rear view mirror JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 512 of 2198

POWER MIRRORS

CONTENTS

page page

DIAGNOSIS............................. 1

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 4

GENERAL INFORMATION

Power outside rear view mirrors are an available

option on XJ (Cherokee) models. Following are gen-

eral descriptions of the major components in the

power mirror system. Refer to Group 8W - Wiring Di-

agrams for complete circuit descriptions and dia-

grams.

POWER MIRROR

The power mirrors are connected to battery feed at

all times. Each mirror head contains two electric mo-

tors, two drive mechanisms and the mirror glass.

One motor and drive controls mirror up-and-down

movement, and the other controls right-and-left

movement.

The mirror glass is the only serviced replacement

part for the power mirror assembly. If any other com-ponent of the mirror unit is faulty or damaged, the

entire assembly must be replaced.

POWER MIRROR SWITCH

Both the right and left mirror are controlled by a

multi-function switch located on the front of the cen-

ter console storage compartment, directly below the

armrest. The selector switch is moved right (right

mirror control), left (left mirror control), or center to

turn power mirrors off. Then one of four directional

control buttons is depressed to control movement of

the selected mirror up, down, right, or left. The

power mirror switch is serviced only as a complete

unit.

DIAGNOSIS

POWER MIRROR SYSTEM

(1) Check fuse 16 in Power Distribution Center

(PDC) and fuse 9 in fuseblock module. If OK, go to

next step. If not OK, replace fuse.

(2) Check for battery voltage at fuse 9 in fuseblock

module. If OK, go to next step. If not OK, repair cir-

cuit to fuse 16 in PDC.

(3) Remove power mirror switch from the center

console. See Power Mirror Switch Remove/Install.

(4) Disconnect wiring harness connector from

switch. Check for battery voltage at pink wire. If OK,

go to next step. If not OK, repair circuit to fuse 9 in

fuseblock module.

(5) Check for continuity between black wire in

switch harness connector and a good ground. There

should be continuity. If OK, go to next step. If not

OK, repair circuit to ground.

(6) Check switch continuity as shown in the Mirror

Switch Continuity charts. If OK, go to next step. If

not OK, replace switch.(7) See Power Mirror Switch illustration. Connect

a jumper wire from mirror switch connector cavity

for pin E to cavity for pin F. Now connect a second

jumper from connector cavity for pin G to each of the

following pin cavities: A, B, C, then D. In each case,

the selected mirror head should move. If OK, replace

switch. If not OK, go to next step.

(8) Remove door trim panel and unplug power mir-

ror connector inside door. Connect one jumper wire to

a good ground and a second jumper wire to a battery

feed. Connect other ends of jumpers to the mirror

side of connector in door (refer to Group 8W - Wiring

Diagrams for connector cavity identification). Mirror

head should move in each of the four directions. If

OK, repair wiring between mirror switch and door

connectors. If not OK, replace mirror.

JPOWER MIRRORS 8T - 1

Page 1760 of 2198

(3) Attach the hoses to the tubes with clamps.

Tighten the clamp screws to 4 Nzm (35 in-lbs) torque.

(4) Install the cap on nozzle.

(5) Install the fuel filler hose splash shield on the

quarter inner panel and frame rail.

(6) Install the fuel filler door on the quarter panel.

FUEL FILLER DOOR BUMPERSÐXJ

REPLACEMENT

(1) Grasp the bumper (Fig. 23) with pliers and pull

outward to remove it from the hole.

²It may be necessary to remove the door (Fig. 24) to

replace the door-stop bumper.

(2) Insert bumpers in the holes and force them in-

ward until they are seated in the holes.

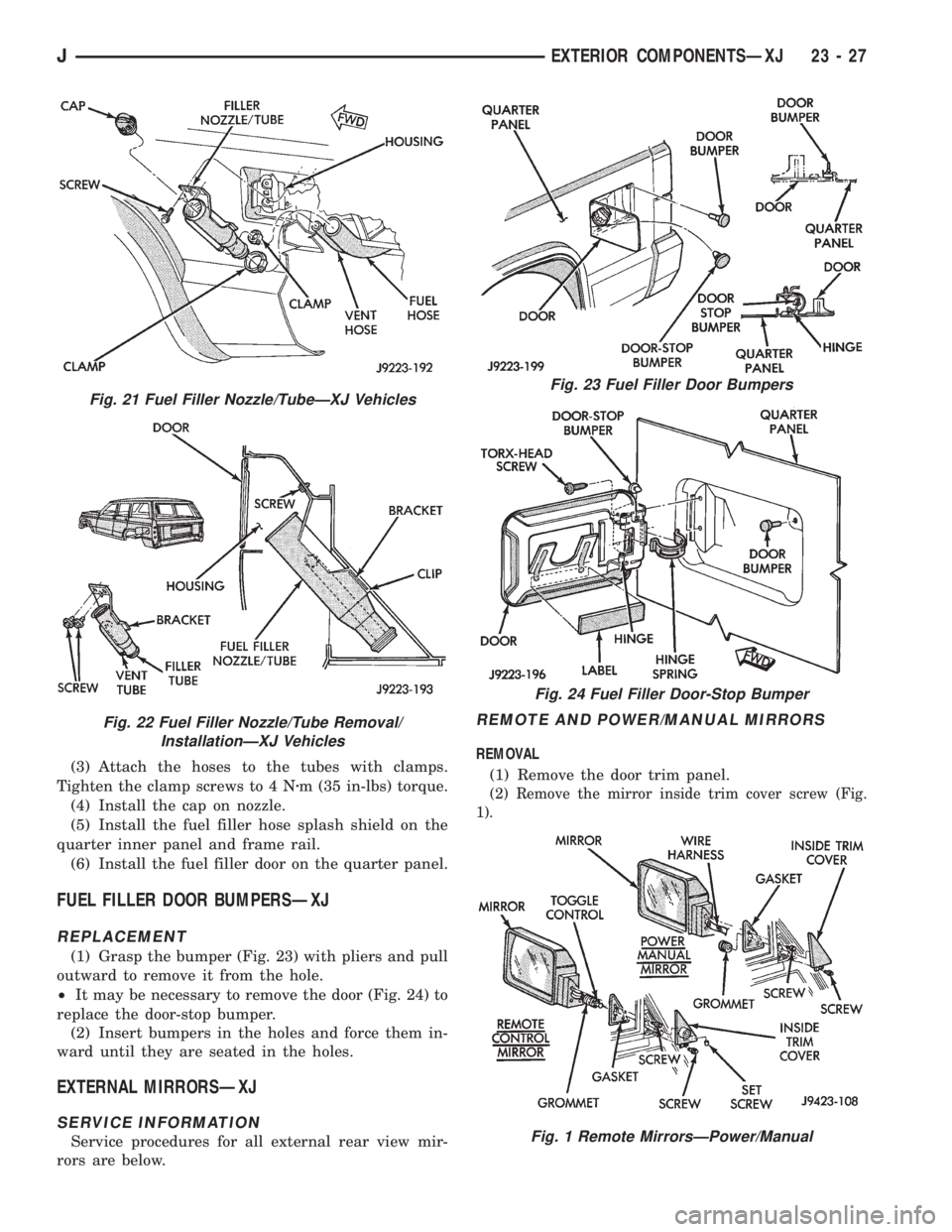

EXTERNAL MIRRORSÐXJ

SERVICE INFORMATION

Service procedures for all external rear view mir-

rors are below.

REMOTE AND POWER/MANUAL MIRRORS

REMOVAL

(1) Remove the door trim panel.

(2) Remove the mirror inside trim cover screw (Fig.

1).

Fig. 21 Fuel Filler Nozzle/TubeÐXJ Vehicles

Fig. 22 Fuel Filler Nozzle/Tube Removal/

InstallationÐXJ Vehicles

Fig. 23 Fuel Filler Door Bumpers

Fig. 24 Fuel Filler Door-Stop Bumper

Fig. 1 Remote MirrorsÐPower/Manual

JEXTERIOR COMPONENTSÐXJ 23 - 27

Page 1799 of 2198

STATIONARY WINDOW GLASS

INDEX

page page

Interior Rearview MirrorÐXJ Removal and

Installation............................. 66

Interior Rearview Mirror Support Bracket

ReplacementÐXJ Preparation and Installation . . . 66

Description and Operation.......... ..........67

InstallationÐShort Method.......... ..........69

InstallationÐExtended Method........ ........71Rear Door Stationary Window Glass...... ......72

Rear Quarter Vent Window GlassÐXJ Removal

and Installation............. .............73

Rear Quarter Window Glass/Rear Quarter Plastic

InsertÐXJ Removal and Installation..... .....73

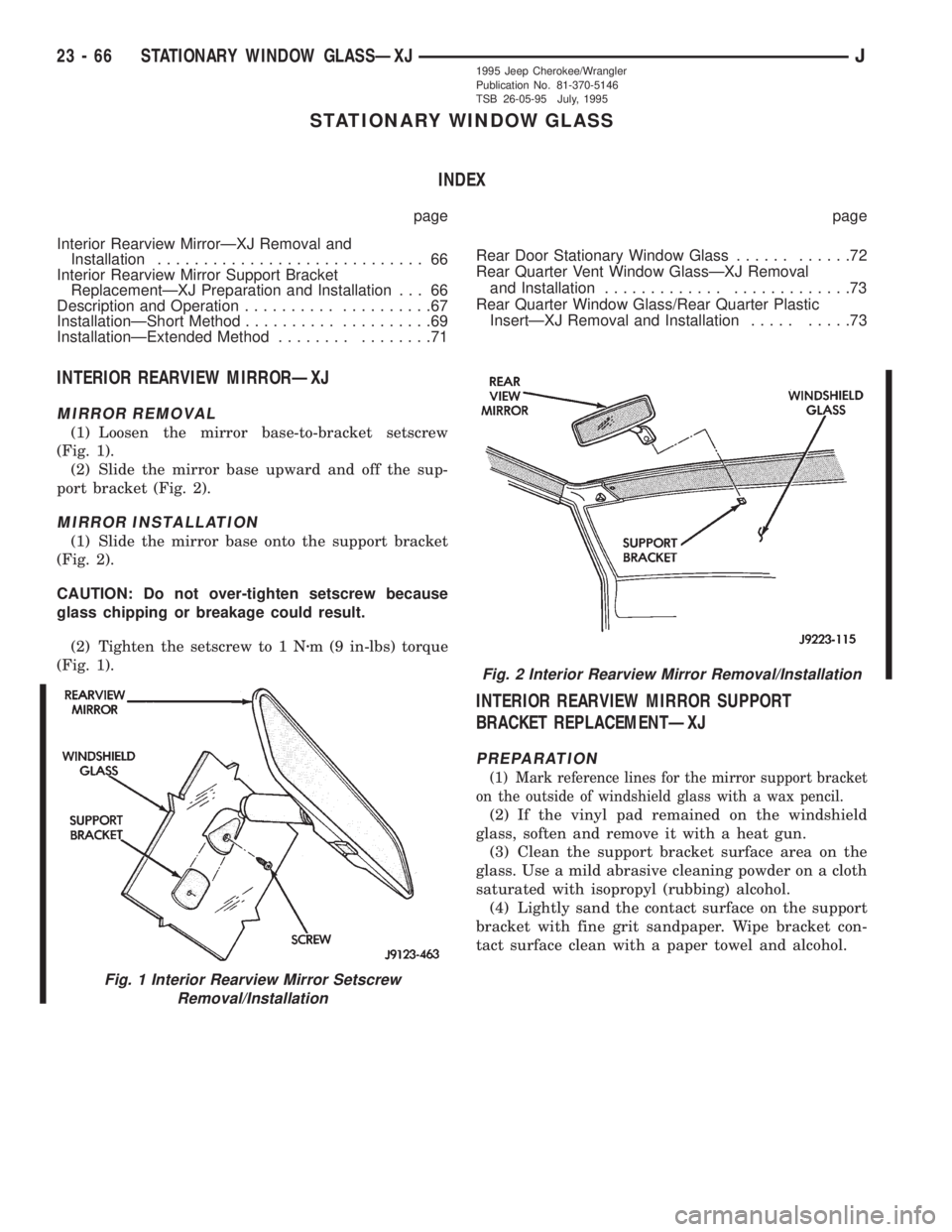

INTERIOR REARVIEW MIRRORÐXJ

MIRROR REMOVAL

(1) Loosen the mirror base-to-bracket setscrew

(Fig. 1).

(2) Slide the mirror base upward and off the sup-

port bracket (Fig. 2).

MIRROR INSTALLATION

(1) Slide the mirror base onto the support bracket

(Fig. 2).

CAUTION: Do not over-tighten setscrew because

glass chipping or breakage could result.

(2) Tighten the setscrew to 1 Nzm (9 in-lbs) torque

(Fig. 1).

INTERIOR REARVIEW MIRROR SUPPORT

BRACKET REPLACEMENTÐXJ

PREPARATION

(1) Mark reference lines for the mirror support bracket

on the outside of windshield glass with a wax pencil.

(2) If the vinyl pad remained on the windshield

glass, soften and remove it with a heat gun.

(3) Clean the support bracket surface area on the

glass. Use a mild abrasive cleaning powder on a cloth

saturated with isopropyl (rubbing) alcohol.

(4) Lightly sand the contact surface on the support

bracket with fine grit sandpaper. Wipe bracket con-

tact surface clean with a paper towel and alcohol.

Fig. 1 Interior Rearview Mirror Setscrew

Removal/Installation

Fig. 2 Interior Rearview Mirror Removal/Installation

23 - 66 STATIONARY WINDOW GLASSÐXJJ1995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995

Page 1801 of 2198

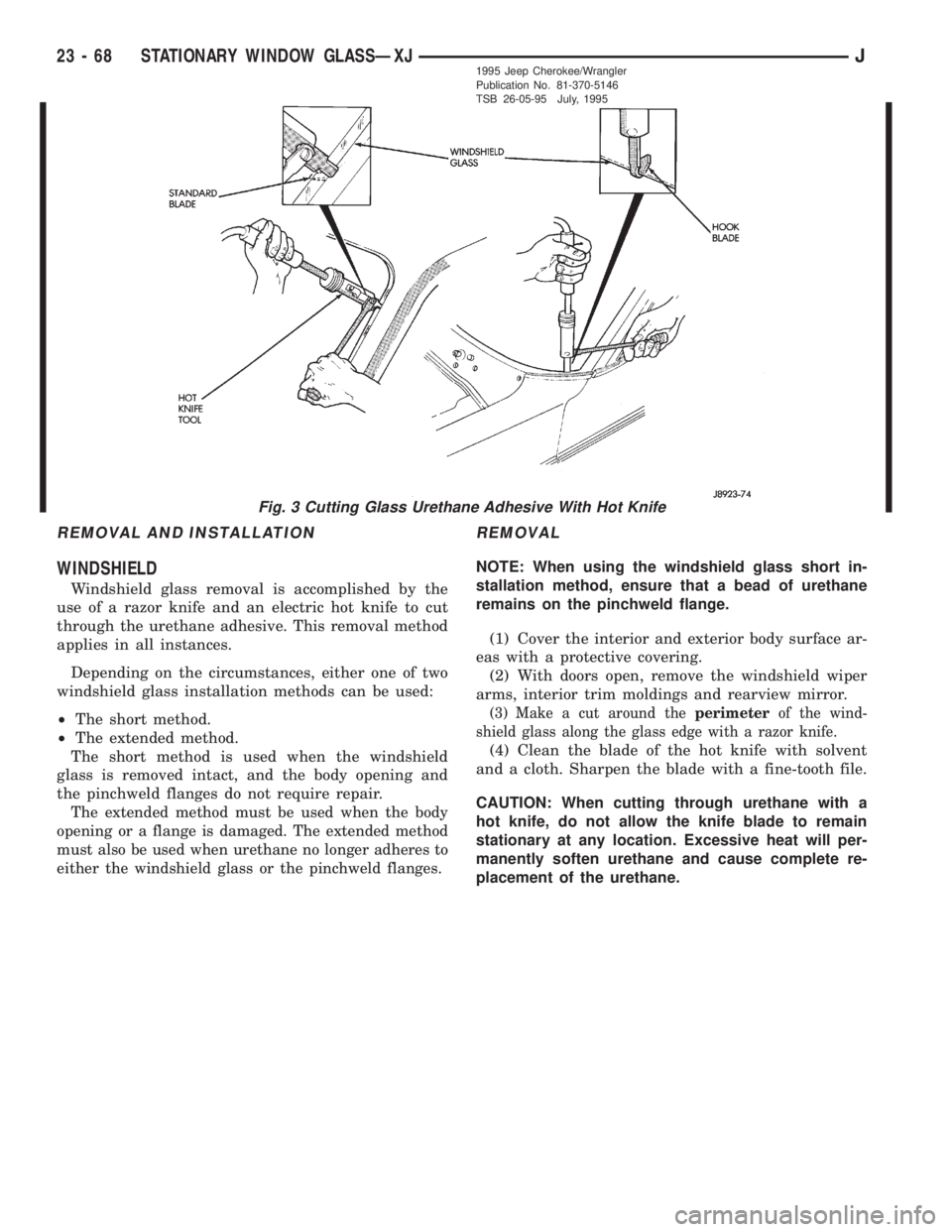

REMOVAL AND INSTALLATION

WINDSHIELD

Windshield glass removal is accomplished by the

use of a razor knife and an electric hot knife to cut

through the urethane adhesive. This removal method

applies in all instances.

Depending on the circumstances, either one of two

windshield glass installation methods can be used:

²The short method.

²The extended method.

The short method is used when the windshield

glass is removed intact, and the body opening and

the pinchweld flanges do not require repair.

The extended method must be used when the body

opening or a flange is damaged. The extended method

must also be used when urethane no longer adheres to

either the windshield glass or the pinchweld flanges.

REMOVAL

NOTE: When using the windshield glass short in-

stallation method, ensure that a bead of urethane

remains on the pinchweld flange.

(1) Cover the interior and exterior body surface ar-

eas with a protective covering.

(2) With doors open, remove the windshield wiper

arms, interior trim moldings and rearview mirror.

(3) Make a cut around theperimeterof the wind-

shield glass along the glass edge with a razor knife.

(4) Clean the blade of the hot knife with solvent

and a cloth. Sharpen the blade with a fine-tooth file.

CAUTION: When cutting through urethane with a

hot knife, do not allow the knife blade to remain

stationary at any location. Excessive heat will per-

manently soften urethane and cause complete re-

placement of the urethane.

Fig. 3 Cutting Glass Urethane Adhesive With Hot Knife

23 - 68 STATIONARY WINDOW GLASSÐXJJ1995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995

Page 1802 of 2198

(5) Start the hot knife blade (special tool C-4386)

between the glass and the urethane. Next, cut the

adhesive as close to the glass edge as possible (Fig.

1). Allow as much adhesive to remain on the pinch-

weld flange as possible.For best cutting results,

clean the knife blade frequently with steel wool

while the blade is hot.

(6) Remove the windshield glass from the body

opening.

(7) After the hot knife blade has cooled, clean the

blade with solvent and a clean cloth.

INSTALLATIONÐSHORT METHOD

Normally, after a replacement windshield glass is

installed, the rearview mirror bracket also requires

installation.Do not install the bracket until after

the windshield glass installation is completed.

(1) Inspect the windshield opening pinchweld

flanges. Prime any bare spots with urethane primer.

Allow a minimum of 18 minutes for dry time.

(2) Inspect urethane bead for high spots. Level

bead by shaving off high spots with a razor knife.

(3) Clean the outer edge of windshield glass with

naphtha or an equivalent product.

(4) Prime outer perimeter of interior side of glass 16

mm (5/8 inch) from edge. Use a wipe-off type urethane

primer and wipe glass dry after primer application.

NOTE: The reveal molding has an adhesive applied

to the windshield contact surface to help secure the

molding to the windshield during the installation

procedure.

(5) Apply the molding to the windshield:

²With the molding at room temperature, press the

molding onto the windshield corners.

²From corner to corner, work the molding to the

center of each side. (Some stretching of the mold-

ing may be required during this procedure.)(6) Place the glass on the pinchweld flanges and

inspect for gaps in the urethane. Gaps in excess of 3

mm (1/8 inch) must be filled with urethane.

(7) Adjust windshield glass position until it is

aligned with the flanges and adhesive. Next, make

alignment marks on the glass and body.

(8) Remove the windshield glass and position it on

a flat surface.

CAUTION: Avoid spilling or dripping primer on

painted surfaces. Clean spills or drips immediately.

The primer will damage the paint if it remains on

the surface for any length of time.

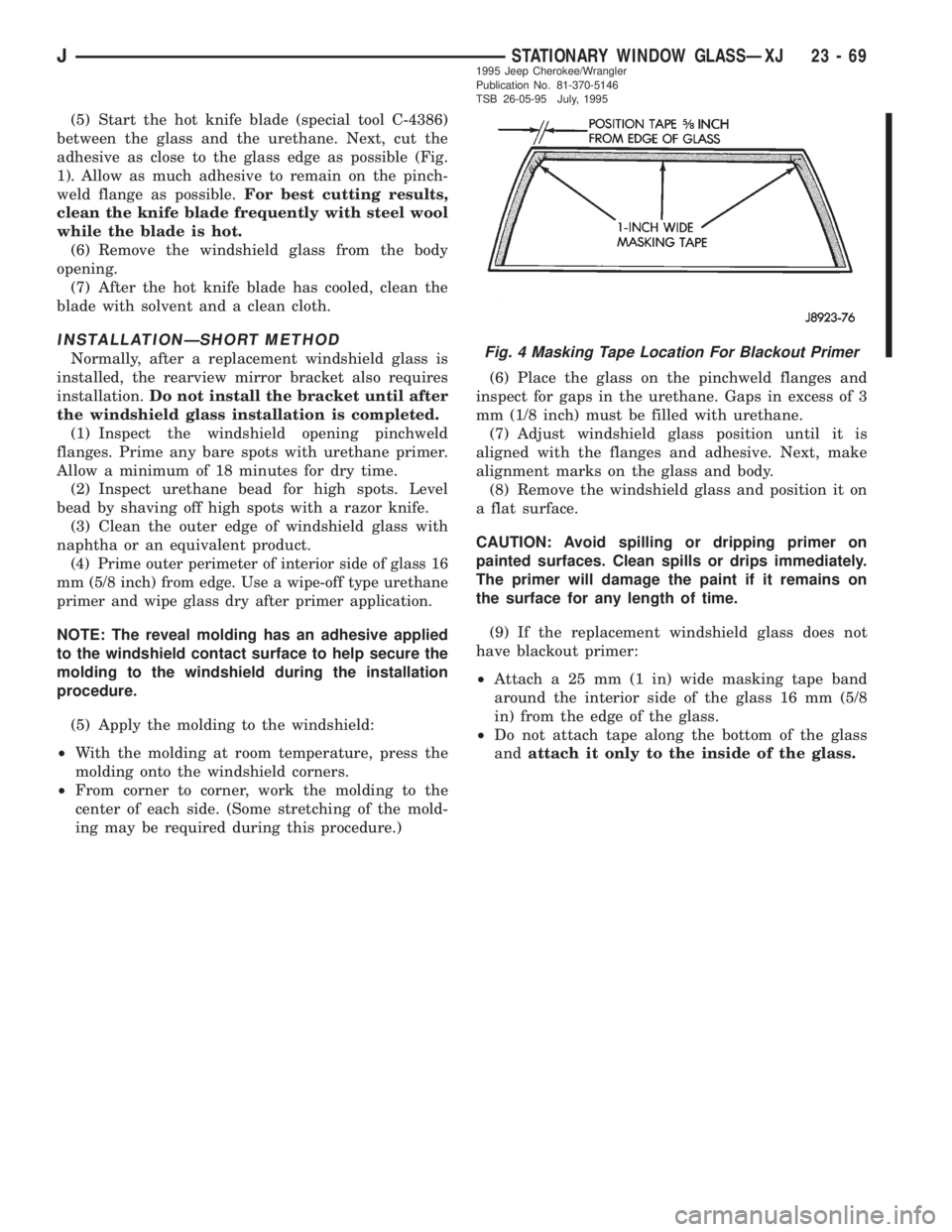

(9) If the replacement windshield glass does not

have blackout primer:

²Attach a 25 mm (1 in) wide masking tape band

around the interior side of the glass 16 mm (5/8

in) from the edge of the glass.

²Do not attach tape along the bottom of the glass

andattach it only to the inside of the glass.

Fig. 4 Masking Tape Location For Blackout Primer

JSTATIONARY WINDOW GLASSÐXJ 23 - 691995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995

Page 1803 of 2198

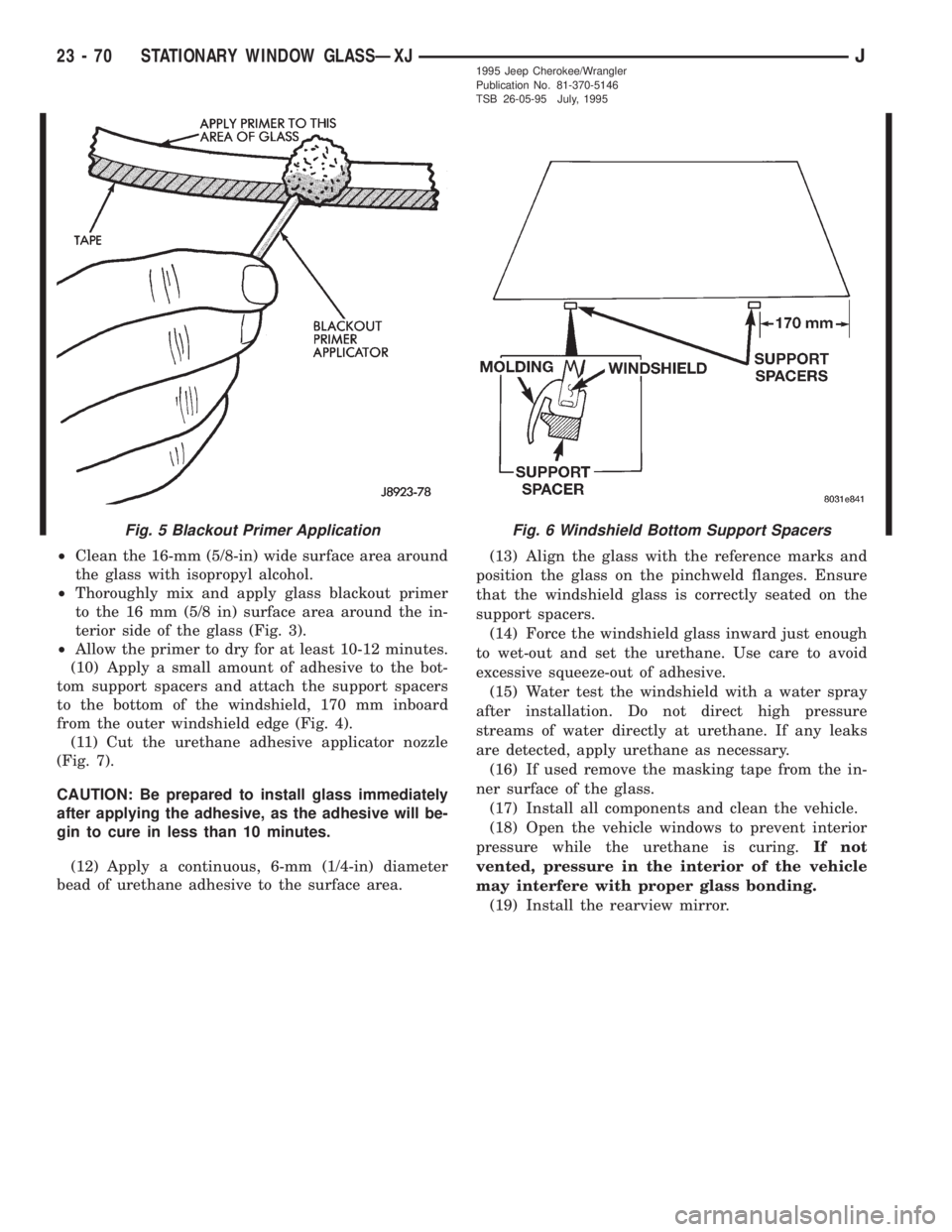

²Clean the 16-mm (5/8-in) wide surface area around

the glass with isopropyl alcohol.

²Thoroughly mix and apply glass blackout primer

to the 16 mm (5/8 in) surface area around the in-

terior side of the glass (Fig. 3).

²Allow the primer to dry for at least 10-12 minutes.

(10) Apply a small amount of adhesive to the bot-

tom support spacers and attach the support spacers

to the bottom of the windshield, 170 mm inboard

from the outer windshield edge (Fig. 4).

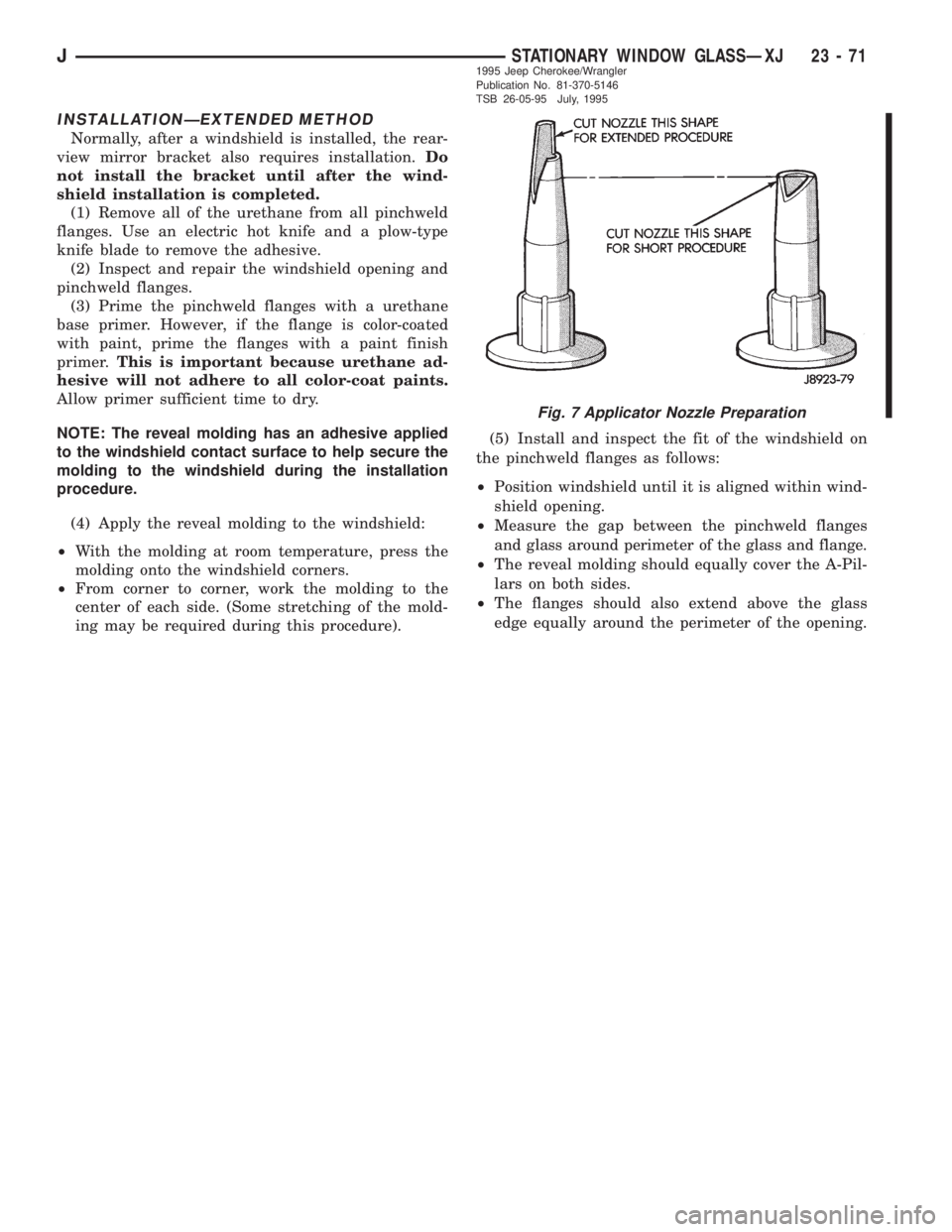

(11) Cut the urethane adhesive applicator nozzle

(Fig. 7).

CAUTION: Be prepared to install glass immediately

after applying the adhesive, as the adhesive will be-

gin to cure in less than 10 minutes.

(12) Apply a continuous, 6-mm (1/4-in) diameter

bead of urethane adhesive to the surface area.(13) Align the glass with the reference marks and

position the glass on the pinchweld flanges. Ensure

that the windshield glass is correctly seated on the

support spacers.

(14) Force the windshield glass inward just enough

to wet-out and set the urethane. Use care to avoid

excessive squeeze-out of adhesive.

(15) Water test the windshield with a water spray

after installation. Do not direct high pressure

streams of water directly at urethane. If any leaks

are detected, apply urethane as necessary.

(16) If used remove the masking tape from the in-

ner surface of the glass.

(17) Install all components and clean the vehicle.

(18) Open the vehicle windows to prevent interior

pressure while the urethane is curing.If not

vented, pressure in the interior of the vehicle

may interfere with proper glass bonding.

(19) Install the rearview mirror.

Fig. 6 Windshield Bottom Support SpacersFig. 5 Blackout Primer Application

23 - 70 STATIONARY WINDOW GLASSÐXJJ1995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995

Page 1804 of 2198

INSTALLATIONÐEXTENDED METHOD

Normally, after a windshield is installed, the rear-

view mirror bracket also requires installation.Do

not install the bracket until after the wind-

shield installation is completed.

(1) Remove all of the urethane from all pinchweld

flanges. Use an electric hot knife and a plow-type

knife blade to remove the adhesive.

(2) Inspect and repair the windshield opening and

pinchweld flanges.

(3) Prime the pinchweld flanges with a urethane

base primer. However, if the flange is color-coated

with paint, prime the flanges with a paint finish

primer.This is important because urethane ad-

hesive will not adhere to all color-coat paints.

Allow primer sufficient time to dry.

NOTE: The reveal molding has an adhesive applied

to the windshield contact surface to help secure the

molding to the windshield during the installation

procedure.

(4) Apply the reveal molding to the windshield:

²With the molding at room temperature, press the

molding onto the windshield corners.

²From corner to corner, work the molding to the

center of each side. (Some stretching of the mold-

ing may be required during this procedure).(5) Install and inspect the fit of the windshield on

the pinchweld flanges as follows:

²Position windshield until it is aligned within wind-

shield opening.

²

Measure the gap between the pinchweld flanges

and glass around perimeter of the glass and flange.

²The reveal molding should equally cover the A-Pil-

lars on both sides.

²The flanges should also extend above the glass

edge equally around the perimeter of the opening.

Fig. 7 Applicator Nozzle Preparation

JSTATIONARY WINDOW GLASSÐXJ 23 - 711995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995

Page 1805 of 2198

(6) If the pinchweld flanges require repair, remove

the windshield glass and straighten, align, or repair

the flange(s) as necessary.

(7) Position the windshield in the opening and in-

spect the windshield fit again. Mark the windshield

final position on the glass and body with a wax pen-

cil (or use masking tape). The marks (or masking

tape) will be used for installation alignment refer-

ence.

(8) If the replacement windshield does not have

blackout primer:

²Attach a 25-mm (1-in) wide masking tape band

around the interior side of glass 16 mm (5/8 in)

from edge of glass (Fig. 2).

²Do not attach tape along the bottom of the glass

and attach only to the inside of glass.

²Thoroughly mix and apply blackout primer to the

16 mm (5/8 in) surface area around the interior

side of the glass (Fig. 4).

²Allow the primer to dry for at least 10-12 minutes.

(9) Apply a small amount of adhesive to the bot-

tom support spacers and attach the support spacers

to the bottom of the windshield, 170 mm inboard

from the outer windshield edge (Fig. 6).

(10) Cut the urethane applicator nozzle (Fig. 7).

(11) Apply a continuous bead of urethane to the

surface area with blackout primer on the interior

side of glass. The bead should be 9-mm (3/8-in) wide

by 12.7-mm (1/2-in) deep for best results.CAUTION: Be prepared to install the windshield im-

mediately after applying the adhesive, as the adhe-

sive will begin to cure in less than 10 minutes.

(12) Align the windshield with the wax pencil in-

stallation alignment reference marks (or the tape

strips). Position the windshield on pinchweld flanges

and spacers.

(13) Force the windshield inward just enough to

wet-out and set the urethane. Use care to avoid ex-

cessive squeeze-out of adhesive.

(14) Water test the windshield with a water spray

after installation. Do not direct high pressure

streams of water directly at the urethane. If any

leaks are detected, apply urethane as necessary.

(15) If used, remove the masking tape from the in-

ner surface of glass.

(16) Install all components and clean the vehicle. If

necessary, refer to the installation procedures.

(17) Open the vehicle windows to prevent interior

pressure while the urethane adhesive is curing.If

not vented, pressure in the interior of vehicle

will interfere with glass bonding.

(18) Install the rearview mirror on the bracket.

REAR DOOR STATIONARY WINDOW GLASS

REMOVAL

(1) Lower the window glass.

(2) Pry the window beltline molding away from the

clips and remove the molding from the door.

(3) Remove the window weatherstrip seals from

the door.

23 - 72 STATIONARY WINDOW GLASSÐXJJ1995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995

Page 1877 of 2198

STATIONARY GLASS

INDEX

page page

Hard Top Quarter Window GlassÐYJ......... 149

Rearview Mirror Retaining BracketÐYJ........ 144

Rearview MirrorÐYJ...................... 144

Stationary Glass Water Leak Detection and

RepairÐYJ........................... 150Windshield Frame Weatherstrip SealÐYJ...... 146

Windshield FrameÐYJ.................... 145

Windshield GlassÐYJ..................... 146

Windshield Reveal MoldingÐYJ............. 144

WINDSHIELD REVEAL MOLDINGÐYJ

REMOVAL

(1) Disengage the reveal molding around the pe-

rimeter of the windshield glass with an appropriate

tool.

(2) Remove the moldings from the windshield

frame.

(3) Inspect the reveal molding retainers. Replace

the molding if it has broken, distorted or ineffective

retainers.

INSTALLATION

(1) Position the reveal moldings on the windshield

frame.

(2) Attach the moldings to the frame by tapping

each molding with a rubber mallet to seat the retain-

ers.

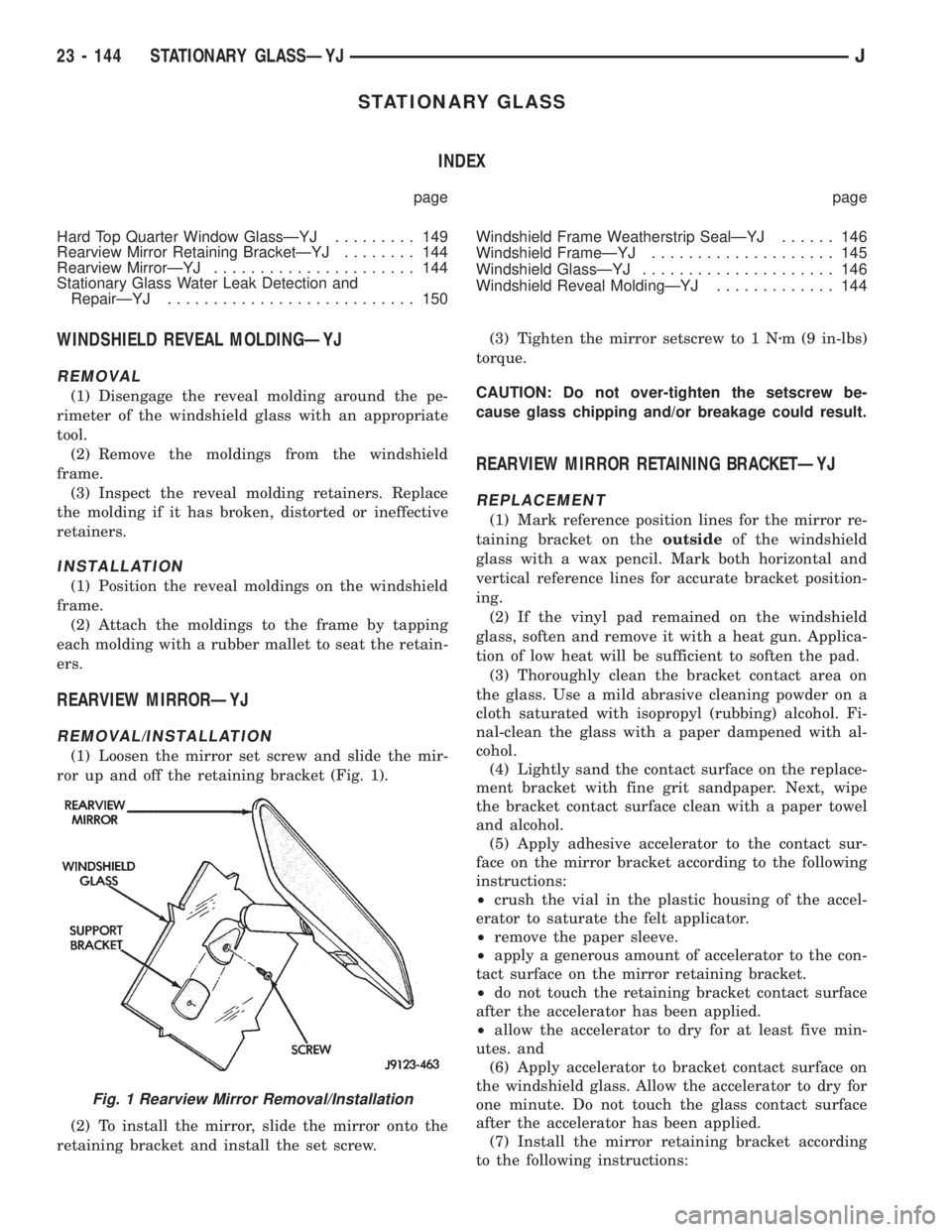

REARVIEW MIRRORÐYJ

REMOVAL/INSTALLATION

(1) Loosen the mirror set screw and slide the mir-

ror up and off the retaining bracket (Fig. 1).

(2) To install the mirror, slide the mirror onto the

retaining bracket and install the set screw.(3) Tighten the mirror setscrew to 1 Nzm (9 in-lbs)

torque.

CAUTION: Do not over-tighten the setscrew be-

cause glass chipping and/or breakage could result.

REARVIEW MIRROR RETAINING BRACKETÐYJ

REPLACEMENT

(1) Mark reference position lines for the mirror re-

taining bracket on theoutsideof the windshield

glass with a wax pencil. Mark both horizontal and

vertical reference lines for accurate bracket position-

ing.

(2) If the vinyl pad remained on the windshield

glass, soften and remove it with a heat gun. Applica-

tion of low heat will be sufficient to soften the pad.

(3) Thoroughly clean the bracket contact area on

the glass. Use a mild abrasive cleaning powder on a

cloth saturated with isopropyl (rubbing) alcohol. Fi-

nal-clean the glass with a paper dampened with al-

cohol.

(4) Lightly sand the contact surface on the replace-

ment bracket with fine grit sandpaper. Next, wipe

the bracket contact surface clean with a paper towel

and alcohol.

(5) Apply adhesive accelerator to the contact sur-

face on the mirror bracket according to the following

instructions:

²crush the vial in the plastic housing of the accel-

erator to saturate the felt applicator.

²remove the paper sleeve.

²apply a generous amount of accelerator to the con-

tact surface on the mirror retaining bracket.

²do not touch the retaining bracket contact surface

after the accelerator has been applied.

²allow the accelerator to dry for at least five min-

utes. and

(6) Apply accelerator to bracket contact surface on

the windshield glass. Allow the accelerator to dry for

one minute. Do not touch the glass contact surface

after the accelerator has been applied.

(7) Install the mirror retaining bracket according

to the following instructions:

Fig. 1 Rearview Mirror Removal/Installation

23 - 144 STATIONARY GLASSÐYJJ

Page 1879 of 2198

WINDSHIELD FRAME WEATHERSTRIP SEALÐYJ

REMOVAL

The windshield frame weatherstrip seal can be re-

moved and installed with the frame tilted forward to

the full horizontal position (Fig. 4).

(1) Disconnect the top from the windshield frame.

If necessary, refer to the windshield frame removal

procedure.

(2) Remove the holddown bracket retaining screws

from the cowl.

(3) Tilt the windshield frame forward to the full

horizontal position (Fig. 4).

(4) Remove the retaining screws and the weather-

strip seal from the windshield frame (Fig. 4).

INSTALLATION

(1) Position the weatherstrip seal on the windshield

frame. Ensure that the frame outer panel flange is

properly seated in the seal groove.

(2) Install the seal retaining screws in the wind-

shield frame (Fig. 4).

(3) Tilt the windshield frame rearward to the full

vertical position.

(4) Install the holddown bracket retaining screws

in the cowl.

(5) Connect the top to the windshield frame. If

necessary, refer to the windshield frame installation

procedure.

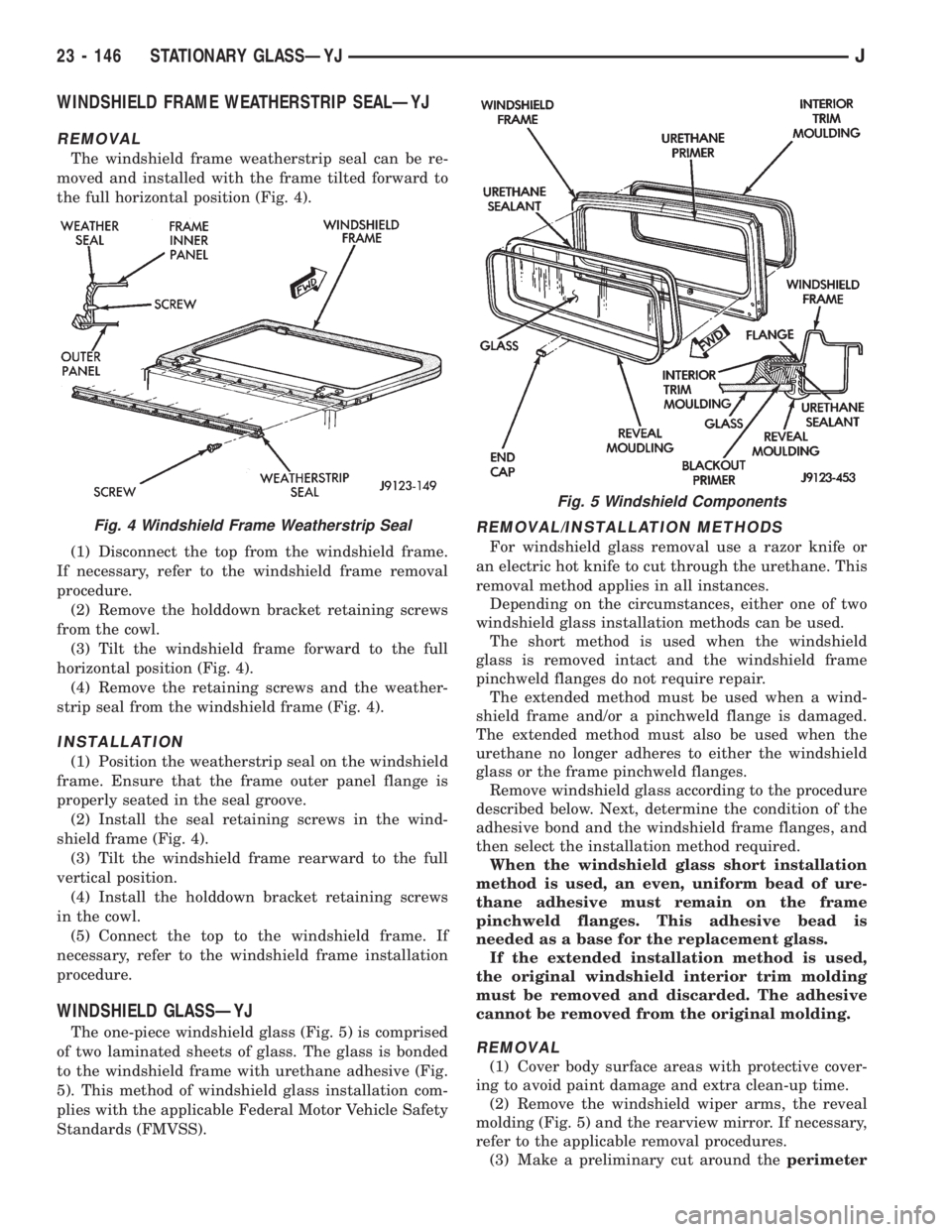

WINDSHIELD GLASSÐYJ

The one-piece windshield glass (Fig. 5) is comprised

of two laminated sheets of glass. The glass is bonded

to the windshield frame with urethane adhesive (Fig.

5). This method of windshield glass installation com-

plies with the applicable Federal Motor Vehicle Safety

Standards (FMVSS).

REMOVAL/INSTALLATION METHODS

For windshield glass removal use a razor knife or

an electric hot knife to cut through the urethane. This

removal method applies in all instances.

Depending on the circumstances, either one of two

windshield glass installation methods can be used.

The short method is used when the windshield

glass is removed intact and the windshield frame

pinchweld flanges do not require repair.

The extended method must be used when a wind-

shield frame and/or a pinchweld flange is damaged.

The extended method must also be used when the

urethane no longer adheres to either the windshield

glass or the frame pinchweld flanges.

Remove windshield glass according to the procedure

described below. Next, determine the condition of the

adhesive bond and the windshield frame flanges, and

then select the installation method required.

When the windshield glass short installation

method is used, an even, uniform bead of ure-

thane adhesive must remain on the frame

pinchweld flanges. This adhesive bead is

needed as a base for the replacement glass.

If the extended installation method is used,

the original windshield interior trim molding

must be removed and discarded. The adhesive

cannot be removed from the original molding.

REMOVAL

(1) Cover body surface areas with protective cover-

ing to avoid paint damage and extra clean-up time.

(2) Remove the windshield wiper arms, the reveal

molding (Fig. 5) and the rearview mirror. If necessary,

refer to the applicable removal procedures.

(3) Make a preliminary cut around theperimeter

Fig. 4 Windshield Frame Weatherstrip Seal

Fig. 5 Windshield Components

23 - 146 STATIONARY GLASSÐYJJ