lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 964 of 2198

POWER WINDOWS

INDEX

page page

Diagram Index............................ 2

Helpful Information......................... 2Power Windows........................... 1

POWER WINDOWS

When the ignition switch is in the ACCESSORY or

RUN position, it connects circuit A1 from fuse 6 in

the Power Distribution Center (PDC) to circuit A48.

Circuit A48 powers circuit F81 through fuse 12 in the

fuse block. Circuit F81 supplies voltage to the power

window system.

Circuit F81 connects to the master window switch.

Circuit Z1 provides ground for the power windows.

A LOCK-OUT feature is provided on the driver's

door window switch. When this feature is engaged

the other windows in the system will not operate.

RIGHT FRONT WINDOW OPERATION

When the operator selects window DOWN opera-

tion power is supplied on the F81 circuit through the

switch to circuit Q12. Circuit Q12 goes from the

switch to the power window motor. Ground for the

motor is supplied on the Q22 circuit back to the

switch. A bus bar, internal to the switch, connects the

Q22 circuit to the Z1 circuit.

For window UP operation the circuits are reversed.

Circuit Q22 is the feed, and circuit Q12 is the

ground.

LEFT FRONT WINDOW OPERATION

When the DRIVER selects window DOWN opera-

tion, power is supplied on the F81 circuit through the

switch to circuit Q26.

Circuit Q26 goes from the drivers door switch to

the left front door switch. Power is passed through

this switch to circuit Q21. The Q21 circuit then goes

to the right front window motor.

Ground for the window motor is supplied on the

Q11 circuit back to the right door switch. Circuity in-

ternal to the switch then passes the ground to circuit

Q16. Circuit Q16 goes from the right front door

switch to the master switch. A bus bar, internal to

the switch, connects the Q16 circuit to the Z1 circuit.

For window UP operation the circuits are reversed.

Circuits Q16 and Q11 are the feeds, and circuits Q21

and Q26 are the grounds.

If the switch is being operated from the PASSEN-

GER'S front door, and the operator is requesting win-

dow DOWN operation, power is supplied on the Q1

circuit from the driver's master switch circuit

through the switch to the Q21 circuit.Ground for the motor is supplied on the Q11 circuit

through the switch and back to the master switch on

circuit Q16. A bus bar, internal to the switch, con-

nects the Q16 circuit to the Z1 circuit.

For window UP operation, the circuits are reversed.

Circuit Q11 is the power and circuit Q21 is the

ground.

LEFT REAR WINDOW

When the DRIVER selects window DOWN opera-

tion power is supplied on the F81 circuit through the

switch to circuit Q17.

Circuit Q17 goes from the drivers door switch to

the left rear door power window switch. Power is

passed through the switch to circuit Q22. The Q22

circuit then goes to the left rear window motor.

Ground for the window motor is supplied on the

Q12 circuit back to the left rear door switch. Circuity

internal to the switch then passes the ground to cir-

cuit Q27. Circuit Q27 goes from the left rear door

switch to the master switch. A bus bar, internal to

the switch, connects the Q27 circuit to the Z1 circuit.

For window UP operation the circuits are reversed.

Circuits Q27 and Q12 are the feeds, and circuits Q22

and Q17 are the grounds.

If the switch is being operated from the LEFT

REAR door, and the operator is requesting window

DOWN operation, power is supplied on the Q1 circuit

from the driver's master switch circuit through the

switch to the Q22 circuit.

Ground for the motor is supplied on the Q12 circuit

through the switch and to circuit Q27. Circuit Q27

connects to the master window switch. A bus bar, in-

ternal to the switch, connects the Q27 circuit to the

Z1 circuit.

For window UP operation, the circuits are reversed.

Circuit Q12 is the power and circuits Q22, and Q17

are the grounds.

RIGHT REAR WINDOW

When the DRIVER selects window DOWN opera-

tion, power is supplied on the F81 circuit through the

switch to circuit Q18.

Circuit Q18 goes from the drivers door switch to

the right rear door window switch connector. Power

is passed through this switch to circuit Q22. The Q22

circuit then goes to the right rear window motor.

J8W-60 POWER WINDOWSÐXJ-RHD 8W - 60 - 1

Page 965 of 2198

Ground for the window motor is supplied on the

Q12 circuit back to the right rear door switch. Circu-

ity internal to the switch then passes the ground to

circuit Q28. Circuit Q28 goes from the right rear door

switch to the master switch. A bus bar, internal to

the switch, connects the Q28 circuit to the Z1 circuit.

For window UP operation the circuits are reversed.

Circuits Q28 and Q12 are the feeds, and circuits Q22,

Q33 and Q18 are the grounds.

If the switch is being operated from the RIGHT

REAR door, and the operator is requesting window

DOWN operation, power is supplied on the Q1 circuit

from the driver's master switch circuit through the

switch to the Q22 circuit.

Ground for the motor is supplied on the Q12 circuit

through the switch and back to the master switch on

circuit Q28. A bus bar, internal to the switch, con-

nects the Q28 circuit to the Z1 circuit.For window UP operation, the circuits are reversed.

Circuit Q12 is the power and circuits Q22 and Q18

are the ground.

HELPFUL INFORMATION

Refer to the appropriate group of the Service Man-

ual for test procedures.

DIAGRAM INDEX

Component Page

Fuse 6 (PDC)...........................8W-60-3

Fuse 12 (Fuse Block)......................8W-60-3

Ignition Switch..........................8W-60-3

Power Window Door Switches................8W-60-4

Power Window Master Switch................8W-60-3

Power Window Motors.....................8W-60-4

8W - 60 - 2 8W-60 POWER WINDOWSÐXJ-RHDJ

Page 968 of 2198

POWER DOOR LOCKS

POWER DOOR LOCKS

Two relays provide power for the power door lock

motors. The Unlock relay provides power for the un-

lock circuits while the Lock relay powers the lock cir-

cuits. Either power door lock switch can operate the

Unlock and Lock relays.

LOCK RELAY

Circuit A7 from fuse 3 in the Power Distribution

Center (PDC) powers circuits P37 and P38 through

fuse 6 in the fuse block. When either power door lock

switch is put in the LOCK position, the switch con-

nects circuit P38 to circuit P35. Circuit P35 supplies

power to the coil side of the lock relay, causing the

relay contacts to close. Circuit Z1 provides ground for

the coil side of the lock relay.

When the lock relay contacts close, they connect

battery voltage from circuit P37 to circuit P2. Circuit

P2 then supplies battery voltage to the power door

lock motors to LOCK the doors.

When the power doors LOCK, ground for the mo-

tors is on circuit P34 through the normally closed

contacts in the door unlock relay to ground on circuit

Z1.

UNLOCK RELAY

Circuit A7 from fuse 3 in the Power Distribution

Center (PDC) powers circuits P37 and P38 through

fuse 6 in the fuse block. When either power door lock

switch is put in the UNLOCK position, the switch

connects circuit P38 to circuit P36. Circuit P36 sup-

plies power to the coil side of the unlock relay, caus-

ing the relay contacts to close. Circuit Z1 provides

ground for the coil side of the unlock relay.

When the unlock relay contacts close, they connect

battery voltage from circuit P37 to circuit P34. Cir-

cuit P34 then supplies battery voltage to the power

door lock motors to UNLOCK the doors.

When the power doors UNLOCK, ground for the

motors is on circuit P2 through the normally closed

contacts in the door lock relay to ground on circuit

Z1.

DIAGRAM INDEX

Component Page

Fuse 3 (PDC)...........................8W-61-2

Fuse 6 (Fuse Block).......................8W-61-2

Liftgate Lock Motor.......................8W-61-3

Power Door Lock Motors...................8W-61-3

Power Door Lock Relay....................8W-61-2

Power Door Lock Switches..................8W-61-2

Power Door Unlock Relay...................8W-61-2

J8W-61 POWER DOOR LOCKSÐXJ-RHD 8W - 61 - 1

Page 972 of 2198

POWER MIRRORS

INDEX

page page

Diagram Index............................ 1

Heater Elements........................... 1Power Mirrors............................. 1

POWER MIRRORS

Four switches operates the left and right power

mirrors. One switch selects right or left mirror. Each

mirror has two motors; a LEFT/RIGHT motor and a

UP/DOWN motor. The motors switch polarity to al-

low mirror adjustment.

Circuit A7 from fuse 13 in the Power Distribution

Center (PDC) supplies battery voltage to fuse 8 in

the fuse block. Fuse 8 supplies voltage to circuit P60.

Circuit P60 powers the power mirror switch. Circuit

Z1 connects to the power mirror switch and supplies

ground for the power mirror system.

RIGHT POWER MIRROR OPERATION

In the right position, the power mirror switch sup-

plies power to the right mirror LEFT/RIGHT motor

on circuit P79 when a rightward adjustment is made.

Circuit P77 provides the ground path the for right-

ward adjustments.

When the operator makes leftward adjustment, po-

larity reverses. For leftward adjustments, the switch

supplies battery voltage to the right mirror LEFT/

RIGHT motor on circuit P77. Circuit P79 supplies

ground for leftward adjustments.

During upward adjustments, the switch supplies

voltage to the right mirror UP/DOWN motor on cir-

cuit P79. Circuit P80 supplies ground during upward

adjustments.

For downward adjustments, the polarity is re-

versed, the switch powers the right mirror UP/

DOWN motor on circuit P80. Circuit P79 supplies the

ground path.

LEFT POWER MIRROR OPERATION

In the left position, the power mirror switch sup-

plies power to the left mirror LEFT/RIGHT motor on

circuit P79 when a rightward adjustment is made.

Circuit P81 provides the ground path the for right-

ward adjustments.

When the operator makes leftward adjustment, po-

larity reverses. For leftward adjustments, the switch

supplies battery voltage the left mirror LEFT/RIGHT

motor on circuit P81. Circuit P79 supplies ground for

leftward adjustments.

During upward adjustments, the switch supplies

voltage to the left mirror UP/DOWN motor on circuit

P79. Circuit P78 supplies ground during upward ad-

justments.For downward adjustments, the polarity is re-

versed, the switch powers the left mirror UP/DOWN

motor on circuit P78. Circuit P79 supplies the ground

path.

HELPFUL INFORMATION

²Check fuse 3 in the PDC and fuse 8 in the fuse

block in the PDC

HEATER ELEMENTS

The heated rear window relay powers the heater

elements in power mirrors. When the relay energizes,

it supplies power to the heater elements on circuit

C15. Circuit Z1 provides ground for the power mirror

heater elements.

HELPFUL INFORMATION

²Circuit F82 from fuse 2 in the fuse block powers

circuit C15 when the heated rear window relay ener-

gizes.

²Circuit A4 from fuse 7 in the Power Distribution

Center (PDC) supplies battery voltage to the fuse

block for fuse 2 and circuit F85.

²Check fuse 2 in the fuse block.

²Check fuse 7 in the PDC.

DIAGRAM INDEX

Component Page

Fuse 1 (Fuse Block).......................8W-63-2

Fuse 3 (PDC)...........................8W-63-2

Power Seat............................8W-63-2

Power Seat Switch.......................8W-63-2

Fuse 2 (Fuse Block).......................8W-62-3

Fuse 3 (PDC)...........................8W-62-2

Fuse 7 (Fuse Block).......................8W-62-2

Fuse 7 (PDC)...........................8W-62-3

Fuse 8 (Fuse Block).......................8W-62-2

Fuse 16 (PDC)..........................8W-62-2

Heated Rear Window Relay..................8W-62-3

Power Mirrors..........................8W-62-2

Power Mirror Heater Elements................8W-62-3

Power Mirror Switch......................8W-62-2

J8W-62 POWER MIRRORSÐXJ-RHD 8W - 62 - 1

Page 976 of 2198

POWER SEAT

POWER SEAT

Battery voltage for the power seat system is sup-

plied by circuit A11 from fuse 1 in the fuse block. Cir-

cuit A11 is HOT at all times and supplies battery

voltage to the power seat switch.

A BUS bar internal to the power seat switch con-

nects the power from circuit A11 to the switches.

Grounding for the seat system is supplied on circuit

Z1.

The motors located under the seat are protected by

circuit breakers wired in with the motors. Each mo-

tor has its own circuit breaker.

When the operator selects the FRONT VERTICAL

UP function, power is passed on the A11 circuit

through the closed contacts in the switch to the S5

circuit. The S5 circuit connects to the motor. Ground

is provided on the S6 circuit back to the switch. A

ground BUS bar internal to the switch then connects

to the Z1 circuit.

For FRONT VERTICAL DOWN function the cir-

cuits are reversed. S6 is the feed and S5 is the

ground.

When the operator selects the SEAT FORWARD

function, power is passed on the A11 circuit through

the closed contacts in the switch to the S3 circuit.

The S3 circuit connects to the motor. Ground is pro-

vided on the S4 circuit back to the switch. A ground

BUS bar internal to the switch then connects to the

Z1 circuit.

For SEAT REARWARD function the circuits are re-

versed. S4 is the feed and S3 is the ground.When the operator selects the REAR VERTICAL

UP function, power is passed on the A11 circuit

through the closed contacts in the switch to the S1

circuit. The S1 circuit connects to the motor. Ground

is provided on the S2 circuit back to the switch. A

ground BUS bar internal to the switch then connects

to the Z1 circuit.

For REAR VERTICAL DOWN function the circuits

are reversed. S2 is the feed and S1 is the ground.

When the operator selects the SEAT UP function

power is passed on the A11 circuit through the closed

contacts in the switch to the S1 and S5 circuits. The

S1 circuit connects to the rear UP/DOWN motor, and

S5 connects to the front UP/DOWN motor. Ground is

provided on the S2 and S6 circuits back to the

switch. A ground BUS bar internal to the switch then

connects to the Z1 circuit.

For SEAT DOWN function the circuits are re-

versed. S2 and S6 circuits are the feeds and S1 and

S5 are the grounds.

DIAGRAM INDEX

Component Page

Fuse 1 (Fuse Block).......................8W-63-2

Fuse 3 (PDC)...........................8W-63-2

Power Seat............................8W-63-2

Power Seat Switch.......................8W-63-2

J8W-63 POWER SEATÐXJ-RHD 8W - 63 - 1

Page 1072 of 2198

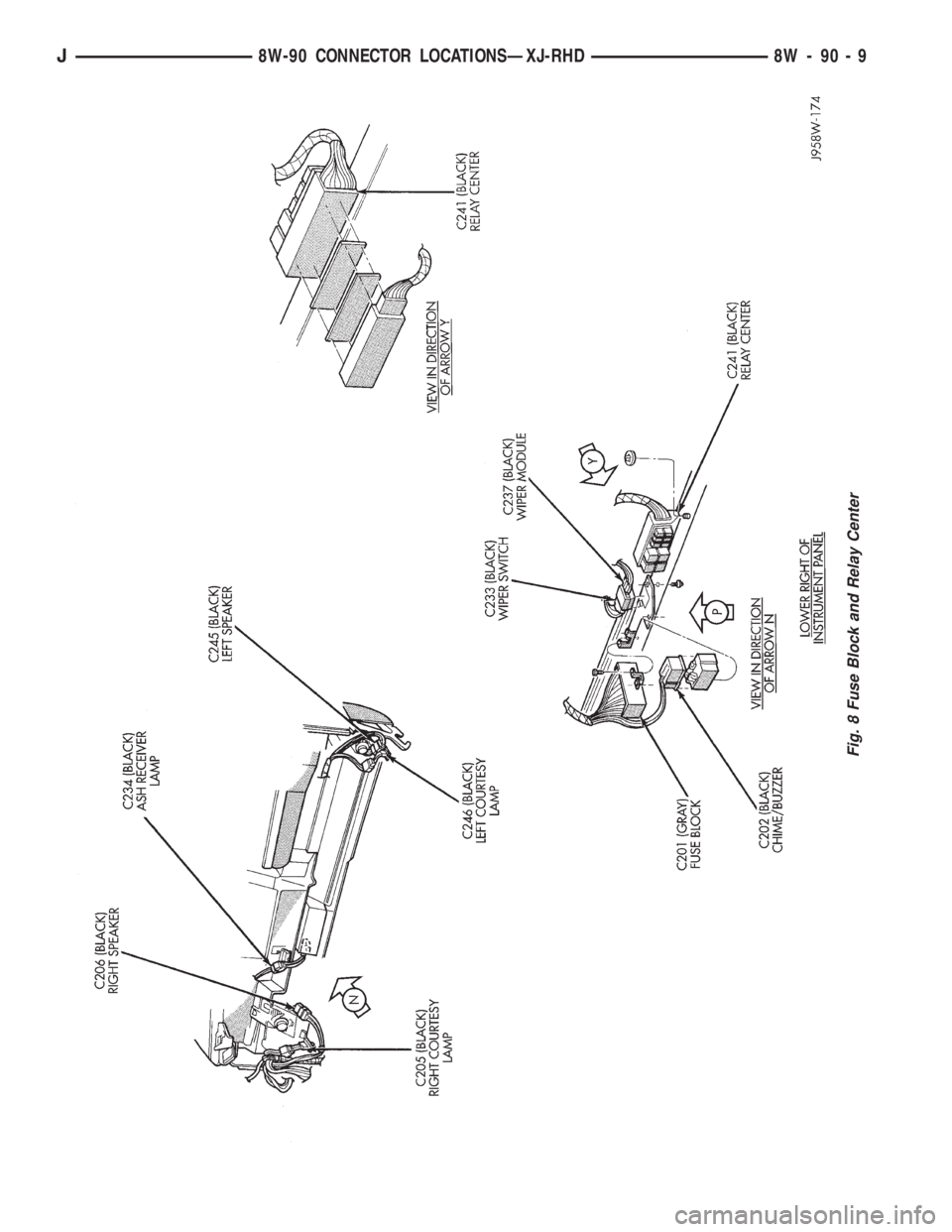

Fig. 8 Fuse Block and Relay Center

J8W-90 CONNECTOR LOCATIONSÐXJ-RHD 8W - 90 - 9

Page 1082 of 2198

SPLICE LOCATIONS

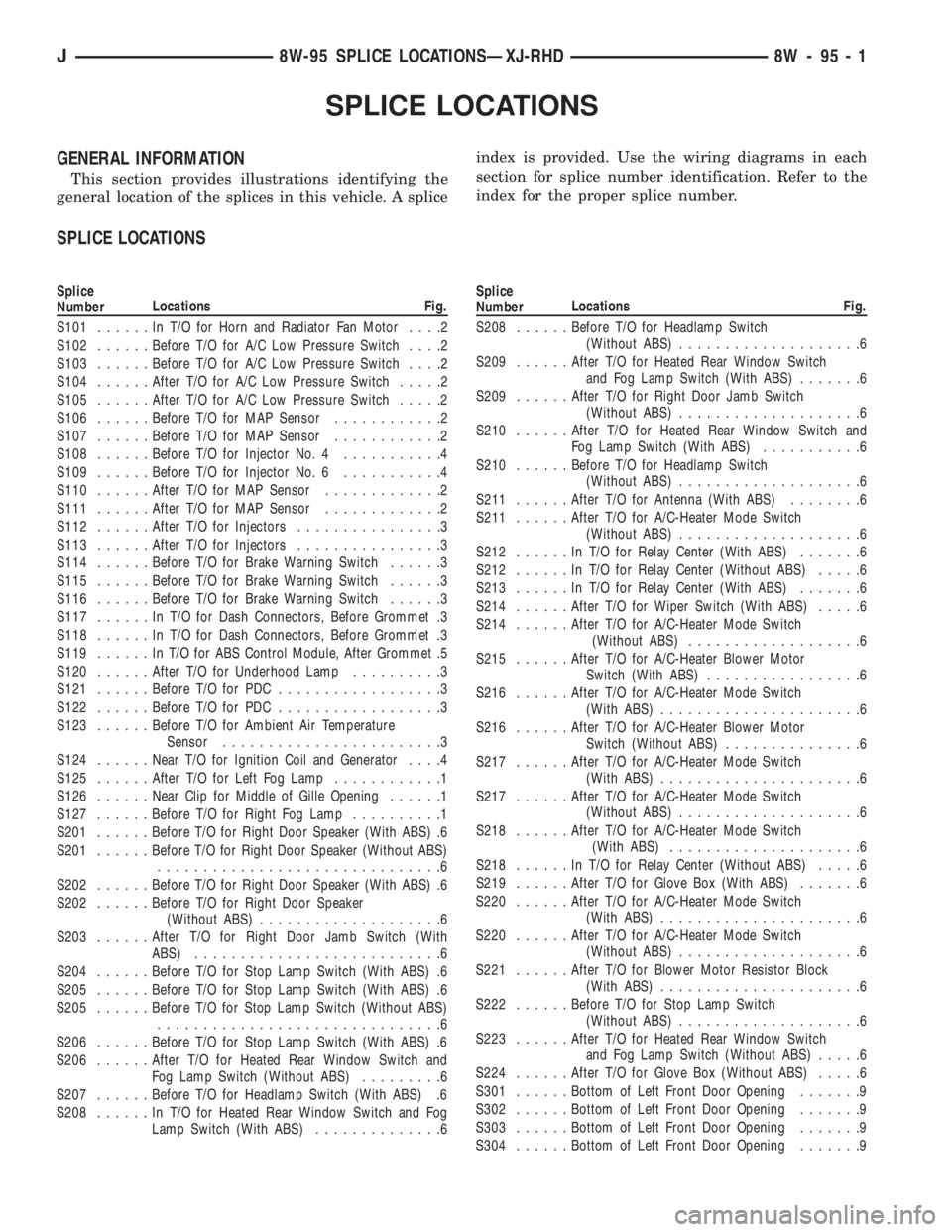

GENERAL INFORMATION

This section provides illustrations identifying the

general location of the splices in this vehicle. A spliceindex is provided. Use the wiring diagrams in each

section for splice number identification. Refer to the

index for the proper splice number.

SPLICE LOCATIONS

Splice

NumberLocations Fig.

S101......InT/OforHorn and Radiator Fan Motor....2

S102......Before T/O for A/C Low Pressure Switch....2

S103......Before T/O for A/C Low Pressure Switch....2

S104......After T/O for A/C Low Pressure Switch.....2

S105......After T/O for A/C Low Pressure Switch.....2

S106......Before T/O for MAP Sensor............2

S107......Before T/O for MAP Sensor............2

S108......Before T/O for Injector No. 4...........4

S109......Before T/O for Injector No. 6...........4

S110......After T/O for MAP Sensor.............2

S111......After T/O for MAP Sensor.............2

S112......After T/O for Injectors................3

S113......After T/O for Injectors................3

S114......Before T/O for Brake Warning Switch......3

S115......Before T/O for Brake Warning Switch......3

S116......Before T/O for Brake Warning Switch......3

S117......InT/OforDash Connectors, Before Grommet .3

S118......InT/OforDash Connectors, Before Grommet .3

S119......InT/OforABSControl Module, After Grommet .5

S120......After T/O for Underhood Lamp..........3

S121......Before T/O for PDC..................3

S122......Before T/O for PDC..................3

S123......Before T/O for Ambient Air Temperature

Sensor........................3

S124......Near T/O for Ignition Coil and Generator....4

S125......After T/O for Left Fog Lamp............1

S126......Near Clip for Middle of Gille Opening......1

S127......Before T/O for Right Fog Lamp..........1

S201......Before T/O for Right Door Speaker (With ABS) .6

S201......Before T/O for Right Door Speaker (Without ABS)

...............................6

S202......Before T/O for Right Door Speaker (With ABS) .6

S202......Before T/O for Right Door Speaker

(Without ABS)....................6

S203......After T/O for Right Door Jamb Switch (With

ABS)...........................6

S204......Before T/O for Stop Lamp Switch (With ABS) .6

S205......Before T/O for Stop Lamp Switch (With ABS) .6

S205......Before T/O for Stop Lamp Switch (Without ABS)

...............................6

S206......Before T/O for Stop Lamp Switch (With ABS) .6

S206......After T/O for Heated Rear Window Switch and

Fog Lamp Switch (Without ABS).........6

S207......Before T/O for Headlamp Switch (With ABS) .6

S208......InT/OforHeated Rear Window Switch and Fog

Lamp Switch (With ABS)..............6Splice

NumberLocations Fig.

S208......Before T/O for Headlamp Switch

(Without ABS)....................6

S209......After T/O for Heated Rear Window Switch

and Fog Lamp Switch (With ABS).......6

S209......After T/O for Right Door Jamb Switch

(Without ABS)....................6

S210......After T/O for Heated Rear Window Switch and

Fog Lamp Switch (With ABS)...........6

S210......Before T/O for Headlamp Switch

(Without ABS)....................6

S211......After T/O for Antenna (With ABS)........6

S211......After T/O for A/C-Heater Mode Switch

(Without ABS)....................6

S212......InT/OforRelay Center (With ABS).......6

S212......InT/OforRelay Center (Without ABS).....6

S213......InT/OforRelay Center (With ABS).......6

S214......After T/O for Wiper Switch (With ABS).....6

S214......After T/O for A/C-Heater Mode Switch

(Without ABS)...................6

S215......After T/O for A/C-Heater Blower Motor

Switch (With ABS).................6

S216......After T/O for A/C-Heater Mode Switch

(With ABS)......................6

S216......After T/O for A/C-Heater Blower Motor

Switch (Without ABS)...............6

S217......After T/O for A/C-Heater Mode Switch

(With ABS)......................6

S217......After T/O for A/C-Heater Mode Switch

(Without ABS)....................6

S218......After T/O for A/C-Heater Mode Switch

(With ABS).....................6

S218......InT/OforRelay Center (Without ABS).....6

S219......After T/O for Glove Box (With ABS).......6

S220......After T/O for A/C-Heater Mode Switch

(With ABS)......................6

S220......After T/O for A/C-Heater Mode Switch

(Without ABS)....................6

S221......After T/O for Blower Motor Resistor Block

(With ABS)......................6

S222......Before T/O for Stop Lamp Switch

(Without ABS)....................6

S223......After T/O for Heated Rear Window Switch

and Fog Lamp Switch (Without ABS).....6

S224......After T/O for Glove Box (Without ABS).....6

S301......Bottom of Left Front Door Opening.......9

S302......Bottom of Left Front Door Opening.......9

S303......Bottom of Left Front Door Opening.......9

S304......Bottom of Left Front Door Opening.......9

J8W-95 SPLICE LOCATIONSÐXJ-RHD 8W - 95 - 1

Page 1092 of 2198

ENGINES

CONTENTS

page page

LUBRICATION SYSTEM................... 37

LUBRICATION SYSTEM................... 79

2.5L ENGINE SERVICE PROCEDURES....... 134.0L ENGINE SERVICE PROCEDURES....... 55

ENGINE DIAGNOSIS...................... 5

STANDARD SERVICE PROCEDURES......... 1

STANDARD SERVICE PROCEDURES

INDEX

page page

Engine Performance........................ 2

Form-In-Place Gaskets...................... 1

Honing Cylinder Bores...................... 2

Hydrostatic Lock........................... 4Measuring with Plastigage.................... 3

Repair Damaged or Worn Threads............. 4

Service Engine Assembly (Short Block).......... 4

FORM-IN-PLACE GASKETS

There are several places where form-in-place gas-

kets are used on the engine.DO NOT use form-in-

place gasket material unless specified.Care

must be taken when applying form-in-place gaskets.

Bead size, continuity and location are of great impor-

tance. Too thin a bead can result in leakage while too

much can result in spill-over. A continuous bead of

the proper width is essential to obtain a leak-free

joint.

Two types of form-in-place gasket materials are

used in the engine area (Mopar Silicone Rubber Ad-

hesive Sealant and Mopar Gasket Maker). Each have

different properties and cannot be used interchange-

ably.

MOPAR SILICONE RUBBER ADHESIVE

SEALANT

Mopar Silicone Rubber Adhesive Sealant, normally

black in color, is available in 3 ounce tubes. Moisture

in the air causes the sealant material to cure. This

material is normally used on flexible metal flanges.

It has a shelf life of a year and will not properly cure

if over aged. Always inspect the package for the ex-

piration date before use.

MOPAR GASKET MAKER

Mopar Gasket Maker, normally red in color, is

available in 6 cc tubes. This anaerobic type gasket

material cures in the absence of air when squeezedbetween smooth machined metallic surfaces. It will

not cure if left in the uncovered tube. DO NOT use

on flexible metal flanges.

SURFACE PREPARATION

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some in-

stances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper

may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

Scrape or wire brush all gasket surfaces to remove

all loose material. Inspect stamped parts to ensure

gasket rails are flat. Flatten rails with a hammer on

a flat plate, if required. Gasket surfaces must be free

of oil and dirt. Make sure the old gasket material is

removed from blind attaching holes.

GASKET APPLICATION

Assembling parts using a form-in-place gasket re-

quires care.

Mopar Silicone Rubber Adhesive Sealant should be

applied in a continuous bead approximately 3 mm

(0.12 inch) in diameter. All mounting holes must be

circled. For corner sealing,a3or6mm(1/8 or 1/4

inch) drop is placed in the center of the gasket con-

tact area. Uncured sealant may be removed with a

shop towel. Components should be torqued in place

while the sealant is still wet to the touch (within 10

JENGINES 9 - 1

Page 1094 of 2198

CAUTION: DO NOT use engine or transmission oil,

mineral spirits or kerosene.

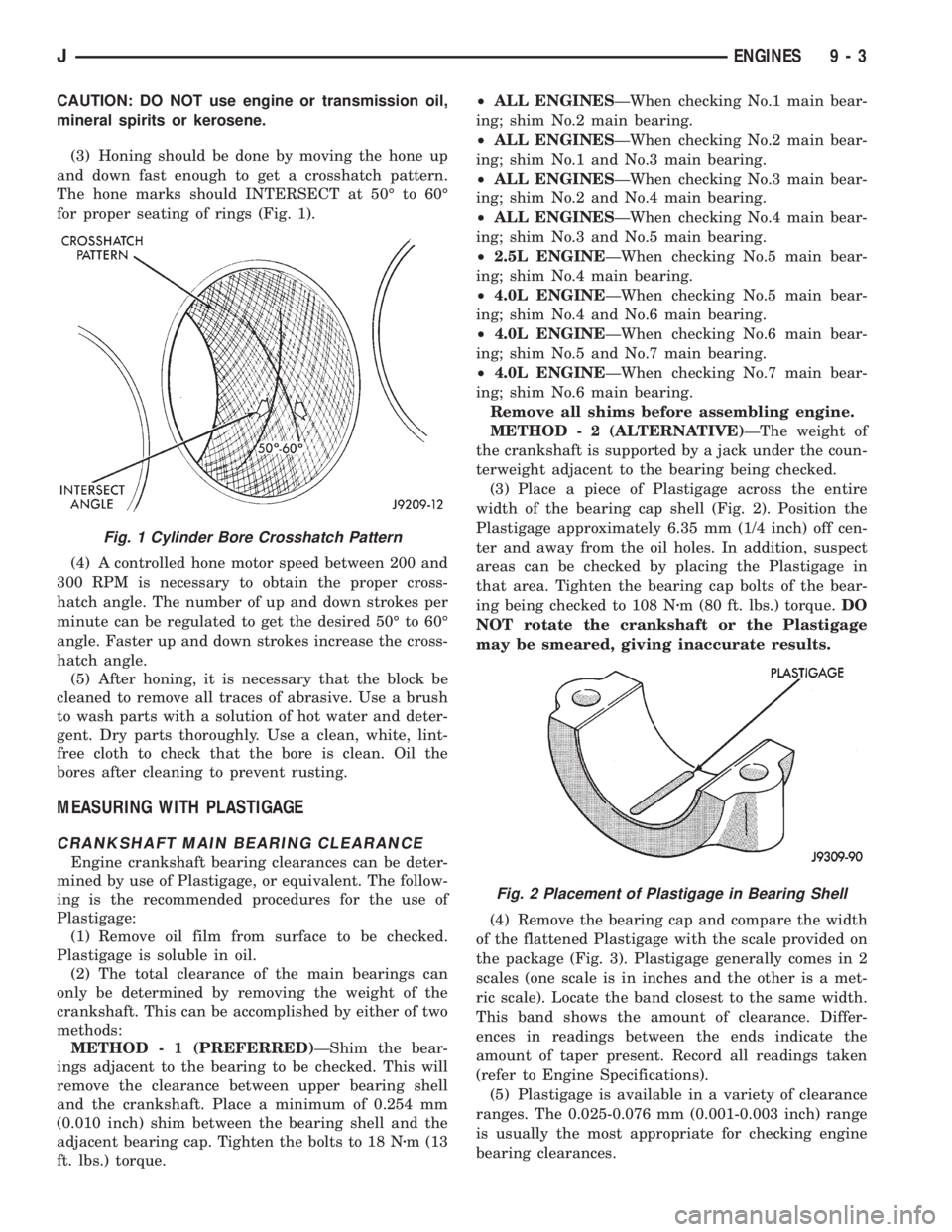

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 1).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

MEASURING WITH PLASTIGAGE

CRANKSHAFT MAIN BEARING CLEARANCE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage, or equivalent. The follow-

ing is the recommended procedures for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) The total clearance of the main bearings can

only be determined by removing the weight of the

crankshaft. This can be accomplished by either of two

methods:

METHOD - 1 (PREFERRED)ÐShim the bear-

ings adjacent to the bearing to be checked. This will

remove the clearance between upper bearing shell

and the crankshaft. Place a minimum of 0.254 mm

(0.010 inch) shim between the bearing shell and the

adjacent bearing cap. Tighten the bolts to 18 Nzm (13

ft. lbs.) torque.²ALL ENGINESÐWhen checking No.1 main bear-

ing; shim No.2 main bearing.

²ALL ENGINESÐWhen checking No.2 main bear-

ing; shim No.1 and No.3 main bearing.

²ALL ENGINESÐWhen checking No.3 main bear-

ing; shim No.2 and No.4 main bearing.

²ALL ENGINESÐWhen checking No.4 main bear-

ing; shim No.3 and No.5 main bearing.

²2.5L ENGINEÐWhen checking No.5 main bear-

ing; shim No.4 main bearing.

²4.0L ENGINEÐWhen checking No.5 main bear-

ing; shim No.4 and No.6 main bearing.

²4.0L ENGINEÐWhen checking No.6 main bear-

ing; shim No.5 and No.7 main bearing.

²4.0L ENGINEÐWhen checking No.7 main bear-

ing; shim No.6 main bearing.

Remove all shims before assembling engine.

METHOD - 2 (ALTERNATIVE)ÐThe weight of

the crankshaft is supported by a jack under the coun-

terweight adjacent to the bearing being checked.

(3) Place a piece of Plastigage across the entire

width of the bearing cap shell (Fig. 2). Position the

Plastigage approximately 6.35 mm (1/4 inch) off cen-

ter and away from the oil holes. In addition, suspect

areas can be checked by placing the Plastigage in

that area. Tighten the bearing cap bolts of the bear-

ing being checked to 108 Nzm (80 ft. lbs.) torque.DO

NOT rotate the crankshaft or the Plastigage

may be smeared, giving inaccurate results.

(4) Remove the bearing cap and compare the width

of the flattened Plastigage with the scale provided on

the package (Fig. 3). Plastigage generally comes in 2

scales (one scale is in inches and the other is a met-

ric scale). Locate the band closest to the same width.

This band shows the amount of clearance. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken

(refer to Engine Specifications).

(5) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076 mm (0.001-0.003 inch) range

is usually the most appropriate for checking engine

bearing clearances.

Fig. 1 Cylinder Bore Crosshatch Pattern

Fig. 2 Placement of Plastigage in Bearing Shell

JENGINES 9 - 3

Page 1095 of 2198

CONNECTING ROD BEARING CLEARANCE

Engine connecting rod bearing clearances can be

determined by use of Plastigage, or equivalent. The

following is the recommended procedures for the use

of Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire width

of the bearing cap shell (Fig. 2). Position the Plastigage

approximately 6.35 mm (1/4 inch) off center and away

from the oil holes. In addition, suspect areas can be

checked by placing the Plastigage in the suspect area.

(3) The crankshaft must be turned until the connect-

ing rod to be checked starts moving toward the top of

the engine. Only then should the rod cap with Plasti-

gage in place be assembled. Tighten the rod cap nut to

45 Nzm (33 ft. lbs.) torque.DO NOT rotate the crank-

shaft or the Plastigage may be smeared, giving in-

accurate results.

(4) Remove the bearing cap and compare the width

of the flattened Plastigage with the scale provided on

the package (Fig. 3). Plastigage generally comes in 2

scales (one scale is in inches and the other is a met-

ric scale). Locate the band closest to the same width.

This band shows the amount of clearance. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken

(refer to Engine Specifications).

(5) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076 mm (0.001-0.003 inch) range

is usually the most appropriate for checking engine

bearing clearances.

REPAIR DAMAGED OR WORN THREADS

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole.

This brings the hole back to its original thread

size.

CAUTION: Be sure that the tapped holes maintain

the original center line.Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

SERVICE ENGINE ASSEMBLY (SHORT BLOCK)

A service replacement engine assembly (short

block) may be installed whenever the original cylin-

der block is defective or damaged beyond repair. It

consists of the cylinder block, crankshaft, piston and

rod assemblies. If needed, the camshaft must be pro-

cured separately and installed before the engine is

installed in the vehicle.

A short block is identified with the letter ``S'' stamped

on the same machined surface where the build date

code is stamped for complete engine assemblies.

Installation includes the transfer of components

from the defective or damaged original engine. Fol-

low the appropriate procedures for cleaning, inspec-

tion and torque tightening.

HYDROSTATIC LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System).

(2) Disconnect the negative cable from the battery.

(3) Inspect air cleaner, induction system and in-

take manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure in

the cylinder head. Remove the plugs from the engine.

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (i.e. coolant,

fuel, oil, etc.).

(7) Make sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt engine oil into the cylinders to lubricate

the walls. This will prevent damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 37 Nzm (27 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

Nzm (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil (refer to Group 0, Lubrica-

tion and Maintenance).

(15) Connect the negative cable to the battery.

(16) Start the engine and check for any leaks.

Fig. 3 Clearance Measurement

9 - 4 ENGINESJ