYLINDER.....................9-5

HEADLAMP BEAM ADJUSTMENT...........8L-3

HEADLAMP BULB REPLACEMENT

..........8L-3

HEADLAMP DELAY FUNCTION TROUBLE

DIAGNOSISÐXJ VEHICLES

.............8L-16

HEADLAMP DELAY MODULE

REPLACEMENTÐXJ VEHICLES

..........8L-16

HEADLAMP DELAY MODULEÐXJ

VEHICLES, SENTINEL

.................8L-15HEADLAMP DIMMER SWITCH

REPLACEMENT.......................8L-6

HEADLAMP SWITCH REPLACEMENT........8L-4

HEADLAMP SWITCH/ILLUMINATION

RHEOSTAT..........................8E-21

HEADLAMP TROUBLE DIAGNOSISÐ

XJ VEHICLES.........................8L-1

HEADLAMP TROUBLE DIAGNOSISÐYJ

VEHICLES...........................8L-2

HEADLAMPS...........................0-35

HEADLINER.........................23-121

HEAT SHIELDS........................14-12

HEAT SHIELDS, EXHAUST................11-1

HEAT SHIELDS, MUFFLER AND TAILPIPE . . . 13-17

HEATER AND A/C CONTROL PANEL

REPLACEMENT......................24-26

HEATER CONTROL CABLE REPLACEMENT . . . 24-30

HEATER CONTROL PANEL REPLACEMENT . . . 24-39

HEATER CORE........................24-28

HEATER CORE AND HOUSING............24-40

HEATER CORE HOUSING REPLACEMENT . . . 24-29

HEATER, ENGINE BLOCK.................7-37

HEATER/DEFROSTER OPERATION.........24-37

HEATER/DEFROSTER/INSTRUMENT

PANEL OUTLET DOOR VACUUM MOTOR

REPLACEMENT......................24-30

HEATING ELEMENT TEST, OXYGEN

SENSOR (O2S)......................14-45

HEATING SCHEMATIC...................24-24

HEATING SYSTEM DIAGNOSIS............24-11

HEATING SYSTEMÐYJ VEHICLES.........24-14

HIGH LINE CLUSTER...................8E-12

HIGH MOUNTED STOP LAMP (CHMSL)Ð

XJ, CENTER.........................8L-10

HIGH MOUNTED STOP LAMP (CHMSL)Ð

YJ, CENTER.........................8L-11

HINGE, LIFTGATE......................23-67

HINGE REPLACEMENT, HOOD.............23-9

HINGE, TAILGATE.....................23-159

HINGE/HINGE PIN REPLACEMENT, DOOR . . . 23-58

HINGES, FULL-METAL DOOR............23-179

HITCHES, TRAILER.....................23-88

HOISTING AND TOWING, JUMP

STARTING,............................0-7

HOLDDOWN AND FLOOR BRACKETSÐ

XJ VEHICLES, SPARE TIRE/WHEEL......23-128

HONING CYLINDER BORES................9-2

HOOD..........................23-6,23-137

HOOD ADJUSTMENT....................23-9

HOOD ALIGNMENT....................23-138

HOOD HINGE REPLACEMENT..............23-9

HOOD INSULATOR PANEL..............23-138

HOOD LATCH REPLACEMENT............23-10

HOOD LATCH STRIKER REPLACEMENT.....23-10

HOOD SAFETY LATCH.................23-139

HOOKÐXJ VEHICLES, REAR TOW.........23-87

HOOKS, FRONT TOW....................13-5

HOOKS, TOW.........................13-14

HORN PAD REPLACEMENT, HORN SWITCH . . . 8G-3

HORN SWITCH (HORN PAD)

REPLACEMENT.......................8G-3

HOSE REPLACEMENT, PRESSURE AND

RETURN............................19-9

HOSE ROUTING SCHEMATICS,

VACUUM............................25-1

HOSE SPLASH SHIELDÐXJ VEHICLES,

FUEL FILLER........................23-86

HOSES, BRAKE BLEEDINGÐBRAKE FLUID

AND LEVELÐBRAKELINES..............5-13

HOSES, BRAKELINES....................5-15

HOSES, COOLING SYSTEM...............7-26

HOSES/TUBING, RUBBER AND PLASTIC.....0-28

HOUSING, AIR CLEANER; EMISSION

CONTROL SYSTEMS...................25-8

HOUSING, AIR CLEANER; FUEL SYSTEM....14-54

HOUSING AND PARK LOCK COMPONENT

OVERHAUL, ADAPTER................21-120

HOUSING END PLUG...................19-26

HOUSING, EVAPORATOR................24-42

HOUSING, EVAPORATOR/BLOWER.........24-33

HOUSING, HEATER CORE................24-40

HOUSING LEAK DIAGNOSIS, CONVERTER

. . . 21-73

HOUSING, LIFTGATE LICENSE PLATE

LAMP

..............................23-72

HOUSING REPLACEMENT, CLUTCH

.........6-11

HOUSING REPLACEMENT, HEATER CORE

. . . 24-29HOUSING SEAL REPLACEMENT,

ADAPTER..........................21-182

HOUSINGS, INSTRUMENT CLUSTER

AND GAUGE........................23-190

HUB BEARING AND AXLE SHAFT...........2-24

HYDRAULIC CLUTCH....................0-22

HYDRAULIC COMPONENTS................5-1

HYDRAULIC CONTROL UNIT (HCU).........5-39

HYDRAULIC FLOW DURING FULL

THROTTLE 3-2 DOWNSHIFT............21-92

HYDRAULIC FLOW DURING PART

THROTTLE 3-2 DOWNSHIFT............21-91

HYDRAULIC FLOW IN D RANGE FIRST

GEAR..............................21-87

HYDRAULIC FLOW IN D RANGE SECOND

GEAR..............................21-88

HYDRAULIC FLOW IN D RANGE THIRD

GEAR..............................21-89

HYDRAULIC FLOW IN MANUAL FIRST

GEAR (1) POSITION..................21-94

HYDRAULIC FLOW IN MANUAL SECOND

(2) RANGE..........................21-93

HYDRAULIC FLOW IN PARK AND NEUTRAL . . . 21-86

HYDRAULIC FLOW IN REVERSE..........21-95

HYDRAULIC FLOW IN THIRD GEAR

(CONVERTER CLUTCH ENGAGED)........21-90

HYDRAULIC LINKAGE INSTALLATION,

CLUTCH.............................6-12

HYDRAULIC LINKAGE REMOVAL,

CLUTCH.............................6-11

HYDRAULIC PRESSURE TEST......21-71,21-168

HYDRAULIC SYSTEM..................21-160

HYDRAULIC TAPPETS...............9-24,9-65

HYDROMETER TEST....................8A-3

IDENTIFICATION, AW-4 VALVE AND

SPRING...........................21-330

IDENTIFICATION, CIRCUIT................8W-2

IDENTIFICATION, COMPONENT............8W-2

IDENTIFICATION, ENGINE AND

TRANSMISSION/TRANSFER CASE.....INTRO.-3

IDENTIFICATION, MAJOR COMPONENT . . INTRO.-3

IDENTIFICATION NUMBER (VIN)

DECODING, VEHICLE...............INTRO.-2

IDENTIFICATION NUMBER (VIN) PLATE,

VEHICLE.........................INTRO.-1

IDENTIFICATION, TRANSFER CASE

. 21-273,21-293

IDENTIFICATION, TRANSMISSION

.....21-1,21-32,

21-66,21-157

IDENTIFICATION, WIRE CODE

.............8W-2

IDENTIFICATION, WIRING AND

COMPONENT

.......................8W-13

IDLE AIR CONTROL (IAC) MOTOR

.........14-56

IDLE AIR CONTROL (IAC) MOTORÐPCM

OUTPUT

............................14-25

IDLE AIR CONTROL MOTOR TEST

.........14-46

IDLE SWITCHÐPCM INPUT, EXTENDED

....14-21

IDLE SWITCH TEST, EXTENDED

...........14-45

IGNITION CABLES, DISTRIBUTOR CAP

AND ROTOR

.........................0-18

IGNITION CIRCUIT SENSEÐPCM INPUT

....14-21

IGNITION COIL; FUEL SYSTEM

...........14-57

IGNITION COIL; IGNITION SYSTEMS

. . 8D-4,8D-11,

8D-26

IGNITION COILÐPCM OUTPUT

...........14-26

IGNITION COIL RESISTANCE

.............8D-11

IGNITION KEY WARNING SWITCH

REPLACEMENT

.......................8U-4

IGNITION OFF DRAW (IOD) DIAGNOSIS

.....8A-8

IGNITION SECONDARY CIRCUIT

DIAGNOSIS

.........................8D-12

IGNITION SWITCH; BRAKES

...............5-42

IGNITION SWITCH CONTINUITY TESTS

.....8D-31

IGNITION SWITCH; IGNITION SYSTEMS

....8D-30

IGNITION SWITCH INSTALLATION/

ADJUSTMENT

.......................8D-31

IGNITION SWITCH REMOVAL

............8D-30

IGNITION SWITCH TESTING

.............8D-30

IGNITION TIMING

......................8D-14

IGNITION WIRING, SECONDARY

...........8W-1

ILLUMINATED ENTRY SYSTEM SERVICE

INFORMATION

.......................8L-20

ILLUMINATED ENTRY SYSTEM TROUBLE

DIAGNOSIS

....................8L-21,8L-22

JINDEX11

Description Group-Page Description Group-Page Description Group-Page

Page 1757 of 1784

INSTRUMENT PANEL ILLUMINATION

LAMPS............................8E-16

INSTRUMENT PANEL LAMPS..............8E-4

INSTRUMENT PANEL REPLACEMENT.......8E-8

INSTRUMENT PANEL SERVICE..........23-192

INSULATION PANEL, DASH PANEL........23-95

INSULATOR PANEL, DASH PANEL.........23-11

INSULATOR PANEL, HOOD..............23-138

INTAKE AIR TEMPERATURE SENSOR......14-54

INTAKE AIR TEMPERATURE SENSORÐ

PCM INPUT.........................14-20

INTAKE AIR TEMPERATURE SENSOR TEST . . . 14-43

INTAKE DUCT, FRESH AIR...............24-41

INTAKE MANIFOLD.....................14-57

INTAKE MANIFOLDÐ2.5L ENGINE..........11-8

INTAKE MANIFOLDÐ4.0L ENGINE..........11-9

INTAKE MANIFOLD AIR TEMPERATURE

SENSOR.......................8D-5,8D-27

INTAKE MANIFOLD AIR TEMPERATURE

SENSOR TEST.......................8D-14

INTAKE MANIFOLD LEAKAGE DIAGNOSIS.....9-5

INTERCHANGEABILITY, PARTS............21-66

INTERIOR COMPONENTS..........23-91,23-190

INTERIOR LAMPS......................8L-19

INTERIOR LAMPS, XJ..................8L-23

INTERIOR LAMPS, YJ..................8L-23

INTERIOR PAINT CODES, XJ............23-205

INTERIOR PAINT CODES, YJ............23-206

INTERIOR REARVIEW MIRROR...........23-74

INTERIOR REARVIEW MIRROR

SUPPORT BRACKET REPLACEMENT......23-75

INTERIOR TRIM PANELS AND SCUFF

PLATESÐXJ VEHICLES...............23-112

INTERLOCK CABLE ADJUSTMENT (XJ),

PARK........................21-97,21-186

INTERMEDIATE (COUPLING) SHAFT . . 19-21,19-43

INTERMITTENT WINDSHIELD WASHER,

DIAGNOSING........................8K-12

INTERMITTENT WIPER MODULE...........8K-5

INTERMITTENT WIPER WASHER..........8K-20

INTERNATIONAL VEHICLE CONTROL

AND DISPLAY SYMBOLS............INTRO.-3

IN-VEHICLE SERVICE, 30RH/32RH.........21-96

IN-VEHICLE SERVICE, AW-4.............21-173

ISOLATION, COMPRESSOR..............24-17

JACK STORAGEÐXJ VEHICLES..........23-127

JOINT ANGLE MEASUREMENT,

UNIVERSAL..........................16-4

JOINT REPLACEMENT, UNIVERSAL.........16-9

JOINTS, UNIVERSAL....................16-2

JOUNCE BUMPER, REAR................13-18

JUMP STARTING........................0-7

JUMP STARTING, HOISTING AND TOWING.....0-7

KEY LOCK CYLINDER, DOOR.............23-54

KEY LOCK CYLINDER, FULL-METAL

DOOR............................23-178

KEY LOCK CYLINDERS.............23-2,23-132

KEY WARNING SWITCH REPLACEMENT,

IGNITION............................8U-4

KEYLESS ENTRY.......................8P-8

KNOCK, LOW SPEED; FRONT

SUSPENSION AND AXLE................2-17

KNOCK, LOW SPEED; REAR SUSPENSION

AND AXLES...........................3-8

KNUCKLE AND BALL STUDS, STEERING.....2-30

LABEL, TIRE INFLATION PRESSURE.....INTRO.-3

LABEL, VEHICLE EMISSION CONTROL

INFORMATION (VECI)

..................25-1

LABEL, VEHICLE SAFETY CERTIFICATION

. INTRO.-1

LABELS/DECALS/PLATES

...........23-1,23-132

LABELS/PLATES, CODES AND

DIMENSIONS, DESIGNATIONS,

.......INTRO.-1

LAG TEST, TIME

......................21-169

LAMP, 4WD INDICATOR

..................8E-2

LAMP, ANTI-LOCK BRAKE SYSTEM (ABS)

INDICATOR

..........................8E-2

LAMP BEAM ADJUSTMENT, FOG

..........8L-12

LAMP, BRAKE INDICATOR; INSTRUMENT

PANEL AND GAUGESÐXJ

...............8E-2

LAMP, BRAKE INDICATOR; INSTRUMENT

PANEL AND GAUGESÐYJ

..............8E-16

LAMP BULB REPLACEMENT, BACK-UP/

REAR TURN SIGNAL/TAIL

...............8L-9

LAMP BULB REPLACEMENT, FRONT PARK/

TURN SIGNAL

........................8L-8LAMP BULB REPLACEMENT, SIDE

MARKER............................8L-7

LAMP BULB REPLACEMENT,

UNDERHOOD........................8L-18

LAMP BULB REPLACEMENTÐYJ

VEHICLES, HARDTOP DOME/CARGO.....8L-20

LAMP BULB/ELEMENT REPLACEMENT,

FOG ...............................8L-13

LAMP (CHECK ENGINE), MALFUNCTION

INDICATOR; INSTRUMENT PANEL

AND GAUGESÐXJ................8E-2,8E-4

LAMP (CHECK ENGINE), MALFUNCTION

INDICATOR; INSTRUMENT PANEL

AND GAUGESÐYJ...................8E-16

LAMP (CHMSL)ÐXJ, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP (CHMSL)ÐYJ, CENTER HIGH

MOUNTED STOP.....................8L-11

LAMP, COOLANT TEMPERATURE

INDICATOR..........................8E-1

LAMP FOR DIAGNOSTIC TROUBLE CODES,

INDICATOR (CHECK ENGINE)...........8A-19

LAMP HOUSING, LIFTGATE LICENSE

PLATE .............................23-72

LAMP, I/P ASH RECEIVER TRAY..........23-92

LAMP, LICENSE PLATE..................8L-10

LAMP, LOW FUEL WARNING..............8E-2

LAMPÐPCM OUTPUT, EMR..............14-24

LAMPÐPCM OUTPUT, GENERATOR.......14-25

LAMPÐPCM OUTPUT, MALFUNCTION

INDICATOR.........................14-26

LAMP REPLACEMENT, DOME.............8L-20

LAMP REPLACEMENT, FOG..............8L-15

LAMP REPLACEMENT, UNDERHOOD.......8L-18

LAMP, SEAT BELT REMINDER............8E-16

LAMP SERVICE INFORMATION, DOME/

COURTESY.........................8L-19

LAMP SERVICE INFORMATION, FOG.......8L-12

LAMP SERVICE INFORMATION,

UNDERHOOD........................8L-17

LAMP, SERVICE REMINDER INDICATOR

(SRI)...............................25-1

LAMP SPEED CONTROL SWITCH TEST,

STOP...............................8H-7

LAMP SUPPORT BRACKET, I/P TWEETER

SPEAKER/COURTESY.................23-95

LAMP SWITCH REPLACEMENT, FOG.......8L-14

LAMP TROUBLE DIAGNOSIS, DOME/

COURTESY.........................8L-19

LAMP TROUBLE DIAGNOSIS, FOG.........8L-12

LAMP, UPSHIFT INDICATOR;

INSTRUMENT PANELAND GAUGESÐXJ....8E-2

LAMP, UPSHIFT INDICATOR;

INSTRUMENT PANELAND GAUGESÐYJ . . . 8E-16

LAMPÐYJ RENEGADE VEHICLES, FOG....23-150

LAMP/REAR WIPER SWITCHES, REAR

DEFOGGER/FOG......................8E-21

LAMPS, EXTERIOR......................8L-1

LAMPS, INDICATOR....................8E-14

LAMPS INOPERATIVE, DIAGNOSISÐ

HAZARD.........................8J-1,8J-2

LAMPS, INSTRUMENT PANEL.............8E-4

LAMPS, INSTRUMENT PANEL

ILLUMINATION......................8E-16

LAMPS, INTERIOR.....................8L-19

LAMPS OUT, DIAGNOSINGÐALL..........8E-16

LAMPS, XJ EXTERIOR..................8L-23

LAMPSÐXJ, HAZARD...................8J-1

LAMPS, XJ INTERIOR..................8L-23

LAMPS, YJ EXTERIOR..................8L-23

LAMPSÐYJ, HAZARD...................8J-2

LAMPS, YJ INTERIOR..................8L-23

LATCH ADJUSTMENT, DOOR.............23-55

LATCH AND RELEASE HANDLE,

TAILGATE..........................23-160

LATCH ASSEMBLY REPLACEMENT,

SOLENOID...........................8P-6

LATCH, DOOR.........................23-56

LATCH EXTERNAL RELEASE HANDLE,

FULL-METAL DOOR..................23-178

LATCH, FULL-METAL DOOR

.............23-179

LATCH, HOOD SAFETY

.................23-139

LATCH INSIDE RELEASE AND LOCK

HANDLE, FULL-METAL DOOR

..........23-175

LATCH RELEASE AND LOCK RODS,

DOOR INSIDE

.......................23-57LATCH RELEASE CABLE REPLACEMENT....23-10

LATCH REPLACEMENT, HOOD............23-10

LATCH STRIKER AND BUMPERÐXJ

VEHICLES, REAR SEATBACK...........23-111

LATCH STRIKER, HALF-METAL DOOR.....23-175

LATCH STRIKER REPLACEMENT, HOOD....23-10

LATCH STRIKER REPLACEMENT, SAFETY . . . 23-10

LATCH STRIKER, TAILGATE.............23-161

LATCH/KEY LOCK CYLINDER/STRIKER,

LIFTGATE...........................23-68

LEAD CORRECTION CHART...............22-5

LEAF SPRING; FRONT SUSPENSION AND

AXLE...............................2-14

LEAF SPRING; REAR SUSPENSION AND

AXLES............................3-3,3-6

LEAF SPRING EYE BUSHING

REPLACEMENT; FRONT SUSPENSION

AND AXLE...........................2-15

LEAF SPRING EYE BUSHING

REPLACEMENT; REAR SUSPENSION

AND AXLES........................3-4,3-6

LEAK DETECTION AND REPAIR, FIXED

GLASS WATER................23-83,23-189

LEAK DIAGNOSIS, CONVERTER HOUSING . . . 21-73

LEAK DOWN TEST, FUEL PRESSURE........14-7

LEAK TEST, REFRIGERANT................24-8

LEAKAGE DIAGNOSIS, GEAR

..............19-8

LEAKAGE DIAGNOSIS, INTAKE

MANIFOLD

............................9-5

LEAKAGE DIAGNOSIS, PUMP

..............19-8

LEAKAGE TEST, CYLINDER COMBUSTION

PRESSURE

...........................9-6

LEAKAGE TEST DIAGNOSIS, CYLINDER

COMBUSTION PRESSURE

................9-6

LEAKS, REPAIRING

.....................22-3

LEAKS, TESTING COOLING SYSTEM FOR

....7-18

LEFT HAND DRIVE, DRIVERS DOOR

POWER LOCK SWITCHÐ2-DOOR

.........8P-2

LEFT HAND DRIVE, DRIVERS DOOR

POWER WINDOW SWITCHÐ2-DOOR

......8S-6

LETTERS, JEEP BODY CODE

...............5-2

LEVEL AND CONDITION, CHECKING

FLUID

.......................21-96,21-173

LEVEL AND CONDITION, FLUID

...........21-69

LEVEL, BRAKE FLUID

....................5-13

LEVELÐBRAKELINES AND HOSES,

BRAKE BLEEDINGÐBRAKE FLUID

........5-13

LEVEL, CLUTCH FLUID

...................6-14

LEVEL, COMPRESSOR OIL

................24-6

LEVEL, CORRECT FLUID

.................5-48

LEVEL, TRANSFER CASE FILL

...........21-294

LEVELS, OPERATING SOUND

...............5-3

LEVER INSTALLATION (XJ WITH FULL

CONSOLE), PARKING BRAKE

............5-60

LEVER INSTALLATION (XJ WITH MINI

CONSOLE), PARKING BRAKE

............5-58

LEVER INSTALLATION (XJ WITHOUT

CONSOLE), PARKING BRAKE

............5-60

LEVER POSITIONS, TRANSMISSION

RANGES AND SHIFT

.................21-157

LEVER REMOVAL (XJ WITH FULL

CONSOLE), PARKING BRAKE

............5-59

LEVER REMOVAL (XJ WITH MINI

CONSOLE), PARKING BRAKE

............5-58

LEVER REMOVAL (XJ WITHOUT

CONSOLE), PARKING BRAKE

............5-60

LICENSE PLATE LAMP

..................8L-10

LICENSE PLATE LAMP HOUSING,

LIFTGATE

...........................23-72

LICENSE PLATE SCREW ANCHOR

AND BUMPER, LIFTGATE

..............23-72

LIFTGATE ADJUSTMENT

.................23-70

LIFTGATE GLASS, HARD TOP

............23-162

LIFTGATE GLASS WEATHERSTRIP SEAL

REPLACEMENT

.....................23-163

LIFTGATE HINGE

.......................23-67

LIFTGATE LATCH/KEY LOCK CYLINDER/

STRIKER

...........................23-68

LIFTGATE LICENSE PLATE LAMP

HOUSING

...........................23-72

LIFTGATE LICENSE PLATE SCREW

ANCHOR AND BUMPER

...............23-72

JINDEX13

Description Group-Page Description Group-Page Description Group-Page