wheel alignment JEEP CHEROKEE 1995 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 95 of 2198

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion gear shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft

²Missing drive shaft balance weight

²Worn, out-of-balance wheels

²Loose wheel lug nuts

²Worn U-joint

²Loose spring U-bolts

²Loose/broken springs

²Damaged axle shaft bearings

²Loose pinion gear nut

²Excessive pinion yoke run out

²Bent axle shaft

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear-end vi-

bration. Do not overlook engine accessories, brackets

and drive belts.

All driveline components should be examined be-

fore starting any repair.

Refer to Group 22, Wheels and Tires for additional

information.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed

²Loose engine/transmission/transfer case mounts

²Worn U-joints

²Loose spring mounts

²Loose pinion gear nut and yoke

²Excessive ring gear backlash

²Excessive side gear\ase clearance

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the ve-

hicle on a hoist with the wheels free to rotate.

Instruct the helper to shift the transmission into

gear. Listen for the noise, a mechanics stethoscope is

helpful in isolating the source of a noise.

REAR AXLE ALIGNMENT

MEASUREMENT

The following procedure can be used to determine

if abnormal rear tire tread wear is the result of a

bent or deformed rear axle shaft.

(1) Raise both rear wheels off the surface with a

frame contact hoist.

(2) Attach a one-inch long piece of masking tape at

the center of each tire tread for use as reference marks.

(3) Rotate the rear wheels until both reference

marks face the front of the vehicle. Measure the dis-

tance between the outside edges of the two pieces of

tape. Record this measurement as the front of tire

(FTR) measurement.

(4) Rotate the rear wheels until both reference

marks face the rear of the vehicle. Measure the dis-

tance between the outside edges of the two pieces of

tape. Record this measurement as the rear of tire

(RTR) measurement.

(5) Subtract the (RTR) measurement from the

(FTR) measurement to obtain the amount of wheel

toe. The acceptable rear wheel toe-in position is 1/16

inch (1.6 mm) to 3/16 inch (4.8 mm) toe-out.

(6) Rotate the rear wheels until the reference

marks are facing downward. Measure the distance

between the outside edges of the two pieces of tape.

Record this measurement as the bottom of tire (BTR)

measurement.

(7) Average the (FTR) and the (RTR) distance mea-

surements. Subtract the (BTR) measurement from

this average distance to obtain the camber. The ac-

ceptable amount of camber is 1/16 inch to 3/32 inch

(1.6 to 2.4 mm).

(FTR + RTR) DIVIDED BY 2 (TWO) MINUS

BTR EQUALS CAMBER

If the (BTR) distance measurement is less

than the average FTR and RTR distance mea-

surement, the camber will be positive(+).If

the (BTR) distance measurement is greater

than the average FTR and RTR distance, the

camber will be negative(-).

If the toe position or camber is not acceptable, a bent

or deformed rear axle shaft is most likely the cause.

LIMITED SLIP DIFFERENTIAL

Under normal traction conditions, engine torque is di-

vided evenly. With low-traction surfaces, engine torque

is transferred to the wheel with the most tire traction.

When diagnosing a limited-slip differential the wheel

with the least traction can continue spinning.

The most common problem is a chatter noise when

turning corners. Check for incorrect or contaminated

lubricant. Replace the gear lubricant if necessary.

²With Trac-LokŸ differentials add a container of

MOPAR Trac-Lok Lubricant.

This will correct the condition in most instances. If

the chatter persists, clutch damage could have oc-

curred.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches.

3 - 10 REAR SUSPENSION AND AXLESJ

Page 99 of 2198

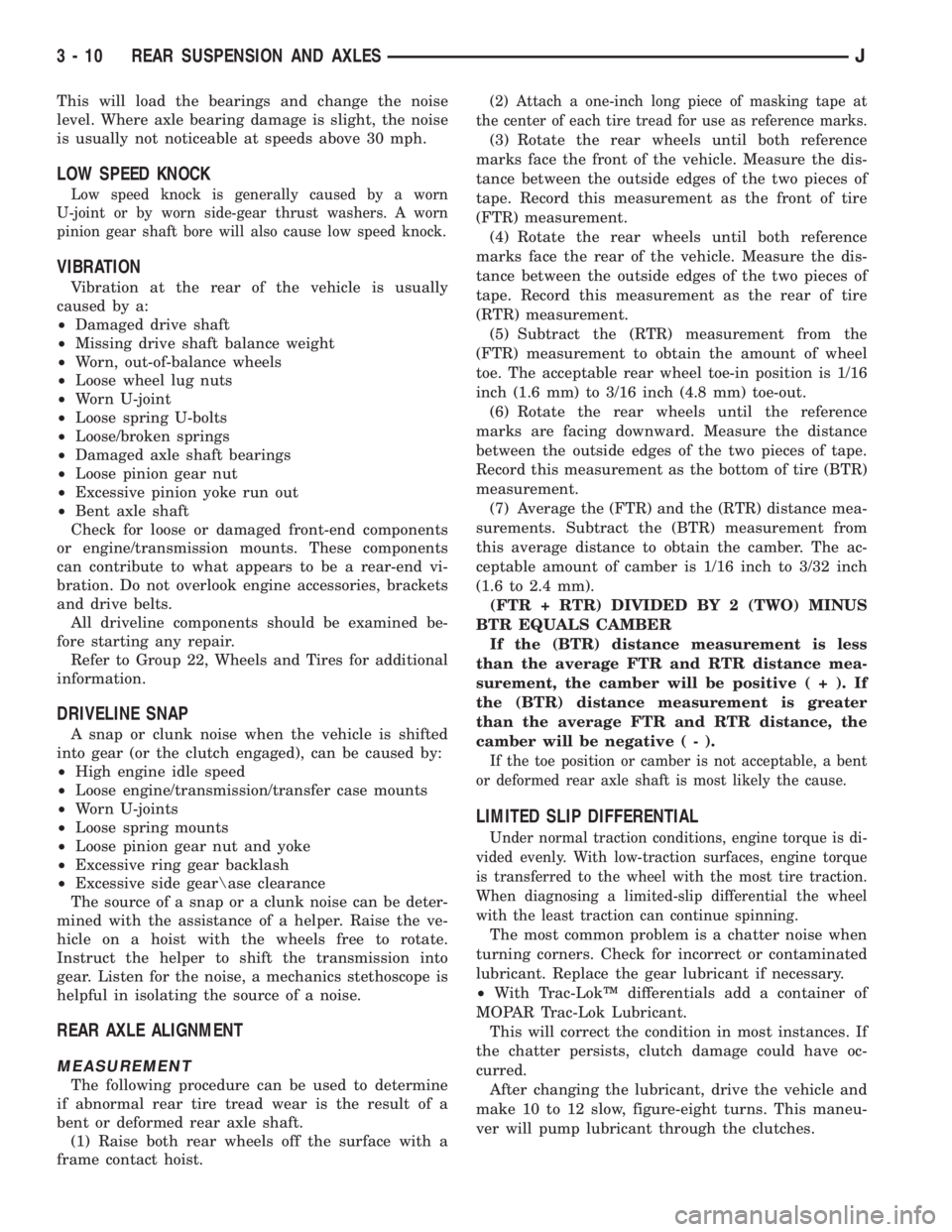

CAUTION: Overfilling the differential can result in

lubricant foaming and overheating.

Trac-Lok Differentials; A container of Trac-Lok lu-

bricant (friction modifier) should be added after re-

pair service or a lubricant change.

(9) Install the fill hole plug and lower the vehicle.

LIMITED SLIP DIFFERENTIAL vehicles should

be road tested by making 10 to 12 slow figure-eight

turns. This maneuver will pump the lubricant

through the clutch discs to eliminate a possible chat-

ter noise complaint.

DRIVE AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES

REMOVAL

(1) Raise the vehicle and position support stands

under the frame rails slightly in front the springs.

(2) Remove the rear wheels.

(3) Mark the drive shaft yoke and axle pinion yoke

for alignment reference. Disconnect the drive shaft

from the axle.

(4) Disconnect the axle vent hose.

(5) Disconnect the parking brake cables at the

equalizer or backing plate.

(6) Disconnect the shock absorbers from the axle

brackets.

(7) Disconnect the brake hose at the axle junction

block.Do not disconnect the wheel cylinder tub-

ing fittings.

(8) If equipped, disconnect ABS wiring connections

at the axle.(9) Support the axle with a hydraulic jack under

the differential.

(10) Remove the spring U-bolts from the plate

brackets.

(11) Lower the jack enough to remove the axle.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

(1) Support the axle on a hydraulic jack under the

differential. Position the axle under the vehicle.

(2) Raise the axle and align the spring center bolts

with the locating holes in the axle pads and plate

brackets.

(3) Install the spring U-bolts through the plate

brackets and tighten to 70 Nzm (52 ft. lbs.) torque.

(4) Install ABS wiring connections (if equipped) at

the axle.

(5) Connect the brake hose at the axle junction

block.

(6) Install the shock absorbers to the axle brackets

and tighten to 62 Nzm (46 ft. lbs.) torque.

(7) Connect the parking brake cables at the equal-

izer or backing plate.

(8) Connect the vent hose to the tube fitting.

(9) Align the reference marks and connect the

drive shaft to the axle yoke. Tighten the U-joint

clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(10) Check differential lubricant and add if neces-

sary.

(11) Install the wheel and tire.

(12) Bleed the brakes.

(13) Remove the supports and lower the vehicle.

DRIVE AXLE ASSEMBLY REPLACEMENTÐYJ

VEHICLES

REMOVAL

(1) Raise the vehicle and position support stands

under the frame rails slightly in front the springs.

(2) Remove the rear wheels.

(3) Mark the drive shaft yoke and axle pinion yoke

for alignment reference. Disconnect the drive shaft

from the axle.

(4) Disconnect the axle vent hose.

(5) Disconnect the parking brake cables at the

equalizer or backing plate.

(6) Disconnect the shock absorbers from the plate

brackets.

Fig. 1 Typical Housing Cover With Sealant

3 - 14 REAR SUSPENSION AND AXLESJ

Page 100 of 2198

(7) Disconnect the brake hose at the axle junction

block.Do not disconnect the wheel cylinder tub-

ing fittings.

(8) Disconnect the track bar at the axle bracket.

(9) Support the axle with a hydraulic jack under

the differential. Raise the axle just enough to relieve

the axle weight from the springs.

(10) Remove the spring U-bolts from the plate

brackets.

(11) Loosen BUT DO NOT REMOVE the bolts that

attach the spring front pivot at the frame rail brack-

ets. This will allow the springs to pivot without bind-

ing on the bushings.

(12) Disconnect shackle from the springs and lower

the springs to the surface.

(13) Lower the jack enough to remove the axle.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

(1) Support the axle on a hydraulic jack under the

differential. Position the axle under the vehicle.

(2) Raise the springs and install the spring shackle

bolts.Do not tighten at this time.

(3) Lower the axle and align the spring center

bolts with the locating holes in the axle pads and

plate brackets.

(4) Install the spring U-bolts through the plate

brackets and tighten to 122 Nzm (90 ft. lbs.) torque.

(5) Connect the track bar to the axle bracket and

install the bolt. Do not tighten at this time.

It is important that the springs support the

weight of the vehicle when the track bar is con-

nected. If the springs are not at their usual po-

sition, vehicle ride comfort could be affected.

(6) Connect the brake hose at the axle junction

block.

(7) Install the shock absorbers to the axle brackets

and tighten to 61 Nzm (45 ft. lbs.) torque.

(8) Connect the parking brake cables at the equal-

izer or backing plate.

(9) Connect the vent hose to the tube fitting.

(10) Align the reference marks and connect the

drive shaft to the axle yoke. Tighten the U-joint

clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(11) Check differential lubricant and add if neces-

sary.

(12) Install the wheel and tire.

(13) Bleed the brakes.

(14) Remove the supports and lower the vehicle.(15) Tighten the spring front pivot bolt/nut to 142

Nzm (105 ft. lbs.) torque. Tighten the spring shackle

bolt/nut to 135 Nzm (100 ft. lbs.) torque.

(16) Tighten the track bar bolt at the axle bracket

to 142 Nzm (105 ft. lbs.) torque.

PINION SHAFT SEAL REPLACEMENT

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Mark the drive shaft yoke and pinion yoke for

installation alignment reference.

(4) Remove the drive shaft from the yoke.

(5) Rotate the pinion gear three or four times.

Make sure brakes are not dragging during this

procedure.

(6) Measure the amount of torque (in Newton-

meters or inch-pounds) necessary to rotate the pinion

gear with a torque wrench. Note the torque for in-

stallation reference.It must be known to properly

adjust the pinion gear bearing preload torque

after seal installation.

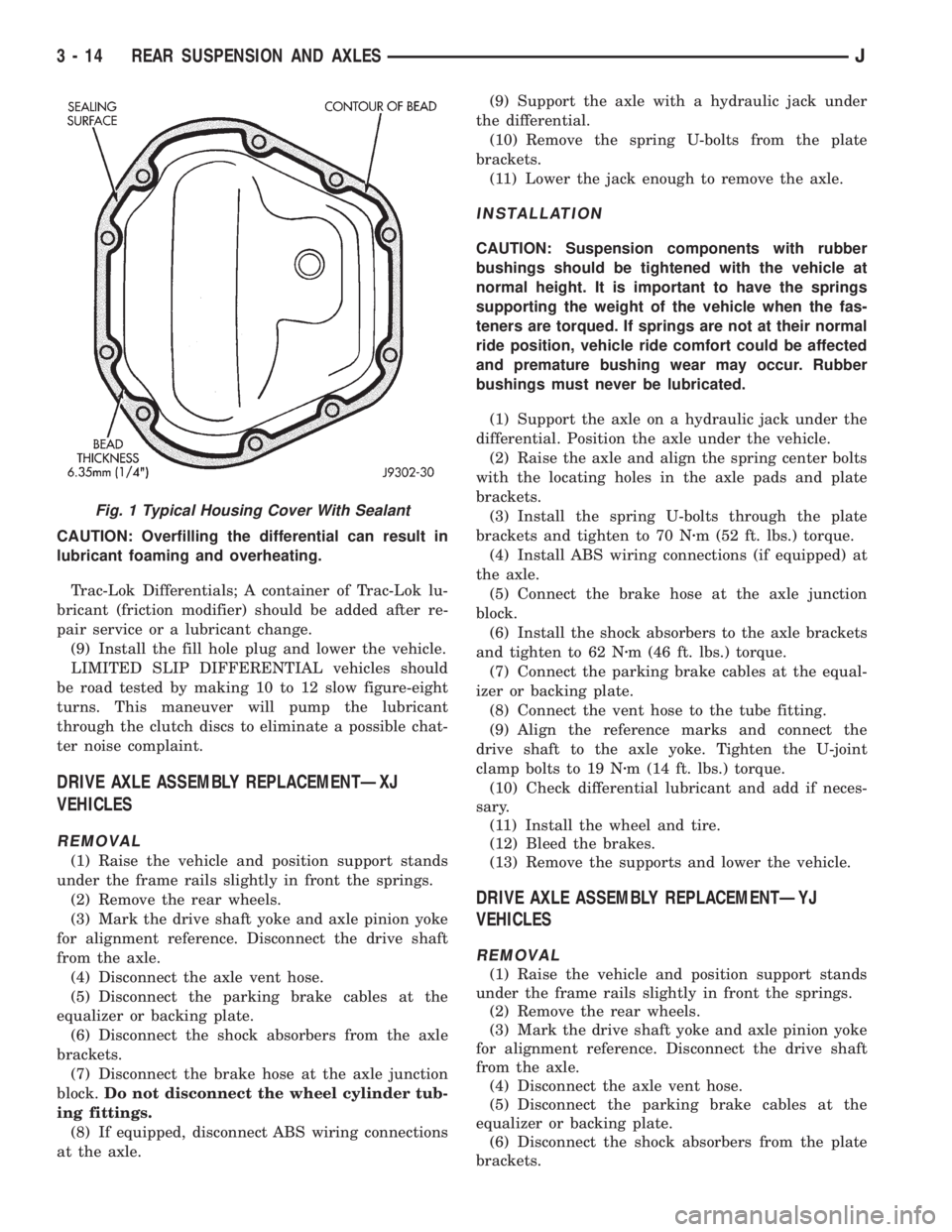

(7) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 2).

(8) Mark the positions of the yoke and pinion gear

for installation alignment reference.

(9) Use Remover 7794A and slide hammer to re-

move the pinion gear seal (Fig. 3).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with Installer D-163

and Handle C-4171 (Fig. 4).

(2) Align the installation reference marks and in-

stall yoke on the pinion gear with Installer W-162-D.

(3) Install a new nut on the pinion gear.Tighten

the nut only enough to remove the shaft end

play.

Fig. 2 Pinion Yoke Removal

JREAR SUSPENSION AND AXLES 3 - 15

Page 116 of 2198

LUBRICANT SPECIFICATIONS

Multi-purpose, hypoid gear lubricant should be

used in the 8 1/4 inch axle. The lubricant should

have MIL-L-2105C and API GL 5 quality specifica-

tions. MOPARtHypoid Gear Lubricant conforms to

both of these specifications.

²The factory installed lubricant for the 8 1/4 inch

rear axle is SAE 80W 90 gear lubricant.

²The factory installed lubricant quantity is 6762

fluid oz.

CAUTION: Overfilling the differential can result in

lubricant foaming and overheating.

Refer to Group 0, Lubrication and Maintenance for

additional information.

CAUTION: If axle is submerged in water, lubricant

must be replaced immediately to avoid possible

premature axle failure.

DRIVE AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES

REMOVAL

(1) Raise the vehicle. Position support stands un-

der the frame rails slightly in front the springs.

(2) Remove the rear wheels.

(3) Mark the drive shaft yoke and axle pinion yoke

for alignment reference. Disconnect the drive shaft

from the axle.

(4) Disconnect the axle vent hose.

(5) Disconnect the parking brake cables at the

equalizer or backing plate.

(6) Disconnect the shock absorbers from the axle

brackets.

(7) Disconnect the brake hose at the axle junction

block.Do not disconnect the wheel cylinder tub-

ing fittings.

(8) If equipped, disconnect ABS wiring connections

at the axle.

(9) Support the axle with a hydraulic jack under

the differential.

(10) Remove the spring U-bolts from the plate

brackets.

(11) Lower the jack enough to remove the axle.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.(1) Support the axle on a hydraulic jack under the

differential. Position the axle under the vehicle.

(2) Raise the axle and align the spring center bolts

with the locating holes in the axle pads and plate

brackets.

(3) Install the spring U-bolts through the plate

brackets and tighten to 70 Nzm (52 ft. lbs.) torque.

(4) Install ABS wiring connections (if equipped) at

the axle.

(5) Connect the brake hose at the axle junction

block.

(6) Install the shock absorbers to the axle brackets

and tighten to 62 Nzm (46 ft. lbs.) torque.

(7) Connect the parking brake cables at the equal-

izer or backing plate.

(8) Connect the vent hose to the tube fitting.

(9) Align the reference marks and connect the

drive shaft to the axle yoke. Tighten the U-joint

clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(10) Check differential lubricant and add if neces-

sary.

(11) Install the wheel and tire.

(12) Bleed the brakes.

(13) Remove the supports and lower the vehicle.

LUBRICANT CHANGE

The gear lubricant will drain quicker if the vehicle

has been recently driven.

(1) Raise and support the vehicle.

(2) Remove the lubricant fill hole plug from the dif-

ferential housing cover.

(3) Remove the differential housing cover and

drain the lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove the sealant from the housing and cover

surfaces. Use solvent to clean the mating surfaces.

(6) Apply a bead of MOPARtSilicone Rubber Seal-

ant to the housing cover (Fig. 2). Allow the sealant to

cure for a few minutes.

Install the housing cover within 5 minutes after

applying the sealant. If not installed the sealant

must be removed and another bead applied.

(7) Install the cover and any identification tag.

Tighten the cover bolts in a criss-cross pattern to 47

Nzm (35 ft. lbs.) torque.

(8) Refill the differential with Mopar Hypoid Gear

Lubricant 13 mm (1/2 in.) below the fill plug hole.

With Trac-Lok differentials, add a container of Mopar

Hypoid Gear Lubricant Additive.

CAUTION: Overfilling the differential can result in

lubricant foaming and overheating.

(9) Install the fill hole plug and lower the vehicle.

JREAR SUSPENSION AND AXLES 3 - 31

Page 206 of 2198

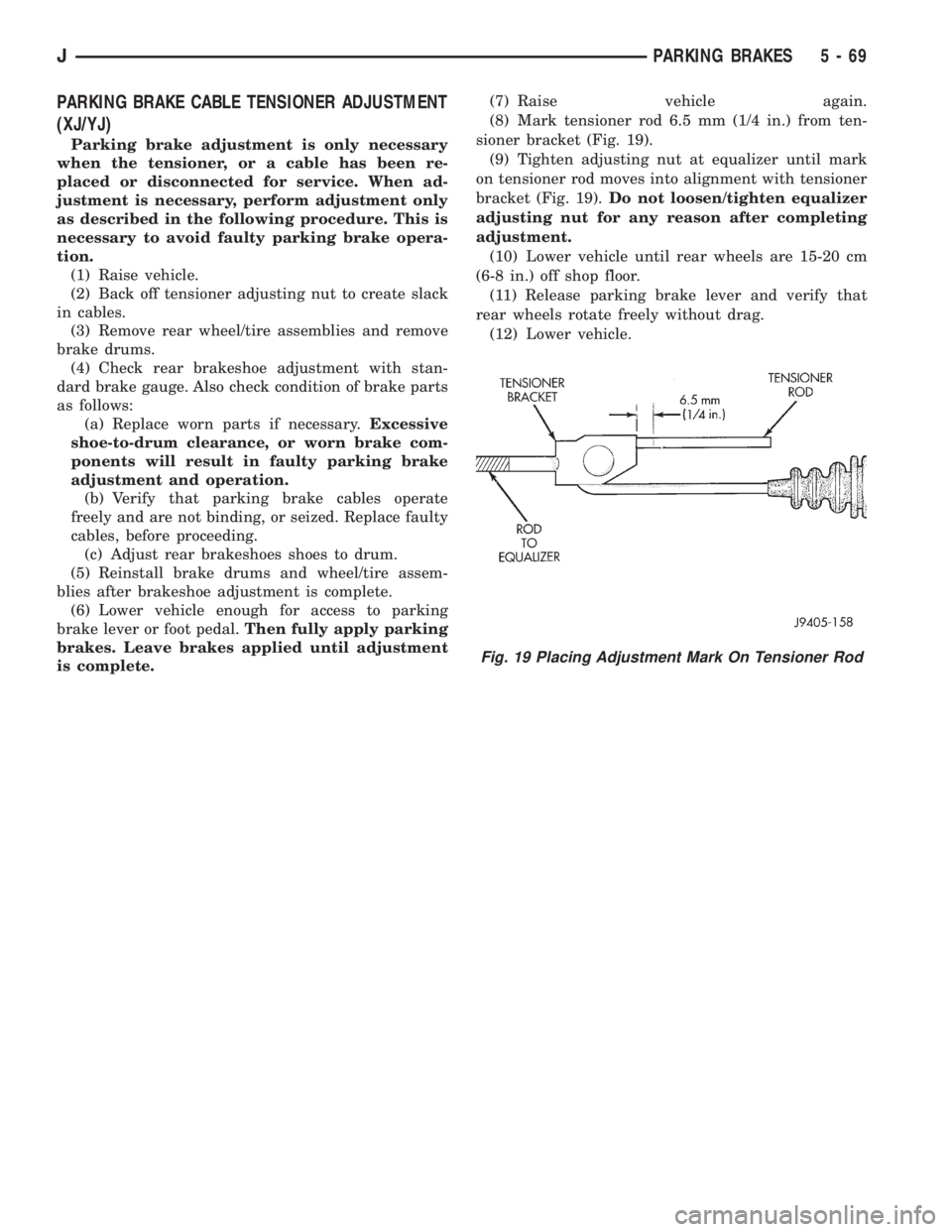

PARKING BRAKE CABLE TENSIONER ADJUSTMENT

(XJ/YJ)

Parking brake adjustment is only necessary

when the tensioner, or a cable has been re-

placed or disconnected for service. When ad-

justment is necessary, perform adjustment only

as described in the following procedure. This is

necessary to avoid faulty parking brake opera-

tion.

(1) Raise vehicle.

(2) Back off tensioner adjusting nut to create slack

in cables.

(3) Remove rear wheel/tire assemblies and remove

brake drums.

(4) Check rear brakeshoe adjustment with stan-

dard brake gauge. Also check condition of brake parts

as follows:

(a) Replace worn parts if necessary.Excessive

shoe-to-drum clearance, or worn brake com-

ponents will result in faulty parking brake

adjustment and operation.

(b) Verify that parking brake cables operate

freely and are not binding, or seized. Replace faulty

cables, before proceeding.

(c) Adjust rear brakeshoes shoes to drum.

(5) Reinstall brake drums and wheel/tire assem-

blies after brakeshoe adjustment is complete.

(6) Lower vehicle enough for access to parking

brake lever or foot pedal.Then fully apply parking

brakes. Leave brakes applied until adjustment

is complete.(7) Raise vehicle again.

(8) Mark tensioner rod 6.5 mm (1/4 in.) from ten-

sioner bracket (Fig. 19).

(9) Tighten adjusting nut at equalizer until mark

on tensioner rod moves into alignment with tensioner

bracket (Fig. 19).Do not loosen/tighten equalizer

adjusting nut for any reason after completing

adjustment.

(10) Lower vehicle until rear wheels are 15-20 cm

(6-8 in.) off shop floor.

(11) Release parking brake lever and verify that

rear wheels rotate freely without drag.

(12) Lower vehicle.

Fig. 19 Placing Adjustment Mark On Tensioner Rod

JPARKING BRAKES 5 - 69

Page 210 of 2198

CLUTCH DIAGNOSIS

INDEX

page page

Clutch Contamination....................... 3

Clutch Cover and Disc Runout................ 3

Clutch Housing Misalignment................. 4

Clutch Misalignment........................ 3Flywheel Runout........................... 3

General Diagnosis Information................ 3

Inspection and Diagnosis Charts............... 4

Installation Methods and Parts Usage........... 4

GENERAL DIAGNOSIS INFORMATION

Unless the cause of a clutch problem is obvious, ac-

curate problem diagnosis will usually require a road

test to confirm a problem. Component inspection will

then be required to determine the actual problem

cause.

During a road test, drive the vehicle at normal

speeds. Shift the transmission through all gear

ranges and observe clutch action. If chatter, grab,

slip, or improper release is experienced, remove and

inspect the clutch components. However, if the prob-

lem is noise or hard shifting, further diagnosis may

be needed as the transmission or another driveline

component may be at fault. Careful observation dur-

ing the test will help narrow the problem area.

CLUTCH CONTAMINATION

Fluid contamination is a frequent cause of clutch

malfunctions. Oil, water, or clutch fluid on the clutch

disc and pressure plate surfaces will cause chatter,

slip and grab.

During inspection, note if any components are con-

taminated with oil, hydraulic fluid, or water/road

splash.

Oil contamination indicates a leak at either the

rear main seal or transmission input shaft. Oil leak-

age produces a residue of oil on the housing interior

and on the clutch cover and flywheel. Heat buildup

caused by slippage between the cover, disc and fly-

wheel, can sometimes bake the oil residue onto the

components. The glaze-like residue ranges in color

from amber to black.

Road splash contamination means dirt/water is en-

tering the clutch housing due to loose bolts, housing

cracks, or through hydraulic line openings. Driving

through deep water puddles can force water/road

splash into the housing through such openings.

Clutch fluid leaks are usually from damaged slave

cylinder push rod seals. This type of leak can only be

confirmed by visual inspection.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.Misalignment caused by excessive runout or warpage

of any clutch component will cause grab, chatter and

improper clutch release.

FLYWHEEL RUNOUT

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator. Mount the in-

dicator on a stud installed in place of one of the fly-

wheel bolts.

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. However, mi-

nor flywheel scoring can be cleaned up by hand with

180 grit emery, or with surface grinding equipment.

Remove only enough material to reduce scoring (ap-

proximately 0.001 - 0.003 in.). Heavy stock removal

isnot recommended.Replace the flywheel if scor-

ing is severe and deeper than 0.076 mm (0.003 in.).

Excessive stock removal can result in flywheel crack-

ing or warpage after installation; it can also weaken

the flywheel and interfere with proper clutch release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with Mopar Lock And Seal. Tighten flywheel

bolts to specified torque only. Overtightening can dis-

tort the flywheel hub causing runout.

CLUTCH COVER AND DISC RUNOUT

Check the clutch disc before installation. Axial

(face) runout of anewdisc should not exceed 0.50

mm (0.020 in.). Measure runout about 6 mm (1/4 in.)

from the outer edge of the disc facing. Obtain an-

other disc if runout is excessive.

Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab

and incomplete release or engagement. Be careful

JCLUTCH DIAGNOSIS 6 - 3

Page 211 of 2198

when handling the cover and disc. Impact can distort

the cover, diaphragm spring, release fingers and the

hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign-

ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and

consequent misalignment) is improper bolt tighten-

ing. To avoid warping the cover, the bolts must tight-

ened alternately (diagonal pattern) and evenly (2-3

threads at a time) to specified torque.

CLUTCH HOUSING MISALIGNMENT

Clutch housing alignment is important to proper

clutch operation. The housing maintains alignment

between the crankshaft and transmission input

shaft. Misalignment can cause clutch noise, hard

shifting, incomplete release and chatter. It can also

result in premature wear of the pilot bearing, cover

release fingers and clutch disc. In severe cases, mis-

alignment can also cause premature wear of the

transmission input shaft and front bearing.

Housing misalignment is generally caused by incor-

rect seating on the engine or transmission, loose

housing bolts, missing alignment dowels, or housing

damage. Infrequently, misalignment may also be

caused by housing mounting surfaces that are not

completely parallel. Misalignment can be corrected

with shims.

INSTALLATION METHODS AND PARTS USAGE

Distortion of clutch components during installation

and the use of non-standard components are addi-

tional causes of clutch malfunction.Improper clutch cover bolt tightening can distort

the cover. The usual result is clutch grab, chatter

and rapid wear. Tighten the cover bolts as described

in Clutch Service section.

An improperly seated flywheel and/or clutch hous-

ing are additional causes of clutch failure. Improper

seating will produce misalignment and additional

clutch problems.

The use of non-standard or low quality parts will

also lead to problems and wear. Use recommended

factory quality parts to avoid comebacks.

A cocked pilot bearing is another cause of clutch

noise, drag, and hard shifting, and rapid bearing

wear. Always use an alignment tool to install a new

bearing. This practice helps avoid cocking the bear-

ing during installation.

INSPECTION AND DIAGNOSIS CHARTS

The clutch inspection chart (Fig. 1) outlines items

to be checked before and during clutch installation.

Use the chart as a check list to help avoid overlook-

ing potential problem sources during service opera-

tions.

The diagnosis charts describe common clutch prob-

lems, causes and correction. Fault conditions are

listed at the top of each chart. Conditions, causes and

corrective action are outlined in the indicated col-

umns.

The charts are provided as a convenient reference

when diagnosing faulty clutch operation.

6 - 4 CLUTCH DIAGNOSISJ

Page 218 of 2198

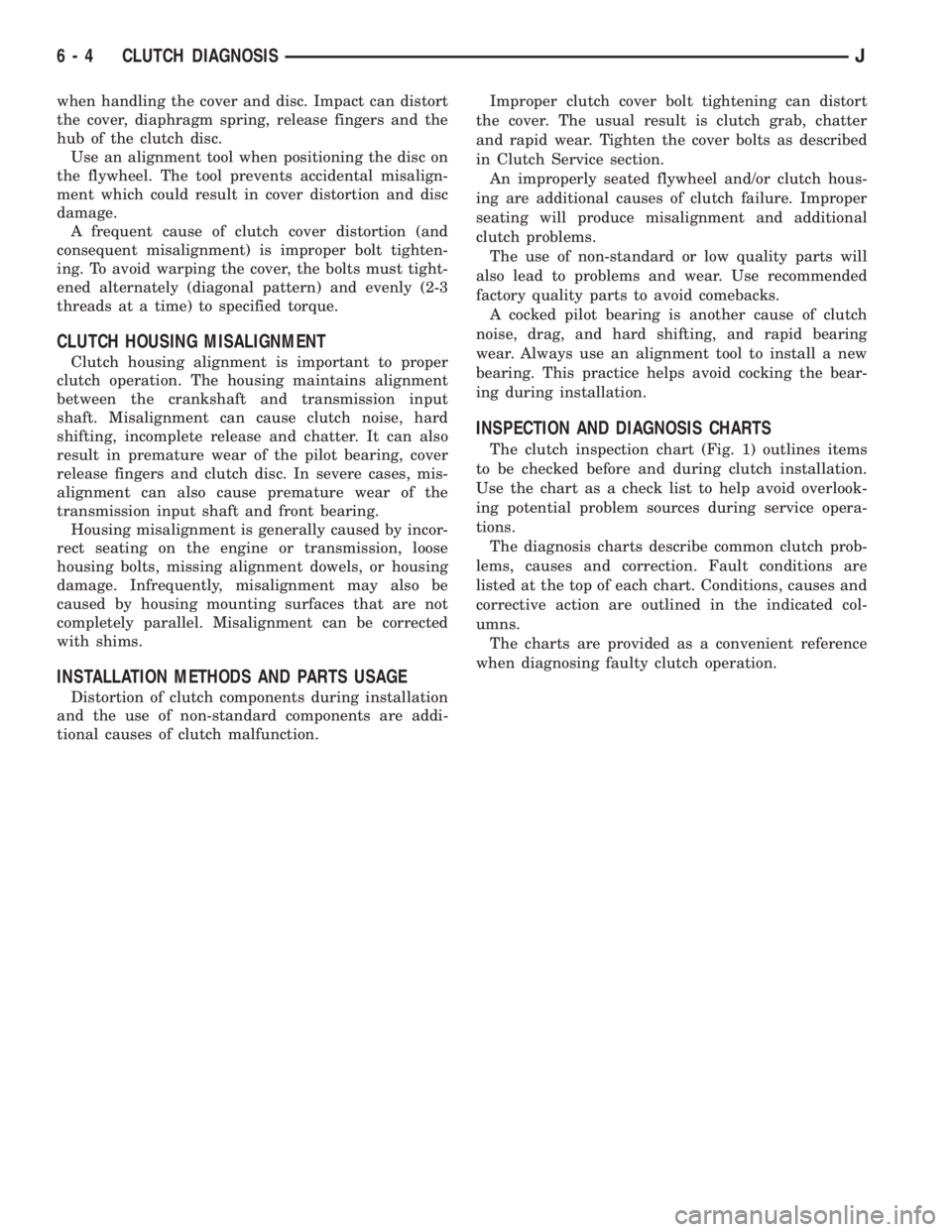

(4) Position clutch disc on flywheel. Be sure side of

disc marked flywheel side is positioned against fly-

wheel (Fig. 2). If disc is not marked, be sure flat side

of disc hub is toward flywheel.

(5) Inspect condition of pressure plate surface of

clutch cover (Fig. 2). Replace cover if this surface is

worn, heat checked, cracked, or scored.

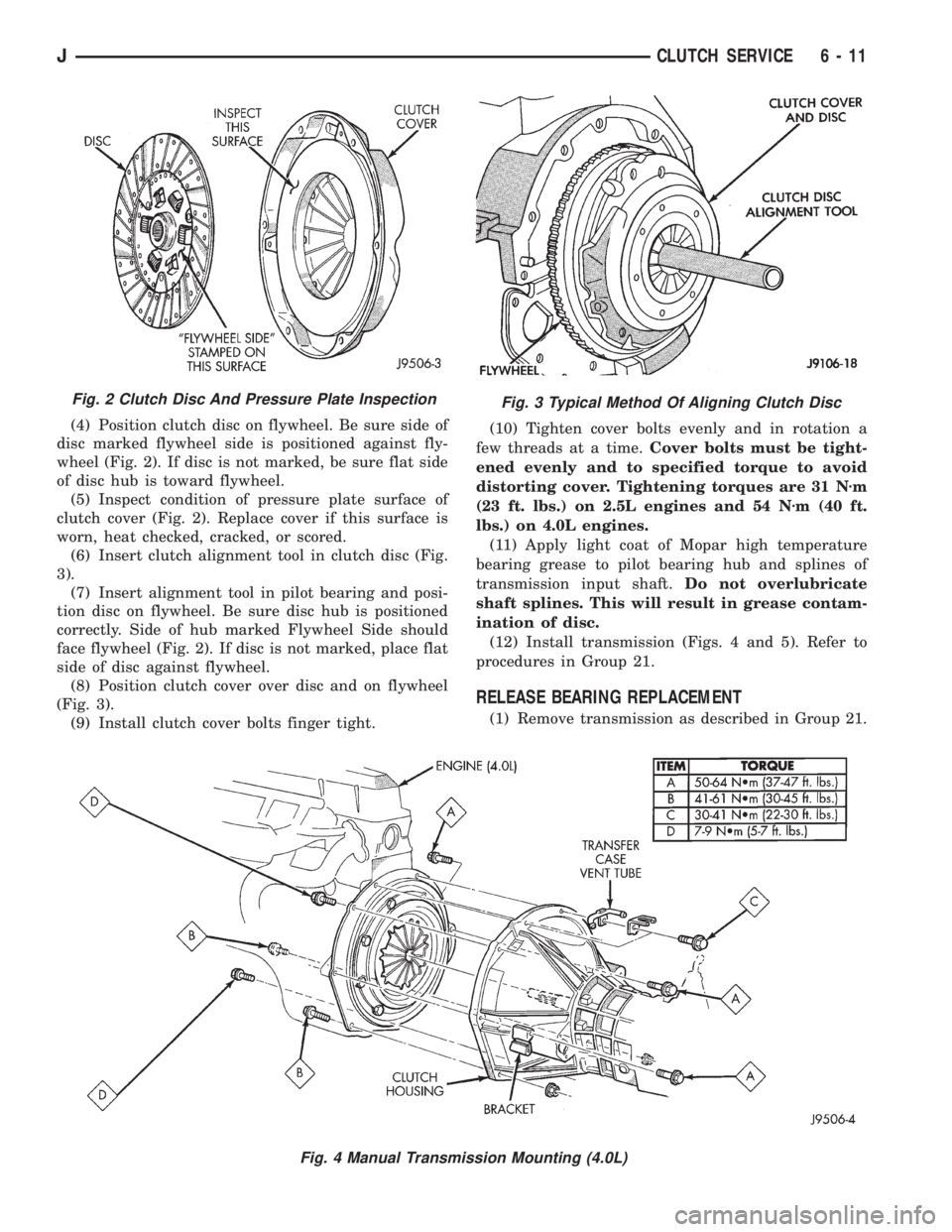

(6) Insert clutch alignment tool in clutch disc (Fig.

3).

(7) Insert alignment tool in pilot bearing and posi-

tion disc on flywheel. Be sure disc hub is positioned

correctly. Side of hub marked Flywheel Side should

face flywheel (Fig. 2). If disc is not marked, place flat

side of disc against flywheel.

(8) Position clutch cover over disc and on flywheel

(Fig. 3).

(9) Install clutch cover bolts finger tight.(10) Tighten cover bolts evenly and in rotation a

few threads at a time.Cover bolts must be tight-

ened evenly and to specified torque to avoid

distorting cover. Tightening torques are 31 Nzm

(23 ft. lbs.) on 2.5L engines and 54 Nzm (40 ft.

lbs.) on 4.0L engines.

(11) Apply light coat of Mopar high temperature

bearing grease to pilot bearing hub and splines of

transmission input shaft.Do not overlubricate

shaft splines. This will result in grease contam-

ination of disc.

(12) Install transmission (Figs. 4 and 5). Refer to

procedures in Group 21.

RELEASE BEARING REPLACEMENT

(1) Remove transmission as described in Group 21.

Fig. 2 Clutch Disc And Pressure Plate InspectionFig. 3 Typical Method Of Aligning Clutch Disc

Fig. 4 Manual Transmission Mounting (4.0L)

JCLUTCH SERVICE 6 - 11

Page 219 of 2198

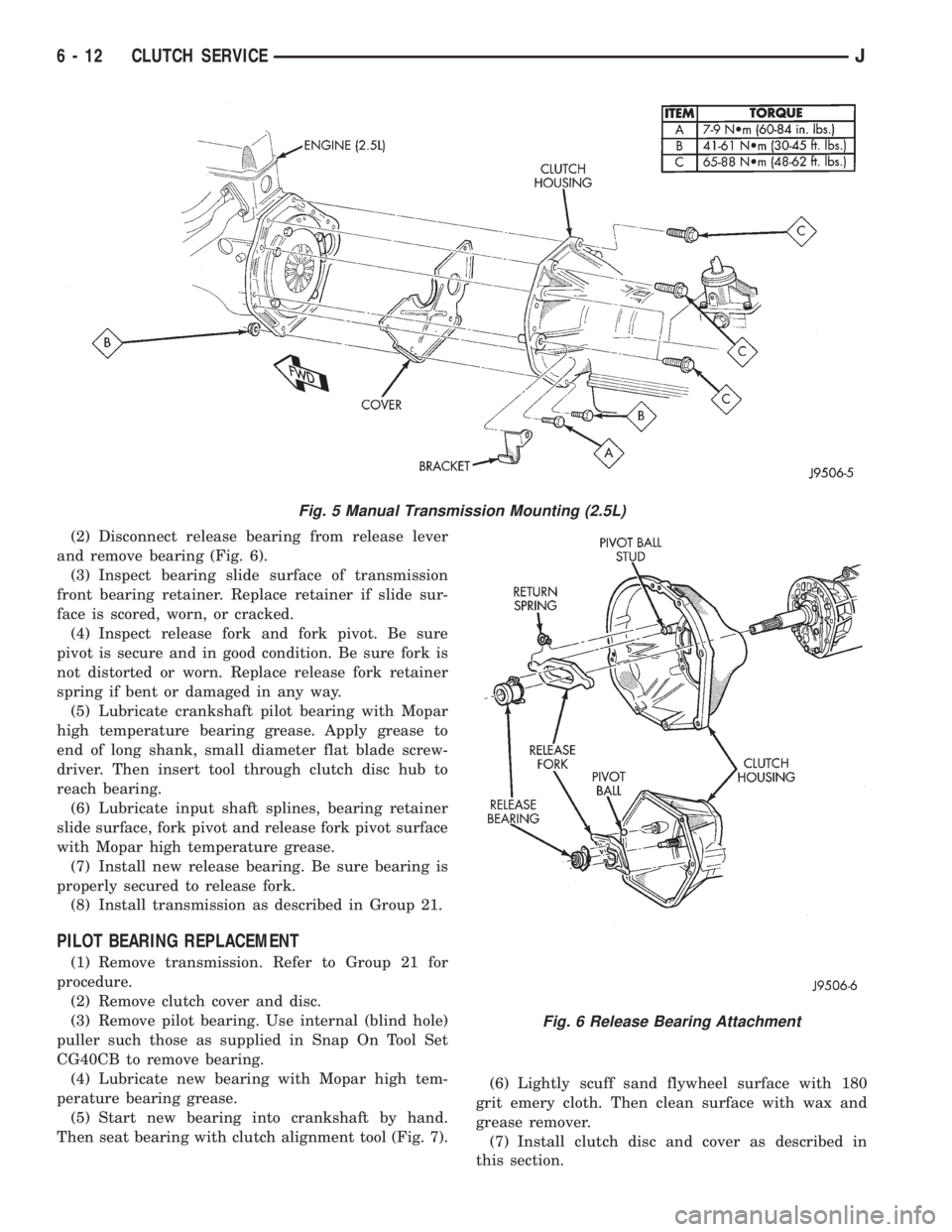

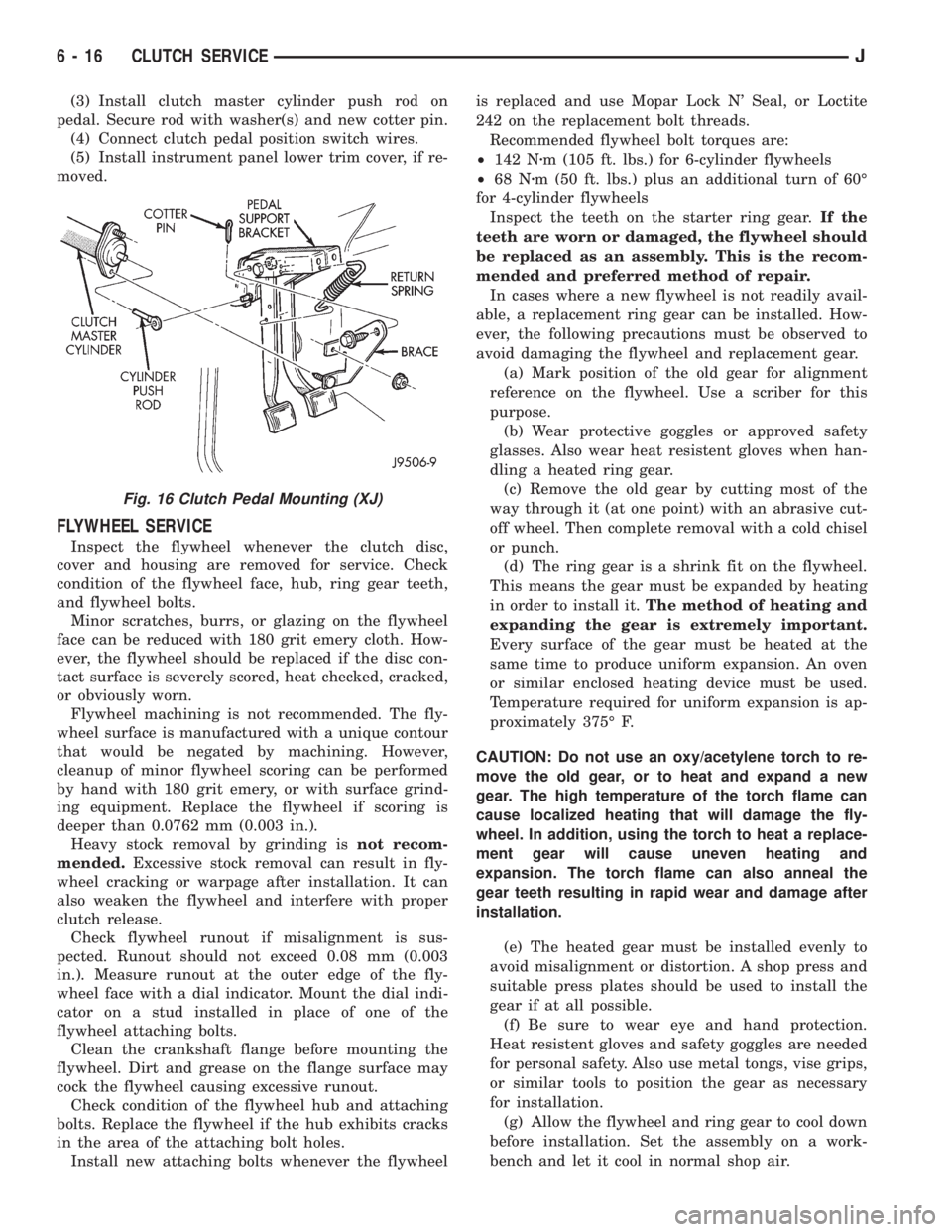

(2) Disconnect release bearing from release lever

and remove bearing (Fig. 6).

(3) Inspect bearing slide surface of transmission

front bearing retainer. Replace retainer if slide sur-

face is scored, worn, or cracked.

(4) Inspect release fork and fork pivot. Be sure

pivot is secure and in good condition. Be sure fork is

not distorted or worn. Replace release fork retainer

spring if bent or damaged in any way.

(5) Lubricate crankshaft pilot bearing with Mopar

high temperature bearing grease. Apply grease to

end of long shank, small diameter flat blade screw-

driver. Then insert tool through clutch disc hub to

reach bearing.

(6) Lubricate input shaft splines, bearing retainer

slide surface, fork pivot and release fork pivot surface

with Mopar high temperature grease.

(7) Install new release bearing. Be sure bearing is

properly secured to release fork.

(8) Install transmission as described in Group 21.

PILOT BEARING REPLACEMENT

(1) Remove transmission. Refer to Group 21 for

procedure.

(2) Remove clutch cover and disc.

(3) Remove pilot bearing. Use internal (blind hole)

puller such those as supplied in Snap On Tool Set

CG40CB to remove bearing.

(4) Lubricate new bearing with Mopar high tem-

perature bearing grease.

(5) Start new bearing into crankshaft by hand.

Then seat bearing with clutch alignment tool (Fig. 7).(6) Lightly scuff sand flywheel surface with 180

grit emery cloth. Then clean surface with wax and

grease remover.

(7) Install clutch disc and cover as described in

this section.

Fig. 5 Manual Transmission Mounting (2.5L)

Fig. 6 Release Bearing Attachment

6 - 12 CLUTCH SERVICEJ

Page 223 of 2198

(3) Install clutch master cylinder push rod on

pedal. Secure rod with washer(s) and new cotter pin.

(4) Connect clutch pedal position switch wires.

(5) Install instrument panel lower trim cover, if re-

moved.

FLYWHEEL SERVICE

Inspect the flywheel whenever the clutch disc,

cover and housing are removed for service. Check

condition of the flywheel face, hub, ring gear teeth,

and flywheel bolts.

Minor scratches, burrs, or glazing on the flywheel

face can be reduced with 180 grit emery cloth. How-

ever, the flywheel should be replaced if the disc con-

tact surface is severely scored, heat checked, cracked,

or obviously worn.

Flywheel machining is not recommended. The fly-

wheel surface is manufactured with a unique contour

that would be negated by machining. However,

cleanup of minor flywheel scoring can be performed

by hand with 180 grit emery, or with surface grind-

ing equipment. Replace the flywheel if scoring is

deeper than 0.0762 mm (0.003 in.).

Heavy stock removal by grinding isnot recom-

mended.Excessive stock removal can result in fly-

wheel cracking or warpage after installation. It can

also weaken the flywheel and interfere with proper

clutch release.

Check flywheel runout if misalignment is sus-

pected. Runout should not exceed 0.08 mm (0.003

in.). Measure runout at the outer edge of the fly-

wheel face with a dial indicator. Mount the dial indi-

cator on a stud installed in place of one of the

flywheel attaching bolts.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout.

Check condition of the flywheel hub and attaching

bolts. Replace the flywheel if the hub exhibits cracks

in the area of the attaching bolt holes.

Install new attaching bolts whenever the flywheelis replaced and use Mopar Lock N' Seal, or Loctite

242 on the replacement bolt threads.

Recommended flywheel bolt torques are:

²142 Nzm (105 ft. lbs.) for 6-cylinder flywheels

²68 Nzm (50 ft. lbs.) plus an additional turn of 60É

for 4-cylinder flywheels

Inspect the teeth on the starter ring gear.If the

teeth are worn or damaged, the flywheel should

be replaced as an assembly. This is the recom-

mended and preferred method of repair.

In cases where a new flywheel is not readily avail-

able, a replacement ring gear can be installed. How-

ever, the following precautions must be observed to

avoid damaging the flywheel and replacement gear.

(a) Mark position of the old gear for alignment

reference on the flywheel. Use a scriber for this

purpose.

(b) Wear protective goggles or approved safety

glasses. Also wear heat resistent gloves when han-

dling a heated ring gear.

(c) Remove the old gear by cutting most of the

way through it (at one point) with an abrasive cut-

off wheel. Then complete removal with a cold chisel

or punch.

(d) The ring gear is a shrink fit on the flywheel.

This means the gear must be expanded by heating

in order to install it.The method of heating and

expanding the gear is extremely important.

Every surface of the gear must be heated at the

same time to produce uniform expansion. An oven

or similar enclosed heating device must be used.

Temperature required for uniform expansion is ap-

proximately 375É F.

CAUTION: Do not use an oxy/acetylene torch to re-

move the old gear, or to heat and expand a new

gear. The high temperature of the torch flame can

cause localized heating that will damage the fly-

wheel. In addition, using the torch to heat a replace-

ment gear will cause uneven heating and

expansion. The torch flame can also anneal the

gear teeth resulting in rapid wear and damage after

installation.

(e) The heated gear must be installed evenly to

avoid misalignment or distortion. A shop press and

suitable press plates should be used to install the

gear if at all possible.

(f) Be sure to wear eye and hand protection.

Heat resistent gloves and safety goggles are needed

for personal safety. Also use metal tongs, vise grips,

or similar tools to position the gear as necessary

for installation.

(g) Allow the flywheel and ring gear to cool down

before installation. Set the assembly on a work-

bench and let it cool in normal shop air.

Fig. 16 Clutch Pedal Mounting (XJ)

6 - 16 CLUTCH SERVICEJ