Back JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1554 of 2198

(2) Verify transmission throttle cable operation.

Repair or replace cable if necessary.

(3) Check engine throttle operation. Operate accel-

erator pedal and observe injector throttle plate move-

ment. Adjust linkage if throttle plate does not reach

wide open position.

(4) Check transmission fluid level when fluid is at

normal operating temperature. Start engine. Shift

transmission through all gear ranges then back to

Neutral. Correct level is to Full or Add mark on dip-

stick with engine at curb idle speed.

(5) Check and adjust park/neutral position switch

if necessary.

(6) Check throttle position sensor adjustment and

operation. Adjust the sensor if necessary.

MANUAL SHIFTING TEST

(1) This test determines if problem is related to

mechanical or electrical component.

(2) Stop engine and disconnect transmission con-

trol module or module fuse.

(3) Road test vehicle. Shift transmission into each

gear range. Transmission should operate as follows:

²lock in Park

²back up in Reverse

²not move in Neutral

²provide first gear only with shift lever in 1-2 posi-

tion

²operate in third gear only with shift lever in 3 po-

sition

²operate in overdrive fourth gear in D position

(4) If transmission operates as described, proceed

to next step. However, if forward gear ranges were

difficult to distinguish (all feel the same), or vehicle

would not back up, refer to diagnosis charts. Do not

perform stall or time lag tests.

CAUTION: Do not overspeed the engine during the

next test step. Ease off the throttle and allow the

vehicle to slow before downshifting.

(5) Continue road test. Manually downshift trans-

mission from D to 3, and from 3 to 1-2 position. Then

manually upshift transmission through forward

ranges again.

(6) If transmission operation is OK, perform stall,

time lag and pressure tests. If transmission shifting

problem is encountered, refer to diagnosis charts.

(7) If a problem still exists, continue testing with

DRB scan tool.

HYDRAULIC PRESSURE TEST

PRESSURE TEST PROCEDURE

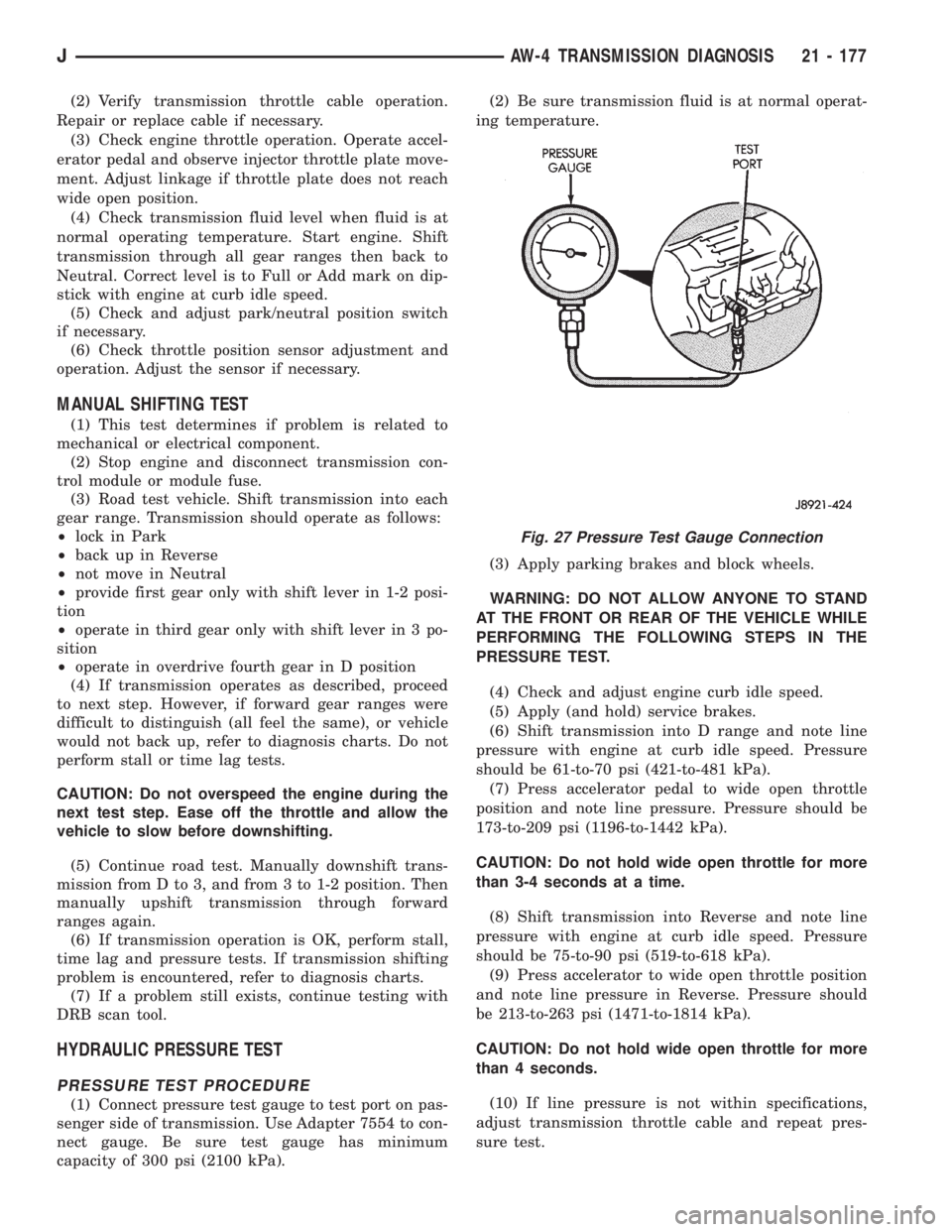

(1) Connect pressure test gauge to test port on pas-

senger side of transmission. Use Adapter 7554 to con-

nect gauge. Be sure test gauge has minimum

capacity of 300 psi (2100 kPa).(2) Be sure transmission fluid is at normal operat-

ing temperature.

(3) Apply parking brakes and block wheels.

WARNING: DO NOT ALLOW ANYONE TO STAND

AT THE FRONT OR REAR OF THE VEHICLE WHILE

PERFORMING THE FOLLOWING STEPS IN THE

PRESSURE TEST.

(4) Check and adjust engine curb idle speed.

(5) Apply (and hold) service brakes.

(6) Shift transmission into D range and note line

pressure with engine at curb idle speed. Pressure

should be 61-to-70 psi (421-to-481 kPa).

(7) Press accelerator pedal to wide open throttle

position and note line pressure. Pressure should be

173-to-209 psi (1196-to-1442 kPa).

CAUTION: Do not hold wide open throttle for more

than 3-4 seconds at a time.

(8) Shift transmission into Reverse and note line

pressure with engine at curb idle speed. Pressure

should be 75-to-90 psi (519-to-618 kPa).

(9) Press accelerator to wide open throttle position

and note line pressure in Reverse. Pressure should

be 213-to-263 psi (1471-to-1814 kPa).

CAUTION: Do not hold wide open throttle for more

than 4 seconds.

(10) If line pressure is not within specifications,

adjust transmission throttle cable and repeat pres-

sure test.

Fig. 27 Pressure Test Gauge Connection

JAW-4 TRANSMISSION DIAGNOSIS 21 - 177

Page 1556 of 2198

(3) Apply parking brakes and turn off air condi-

tioning unit.

(4) Shift transfer case into 2H range.

(5) Start engine and check curb idle speed. Adjust

speed if necessary. Curb idle must be correct to en-

sure accurate test results.

(6) Shift transmission into Neutral and set stop

watch.

(7) During following test steps, start stop watch as

soon as shift lever reaches D and Reverse ranges.

(8) Shift transmission into D range and record

time it takes for engagement. Repeat test two more

times.

(9) Reset stop watch and shift transmission back to

Neutral.

(10) Shift transmission into Reverse and record

time it takes for engagement. Repeat test two more

times.(11) Engagement time in D range should be a max-

imum of 1.2 seconds. Engagement time for Reverse

should be a maximum of 1.5 seconds.

TIME LAG TEST ANALYSIS

If engagement time is longer than specified for D

range, check for the following:

²shift cable misadjusted

²line pressure low

²forward clutch worn

²overdrive clutch worn or damaged

If engagement time is longer than specified for Re-

verse, check for the following:

²shift cable misadjusted

²line pressure low

²direct clutch worn

²first/reverse brake worn

²overdrive clutch worn or damaged

JAW-4 TRANSMISSION DIAGNOSIS 21 - 179

Page 1559 of 2198

AW-4 IN-VEHICLE SERVICE

INDEX

page page

Accumulator Pistons and Springs............. 189

Adapter Housing Seal Replacement........... 191

Checking Fluid Level and Condition........... 182

Manual Valve Shaft Seal Replacement......... 187

Park Interlock Cable Adjustment............. 195

Park Rod and Pawl Service................. 190

Park/Neutral Position Switch................ 183

Refilling After Overhaul or Fluid/Filter Change . . . 182

Second Coast Brake Servo................. 190

Shift Cable Adjustment.................... 195

Speed Sensor........................... 192Speed Sensor RotorÐSpeedometer Drive Gear . . 193

Throttle Position Sensor (TPS) Service........ 193

Transmission Control Module (TCM) Service.... 183

Transmission Cooler Line Fittings............ 197

Transmission Cooler Service................ 196

Transmission Throttle Cable Adjustment........ 194

Transmission Throttle Cable Replacement...... 193

Transmission Valve Body Installation.......... 187

Transmission Valve Body Removal........... 186

Transmission Valve Body Solenoids........... 184

CHECKING FLUID LEVEL AND CONDITION

Recommended fluid for AW-4 transmissions is Mo-

par Dexron IIE/Mercon.

Mopar Dexron II can also be used but only when

Mercon fluid is not available.

CHECKING FLUID LEVEL

(1) Be sure transmission fluid is at normal operat-

ing temperature. Normal operating temperature is

reached after approximately 15 miles (25 km) of op-

eration.

(2) Position vehicle on level surface. This is impor-

tant for an accurate fluid level check.

(3) Shift transmission through all gear ranges and

back to Park.

(4) Apply parking brakes.

(5) Verify that transmission is in Park.

(6) Wipe off dipstick handle to prevent dirt from

entering fill tube. Then remove dipstick and check

fluid level and condition.

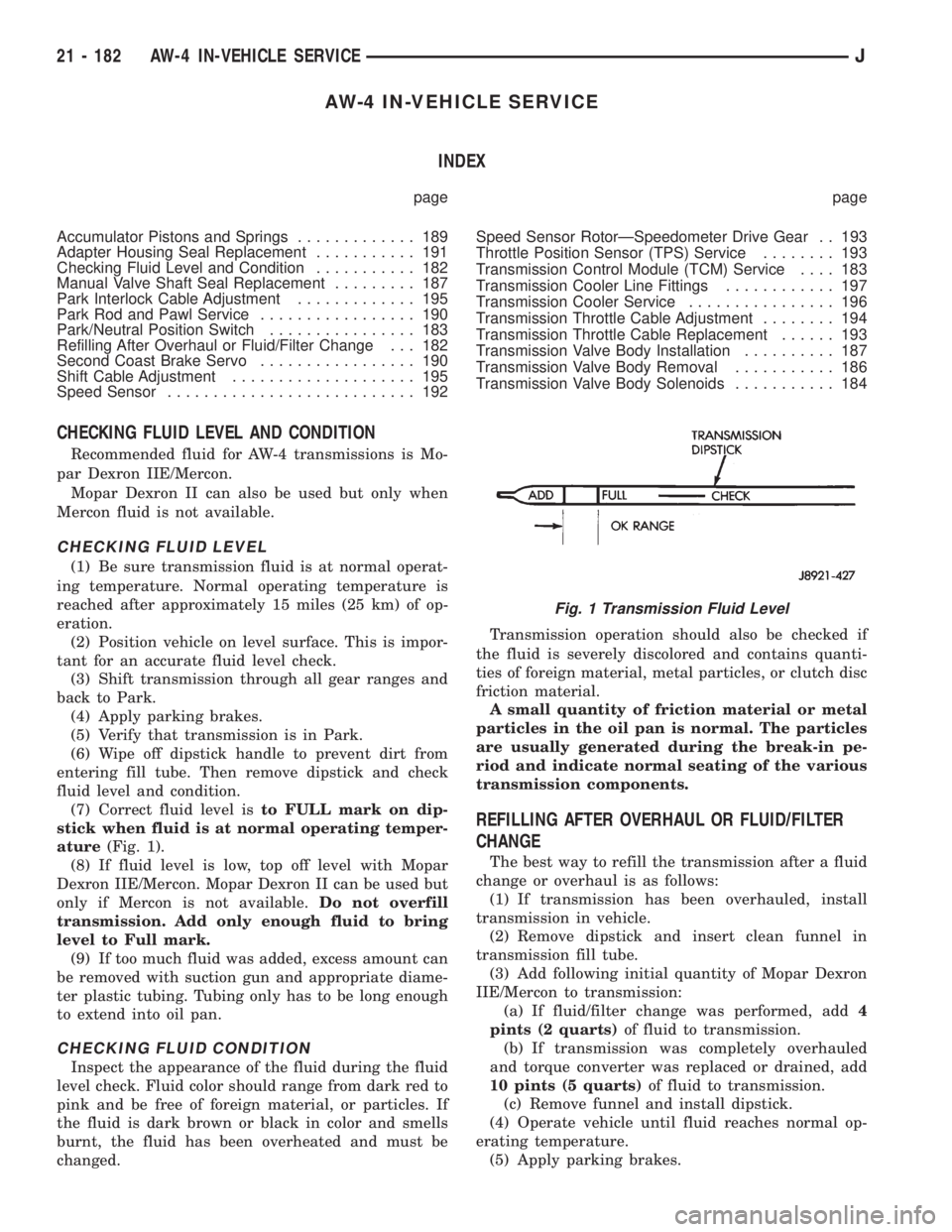

(7) Correct fluid level isto FULL mark on dip-

stick when fluid is at normal operating temper-

ature(Fig. 1).

(8) If fluid level is low, top off level with Mopar

Dexron IIE/Mercon. Mopar Dexron II can be used but

only if Mercon is not available.Do not overfill

transmission. Add only enough fluid to bring

level to Full mark.

(9) If too much fluid was added, excess amount can

be removed with suction gun and appropriate diame-

ter plastic tubing. Tubing only has to be long enough

to extend into oil pan.

CHECKING FLUID CONDITION

Inspect the appearance of the fluid during the fluid

level check. Fluid color should range from dark red to

pink and be free of foreign material, or particles. If

the fluid is dark brown or black in color and smells

burnt, the fluid has been overheated and must be

changed.Transmission operation should also be checked if

the fluid is severely discolored and contains quanti-

ties of foreign material, metal particles, or clutch disc

friction material.

A small quantity of friction material or metal

particles in the oil pan is normal. The particles

are usually generated during the break-in pe-

riod and indicate normal seating of the various

transmission components.

REFILLING AFTER OVERHAUL OR FLUID/FILTER

CHANGE

The best way to refill the transmission after a fluid

change or overhaul is as follows:

(1) If transmission has been overhauled, install

transmission in vehicle.

(2) Remove dipstick and insert clean funnel in

transmission fill tube.

(3) Add following initial quantity of Mopar Dexron

IIE/Mercon to transmission:

(a) If fluid/filter change was performed, add4

pints (2 quarts)of fluid to transmission.

(b) If transmission was completely overhauled

and torque converter was replaced or drained, add

10 pints (5 quarts)of fluid to transmission.

(c) Remove funnel and install dipstick.

(4) Operate vehicle until fluid reaches normal op-

erating temperature.

(5) Apply parking brakes.

Fig. 1 Transmission Fluid Level

21 - 182 AW-4 IN-VEHICLE SERVICEJ

Page 1560 of 2198

(6) Let engine run at normal curb idle speed, apply

service brakes. Then shift transmission through all

gear ranges and back to PARK (leave engine run-

ning).

(7) Remove dipstick and check fluid level. Add only

enough fluid to bring level to Full mark on dipstick.

Do not overfill.If too much fluid is added, excess

amount can be removed with suction gun and

plastic tubing. Tubing only has to be long

enough to extend into oil pan.

(8) When fluid level is correct, shut engine off, re-

lease park brake, remove funnel, and reseat dipstick

in fill tube.

TRANSMISSION CONTROL MODULE (TCM)

SERVICE

Use the DRB scan tool to diagnose transmission

control module function whenever a fault is sus-

pected. Replace the module only when the scan tool

indicates the module is actually faulty.

TRANSMISSION CONTROL MODULE

REPLACEMENT

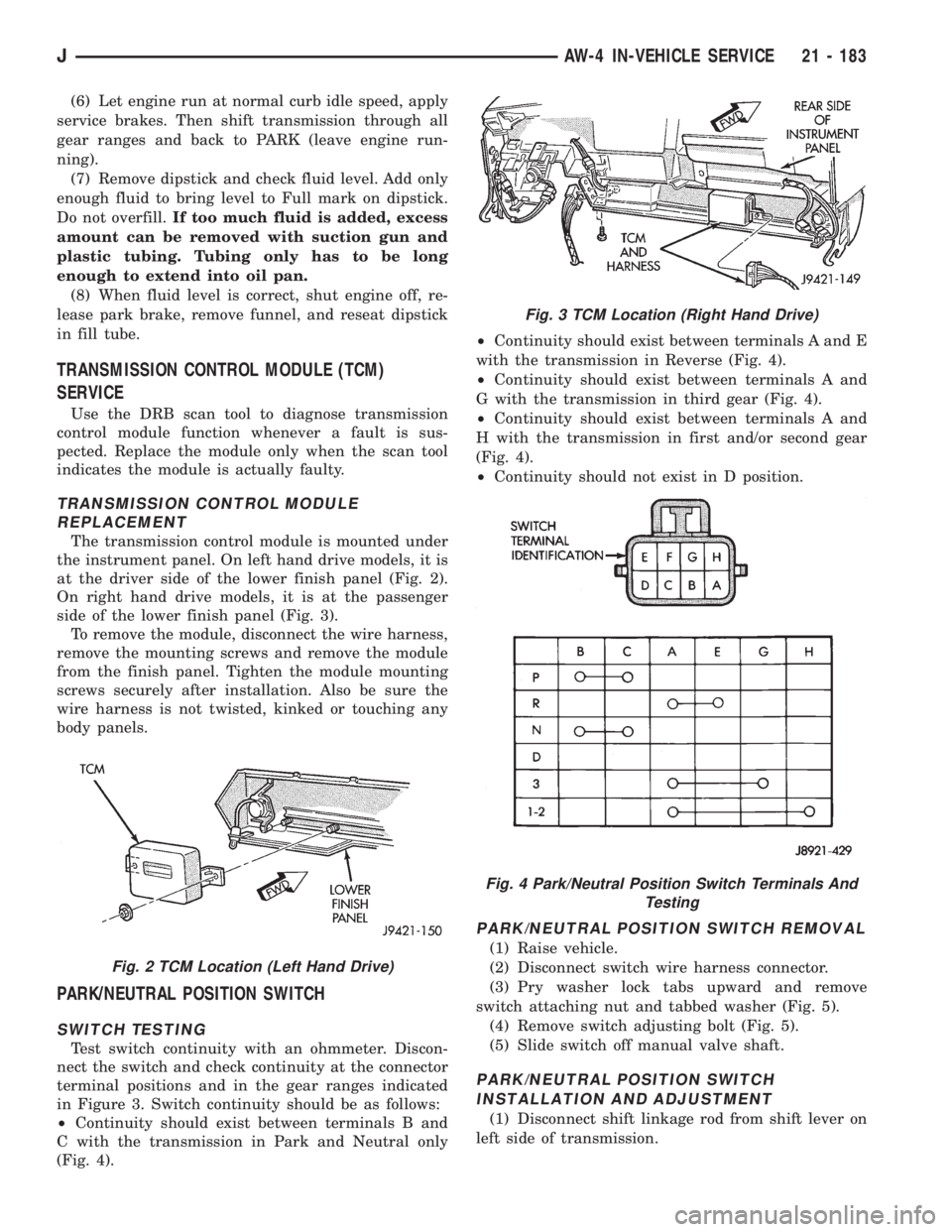

The transmission control module is mounted under

the instrument panel. On left hand drive models, it is

at the driver side of the lower finish panel (Fig. 2).

On right hand drive models, it is at the passenger

side of the lower finish panel (Fig. 3).

To remove the module, disconnect the wire harness,

remove the mounting screws and remove the module

from the finish panel. Tighten the module mounting

screws securely after installation. Also be sure the

wire harness is not twisted, kinked or touching any

body panels.

PARK/NEUTRAL POSITION SWITCH

SWITCH TESTING

Test switch continuity with an ohmmeter. Discon-

nect the switch and check continuity at the connector

terminal positions and in the gear ranges indicated

in Figure 3. Switch continuity should be as follows:

²Continuity should exist between terminals B and

C with the transmission in Park and Neutral only

(Fig. 4).²Continuity should exist between terminals A and E

with the transmission in Reverse (Fig. 4).

²Continuity should exist between terminals A and

G with the transmission in third gear (Fig. 4).

²Continuity should exist between terminals A and

H with the transmission in first and/or second gear

(Fig. 4).

²Continuity should not exist in D position.

PARK/NEUTRAL POSITION SWITCH REMOVAL

(1) Raise vehicle.

(2) Disconnect switch wire harness connector.

(3) Pry washer lock tabs upward and remove

switch attaching nut and tabbed washer (Fig. 5).

(4) Remove switch adjusting bolt (Fig. 5).

(5) Slide switch off manual valve shaft.

PARK/NEUTRAL POSITION SWITCH

INSTALLATION AND ADJUSTMENT

(1) Disconnect shift linkage rod from shift lever on

left side of transmission.

Fig. 2 TCM Location (Left Hand Drive)

Fig. 3 TCM Location (Right Hand Drive)

Fig. 4 Park/Neutral Position Switch Terminals And

Testing

JAW-4 IN-VEHICLE SERVICE 21 - 183

Page 1571 of 2198

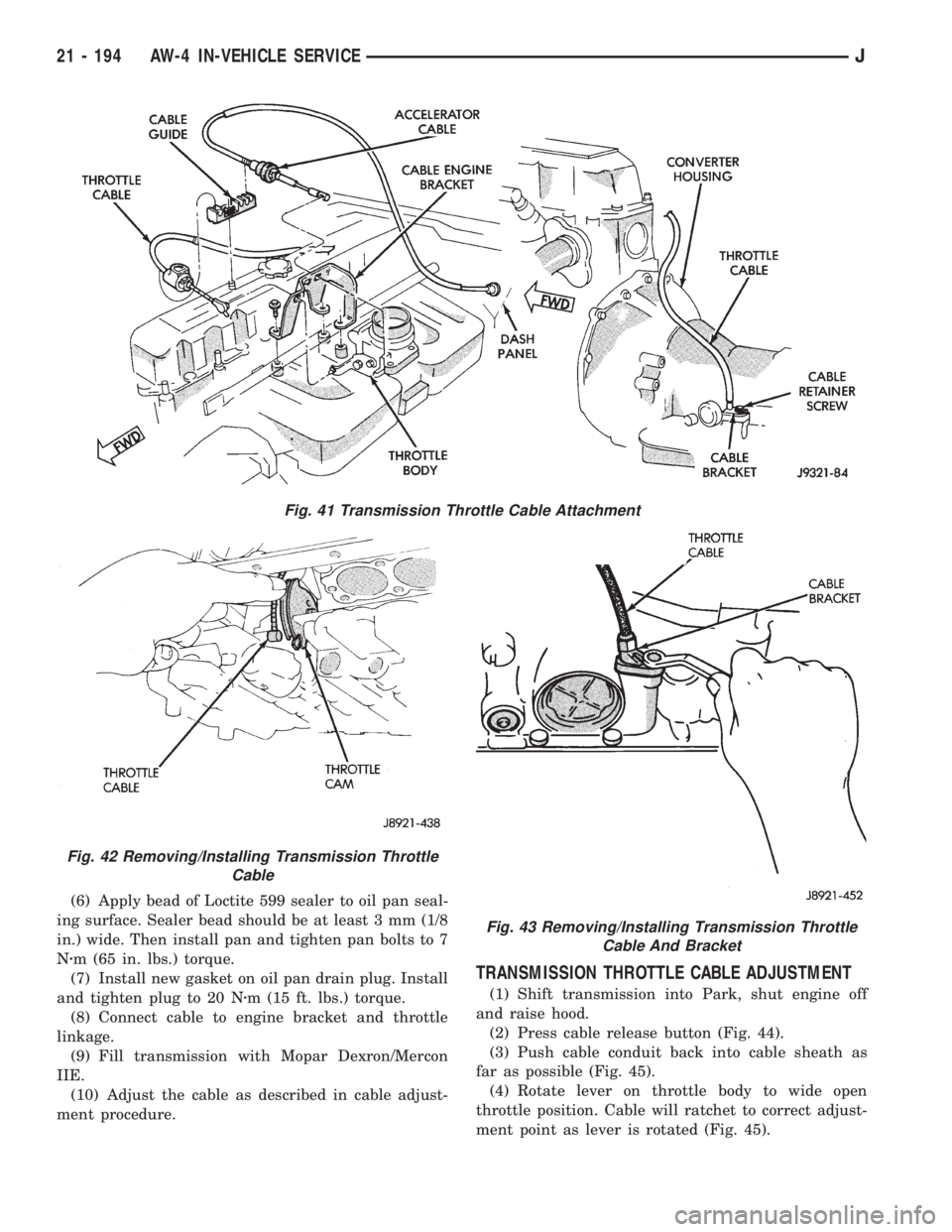

(6) Apply bead of Loctite 599 sealer to oil pan seal-

ing surface. Sealer bead should be at least 3 mm (1/8

in.) wide. Then install pan and tighten pan bolts to 7

Nzm (65 in. lbs.) torque.

(7) Install new gasket on oil pan drain plug. Install

and tighten plug to 20 Nzm (15 ft. lbs.) torque.

(8) Connect cable to engine bracket and throttle

linkage.

(9) Fill transmission with Mopar Dexron/Mercon

IIE.

(10) Adjust the cable as described in cable adjust-

ment procedure.

TRANSMISSION THROTTLE CABLE ADJUSTMENT

(1) Shift transmission into Park, shut engine off

and raise hood.

(2) Press cable release button (Fig. 44).

(3) Push cable conduit back into cable sheath as

far as possible (Fig. 45).

(4) Rotate lever on throttle body to wide open

throttle position. Cable will ratchet to correct adjust-

ment point as lever is rotated (Fig. 45).

Fig. 43 Removing/Installing Transmission Throttle

Cable And Bracket

Fig. 41 Transmission Throttle Cable Attachment

Fig. 42 Removing/Installing Transmission Throttle

Cable

21 - 194 AW-4 IN-VEHICLE SERVICEJ

Page 1573 of 2198

(a) Check movement of release shift handle but-

ton (floor shift) or release lever (column shift). You

should not be able to press button inward or move

column lever.

(b) Turn ignition switch to On position.

(c) Press floor shift lever release button or move

column lever. Then shift into Neutral. If cable ad-

justment is correct, ignition switch can not be

turned to Lock position. Perform same check with

transmission in D range.

(7) Move shift lever back to Park and check igni-

tion switch operation. You should be able to turn

switch to Lock position and shift lever release button/

lever should not move.

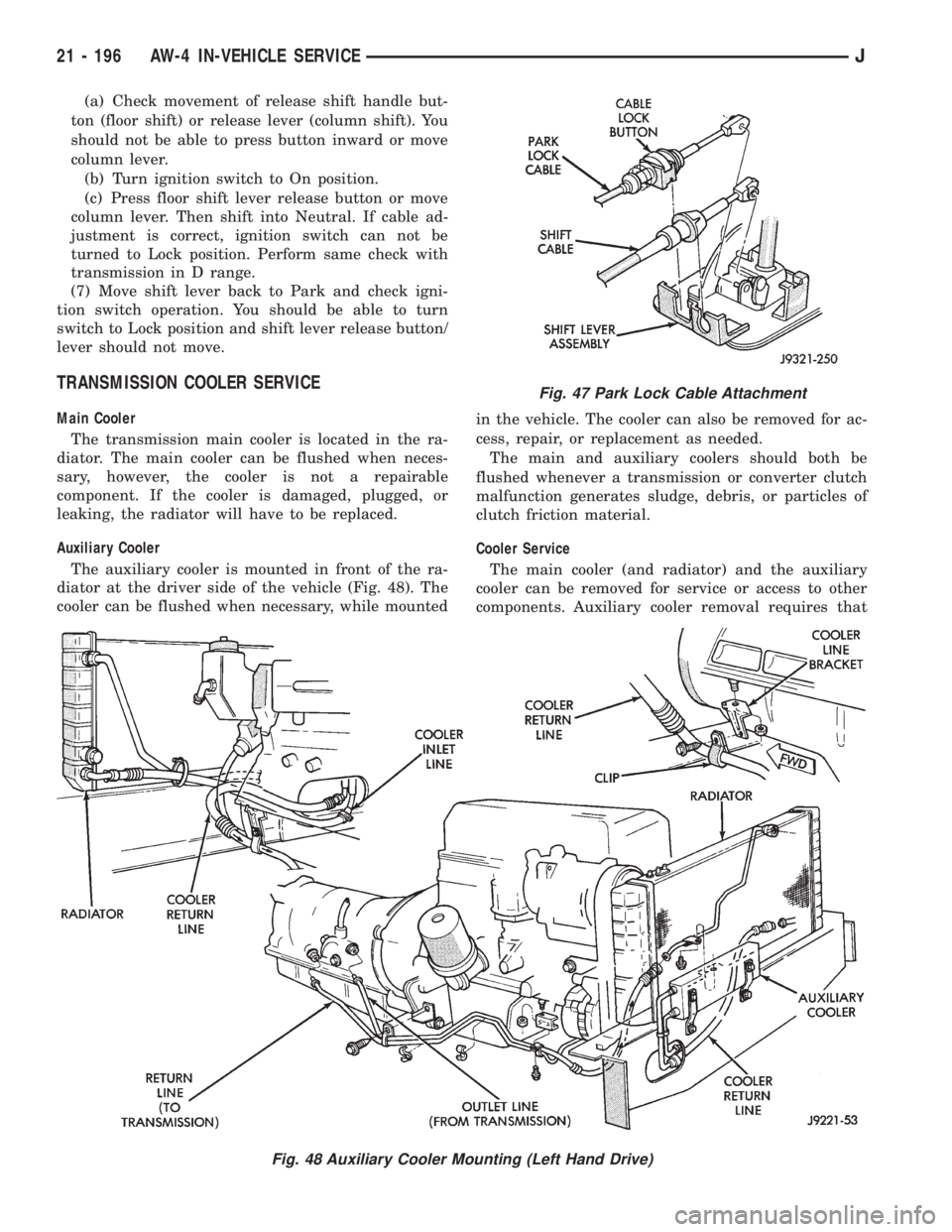

TRANSMISSION COOLER SERVICE

Main Cooler

The transmission main cooler is located in the ra-

diator. The main cooler can be flushed when neces-

sary, however, the cooler is not a repairable

component. If the cooler is damaged, plugged, or

leaking, the radiator will have to be replaced.

Auxiliary Cooler

The auxiliary cooler is mounted in front of the ra-

diator at the driver side of the vehicle (Fig. 48). The

cooler can be flushed when necessary, while mountedin the vehicle. The cooler can also be removed for ac-

cess, repair, or replacement as needed.

The main and auxiliary coolers should both be

flushed whenever a transmission or converter clutch

malfunction generates sludge, debris, or particles of

clutch friction material.

Cooler Service

The main cooler (and radiator) and the auxiliary

cooler can be removed for service or access to other

components. Auxiliary cooler removal requires that

Fig. 47 Park Lock Cable Attachment

Fig. 48 Auxiliary Cooler Mounting (Left Hand Drive)

21 - 196 AW-4 IN-VEHICLE SERVICEJ

Page 1574 of 2198

the front bumper and radiator support be removed

for access to the cooler lines and attaching bracket.

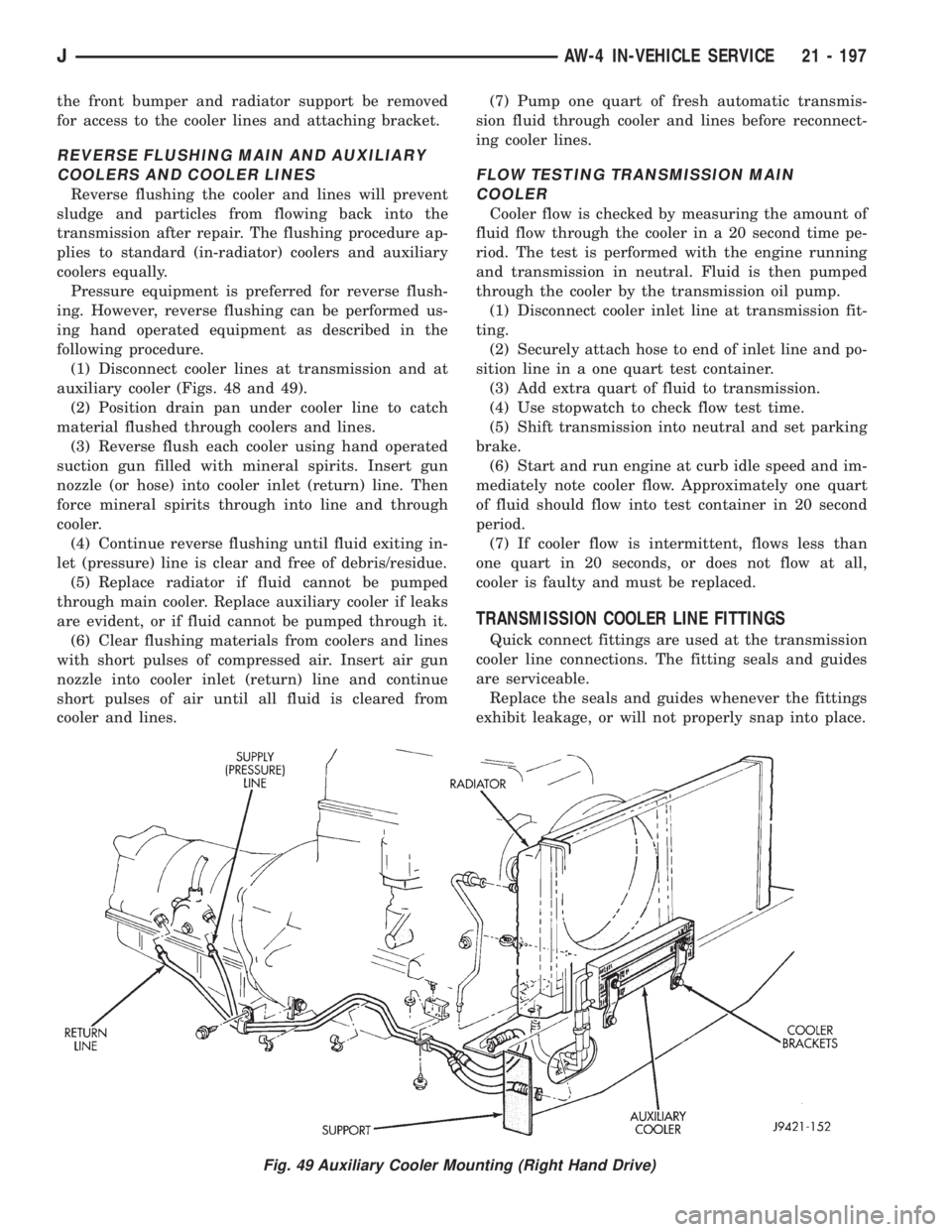

REVERSE FLUSHING MAIN AND AUXILIARY

COOLERS AND COOLER LINES

Reverse flushing the cooler and lines will prevent

sludge and particles from flowing back into the

transmission after repair. The flushing procedure ap-

plies to standard (in-radiator) coolers and auxiliary

coolers equally.

Pressure equipment is preferred for reverse flush-

ing. However, reverse flushing can be performed us-

ing hand operated equipment as described in the

following procedure.

(1) Disconnect cooler lines at transmission and at

auxiliary cooler (Figs. 48 and 49).

(2) Position drain pan under cooler line to catch

material flushed through coolers and lines.

(3) Reverse flush each cooler using hand operated

suction gun filled with mineral spirits. Insert gun

nozzle (or hose) into cooler inlet (return) line. Then

force mineral spirits through into line and through

cooler.

(4) Continue reverse flushing until fluid exiting in-

let (pressure) line is clear and free of debris/residue.

(5) Replace radiator if fluid cannot be pumped

through main cooler. Replace auxiliary cooler if leaks

are evident, or if fluid cannot be pumped through it.

(6) Clear flushing materials from coolers and lines

with short pulses of compressed air. Insert air gun

nozzle into cooler inlet (return) line and continue

short pulses of air until all fluid is cleared from

cooler and lines.(7) Pump one quart of fresh automatic transmis-

sion fluid through cooler and lines before reconnect-

ing cooler lines.

FLOW TESTING TRANSMISSION MAIN

COOLER

Cooler flow is checked by measuring the amount of

fluid flow through the cooler in a 20 second time pe-

riod. The test is performed with the engine running

and transmission in neutral. Fluid is then pumped

through the cooler by the transmission oil pump.

(1) Disconnect cooler inlet line at transmission fit-

ting.

(2) Securely attach hose to end of inlet line and po-

sition line in a one quart test container.

(3) Add extra quart of fluid to transmission.

(4) Use stopwatch to check flow test time.

(5) Shift transmission into neutral and set parking

brake.

(6) Start and run engine at curb idle speed and im-

mediately note cooler flow. Approximately one quart

of fluid should flow into test container in 20 second

period.

(7) If cooler flow is intermittent, flows less than

one quart in 20 seconds, or does not flow at all,

cooler is faulty and must be replaced.

TRANSMISSION COOLER LINE FITTINGS

Quick connect fittings are used at the transmission

cooler line connections. The fitting seals and guides

are serviceable.

Replace the seals and guides whenever the fittings

exhibit leakage, or will not properly snap into place.

Fig. 49 Auxiliary Cooler Mounting (Right Hand Drive)

JAW-4 IN-VEHICLE SERVICE 21 - 197

Page 1635 of 2198

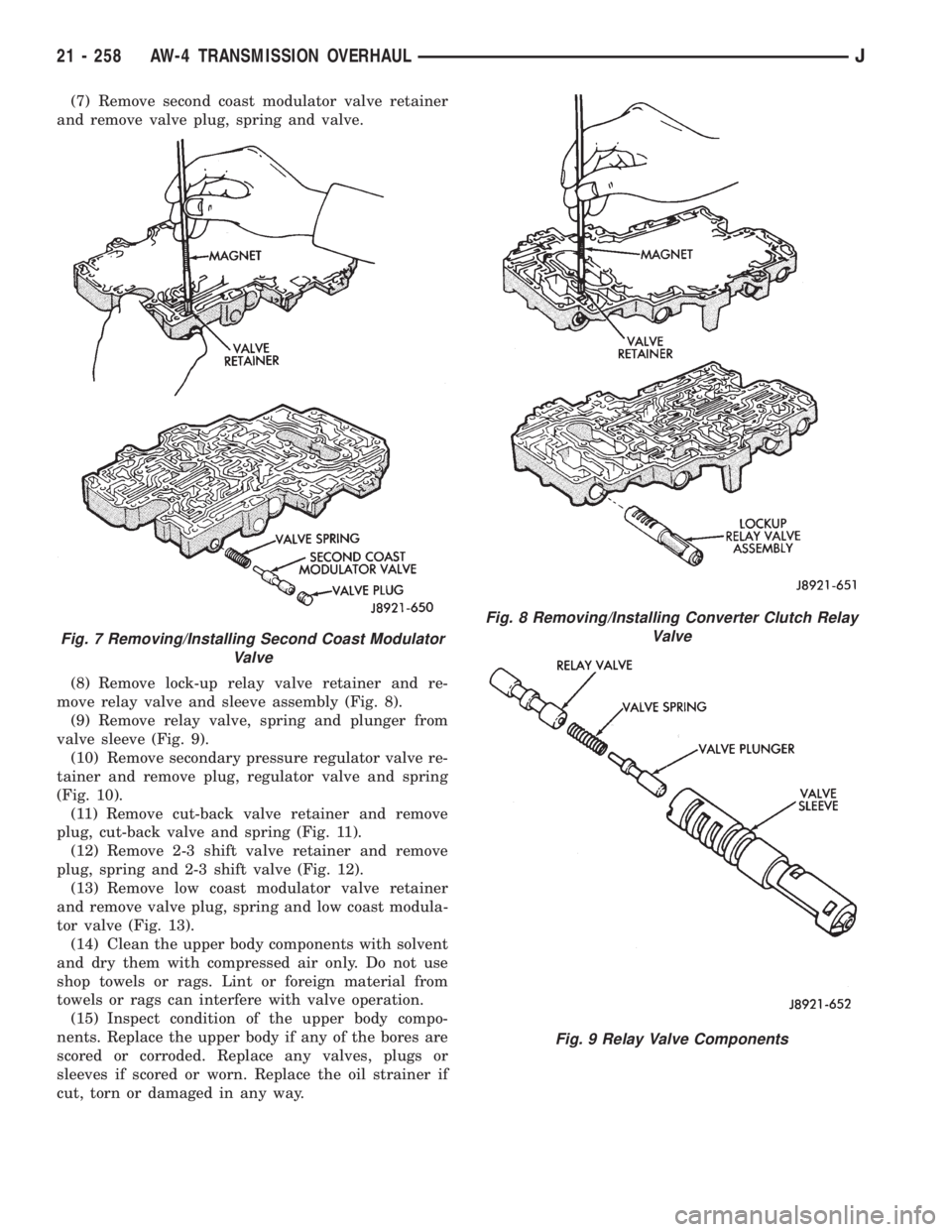

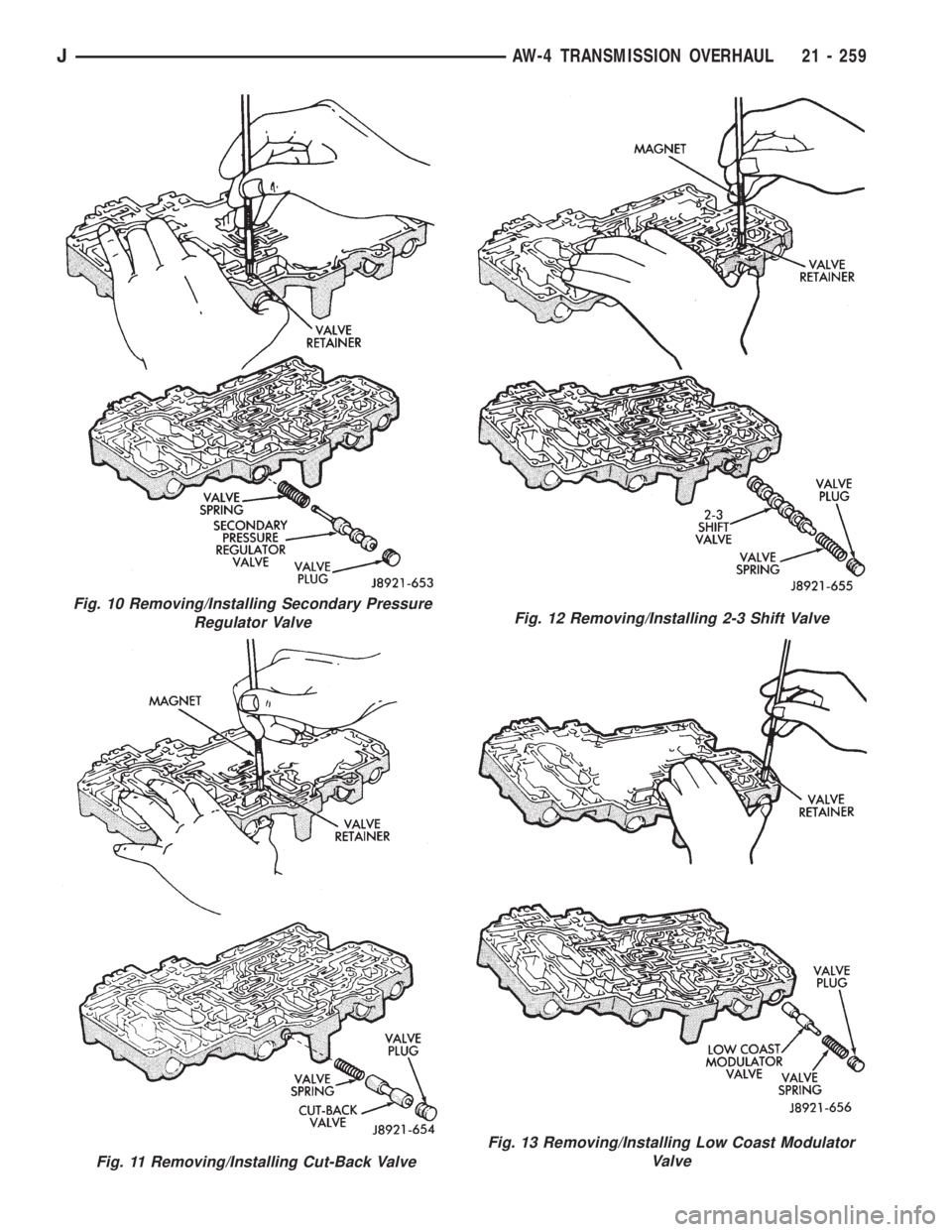

(7) Remove second coast modulator valve retainer

and remove valve plug, spring and valve.

(8) Remove lock-up relay valve retainer and re-

move relay valve and sleeve assembly (Fig. 8).

(9) Remove relay valve, spring and plunger from

valve sleeve (Fig. 9).

(10) Remove secondary pressure regulator valve re-

tainer and remove plug, regulator valve and spring

(Fig. 10).

(11) Remove cut-back valve retainer and remove

plug, cut-back valve and spring (Fig. 11).

(12) Remove 2-3 shift valve retainer and remove

plug, spring and 2-3 shift valve (Fig. 12).

(13) Remove low coast modulator valve retainer

and remove valve plug, spring and low coast modula-

tor valve (Fig. 13).

(14) Clean the upper body components with solvent

and dry them with compressed air only. Do not use

shop towels or rags. Lint or foreign material from

towels or rags can interfere with valve operation.

(15) Inspect condition of the upper body compo-

nents. Replace the upper body if any of the bores are

scored or corroded. Replace any valves, plugs or

sleeves if scored or worn. Replace the oil strainer if

cut, torn or damaged in any way.

Fig. 7 Removing/Installing Second Coast Modulator

Valve

Fig. 8 Removing/Installing Converter Clutch Relay

Valve

Fig. 9 Relay Valve Components

21 - 258 AW-4 TRANSMISSION OVERHAULJ

Page 1636 of 2198

Fig. 10 Removing/Installing Secondary Pressure

Regulator Valve

Fig. 11 Removing/Installing Cut-Back Valve

Fig. 12 Removing/Installing 2-3 Shift Valve

Fig. 13 Removing/Installing Low Coast Modulator

Valve

JAW-4 TRANSMISSION OVERHAUL 21 - 259

Page 1637 of 2198

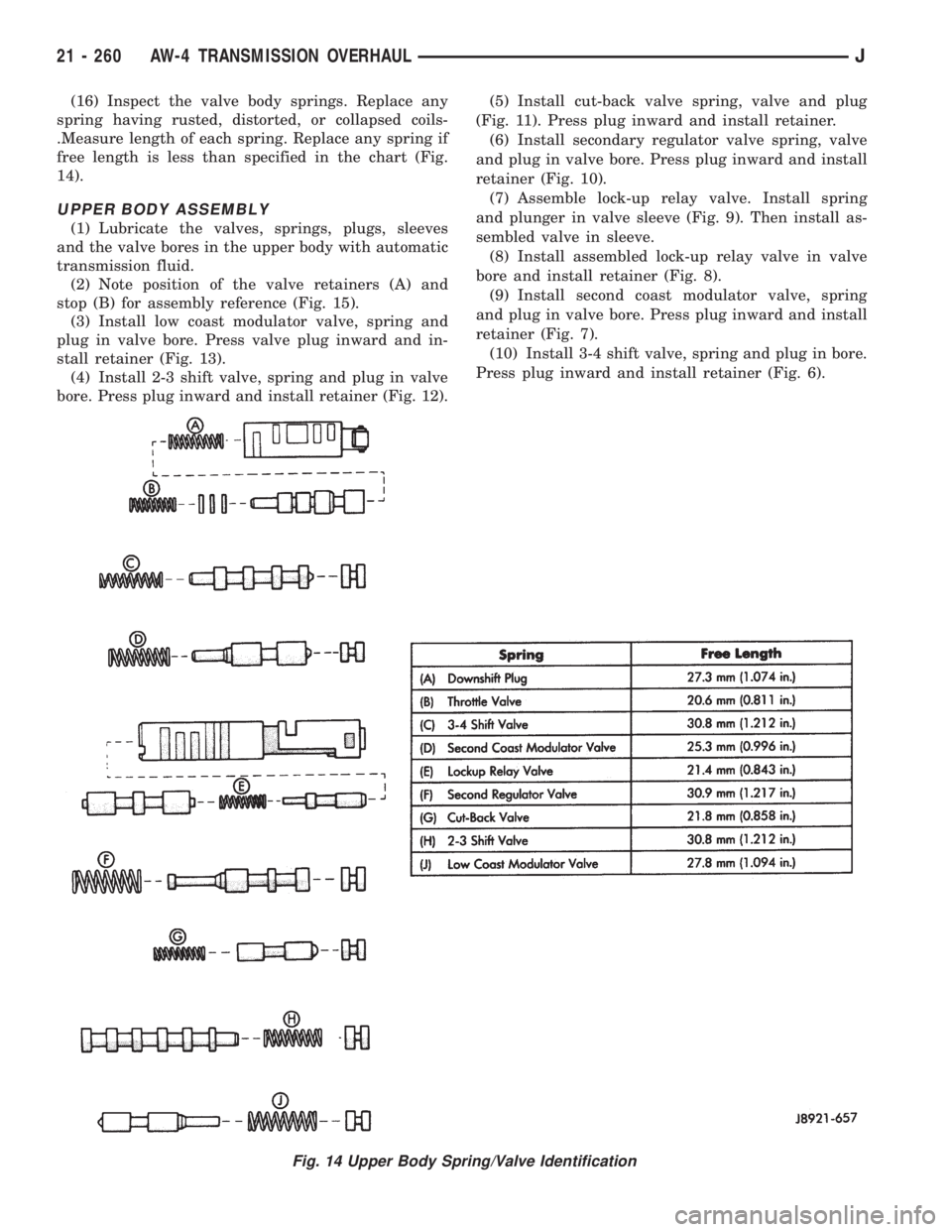

(16) Inspect the valve body springs. Replace any

spring having rusted, distorted, or collapsed coils-

.Measure length of each spring. Replace any spring if

free length is less than specified in the chart (Fig.

14).

UPPER BODY ASSEMBLY

(1) Lubricate the valves, springs, plugs, sleeves

and the valve bores in the upper body with automatic

transmission fluid.

(2) Note position of the valve retainers (A) and

stop (B) for assembly reference (Fig. 15).

(3) Install low coast modulator valve, spring and

plug in valve bore. Press valve plug inward and in-

stall retainer (Fig. 13).

(4) Install 2-3 shift valve, spring and plug in valve

bore. Press plug inward and install retainer (Fig. 12).(5) Install cut-back valve spring, valve and plug

(Fig. 11). Press plug inward and install retainer.

(6) Install secondary regulator valve spring, valve

and plug in valve bore. Press plug inward and install

retainer (Fig. 10).

(7) Assemble lock-up relay valve. Install spring

and plunger in valve sleeve (Fig. 9). Then install as-

sembled valve in sleeve.

(8) Install assembled lock-up relay valve in valve

bore and install retainer (Fig. 8).

(9) Install second coast modulator valve, spring

and plug in valve bore. Press plug inward and install

retainer (Fig. 7).

(10) Install 3-4 shift valve, spring and plug in bore.

Press plug inward and install retainer (Fig. 6).

Fig. 14 Upper Body Spring/Valve Identification

21 - 260 AW-4 TRANSMISSION OVERHAULJ