ABS JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 12 of 2198

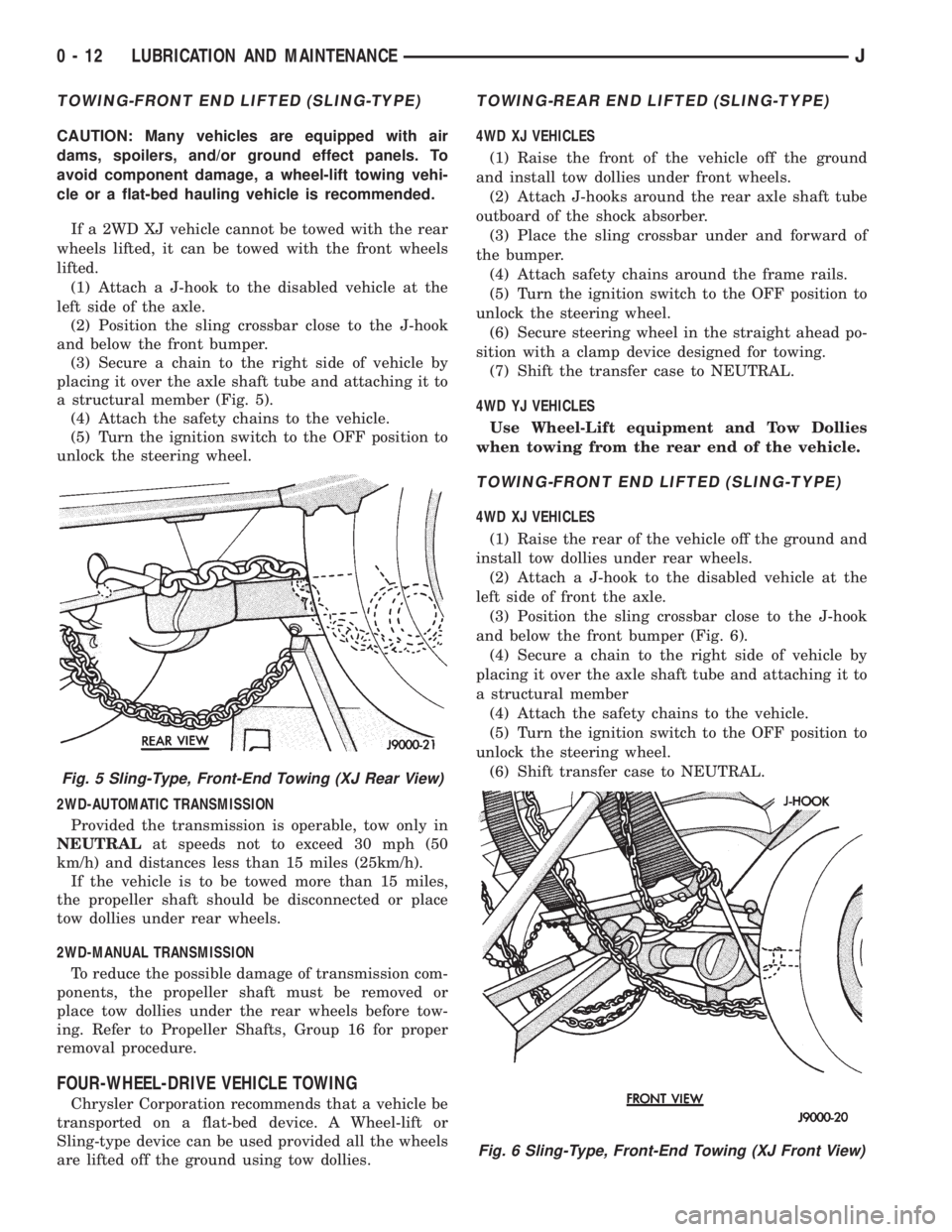

²Do not allow passengers to ride in a vehicle being

towed.

²Always observe state and local laws regarding tow-

ing regulations.²Do not tow a vehicle in a manner that could jeop-

ardize the safety of the operator, pedestrians or other

motorists.

²Do not attach tow chains, T-hooks, J-hooks, or a

tow sling to a bumper, steering linkage, drive shafts

or a non-reinforced frame hole.

GROUND CLEARANCE AND RAMP ANGLE

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing over

rough terrain or steep rises in the road. If necessary,

remove the wheels from the lifted end of the vehicle

and lower the vehicle closer to the ground, to in-

crease the ground clearance at the opposite end of

the vehicle. Install lug nuts on wheel attaching studs

to retain brake drums.

FLAT-BED TOWING RAMP ANGLE

If a vehicle with flat-bed towing equipment is used,

the approach ramp angle should not exceed 15 de-

grees.

TWO-WHEEL-DRIVE VEHICLE TOWINGÐXJ

Chrysler Corporation recommends that a vehicle be

towed with the rear end lifted, whenever possible.

TOWING-REAR END LIFTED (SLING-TYPE)

CAUTION: Do not use steering column lock to se-

cure steering wheel during towing operation.

2WD XJ vehicles can be towed with the front

wheels on the surface for extended distances at

speeds not exceeding 48 km/h (30 mph).

(1) Attach J-hooks around the axle shaft tube out-

board of the shock absorber.

(2) Place the sling crossbar under and forward of

the bumper.

(3) Attach safety chains around the frame rails.

(4) Turn the ignition switch to the OFF position to

unlock the steering wheel.

(5) Secure steering wheel in the straight ahead po-

sition with a clamp device designed for towing.

(6) Verify that steering components are in good

condition.

(7) Shift the transmission to NEUTRAL.

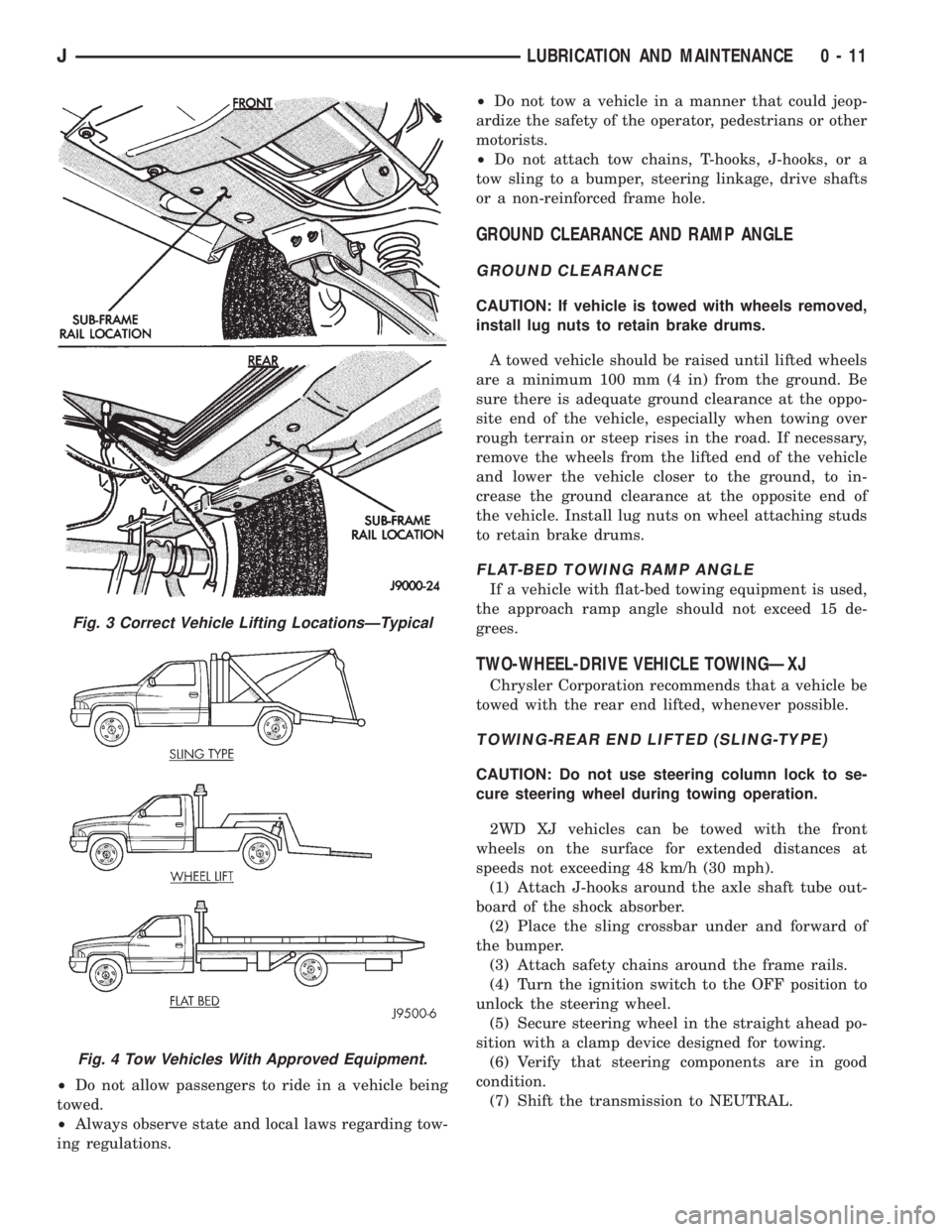

Fig. 3 Correct Vehicle Lifting LocationsÐTypical

Fig. 4 Tow Vehicles With Approved Equipment.

JLUBRICATION AND MAINTENANCE 0 - 11

Page 13 of 2198

TOWING-FRONT END LIFTED (SLING-TYPE)

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

If a 2WD XJ vehicle cannot be towed with the rear

wheels lifted, it can be towed with the front wheels

lifted.

(1) Attach a J-hook to the disabled vehicle at the

left side of the axle.

(2) Position the sling crossbar close to the J-hook

and below the front bumper.

(3) Secure a chain to the right side of vehicle by

placing it over the axle shaft tube and attaching it to

a structural member (Fig. 5).

(4) Attach the safety chains to the vehicle.

(5) Turn the ignition switch to the OFF position to

unlock the steering wheel.

2WD-AUTOMATIC TRANSMISSION

Provided the transmission is operable, tow only in

NEUTRALat speeds not to exceed 30 mph (50

km/h) and distances less than 15 miles (25km/h).

If the vehicle is to be towed more than 15 miles,

the propeller shaft should be disconnected or place

tow dollies under rear wheels.

2WD-MANUAL TRANSMISSION

To reduce the possible damage of transmission com-

ponents, the propeller shaft must be removed or

place tow dollies under the rear wheels before tow-

ing. Refer to Propeller Shafts, Group 16 for proper

removal procedure.

FOUR-WHEEL-DRIVE VEHICLE TOWING

Chrysler Corporation recommends that a vehicle be

transported on a flat-bed device. A Wheel-lift or

Sling-type device can be used provided all the wheels

are lifted off the ground using tow dollies.

TOWING-REAR END LIFTED (SLING-TYPE)

4WD XJ VEHICLES

(1) Raise the front of the vehicle off the ground

and install tow dollies under front wheels.

(2) Attach J-hooks around the rear axle shaft tube

outboard of the shock absorber.

(3) Place the sling crossbar under and forward of

the bumper.

(4) Attach safety chains around the frame rails.

(5) Turn the ignition switch to the OFF position to

unlock the steering wheel.

(6) Secure steering wheel in the straight ahead po-

sition with a clamp device designed for towing.

(7) Shift the transfer case to NEUTRAL.

4WD YJ VEHICLES

Use Wheel-Lift equipment and Tow Dollies

when towing from the rear end of the vehicle.

TOWING-FRONT END LIFTED (SLING-TYPE)

4WD XJ VEHICLES

(1) Raise the rear of the vehicle off the ground and

install tow dollies under rear wheels.

(2) Attach a J-hook to the disabled vehicle at the

left side of front the axle.

(3) Position the sling crossbar close to the J-hook

and below the front bumper (Fig. 6).

(4) Secure a chain to the right side of vehicle by

placing it over the axle shaft tube and attaching it to

a structural member

(4) Attach the safety chains to the vehicle.

(5) Turn the ignition switch to the OFF position to

unlock the steering wheel.

(6) Shift transfer case to NEUTRAL.

Fig. 5 Sling-Type, Front-End Towing (XJ Rear View)

Fig. 6 Sling-Type, Front-End Towing (XJ Front View)

0 - 12 LUBRICATION AND MAINTENANCEJ

Page 23 of 2198

DRIVETRAIN

INDEX

page page

Automatic Transmission.................... 23

Clutch and Brake Pedal Bushings............. 22

Clutch Master Cylinder..................... 22

Drive Shafts............................. 26Front and Rear Axles...................... 24

Manual Transmission...................... 22

Rubber and Plastic Hoses/Tubing............. 26

Transfer Case (4WD Vehicles)................ 24

CLUTCH AND BRAKE PEDAL BUSHINGS

If the clutch and brake pedal mechanism squeaks,

the pivot bushings should be lubricated. Use Mopar

Multi-Purpose Lubricant, or an equivalent. Refer to

Group 5, Brakes for location of bushings.

CLUTCH MASTER CYLINDER

LEVEL INSPECTION

WARNING: DO NOT ALLOW PETROLEUM OR WA-

TER BASE LIQUIDS TO CONTAMINATE CLUTCH

FLUID, SEAL DAMAGE AND CLUTCH FAILURE CAN

RESULT.

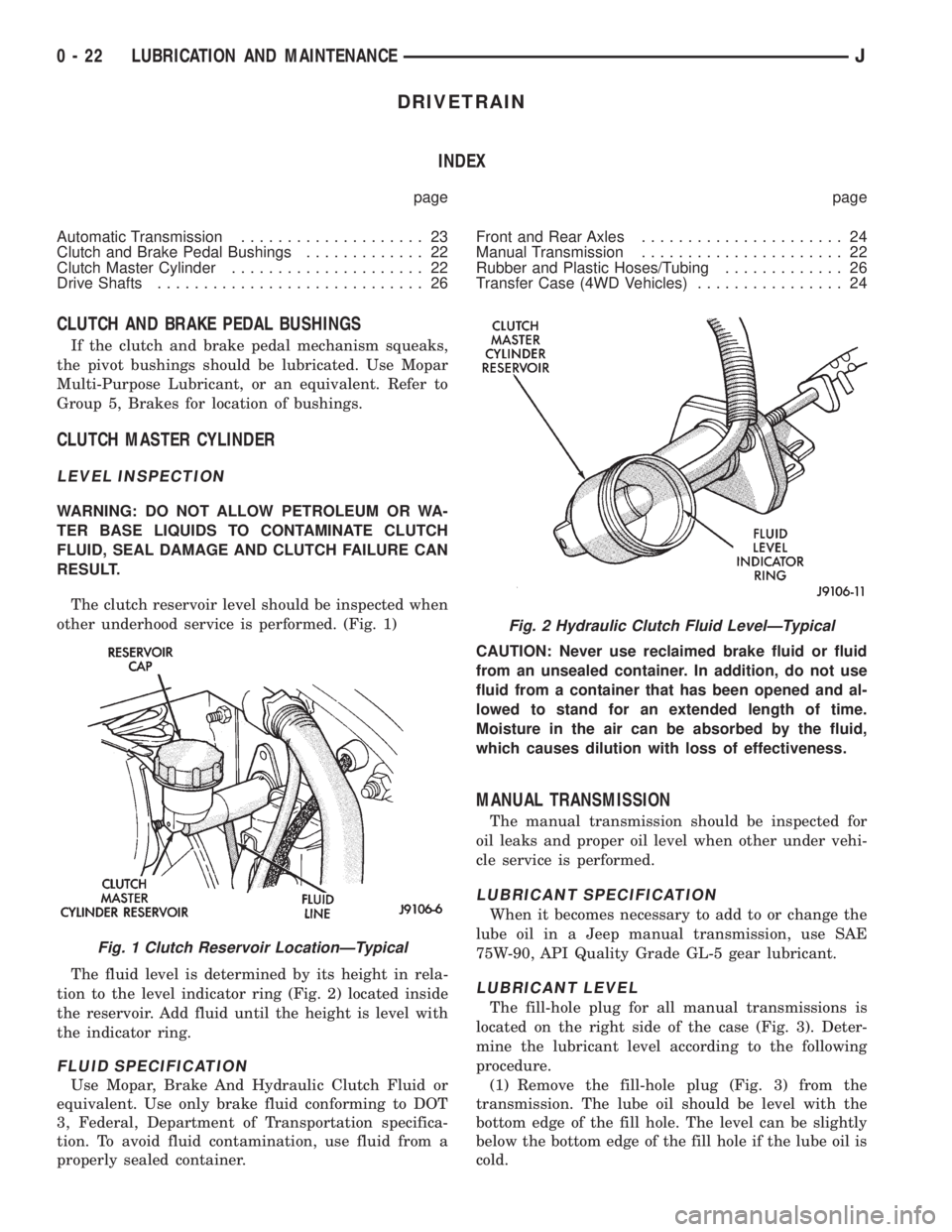

The clutch reservoir level should be inspected when

other underhood service is performed. (Fig. 1)

The fluid level is determined by its height in rela-

tion to the level indicator ring (Fig. 2) located inside

the reservoir. Add fluid until the height is level with

the indicator ring.

FLUID SPECIFICATION

Use Mopar, Brake And Hydraulic Clutch Fluid or

equivalent. Use only brake fluid conforming to DOT

3, Federal, Department of Transportation specifica-

tion. To avoid fluid contamination, use fluid from a

properly sealed container.CAUTION: Never use reclaimed brake fluid or fluid

from an unsealed container. In addition, do not use

fluid from a container that has been opened and al-

lowed to stand for an extended length of time.

Moisture in the air can be absorbed by the fluid,

which causes dilution with loss of effectiveness.

MANUAL TRANSMISSION

The manual transmission should be inspected for

oil leaks and proper oil level when other under vehi-

cle service is performed.

LUBRICANT SPECIFICATION

When it becomes necessary to add to or change the

lube oil in a Jeep manual transmission, use SAE

75W-90, API Quality Grade GL-5 gear lubricant.

LUBRICANT LEVEL

The fill-hole plug for all manual transmissions is

located on the right side of the case (Fig. 3). Deter-

mine the lubricant level according to the following

procedure.

(1) Remove the fill-hole plug (Fig. 3) from the

transmission. The lube oil should be level with the

bottom edge of the fill hole. The level can be slightly

below the bottom edge of the fill hole if the lube oil is

cold.

Fig. 1 Clutch Reservoir LocationÐTypical

Fig. 2 Hydraulic Clutch Fluid LevelÐTypical

0 - 22 LUBRICATION AND MAINTENANCEJ

Page 36 of 2198

FRONT SUSPENSION AND AXLE

CONTENTS

page page

AXLE NOISE/VIBRATION DIAGNOSIS........ 18

AXLE SPECIFICATIONS................... 49

FRONT WHEEL ALIGNMENT................ 5

GENERAL INFORMATION.................. 1MODEL 30 AXLE AND TUBE AXLE (2WD).... 22

TORQUE SPECIFICATIONS................ 49

XJ FRONT SUSPENSION.................. 11

YJ FRONT SUSPENSION.................. 15

GENERAL INFORMATION

FRONT SUSPENSION

XJ VEHICLES

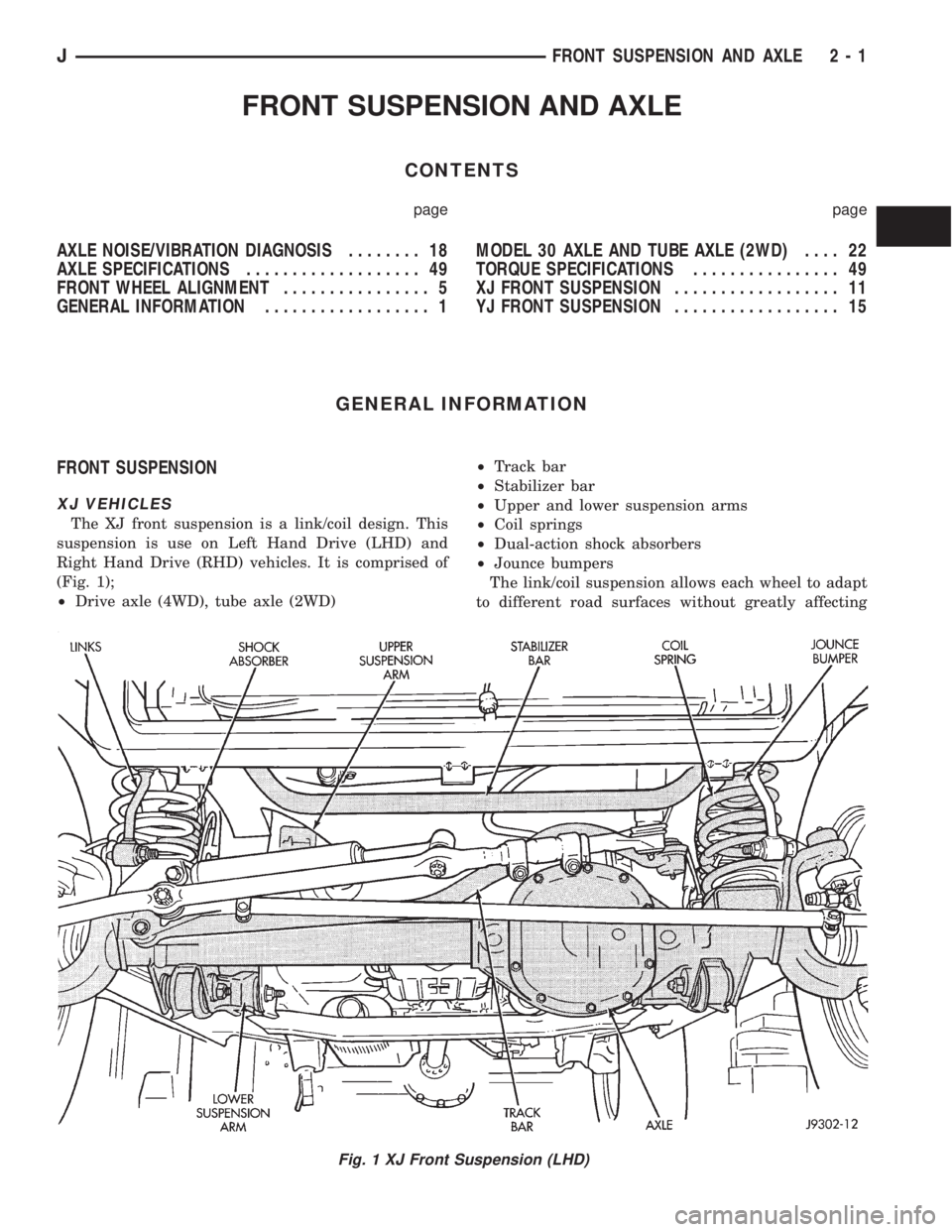

The XJ front suspension is a link/coil design. This

suspension is use on Left Hand Drive (LHD) and

Right Hand Drive (RHD) vehicles. It is comprised of

(Fig. 1);

²Drive axle (4WD), tube axle (2WD)²Track bar

²Stabilizer bar

²Upper and lower suspension arms

²Coil springs

²Dual-action shock absorbers

²Jounce bumpers

The link/coil suspension allows each wheel to adapt

to different road surfaces without greatly affecting

Fig. 1 XJ Front Suspension (LHD)

JFRONT SUSPENSION AND AXLE 2 - 1

Page 37 of 2198

the opposite wheel. Wheels are attached to a hub/

bearings which bolts to the knuckles. The hub/bear-

ing is not serviceable and is replaced as a unit.

Steering knuckles pivot on replaceable ball studs at-

tached to the axle tube yokes.

The upper and lower suspension arms are different

lengths, with bushings at both ends. They bolt the

axle assembly to the body. The lower arms uses

shims at the body mount to allow for adjustment of

caster and drive shaft pinion angle. The suspension

arm travel is limited through the use of jounce

bumpers in compression and shocks absorbers in re-

bound.

Suspension components which use rubber bushings

should be tightened at vehicle ride height. This will

prevent premature failure of the bushing and main-

tain ride comfort. Bushings must never be lubricated.

The coil springs control ride quality and maintain

proper ride height. The coil springs mount up in the

fender shield which is part of the unitized body

bracket. A rubber isolator is located between the top

of the spring and the frame. The bottom of the spring

seats on a axle pad and is retained with a clip.

The shock absorbers dampen jounce and rebound of

the vehicle over various road conditions. The top of

the shock absorbers are bolted to the body. The bot-

tom of the shocks are bolted to the axle spring

bracket.

The stabilizer bar is used to minimize vehicle body

roll during turns. The spring steel bar helps to con-

trol the vehicle body in relationship to the suspen-

sion. The bar extends across the front underside of

the chassis and connects to the body rails. Links are

connected from the bar to the axle brackets. Stabi-

lizer bar mounts are isolated by rubber bushings.

The track bar is used to minimize front axle side-

to-side movement. The bar is attached to a frame rail

bracket with a ball stud and isolated with a bushing

at the axle bracket.

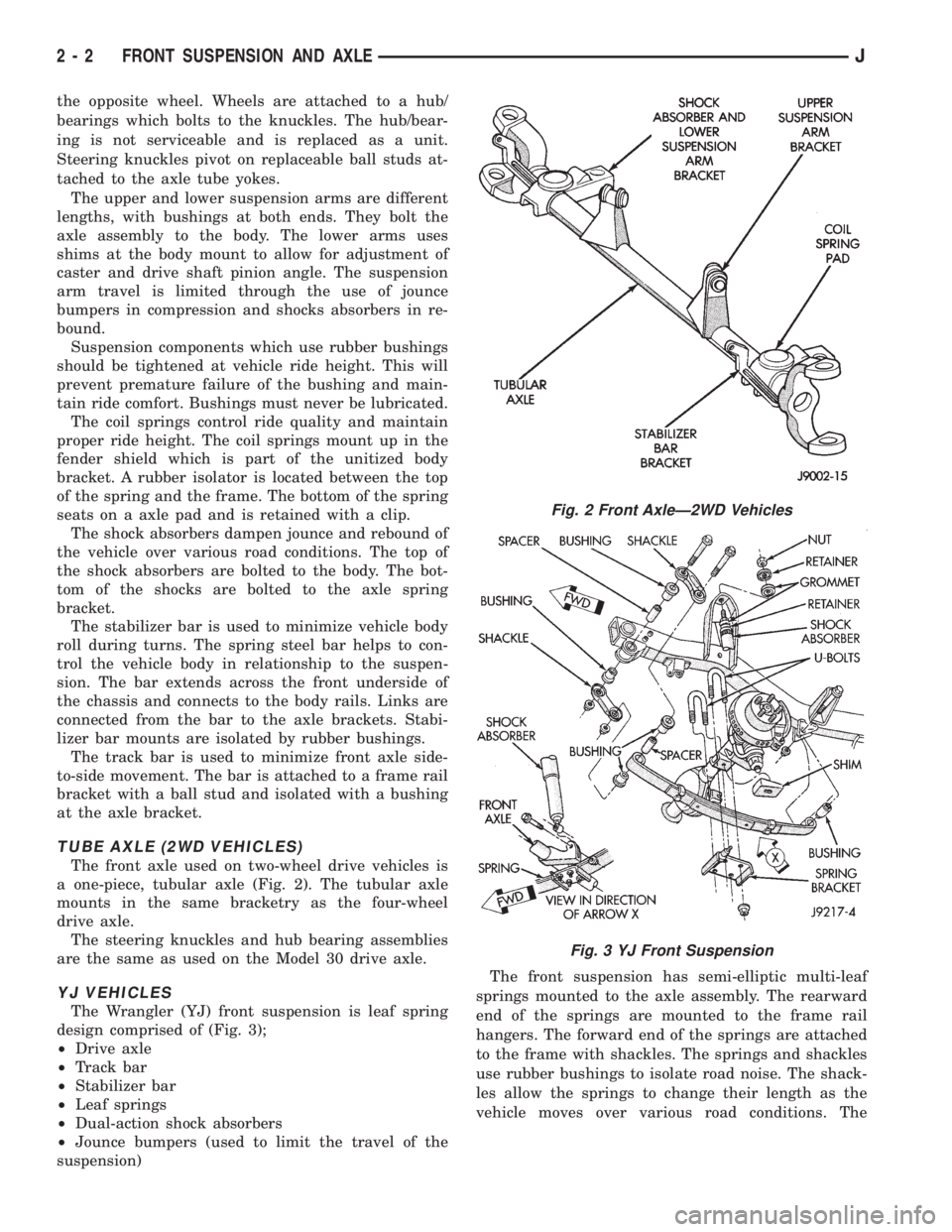

TUBE AXLE (2WD VEHICLES)

The front axle used on two-wheel drive vehicles is

a one-piece, tubular axle (Fig. 2). The tubular axle

mounts in the same bracketry as the four-wheel

drive axle.

The steering knuckles and hub bearing assemblies

are the same as used on the Model 30 drive axle.

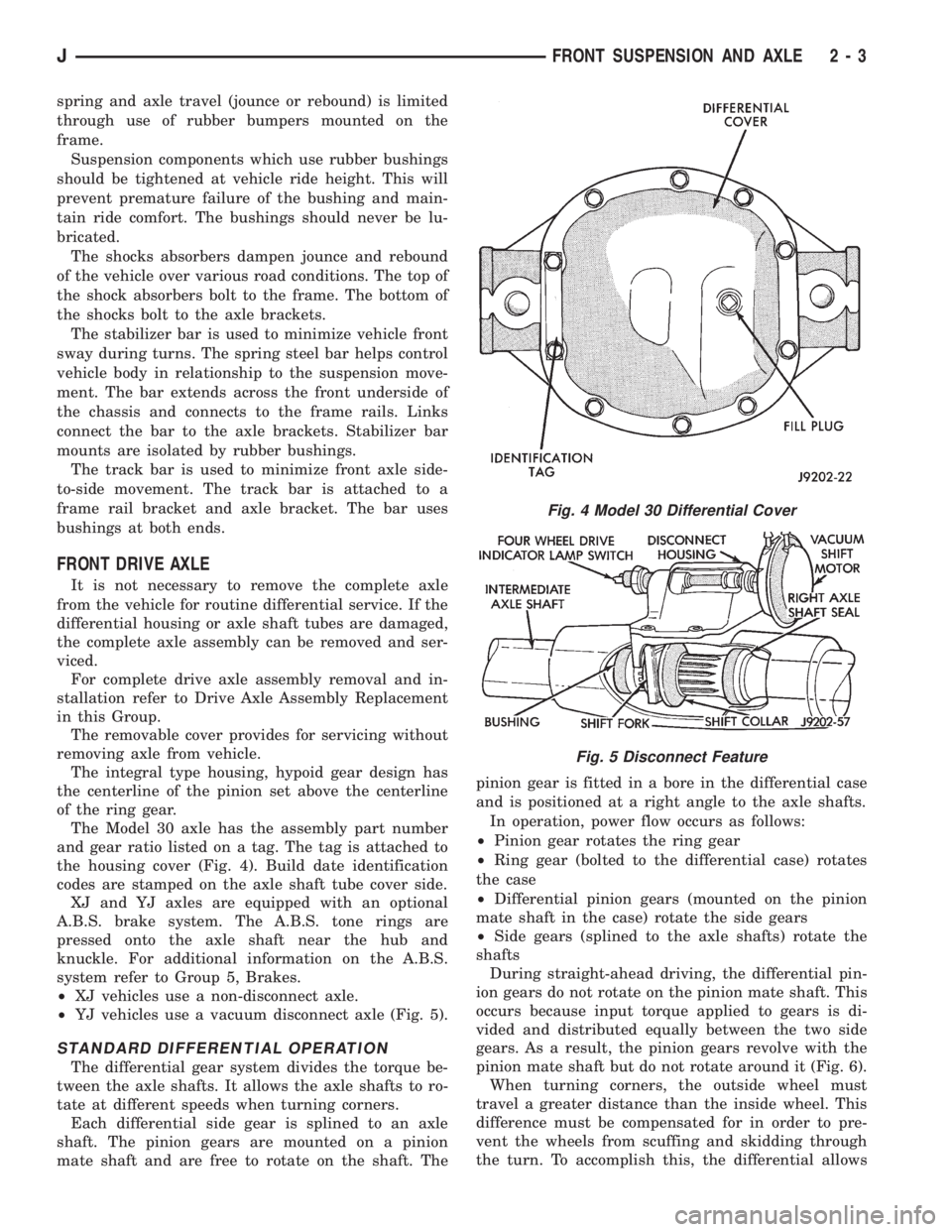

YJ VEHICLES

The Wrangler (YJ) front suspension is leaf spring

design comprised of (Fig. 3);

²Drive axle

²Track bar

²Stabilizer bar

²Leaf springs

²Dual-action shock absorbers

²Jounce bumpers (used to limit the travel of the

suspension)The front suspension has semi-elliptic multi-leaf

springs mounted to the axle assembly. The rearward

end of the springs are mounted to the frame rail

hangers. The forward end of the springs are attached

to the frame with shackles. The springs and shackles

use rubber bushings to isolate road noise. The shack-

les allow the springs to change their length as the

vehicle moves over various road conditions. The

Fig. 2 Front AxleÐ2WD Vehicles

Fig. 3 YJ Front Suspension

2 - 2 FRONT SUSPENSION AND AXLEJ

Page 38 of 2198

spring and axle travel (jounce or rebound) is limited

through use of rubber bumpers mounted on the

frame.

Suspension components which use rubber bushings

should be tightened at vehicle ride height. This will

prevent premature failure of the bushing and main-

tain ride comfort. The bushings should never be lu-

bricated.

The shocks absorbers dampen jounce and rebound

of the vehicle over various road conditions. The top of

the shock absorbers bolt to the frame. The bottom of

the shocks bolt to the axle brackets.

The stabilizer bar is used to minimize vehicle front

sway during turns. The spring steel bar helps control

vehicle body in relationship to the suspension move-

ment. The bar extends across the front underside of

the chassis and connects to the frame rails. Links

connect the bar to the axle brackets. Stabilizer bar

mounts are isolated by rubber bushings.

The track bar is used to minimize front axle side-

to-side movement. The track bar is attached to a

frame rail bracket and axle bracket. The bar uses

bushings at both ends.

FRONT DRIVE AXLE

It is not necessary to remove the complete axle

from the vehicle for routine differential service. If the

differential housing or axle shaft tubes are damaged,

the complete axle assembly can be removed and ser-

viced.

For complete drive axle assembly removal and in-

stallation refer to Drive Axle Assembly Replacement

in this Group.

The removable cover provides for servicing without

removing axle from vehicle.

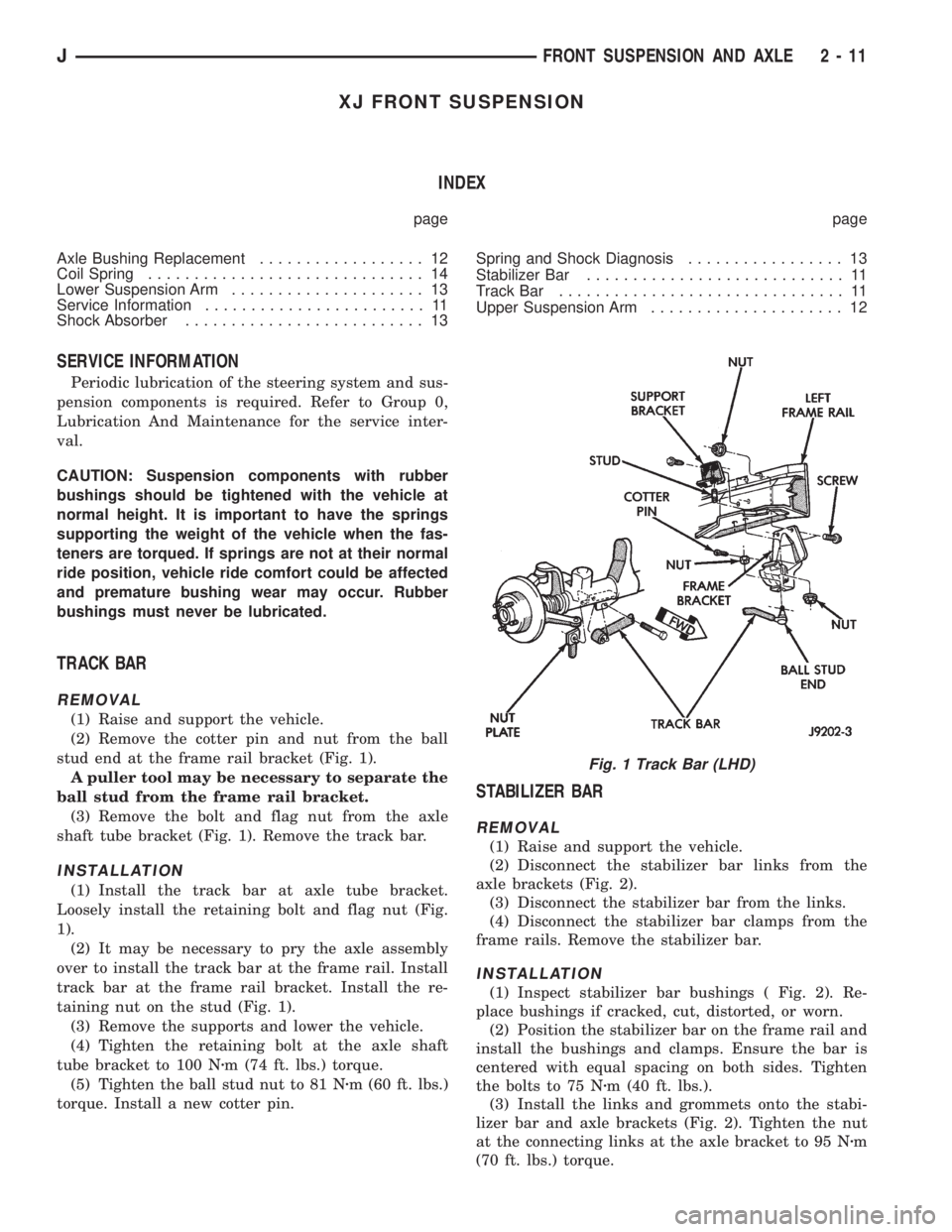

The integral type housing, hypoid gear design has

the centerline of the pinion set above the centerline

of the ring gear.

The Model 30 axle has the assembly part number

and gear ratio listed on a tag. The tag is attached to

the housing cover (Fig. 4). Build date identification

codes are stamped on the axle shaft tube cover side.

XJ and YJ axles are equipped with an optional

A.B.S. brake system. The A.B.S. tone rings are

pressed onto the axle shaft near the hub and

knuckle. For additional information on the A.B.S.

system refer to Group 5, Brakes.

²XJ vehicles use a non-disconnect axle.

²YJ vehicles use a vacuum disconnect axle (Fig. 5).

STANDARD DIFFERENTIAL OPERATION

The differential gear system divides the torque be-

tween the axle shafts. It allows the axle shafts to ro-

tate at different speeds when turning corners.

Each differential side gear is splined to an axle

shaft. The pinion gears are mounted on a pinion

mate shaft and are free to rotate on the shaft. Thepinion gear is fitted in a bore in the differential case

and is positioned at a right angle to the axle shafts.

In operation, power flow occurs as follows:

²Pinion gear rotates the ring gear

²Ring gear (bolted to the differential case) rotates

the case

²Differential pinion gears (mounted on the pinion

mate shaft in the case) rotate the side gears

²Side gears (splined to the axle shafts) rotate the

shafts

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to gears is di-

vided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig. 6).

When turning corners, the outside wheel must

travel a greater distance than the inside wheel. This

difference must be compensated for in order to pre-

vent the wheels from scuffing and skidding through

the turn. To accomplish this, the differential allows

Fig. 4 Model 30 Differential Cover

Fig. 5 Disconnect Feature

JFRONT SUSPENSION AND AXLE 2 - 3

Page 46 of 2198

XJ FRONT SUSPENSION

INDEX

page page

Axle Bushing Replacement.................. 12

Coil Spring.............................. 14

Lower Suspension Arm..................... 13

Service Information........................ 11

Shock Absorber.......................... 13Spring and Shock Diagnosis................. 13

Stabilizer Bar............................ 11

Track Bar............................... 11

Upper Suspension Arm..................... 12

SERVICE INFORMATION

Periodic lubrication of the steering system and sus-

pension components is required. Refer to Group 0,

Lubrication And Maintenance for the service inter-

val.

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

TRACK BAR

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the cotter pin and nut from the ball

stud end at the frame rail bracket (Fig. 1).

A puller tool may be necessary to separate the

ball stud from the frame rail bracket.

(3) Remove the bolt and flag nut from the axle

shaft tube bracket (Fig. 1). Remove the track bar.

INSTALLATION

(1) Install the track bar at axle tube bracket.

Loosely install the retaining bolt and flag nut (Fig.

1).

(2) It may be necessary to pry the axle assembly

over to install the track bar at the frame rail. Install

track bar at the frame rail bracket. Install the re-

taining nut on the stud (Fig. 1).

(3) Remove the supports and lower the vehicle.

(4) Tighten the retaining bolt at the axle shaft

tube bracket to 100 Nzm (74 ft. lbs.) torque.

(5) Tighten the ball stud nut to 81 Nzm (60 ft. lbs.)

torque. Install a new cotter pin.

STABILIZER BAR

REMOVAL

(1) Raise and support the vehicle.

(2) Disconnect the stabilizer bar links from the

axle brackets (Fig. 2).

(3) Disconnect the stabilizer bar from the links.

(4) Disconnect the stabilizer bar clamps from the

frame rails. Remove the stabilizer bar.

INSTALLATION

(1) Inspect stabilizer bar bushings ( Fig. 2). Re-

place bushings if cracked, cut, distorted, or worn.

(2) Position the stabilizer bar on the frame rail and

install the bushings and clamps. Ensure the bar is

centered with equal spacing on both sides. Tighten

the bolts to 75 Nzm (40 ft. lbs.).

(3) Install the links and grommets onto the stabi-

lizer bar and axle brackets (Fig. 2). Tighten the nut

at the connecting links at the axle bracket to 95 Nzm

(70 ft. lbs.) torque.

Fig. 1 Track Bar (LHD)

JFRONT SUSPENSION AND AXLE 2 - 11

Page 48 of 2198

LOWER SUSPENSION ARM

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the lower suspension arm nut and bolt

from the axle bracket (Fig. 3).

(3) Remove the nut and bolt (Fig. 3) from the rear

bracket and remove the lower suspension arm.

INSTALLATION

(1) Position the lower suspension arm at the axle

bracket and rear bracket (Fig. 3).

(2) Install the bolts and finger tighten the nuts

(Fig. 3).

(3) Remove support and lower the vehicle.

(4) Tighten the front and rear nuts to 115 Nzm (85

ft. lbs.) torque.

SPRING AND SHOCK DIAGNOSIS

A squeak noise from the shock absorber can be pro-

duced if movement between the rubber bushings and

the metal occurs. This noise can usually be stopped

by tightening the attaching nuts. If the squeak noise

persists, inspect for damaged and worn bushings,

and attaching components. Repair as necessary.

The shock absorber bushings do not require any

type of lubrication. Do not lubricate the bushings to

reduce bushing noise. Grease or mineral oil-base lu-

bricants will deteriorate the bushing rubber.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston into and out

of the cylinder four or five times. The action through-

out each stroke should be smooth and even.

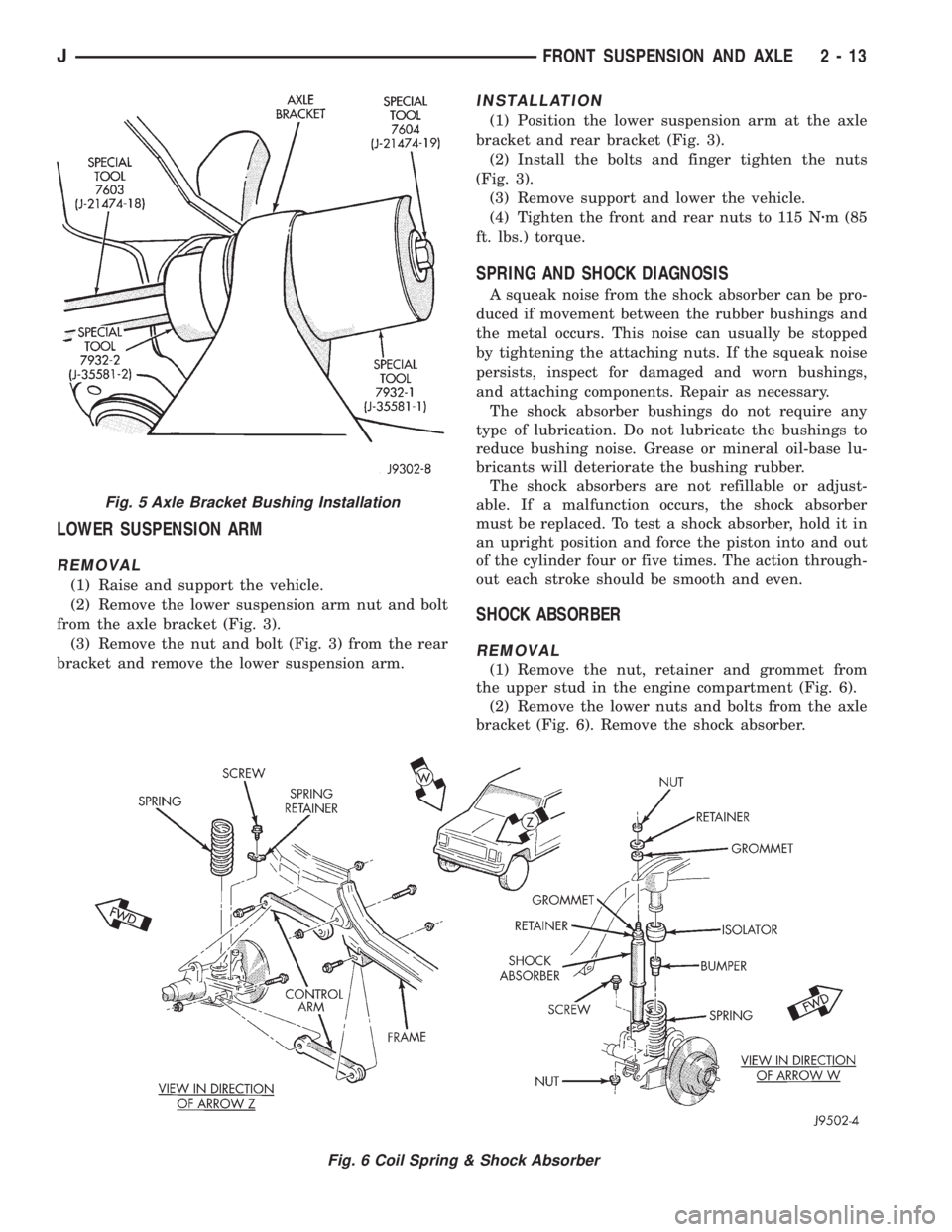

SHOCK ABSORBER

REMOVAL

(1) Remove the nut, retainer and grommet from

the upper stud in the engine compartment (Fig. 6).

(2) Remove the lower nuts and bolts from the axle

bracket (Fig. 6). Remove the shock absorber.

Fig. 6 Coil Spring & Shock Absorber

Fig. 5 Axle Bracket Bushing Installation

JFRONT SUSPENSION AND AXLE 2 - 13

Page 49 of 2198

INSTALLATION

(1) Position the lower retainer and grommet on the

upper stud. Insert the shock absorber through the

shock tower hole.

(2) Install the lower bolts and nuts. Tighten nuts

to 23 Nzm (17 ft. lbs.) torque.

(3) Install the upper grommet and retainer on the

stud in the engine compartment. Install the nut and

tighten to 10 Nzm (8 ft. lbs.) torque.

COIL SPRING

REMOVAL

(1) Raise and support the vehicle. Position a hy-

draulic jack under the axle to support it.

(2) Remove the wheel if necessary.

(3) Mark and disconnect the front propeller shaft

from the axle.

(4) Disconnect the lower suspension arms from the

axle (Fig. 6).

(5) Disconnect the stabilizer bar link and shock ab-

sorber from the axle.

(6) Disconnect the track bar from the frame rail

bracket.(7) Disconnect the drag link from the pitman arm.

(8) Lower the axle until the spring is free from the

upper mount. Remove the coil spring clip (Fig. 6) and

remove the spring.

(9) Pull jounce bumper out of mount.

INSTALLATION

(1) Install jounce bumper into mount.

(2) Position the coil spring on the axle pad. Install

the spring clip and bolt (Fig. 6). Tighten bolt to 21

Nzm (16 ft. lbs.) torque.

(3) Raise the axle into position until the spring

seats in the upper mount.

(4) Connect the stabilizer bar links and shock ab-

sorbers to the axle bracket. Connect the track bar to

the frame rail bracket.

(5) Install the lower suspension arms to the axle.

DO NOT TIGHTEN AT THIS TIME.

(6) Install the front propeller shaft to the axle.

(7) Remove the supports and lower the vehicle.

(8) Tighten lower suspension arms nuts to 115 Nzm

(85 ft. lbs.) torque.

2 - 14 FRONT SUSPENSION AND AXLEJ

Page 50 of 2198

YJ FRONT SUSPENSION

INDEX

page page

Leaf Spring.............................. 16

Leaf Spring Eye Bushing Replacement......... 17

Service Information........................ 15

Shock Absorber.......................... 16Spring and Shock Diagnosis................. 15

Stabilizer Bar............................ 15

Track Bar............................... 15

SERVICE INFORMATION

Periodic lubrication of the steering system and sus-

pension components is required. Refer to Group 0,

Lubrication And Maintenance for the service inter-

val.

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

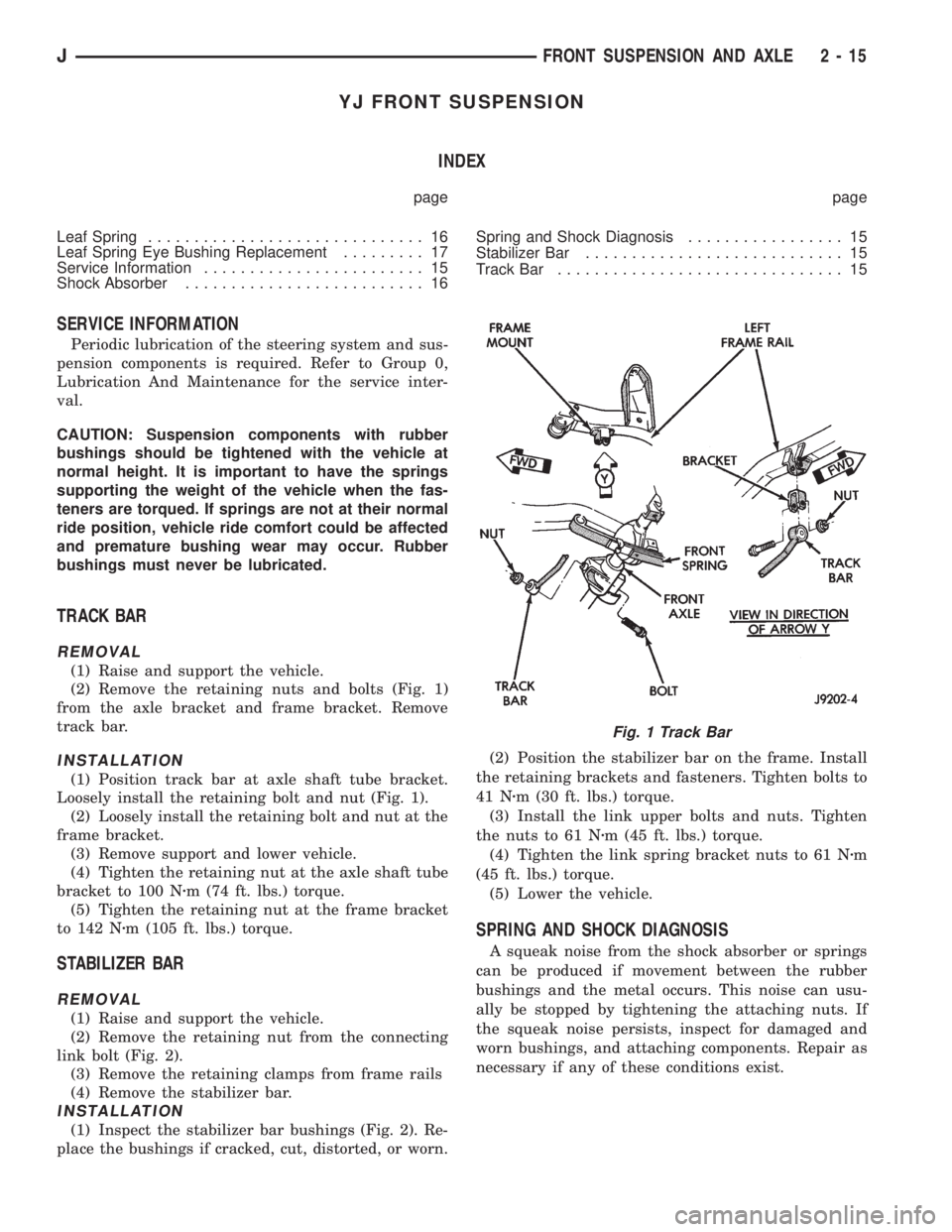

TRACK BAR

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the retaining nuts and bolts (Fig. 1)

from the axle bracket and frame bracket. Remove

track bar.

INSTALLATION

(1) Position track bar at axle shaft tube bracket.

Loosely install the retaining bolt and nut (Fig. 1).

(2) Loosely install the retaining bolt and nut at the

frame bracket.

(3) Remove support and lower vehicle.

(4) Tighten the retaining nut at the axle shaft tube

bracket to 100 Nzm (74 ft. lbs.) torque.

(5) Tighten the retaining nut at the frame bracket

to 142 Nzm (105 ft. lbs.) torque.

STABILIZER BAR

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the retaining nut from the connecting

link bolt (Fig. 2).

(3) Remove the retaining clamps from frame rails

(4) Remove the stabilizer bar.

INSTALLATION

(1) Inspect the stabilizer bar bushings (Fig. 2). Re-

place the bushings if cracked, cut, distorted, or worn.(2) Position the stabilizer bar on the frame. Install

the retaining brackets and fasteners. Tighten bolts to

41 Nzm (30 ft. lbs.) torque.

(3) Install the link upper bolts and nuts. Tighten

the nuts to 61 Nzm (45 ft. lbs.) torque.

(4) Tighten the link spring bracket nuts to 61 Nzm

(45 ft. lbs.) torque.

(5) Lower the vehicle.

SPRING AND SHOCK DIAGNOSIS

A squeak noise from the shock absorber or springs

can be produced if movement between the rubber

bushings and the metal occurs. This noise can usu-

ally be stopped by tightening the attaching nuts. If

the squeak noise persists, inspect for damaged and

worn bushings, and attaching components. Repair as

necessary if any of these conditions exist.

Fig. 1 Track Bar

JFRONT SUSPENSION AND AXLE 2 - 15