light JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 908 of 2198

INTERIOR LIGHTING

INDEX

page page

Cargo Lamp and Dome Lamp................. 1

Chime/Buzzer Module....................... 2

Diagram Index............................ 2

General Information........................ 1

Glove Box Lamp........................... 1Ignition Switch Lamp........................ 1

Instrument Panel Illumination Lamps............ 1

Reading Lamps........................... 1

Underhood Lamp.......................... 1

Visor Vanity Mirror Lamps.................... 1

GENERAL INFORMATION

Circuit M1 supplies power to the glove box lamp,

dome lamp, reading lamps, cargo lamp and vanity

lamps. Circuit M1 is protected by fuse 16 in the

Power Distribution Center (PDC).

Circuit E2 supplies power for the instrument panel

illumination lamps.

INSTRUMENT PANEL ILLUMINATION LAMPS

Circuit E2 from the headlamp switch splices to

supply power to the following illumination lamps:

²Ash receiver lamp

²Cigar lighter lamp

²Transmission range indicator lamp

²Transfer case range indicator lamp

²A/C-Heater switch lamp

²Heated rear window switch lamp

²Rear wiper switch lamp

²Fog lamp switch lamp

Fuse 25 in the fuse block protects circuit E2. Cir-

cuit Z1 provides ground for all of the illumination

lamps except for the cigar lighter lamp. The cigar

lighter lamp is case grounded.

HELPFUL INFORMATION

Circuit E2 also supplies power to the radio, LCD

relay and the illumination lamps in the instrument

cluster.

IGNITION SWITCH LAMP

Circuit M50 supplies voltage to the ignition switch

lamp. Circuit Z1 provides ground for the lamp.

GLOVE BOX LAMP

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) powers the glove box lamp. A case

grounded switch, in series after the lamp, closes

when the glove box door is opened. The switch com-

pletes a path to ground on circuit Z1.

CARGO LAMP AND DOME LAMP

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power to the cargo lamp anddome lamp. The M1 circuit is HOT at all times. The

ground path for the lamp is provided in three differ-

ent ways.

One way is through the door jamb switches. Circuit

M2 connects to the door jamb switches to the dome

lamp and cargo lamp. The switches are connected to

ground circuit Z1. When a door is opened, the

plunger in the switch closes, completing a path to

ground.

The second way is through the liftgate switch. Cir-

cuit G71 connects to circuit M2 at the cargo lamp

connector. Circuit G71 connects to the liftgate switch.

The liftgate switch connects to ground circuit Z1.

When the lift gate opens, the plunger in the switch

closes, completing a path to ground.

The third ground path is through the headlamp

switch. Circuit M2 is spliced in with the headlamp

switch. When the operator turns the headlamp

switch to the dome lamp ON position, a ground path

is provided through the switch.

READING LAMPS

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power to the reading lamps.

Circuit M1 is HOT at all times. When the operator

depresses the reading lamp, the reading lamp switch

closes and supplies ground on circuit Z1.

VISOR VANITY MIRROR LAMPS

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power to the vanity lamps.

Circuit M1 is HOT at all times. When the vanity

lamps switch closes, voltage flows to vanity mirror

lamps. The vanity mirror is case grounded.

UNDERHOOD LAMP

Circuit A7 from fuse 16 in the Power Distribution

Center (PDC) supplies battery voltage for the under-

hood lamp. A mercury switch, in series after the

lamp, connects the lamp to ground on circuit Z1.

When the hood is raised, mercury inside the switch

moves to a position where it connects circuit M1 to

ground circuit Z1, illuminating the lamp.

J8W-44 INTERIOR LIGHTINGÐXJ-RHD 8W - 44 - 1

Page 909 of 2198

CHIME/BUZZER MODULE

The buzzer or optional chime module sounds an au-

dible warning tone. The tone sounds for seat belt

warning and when the ignition key is in the ignition

switch while the drivers door is open. The tone also

sounds when the ignition key is in the ON position

while the drivers side seat belt is not buckled. Lastly,

the tone sounds when the headlamps are ON when

the ignition is OFF. Refer to Group 8U for system op-

eration.

When the ignition switch is in the RUN or START

position, fuse F87 from fuse 26 in the fuse block sup-

plies power to the chime/buzzer module. Circuit A21

from the ignition switch supplies power to fuse 26.

Circuit L7 from fuse 9 in the fuse block also sup-

plies power to the chime/buzzer module. Circuit A3

from fuse 5 in the Power Distribution Center (PDC)

powers fuse 9.

When the parking lamps or headlamps are ON, the

headlamp switch connects circuit G26 with the driv-

ers side door jamb switch. Circuit G26 also connects

to the key-in switch. Circuit M11 connects the key-in

switch to the chime module and the headlamp

switch.

If the headlamps are ON, and the drivers door

opens, ground for the chime/buzzer is on circuit C26

from the headlamp switch through the door jamb

switch to circuit Z1.

If the headlamps are OFF with the key in the ig-

nition while the drivers side door is open, ground for

the chime/buzzer is supplied through the key-in

switch. The ground path is over circuit M11, through

the closed key-in switch to circuit C26. From circuit

C26, the ground path continues through the drivers

door jamb switch to circuit Z1.

Circuit G11 from the buzzer powers the seat belt

warning lamp in the instrument cluster. Circuit Z1

at the instrument cluster provides ground for the

lamp.Circuit G10 from the buzzer connects to the seat

belt switch. When the seat belt switch closes a path

to ground is completed on circuit Z1 and the tone

sounds momentarily.

Circuit Z1 also grounds the chime buzzer module.

HELPFUL INFORMATION

Circuit F87 also powers the instrument cluster and

the headlamp delay module.

DIAGRAM INDEX

Component Page

Cargo Lamp............................8W-44-6

Chime/Buzzer Module......................8W-44-3

Courtesy Lamps.........................8W-44-5

Dome Lamp............................8W-44-6

Door Jamb Switches......................8W-44-7

Fuse 3 (PDC)...........................8W-44-6

Fuse 5 (PDC).........................8W-44-5, 8

Fuse 6 (PDC)...........................8W-44-6

Fuse 9 (Fuse Block).....................8W-44-3, 8

Fuse 16 (PDC)........................8W-44-4, 6

Fuse 25 (Fuse Block)......................8W-44-8

Fuse 26 (Fuse Block)......................8W-44-3

Glove Box Lamp and Switch.................8W-44-5

Headlamp Switch....................8W-44-3, thru 8

Headlamp Delay Module....................8W-44-3

Ignition Switch..........................8W-44-3

Instrument Cluster......................8W-44-3, 9

Instrument Panel Illumination Lamps..........8W-44-8, 9

Key-In Switch...........................8W-44-4

Liftgate Switch..........................8W-44-6

Reading Lamps..........................8W-44-6

Seat Belt Switch.........................8W-44-3

Telltale Connector (Instrument Cluster)...........8W-44-3

Time Delay Relay........................8W-44-4

Underhood Lamp.........................8W-44-4

8W - 44 - 2 8W-44 INTERIOR LIGHTINGÐXJ-RHDJ

Page 934 of 2198

FRONT LIGHTING

INDEX

page page

Diagram Index............................ 3

Dimming Module........................... 1

Fog Lamps............................... 2

Headlamp Delay Module..................... 1Headlamp Relay........................... 1

Headlamps............................... 1

Parking Lamps............................ 2

HEADLAMPS

The headlamp switch has three positions: ON,

PARK (parking lamps) and OFF. Circuit A3 from fuse

12 in the PDC connects to the headlamp switch and

feeds circuit L7 through fuse 9 in the fuse block. Cir-

cuit L7 connects to the headlamp switch.

Circuit A3 also splices to feed circuit L11 through

fuse 10 in the fuse block. Circuit L11 connects to the

dimmer switch circuitry in the multi-function switch.

The headlamp switch has an internal circuit

breaker that connects circuit A3 to circuit F34. Cir-

cuit F34 connects to the headlamp relay.

HEADLAMP RELAY

When the headlamp switch is in the ON position it

connects circuit A3 from fuse 5 in the Power Distri-

bution Center (PDC) to circuit F34. Circuit A3 is

HOT at all times.

Circuit F34 supplies battery voltage to the coil and

contact sides of the headlamp relay. Circuit Z1 sup-

plies ground for the relay. When voltage is present on

circuit F34, the relay contacts close and connect cir-

cuit F39 to circuit F34.

Circuit F39 powers the headlamps through the

dimmer switch circuitry in the multi-function switch.

HEADLAMP SWITCH IN OFF OR PARKING

LAMP POSITION

Circuit L11 connects to the dimmer switch portion

of the multi-function switch. Circuit L11 supplies

power for the high beams on circuit L3 when the op-

erator flashes the headlamps with the turn signal

stalk of the multi-function switch.

HEADLAMP SWITCH IN ON POSITION

When the headlamp switch is in the ON position,

circuit A3 from fuse 12 in the Power Distribution

Center (PDC) connects to circuit F34. Circuit F34

connects to circuit F39 through the headlamp relay.

Circuit F39 feeds circuit L4 through the headlamp

dimmer switch circuitry in the multi-function switch.

Circuit L4 powers the low beam of the headlamps.

When the operator selects high beam operation

with the turn signal stalk of the multi-functionswitch, circuit L11 connects to the L3 circuit. Circuit

L3 powers high beam operation.

HEADLAMP GROUND

Circuit Z1 provides ground for both the right and

left headlamps. Circuit Z1 also supplies ground the

fog lamps, if equipped.

HELPFUL INFORMATION

²Check fuse 5 in the PDC.

²The headlamp switch has an internal circuit

breaker.

²Circuit L7 is double crimped at the headlamp

switch and branches to the chime module.

HEADLAMP DELAY MODULE

When the operator turns off the ignition switch and

the headlamp switch, the headlamp delay module

powers the headlamps for approximately 45 seconds.

When the ignition switch is in the RUN position,

circuit A21 powers circuit F87 through fuse 17 in the

fuse block. Circuit F87 supplies the IGNITION ON/

OFF signal to the headlamp delay module. Circuit Z1

provides ground for the module.

When the headlamp delay module activates, it con-

nects circuit X4 from fuse 5 in the fuse block to cir-

cuit F34. Circuit F34 connects to the circuit F39

through the headlamp relay. Circuit F39 powers the

headlamps through the headlamp dimmer switch cir-

cuit L4.

HELPFUL INFORMATION

Circuit A7 from fuse 3 in the PDC supplies voltage

to the fuse block bus bar that powers circuit X4

through the fuse in cavity 5.

DIMMING MODULE

Some vehicles are equipped with a dimming mod-

ule. The module is powered by the dimming relay.

In the RUN position, the ignition switch connects

circuit A1 from fuse 6 in the Power Distribution Cen-

ter (PDC) to circuit A38. Circuit A38 powers circuit

L170 through fuse 20 in the fuse block. Circuit L170

supplies power to the dimming relay.

When the headlamps are ON, circuit L90 from the

headlamp switch energizes the dimming relay. When

J8W-50 FRONT LIGHTINGÐXJ-RHD 8W - 50 - 1

Page 935 of 2198

energized, the relay supplies power to the dimming

module on a branch of circuit A38. Circuit Z1 pro-

vides ground for the dimming relay.

The dimming module connects to the headlamp

dimmer switch on circuits L3 and L4.

PARKING LAMPS

Circuit A3 from fuse 5 in the Power Distribution

Center (PDC) connects to a bus bar in the fuse block

which feeds circuit L7. Fuse 9 in the fuse block pro-

tects circuit L7.

The headlamp switch has three positions: ON,

PARK (parking lamps) and OFF, plus a dimmer

switch. When the headlamp switch is in the PARK or

ON position, the switch connects circuit L7 to circuit

L90. From the headlamp switch, circuit L90 branches

to power the front parking lamps and rear tail

lamps, side marker lamps, and rear license plate

lamps.

GROUND CIRCUIT

Circuit Z1 provides a ground for the parking lamps

and side marker lamps. The Z1 circuit also provide

ground for the headlamps.

HELPFUL INFORMATION

²Check fuse 5 in PDC.

²Check fuse 9 in the fuse block.

²When the headlamp switch is in the PARK or ON

position, the dimmer circuit, L7, also connects to cir-

cuit E2. Circuit E2 continues through fuse 25 in the

fuse block. Circuit E2 powers the illumination lamps.

FOG LAMPS

The fog lamps are controlled by the fog lamp

switch and fog lamp relay. The fog lamps operate

only when the headlamp switch is in the ON posi-

tion, and the operator has selected low-beam opera-

tion. When the headlamps are in high-beam

operation, the fog lamps will not operate.

Circuit F39 from fuse 13 in the Power Distribution

Center (PDC) supplies voltage to the contact side of

the park lamp relay.

When the fog lamp switch closes, it connects circuit

F34 from the headlamp relay to L35. Circuit L35

supplies power to the coil side of the fog lamp relay

and energizes the relay. Ground for the coil side of

the fog lamp relay is provided on circuit Z1.

When fog lamp relay energizes, it connects circuit

F39 to circuit 117. Circuit 117 supplies power to the

fog lamps. Circuit Z1 provides ground for the fog

lamps.

If the high beam lamps are ON, the dimmer switch

does not power circuit L4 and the fog lamp relay

opens. When the relay opens, battery voltage is re-

moved from the fog lamps.

8W - 50 - 2 8W-50 FRONT LIGHTINGÐXJ-RHDJ

Page 936 of 2198

DIAGRAM INDEX

Component Page

Chime/Buzzer Module......................8W-50-6

Dimming Module.........................8W-50-9

Dimming Relay..........................8W-50-8

Fog Lamp Relay........................8W-50-10

Fog Lamp Switch........................8W-50-10

Fuse 5 (Fuse Block).......................8W-50-7

Fuse 5 (PDC).........................8W-50-4, 8

Fuse 6 (PDC).........................8W-50-6, 8

Fuse 7 (PDC)..........................8W-50-10

Fuse 9 (Fuse Block).......................8W-50-4

Fuse 10 (Fuse Block)......................8W-50-7

Fuse 11 (Fuse Block)......................8W-50-8

Fuse 13 (PDC).........................8W-50-10

Fuse 20 (Fuse Block)......................8W-50-8

Fuse 26 (Fuse Block)......................8W-50-6

Headlamp Delay Module....................8W-50-7

Headlamp Dimmer Switch.................8W-50-4, 7

Headlamp Switch.....................8W-50-4, 7, 9

Headlamp Relay.........................8W-50-9

Ignition Switch........................8W-50-6, 8

Instrument Cluster........................8W-50-5

Left Fog Lamp.........................8W-50-10

Left Headlamp..........................8W-50-5

Left Marker Lamp........................8W-50-5

Left Tail, Stop and Turn Signal Lamp............8W-50-5

Overhead Console......................8W-50-4, 8

Right Fog Lamp........................8W-50-10

Right Headlamp.........................8W-50-5

Right Tail, Stop and Turn Signal Lamp...........8W-50-5

Telltale Connector (Instrument Cluster)...........8W-50-9

J8W-50 FRONT LIGHTINGÐXJ-RHD 8W - 50 - 3

Page 944 of 2198

REAR LIGHTING

TAIL LAMPS AND REAR LICENSE PLATE LAMPS

Circuit A3 from fuse 5 in the Power Distribution

Center (PDC) connects to a bus bar in the fuse block

which feeds circuit L7. Fuse 9 in the fuse block pro-

tects circuit L7.

The headlamp switch has three positions: ON,

PARK (parking lamps) and OFF, plus a dimmer

switch. When the headlamp switch is in the PARK or

ON position, the switch connects circuit L7 to circuit

L90. From the headlamp switch, circuit L90 branches

to power the front parking lamps and rear tail

lamps, side marker lamps, and rear license plate

lamps.

GROUND CIRCUIT

Circuit Z1 provides a ground for the parking lamps,

tail lamps, and rear license plate lamps.

HELPFUL INFORMATION

²Check fuse 5 in PDC.

²Check fuse 9 in the fuse block.

²When the headlamp switch is in the PARK or ON

position, circuit L7 also connects to circuit E2. Cir-

cuit E2 continues through fuse 25 in the fuse block.

Circuit E2 powers the illumination lamps.

STOP LAMPS AND CHMSL LAMPS

Circuit L9 from fuse 4 in the Power Distribution

Center (PDC) connects to the stop lamp switch.

When the operator depresses the brake pedal, the

stop lamp switch closes and connects circuit L9 to

circuit L50. Circuit L50 connects to the stop lamps

and center high mounted stop lamps (CHMSL). Cir-

cuit Z1 provides a ground for the stop lamps.

HELPFUL INFORMATION

²Check fuses 13 in the PDC.

²Check for continuity across the stop lamp switch

when it is closed.

BACK-UP LAMPS

In the START or RUN position, the ignition switch

connects circuit A1 from fuse 6 in the Power Distri-

bution Center (PDC) to circuit A21. Circuit A21 feeds

a bus bar in the PDC that powers circuit F12

through fuse 11.

Circuit F12 supplies power to the back-up lamp

switch. On automatic transmission equipped vehicles,

the back-up lamp switch is part of an assembly that

includes the PARK/NEUTRAL position switch. When

the operator puts the transmission in REVERSE, the

back-up lamp switch connects circuit F12 to circuit

L10. Circuit L10 feeds the back-up lamps. Circuit Z1

provides ground for the back-up lamps.

HELPFUL INFORMATION

²Check fuses 6 and 11 in the PDC.

²Check for continuity across the back-up lamp

switch when it is closed.

DIAGRAM INDEX

Component Page

Center High Mounted Stop Lamps (CHMSL).......8W-51-3

Fuse 4 (PDC)...........................8W-51-3

Fuse 5 (PDC)...........................8W-51-2

Fuse 6 (Fuse Block).......................8W-51-2

Fuse 6 (PDC)...........................8W-51-2

Fuse 9 (Fuse Block).......................8W-51-2

Headlamp Switch.........................8W-51-2

Ignition Switch..........................8W-51-2

Left Back-Up Lamp.......................8W-51-4

Left Side Marker Lamp.....................8W-51-4

Left Tail/Stop Lamp.......................8W-51-4

Left Turn Signal Lamp.....................8W-51-4

License Plate Lamp.......................8W-51-3

Park/Neutral Position Switch.................8W-51-2

Right Back-Up Lamp......................8W-51-5

Right Side Marker Lamp....................8W-51-5

Right Tail/Stop Lamp......................8W-51-4

Right Turn Signal Lamp....................8W-51-5

Stop Lamp Switch........................8W-51-3

J8W-51 REAR LIGHTINGÐXJ-RHD 8W - 51 - 1

Page 1066 of 2198

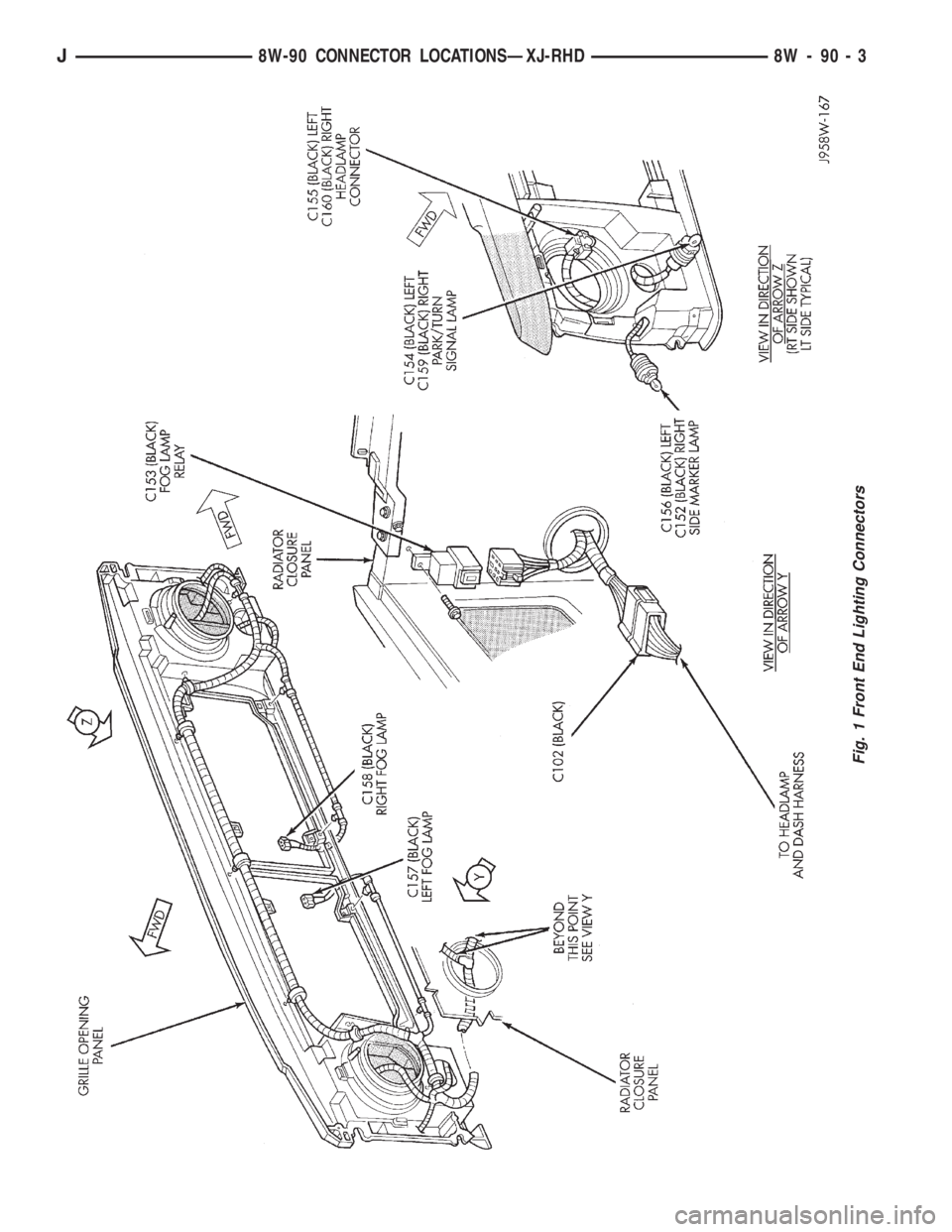

Fig. 1 Front End Lighting Connectors

J8W-90 CONNECTOR LOCATIONSÐXJ-RHD 8W - 90 - 3

Page 1084 of 2198

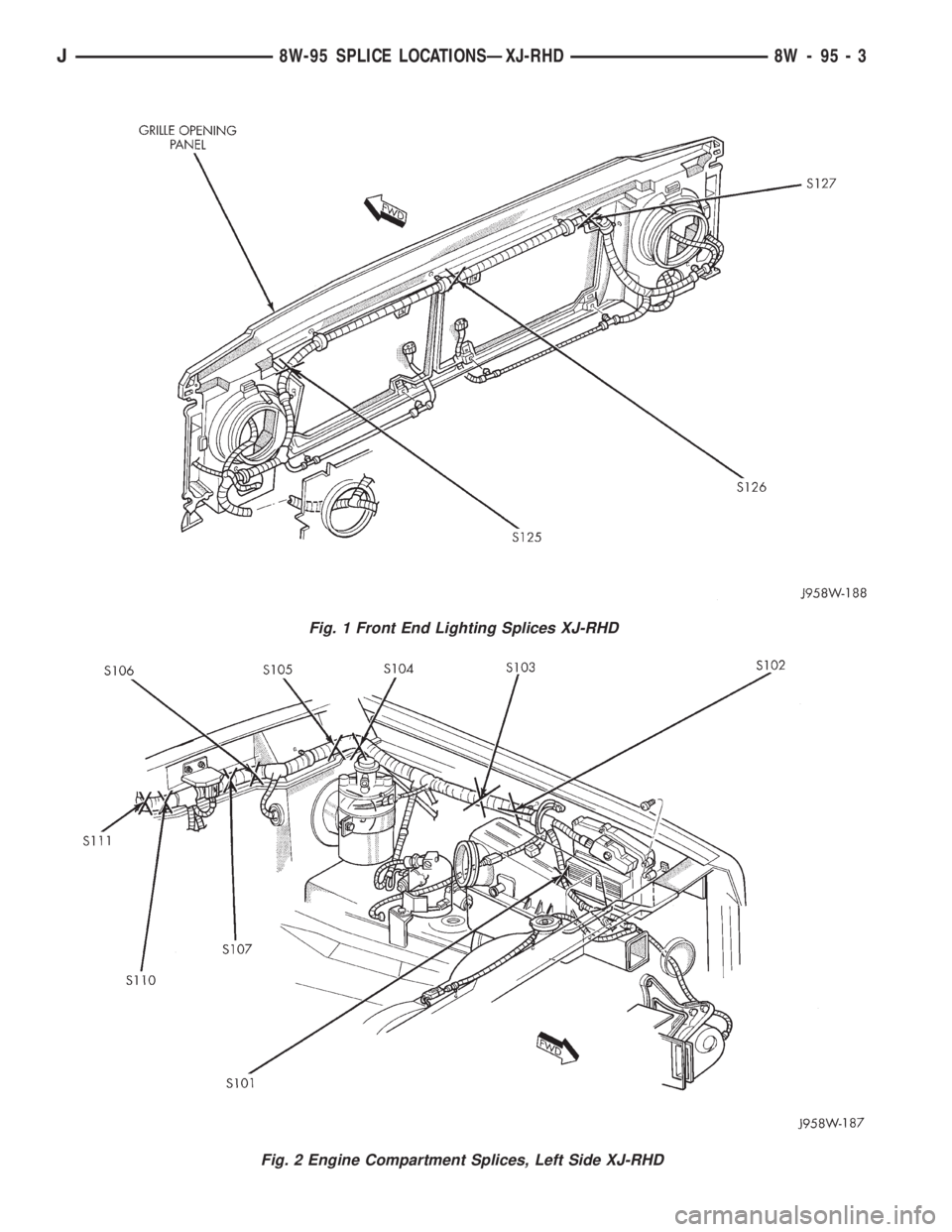

Fig. 1 Front End Lighting Splices XJ-RHD

Fig. 2 Engine Compartment Splices, Left Side XJ-RHD

J8W-95 SPLICE LOCATIONSÐXJ-RHD 8W - 95 - 3

Page 1092 of 2198

ENGINES

CONTENTS

page page

LUBRICATION SYSTEM................... 37

LUBRICATION SYSTEM................... 79

2.5L ENGINE SERVICE PROCEDURES....... 134.0L ENGINE SERVICE PROCEDURES....... 55

ENGINE DIAGNOSIS...................... 5

STANDARD SERVICE PROCEDURES......... 1

STANDARD SERVICE PROCEDURES

INDEX

page page

Engine Performance........................ 2

Form-In-Place Gaskets...................... 1

Honing Cylinder Bores...................... 2

Hydrostatic Lock........................... 4Measuring with Plastigage.................... 3

Repair Damaged or Worn Threads............. 4

Service Engine Assembly (Short Block).......... 4

FORM-IN-PLACE GASKETS

There are several places where form-in-place gas-

kets are used on the engine.DO NOT use form-in-

place gasket material unless specified.Care

must be taken when applying form-in-place gaskets.

Bead size, continuity and location are of great impor-

tance. Too thin a bead can result in leakage while too

much can result in spill-over. A continuous bead of

the proper width is essential to obtain a leak-free

joint.

Two types of form-in-place gasket materials are

used in the engine area (Mopar Silicone Rubber Ad-

hesive Sealant and Mopar Gasket Maker). Each have

different properties and cannot be used interchange-

ably.

MOPAR SILICONE RUBBER ADHESIVE

SEALANT

Mopar Silicone Rubber Adhesive Sealant, normally

black in color, is available in 3 ounce tubes. Moisture

in the air causes the sealant material to cure. This

material is normally used on flexible metal flanges.

It has a shelf life of a year and will not properly cure

if over aged. Always inspect the package for the ex-

piration date before use.

MOPAR GASKET MAKER

Mopar Gasket Maker, normally red in color, is

available in 6 cc tubes. This anaerobic type gasket

material cures in the absence of air when squeezedbetween smooth machined metallic surfaces. It will

not cure if left in the uncovered tube. DO NOT use

on flexible metal flanges.

SURFACE PREPARATION

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some in-

stances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper

may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

Scrape or wire brush all gasket surfaces to remove

all loose material. Inspect stamped parts to ensure

gasket rails are flat. Flatten rails with a hammer on

a flat plate, if required. Gasket surfaces must be free

of oil and dirt. Make sure the old gasket material is

removed from blind attaching holes.

GASKET APPLICATION

Assembling parts using a form-in-place gasket re-

quires care.

Mopar Silicone Rubber Adhesive Sealant should be

applied in a continuous bead approximately 3 mm

(0.12 inch) in diameter. All mounting holes must be

circled. For corner sealing,a3or6mm(1/8 or 1/4

inch) drop is placed in the center of the gasket con-

tact area. Uncured sealant may be removed with a

shop towel. Components should be torqued in place

while the sealant is still wet to the touch (within 10

JENGINES 9 - 1

Page 1093 of 2198

minutes). The use of a locating dowel is recom-

mended during assembly to prevent smearing the

material off location.

Mopar Gasket Maker should be applied sparingly

to one gasket surface. The sealant diameter should

be 1.00 mm (0.04 inch) or less. Be certain the mate-

rial surrounds each mounting hole. Excess material

can easily be wiped off. Components should be

torqued in place within 15 minutes. The use of a lo-

cating dowel is recommended during assembly to pre-

vent smearing the material off location.

ENGINE PERFORMANCE

To provide best vehicle performance and lowest ve-

hicle emissions, it is most important that the tune-up

be done accurately. Use the specifications listed on

the Vehicle Emission Control Information label found

on the engine compartment hood.

(1) Test battery specific gravity. Add water, if nec-

essary. Clean and tighten battery connections.

(2) Test cranking amperage draw (refer to Group

8B, Battery/Starter Service for the proper proce-

dures).

(3) Tighten the intake manifold bolts (refer to

Group 11, Exhaust System and Intake Manifold for

the proper specifications).

(4) Perform cylinder compression test:

(a) Check engine oil level and add oil, if neces-

sary.

(b) Drive the vehicle until engine reaches normal

operating temperature.

(c) Select a route free from traffic and other

forms of congestion, observe all traffic laws and

briskly accelerate through the gears several times.

The higher engine speed may help clean out valve

seat deposits which can prevent accurate compres-

sion readings.

CAUTION: DO NOT overspeed the engine.

(d) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for ab-

normal firing indicatorsÐfouled, hot, oily, etc.

Record cylinder number of spark plug for future

reference.

(e) Disconnect coil wire from distributor and se-

cure to good ground to prevent a spark from start-

ing a fire.

(f) Be sure throttle blades are fully open during

the compression check.

(g) Insert compression gage adaptor into the

No.1 spark plug hole. Crank engine until maximum

pressure is reached on gauge. Record this pressure

as No.1 cylinder pressure.

(h) Repeat Step 4g for all remaining cylinders.

(i) Compression should not be less than 689 kPa

(100 psi) and not vary more than 172 kPa (25 psi)

from cylinder to cylinder.(j) If cylinder(s) have abnormally low compres-

sion pressures, repeat steps 4a through 4h.

(k) If the same cylinder(s) repeat an abnormally

low reading, it could indicate the existence of a

problem in the cylinder.

The recommended compression pressures are

to be used only as a guide to diagnosing engine

problems. An engine should NOT be disassem-

bled to determine the cause of low compression

unless some malfunction is present.

(5) Clean or replace spark plugs as necessary. Ad-

just gap (refer to Group 8D, Ignition System for gap

adjustment and torque).

(6) Test resistance of spark plug cables (refer to

Group 8D, Ignition System).

(7) Inspect the primary wire. Test coil output volt-

age, primary and secondary resistance. Replace parts

as necessary (refer to Group 8D, Ignition System and

make necessary adjustment).

(8) Perform a combustion analysis.

(9) Test fuel pump for pressure (refer to Group 14,

Fuel System for the proper specifications).

(10) Inspect air filter element (refer to Group 0,

Lubrication and Maintenance for the proper proce-

dure).

(11) Inspect crankcase ventilation system (refer to

Group 0, Lubrication and Maintenance for the proper

procedure).

(12) For emission controls refer to Group 25, Emis-

sion Controls System for service procedures.

(13) Inspect and adjust accessory belt drives (refer

to Group 7, Cooling System for the proper adjust-

ments).

(14) Road test vehicle as a final test.

HONING CYLINDER BORES

Before honing, stuff plenty of clean shop towels un-

der the bores and over the crankshaft to keep abra-

sive materials from entering the crankshaft area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823 equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). 20-60 strokes, de-

pending on the bore condition, will be sufficient to

provide a satisfactory surface. Using honing oil

C-3501-3880 or a light honing oil available from ma-

jor oil distributors.

9 - 2 ENGINESJ