lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1097 of 2198

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

Perform the test procedures on each cylinder ac-

cording to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to the Cylinder Combustion Pressure Leak-

age Test Diagnosis chart.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the en-

gine, particularly at the area of the suspected leak. If

an oil leak source is not readily identifiable, the fol-

lowing steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for ap-

proximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified, re-

pair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat step (3).

If the oil leak source is not positively identi-

fied at this time, proceed with the air leak detec-

tion test method as follows:

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is de-

tected and identified, repair per service manual pro-

cedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps. In-

stall the PCV valve and breather cap hose. Proceed

to step 7.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the en-

gine, a more involved inspection is necessary. The fol-

lowing steps should be followed to help pinpoint the

source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

9 - 6 ENGINESJ

Page 1098 of 2198

filter runoff, and main bearing cap to cylinder

block mating surfaces. See Group 9, Engines for

proper repair procedures of these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is de-

tected between the crankshaft and seal while slowly

turning the crankshaft, it is possible the crankshaft

seal surface is damaged. The seal area on the crank-

shaft could have minor nicks or scratches that can be

polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.(6) For bubbles that remain steady with shaft ro-

tation, no further inspection can be done until disas-

sembled. Refer to the service DiagnosisÐMechanical,

under the Oil Leak row for components inspections

on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, Refer to Group

9, EnginesÐCrankshaft Rear Oil Seals, for proper re-

placement procedures.

ENGINE OIL PRESSURE

(1) Remove oil pressure sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292. Start engine and record pressure. Refer to

Oil Pressure in Engine Specifications for the proper

pressures.

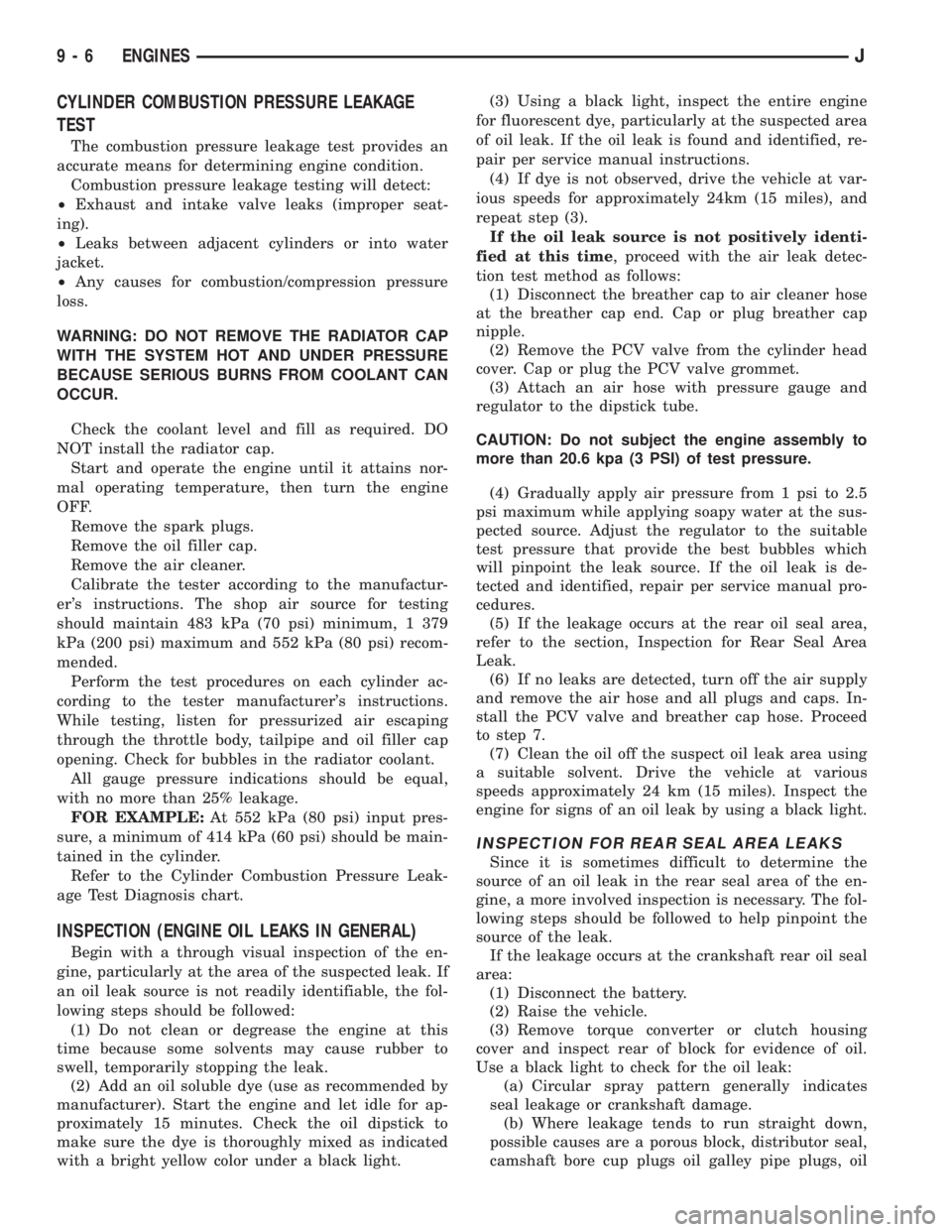

CYLINDER COMBUSTION PRESSURE LEAKAGE TEST DIAGNOSIS

JENGINES 9 - 7

Page 1104 of 2198

2.5L ENGINE SERVICE PROCEDURES

INDEX

page page

Camshaft............................... 32

Camshaft Pin Replacement.................. 34

Engine AssemblyÐXJ Vehicles............... 18

Engine AssemblyÐYJ Vehicles............... 20

Engine Cylinder Head...................... 25

Engine Cylinder Head Cover................. 22

Engine Damper........................... 17

Engine MountÐRear....................... 16

Engine MountsÐFront..................... 14

General Information....................... 13

Hydraulic Tappets......................... 24OilPan ................................. 36

Rocker Arms and Push Rods................ 23

Timing Case Cover........................ 31

Timing Case Cover Oil Seal Replacement....... 30

Timing Chain and Sprockets................. 31

Valve Component ReplaceÐCylinder Head Not

Removed.............................. 23

Valve Springs and Oil Seals................. 23

Valve Timing............................. 30

Valves and Valve Springs................... 27

Vibration Damper......................... 30

GENERAL INFORMATION

The 2.5 liter (150 CID) four-cylinder engine is an

In-line, lightweight, overhead valve engine (Fig. 1).

This engine is designed for unleaded fuel.

The engine cylinder head has dual quench-type

combustion chambers that create turbulence and fast

burning of the air/fuel mixture. This results in good

fuel economy.

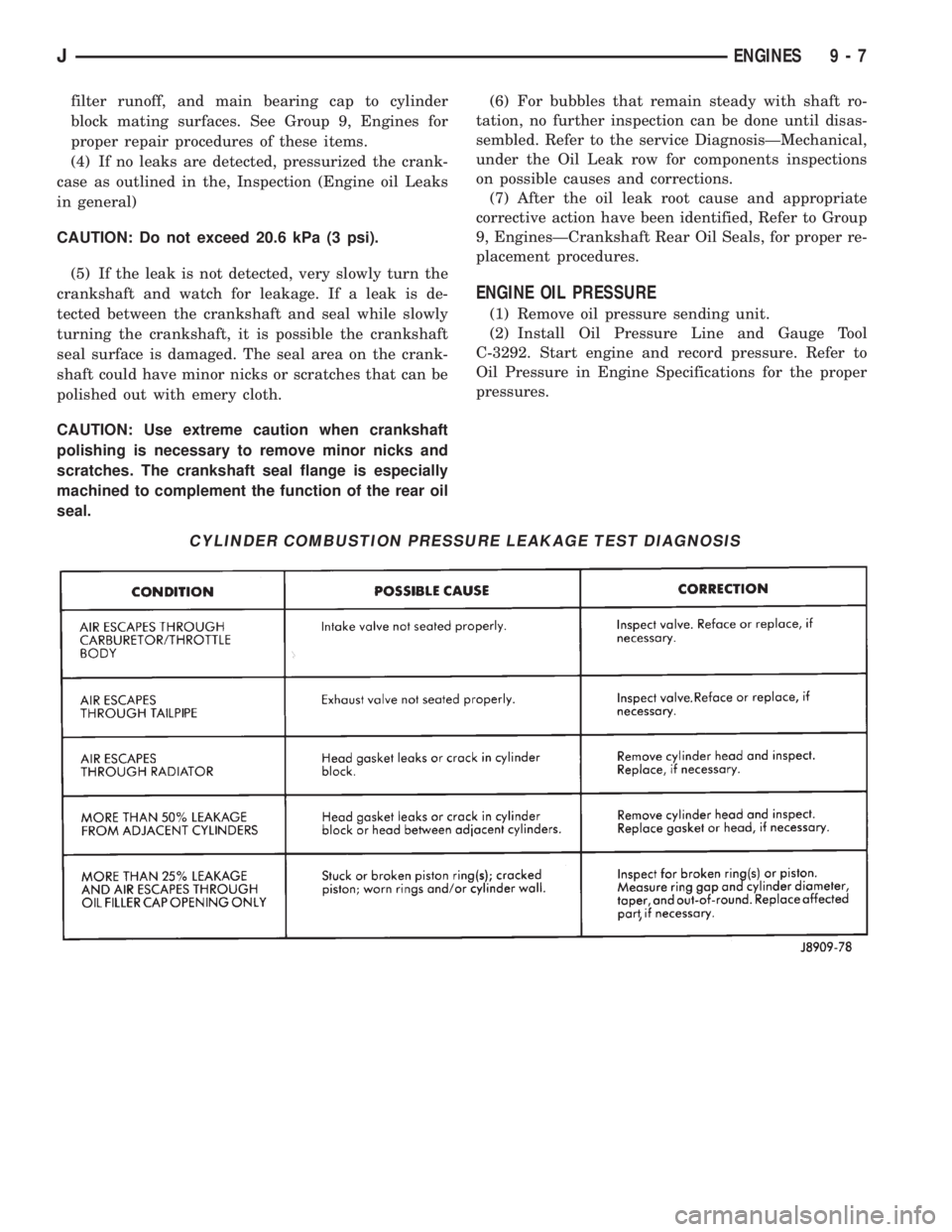

The cylinders are numbered 1 through 4 from front

to rear. The firing order is 1-3-4-2 (Fig. 2).

The crankshaft rotation is clockwise, when viewed

from the front of the engine. The crankshaft rotates

within five main bearings and the camshaft rotates

within four bearings.

BUILD DATE CODE

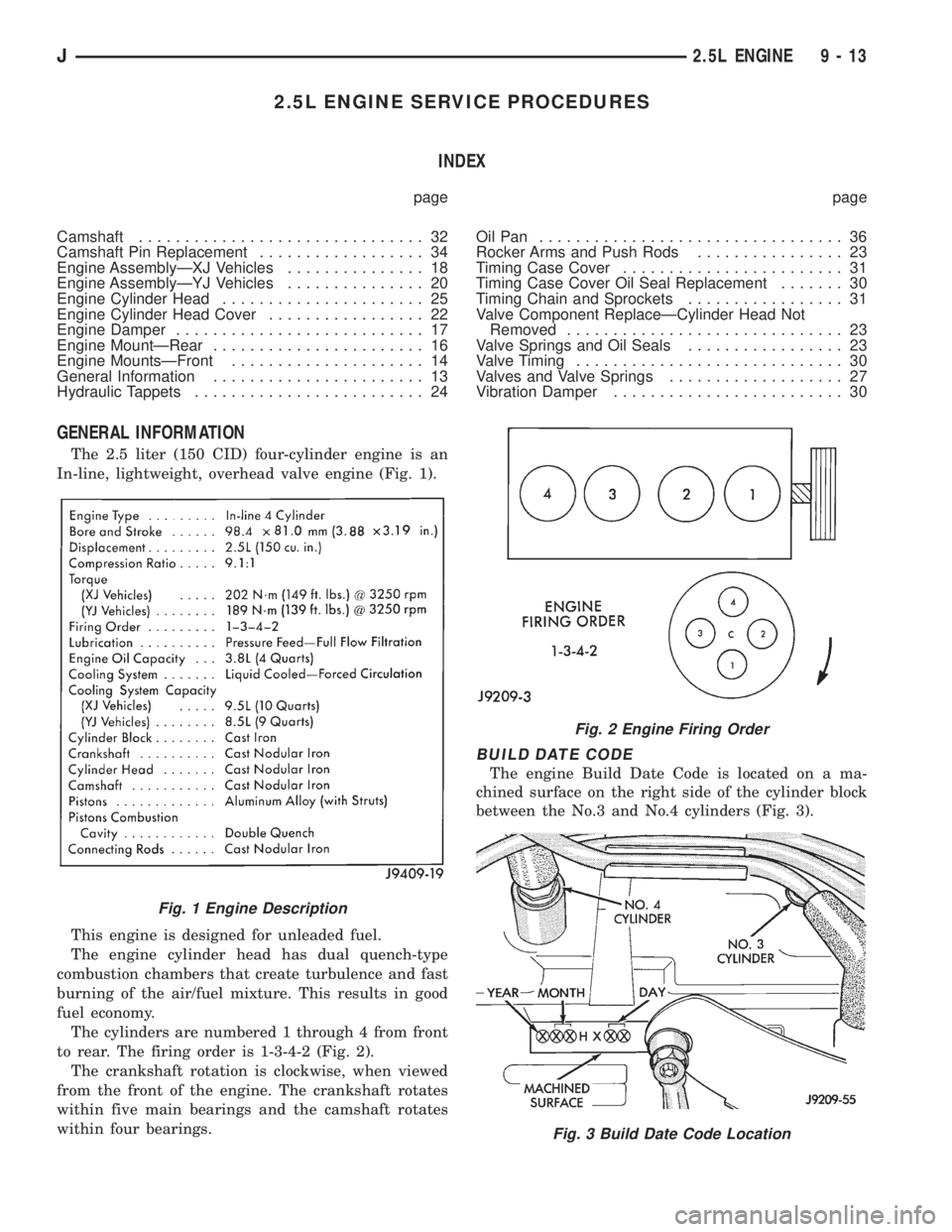

The engine Build Date Code is located on a ma-

chined surface on the right side of the cylinder block

between the No.3 and No.4 cylinders (Fig. 3).

Fig. 1 Engine Description

Fig. 2 Engine Firing Order

Fig. 3 Build Date Code Location

J2.5L ENGINE 9 - 13

Page 1105 of 2198

The digits of the code identify:

(1) 1st DigitÐThe year (4 = 1994).

(2) 2nd & 3rd DigitsÐThe month (01 - 12).

(3) 4th & 5th DigitsÐThe engine type/fuel system/

compression ratio (HX = A 2.5 liter (150 CID) 9.1:1

compression ratio engine with a multi-point fuel in-

jection system).

(4) 6th & 7th DigitsÐThe day of engine build (01 -

31).

FOR EXAMPLE:Code * 401HX23 * identifies a

2.5 liter (150 CID) engine with a multi-point fuel in-

jection system, 9.1:1 compression ratio and built on

January 23, 1994.

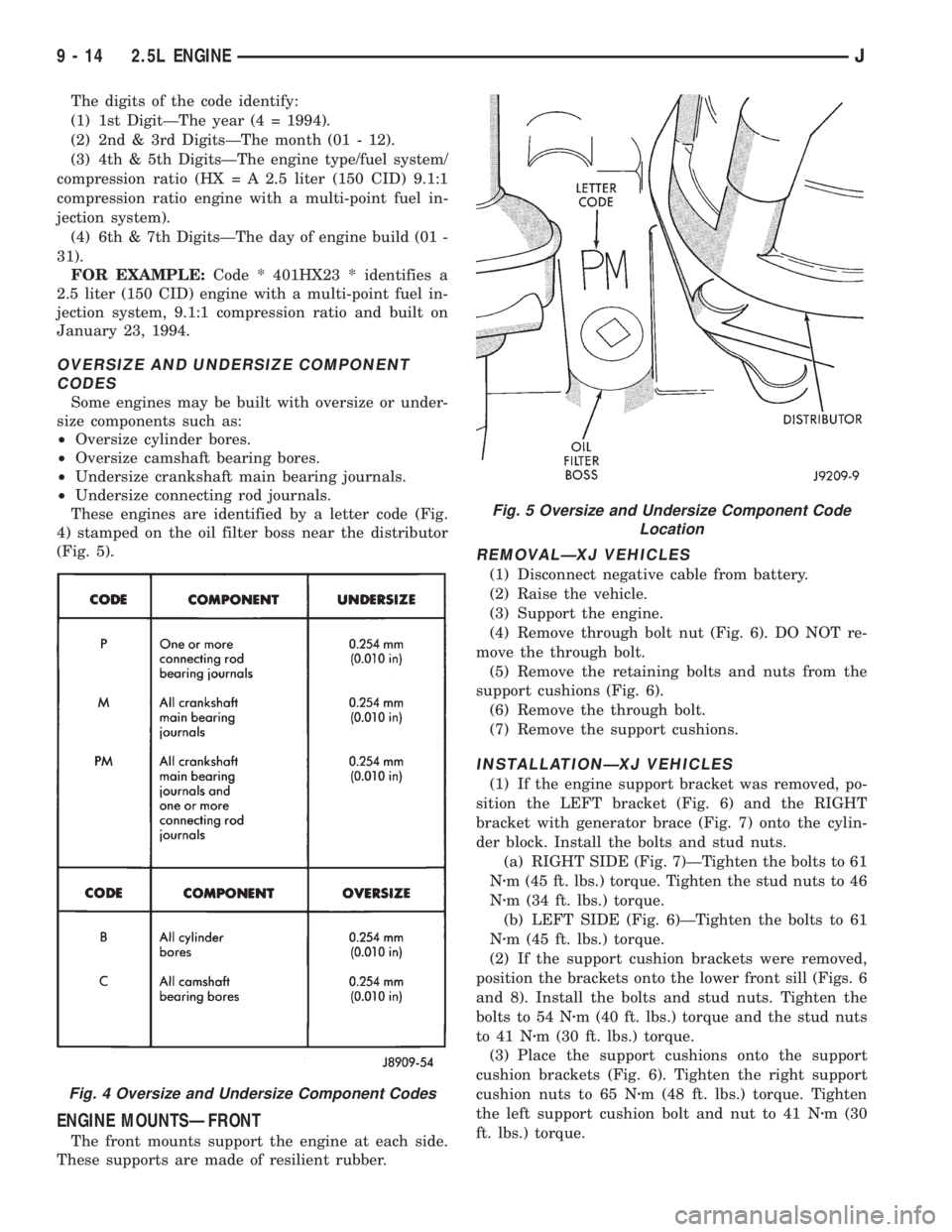

OVERSIZE AND UNDERSIZE COMPONENT

CODES

Some engines may be built with oversize or under-

size components such as:

²Oversize cylinder bores.

²Oversize camshaft bearing bores.

²Undersize crankshaft main bearing journals.

²Undersize connecting rod journals.

These engines are identified by a letter code (Fig.

4) stamped on the oil filter boss near the distributor

(Fig. 5).

ENGINE MOUNTSÐFRONT

The front mounts support the engine at each side.

These supports are made of resilient rubber.

REMOVALÐXJ VEHICLES

(1) Disconnect negative cable from battery.

(2) Raise the vehicle.

(3) Support the engine.

(4) Remove through bolt nut (Fig. 6). DO NOT re-

move the through bolt.

(5) Remove the retaining bolts and nuts from the

support cushions (Fig. 6).

(6) Remove the through bolt.

(7) Remove the support cushions.

INSTALLATIONÐXJ VEHICLES

(1) If the engine support bracket was removed, po-

sition the LEFT bracket (Fig. 6) and the RIGHT

bracket with generator brace (Fig. 7) onto the cylin-

der block. Install the bolts and stud nuts.

(a) RIGHT SIDE (Fig. 7)ÐTighten the bolts to 61

Nzm (45 ft. lbs.) torque. Tighten the stud nuts to 46

Nzm (34 ft. lbs.) torque.

(b) LEFT SIDE (Fig. 6)ÐTighten the bolts to 61

Nzm (45 ft. lbs.) torque.

(2) If the support cushion brackets were removed,

position the brackets onto the lower front sill (Figs. 6

and 8). Install the bolts and stud nuts. Tighten the

bolts to 54 Nzm (40 ft. lbs.) torque and the stud nuts

to 41 Nzm (30 ft. lbs.) torque.

(3) Place the support cushions onto the support

cushion brackets (Fig. 6). Tighten the right support

cushion nuts to 65 Nzm (48 ft. lbs.) torque. Tighten

the left support cushion bolt and nut to 41 Nzm (30

ft. lbs.) torque.

Fig. 4 Oversize and Undersize Component Codes

Fig. 5 Oversize and Undersize Component Code

Location

9 - 14 2.5L ENGINEJ

Page 1107 of 2198

INSTALLATIONÐYJ VEHICLES

(1) If the engine support bracket was removed, po-

sition the bracket onto the block and install the at-

taching bolts (Fig. 9). Tighten the bolts to 62 Nzm (46

ft. lbs.) torque.

(2) Place the support cushion on the support cush-

ion bracket (Fig. 9). Install the support cushion re-

taining bolts and nuts. Tighten the bolts and nuts to

52 Nzm (38 ft. lbs.) torque.

(3) Install the through bolt and the retaining nut

(Fig. 9). Tighten the through bolt nut to 69 Nzm (51

ft. lbs.) torque.

(4) Remove the engine support.

(5) Lower the vehicle.

(6) Connect negative cable to battery.

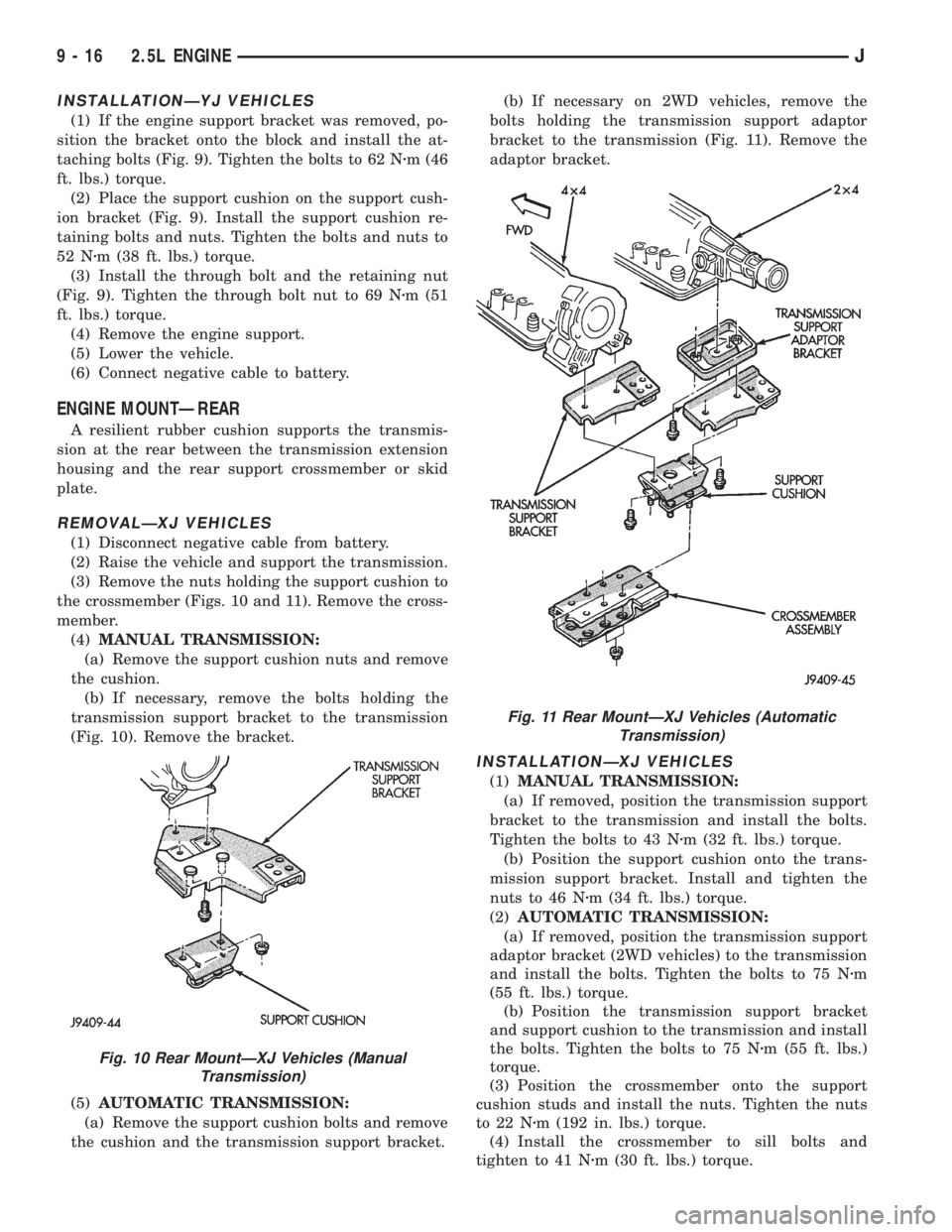

ENGINE MOUNTÐREAR

A resilient rubber cushion supports the transmis-

sion at the rear between the transmission extension

housing and the rear support crossmember or skid

plate.

REMOVALÐXJ VEHICLES

(1) Disconnect negative cable from battery.

(2) Raise the vehicle and support the transmission.

(3) Remove the nuts holding the support cushion to

the crossmember (Figs. 10 and 11). Remove the cross-

member.

(4)MANUAL TRANSMISSION:

(a) Remove the support cushion nuts and remove

the cushion.

(b) If necessary, remove the bolts holding the

transmission support bracket to the transmission

(Fig. 10). Remove the bracket.

(5)AUTOMATIC TRANSMISSION:

(a) Remove the support cushion bolts and remove

the cushion and the transmission support bracket.(b) If necessary on 2WD vehicles, remove the

bolts holding the transmission support adaptor

bracket to the transmission (Fig. 11). Remove the

adaptor bracket.

INSTALLATIONÐXJ VEHICLES

(1)MANUAL TRANSMISSION:

(a) If removed, position the transmission support

bracket to the transmission and install the bolts.

Tighten the bolts to 43 Nzm (32 ft. lbs.) torque.

(b) Position the support cushion onto the trans-

mission support bracket. Install and tighten the

nuts to 46 Nzm (34 ft. lbs.) torque.

(2)AUTOMATIC TRANSMISSION:

(a) If removed, position the transmission support

adaptor bracket (2WD vehicles) to the transmission

and install the bolts. Tighten the bolts to 75 Nzm

(55 ft. lbs.) torque.

(b) Position the transmission support bracket

and support cushion to the transmission and install

the bolts. Tighten the bolts to 75 Nzm (55 ft. lbs.)

torque.

(3) Position the crossmember onto the support

cushion studs and install the nuts. Tighten the nuts

to 22 Nzm (192 in. lbs.) torque.

(4) Install the crossmember to sill bolts and

tighten to 41 Nzm (30 ft. lbs.) torque.

Fig. 10 Rear MountÐXJ Vehicles (Manual

Transmission)

Fig. 11 Rear MountÐXJ Vehicles (Automatic

Transmission)

9 - 16 2.5L ENGINEJ

Page 1113 of 2198

(14) Install the remaining flywheel housing bolts.

Tighten the bolts to 38 Nzm (28 ft. lbs.) torque.

(15) Install the starter motor and connect the ca-

ble. Tighten the bolts to 45 Nzm (33 ft. lbs.) torque.

(16) Install the oil filter.

(17) Lower the vehicle.

(18) Connect the coolant hoses and tighten the

clamps.

(19) If equipped with power steering:

(a) Remove the protective caps

(b) Connect the hoses to the fittings at the steer-

ing gear. Tighten the nut to 52 Nzm (38 ft. lbs.)

torque.

(c) Fill the pump reservoir with fluid.

(20) Remove the pulley-to-water pump flange

alignment capscrew and install the fan and spacer or

Tempatrol fan assembly.

(21) Tighten the serpentine drive belt according to

the specifications listed in Group 7, Cooling System.

(22) Install the fan shroud and radiator.

(23) Connect the radiator hoses.

(24) Connect the heater hoses.

(25) Connect the throttle valve rod and retainer.

(26) Connect the throttle cable and install the rod.

(27) Install the throttle valve rod spring.

(28) Connect the speed control cable, if equipped.

(29) Connect the oxygen sensor wire connector.

(30) Install the vacuum hose and check valve on

the brake booster.

(31) Connect the coolant temperature sensor wire

connector.

(32) Connect the idle speed actuator wire connec-

tor.

(33) Connect the fuel inlet and return hoses at the

fuel rail. Verify that the quick-connect fitting assem-

bly fits securely over the fuel lines by giving the fuel

lines a firm tug.

(34) Install the fuel line bracket to the intake man-

ifold.

(35) Connect all fuel injection wire connections.

(36) Install the engine ground strap.

(37) Connect the ignition coil wire connector.

(38) Remove the coolant temperature sending unit

to permit air to escape from the block. Fill the cool-

ing system with coolant. Install the coolant tempera-

ture sending unit when the system is filled.

(39) Install the battery and connect the battery ca-

bles.

(40) Install the air cleaner bonnet to the throttle

body.

(41) Install the air cleaner.

(42) Lower the hood and secure in place.

(43) Start the engine and inspect for leaks.

(44) Stop the engine and check the fluid levels.

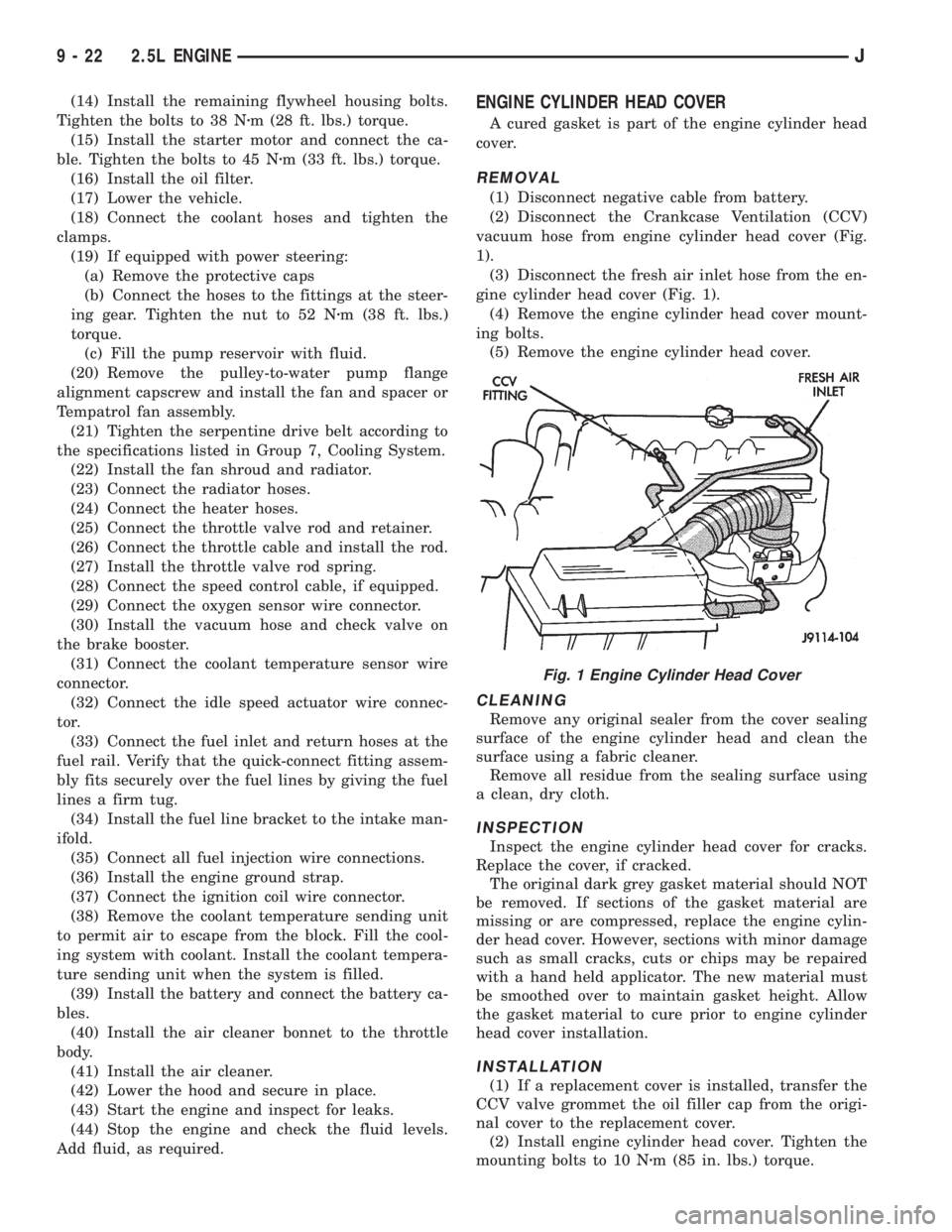

Add fluid, as required.ENGINE CYLINDER HEAD COVER

A cured gasket is part of the engine cylinder head

cover.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Disconnect the Crankcase Ventilation (CCV)

vacuum hose from engine cylinder head cover (Fig.

1).

(3) Disconnect the fresh air inlet hose from the en-

gine cylinder head cover (Fig. 1).

(4) Remove the engine cylinder head cover mount-

ing bolts.

(5) Remove the engine cylinder head cover.

CLEANING

Remove any original sealer from the cover sealing

surface of the engine cylinder head and clean the

surface using a fabric cleaner.

Remove all residue from the sealing surface using

a clean, dry cloth.

INSPECTION

Inspect the engine cylinder head cover for cracks.

Replace the cover, if cracked.

The original dark grey gasket material should NOT

be removed. If sections of the gasket material are

missing or are compressed, replace the engine cylin-

der head cover. However, sections with minor damage

such as small cracks, cuts or chips may be repaired

with a hand held applicator. The new material must

be smoothed over to maintain gasket height. Allow

the gasket material to cure prior to engine cylinder

head cover installation.

INSTALLATION

(1) If a replacement cover is installed, transfer the

CCV valve grommet the oil filler cap from the origi-

nal cover to the replacement cover.

(2) Install engine cylinder head cover. Tighten the

mounting bolts to 10 Nzm (85 in. lbs.) torque.

Fig. 1 Engine Cylinder Head Cover

9 - 22 2.5L ENGINEJ

Page 1114 of 2198

(3) Connect the CCV hoses (Fig. 1).

(4) Connect negative cable to battery.

VALVE COMPONENT REPLACEÐCYLINDER HEAD

NOT REMOVED

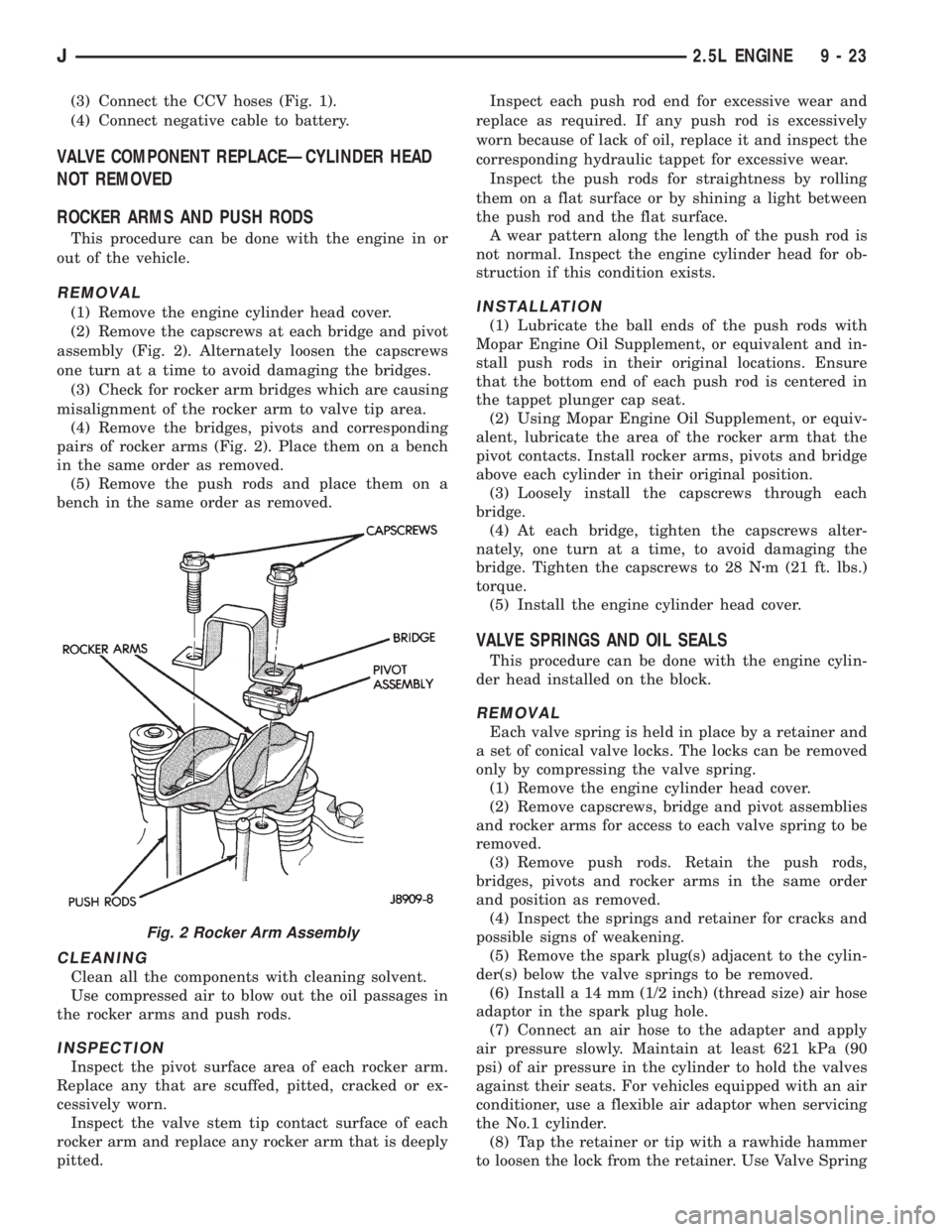

ROCKER ARMS AND PUSH RODS

This procedure can be done with the engine in or

out of the vehicle.

REMOVAL

(1) Remove the engine cylinder head cover.

(2) Remove the capscrews at each bridge and pivot

assembly (Fig. 2). Alternately loosen the capscrews

one turn at a time to avoid damaging the bridges.

(3) Check for rocker arm bridges which are causing

misalignment of the rocker arm to valve tip area.

(4) Remove the bridges, pivots and corresponding

pairs of rocker arms (Fig. 2). Place them on a bench

in the same order as removed.

(5) Remove the push rods and place them on a

bench in the same order as removed.

CLEANING

Clean all the components with cleaning solvent.

Use compressed air to blow out the oil passages in

the rocker arms and push rods.

INSPECTION

Inspect the pivot surface area of each rocker arm.

Replace any that are scuffed, pitted, cracked or ex-

cessively worn.

Inspect the valve stem tip contact surface of each

rocker arm and replace any rocker arm that is deeply

pitted.Inspect each push rod end for excessive wear and

replace as required. If any push rod is excessively

worn because of lack of oil, replace it and inspect the

corresponding hydraulic tappet for excessive wear.

Inspect the push rods for straightness by rolling

them on a flat surface or by shining a light between

the push rod and the flat surface.

A wear pattern along the length of the push rod is

not normal. Inspect the engine cylinder head for ob-

struction if this condition exists.

INSTALLATION

(1) Lubricate the ball ends of the push rods with

Mopar Engine Oil Supplement, or equivalent and in-

stall push rods in their original locations. Ensure

that the bottom end of each push rod is centered in

the tappet plunger cap seat.

(2) Using Mopar Engine Oil Supplement, or equiv-

alent, lubricate the area of the rocker arm that the

pivot contacts. Install rocker arms, pivots and bridge

above each cylinder in their original position.

(3) Loosely install the capscrews through each

bridge.

(4) At each bridge, tighten the capscrews alter-

nately, one turn at a time, to avoid damaging the

bridge. Tighten the capscrews to 28 Nzm (21 ft. lbs.)

torque.

(5) Install the engine cylinder head cover.

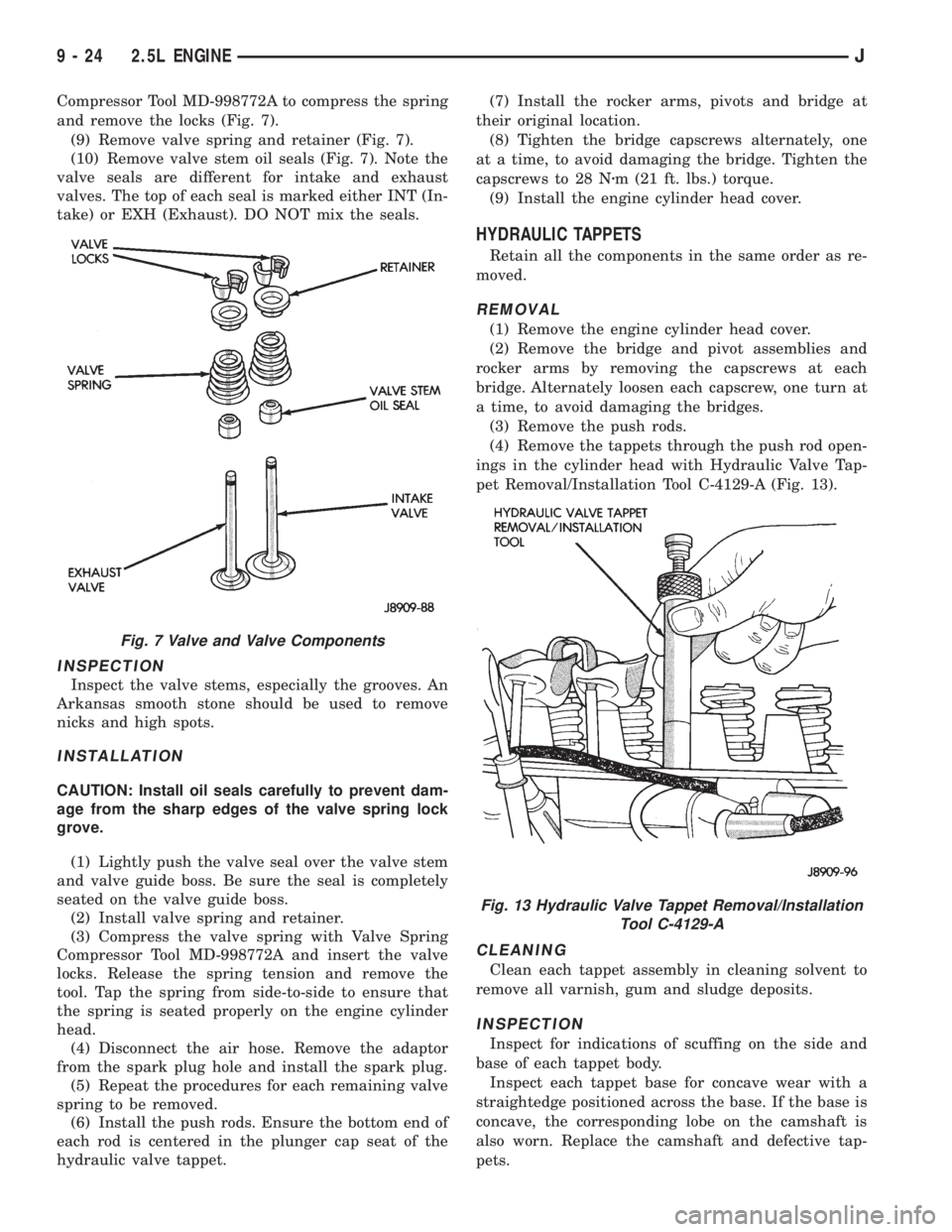

VALVE SPRINGS AND OIL SEALS

This procedure can be done with the engine cylin-

der head installed on the block.

REMOVAL

Each valve spring is held in place by a retainer and

a set of conical valve locks. The locks can be removed

only by compressing the valve spring.

(1) Remove the engine cylinder head cover.

(2) Remove capscrews, bridge and pivot assemblies

and rocker arms for access to each valve spring to be

removed.

(3) Remove push rods. Retain the push rods,

bridges, pivots and rocker arms in the same order

and position as removed.

(4) Inspect the springs and retainer for cracks and

possible signs of weakening.

(5) Remove the spark plug(s) adjacent to the cylin-

der(s) below the valve springs to be removed.

(6) Install a 14 mm (1/2 inch) (thread size) air hose

adaptor in the spark plug hole.

(7) Connect an air hose to the adapter and apply

air pressure slowly. Maintain at least 621 kPa (90

psi) of air pressure in the cylinder to hold the valves

against their seats. For vehicles equipped with an air

conditioner, use a flexible air adaptor when servicing

the No.1 cylinder.

(8) Tap the retainer or tip with a rawhide hammer

to loosen the lock from the retainer. Use Valve Spring

Fig. 2 Rocker Arm Assembly

J2.5L ENGINE 9 - 23

Page 1115 of 2198

Compressor Tool MD-998772A to compress the spring

and remove the locks (Fig. 7).

(9) Remove valve spring and retainer (Fig. 7).

(10) Remove valve stem oil seals (Fig. 7). Note the

valve seals are different for intake and exhaust

valves. The top of each seal is marked either INT (In-

take) or EXH (Exhaust). DO NOT mix the seals.

INSPECTION

Inspect the valve stems, especially the grooves. An

Arkansas smooth stone should be used to remove

nicks and high spots.

INSTALLATION

CAUTION: Install oil seals carefully to prevent dam-

age from the sharp edges of the valve spring lock

grove.

(1) Lightly push the valve seal over the valve stem

and valve guide boss. Be sure the seal is completely

seated on the valve guide boss.

(2) Install valve spring and retainer.

(3) Compress the valve spring with Valve Spring

Compressor Tool MD-998772A and insert the valve

locks. Release the spring tension and remove the

tool. Tap the spring from side-to-side to ensure that

the spring is seated properly on the engine cylinder

head.

(4) Disconnect the air hose. Remove the adaptor

from the spark plug hole and install the spark plug.

(5) Repeat the procedures for each remaining valve

spring to be removed.

(6) Install the push rods. Ensure the bottom end of

each rod is centered in the plunger cap seat of the

hydraulic valve tappet.(7) Install the rocker arms, pivots and bridge at

their original location.

(8) Tighten the bridge capscrews alternately, one

at a time, to avoid damaging the bridge. Tighten the

capscrews to 28 Nzm (21 ft. lbs.) torque.

(9) Install the engine cylinder head cover.

HYDRAULIC TAPPETS

Retain all the components in the same order as re-

moved.

REMOVAL

(1) Remove the engine cylinder head cover.

(2) Remove the bridge and pivot assemblies and

rocker arms by removing the capscrews at each

bridge. Alternately loosen each capscrew, one turn at

a time, to avoid damaging the bridges.

(3) Remove the push rods.

(4) Remove the tappets through the push rod open-

ings in the cylinder head with Hydraulic Valve Tap-

pet Removal/Installation Tool C-4129-A (Fig. 13).

CLEANING

Clean each tappet assembly in cleaning solvent to

remove all varnish, gum and sludge deposits.

INSPECTION

Inspect for indications of scuffing on the side and

base of each tappet body.

Inspect each tappet base for concave wear with a

straightedge positioned across the base. If the base is

concave, the corresponding lobe on the camshaft is

also worn. Replace the camshaft and defective tap-

pets.

Fig. 7 Valve and Valve Components

Fig. 13 Hydraulic Valve Tappet Removal/Installation

Tool C-4129-A

9 - 24 2.5L ENGINEJ

Page 1116 of 2198

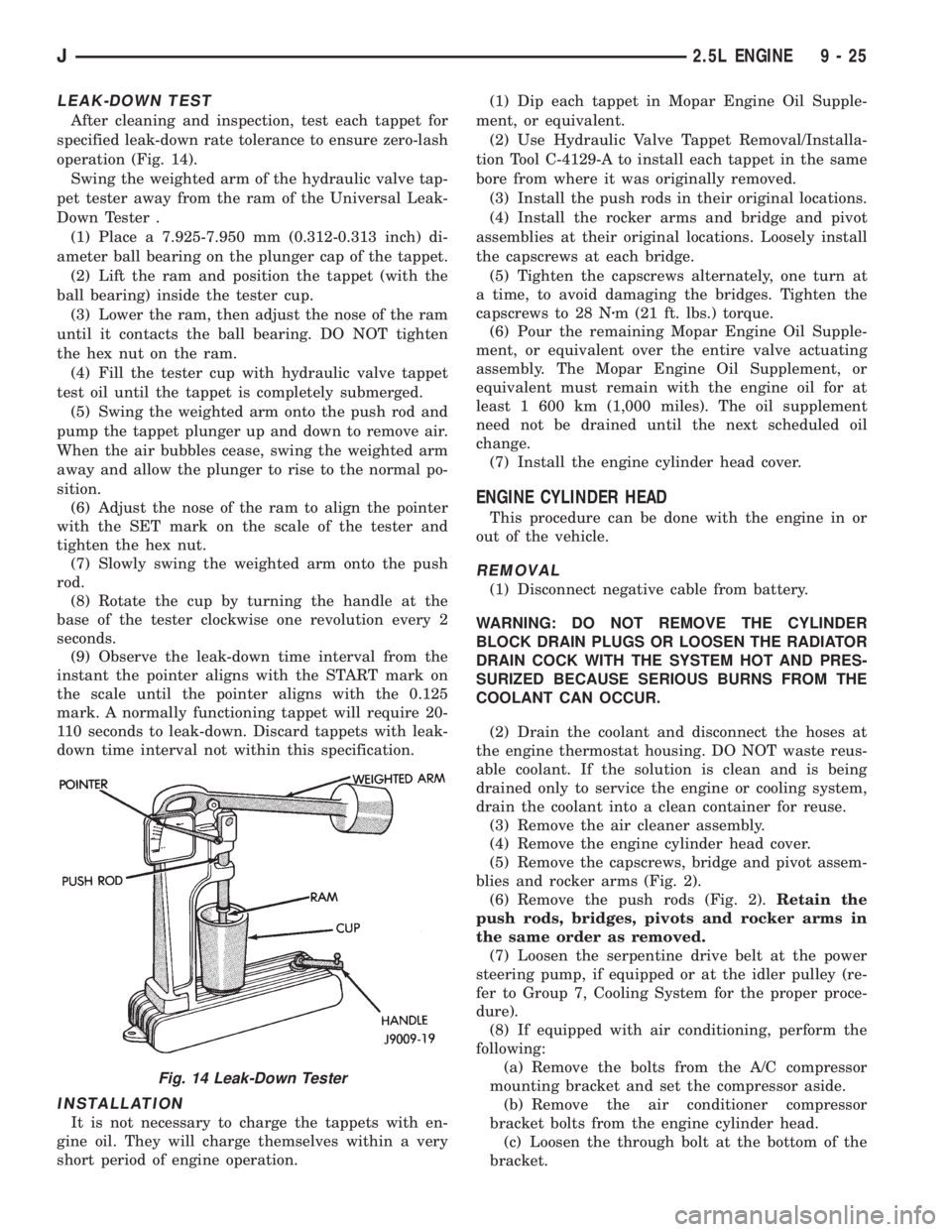

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 14).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester .

(1) Place a 7.925-7.950 mm (0.312-0.313 inch) di-

ameter ball bearing on the plunger cap of the tappet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal po-

sition.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require 20-

110 seconds to leak-down. Discard tappets with leak-

down time interval not within this specification.

INSTALLATION

It is not necessary to charge the tappets with en-

gine oil. They will charge themselves within a very

short period of engine operation.(1) Dip each tappet in Mopar Engine Oil Supple-

ment, or equivalent.

(2) Use Hydraulic Valve Tappet Removal/Installa-

tion Tool C-4129-A to install each tappet in the same

bore from where it was originally removed.

(3) Install the push rods in their original locations.

(4) Install the rocker arms and bridge and pivot

assemblies at their original locations. Loosely install

the capscrews at each bridge.

(5) Tighten the capscrews alternately, one turn at

a time, to avoid damaging the bridges. Tighten the

capscrews to 28 Nzm (21 ft. lbs.) torque.

(6) Pour the remaining Mopar Engine Oil Supple-

ment, or equivalent over the entire valve actuating

assembly. The Mopar Engine Oil Supplement, or

equivalent must remain with the engine oil for at

least 1 600 km (1,000 miles). The oil supplement

need not be drained until the next scheduled oil

change.

(7) Install the engine cylinder head cover.

ENGINE CYLINDER HEAD

This procedure can be done with the engine in or

out of the vehicle.

REMOVAL

(1) Disconnect negative cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

(2) Drain the coolant and disconnect the hoses at

the engine thermostat housing. DO NOT waste reus-

able coolant. If the solution is clean and is being

drained only to service the engine or cooling system,

drain the coolant into a clean container for reuse.

(3) Remove the air cleaner assembly.

(4) Remove the engine cylinder head cover.

(5) Remove the capscrews, bridge and pivot assem-

blies and rocker arms (Fig. 2).

(6) Remove the push rods (Fig. 2).Retain the

push rods, bridges, pivots and rocker arms in

the same order as removed.

(7) Loosen the serpentine drive belt at the power

steering pump, if equipped or at the idler pulley (re-

fer to Group 7, Cooling System for the proper proce-

dure).

(8) If equipped with air conditioning, perform the

following:

(a) Remove the bolts from the A/C compressor

mounting bracket and set the compressor aside.

(b) Remove the air conditioner compressor

bracket bolts from the engine cylinder head.

(c) Loosen the through bolt at the bottom of the

bracket.

Fig. 14 Leak-Down Tester

J2.5L ENGINE 9 - 25

Page 1117 of 2198

(9) If equipped, disconnect the power steering

pump bracket. Set the pump and bracket aside. DO

NOT disconnect the hoses.

(10) Remove the fuel lines and vacuum advance

hose.

(11) Remove the intake and engine exhaust mani-

folds from the engine cylinder head (refer to Group

11, Exhaust System and Intake Manifold for the

proper procedures).

(12) Disconnect the ignition wires and remove the

spark plugs.

(13) Disconnect the temperature sending unit wire

connector.

(14) Remove the ignition coil and bracket assem-

bly.

(15) Remove the engine cylinder head bolts.

(16) Remove the engine cylinder head and gasket

(Fig. 3).

(17) If this was the first time the bolts were re-

moved, put a paint dab on the top of the bolt. If the

bolts have a paint dab on the top of the bolt or it

isn't known if they were used before, discard the

bolts.

(18) Stuff clean lint free shop towels into the cylin-

der bores.

CLEANING

Thoroughly clean the engine cylinder head and cyl-

inder block mating surfaces. Clean the intake and ex-

haust manifold and engine cylinder head mating

surfaces. Remove all gasket material and carbon.

Check to ensure that no coolant or foreign material

has fallen into the tappet bore area.

Remove the carbon deposits from the combustion

chambers and top of the pistons.

INSPECTION

Use a straightedge and feeler gauge to check the

flatness of the engine cylinder head and block mating

surfaces.

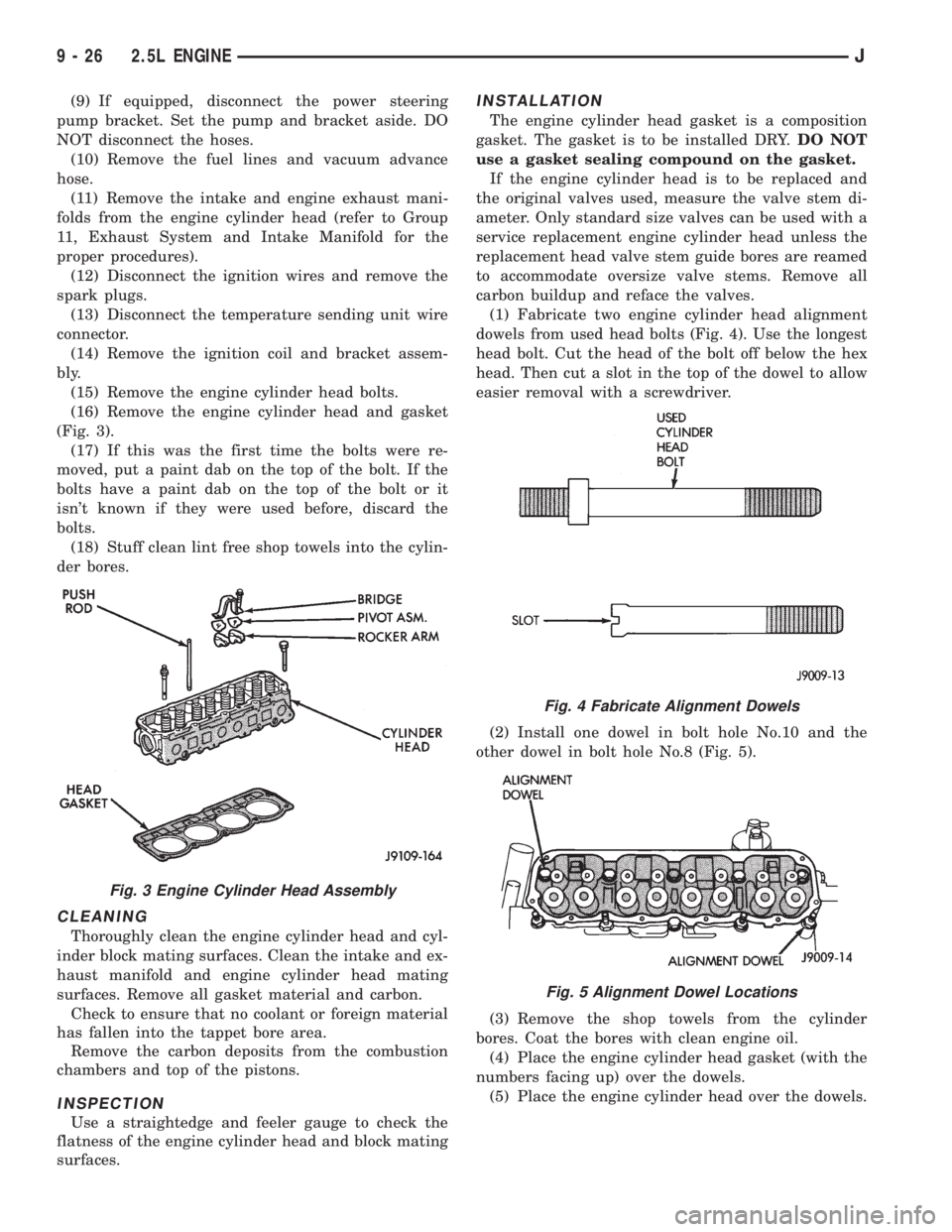

INSTALLATION

The engine cylinder head gasket is a composition

gasket. The gasket is to be installed DRY.DO NOT

use a gasket sealing compound on the gasket.

If the engine cylinder head is to be replaced and

the original valves used, measure the valve stem di-

ameter. Only standard size valves can be used with a

service replacement engine cylinder head unless the

replacement head valve stem guide bores are reamed

to accommodate oversize valve stems. Remove all

carbon buildup and reface the valves.

(1) Fabricate two engine cylinder head alignment

dowels from used head bolts (Fig. 4). Use the longest

head bolt. Cut the head of the bolt off below the hex

head. Then cut a slot in the top of the dowel to allow

easier removal with a screwdriver.

(2) Install one dowel in bolt hole No.10 and the

other dowel in bolt hole No.8 (Fig. 5).

(3) Remove the shop towels from the cylinder

bores. Coat the bores with clean engine oil.

(4) Place the engine cylinder head gasket (with the

numbers facing up) over the dowels.

(5) Place the engine cylinder head over the dowels.

Fig. 3 Engine Cylinder Head Assembly

Fig. 4 Fabricate Alignment Dowels

Fig. 5 Alignment Dowel Locations

9 - 26 2.5L ENGINEJ