ECU JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1665 of 2198

(14) Pull transfer case and jack rearward to disen-

gage transfer case.

(15) Remove transfer case from under vehicle.

(16) If transfer case was removed for overhaul, re-

move damper from rear retainer.

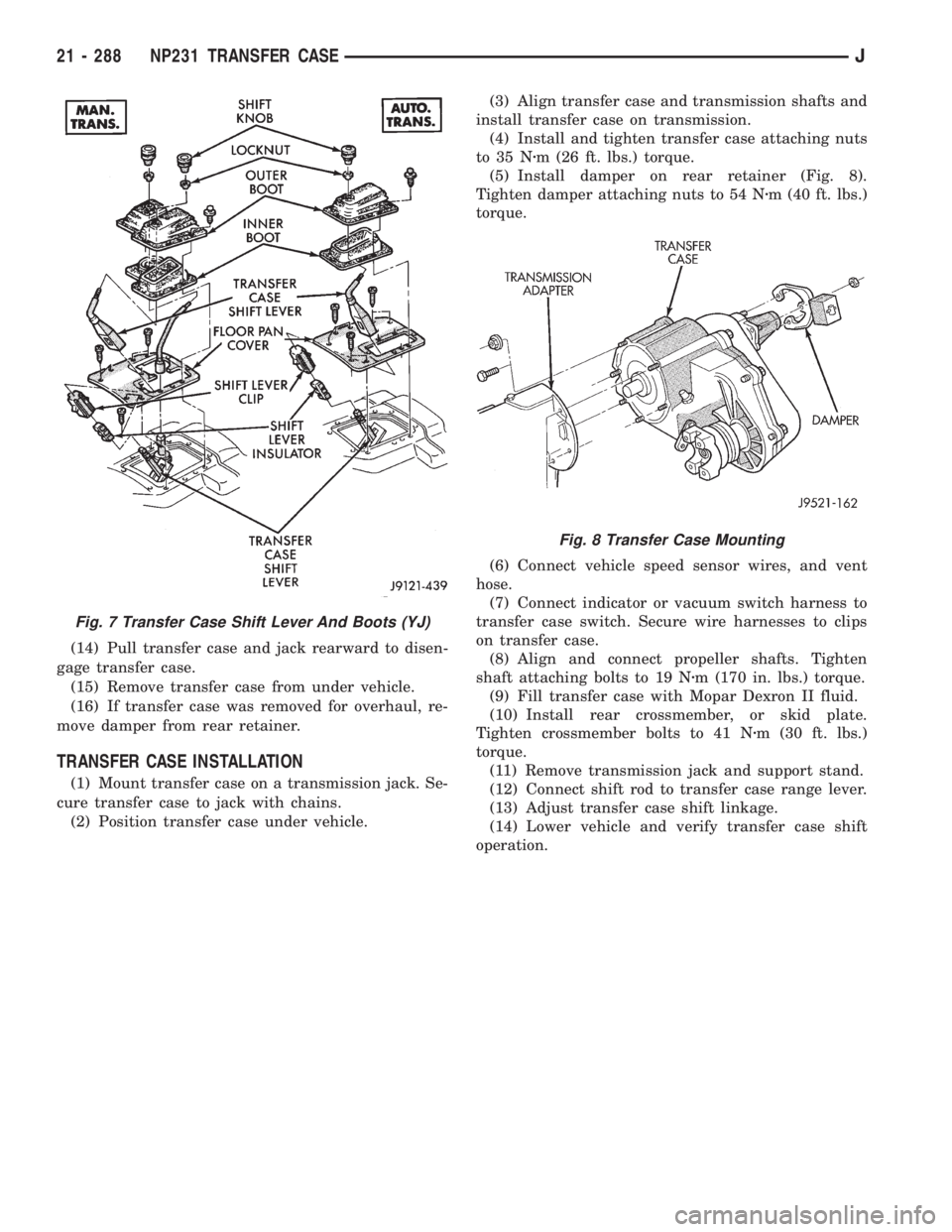

TRANSFER CASE INSTALLATION

(1) Mount transfer case on a transmission jack. Se-

cure transfer case to jack with chains.

(2) Position transfer case under vehicle.(3) Align transfer case and transmission shafts and

install transfer case on transmission.

(4) Install and tighten transfer case attaching nuts

to 35 Nzm (26 ft. lbs.) torque.

(5) Install damper on rear retainer (Fig. 8).

Tighten damper attaching nuts to 54 Nzm (40 ft. lbs.)

torque.

(6) Connect vehicle speed sensor wires, and vent

hose.

(7) Connect indicator or vacuum switch harness to

transfer case switch. Secure wire harnesses to clips

on transfer case.

(8) Align and connect propeller shafts. Tighten

shaft attaching bolts to 19 Nzm (170 in. lbs.) torque.

(9) Fill transfer case with Mopar Dexron II fluid.

(10) Install rear crossmember, or skid plate.

Tighten crossmember bolts to 41 Nzm (30 ft. lbs.)

torque.

(11) Remove transmission jack and support stand.

(12) Connect shift rod to transfer case range lever.

(13) Adjust transfer case shift linkage.

(14) Lower vehicle and verify transfer case shift

operation.

Fig. 7 Transfer Case Shift Lever And Boots (YJ)

Fig. 8 Transfer Case Mounting

21 - 288 NP231 TRANSFER CASEJ

Page 1672 of 2198

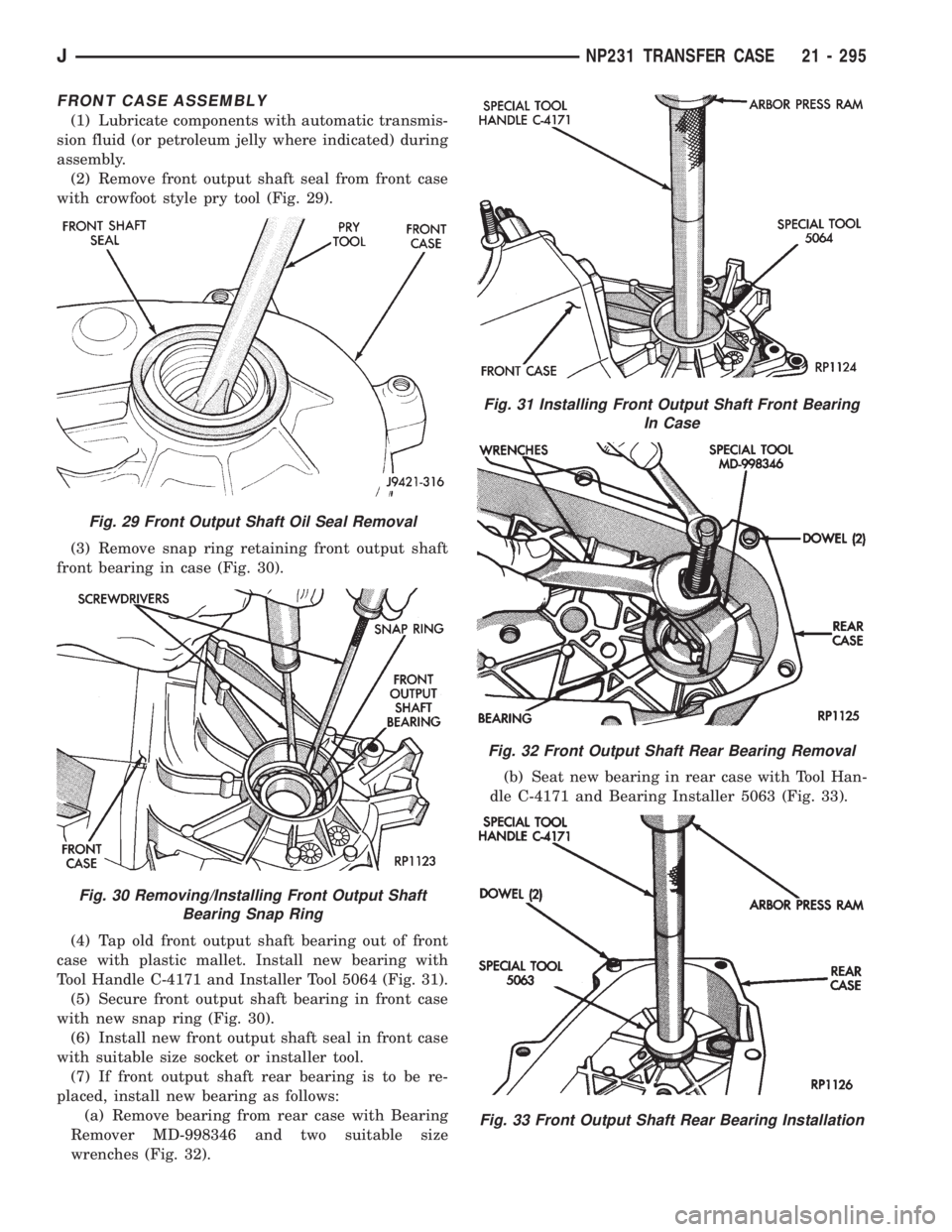

FRONT CASE ASSEMBLY

(1) Lubricate components with automatic transmis-

sion fluid (or petroleum jelly where indicated) during

assembly.

(2) Remove front output shaft seal from front case

with crowfoot style pry tool (Fig. 29).

(3) Remove snap ring retaining front output shaft

front bearing in case (Fig. 30).

(4) Tap old front output shaft bearing out of front

case with plastic mallet. Install new bearing with

Tool Handle C-4171 and Installer Tool 5064 (Fig. 31).

(5) Secure front output shaft bearing in front case

with new snap ring (Fig. 30).

(6) Install new front output shaft seal in front case

with suitable size socket or installer tool.

(7) If front output shaft rear bearing is to be re-

placed, install new bearing as follows:

(a) Remove bearing from rear case with Bearing

Remover MD-998346 and two suitable size

wrenches (Fig. 32).(b) Seat new bearing in rear case with Tool Han-

dle C-4171 and Bearing Installer 5063 (Fig. 33).

Fig. 29 Front Output Shaft Oil Seal Removal

Fig. 30 Removing/Installing Front Output Shaft

Bearing Snap Ring

Fig. 31 Installing Front Output Shaft Front Bearing

In Case

Fig. 32 Front Output Shaft Rear Bearing Removal

Fig. 33 Front Output Shaft Rear Bearing Installation

JNP231 TRANSFER CASE 21 - 295

Page 1676 of 2198

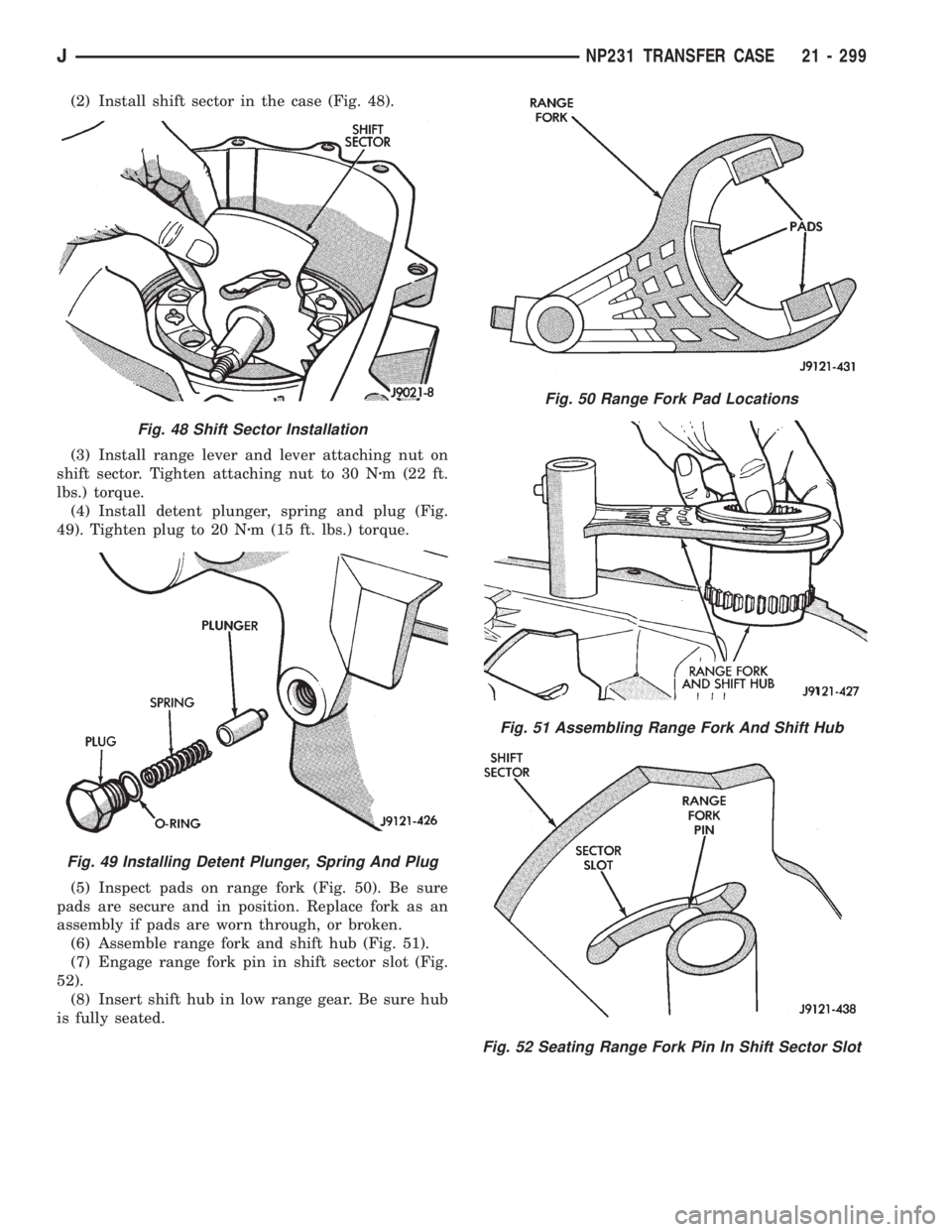

(2) Install shift sector in the case (Fig. 48).

(3) Install range lever and lever attaching nut on

shift sector. Tighten attaching nut to 30 Nzm (22 ft.

lbs.) torque.

(4) Install detent plunger, spring and plug (Fig.

49). Tighten plug to 20 Nzm (15 ft. lbs.) torque.

(5) Inspect pads on range fork (Fig. 50). Be sure

pads are secure and in position. Replace fork as an

assembly if pads are worn through, or broken.

(6) Assemble range fork and shift hub (Fig. 51).

(7) Engage range fork pin in shift sector slot (Fig.

52).

(8) Insert shift hub in low range gear. Be sure hub

is fully seated.

Fig. 48 Shift Sector Installation

Fig. 49 Installing Detent Plunger, Spring And Plug

Fig. 50 Range Fork Pad Locations

Fig. 51 Assembling Range Fork And Shift Hub

Fig. 52 Seating Range Fork Pin In Shift Sector Slot

JNP231 TRANSFER CASE 21 - 299

Page 1681 of 2198

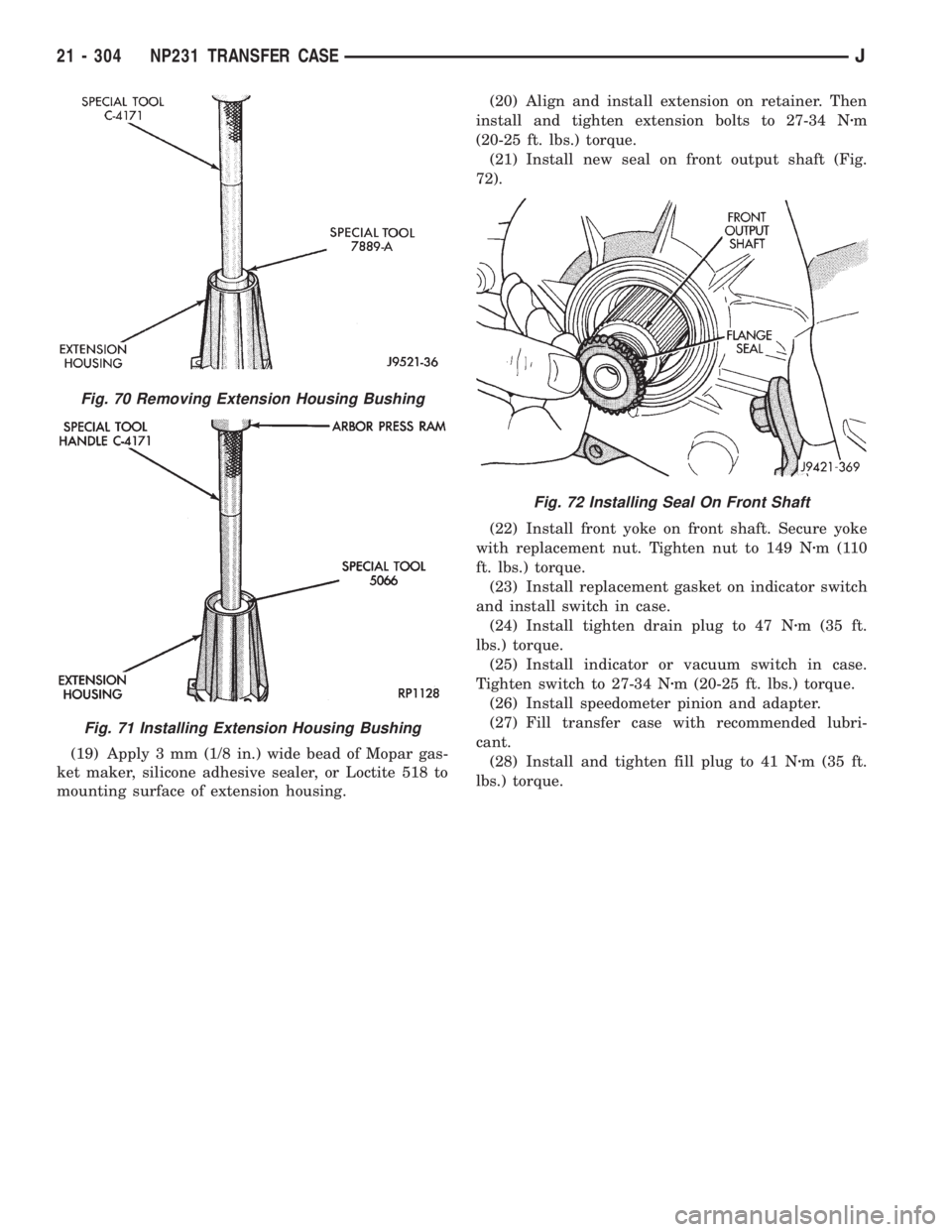

(19) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

mounting surface of extension housing.(20) Align and install extension on retainer. Then

install and tighten extension bolts to 27-34 Nzm

(20-25 ft. lbs.) torque.

(21) Install new seal on front output shaft (Fig.

72).

(22) Install front yoke on front shaft. Secure yoke

with replacement nut. Tighten nut to 149 Nzm(110

ft. lbs.) torque.

(23) Install replacement gasket on indicator switch

and install switch in case.

(24) Install tighten drain plug to 47 Nzm (35 ft.

lbs.) torque.

(25) Install indicator or vacuum switch in case.

Tighten switch to 27-34 Nzm (20-25 ft. lbs.) torque.

(26) Install speedometer pinion and adapter.

(27) Fill transfer case with recommended lubri-

cant.

(28) Install and tighten fill plug to 41 Nzm (35 ft.

lbs.) torque.

Fig. 70 Removing Extension Housing Bushing

Fig. 71 Installing Extension Housing Bushing

Fig. 72 Installing Seal On Front Shaft

21 - 304 NP231 TRANSFER CASEJ

Page 1686 of 2198

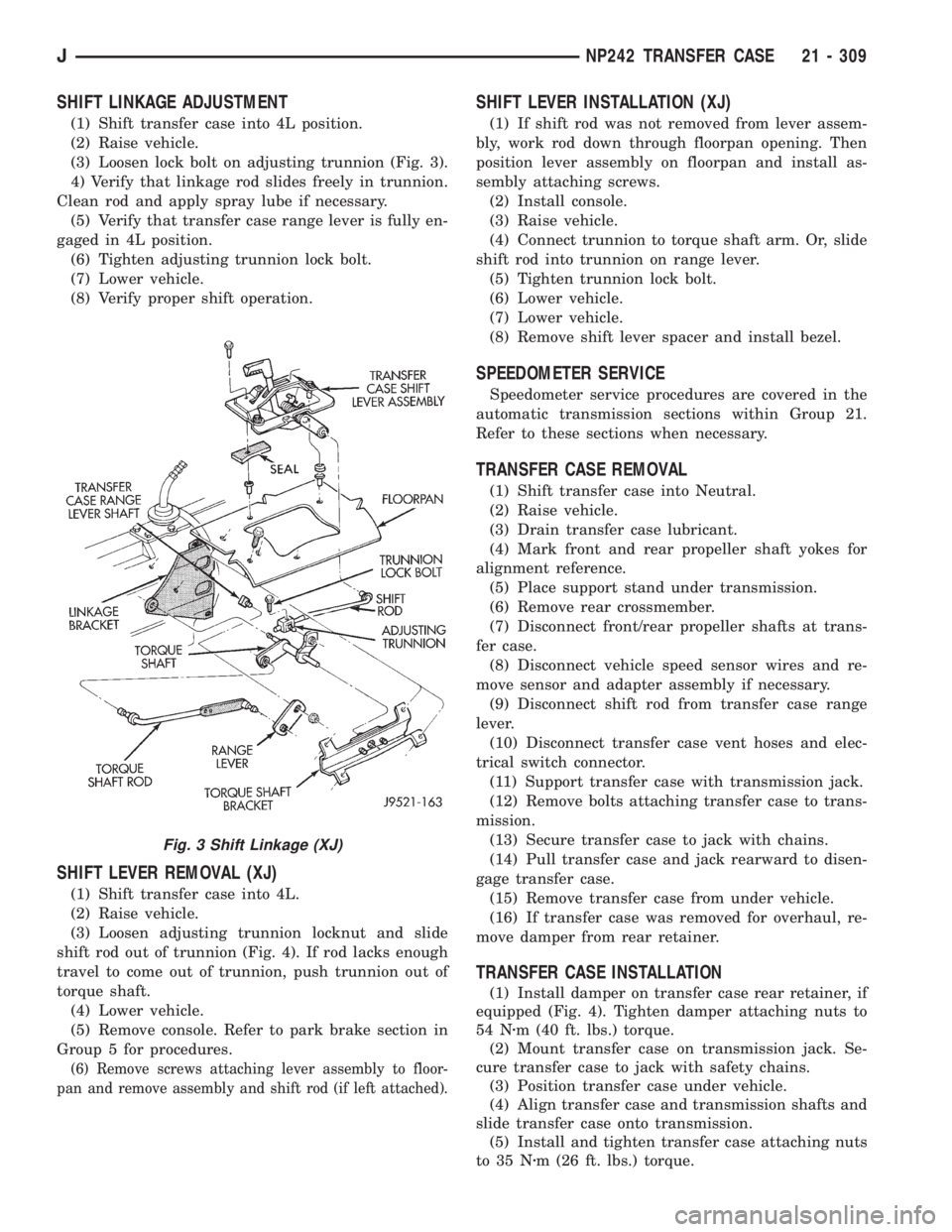

SHIFT LINKAGE ADJUSTMENT

(1) Shift transfer case into 4L position.

(2) Raise vehicle.

(3) Loosen lock bolt on adjusting trunnion (Fig. 3).

4) Verify that linkage rod slides freely in trunnion.

Clean rod and apply spray lube if necessary.

(5) Verify that transfer case range lever is fully en-

gaged in 4L position.

(6) Tighten adjusting trunnion lock bolt.

(7) Lower vehicle.

(8) Verify proper shift operation.

SHIFT LEVER REMOVAL (XJ)

(1) Shift transfer case into 4L.

(2) Raise vehicle.

(3) Loosen adjusting trunnion locknut and slide

shift rod out of trunnion (Fig. 4). If rod lacks enough

travel to come out of trunnion, push trunnion out of

torque shaft.

(4) Lower vehicle.

(5) Remove console. Refer to park brake section in

Group 5 for procedures.

(6) Remove screws attaching lever assembly to floor-

pan and remove assembly and shift rod (if left attached).

SHIFT LEVER INSTALLATION (XJ)

(1) If shift rod was not removed from lever assem-

bly, work rod down through floorpan opening. Then

position lever assembly on floorpan and install as-

sembly attaching screws.

(2) Install console.

(3) Raise vehicle.

(4) Connect trunnion to torque shaft arm. Or, slide

shift rod into trunnion on range lever.

(5) Tighten trunnion lock bolt.

(6) Lower vehicle.

(7) Lower vehicle.

(8) Remove shift lever spacer and install bezel.

SPEEDOMETER SERVICE

Speedometer service procedures are covered in the

automatic transmission sections within Group 21.

Refer to these sections when necessary.

TRANSFER CASE REMOVAL

(1) Shift transfer case into Neutral.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shaft yokes for

alignment reference.

(5) Place support stand under transmission.

(6) Remove rear crossmember.

(7) Disconnect front/rear propeller shafts at trans-

fer case.

(8) Disconnect vehicle speed sensor wires and re-

move sensor and adapter assembly if necessary.

(9) Disconnect shift rod from transfer case range

lever.

(10) Disconnect transfer case vent hoses and elec-

trical switch connector.

(11) Support transfer case with transmission jack.

(12) Remove bolts attaching transfer case to trans-

mission.

(13) Secure transfer case to jack with chains.

(14) Pull transfer case and jack rearward to disen-

gage transfer case.

(15) Remove transfer case from under vehicle.

(16) If transfer case was removed for overhaul, re-

move damper from rear retainer.

TRANSFER CASE INSTALLATION

(1) Install damper on transfer case rear retainer, if

equipped (Fig. 4). Tighten damper attaching nuts to

54 Nzm (40 ft. lbs.) torque.

(2) Mount transfer case on transmission jack. Se-

cure transfer case to jack with safety chains.

(3) Position transfer case under vehicle.

(4) Align transfer case and transmission shafts and

slide transfer case onto transmission.

(5) Install and tighten transfer case attaching nuts

to 35 Nzm (26 ft. lbs.) torque.

Fig. 3 Shift Linkage (XJ)

JNP242 TRANSFER CASE 21 - 309

Page 1703 of 2198

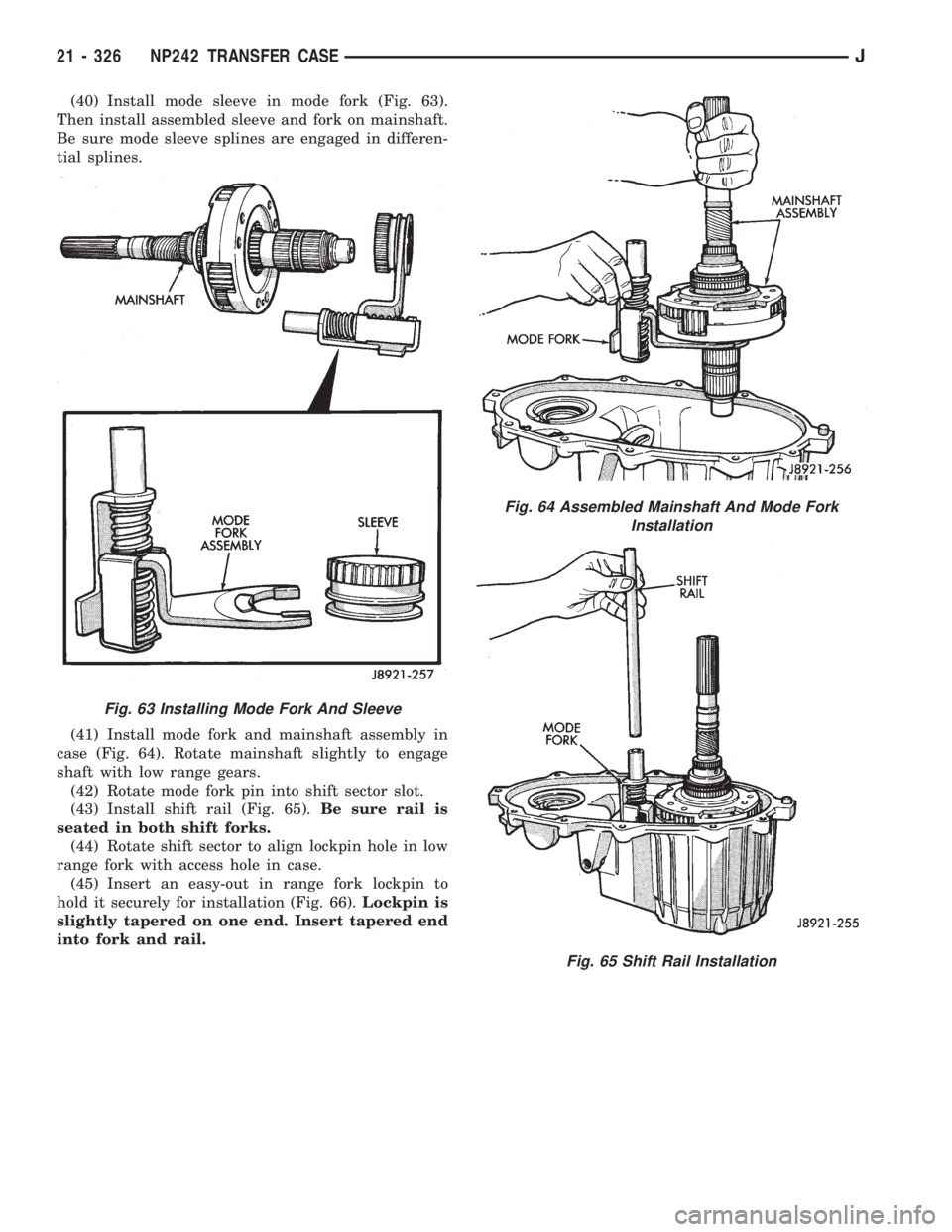

(40) Install mode sleeve in mode fork (Fig. 63).

Then install assembled sleeve and fork on mainshaft.

Be sure mode sleeve splines are engaged in differen-

tial splines.

(41) Install mode fork and mainshaft assembly in

case (Fig. 64). Rotate mainshaft slightly to engage

shaft with low range gears.

(42) Rotate mode fork pin into shift sector slot.

(43) Install shift rail (Fig. 65).Be sure rail is

seated in both shift forks.

(44) Rotate shift sector to align lockpin hole in low

range fork with access hole in case.

(45) Insert an easy-out in range fork lockpin to

hold it securely for installation (Fig. 66).Lockpin is

slightly tapered on one end. Insert tapered end

into fork and rail.

Fig. 63 Installing Mode Fork And Sleeve

Fig. 64 Assembled Mainshaft And Mode Fork

Installation

Fig. 65 Shift Rail Installation

21 - 326 NP242 TRANSFER CASEJ

Page 1707 of 2198

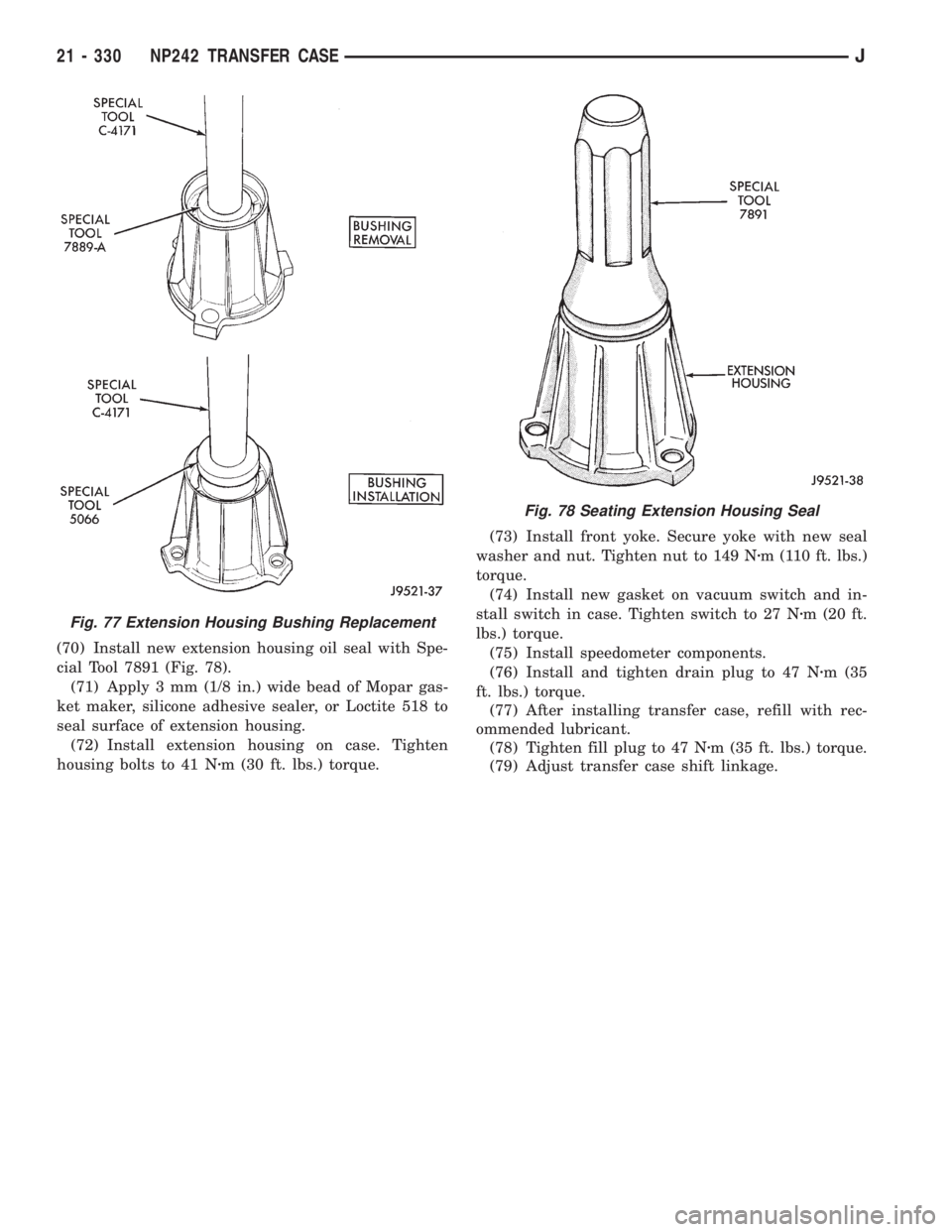

(70) Install new extension housing oil seal with Spe-

cial Tool 7891 (Fig. 78).

(71) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

seal surface of extension housing.

(72) Install extension housing on case. Tighten

housing bolts to 41 Nzm (30 ft. lbs.) torque.(73) Install front yoke. Secure yoke with new seal

washer and nut. Tighten nut to 149 Nzm (110 ft. lbs.)

torque.

(74) Install new gasket on vacuum switch and in-

stall switch in case. Tighten switch to 27 Nzm (20 ft.

lbs.) torque.

(75) Install speedometer components.

(76) Install and tighten drain plug to 47 Nzm (35

ft. lbs.) torque.

(77) After installing transfer case, refill with rec-

ommended lubricant.

(78) Tighten fill plug to 47 Nzm (35 ft. lbs.) torque.

(79) Adjust transfer case shift linkage.

Fig. 77 Extension Housing Bushing Replacement

Fig. 78 Seating Extension Housing Seal

21 - 330 NP242 TRANSFER CASEJ

Page 1761 of 2198

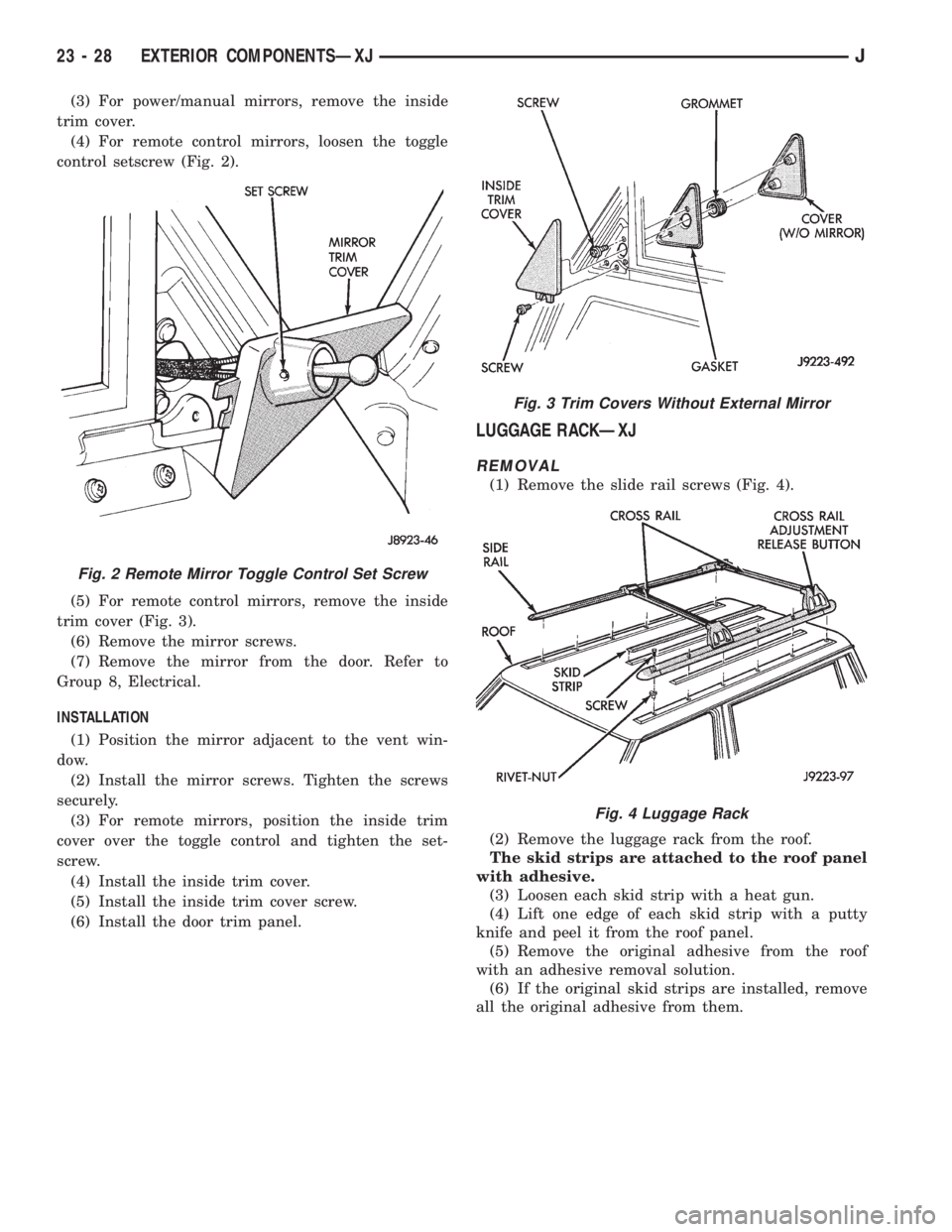

(3) For power/manual mirrors, remove the inside

trim cover.

(4) For remote control mirrors, loosen the toggle

control setscrew (Fig. 2).

(5) For remote control mirrors, remove the inside

trim cover (Fig. 3).

(6) Remove the mirror screws.

(7) Remove the mirror from the door. Refer to

Group 8, Electrical.

INSTALLATION

(1) Position the mirror adjacent to the vent win-

dow.

(2) Install the mirror screws. Tighten the screws

securely.

(3) For remote mirrors, position the inside trim

cover over the toggle control and tighten the set-

screw.

(4) Install the inside trim cover.

(5) Install the inside trim cover screw.

(6) Install the door trim panel.

LUGGAGE RACKÐXJ

REMOVAL

(1) Remove the slide rail screws (Fig. 4).

(2) Remove the luggage rack from the roof.

The skid strips are attached to the roof panel

with adhesive.

(3) Loosen each skid strip with a heat gun.

(4) Lift one edge of each skid strip with a putty

knife and peel it from the roof panel.

(5) Remove the original adhesive from the roof

with an adhesive removal solution.

(6) If the original skid strips are installed, remove

all the original adhesive from them.

Fig. 2 Remote Mirror Toggle Control Set Screw

Fig. 3 Trim Covers Without External Mirror

Fig. 4 Luggage Rack

23 - 28 EXTERIOR COMPONENTSÐXJJ

Page 1768 of 2198

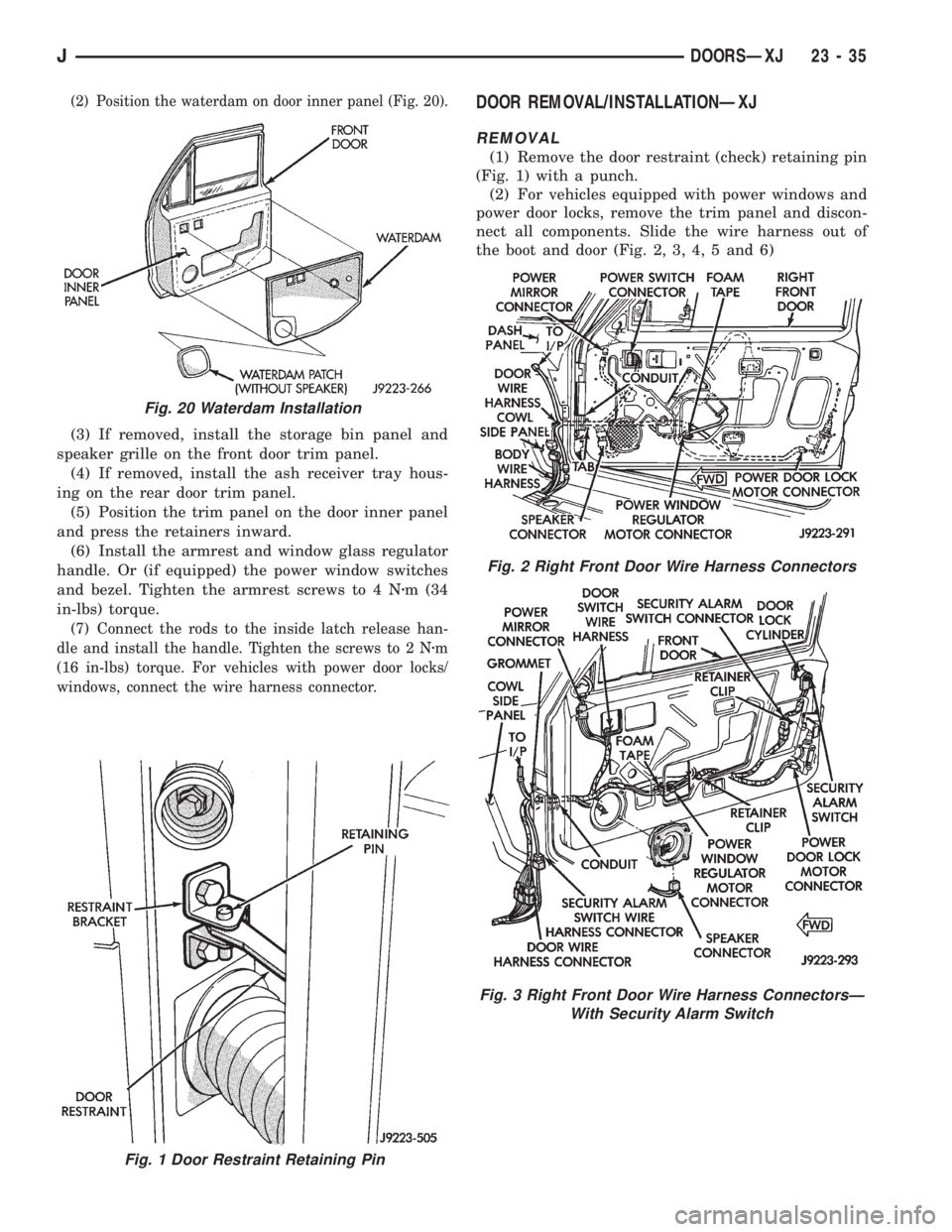

(2) Position the waterdam on door inner panel (Fig. 20).

(3) If removed, install the storage bin panel and

speaker grille on the front door trim panel.

(4) If removed, install the ash receiver tray hous-

ing on the rear door trim panel.

(5) Position the trim panel on the door inner panel

and press the retainers inward.

(6) Install the armrest and window glass regulator

handle. Or (if equipped) the power window switches

and bezel. Tighten the armrest screws to 4 Nzm (34

in-lbs) torque.

(7) Connect the rods to the inside latch release han-

dle and install the handle. Tighten the screws to 2 Nzm

(16 in-lbs) torque. For vehicles with power door locks/

windows, connect the wire harness connector.

DOOR REMOVAL/INSTALLATIONÐXJ

REMOVAL

(1) Remove the door restraint (check) retaining pin

(Fig. 1) with a punch.

(2) For vehicles equipped with power windows and

power door locks, remove the trim panel and discon-

nect all components. Slide the wire harness out of

the boot and door (Fig. 2, 3, 4, 5 and 6)

Fig. 1 Door Restraint Retaining Pin

Fig. 20 Waterdam Installation

Fig. 2 Right Front Door Wire Harness Connectors

Fig. 3 Right Front Door Wire Harness ConnectorsÐ

With Security Alarm Switch

JDOORSÐXJ 23 - 35

Page 1780 of 2198

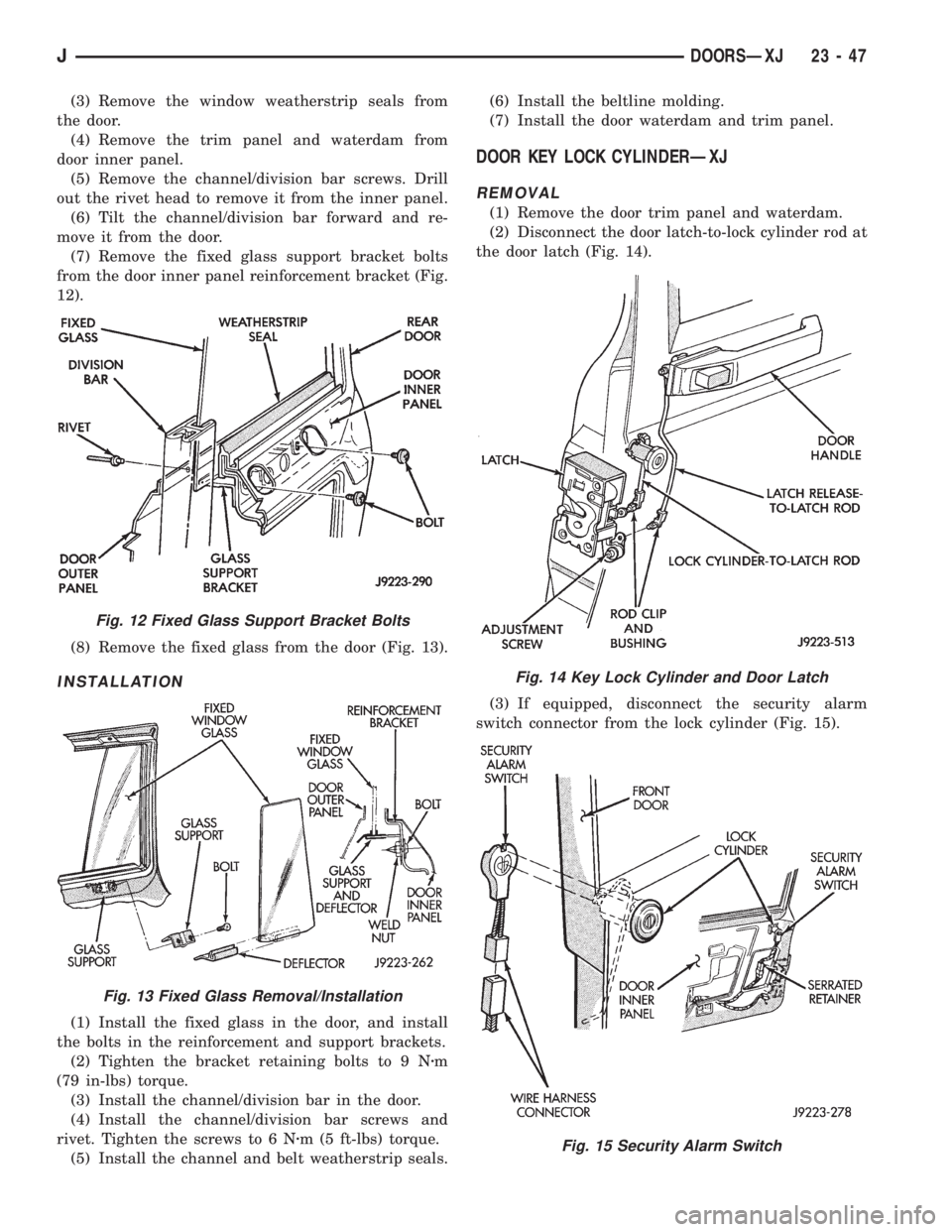

(3) Remove the window weatherstrip seals from

the door.

(4) Remove the trim panel and waterdam from

door inner panel.

(5) Remove the channel/division bar screws. Drill

out the rivet head to remove it from the inner panel.

(6) Tilt the channel/division bar forward and re-

move it from the door.

(7) Remove the fixed glass support bracket bolts

from the door inner panel reinforcement bracket (Fig.

12).

(8) Remove the fixed glass from the door (Fig. 13).

INSTALLATION

(1) Install the fixed glass in the door, and install

the bolts in the reinforcement and support brackets.

(2) Tighten the bracket retaining bolts to 9 Nzm

(79 in-lbs) torque.

(3) Install the channel/division bar in the door.

(4) Install the channel/division bar screws and

rivet. Tighten the screws to 6 Nzm (5 ft-lbs) torque.

(5) Install the channel and belt weatherstrip seals.(6) Install the beltline molding.

(7) Install the door waterdam and trim panel.

DOOR KEY LOCK CYLINDERÐXJ

REMOVAL

(1) Remove the door trim panel and waterdam.

(2) Disconnect the door latch-to-lock cylinder rod at

the door latch (Fig. 14).

(3) If equipped, disconnect the security alarm

switch connector from the lock cylinder (Fig. 15).

Fig. 12 Fixed Glass Support Bracket Bolts

Fig. 13 Fixed Glass Removal/Installation

Fig. 14 Key Lock Cylinder and Door Latch

Fig. 15 Security Alarm Switch

JDOORSÐXJ 23 - 47