Back JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1659 of 2198

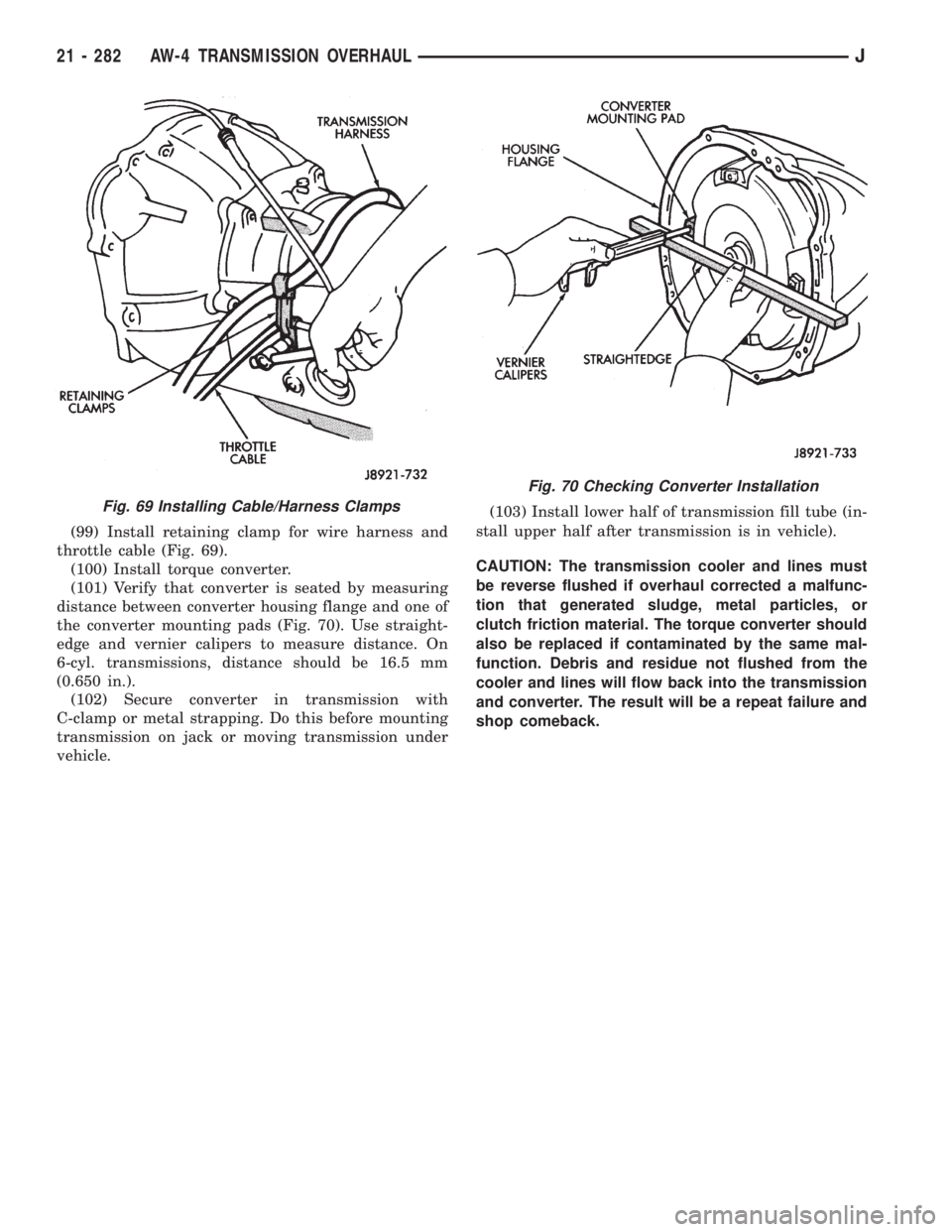

(99) Install retaining clamp for wire harness and

throttle cable (Fig. 69).

(100) Install torque converter.

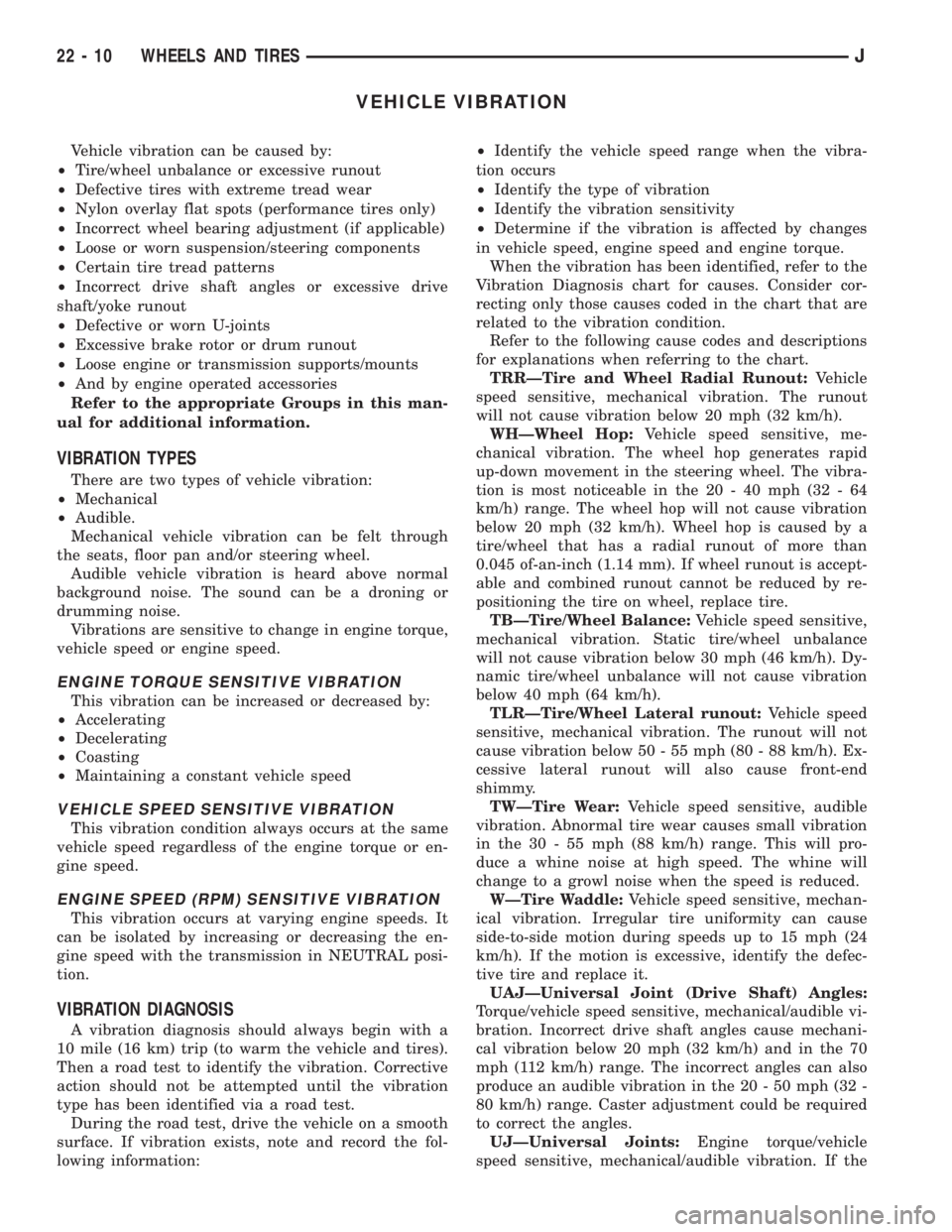

(101) Verify that converter is seated by measuring

distance between converter housing flange and one of

the converter mounting pads (Fig. 70). Use straight-

edge and vernier calipers to measure distance. On

6-cyl. transmissions, distance should be 16.5 mm

(0.650 in.).

(102) Secure converter in transmission with

C-clamp or metal strapping. Do this before mounting

transmission on jack or moving transmission under

vehicle.(103) Install lower half of transmission fill tube (in-

stall upper half after transmission is in vehicle).

CAUTION: The transmission cooler and lines must

be reverse flushed if overhaul corrected a malfunc-

tion that generated sludge, metal particles, or

clutch friction material. The torque converter should

also be replaced if contaminated by the same mal-

function. Debris and residue not flushed from the

cooler and lines will flow back into the transmission

and converter. The result will be a repeat failure and

shop comeback.

Fig. 69 Installing Cable/Harness Clamps

Fig. 70 Checking Converter Installation

21 - 282 AW-4 TRANSMISSION OVERHAULJ

Page 1731 of 2198

VEHICLE VIBRATION

Vehicle vibration can be caused by:

²Tire/wheel unbalance or excessive runout

²Defective tires with extreme tread wear

²Nylon overlay flat spots (performance tires only)

²Incorrect wheel bearing adjustment (if applicable)

²Loose or worn suspension/steering components

²Certain tire tread patterns

²Incorrect drive shaft angles or excessive drive

shaft/yoke runout

²Defective or worn U-joints

²Excessive brake rotor or drum runout

²Loose engine or transmission supports/mounts

²And by engine operated accessories

Refer to the appropriate Groups in this man-

ual for additional information.

VIBRATION TYPES

There are two types of vehicle vibration:

²Mechanical

²Audible.

Mechanical vehicle vibration can be felt through

the seats, floor pan and/or steering wheel.

Audible vehicle vibration is heard above normal

background noise. The sound can be a droning or

drumming noise.

Vibrations are sensitive to change in engine torque,

vehicle speed or engine speed.

ENGINE TORQUE SENSITIVE VIBRATION

This vibration can be increased or decreased by:

²Accelerating

²Decelerating

²Coasting

²Maintaining a constant vehicle speed

VEHICLE SPEED SENSITIVE VIBRATION

This vibration condition always occurs at the same

vehicle speed regardless of the engine torque or en-

gine speed.

ENGINE SPEED (RPM) SENSITIVE VIBRATION

This vibration occurs at varying engine speeds. It

can be isolated by increasing or decreasing the en-

gine speed with the transmission in NEUTRAL posi-

tion.

VIBRATION DIAGNOSIS

A vibration diagnosis should always begin with a

10 mile (16 km) trip (to warm the vehicle and tires).

Then a road test to identify the vibration. Corrective

action should not be attempted until the vibration

type has been identified via a road test.

During the road test, drive the vehicle on a smooth

surface. If vibration exists, note and record the fol-

lowing information:²Identify the vehicle speed range when the vibra-

tion occurs

²Identify the type of vibration

²Identify the vibration sensitivity

²Determine if the vibration is affected by changes

in vehicle speed, engine speed and engine torque.

When the vibration has been identified, refer to the

Vibration Diagnosis chart for causes. Consider cor-

recting only those causes coded in the chart that are

related to the vibration condition.

Refer to the following cause codes and descriptions

for explanations when referring to the chart.

TRRÐTire and Wheel Radial Runout:Vehicle

speed sensitive, mechanical vibration. The runout

will not cause vibration below 20 mph (32 km/h).

WHÐWheel Hop:Vehicle speed sensitive, me-

chanical vibration. The wheel hop generates rapid

up-down movement in the steering wheel. The vibra-

tion is most noticeable in the 20 - 40 mph (32 - 64

km/h) range. The wheel hop will not cause vibration

below 20 mph (32 km/h). Wheel hop is caused by a

tire/wheel that has a radial runout of more than

0.045 of-an-inch (1.14 mm). If wheel runout is accept-

able and combined runout cannot be reduced by re-

positioning the tire on wheel, replace tire.

TBÐTire/Wheel Balance:Vehicle speed sensitive,

mechanical vibration. Static tire/wheel unbalance

will not cause vibration below 30 mph (46 km/h). Dy-

namic tire/wheel unbalance will not cause vibration

below 40 mph (64 km/h).

TLRÐTire/Wheel Lateral runout:Vehicle speed

sensitive, mechanical vibration. The runout will not

cause vibration below 50 - 55 mph (80 - 88 km/h). Ex-

cessive lateral runout will also cause front-end

shimmy.

TWÐTire Wear:Vehicle speed sensitive, audible

vibration. Abnormal tire wear causes small vibration

in the 30 - 55 mph (88 km/h) range. This will pro-

duce a whine noise at high speed. The whine will

change to a growl noise when the speed is reduced.

WÐTire Waddle:Vehicle speed sensitive, mechan-

ical vibration. Irregular tire uniformity can cause

side-to-side motion during speeds up to 15 mph (24

km/h). If the motion is excessive, identify the defec-

tive tire and replace it.

UAJÐUniversal Joint (Drive Shaft) Angles:

Torque/vehicle speed sensitive, mechanical/audible vi-

bration. Incorrect drive shaft angles cause mechani-

cal vibration below 20 mph (32 km/h) and in the 70

mph (112 km/h) range. The incorrect angles can also

produce an audible vibration in the 20 - 50 mph (32 -

80 km/h) range. Caster adjustment could be required

to correct the angles.

UJÐUniversal Joints:Engine torque/vehicle

speed sensitive, mechanical/audible vibration. If the

22 - 10 WHEELS AND TIRESJ

Page 1754 of 2198

(4) If the original molding will be installed, also re-

move all adhesive from it.

INSTALLATION

(1) Install 3M 06379 double-sided tape on the

molding.

(2) For vertical alignment, use masking tape or a

string as reference.

(3) Remove the backing from the tape, align the

molding and position it on the body panel.

(4) Press the molding onto the body panel with a

roller or hand pressure.

BODY STRIPES/DECALSÐXJ

SERVICE INFORMATION

XJ body stripes and decals are weather resistant

tape with a adhesive backing.

REPAIR

Small nicks, scratches and other surface marks in

a body stripe/decal can be touched-up with paint.

To eliminate blisters and air bubbles in a body

stripe/decal, pierce them with a needle or pin.

A heat gun can also be used to remove small wrin-

kles in a stripe/decal.

REQUIREMENTS

Body stripe/decal replacement requires that the

metal repair and paint refinish be completed first.

The work area temperature should be between

18ÉC (65ÉF) and 32ÉC (90ÉF).A tape stripe/decal

should not be replaced if the work area temper-

ature is less than 18ÉC (65ÉF).

The following equipment and material are neces-

sary for removal and installation:

²Commercial tape stripe/decal removal solution.

²Commercial adhesive removal solution.

²Liquid dish detergent (for the wetting solution).

²Mixture of wetting solution.

²Commercial wax and silicone removal solution.

²Isopropyl (rubbing) alcohol.

²Small squeegee (plastic or hard rubber).

²Water bucket and sponge.

²Clean wiping rags or paper towels.

²Heat gun (or infra-red heat bulb).

²Wax pencil.

²

Sharp knife, single edge razor blade or X-acto knife.

²Pair of scissors.

²Needle or pin.

The use of a wetting solution aids the installation of a

tape stripe/decal on a painted panel. Prepare the wet-

ting solution by mixing two or three teaspoons of dish

detergent with 1 gallon of water.Do not use soap.

Too much detergent will reduce the effective-

ness of the mixture.

REMOVAL

(1) Clean the repaired surface, adjacent panels and

door the openings as necessary.

(2) Start at one end of the tape stripe/decal and

apply heat with a heat gun. Slowly peel the stripe/

decal from the panel by pulling it back.Do not pull

the tape stripe/decal outward from panel.

WARNING: USE TAPE STRIPE/DECAL REMOVAL

SOLUTION IN A WELL-VENTILATED AREA ONLY.

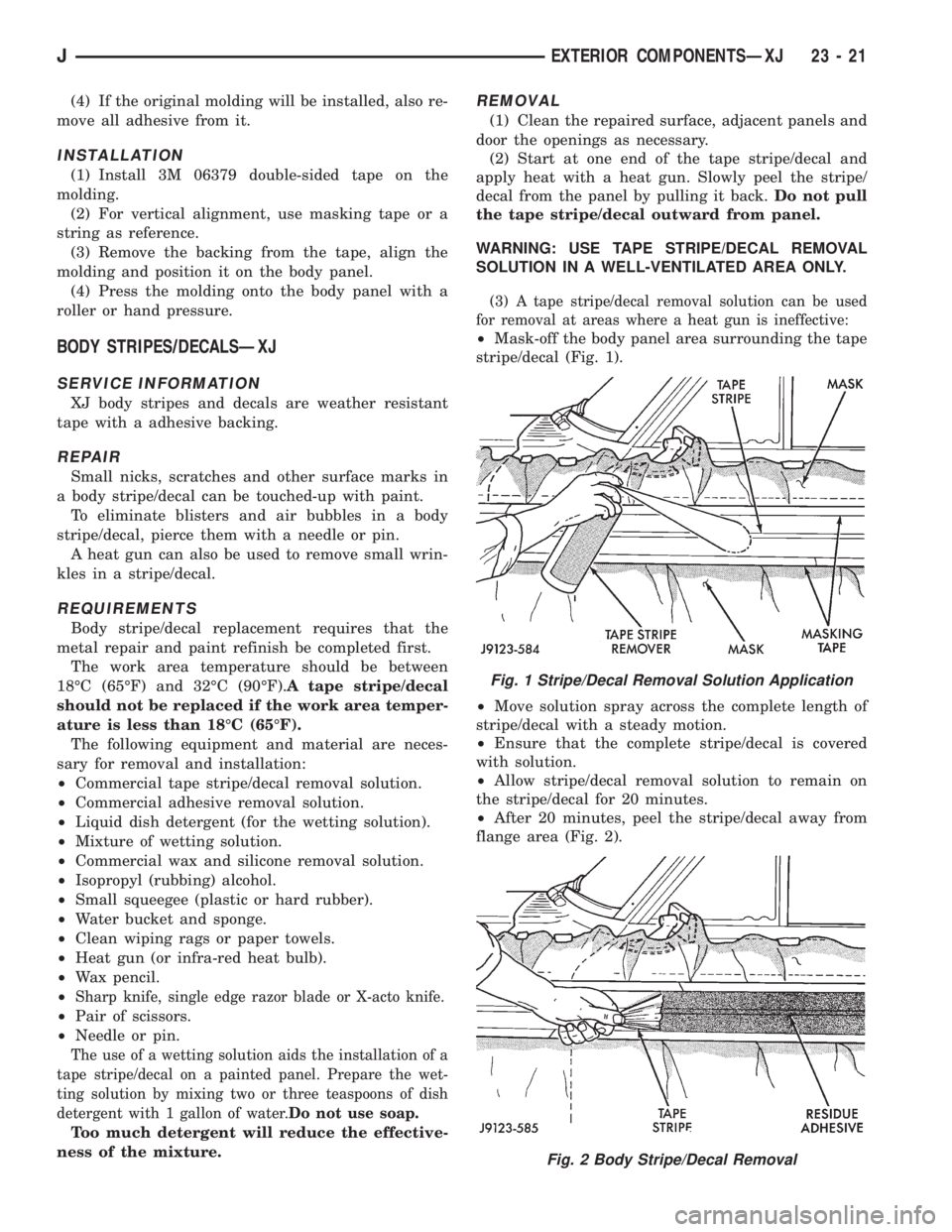

(3) A tape stripe/decal removal solution can be used

for removal at areas where a heat gun is ineffective:

²Mask-off the body panel area surrounding the tape

stripe/decal (Fig. 1).

²Move solution spray across the complete length of

stripe/decal with a steady motion.

²Ensure that the complete stripe/decal is covered

with solution.

²Allow stripe/decal removal solution to remain on

the stripe/decal for 20 minutes.

²After 20 minutes, peel the stripe/decal away from

flange area (Fig. 2).

Fig. 1 Stripe/Decal Removal Solution Application

Fig. 2 Body Stripe/Decal Removal

JEXTERIOR COMPONENTSÐXJ 23 - 21

Page 1756 of 2198

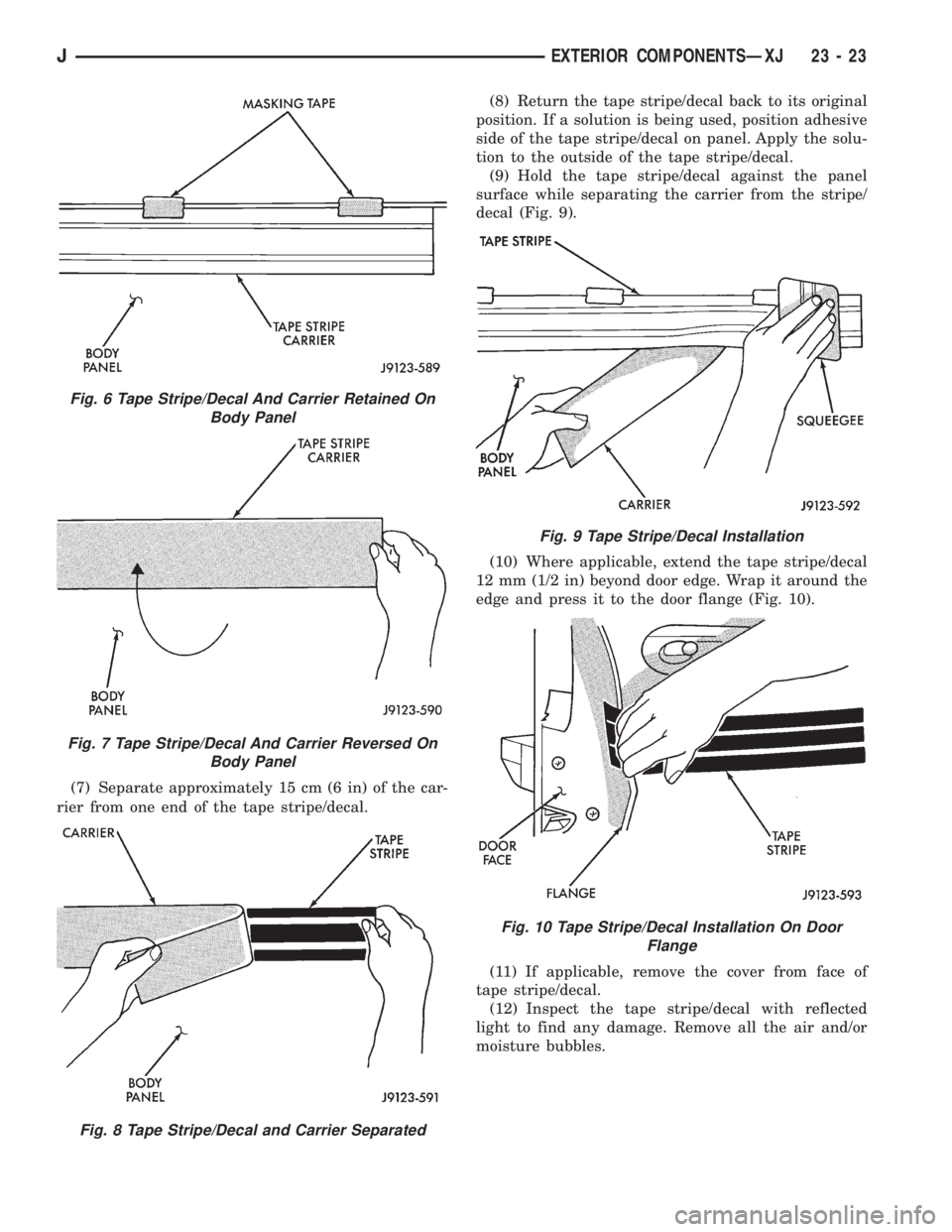

(7) Separate approximately 15 cm (6 in) of the car-

rier from one end of the tape stripe/decal.(8) Return the tape stripe/decal back to its original

position. If a solution is being used, position adhesive

side of the tape stripe/decal on panel. Apply the solu-

tion to the outside of the tape stripe/decal.

(9) Hold the tape stripe/decal against the panel

surface while separating the carrier from the stripe/

decal (Fig. 9).

(10) Where applicable, extend the tape stripe/decal

12 mm (1/2 in) beyond door edge. Wrap it around the

edge and press it to the door flange (Fig. 10).

(11) If applicable, remove the cover from face of

tape stripe/decal.

(12) Inspect the tape stripe/decal with reflected

light to find any damage. Remove all the air and/or

moisture bubbles.

Fig. 6 Tape Stripe/Decal And Carrier Retained On

Body Panel

Fig. 7 Tape Stripe/Decal And Carrier Reversed On

Body Panel

Fig. 8 Tape Stripe/Decal and Carrier Separated

Fig. 9 Tape Stripe/Decal Installation

Fig. 10 Tape Stripe/Decal Installation On Door

Flange

JEXTERIOR COMPONENTSÐXJ 23 - 23

Page 1759 of 2198

(3) Pull downward and remove the grille from ex-

haust port in the door opening panel.

INSTALLATION

(1) Position the slot located in the upper end of re-

placement grille at the exhaust port and insert edge

in the slot.

(2) Push inward and seat the grille in the exhaust

port.

(3) Install the screw to attach the grille to the door

opening panel.

EXTERIOR NAMEPLATESÐXJ

SERVICE INFORMATION

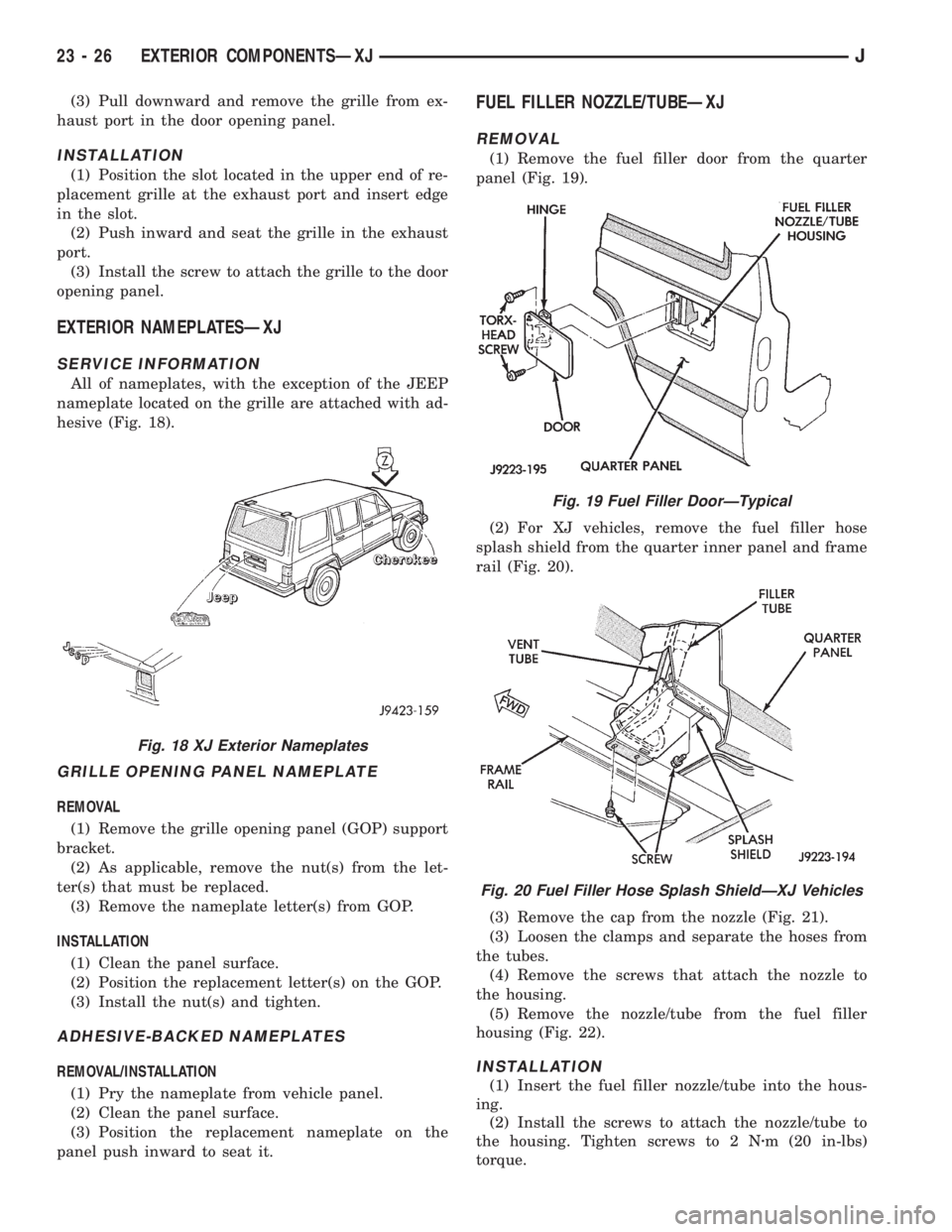

All of nameplates, with the exception of the JEEP

nameplate located on the grille are attached with ad-

hesive (Fig. 18).

GRILLE OPENING PANEL NAMEPLATE

REMOVAL

(1) Remove the grille opening panel (GOP) support

bracket.

(2) As applicable, remove the nut(s) from the let-

ter(s) that must be replaced.

(3) Remove the nameplate letter(s) from GOP.

INSTALLATION

(1) Clean the panel surface.

(2) Position the replacement letter(s) on the GOP.

(3) Install the nut(s) and tighten.

ADHESIVE-BACKED NAMEPLATES

REMOVAL/INSTALLATION

(1) Pry the nameplate from vehicle panel.

(2) Clean the panel surface.

(3) Position the replacement nameplate on the

panel push inward to seat it.

FUEL FILLER NOZZLE/TUBEÐXJ

REMOVAL

(1) Remove the fuel filler door from the quarter

panel (Fig. 19).

(2) For XJ vehicles, remove the fuel filler hose

splash shield from the quarter inner panel and frame

rail (Fig. 20).

(3) Remove the cap from the nozzle (Fig. 21).

(3) Loosen the clamps and separate the hoses from

the tubes.

(4) Remove the screws that attach the nozzle to

the housing.

(5) Remove the nozzle/tube from the fuel filler

housing (Fig. 22).

INSTALLATION

(1) Insert the fuel filler nozzle/tube into the hous-

ing.

(2) Install the screws to attach the nozzle/tube to

the housing. Tighten screws to 2 Nzm (20 in-lbs)

torque.

Fig. 18 XJ Exterior Nameplates

Fig. 19 Fuel Filler DoorÐTypical

Fig. 20 Fuel Filler Hose Splash ShieldÐXJ Vehicles

23 - 26 EXTERIOR COMPONENTSÐXJJ

Page 1762 of 2198

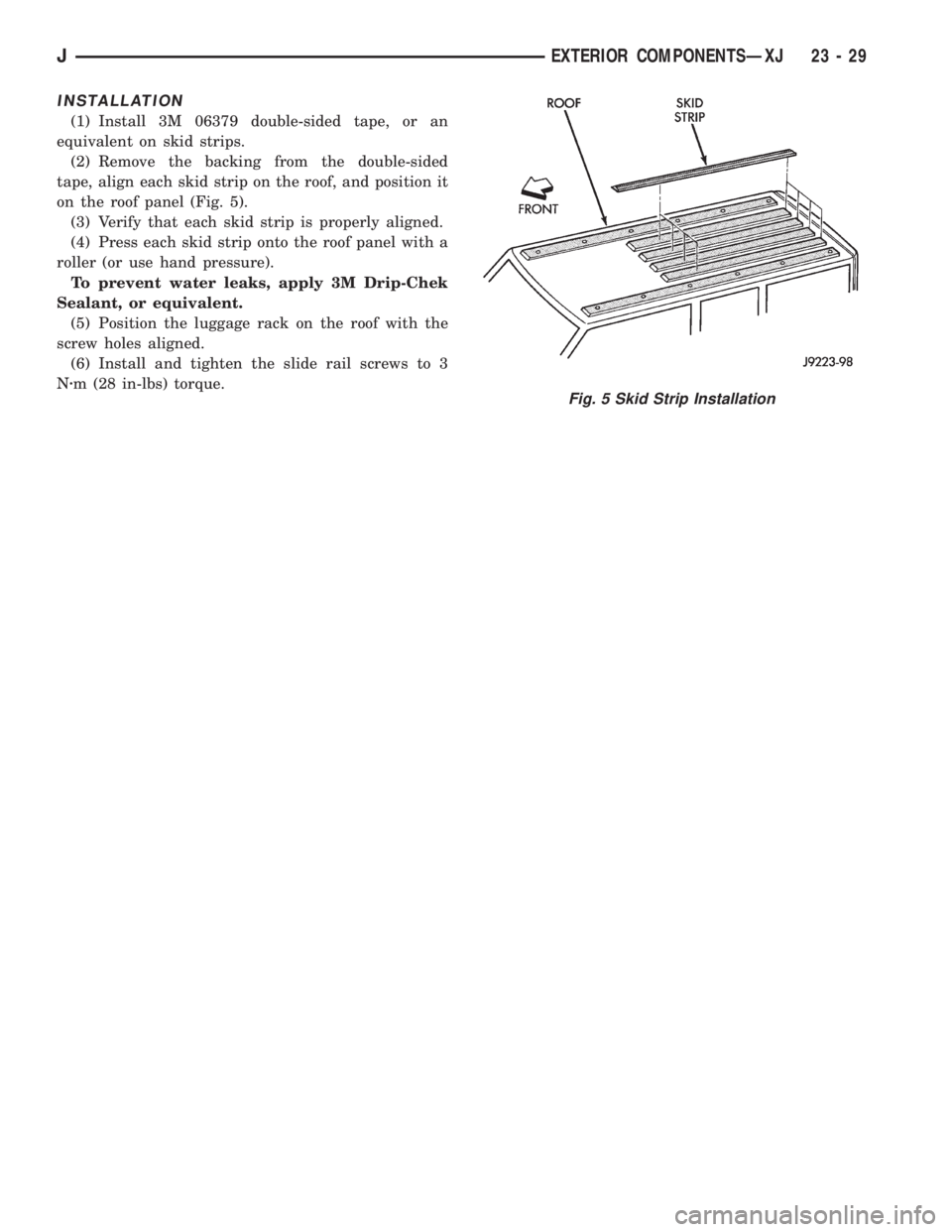

INSTALLATION

(1) Install 3M 06379 double-sided tape, or an

equivalent on skid strips.

(2) Remove the backing from the double-sided

tape, align each skid strip on the roof, and position it

on the roof panel (Fig. 5).

(3) Verify that each skid strip is properly aligned.

(4) Press each skid strip onto the roof panel with a

roller (or use hand pressure).

To prevent water leaks, apply 3M Drip-Chek

Sealant, or equivalent.

(5) Position the luggage rack on the roof with the

screw holes aligned.

(6) Install and tighten the slide rail screws to 3

Nzm (28 in-lbs) torque.

Fig. 5 Skid Strip Installation

JEXTERIOR COMPONENTSÐXJ 23 - 29

Page 1813 of 2198

INTERIOR COMPONENTS

INDEX

page page

Assist HandleÐXJ........................ 89

B/C-Pillar and Liftgate Pillar Trim CoversÐXJ.... 88

Bucket Seat Cushion and CoverÐXJ........... 81

Bucket Seat PlatformÐXJ................... 82

Bucket Seatback Cover and FrameÐXJ........ 81

Cargo BarrierÐXJ........................ 101

Cargo LampÐXJ......................... 94

Carpets and Floor MatsÐXJ................. 99

Dome LampÐXJ......................... 93

Front Bucket SeatsÐXJ.................... 81

Front Carpet/MatÐXJ...................... 99

Front Inner Scuff Plate/Cowl Side Trim PanelÐXJ . 86

Front Shoulder Belt/BuckleÐXJ............... 90

Full Floor ConsoleÐXJ..................... 95

HeadlinerÐXJ............................ 92

I/P Ash Receiver Tray LampÐXJ.............. 80

Instrument Cluster BezelÐXJ................ 80

Interior Trim Panels and Scuff PlatesÐXJ....... 84

Jack StorageÐXJ......................... 97

Keyless Entry ReceiverÐXJ................. 93Mini-Console with Floor ShiftÐXJ............. 94

Mini-Floor ConsoleÐXJ..................... 94

Outer Scuff PlatesÐXJ..................... 89

Overhead ConsoleÐXJ..................... 93

Parking Brake Handle CoverÐXJ............. 94

Quarter and Wheelhouse Trim PanelsÐXJ...... 87

Quarter Trim Panel ExtensionÐXJ............. 87

Rear Carpet/MatÐXJ..................... 100

Rear Seat Cushion CoverÐXJ............... 82

Rear Seat CushionÐXJ.................... 82

Rear Seatback CoverÐXJ................... 84

Rear Seatback Latch Striker and BumperÐXJ.... 84

Rear SeatbackÐXJ........................ 83

Rear Shoulder/Lap Belt/BuckleÐXJ............ 91

Sound BarÐXJ........................... 94

Spare Tire/Wheel Holddown and Floor

BracketsÐXJ........................... 98

SunvisorsÐXJ........................... 93

Windshield Side MoldingÐXJ................ 86

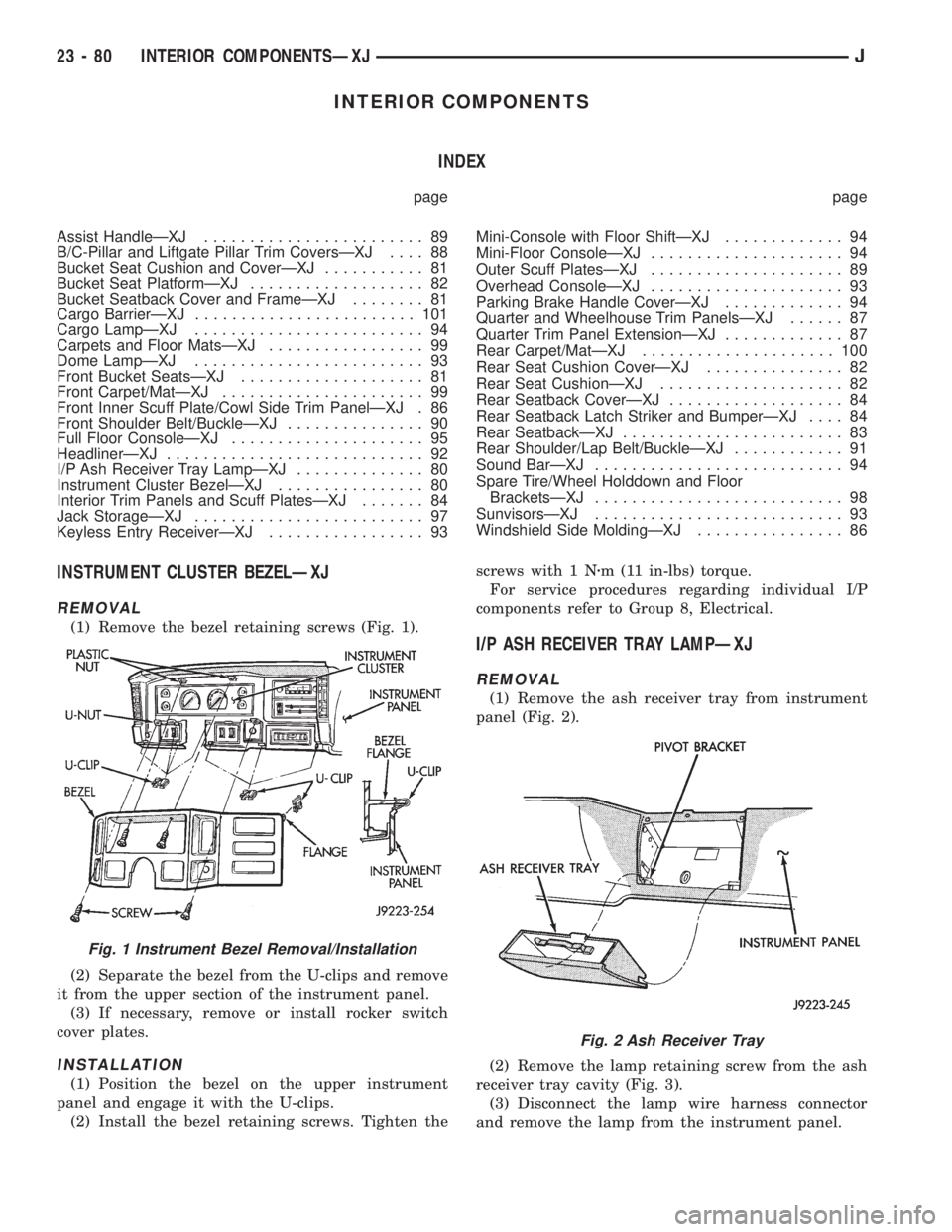

INSTRUMENT CLUSTER BEZELÐXJ

REMOVAL

(1) Remove the bezel retaining screws (Fig. 1).

(2) Separate the bezel from the U-clips and remove

it from the upper section of the instrument panel.

(3) If necessary, remove or install rocker switch

cover plates.

INSTALLATION

(1) Position the bezel on the upper instrument

panel and engage it with the U-clips.

(2) Install the bezel retaining screws. Tighten thescrews with 1 Nzm (11 in-lbs) torque.

For service procedures regarding individual I/P

components refer to Group 8, Electrical.

I/P ASH RECEIVER TRAY LAMPÐXJ

REMOVAL

(1) Remove the ash receiver tray from instrument

panel (Fig. 2).

(2) Remove the lamp retaining screw from the ash

receiver tray cavity (Fig. 3).

(3) Disconnect the lamp wire harness connector

and remove the lamp from the instrument panel.

Fig. 1 Instrument Bezel Removal/Installation

Fig. 2 Ash Receiver Tray

23 - 80 INTERIOR COMPONENTSÐXJJ

Page 1814 of 2198

INSTALLATION

(1) Position the lamp under the instrument panel

and connect the lamp wire harness connector.

(2) Install the lamp retaining screw in the ash re-

ceiver tray cavity.

(3) Install the ash receiver tray in the instrument

panel.

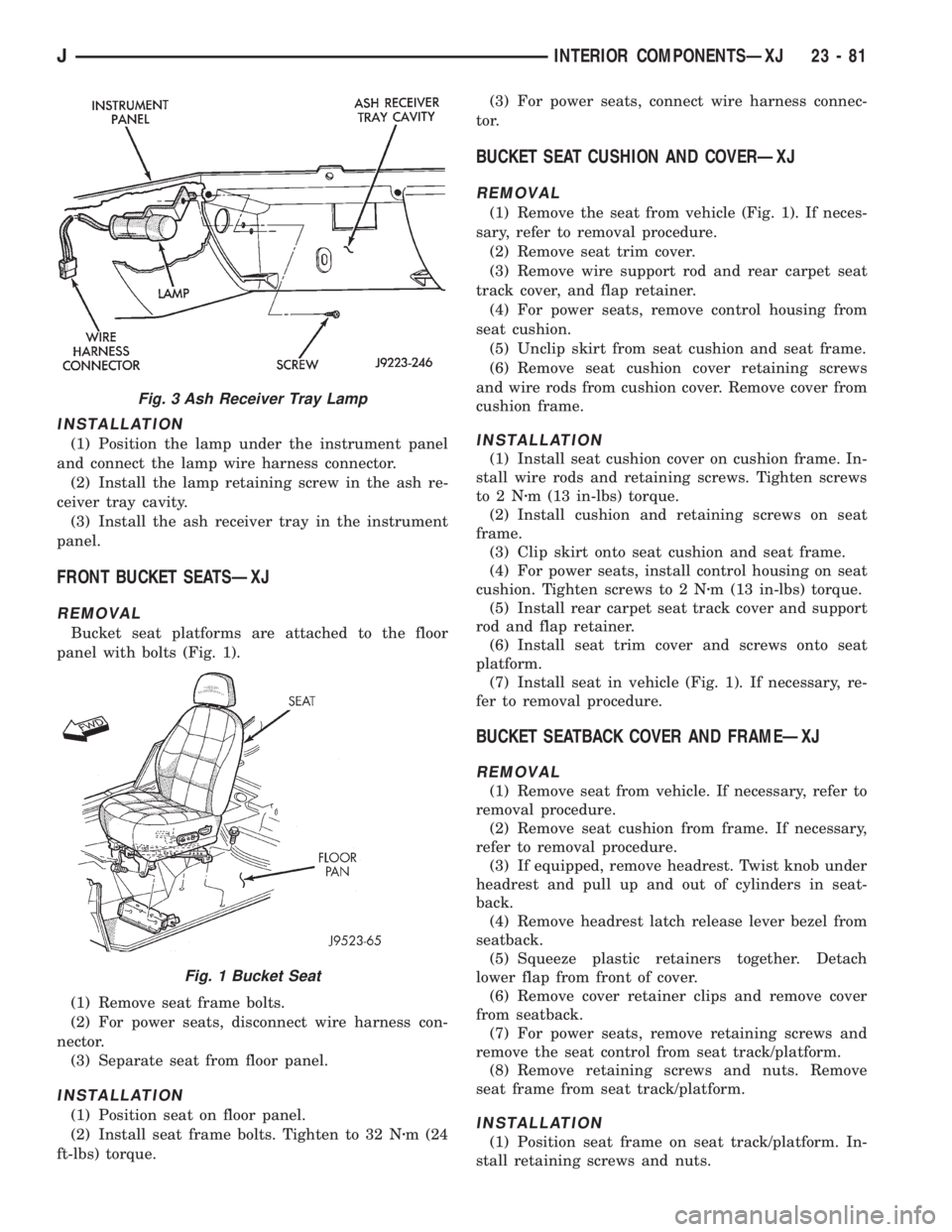

FRONT BUCKET SEATSÐXJ

REMOVAL

Bucket seat platforms are attached to the floor

panel with bolts (Fig. 1).

(1) Remove seat frame bolts.

(2) For power seats, disconnect wire harness con-

nector.

(3) Separate seat from floor panel.

INSTALLATION

(1) Position seat on floor panel.

(2) Install seat frame bolts. Tighten to 32 Nzm (24

ft-lbs) torque.(3) For power seats, connect wire harness connec-

tor.

BUCKET SEAT CUSHION AND COVERÐXJ

REMOVAL

(1) Remove the seat from vehicle (Fig. 1). If neces-

sary, refer to removal procedure.

(2) Remove seat trim cover.

(3) Remove wire support rod and rear carpet seat

track cover, and flap retainer.

(4) For power seats, remove control housing from

seat cushion.

(5) Unclip skirt from seat cushion and seat frame.

(6) Remove seat cushion cover retaining screws

and wire rods from cushion cover. Remove cover from

cushion frame.

INSTALLATION

(1) Install seat cushion cover on cushion frame. In-

stall wire rods and retaining screws. Tighten screws

to2Nzm (13 in-lbs) torque.

(2) Install cushion and retaining screws on seat

frame.

(3) Clip skirt onto seat cushion and seat frame.

(4) For power seats, install control housing on seat

cushion. Tighten screws to 2 Nzm (13 in-lbs) torque.

(5) Install rear carpet seat track cover and support

rod and flap retainer.

(6) Install seat trim cover and screws onto seat

platform.

(7) Install seat in vehicle (Fig. 1). If necessary, re-

fer to removal procedure.

BUCKET SEATBACK COVER AND FRAMEÐXJ

REMOVAL

(1) Remove seat from vehicle. If necessary, refer to

removal procedure.

(2) Remove seat cushion from frame. If necessary,

refer to removal procedure.

(3) If equipped, remove headrest. Twist knob under

headrest and pull up and out of cylinders in seat-

back.

(4) Remove headrest latch release lever bezel from

seatback.

(5) Squeeze plastic retainers together. Detach

lower flap from front of cover.

(6) Remove cover retainer clips and remove cover

from seatback.

(7) For power seats, remove retaining screws and

remove the seat control from seat track/platform.

(8) Remove retaining screws and nuts. Remove

seat frame from seat track/platform.

INSTALLATION

(1) Position seat frame on seat track/platform. In-

stall retaining screws and nuts.

Fig. 3 Ash Receiver Tray Lamp

Fig. 1 Bucket Seat

JINTERIOR COMPONENTSÐXJ 23 - 81

Page 1815 of 2198

(2) For power seats, position seat control on seat

track/platform. Install retaining screws. Tighten

screws securely.

(3) Position cover on seatback. Install cover re-

tainer clips.

(4) Attach cover bottom elastic band or attach Vel-

cro flap to front of cover.

(5) Install seatback insert.

(6) Install headrest latch release lever bezel.

(7) Install headrest by pushing it down into seat-

back cylinders.

(8) Install cushion on frame. If necessary, refer to

installation procedure.

(9) Install seat in the vehicle. If necessary, refer to

the installation procedure.

(10) For power seats, test seat operation.

BUCKET SEAT PLATFORMÐXJ

REPLACEMENT

Bucket seat platforms are not repairable. If the

seat platform is damaged, replace platform as a unit.

REAR SEAT CUSHIONÐXJ

REMOVAL

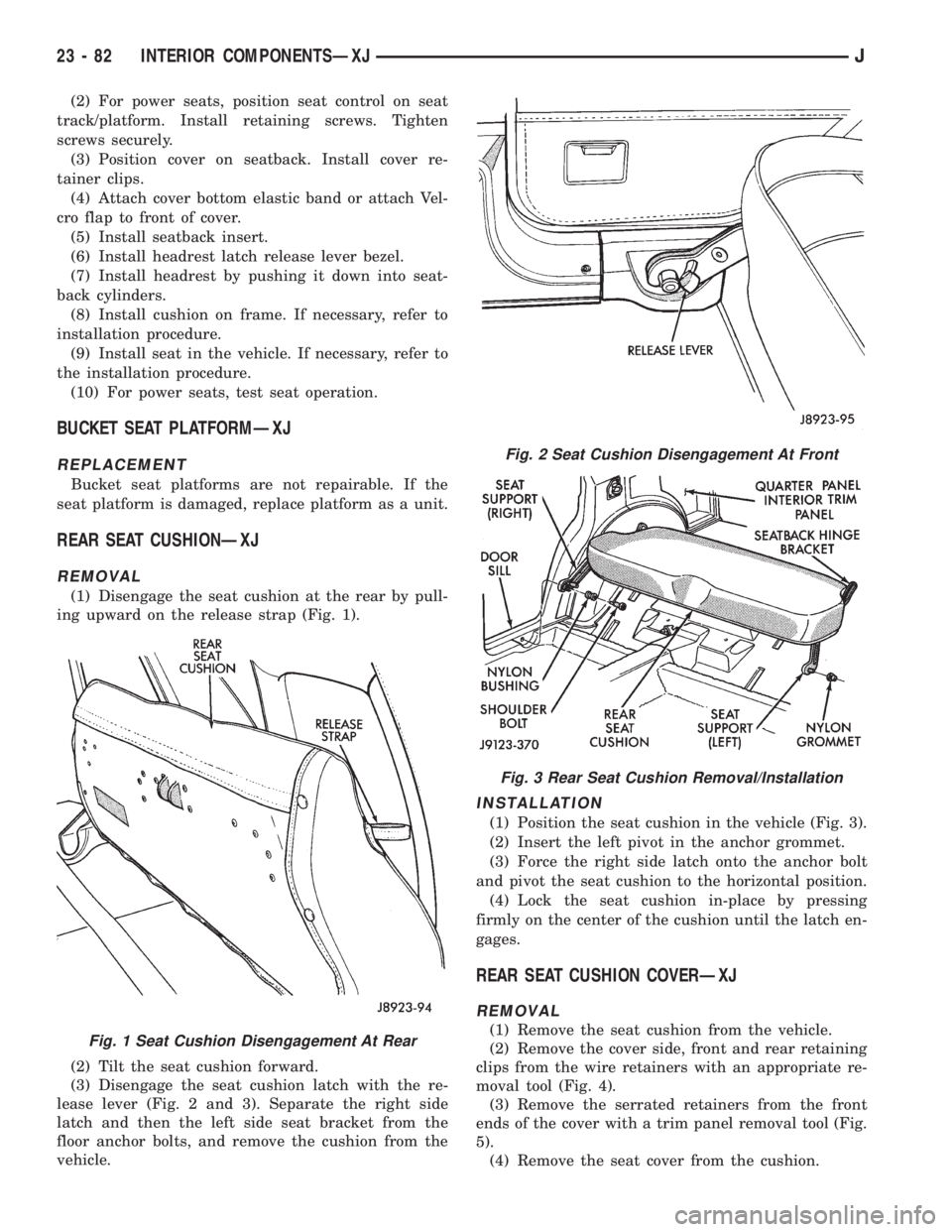

(1) Disengage the seat cushion at the rear by pull-

ing upward on the release strap (Fig. 1).

(2) Tilt the seat cushion forward.

(3) Disengage the seat cushion latch with the re-

lease lever (Fig. 2 and 3). Separate the right side

latch and then the left side seat bracket from the

floor anchor bolts, and remove the cushion from the

vehicle.

INSTALLATION

(1) Position the seat cushion in the vehicle (Fig. 3).

(2) Insert the left pivot in the anchor grommet.

(3) Force the right side latch onto the anchor bolt

and pivot the seat cushion to the horizontal position.

(4) Lock the seat cushion in-place by pressing

firmly on the center of the cushion until the latch en-

gages.

REAR SEAT CUSHION COVERÐXJ

REMOVAL

(1) Remove the seat cushion from the vehicle.

(2) Remove the cover side, front and rear retaining

clips from the wire retainers with an appropriate re-

moval tool (Fig. 4).

(3) Remove the serrated retainers from the front

ends of the cover with a trim panel removal tool (Fig.

5).

(4) Remove the seat cover from the cushion.Fig. 1 Seat Cushion Disengagement At Rear

Fig. 2 Seat Cushion Disengagement At Front

Fig. 3 Rear Seat Cushion Removal/Installation

23 - 82 INTERIOR COMPONENTSÐXJJ

Page 1816 of 2198

INSTALLATION

(1) Position the replacement cover on the cushion.

(2) Compress the cover and attach the retaining

clips to the front and rear wire retainers.

(3) Install the serrated retainers at the ends of the

cover.

(4) Install the seat cushion in the vehicle. If neces-

sary, refer to the installation procedure.

REAR SEATBACKÐXJ

REMOVAL

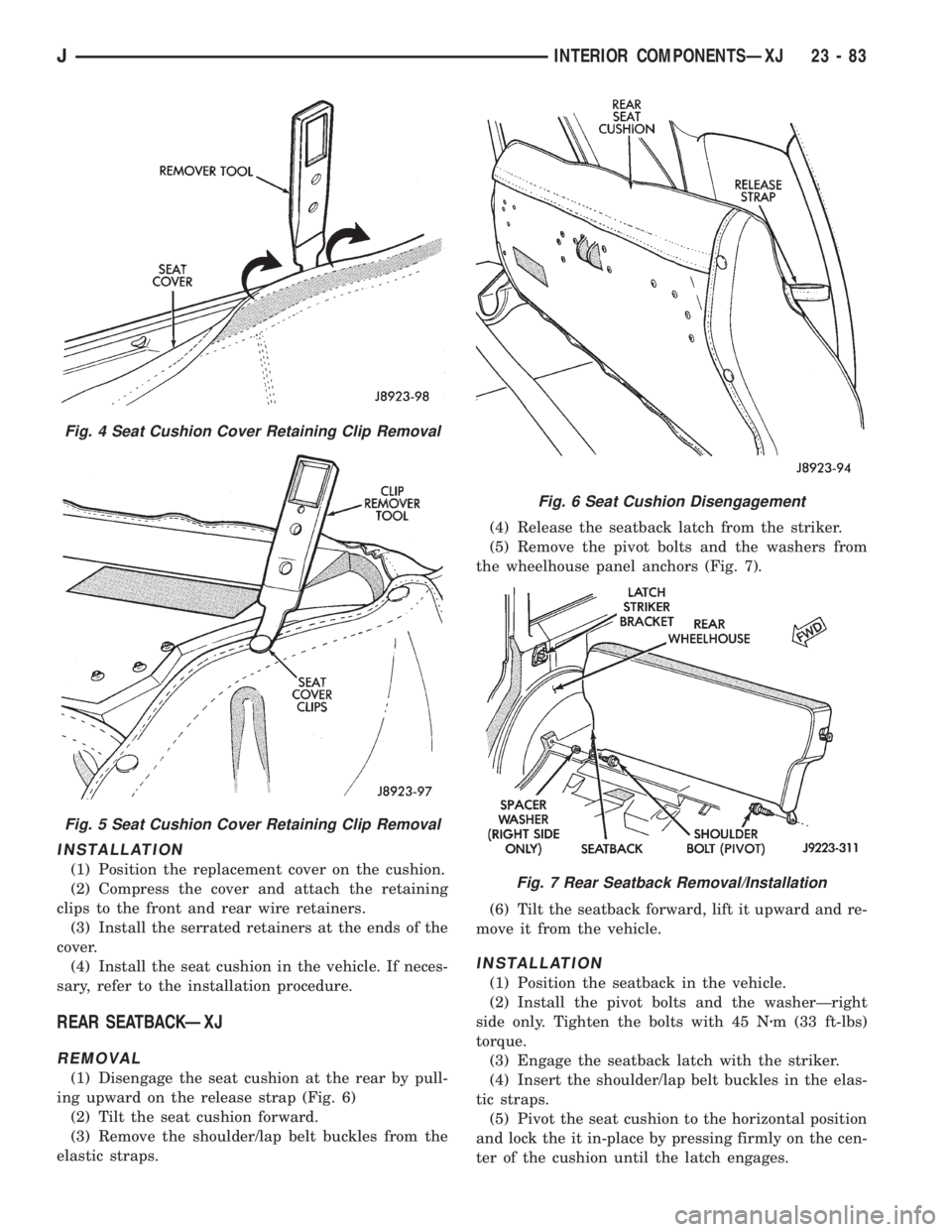

(1) Disengage the seat cushion at the rear by pull-

ing upward on the release strap (Fig. 6)

(2) Tilt the seat cushion forward.

(3) Remove the shoulder/lap belt buckles from the

elastic straps.(4) Release the seatback latch from the striker.

(5) Remove the pivot bolts and the washers from

the wheelhouse panel anchors (Fig. 7).

(6) Tilt the seatback forward, lift it upward and re-

move it from the vehicle.

INSTALLATION

(1) Position the seatback in the vehicle.

(2) Install the pivot bolts and the washerÐright

side only. Tighten the bolts with 45 Nzm (33 ft-lbs)

torque.

(3) Engage the seatback latch with the striker.

(4) Insert the shoulder/lap belt buckles in the elas-

tic straps.

(5) Pivot the seat cushion to the horizontal position

and lock the it in-place by pressing firmly on the cen-

ter of the cushion until the latch engages.

Fig. 4 Seat Cushion Cover Retaining Clip Removal

Fig. 5 Seat Cushion Cover Retaining Clip Removal

Fig. 6 Seat Cushion Disengagement

Fig. 7 Rear Seatback Removal/Installation

JINTERIOR COMPONENTSÐXJ 23 - 83