abs ring JEEP CHEROKEE 1995 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 51 of 2198

The shock absorber bushings do not require any

type of lubrication. Do not lubricate the bushings to

reduce bushing noise. Grease or mineral oil-base lu-

bricants will deteriorate the bushing rubber.

The shock absorbers are not refillable or adjustable.

If a malfunction occurs, the shock absorber must be

replaced. To test a shock absorber, hold it in an up-

right position and force the piston into and out of the

cylinder four or five times. The action throughout

each stroke should be smooth and even.

SHOCK ABSORBER

REMOVAL

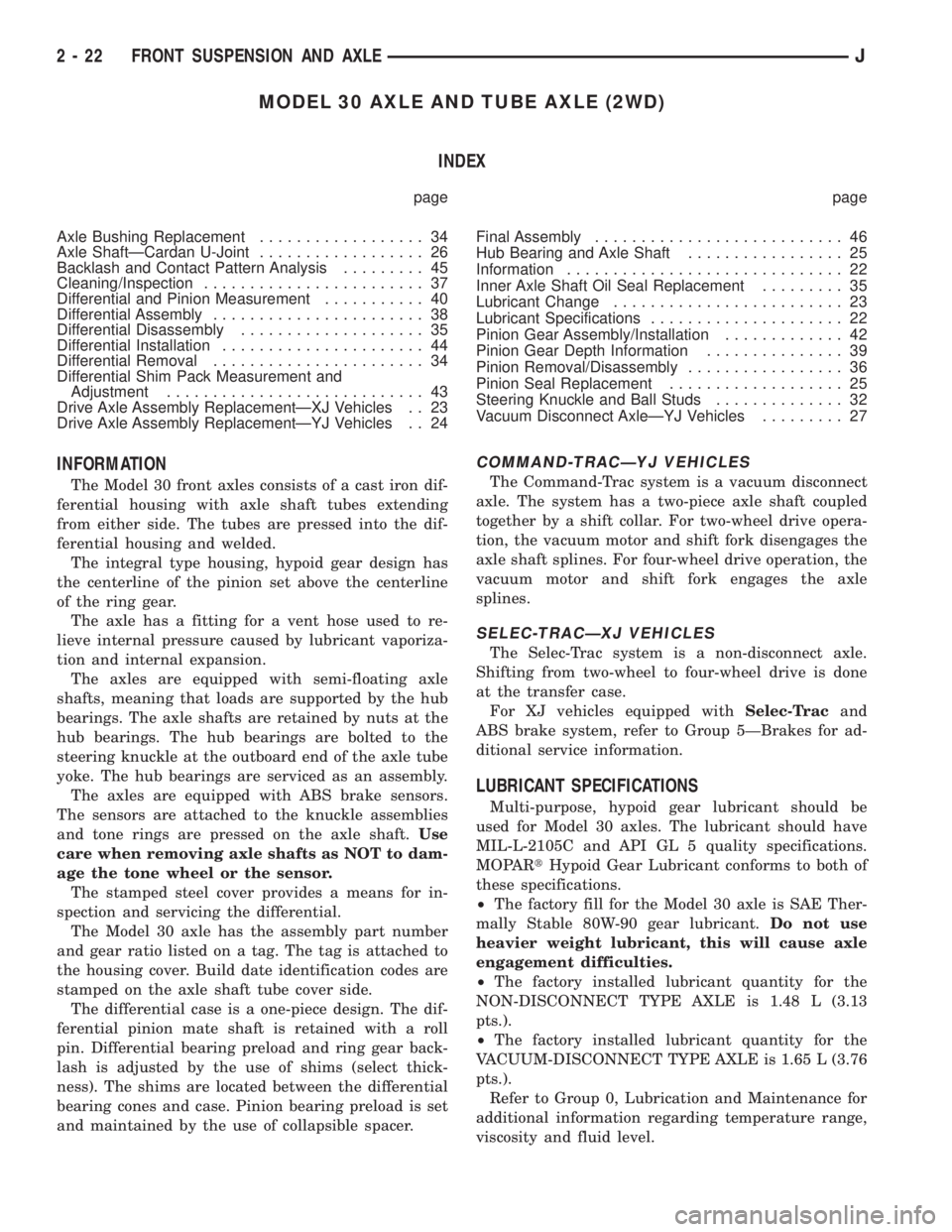

(1) Remove the nut, retainer and grommet from the

upper stud on the frame bracket (Fig. 3).

(2) Raise and support the vehicle.

(3) Remove the nut, washers and bolt from the

shock absorber lower eye (Fig.3).

(4) Remove the shock absorber.

(5) Remove the remaining grommet and retainer

from the shock absorber stud.

INSTALLATION

(1) Position the lower retainer and grommet on the

upper stud. Insert the shock absorber through the

shock tower hole.

(2) Install the lower bolts and nuts. Tighten the

nuts to 61 Nzm (45 ft. lbs.) torque.

(3) Install the upper grommet and retainer on the

stud on the frame bracket. Install the nut and tighten

to 12 Nzm (9 ft. lbs.) torque.

LEAF SPRING

REMOVAL

(1) Raise the vehicle.

(2) Support the vehicle with jack stands placed un-

der the frame.

(3) Position a hydraulic jack under the axle. Raise

the axle to relieve the axle weight from the springs.

(4) Remove the stabilizer bar links attaching nut.

(5) Remove the nuts, the U-bolts and spring

bracket from the axle.

(6) Remove the nut and bolt that attaches the

spring front eye to the shackle (Fig. 3).

(7) Remove the nut and bolt from the spring rear

eye.

(8) Remove the spring from the vehicle.

The spring can be disassembled by removing

the spring clips and the center bolt. If the

spring bushings require replacement, refer to

the bushing removal and installation proce-

dures.

INSTALLATION

(1) Position the spring front eye in the shackle.

Loosely install the attaching bolt and nut. Do not

tighten at this time.

(2) Position the rear eye in the hanger bracket.

Loosely install the attaching bolt and nut (Fig. 3). Do

not tighten at this time.

(3) Position the axle. Install the spring bracket,

U-bolts and nuts (Fig. 3). Tighten the U-bolt nuts to

122 Nzm (90 ft. lbs.) torque.

(4) Attach the stabilizer bar links.

(5) Remove the hydraulic jack.

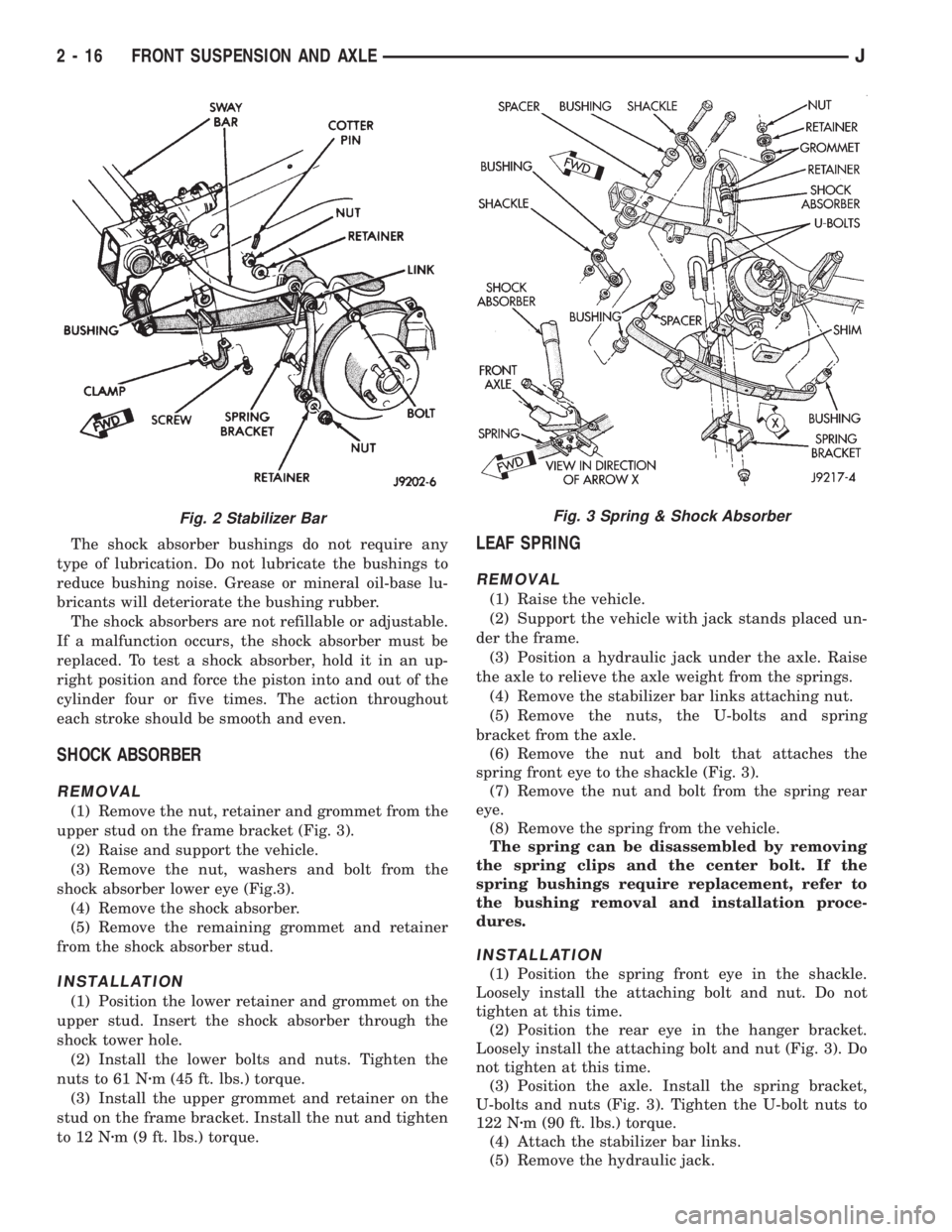

Fig. 2 Stabilizer BarFig. 3 Spring & Shock Absorber

2 - 16 FRONT SUSPENSION AND AXLEJ

Page 57 of 2198

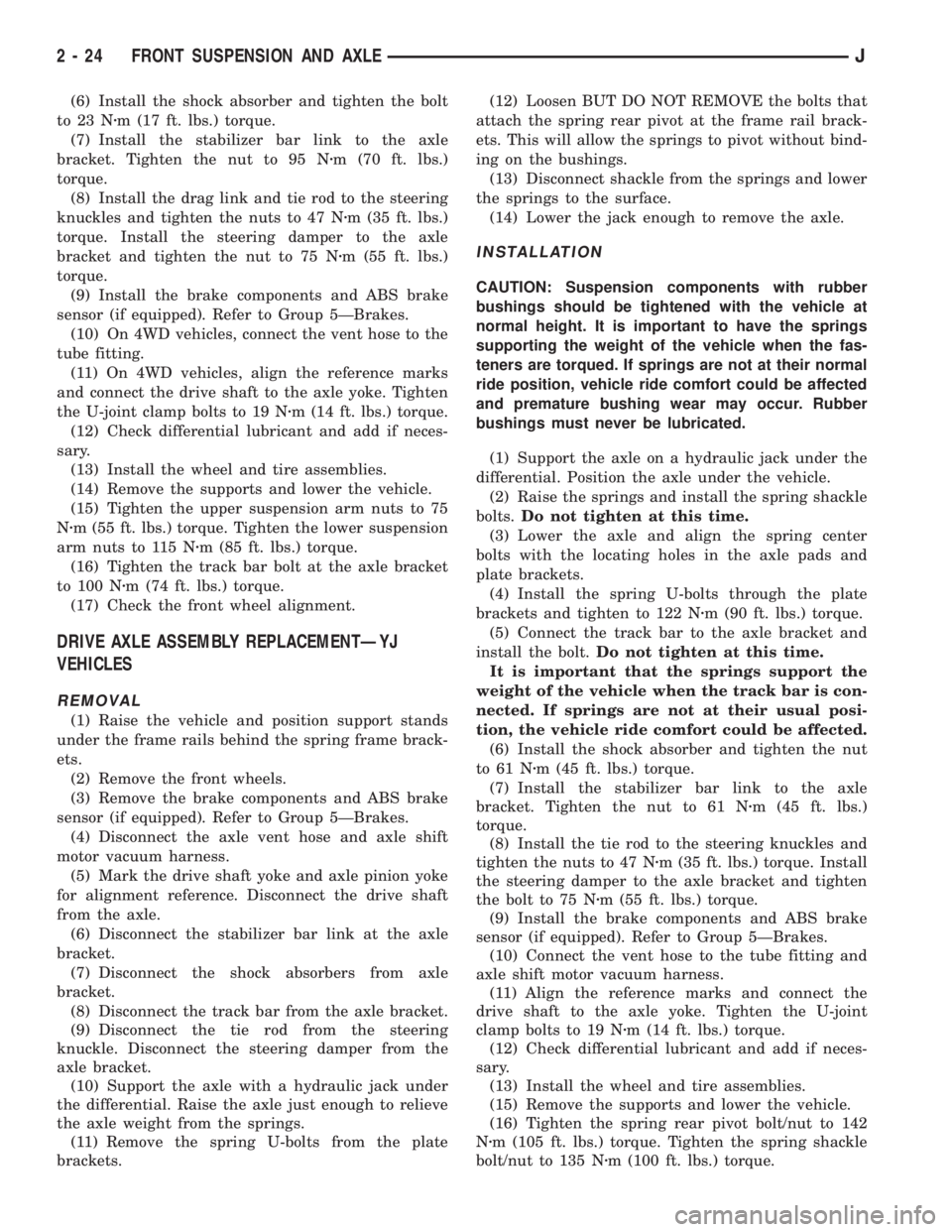

MODEL 30 AXLE AND TUBE AXLE (2WD)

INDEX

page page

Axle Bushing Replacement.................. 34

Axle ShaftÐCardan U-Joint.................. 26

Backlash and Contact Pattern Analysis......... 45

Cleaning/Inspection........................ 37

Differential and Pinion Measurement........... 40

Differential Assembly....................... 38

Differential Disassembly.................... 35

Differential Installation...................... 44

Differential Removal....................... 34

Differential Shim Pack Measurement and

Adjustment............................ 43

Drive Axle Assembly ReplacementÐXJ Vehicles . . 23

Drive Axle Assembly ReplacementÐYJ Vehicles . . 24Final Assembly........................... 46

Hub Bearing and Axle Shaft................. 25

Information.............................. 22

Inner Axle Shaft Oil Seal Replacement......... 35

Lubricant Change......................... 23

Lubricant Specifications..................... 22

Pinion Gear Assembly/Installation............. 42

Pinion Gear Depth Information............... 39

Pinion Removal/Disassembly................. 36

Pinion Seal Replacement................... 25

Steering Knuckle and Ball Studs.............. 32

Vacuum Disconnect AxleÐYJ Vehicles......... 27

INFORMATION

The Model 30 front axles consists of a cast iron dif-

ferential housing with axle shaft tubes extending

from either side. The tubes are pressed into the dif-

ferential housing and welded.

The integral type housing, hypoid gear design has

the centerline of the pinion set above the centerline

of the ring gear.

The axle has a fitting for a vent hose used to re-

lieve internal pressure caused by lubricant vaporiza-

tion and internal expansion.

The axles are equipped with semi-floating axle

shafts, meaning that loads are supported by the hub

bearings. The axle shafts are retained by nuts at the

hub bearings. The hub bearings are bolted to the

steering knuckle at the outboard end of the axle tube

yoke. The hub bearings are serviced as an assembly.

The axles are equipped with ABS brake sensors.

The sensors are attached to the knuckle assemblies

and tone rings are pressed on the axle shaft.Use

care when removing axle shafts as NOT to dam-

age the tone wheel or the sensor.

The stamped steel cover provides a means for in-

spection and servicing the differential.

The Model 30 axle has the assembly part number

and gear ratio listed on a tag. The tag is attached to

the housing cover. Build date identification codes are

stamped on the axle shaft tube cover side.

The differential case is a one-piece design. The dif-

ferential pinion mate shaft is retained with a roll

pin. Differential bearing preload and ring gear back-

lash is adjusted by the use of shims (select thick-

ness). The shims are located between the differential

bearing cones and case. Pinion bearing preload is set

and maintained by the use of collapsible spacer.

COMMAND-TRACÐYJ VEHICLES

The Command-Trac system is a vacuum disconnect

axle. The system has a two-piece axle shaft coupled

together by a shift collar. For two-wheel drive opera-

tion, the vacuum motor and shift fork disengages the

axle shaft splines. For four-wheel drive operation, the

vacuum motor and shift fork engages the axle

splines.

SELEC-TRACÐXJ VEHICLES

The Selec-Trac system is a non-disconnect axle.

Shifting from two-wheel to four-wheel drive is done

at the transfer case.

For XJ vehicles equipped withSelec-Tracand

ABS brake system, refer to Group 5ÐBrakes for ad-

ditional service information.

LUBRICANT SPECIFICATIONS

Multi-purpose, hypoid gear lubricant should be

used for Model 30 axles. The lubricant should have

MIL-L-2105C and API GL 5 quality specifications.

MOPARtHypoid Gear Lubricant conforms to both of

these specifications.

²The factory fill for the Model 30 axle is SAE Ther-

mally Stable 80W-90 gear lubricant.Do not use

heavier weight lubricant, this will cause axle

engagement difficulties.

²The factory installed lubricant quantity for the

NON-DISCONNECT TYPE AXLE is 1.48 L (3.13

pts.).

²The factory installed lubricant quantity for the

VACUUM-DISCONNECT TYPE AXLE is 1.65 L (3.76

pts.).

Refer to Group 0, Lubrication and Maintenance for

additional information regarding temperature range,

viscosity and fluid level.

2 - 22 FRONT SUSPENSION AND AXLEJ

Page 58 of 2198

CAUTION: If axle is submerged in water, lubricant

must be replaced immediately to avoid possible

premature axle failure.

LUBRICANT CHANGE

The gear lubricant will drain quicker if the vehicle

has been recently driven.

(1) Raise and support the vehicle.

(2) Remove the lubricant fill hole plug from the dif-

ferential housing cover.

(3) Remove the differential housing cover and

drain the lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove the sealant from the housing and cover

surfaces. Use solvent to clean the mating surfaces.

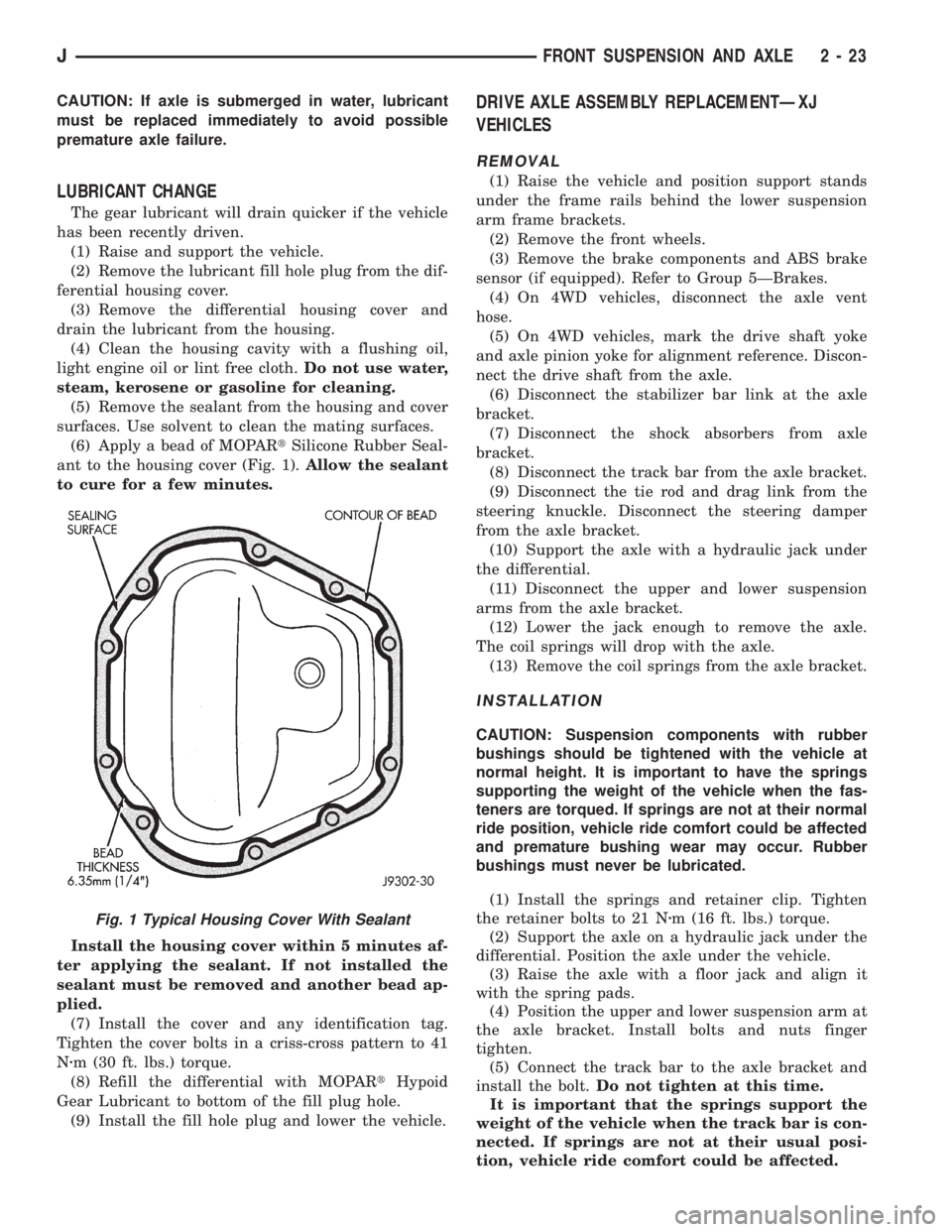

(6) Apply a bead of MOPARtSilicone Rubber Seal-

ant to the housing cover (Fig. 1).Allow the sealant

to cure for a few minutes.

Install the housing cover within 5 minutes af-

ter applying the sealant. If not installed the

sealant must be removed and another bead ap-

plied.

(7) Install the cover and any identification tag.

Tighten the cover bolts in a criss-cross pattern to 41

Nzm (30 ft. lbs.) torque.

(8) Refill the differential with MOPARtHypoid

Gear Lubricant to bottom of the fill plug hole.

(9) Install the fill hole plug and lower the vehicle.

DRIVE AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES

REMOVAL

(1) Raise the vehicle and position support stands

under the frame rails behind the lower suspension

arm frame brackets.

(2) Remove the front wheels.

(3) Remove the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(4) On 4WD vehicles, disconnect the axle vent

hose.

(5) On 4WD vehicles, mark the drive shaft yoke

and axle pinion yoke for alignment reference. Discon-

nect the drive shaft from the axle.

(6) Disconnect the stabilizer bar link at the axle

bracket.

(7) Disconnect the shock absorbers from axle

bracket.

(8) Disconnect the track bar from the axle bracket.

(9) Disconnect the tie rod and drag link from the

steering knuckle. Disconnect the steering damper

from the axle bracket.

(10) Support the axle with a hydraulic jack under

the differential.

(11) Disconnect the upper and lower suspension

arms from the axle bracket.

(12) Lower the jack enough to remove the axle.

The coil springs will drop with the axle.

(13) Remove the coil springs from the axle bracket.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

(1) Install the springs and retainer clip. Tighten

the retainer bolts to 21 Nzm (16 ft. lbs.) torque.

(2) Support the axle on a hydraulic jack under the

differential. Position the axle under the vehicle.

(3) Raise the axle with a floor jack and align it

with the spring pads.

(4) Position the upper and lower suspension arm at

the axle bracket. Install bolts and nuts finger

tighten.

(5) Connect the track bar to the axle bracket and

install the bolt.Do not tighten at this time.

It is important that the springs support the

weight of the vehicle when the track bar is con-

nected. If springs are not at their usual posi-

tion, vehicle ride comfort could be affected.

Fig. 1 Typical Housing Cover With Sealant

JFRONT SUSPENSION AND AXLE 2 - 23

Page 59 of 2198

(6) Install the shock absorber and tighten the bolt

to 23 Nzm (17 ft. lbs.) torque.

(7) Install the stabilizer bar link to the axle

bracket. Tighten the nut to 95 Nzm (70 ft. lbs.)

torque.

(8) Install the drag link and tie rod to the steering

knuckles and tighten the nuts to 47 Nzm (35 ft. lbs.)

torque. Install the steering damper to the axle

bracket and tighten the nut to 75 Nzm (55 ft. lbs.)

torque.

(9) Install the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(10) On 4WD vehicles, connect the vent hose to the

tube fitting.

(11) On 4WD vehicles, align the reference marks

and connect the drive shaft to the axle yoke. Tighten

the U-joint clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(12) Check differential lubricant and add if neces-

sary.

(13) Install the wheel and tire assemblies.

(14) Remove the supports and lower the vehicle.

(15) Tighten the upper suspension arm nuts to 75

Nzm (55 ft. lbs.) torque. Tighten the lower suspension

arm nuts to 115 Nzm (85 ft. lbs.) torque.

(16) Tighten the track bar bolt at the axle bracket

to 100 Nzm (74 ft. lbs.) torque.

(17) Check the front wheel alignment.

DRIVE AXLE ASSEMBLY REPLACEMENTÐYJ

VEHICLES

REMOVAL

(1) Raise the vehicle and position support stands

under the frame rails behind the spring frame brack-

ets.

(2) Remove the front wheels.

(3) Remove the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(4) Disconnect the axle vent hose and axle shift

motor vacuum harness.

(5) Mark the drive shaft yoke and axle pinion yoke

for alignment reference. Disconnect the drive shaft

from the axle.

(6) Disconnect the stabilizer bar link at the axle

bracket.

(7) Disconnect the shock absorbers from axle

bracket.

(8) Disconnect the track bar from the axle bracket.

(9) Disconnect the tie rod from the steering

knuckle. Disconnect the steering damper from the

axle bracket.

(10) Support the axle with a hydraulic jack under

the differential. Raise the axle just enough to relieve

the axle weight from the springs.

(11) Remove the spring U-bolts from the plate

brackets.(12) Loosen BUT DO NOT REMOVE the bolts that

attach the spring rear pivot at the frame rail brack-

ets. This will allow the springs to pivot without bind-

ing on the bushings.

(13) Disconnect shackle from the springs and lower

the springs to the surface.

(14) Lower the jack enough to remove the axle.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

(1) Support the axle on a hydraulic jack under the

differential. Position the axle under the vehicle.

(2) Raise the springs and install the spring shackle

bolts.Do not tighten at this time.

(3) Lower the axle and align the spring center

bolts with the locating holes in the axle pads and

plate brackets.

(4) Install the spring U-bolts through the plate

brackets and tighten to 122 Nzm (90 ft. lbs.) torque.

(5) Connect the track bar to the axle bracket and

install the bolt.Do not tighten at this time.

It is important that the springs support the

weight of the vehicle when the track bar is con-

nected. If springs are not at their usual posi-

tion, the vehicle ride comfort could be affected.

(6) Install the shock absorber and tighten the nut

to 61 Nzm (45 ft. lbs.) torque.

(7) Install the stabilizer bar link to the axle

bracket. Tighten the nut to 61 Nzm (45 ft. lbs.)

torque.

(8) Install the tie rod to the steering knuckles and

tighten the nuts to 47 Nzm (35 ft. lbs.) torque. Install

the steering damper to the axle bracket and tighten

the bolt to 75 Nzm (55 ft. lbs.) torque.

(9) Install the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(10) Connect the vent hose to the tube fitting and

axle shift motor vacuum harness.

(11) Align the reference marks and connect the

drive shaft to the axle yoke. Tighten the U-joint

clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(12) Check differential lubricant and add if neces-

sary.

(13) Install the wheel and tire assemblies.

(15) Remove the supports and lower the vehicle.

(16) Tighten the spring rear pivot bolt/nut to 142

Nzm (105 ft. lbs.) torque. Tighten the spring shackle

bolt/nut to 135 Nzm (100 ft. lbs.) torque.

2 - 24 FRONT SUSPENSION AND AXLEJ

Page 68 of 2198

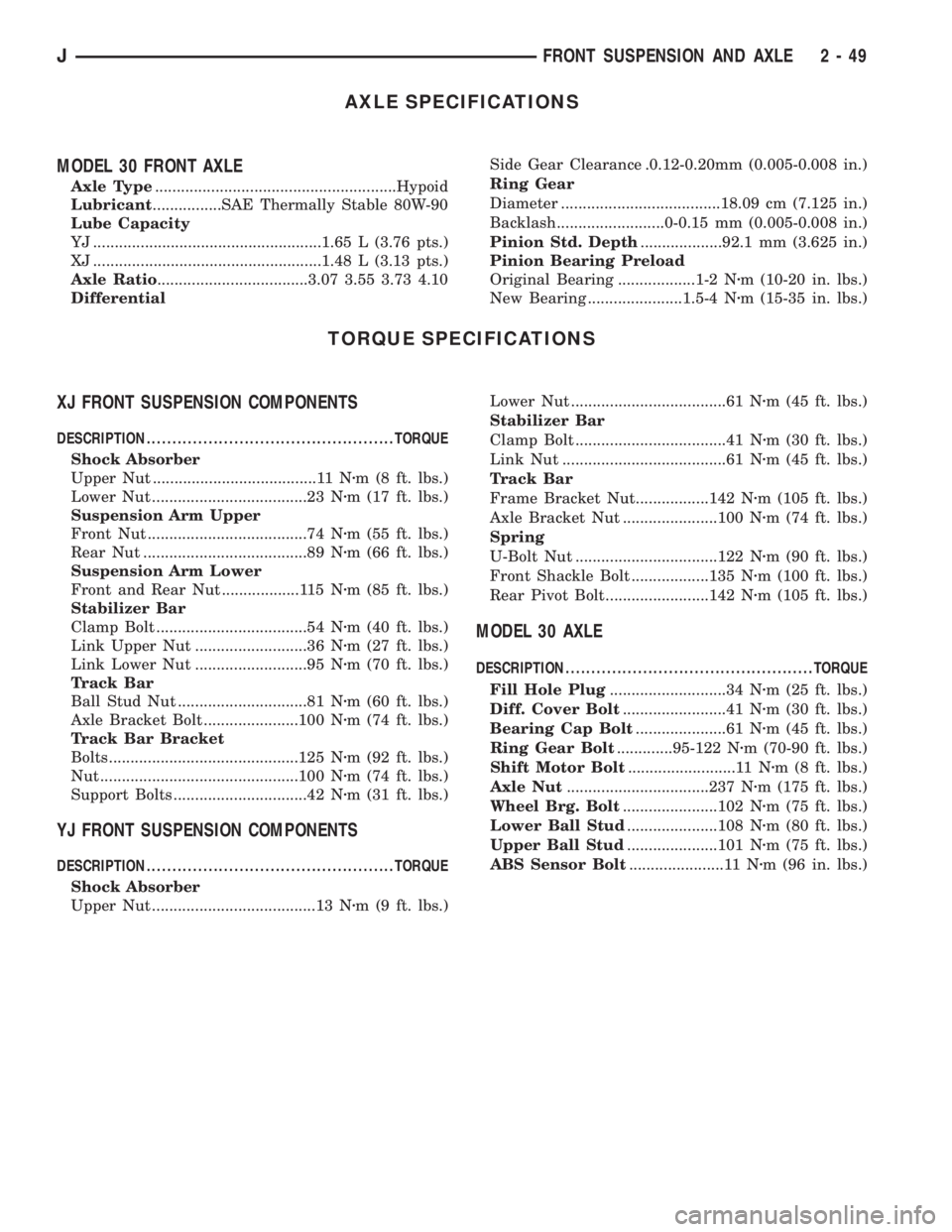

The lower ball stud has two different designs. For

this reason installer 6752 will also be needed. Check

installers for proper fit.

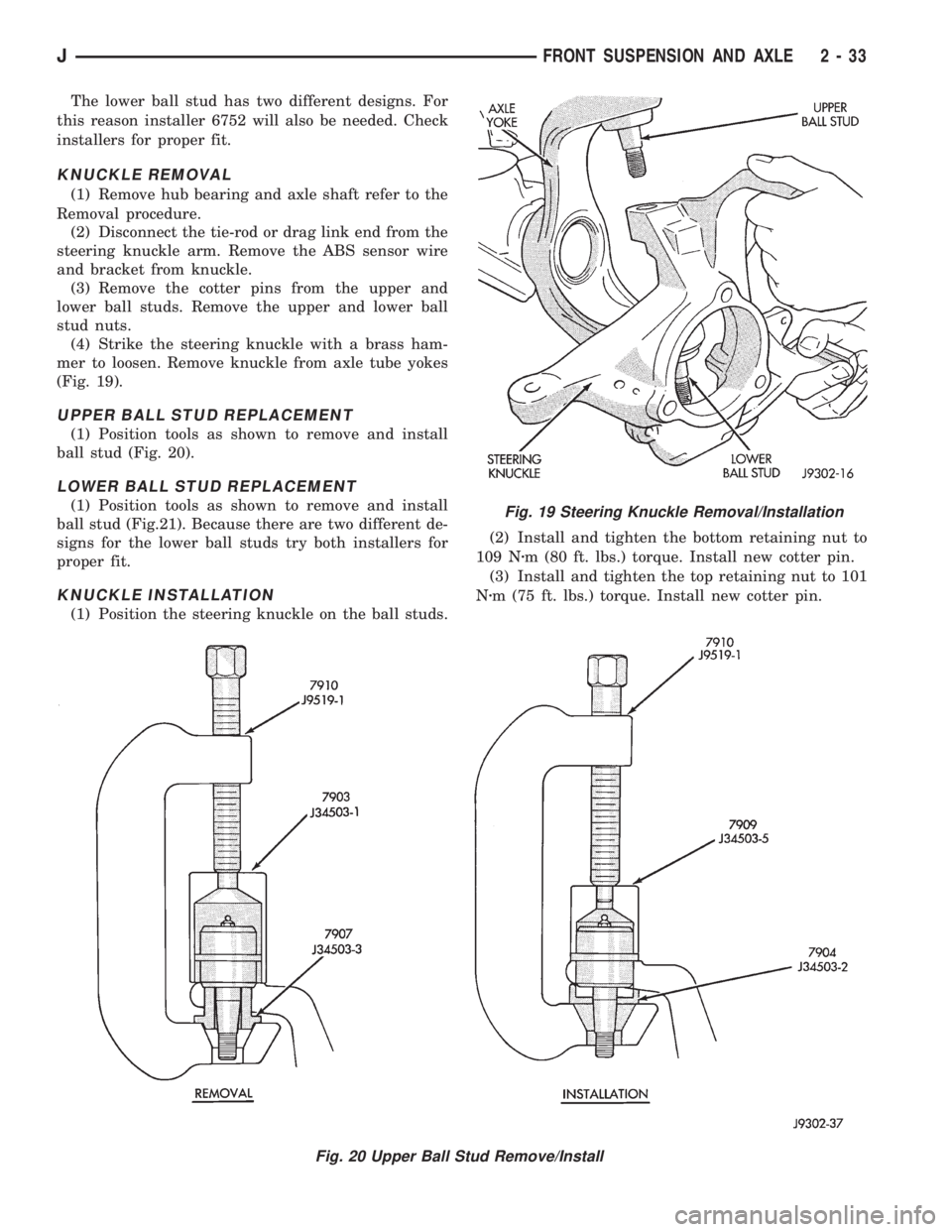

KNUCKLE REMOVAL

(1) Remove hub bearing and axle shaft refer to the

Removal procedure.

(2) Disconnect the tie-rod or drag link end from the

steering knuckle arm. Remove the ABS sensor wire

and bracket from knuckle.

(3) Remove the cotter pins from the upper and

lower ball studs. Remove the upper and lower ball

stud nuts.

(4) Strike the steering knuckle with a brass ham-

mer to loosen. Remove knuckle from axle tube yokes

(Fig. 19).

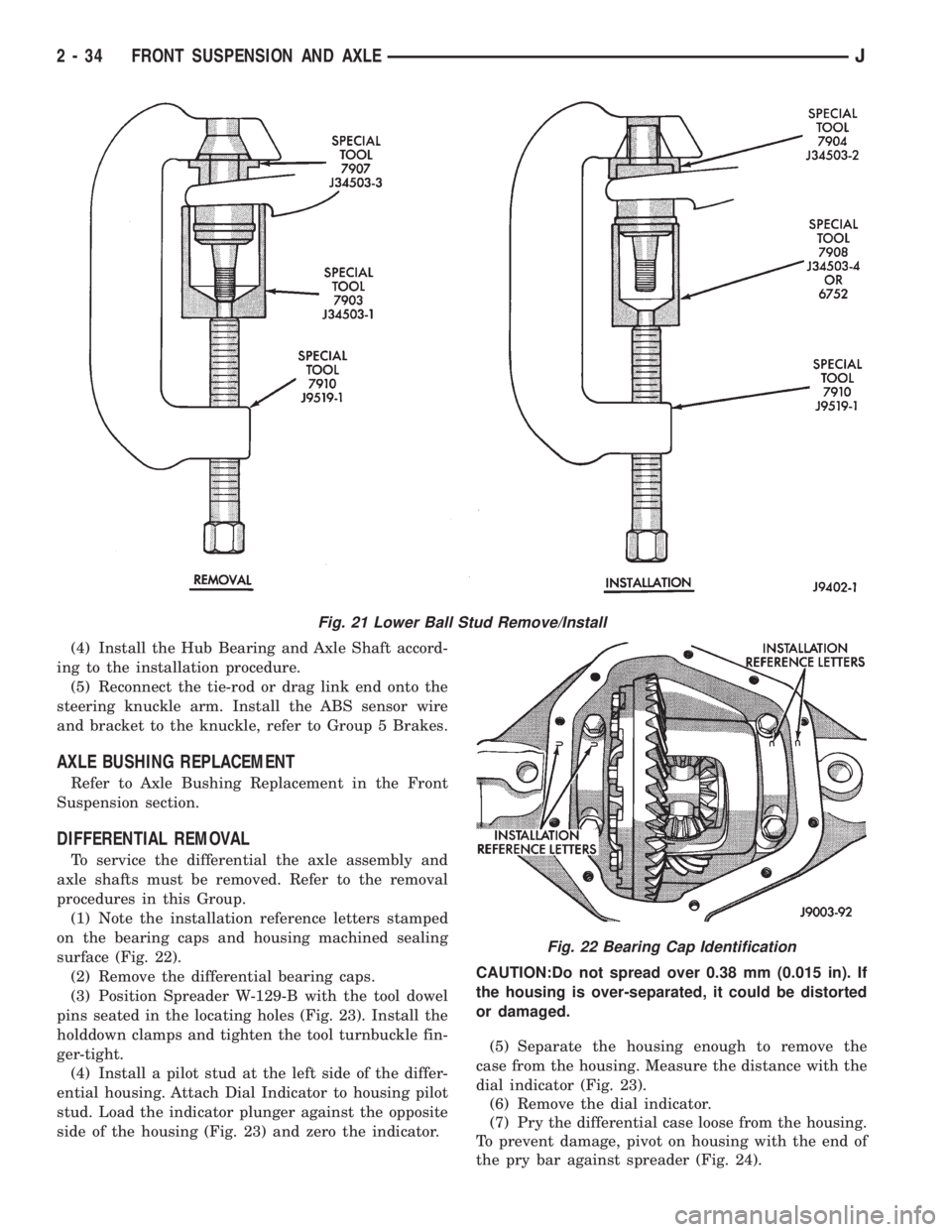

UPPER BALL STUD REPLACEMENT

(1) Position tools as shown to remove and install

ball stud (Fig. 20).

LOWER BALL STUD REPLACEMENT

(1) Position tools as shown to remove and install

ball stud (Fig.21). Because there are two different de-

signs for the lower ball studs try both installers for

proper fit.

KNUCKLE INSTALLATION

(1) Position the steering knuckle on the ball studs.(2) Install and tighten the bottom retaining nut to

109 Nzm (80 ft. lbs.) torque. Install new cotter pin.

(3) Install and tighten the top retaining nut to 101

Nzm (75 ft. lbs.) torque. Install new cotter pin.

Fig. 19 Steering Knuckle Removal/Installation

Fig. 20 Upper Ball Stud Remove/Install

JFRONT SUSPENSION AND AXLE 2 - 33

Page 69 of 2198

(4) Install the Hub Bearing and Axle Shaft accord-

ing to the installation procedure.

(5) Reconnect the tie-rod or drag link end onto the

steering knuckle arm. Install the ABS sensor wire

and bracket to the knuckle, refer to Group 5 Brakes.

AXLE BUSHING REPLACEMENT

Refer to Axle Bushing Replacement in the Front

Suspension section.

DIFFERENTIAL REMOVAL

To service the differential the axle assembly and

axle shafts must be removed. Refer to the removal

procedures in this Group.

(1) Note the installation reference letters stamped

on the bearing caps and housing machined sealing

surface (Fig. 22).

(2) Remove the differential bearing caps.

(3) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 23). Install the

holddown clamps and tighten the tool turnbuckle fin-

ger-tight.

(4) Install a pilot stud at the left side of the differ-

ential housing. Attach Dial Indicator to housing pilot

stud. Load the indicator plunger against the opposite

side of the housing (Fig. 23) and zero the indicator.CAUTION:Do not spread over 0.38 mm (0.015 in). If

the housing is over-separated, it could be distorted

or damaged.

(5) Separate the housing enough to remove the

case from the housing. Measure the distance with the

dial indicator (Fig. 23).

(6) Remove the dial indicator.

(7) Pry the differential case loose from the housing.

To prevent damage, pivot on housing with the end of

the pry bar against spreader (Fig. 24).

Fig. 21 Lower Ball Stud Remove/Install

Fig. 22 Bearing Cap Identification

2 - 34 FRONT SUSPENSION AND AXLEJ

Page 84 of 2198

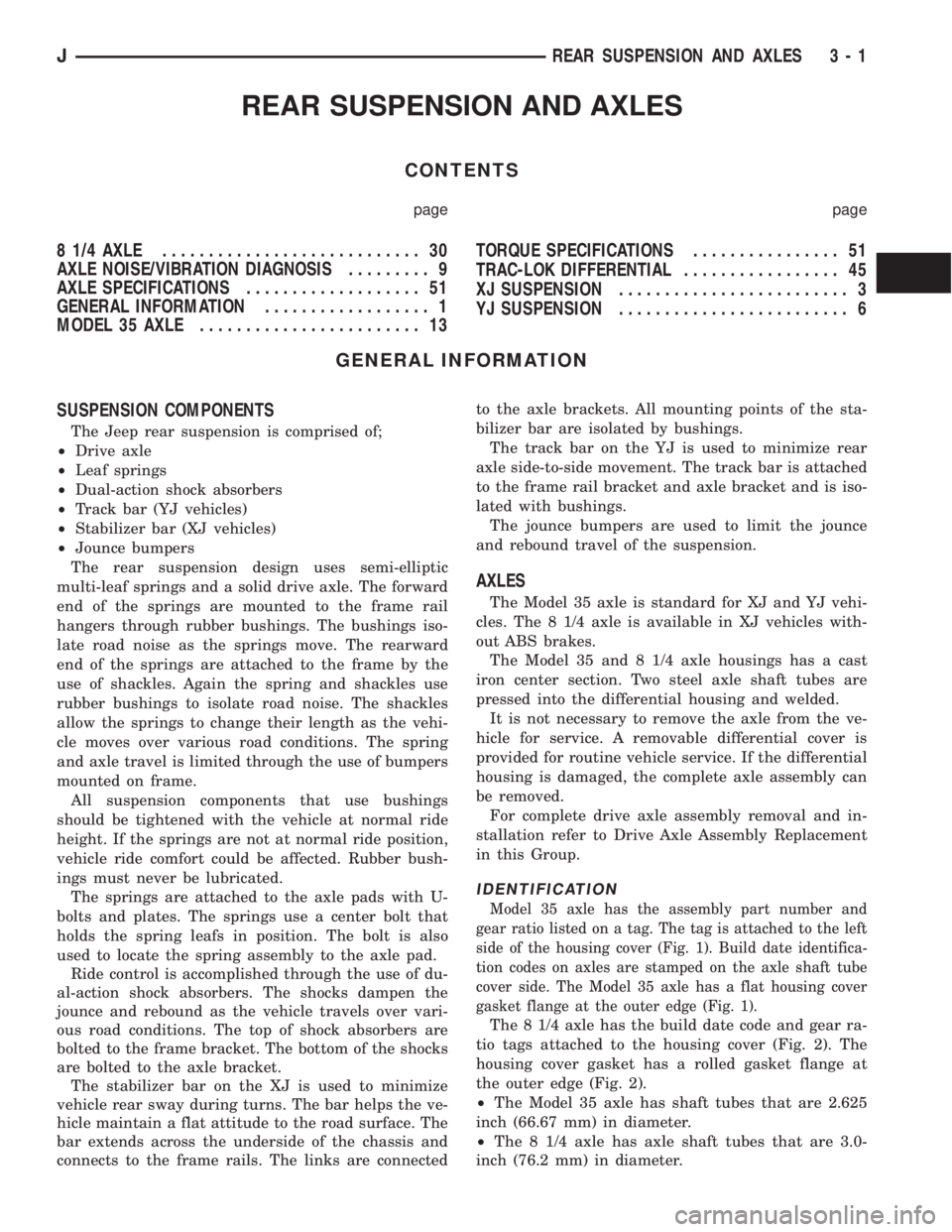

AXLE SPECIFICATIONS

MODEL 30 FRONT AXLE

Axle Type........................................................Hypoid

Lubricant................SAE Thermally Stable 80W-90

Lube Capacity

YJ .....................................................1.65 L (3.76 pts.)

XJ .....................................................1.48 L (3.13 pts.)

Axle Ratio...................................3.07 3.55 3.73 4.10

DifferentialSide Gear Clearance .0.12-0.20mm (0.005-0.008 in.)

Ring Gear

Diameter .....................................18.09 cm (7.125 in.)

Backlash.........................0-0.15 mm (0.005-0.008 in.)

Pinion Std. Depth...................92.1 mm (3.625 in.)

Pinion Bearing Preload

Original Bearing ..................1-2 Nzm (10-20 in. lbs.)

New Bearing ......................1.5-4 Nzm (15-35 in. lbs.)

TORQUE SPECIFICATIONS

XJ FRONT SUSPENSION COMPONENTS

DESCRIPTION ................................................TORQUE

Shock Absorber

Upper Nut ......................................11 Nzm (8 ft. lbs.)

Lower Nut ....................................23 Nzm (17 ft. lbs.)

Suspension Arm Upper

Front Nut .....................................74 Nzm (55 ft. lbs.)

Rear Nut ......................................89 Nzm (66 ft. lbs.)

Suspension Arm Lower

Front and Rear Nut ..................115 Nzm (85 ft. lbs.)

Stabilizer Bar

Clamp Bolt ...................................54 Nzm (40 ft. lbs.)

Link Upper Nut ..........................36 Nzm (27 ft. lbs.)

Link Lower Nut ..........................95 Nzm (70 ft. lbs.)

Track Bar

Ball Stud Nut ..............................81 Nzm (60 ft. lbs.)

Axle Bracket Bolt ......................100 Nzm (74 ft. lbs.)

Track Bar Bracket

Bolts............................................125 Nzm (92 ft. lbs.)

Nut ..............................................100 Nzm (74 ft. lbs.)

Support Bolts ...............................42 Nzm (31 ft. lbs.)

YJ FRONT SUSPENSION COMPONENTS

DESCRIPTION ................................................TORQUE

Shock Absorber

Upper Nut ......................................13 Nzm (9 ft. lbs.)Lower Nut ....................................61 Nzm (45 ft. lbs.)

Stabilizer Bar

Clamp Bolt ...................................41 Nzm (30 ft. lbs.)

Link Nut ......................................61 Nzm (45 ft. lbs.)

Track Bar

Frame Bracket Nut.................142 Nzm (105 ft. lbs.)

Axle Bracket Nut ......................100 Nzm (74 ft. lbs.)

Spring

U-Bolt Nut .................................122 Nzm (90 ft. lbs.)

Front Shackle Bolt ..................135 Nzm (100 ft. lbs.)

Rear Pivot Bolt........................142 Nzm (105 ft. lbs.)

MODEL 30 AXLE

DESCRIPTION ................................................TORQUE

Fill Hole Plug...........................34 Nzm (25 ft. lbs.)

Diff. Cover Bolt........................41 Nzm (30 ft. lbs.)

Bearing Cap Bolt.....................61 Nzm (45 ft. lbs.)

Ring Gear Bolt.............95-122 Nzm (70-90 ft. lbs.)

Shift Motor Bolt.........................11 Nzm (8 ft. lbs.)

Axle Nut.................................237 Nzm (175 ft. lbs.)

Wheel Brg. Bolt......................102 Nzm (75 ft. lbs.)

Lower Ball Stud.....................108 Nzm (80 ft. lbs.)

Upper Ball Stud.....................101 Nzm (75 ft. lbs.)

ABS Sensor Bolt......................11 Nzm (96 in. lbs.)

JFRONT SUSPENSION AND AXLE 2 - 49

Page 86 of 2198

REAR SUSPENSION AND AXLES

CONTENTS

page page

8 1/4 AXLE............................ 30

AXLE NOISE/VIBRATION DIAGNOSIS......... 9

AXLE SPECIFICATIONS................... 51

GENERAL INFORMATION.................. 1

MODEL 35 AXLE........................ 13TORQUE SPECIFICATIONS................ 51

TRAC-LOK DIFFERENTIAL................. 45

XJ SUSPENSION......................... 3

YJ SUSPENSION......................... 6

GENERAL INFORMATION

SUSPENSION COMPONENTS

The Jeep rear suspension is comprised of;

²Drive axle

²Leaf springs

²Dual-action shock absorbers

²Track bar (YJ vehicles)

²Stabilizer bar (XJ vehicles)

²Jounce bumpers

The rear suspension design uses semi-elliptic

multi-leaf springs and a solid drive axle. The forward

end of the springs are mounted to the frame rail

hangers through rubber bushings. The bushings iso-

late road noise as the springs move. The rearward

end of the springs are attached to the frame by the

use of shackles. Again the spring and shackles use

rubber bushings to isolate road noise. The shackles

allow the springs to change their length as the vehi-

cle moves over various road conditions. The spring

and axle travel is limited through the use of bumpers

mounted on frame.

All suspension components that use bushings

should be tightened with the vehicle at normal ride

height. If the springs are not at normal ride position,

vehicle ride comfort could be affected. Rubber bush-

ings must never be lubricated.

The springs are attached to the axle pads with U-

bolts and plates. The springs use a center bolt that

holds the spring leafs in position. The bolt is also

used to locate the spring assembly to the axle pad.

Ride control is accomplished through the use of du-

al-action shock absorbers. The shocks dampen the

jounce and rebound as the vehicle travels over vari-

ous road conditions. The top of shock absorbers are

bolted to the frame bracket. The bottom of the shocks

are bolted to the axle bracket.

The stabilizer bar on the XJ is used to minimize

vehicle rear sway during turns. The bar helps the ve-

hicle maintain a flat attitude to the road surface. The

bar extends across the underside of the chassis and

connects to the frame rails. The links are connectedto the axle brackets. All mounting points of the sta-

bilizer bar are isolated by bushings.

The track bar on the YJ is used to minimize rear

axle side-to-side movement. The track bar is attached

to the frame rail bracket and axle bracket and is iso-

lated with bushings.

The jounce bumpers are used to limit the jounce

and rebound travel of the suspension.

AXLES

The Model 35 axle is standard for XJ and YJ vehi-

cles. The 8 1/4 axle is available in XJ vehicles with-

out ABS brakes.

The Model 35 and 8 1/4 axle housings has a cast

iron center section. Two steel axle shaft tubes are

pressed into the differential housing and welded.

It is not necessary to remove the axle from the ve-

hicle for service. A removable differential cover is

provided for routine vehicle service. If the differential

housing is damaged, the complete axle assembly can

be removed.

For complete drive axle assembly removal and in-

stallation refer to Drive Axle Assembly Replacement

in this Group.

IDENTIFICATION

Model 35 axle has the assembly part number and

gear ratio listed on a tag. The tag is attached to the left

side of the housing cover (Fig. 1). Build date identifica-

tion codes on axles are stamped on the axle shaft tube

cover side. The Model 35 axle has a flat housing cover

gasket flange at the outer edge (Fig. 1).

The 8 1/4 axle has the build date code and gear ra-

tio tags attached to the housing cover (Fig. 2). The

housing cover gasket has a rolled gasket flange at

the outer edge (Fig. 2).

²The Model 35 axle has shaft tubes that are 2.625

inch (66.67 mm) in diameter.

²The 8 1/4 axle has axle shaft tubes that are 3.0-

inch (76.2 mm) in diameter.

JREAR SUSPENSION AND AXLES 3 - 1

Page 88 of 2198

XJ SUSPENSION

INDEX

page page

Leaf Spring............................... 4

Leaf Spring Eye Bushing Replacement.......... 5

Shock Absorber........................... 4Spring and Shock Diagnosis.................. 3

Stabilizer Bar............................. 5

SPRING AND SHOCK DIAGNOSIS

A noise from the shock absorber or spring bushings

can be produced if movement between the rubber

bushings and the metal occurs. This noise can usu-

ally be stopped by tightening the nuts. If the noise

persists, inspect for damaged and worn bushings. Re-

pair as necessary.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston into and out

of the cylinder four or five times. The action through-

out each stroke should be smooth and even.

The spring eye and shock absorber bushings do not

require any type of lubrication.Do not attempt to

stop spring bushing noise by lubricating them.Grease and mineral oil-base lubricants will de-

teriorate the bushing rubber.

If the vehicle is used for severe, off-road operation,

the springs should be examined regularly. Check for

broken and shifted components.

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

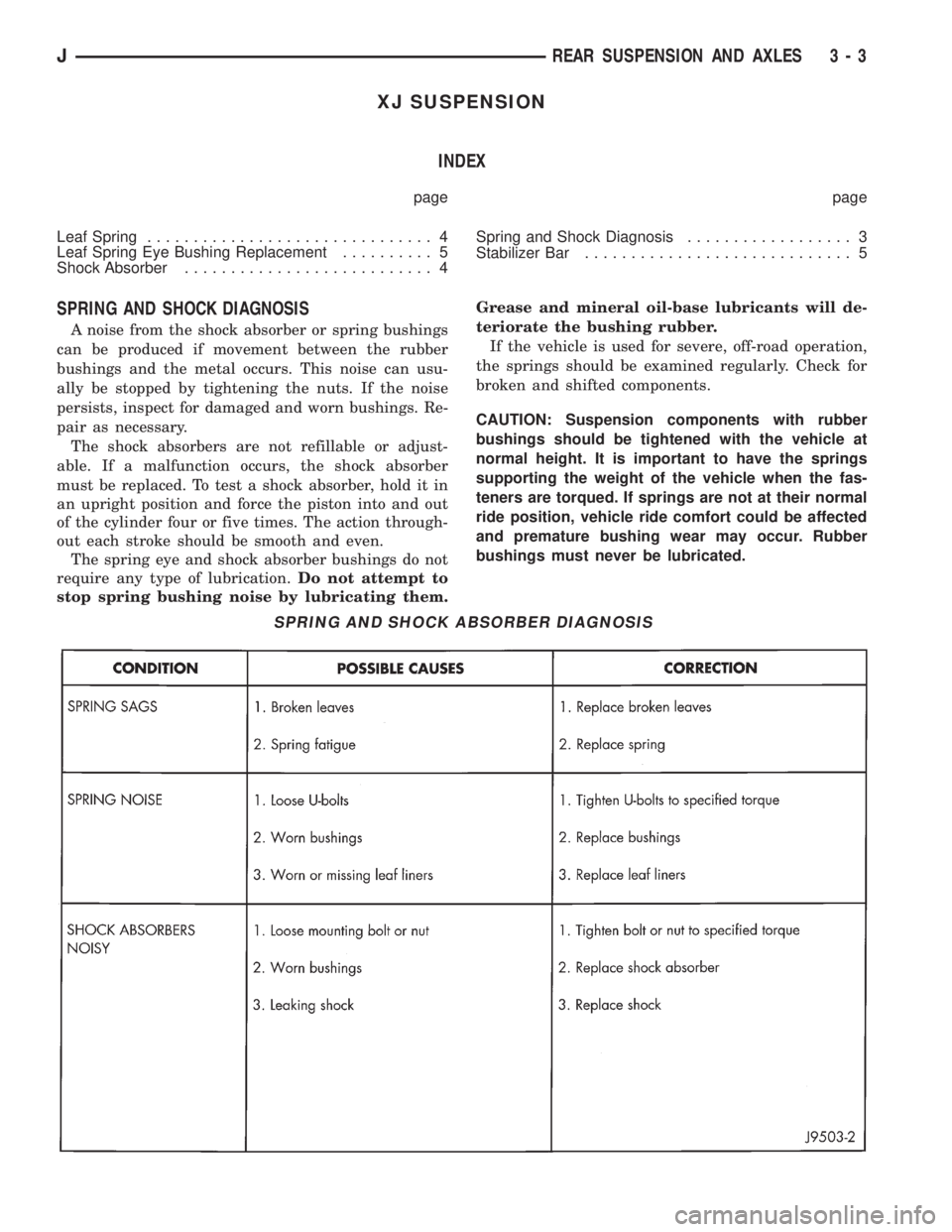

SPRING AND SHOCK ABSORBER DIAGNOSIS

JREAR SUSPENSION AND AXLES 3 - 3

Page 89 of 2198

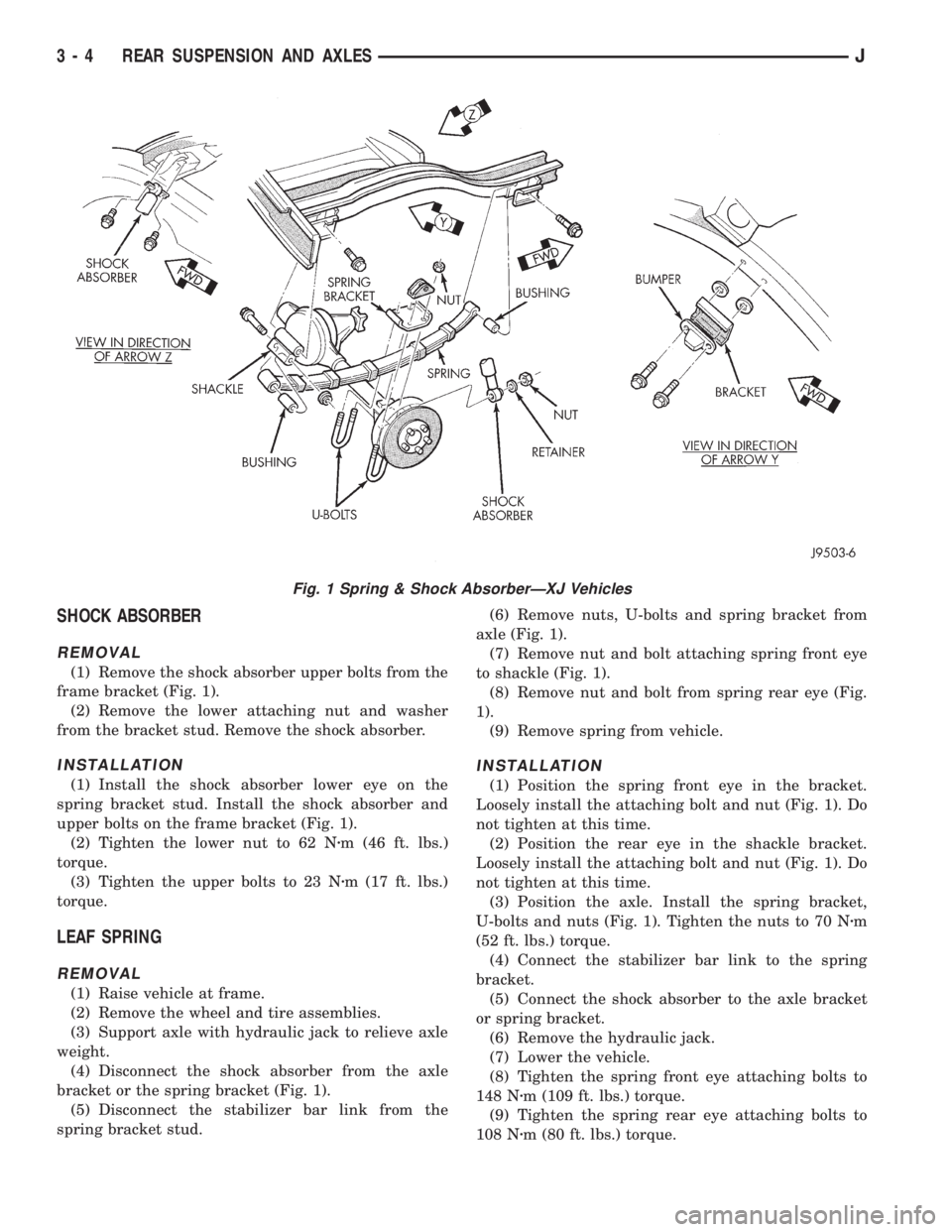

SHOCK ABSORBER

REMOVAL

(1) Remove the shock absorber upper bolts from the

frame bracket (Fig. 1).

(2) Remove the lower attaching nut and washer

from the bracket stud. Remove the shock absorber.

INSTALLATION

(1) Install the shock absorber lower eye on the

spring bracket stud. Install the shock absorber and

upper bolts on the frame bracket (Fig. 1).

(2) Tighten the lower nut to 62 Nzm (46 ft. lbs.)

torque.

(3) Tighten the upper bolts to 23 Nzm (17 ft. lbs.)

torque.

LEAF SPRING

REMOVAL

(1) Raise vehicle at frame.

(2) Remove the wheel and tire assemblies.

(3) Support axle with hydraulic jack to relieve axle

weight.

(4) Disconnect the shock absorber from the axle

bracket or the spring bracket (Fig. 1).

(5) Disconnect the stabilizer bar link from the

spring bracket stud.(6) Remove nuts, U-bolts and spring bracket from

axle (Fig. 1).

(7) Remove nut and bolt attaching spring front eye

to shackle (Fig. 1).

(8) Remove nut and bolt from spring rear eye (Fig.

1).

(9) Remove spring from vehicle.

INSTALLATION

(1) Position the spring front eye in the bracket.

Loosely install the attaching bolt and nut (Fig. 1). Do

not tighten at this time.

(2) Position the rear eye in the shackle bracket.

Loosely install the attaching bolt and nut (Fig. 1). Do

not tighten at this time.

(3) Position the axle. Install the spring bracket,

U-bolts and nuts (Fig. 1). Tighten the nuts to 70 Nzm

(52 ft. lbs.) torque.

(4) Connect the stabilizer bar link to the spring

bracket.

(5) Connect the shock absorber to the axle bracket

or spring bracket.

(6) Remove the hydraulic jack.

(7) Lower the vehicle.

(8) Tighten the spring front eye attaching bolts to

148 Nzm (109 ft. lbs.) torque.

(9) Tighten the spring rear eye attaching bolts to

108 Nzm (80 ft. lbs.) torque.

Fig. 1 Spring & Shock AbsorberÐXJ Vehicles

3 - 4 REAR SUSPENSION AND AXLESJ