light JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 405 of 2198

WARNING: THE USE OF VEHICLE SPEED CON-

TROL IS NOT RECOMMENDED WHEN DRIVING

CONDITIONS DO NOT PERMIT MAINTAINING ACONSTANT SPEED, SUCH AS IN HEAVY TRAFFIC

OR ON ROADS THAT ARE WINDING, ICY, SNOW

COVERED, OR SLIPPERY.

DIAGNOSIS

Before beginning diagnosis, perform a vehicle road

test to verify reports of speed control system mal-

function. The road test should include attention to

the speedometer. Speedometer operation should be

smooth and without flutter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8E -

Instrument Panel and Gauges for speedometer diag-

nosis.

If a road test verifies a system problem and the

speedometer operates properly, check for:

(1) Loose or corroded electrical connections at the

servo. Corrosion should be removed from electricalterminals and a light coating of Mopar MultiPurpose

Grease, or equivalent, applied.

(2) Correct installation of the vacuum check valve

in the hose from servo to vacuum source. The word

VAC on the valve must point toward the vacuum

source.

(3) Loose or leaking vacuum hoses or connections.

(4) Secure attachment of both ends of the speed

control servo cable.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

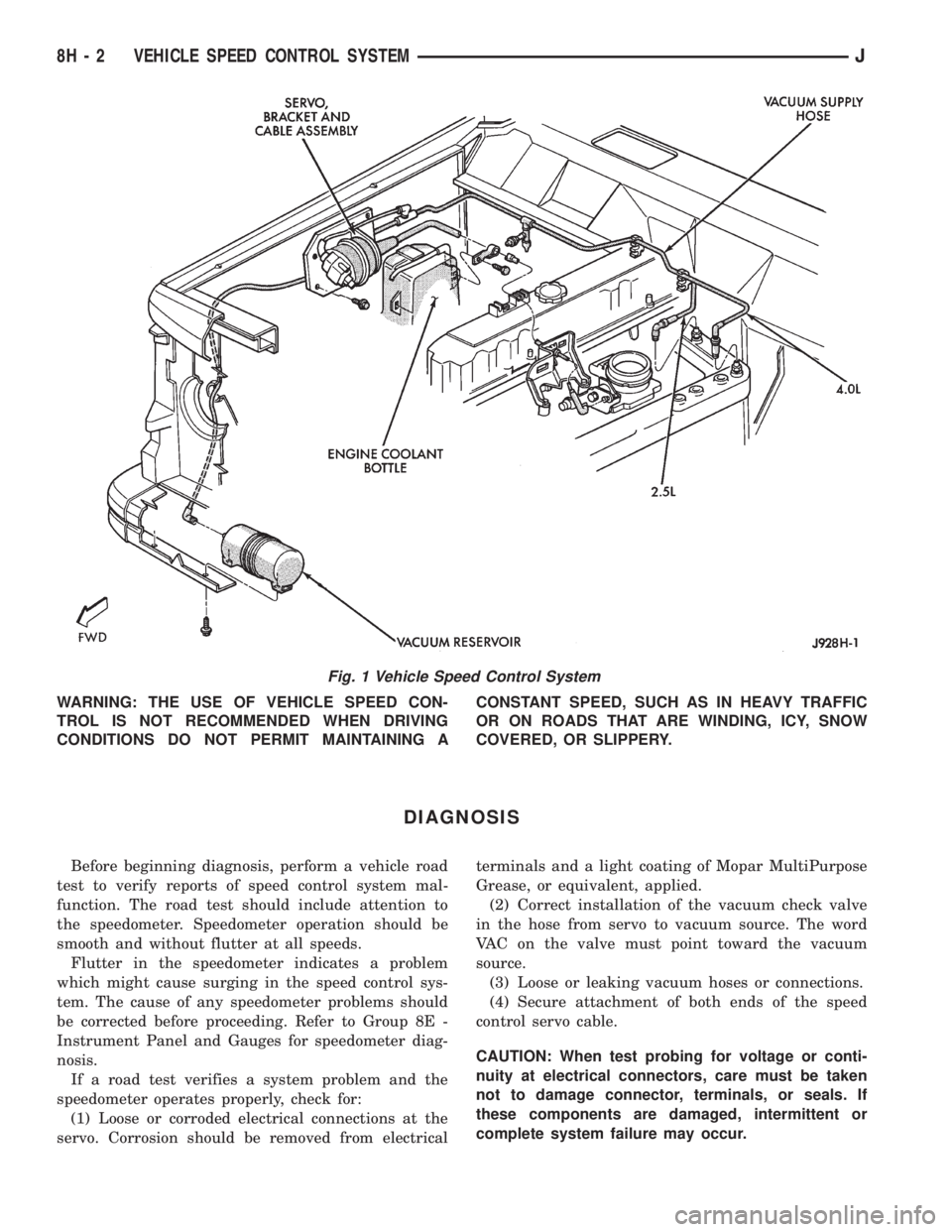

Fig. 1 Vehicle Speed Control System

8H - 2 VEHICLE SPEED CONTROL SYSTEMJ

Page 414 of 2198

TURN SIGNAL AND HAZARD WARNING SYSTEMS

CONTENTS

page page

DIAGNOSIS............................. 3

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 5

GENERAL INFORMATION

Following are general descriptions of the major

components in the XJ (Cherokee)/YJ (Wrangler)

model turn signal and hazard warning systems. Refer

to Group 8W - Wiring Diagrams for complete circuit

descriptions and diagrams.

TURN SIGNAL SYSTEM

With the ignition switch in the ON or ACCESSORY

position and the turn signal switch lever (YJ) or

multi-function switch control lever (XJ) moved up

(right turn) or down (left turn), the turn signal sys-

tem is activated.

When the turn signal system is activated, the se-

lected (right or left) turn signal indicator lamp, front

park/turn signal lamp and rear tail/stop/turn signal

lamp bulb filaments will flash. With the headlamp

switch in the OFF position, the turn and front side

marker lamps flash in unison. With the headlamp

switch in the ON position, the turn and front side

marker lamps flash alternately.

HAZARD WARNING SYSTEM

The hazard warning is activated by a switch button

located below the ignition lock cylinder (YJ) or on the

top of the steering column (XJ) between the steering

wheel and the instrument panel. The hazard warning

flasher (YJ) or combination flasher (XJ) receives bat-

tery feed at all times, and the system is functional

regardless of ignition switch position. The hazard

warning switch button is identified with a double

triangle. On YJ models, push the switch button in to

activate the hazard warning system and pull the

button out to turn system off. On XJ models, push in

on the switch button to latch the switch and activate

the hazard warning system, and push in on the

switch button again to unlatch the switch and turn

the system off.

When the hazard warning system is activated, all

(right and left) turn signal indicator, front park/turn

signal lamp and rear tail/stop/turn signal lamp bulb

filaments will flash.

TURN SIGNAL FLASHER (YJ ONLY)

The turn signal flasher is located in the fuseblock

module. It contains one fixed contact point and one

contact point attached to a flexible bimetal arm. The

contact points are normally closed. When a turn sig-

nal is activated, current flows through the flasher. As

current flows through the bimetal arm it heats and

flexes to pull the contact points open, stopping cur-

rent flow. As the bimetal arm cools it straightens,

until the contact points close and the cycle repeats.

The standard flasher is designed to handle the cur-

rent flow requirements of the factory installed light-

ing. If supplemental lighting is added to the turn

signal circuits such as when towing a trailer with

lights, the current flow through the flasher increases.

This causes the flash rate to increase. It is recom-

mended that the standard flasher be replaced with a

heavy-duty (hazard warning) flasher when supple-

mental lighting is added.

However, when a turn signal bulb fails with a stan-

dard flasher, the remaining bulbs in that circuit will

light, but not flash. This will give the driver an indi-

cation to check the turn signal bulbs. Because a

heavy-duty flasher has different internal circuitry, a

failed bulb will not prevent the remaining bulbs in

the circuit from flashing. Therefore, it is recom-

mended that an occasional visual inspection of exte-

rior turn signal lamp operation be performed when a

heavy-duty flasher is installed.

HAZARD WARNING FLASHER (YJ ONLY)

The hazard warning flasher is located in the fuse-

block module. The hazard warning flasher contains

two normally open contact points mounted to two

flexible arms. A bimetal strip is attached between the

two arms. When the hazard warning is activated,

current flows through the flasher. As the current

flows through the bimetal strip it heats and pulls the

flexible arms together until the contact points close,

JTURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 1

Page 415 of 2198

allowing current flow to the lamps. As the bimetal

strip cools, the contact points are pushed open and

the cycle repeats.

COMBINATION FLASHER (XJ ONLY)

The combination flasher functions as both the turn

signal and hazard warning flasher on XJ models. The

combination flasher is a smart relay that is located in

the relay center under the lower instrument panel

and inboard of the steering column. The combination

flasher can not be repaired. If faulty, it must be

replaced.

The combination flasher is designed to handle the

current flow requirements of the factory installed

lighting. If supplemental lighting is added to the turn

signal circuits such as when towing a trailer with

lights, the combination flasher will automatically

compensate. This allows the flash rate to remain the

same, regardless of electrical load increases. However,

if a bulb fails in the turn signal or hazard warning

circuits, the flash rate of the remaining bulbs in that

circuit will increase to 120 flashes per minute or

higher.

TURN SIGNAL/HAZARD WARNING SWITCH

(YJ ONLY)

The turn signal and hazard warning switches are

combined into a single unit mounted within the upper

steering column bowl and beneath the steering wheel.

The turn signal lever on the left side of the steering

column is moved up or down to select the right or left

turn signal switch position. The turn signals will only

operate with the ignition switch in the ACCESSORY

or ON position.

The hazard warning button on the right side of the

steering column is pushed in to turn the hazard

warning system on, or pulled out to turn the system

off. The hazard warning system will operate regard-

less of ignition switch position. The turn signal/haz-

ard warning switch can not be repaired. If faulty, the

entire unit must be replaced.

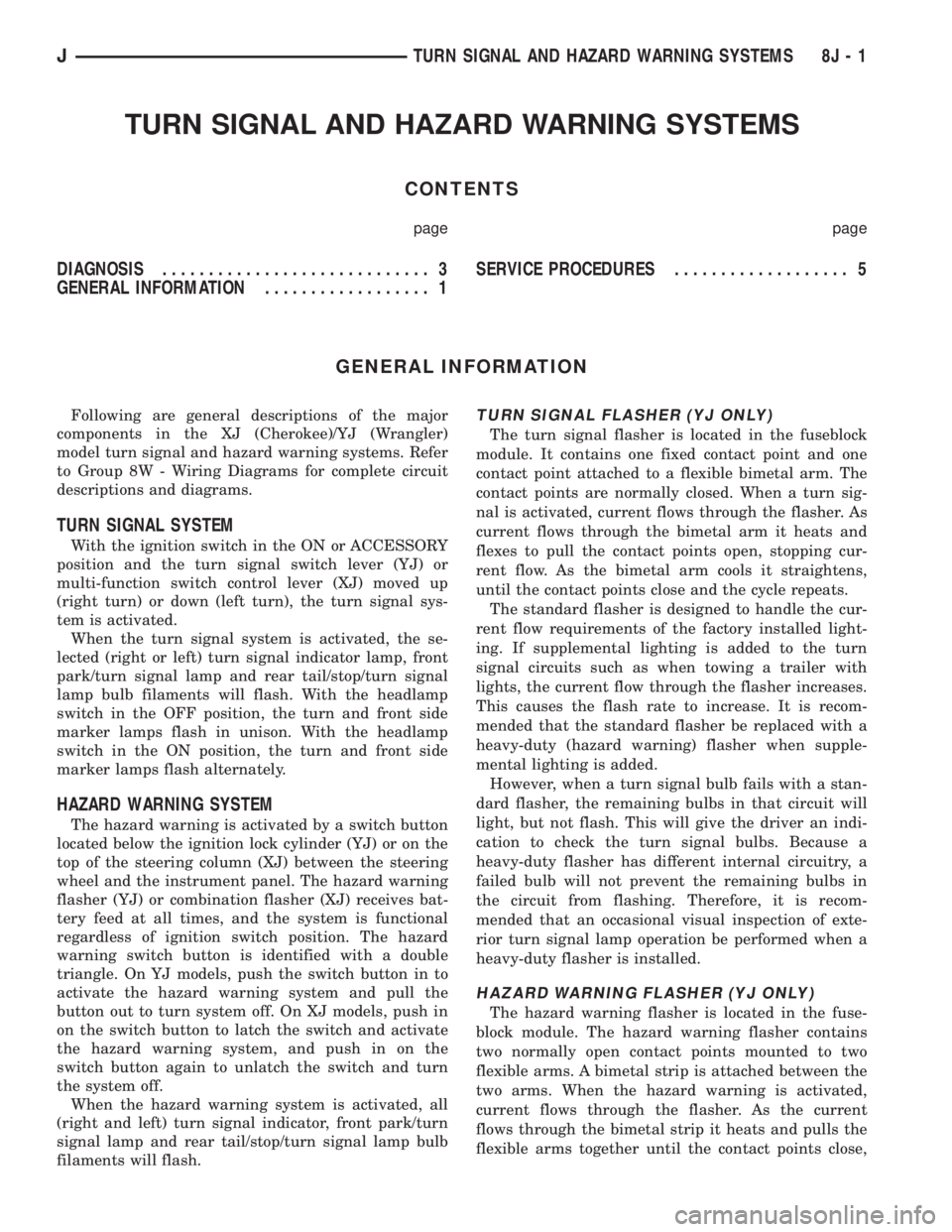

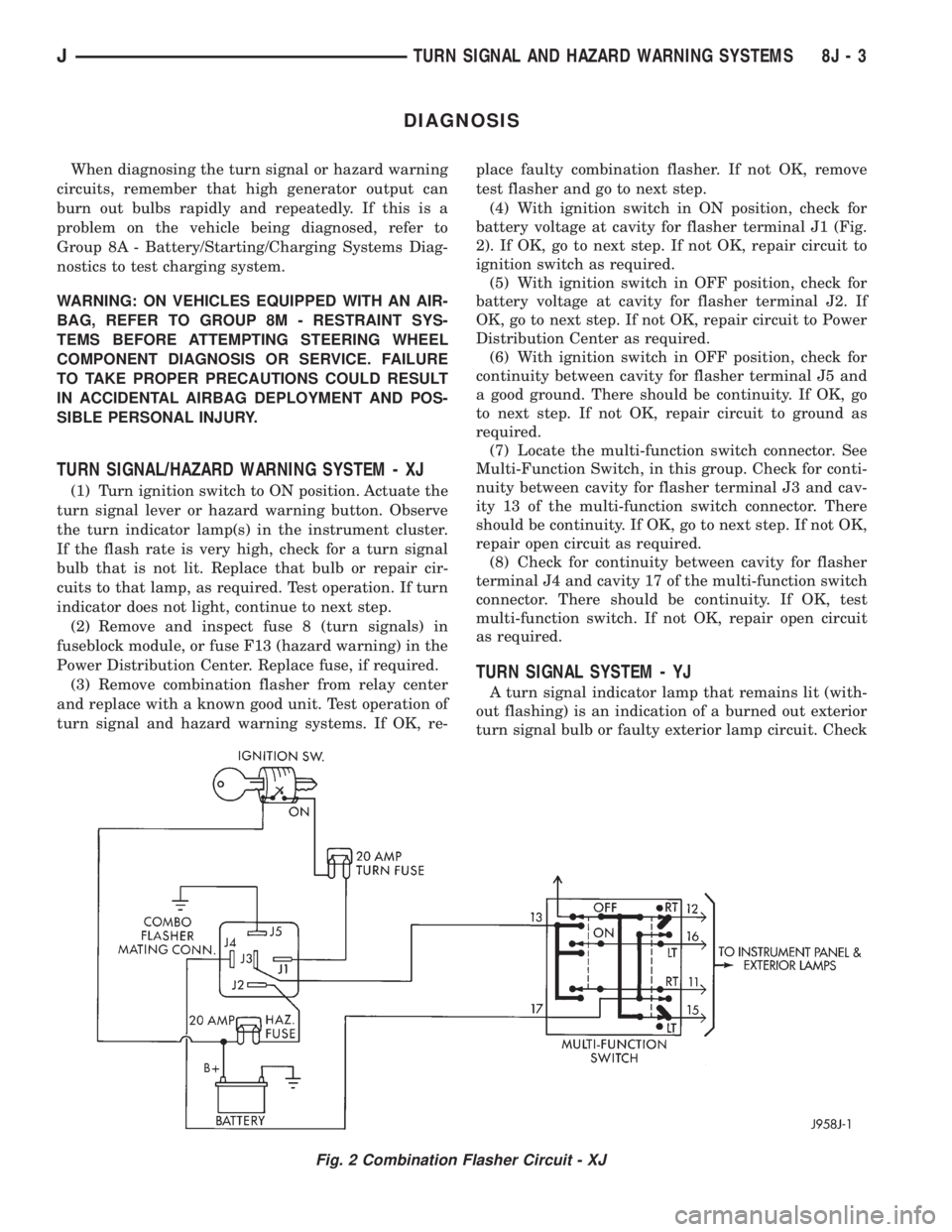

MULTI-FUNCTION SWITCH (XJ ONLY)

The multi-function switch assembly (Fig. 1) is

mounted to the left side of the steering column. This

switch contains electrical circuitry for the following

functions:²turn signals

²hazard warning

²headlamp beam selection

²headlamp optical horn

²windshield wipers

²windshield washers.

The information contained in this group addresses

only the switch functions for the turn signal and

hazard warning circuits. For information relative to

other switch functions, refer to the appropriate group.

However, the multi-function switch can not be re-

paired. If any function of the switch is faulty, the

entire switch assembly must be replaced.

TURN SIGNAL INDICATOR LAMPS

These lamps are located in the instrument cluster.

They flash with the exterior turn signal lamps to give

the driver a visual indication that a turn signal or the

hazard warning circuit is operating. For diagnosis

and service of this component, refer to Group 8E -

Instrument Panel and Gauges.

TURN SIGNAL LAMPS

The exterior lamps included in the turn signal and

hazard warning circuits include: the front park/turn

signal, and the rear tail/stop/turn signal. For diagno-

sis and service of these lamps, refer to Group 8L -

Lamps.

Fig. 1 Multi-Function Switch

8J - 2 TURN SIGNAL AND HAZARD WARNING SYSTEMSJ

Page 416 of 2198

DIAGNOSIS

When diagnosing the turn signal or hazard warning

circuits, remember that high generator output can

burn out bulbs rapidly and repeatedly. If this is a

problem on the vehicle being diagnosed, refer to

Group 8A - Battery/Starting/Charging Systems Diag-

nostics to test charging system.

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

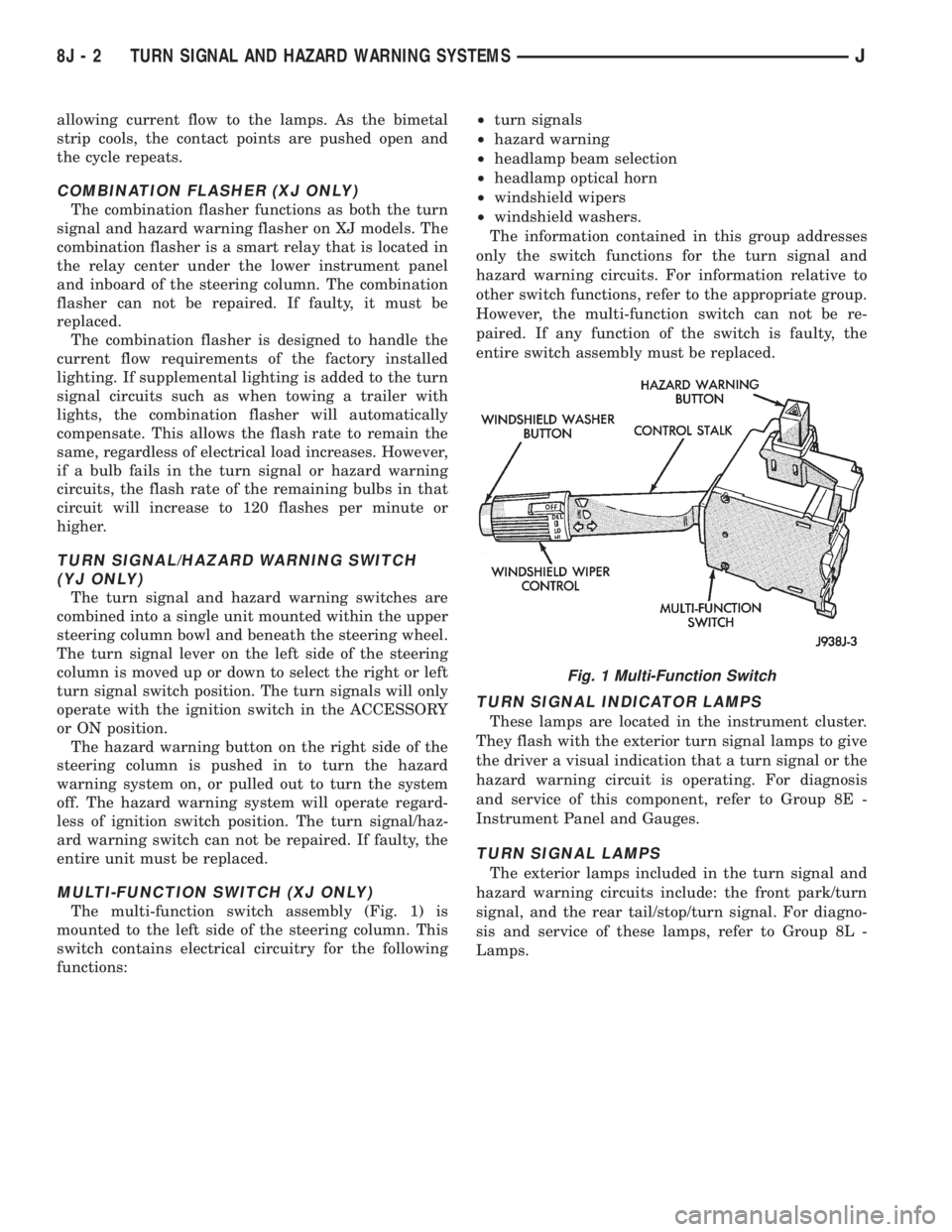

TURN SIGNAL/HAZARD WARNING SYSTEM - XJ

(1) Turn ignition switch to ON position. Actuate the

turn signal lever or hazard warning button. Observe

the turn indicator lamp(s) in the instrument cluster.

If the flash rate is very high, check for a turn signal

bulb that is not lit. Replace that bulb or repair cir-

cuits to that lamp, as required. Test operation. If turn

indicator does not light, continue to next step.

(2) Remove and inspect fuse 8 (turn signals) in

fuseblock module, or fuse F13 (hazard warning) in the

Power Distribution Center. Replace fuse, if required.

(3) Remove combination flasher from relay center

and replace with a known good unit. Test operation of

turn signal and hazard warning systems. If OK, re-place faulty combination flasher. If not OK, remove

test flasher and go to next step.

(4) With ignition switch in ON position, check for

battery voltage at cavity for flasher terminal J1 (Fig.

2). If OK, go to next step. If not OK, repair circuit to

ignition switch as required.

(5) With ignition switch in OFF position, check for

battery voltage at cavity for flasher terminal J2. If

OK, go to next step. If not OK, repair circuit to Power

Distribution Center as required.

(6) With ignition switch in OFF position, check for

continuity between cavity for flasher terminal J5 and

a good ground. There should be continuity. If OK, go

to next step. If not OK, repair circuit to ground as

required.

(7) Locate the multi-function switch connector. See

Multi-Function Switch, in this group. Check for conti-

nuity between cavity for flasher terminal J3 and cav-

ity 13 of the multi-function switch connector. There

should be continuity. If OK, go to next step. If not OK,

repair open circuit as required.

(8) Check for continuity between cavity for flasher

terminal J4 and cavity 17 of the multi-function switch

connector. There should be continuity. If OK, test

multi-function switch. If not OK, repair open circuit

as required.

TURN SIGNAL SYSTEM - YJ

A turn signal indicator lamp that remains lit (with-

out flashing) is an indication of a burned out exterior

turn signal bulb or faulty exterior lamp circuit. Check

Fig. 2 Combination Flasher Circuit - XJ

JTURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 3

Page 417 of 2198

lamps and repair circuits or replace bulbs as re-

quired. If system still does not function properly, pro-

ceed as follows.

(1) Locate fuseblock module under driver's side of

instrument panel. Remove and inspect fuse 4. If OK,

go to next step. If not OK, replace fuse as required.

(2) Replace turn signal flasher (light blue can in

fuseblock module) with a known good unit. Test op-

eration. If OK, replace faulty turn signal flasher. If

not OK, remove test flasher and go to next step.

(3) Turn ignition switch to ACCESSORY position.

Check for battery voltage at flasher cavity on left

(closest to hazard flasher). If OK, go to next step. If

not OK, repair circuit to fuse 4 as required.

(4) Turn ignition switch to OFF position. See Turn

Signal/Hazard Warning Switch Remove/Install to lo-

cate steering column connector. Unplug connector.

(5) Turn ignition switch to ACCESSORY position.

Check for battery voltage at connector terminal L. If

OK, replace turn signal/hazard warning switch. If not

OK, repair circuit between turn signal flasher and

steering column connector.

HAZARD WARNING SYSTEM - YJ

(1) Locate Power Distribution Center (PDC) near

battery tray in engine compartment. Remove and in-

spect fuse F5. If OK, go to next step. If not OK,

replace fuse as required.(2) Replace hazard warning flasher (metal can in

fuseblock module) with a known good unit. Test op-

eration. If OK, replace faulty hazard warning flasher.

If not OK, remove test flasher and go to next step.

(3) Check for battery voltage at flasher cavity on

left (closest to hazard flasher). If OK, go to next step.

If not OK, repair circuit to fuse F5 in PDC as re-

quired.

(4) See Turn Signal/Hazard Warning Switch Re-

move/Install to locate steering column connector. Un-

plug connector.

(5) Check for battery voltage at connector terminal

K. If OK, replace turn signal/hazard warning switch.

If not OK, repair circuit between hazard warning

flasher and steering column connector.

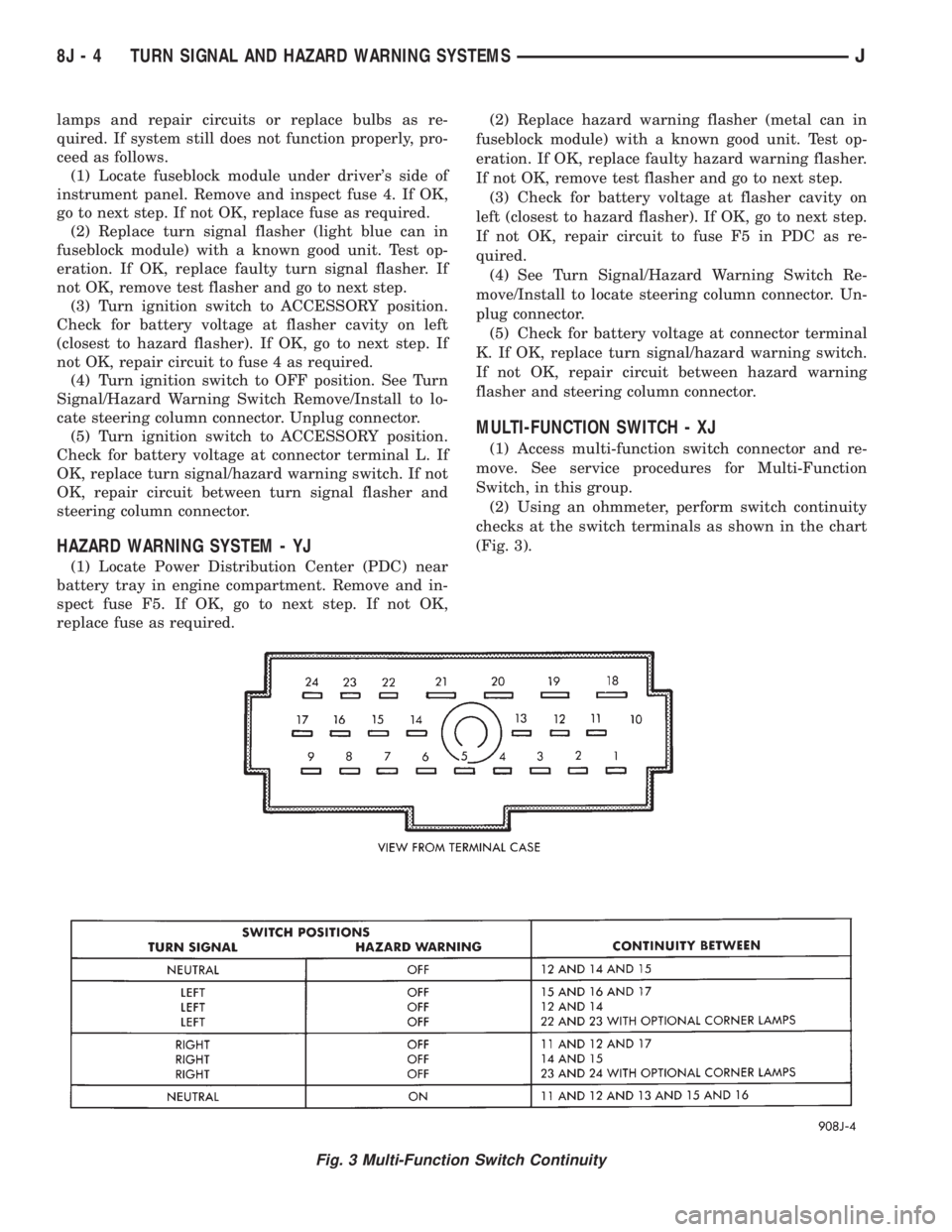

MULTI-FUNCTION SWITCH - XJ

(1) Access multi-function switch connector and re-

move. See service procedures for Multi-Function

Switch, in this group.

(2) Using an ohmmeter, perform switch continuity

checks at the switch terminals as shown in the chart

(Fig. 3).

Fig. 3 Multi-Function Switch Continuity

8J - 4 TURN SIGNAL AND HAZARD WARNING SYSTEMSJ

Page 429 of 2198

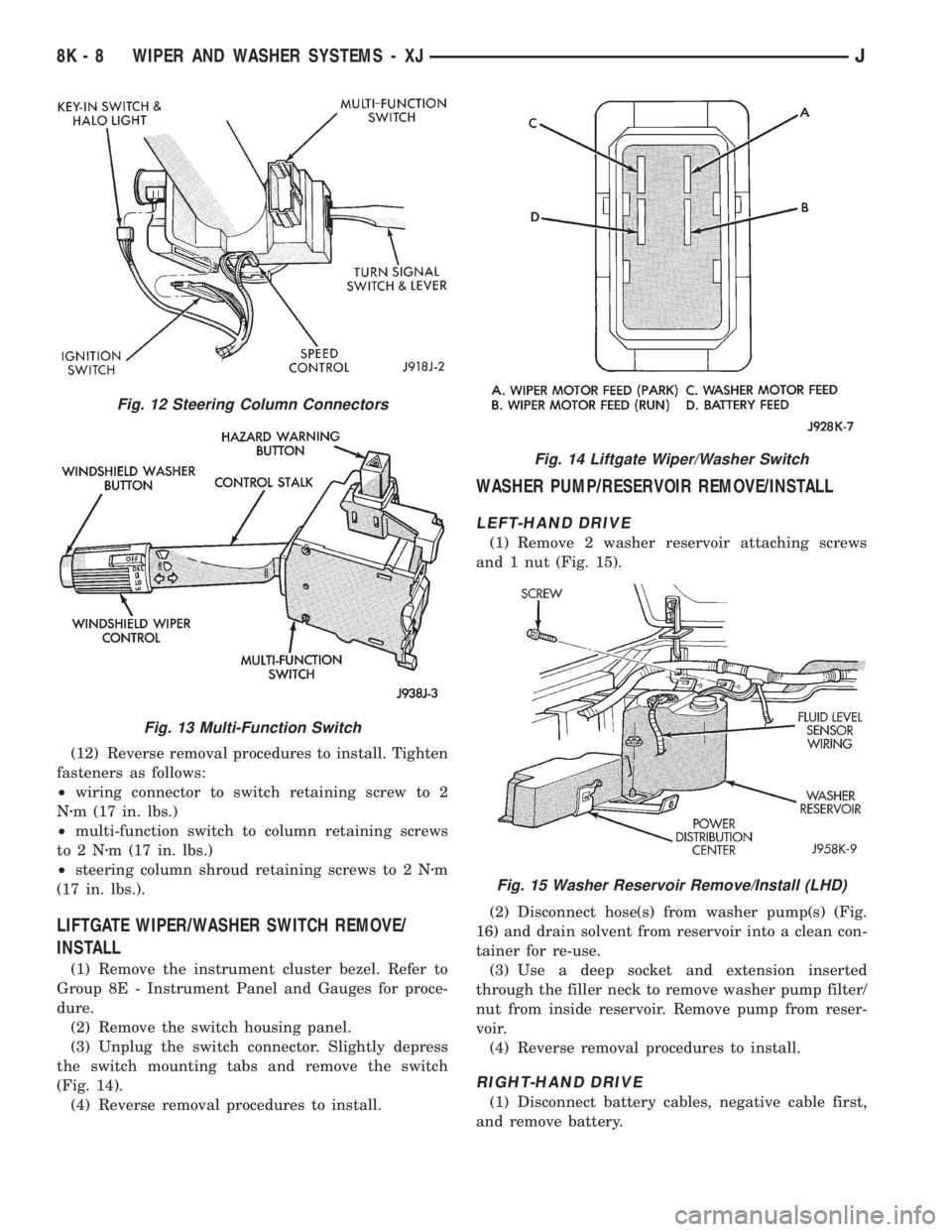

(12) Reverse removal procedures to install. Tighten

fasteners as follows:

²wiring connector to switch retaining screw to 2

Nzm (17 in. lbs.)

²multi-function switch to column retaining screws

to2Nzm (17 in. lbs.)

²steering column shroud retaining screws to 2 Nzm

(17 in. lbs.).

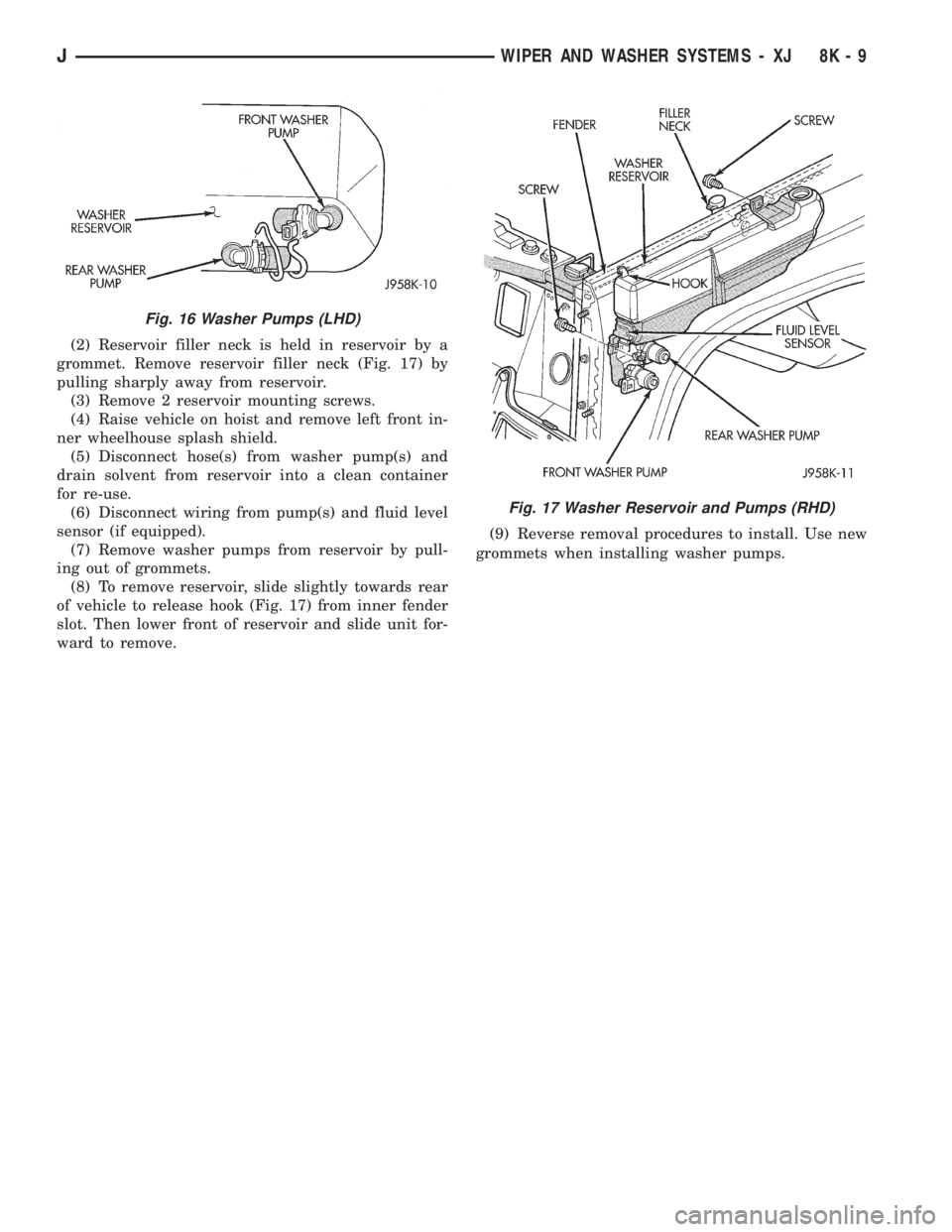

LIFTGATE WIPER/WASHER SWITCH REMOVE/

INSTALL

(1) Remove the instrument cluster bezel. Refer to

Group 8E - Instrument Panel and Gauges for proce-

dure.

(2) Remove the switch housing panel.

(3) Unplug the switch connector. Slightly depress

the switch mounting tabs and remove the switch

(Fig. 14).

(4) Reverse removal procedures to install.

WASHER PUMP/RESERVOIR REMOVE/INSTALL

LEFT-HAND DRIVE

(1) Remove 2 washer reservoir attaching screws

and 1 nut (Fig. 15).

(2) Disconnect hose(s) from washer pump(s) (Fig.

16) and drain solvent from reservoir into a clean con-

tainer for re-use.

(3) Use a deep socket and extension inserted

through the filler neck to remove washer pump filter/

nut from inside reservoir. Remove pump from reser-

voir.

(4) Reverse removal procedures to install.

RIGHT-HAND DRIVE

(1) Disconnect battery cables, negative cable first,

and remove battery.

Fig. 12 Steering Column Connectors

Fig. 13 Multi-Function Switch

Fig. 14 Liftgate Wiper/Washer Switch

Fig. 15 Washer Reservoir Remove/Install (LHD)

8K - 8 WIPER AND WASHER SYSTEMS - XJJ

Page 430 of 2198

(2) Reservoir filler neck is held in reservoir by a

grommet. Remove reservoir filler neck (Fig. 17) by

pulling sharply away from reservoir.

(3) Remove 2 reservoir mounting screws.

(4) Raise vehicle on hoist and remove left front in-

ner wheelhouse splash shield.

(5) Disconnect hose(s) from washer pump(s) and

drain solvent from reservoir into a clean container

for re-use.

(6) Disconnect wiring from pump(s) and fluid level

sensor (if equipped).

(7) Remove washer pumps from reservoir by pull-

ing out of grommets.

(8) To remove reservoir, slide slightly towards rear

of vehicle to release hook (Fig. 17) from inner fender

slot. Then lower front of reservoir and slide unit for-

ward to remove.(9) Reverse removal procedures to install. Use new

grommets when installing washer pumps.

Fig. 16 Washer Pumps (LHD)

Fig. 17 Washer Reservoir and Pumps (RHD)

JWIPER AND WASHER SYSTEMS - XJ 8K - 9

Page 445 of 2198

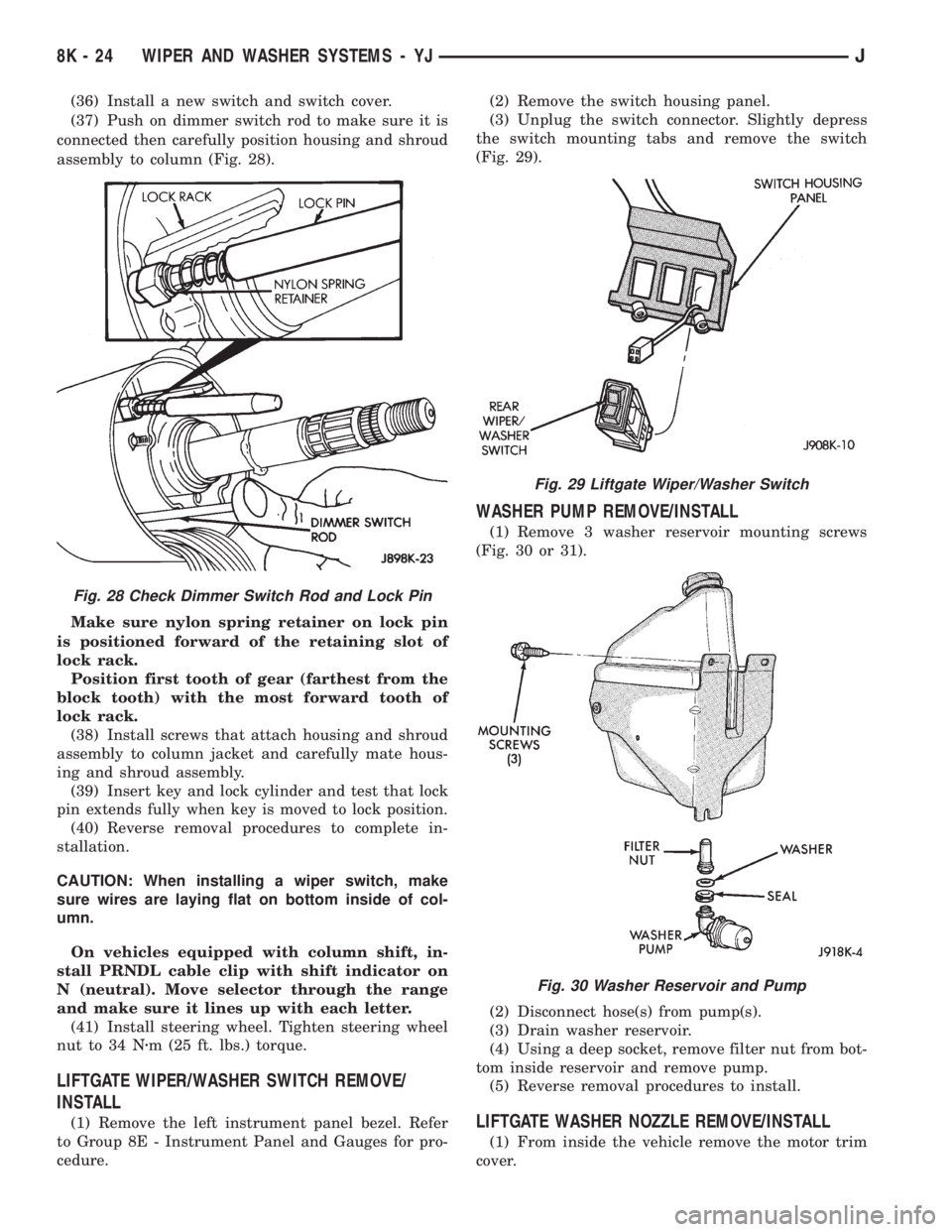

(36) Install a new switch and switch cover.

(37) Push on dimmer switch rod to make sure it is

connected then carefully position housing and shroud

assembly to column (Fig. 28).

Make sure nylon spring retainer on lock pin

is positioned forward of the retaining slot of

lock rack.

Position first tooth of gear (farthest from the

block tooth) with the most forward tooth of

lock rack.

(38) Install screws that attach housing and shroud

assembly to column jacket and carefully mate hous-

ing and shroud assembly.

(39) Insert key and lock cylinder and test that lock

pin extends fully when key is moved to lock position.

(40) Reverse removal procedures to complete in-

stallation.

CAUTION: When installing a wiper switch, make

sure wires are laying flat on bottom inside of col-

umn.

On vehicles equipped with column shift, in-

stall PRNDL cable clip with shift indicator on

N (neutral). Move selector through the range

and make sure it lines up with each letter.

(41) Install steering wheel. Tighten steering wheel

nut to 34 Nzm (25 ft. lbs.) torque.

LIFTGATE WIPER/WASHER SWITCH REMOVE/

INSTALL

(1) Remove the left instrument panel bezel. Refer

to Group 8E - Instrument Panel and Gauges for pro-

cedure.(2) Remove the switch housing panel.

(3) Unplug the switch connector. Slightly depress

the switch mounting tabs and remove the switch

(Fig. 29).

WASHER PUMP REMOVE/INSTALL

(1) Remove 3 washer reservoir mounting screws

(Fig. 30 or 31).

(2) Disconnect hose(s) from pump(s).

(3) Drain washer reservoir.

(4) Using a deep socket, remove filter nut from bot-

tom inside reservoir and remove pump.

(5) Reverse removal procedures to install.

LIFTGATE WASHER NOZZLE REMOVE/INSTALL

(1) From inside the vehicle remove the motor trim

cover.

Fig. 28 Check Dimmer Switch Rod and Lock Pin

Fig. 29 Liftgate Wiper/Washer Switch

Fig. 30 Washer Reservoir and Pump

8K - 24 WIPER AND WASHER SYSTEMS - YJJ

Page 448 of 2198

LAMPS

CONTENTS

page page

BULB APPLICATIONÐXJ VEHICLES......... 18

GENERAL INFORMATION.................. 1INTERIOR LAMPS....................... 16

SERVICE PROCEDURES................... 6

GENERAL INFORMATION

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush and coat the inside of the socket lightly with

Mopar Multi-Purpose Grease or equivalent.

DIAGNOSTIC PROCEDURESÐXJ

When a vehicle experiences problems with the

headlamp system, verify the condition of the batteryconnections, charging system, headlamp bulbs, wire

connectors, relay, high beam dimmer switch and

headlamp switch. Refer to Group 8W, Wiring Dia-

grams for component locations and circuit informa-

tion.

Always begin any diagnosis by testing all of the

fuses and circuit breakers in the system. Refer to

Group 8W, Wiring Diagrams.

JLAMPS 8L - 1

Page 451 of 2198

MULTI-FUNCTION SWITCH TESTING

PROCEDURESÐXJ

The multi-function switch contains electrical cir-

cuitry for:

²Headlamp Dimmer Switch.

²Passing Lights.

²Turn Signals.

²Hazard Warning.

²Windshield Wiper.

²Pulse Wiper.

²Windshield Washer.

This integrated switch is mounted to the left hand

side of the steering column. Should any function of

the switch fail, the entire switch must be replaced.

The multi-function switch also serves as a fog lamp

lock-out circuit. The circuit to the fog lamp switch is

completed only when the dimmer switch is in the low

beam position.

SWITCH TEST

(1) Disconnect battery negative cable.

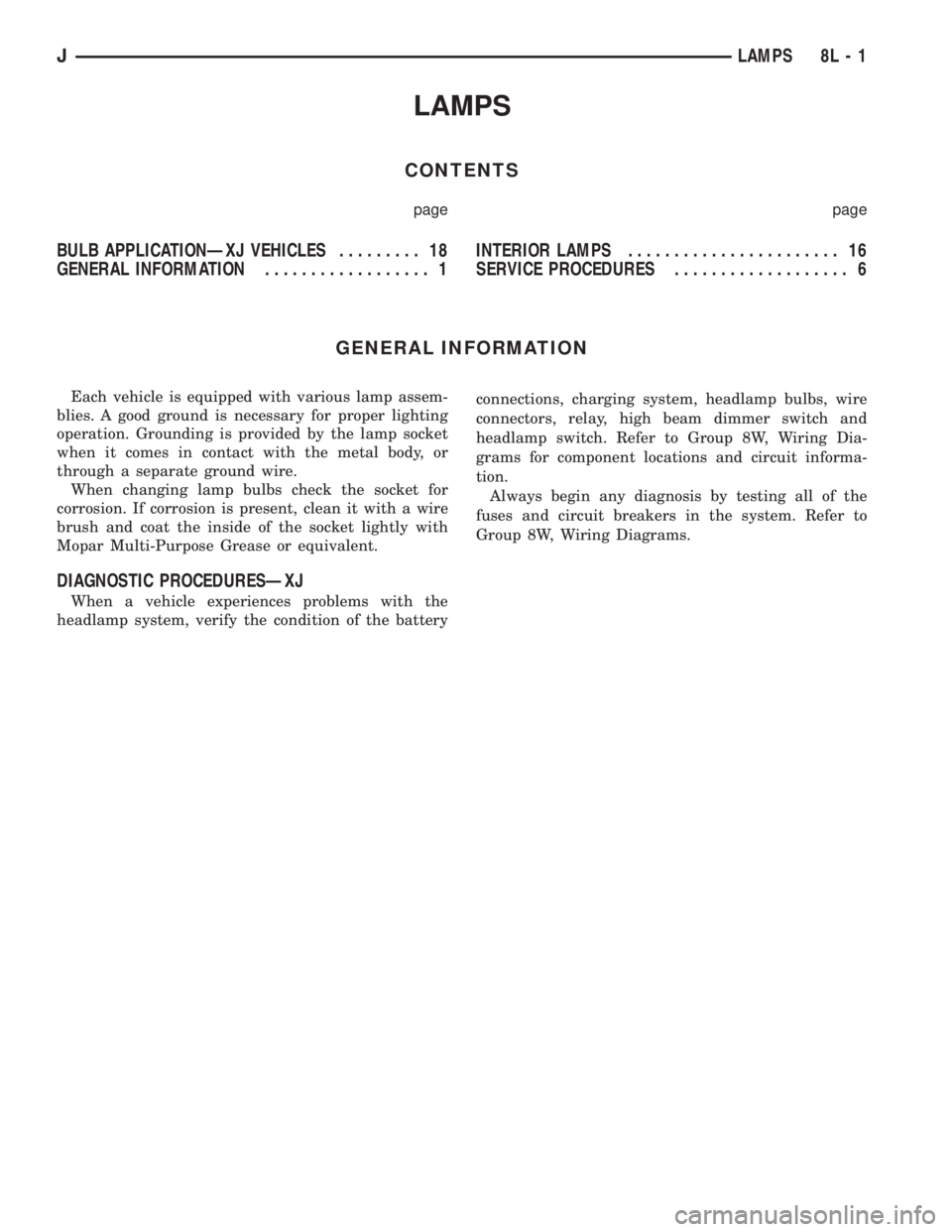

(2) Remove lower instrument panel screws along

bottom edge of steering column (Fig. 1).

(3) Remove lower instrument panel/knee blocker.

(4) Remove tilt lever.

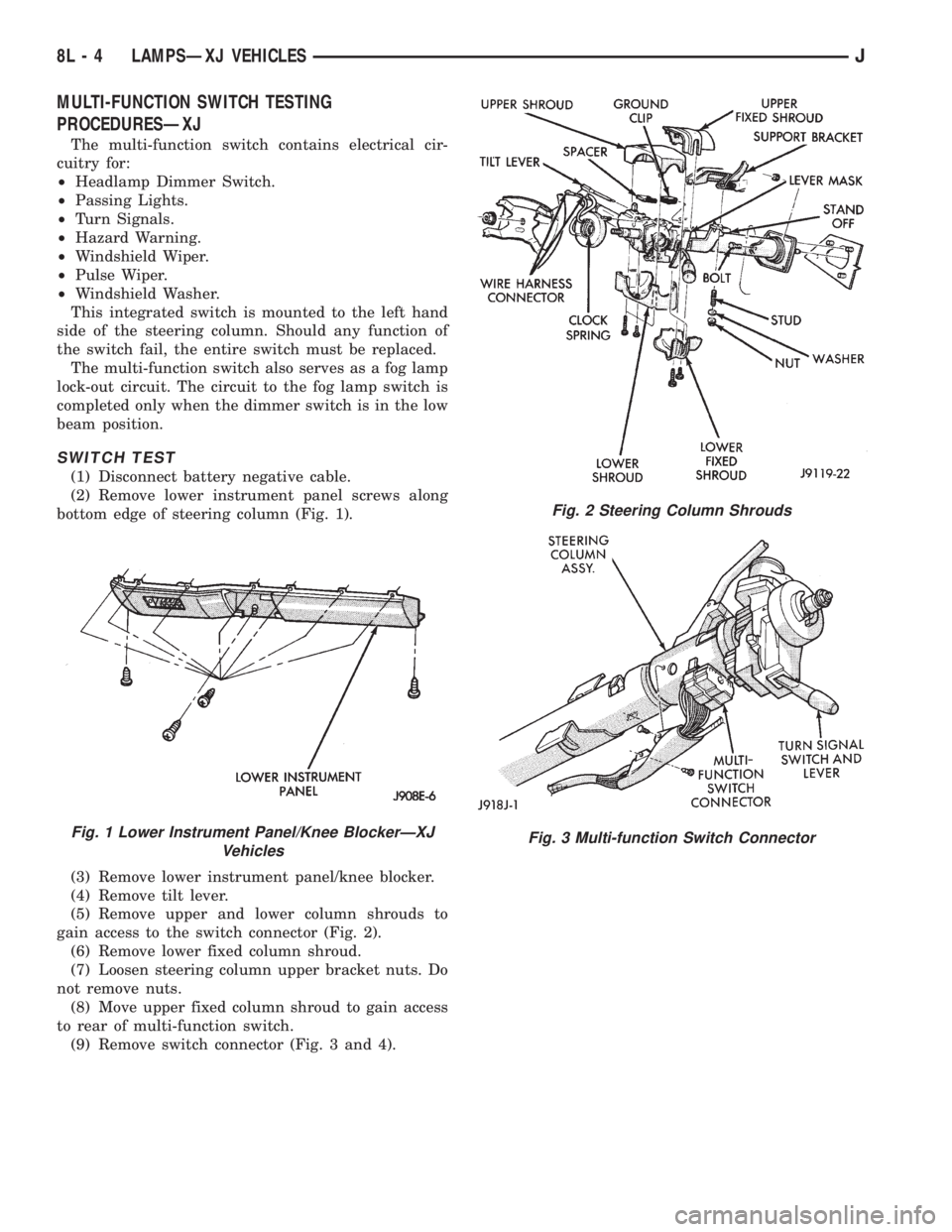

(5) Remove upper and lower column shrouds to

gain access to the switch connector (Fig. 2).

(6) Remove lower fixed column shroud.

(7) Loosen steering column upper bracket nuts. Do

not remove nuts.

(8) Move upper fixed column shroud to gain access

to rear of multi-function switch.

(9) Remove switch connector (Fig. 3 and 4).

Fig. 1 Lower Instrument Panel/Knee BlockerÐXJ

Vehicles

Fig. 2 Steering Column Shrouds

Fig. 3 Multi-function Switch Connector

8L - 4 LAMPSÐXJ VEHICLESJ