button JEEP CHEROKEE 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 488 of 2198

POWER LOCKS

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 8

GENERAL INFORMATION

Power locks are optional equipment on XJ (Chero-

kee) models. Power windows and the keyless entry

system are included on vehicles equipped with the

power lock option. All doors and the liftgate can be

locked and unlocked electrically by operating the

switch on either front door panel, or by operating the

lock and unlock buttons of the remote keyless entry

transmitter. The power lock and keyless entry sys-

tems operate with battery power supplied indepen-

dent of the ignition switch.

Following are general descriptions of the major

components in the power lock system. Refer to Group

8W - Wiring Diagrams for complete circuit descrip-

tions and diagrams. Refer to the owner's manual for

more information on the features and use of these

systems.

POWER LOCK SWITCH

The power locks are controlled by a two-way switch

mounted on the trim panel of each front door. The

switch controls battery feed to the lock and unlock

relays. The door lock switches can not be repaired. If

faulty, the entire switch must be replaced.

POWER LOCK/UNLOCK RELAYS

The power lock and unlock relays are located in the

relay center. The relay center is located on the lower

instrument panel reinforcement behind the lower in-

strument panel and just right of the steering column.

The relays respond to inputs from the power lock

switches and the keyless entry module by sending

the correct battery and ground feeds to the lock mo-

tors. The lock and unlock relays can not be repaired.

If faulty, they must be replaced.

POWER LOCK MOTOR

The locks are actuated by a reversible motor

mounted within each door. The motor direction iscontrolled by the battery and ground feeds from the

power lock/unlock relays. The motor can not be re-

paired. If faulty, the entire motor must be replaced.

KEYLESS ENTRY TRANSMITTER

The keyless entry transmitter is equipped with two

buttons labeled Lock and Unlock. It is also designed

to serve as a key fob and is equipped with a key ring.

Each transmitter has a different vehicle access code,

which must be programmed into the memory of the

keyless entry module in the vehicle in order to oper-

ate the locks. The operating range of the infrared

transmitter signal is up to 4.75 meters (15 feet) from

the receiver.

The transmitter operates on two CR1616 3-volt (or

equivalent) batteries. Typical battery life is from one

to two years.

KEYLESS ENTRY MODULE

The keyless entry module is mounted in a housing

on the headliner near the windshield between the

sunvisors, or inside and towards the rear of the over-

head console (if equipped). This module contains the

keyless entry receiver and program logic for the key-

less entry system.

The keyless entry module has a memory function

to retain the vehicle access code of at least one, and

up to four transmitters. The module receives input

from the remote keyless entry transmitter. In re-

sponse to that input, it is programmed to control out-

puts to the lock and unlock relays. The module can

not be repaired and, if faulty, must be replaced.

JPOWER LOCKS 8P - 1

Page 494 of 2198

POWER LOCK MOTOR

(1) Once it is determined which lock motor is inop-

erative, that motor can be tested. Disconnect the wire

connector at the motor. Apply 12 volts to the motor

terminals to check its operation in one direction. Re-

verse the polarity to check the operation in the other

direction. If OK, repair circuits to power lock/unlock

relays as required. If not OK, replace the motor.

(2) If all lock motors are inoperative, the problem

may be caused by one shorted motor. Disconnecting a

shorted motor will allow the good motors to operate.

Disconnect each motor connector, one at a time, and

re-check both lock and unlock functions while operat-

ing the door lock switch. If disconnecting one motor

causes the other motors to become functional, go

back to step 1 to test the disconnected motor.

KEYLESS ENTRY TRANSMITTER

(1) Depress either transmitter button and note

whether red Light-Emitting Diode (LED) on trans-

mitter case lights. If OK, go to next step. If not OK,

replace batteries as described under Keyless Entry

Transmitter in Service Procedures. Test transmitter

operation. If OK, discard faulty batteries. If not OK,

go to next step.

(2) Perform transmitter program procedure with

suspect transmitter and another known good trans-

mitter, as described in Service Procedures. Test oper-

ation with both transmitters. If both transmitters fail

to operate power locks, see Keyless Entry Module di-

agnosis. If known good transmitter operates power

locks and suspect transmitter does not, replace faulty

transmitter. Be certain to perform transmitter pro-

gram procedure again when replacing faulty trans-

mitter and to erase test transmitter access code from

keyless entry module.

KEYLESS ENTRY MODULE

(1) Check fuse 9 in fuseblock module. If OK, go to

next step. If not OK, replace fuse.

(2) Check for battery voltage at fuse 9. If OK, go to

next step. If not OK, repair circuit from power distri-

bution center.

(3) Access keyless entry module connectors as de-

scribed in Keyless Entry Module Remove/Install.

(4) Unplug module connector from module. Check

connector and receptacle in module for loose, cor-

roded, or damaged terminals and pins. If OK, go to

next step. If not OK, repair as required.

(5) Probe connector cavity for module terminal 1

and check for battery voltage. If OK, go to next step.

If not OK, repair circuit to fuse 9 as required.

(6) Install a jumper wire from connector cavity for

module terminal 1 to connector cavity for module ter-

minal 3. Doors should lock. If OK, go to step 8. If not

OK, go to next step.

(7) Check for continuity between connector cavity

for module terminal 3 and lock relay terminal 3 (86).

There should be continuity. If OK, replace lock relay.

If not OK, repair circuit as required.

(8) Install a jumper wire from connector cavity for

module terminal 1 to connector cavity for module ter-

minal 4. Doors should unlock. If OK, replace module.

If not OK, go to next step.

(9) Check for continuity between connector cavity

for module terminal 4 and unlock relay terminal 3

(86). There should be continuity. If OK, replace un-

lock relay. If not OK, repair circuit as required.

JPOWER LOCKS 8P - 7

Page 495 of 2198

SERVICE PROCEDURES

KEYLESS ENTRY TRANSMITTER

To replace transmitter batteries, separate transmit-

ter case by prying gently with a trim stick or other

wide flat-bladed tool at center seam (Fig. 2). Case

snaps open and shut. Replace with CR1616 3-volt

batteries or equivalent (Fig. 3).

TRANSMITTER PROGRAMMING PROCEDURE

(1) Open the driver's door of the vehicle. Leave it

open through the programming procedure.

(2) Move the mechanical door lock lever to the

LOCK position.

(3) Turn the ignition switch to the ON position.

(4) Within 20 seconds, aim a transmitter at the

keyless entry module receiver dome and press the

LOCK button for at least 5 seconds. Once the module

accepts the programming code, the driver's door will

unlock.

(5) Once the first transmitter has been pro-

grammed, additional transmitters (up to 4) may beprogrammed into the module. Within 20 seconds of

the previous transmitter programming, move the me-

chanical door lock lever to the LOCK position. Aim

another transmitter at the receiver dome and press

the LOCK button for at least 5 seconds. The door

lock will cycle again.

(6) To lock the programmed codes into the module,

the ignition switch must be turned OFF and back

ON within 20 seconds after programming the last

transmitter's code. At that time, all previous codes

are erased from the module.

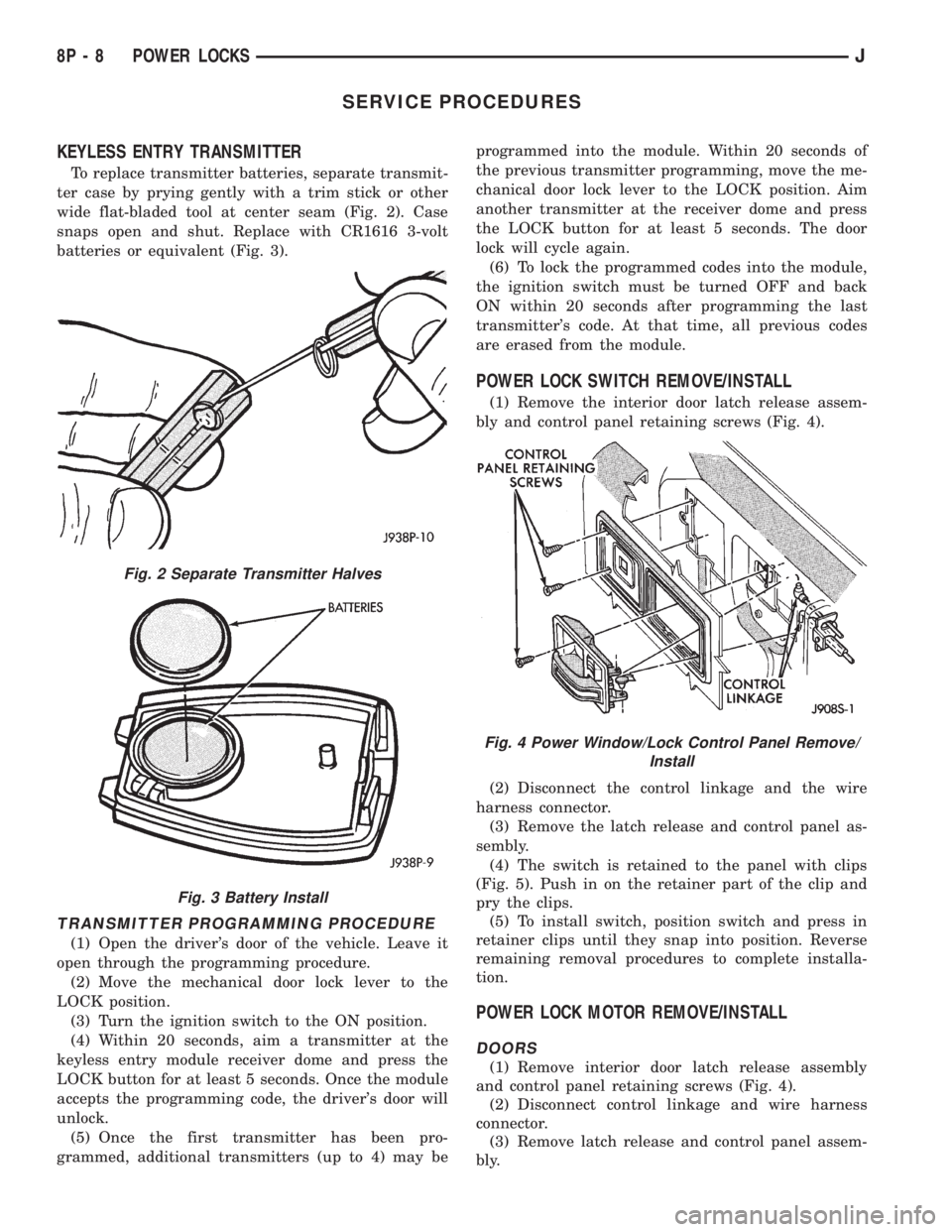

POWER LOCK SWITCH REMOVE/INSTALL

(1) Remove the interior door latch release assem-

bly and control panel retaining screws (Fig. 4).

(2) Disconnect the control linkage and the wire

harness connector.

(3) Remove the latch release and control panel as-

sembly.

(4) The switch is retained to the panel with clips

(Fig. 5). Push in on the retainer part of the clip and

pry the clips.

(5) To install switch, position switch and press in

retainer clips until they snap into position. Reverse

remaining removal procedures to complete installa-

tion.

POWER LOCK MOTOR REMOVE/INSTALL

DOORS

(1) Remove interior door latch release assembly

and control panel retaining screws (Fig. 4).

(2) Disconnect control linkage and wire harness

connector.

(3) Remove latch release and control panel assem-

bly.

Fig. 2 Separate Transmitter Halves

Fig. 3 Battery Install

Fig. 4 Power Window/Lock Control Panel Remove/

Install

8P - 8 POWER LOCKSJ

Page 512 of 2198

POWER MIRRORS

CONTENTS

page page

DIAGNOSIS............................. 1

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 4

GENERAL INFORMATION

Power outside rear view mirrors are an available

option on XJ (Cherokee) models. Following are gen-

eral descriptions of the major components in the

power mirror system. Refer to Group 8W - Wiring Di-

agrams for complete circuit descriptions and dia-

grams.

POWER MIRROR

The power mirrors are connected to battery feed at

all times. Each mirror head contains two electric mo-

tors, two drive mechanisms and the mirror glass.

One motor and drive controls mirror up-and-down

movement, and the other controls right-and-left

movement.

The mirror glass is the only serviced replacement

part for the power mirror assembly. If any other com-ponent of the mirror unit is faulty or damaged, the

entire assembly must be replaced.

POWER MIRROR SWITCH

Both the right and left mirror are controlled by a

multi-function switch located on the front of the cen-

ter console storage compartment, directly below the

armrest. The selector switch is moved right (right

mirror control), left (left mirror control), or center to

turn power mirrors off. Then one of four directional

control buttons is depressed to control movement of

the selected mirror up, down, right, or left. The

power mirror switch is serviced only as a complete

unit.

DIAGNOSIS

POWER MIRROR SYSTEM

(1) Check fuse 16 in Power Distribution Center

(PDC) and fuse 9 in fuseblock module. If OK, go to

next step. If not OK, replace fuse.

(2) Check for battery voltage at fuse 9 in fuseblock

module. If OK, go to next step. If not OK, repair cir-

cuit to fuse 16 in PDC.

(3) Remove power mirror switch from the center

console. See Power Mirror Switch Remove/Install.

(4) Disconnect wiring harness connector from

switch. Check for battery voltage at pink wire. If OK,

go to next step. If not OK, repair circuit to fuse 9 in

fuseblock module.

(5) Check for continuity between black wire in

switch harness connector and a good ground. There

should be continuity. If OK, go to next step. If not

OK, repair circuit to ground.

(6) Check switch continuity as shown in the Mirror

Switch Continuity charts. If OK, go to next step. If

not OK, replace switch.(7) See Power Mirror Switch illustration. Connect

a jumper wire from mirror switch connector cavity

for pin E to cavity for pin F. Now connect a second

jumper from connector cavity for pin G to each of the

following pin cavities: A, B, C, then D. In each case,

the selected mirror head should move. If OK, replace

switch. If not OK, go to next step.

(8) Remove door trim panel and unplug power mir-

ror connector inside door. Connect one jumper wire to

a good ground and a second jumper wire to a battery

feed. Connect other ends of jumpers to the mirror

side of connector in door (refer to Group 8W - Wiring

Diagrams for connector cavity identification). Mirror

head should move in each of the four directions. If

OK, repair wiring between mirror switch and door

connectors. If not OK, replace mirror.

JPOWER MIRRORS 8T - 1

Page 1338 of 2198

(2) Wrap a single layer of plastic tape around the

pitman shaft threads and splines. This will protect

the replacement seals during installation.

(3) Install the seal with a suitable size socket.

(4) Remove the tape from the shaft.

(5) Center the steering gear.

(6) Align and install the pitman arm.

(7) Install the washer and retaining nut on the pit-

man shaft. Tighten the nut to 251 Nzm (185 ft. lbs.)

torque.

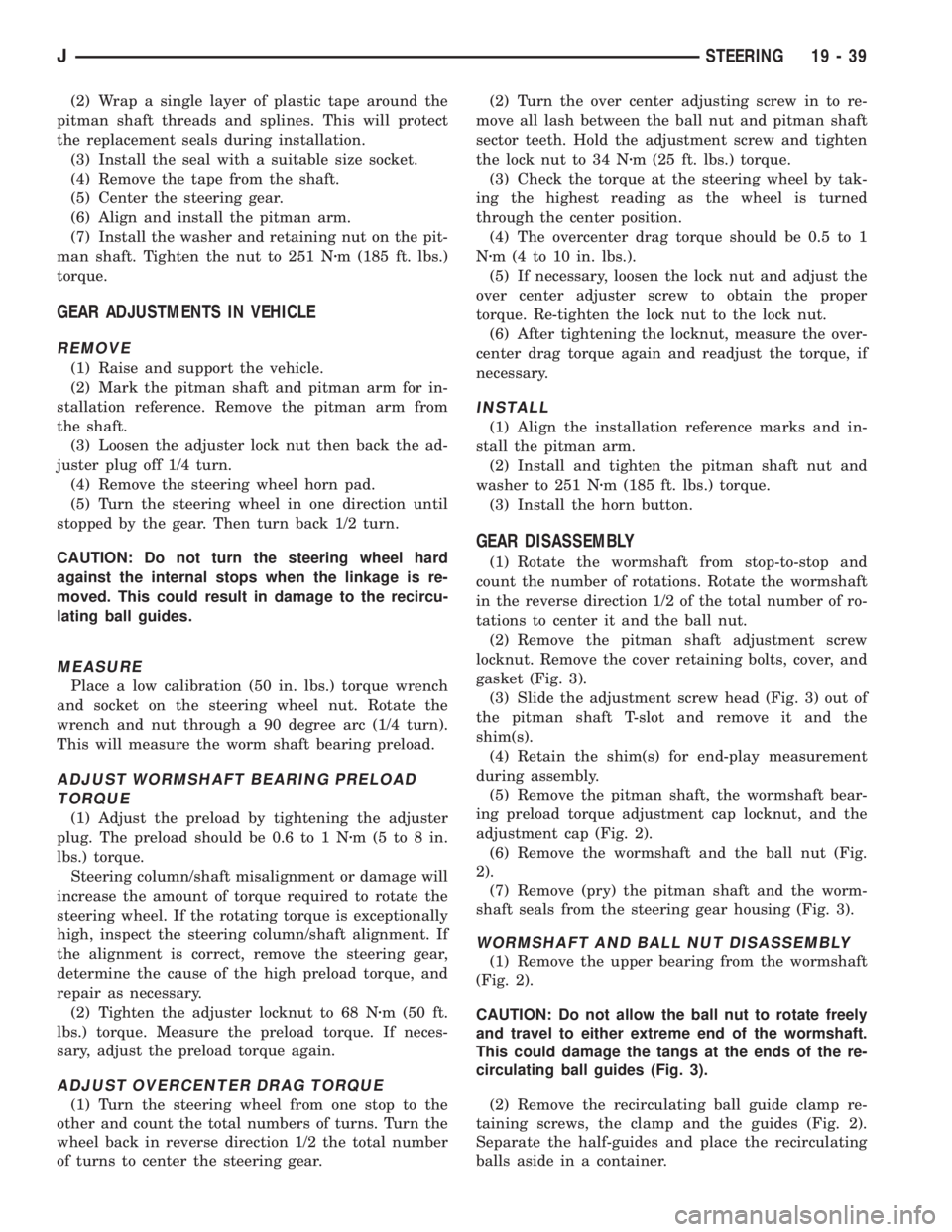

GEAR ADJUSTMENTS IN VEHICLE

REMOVE

(1) Raise and support the vehicle.

(2) Mark the pitman shaft and pitman arm for in-

stallation reference. Remove the pitman arm from

the shaft.

(3) Loosen the adjuster lock nut then back the ad-

juster plug off 1/4 turn.

(4) Remove the steering wheel horn pad.

(5) Turn the steering wheel in one direction until

stopped by the gear. Then turn back 1/2 turn.

CAUTION: Do not turn the steering wheel hard

against the internal stops when the linkage is re-

moved. This could result in damage to the recircu-

lating ball guides.

MEASURE

Place a low calibration (50 in. lbs.) torque wrench

and socket on the steering wheel nut. Rotate the

wrench and nut through a 90 degree arc (1/4 turn).

This will measure the worm shaft bearing preload.

ADJUST WORMSHAFT BEARING PRELOAD

TORQUE

(1) Adjust the preload by tightening the adjuster

plug. The preload should be 0.6 to 1 Nzm(5to8in.

lbs.) torque.

Steering column/shaft misalignment or damage will

increase the amount of torque required to rotate the

steering wheel. If the rotating torque is exceptionally

high, inspect the steering column/shaft alignment. If

the alignment is correct, remove the steering gear,

determine the cause of the high preload torque, and

repair as necessary.

(2) Tighten the adjuster locknut to 68 Nzm (50 ft.

lbs.) torque. Measure the preload torque. If neces-

sary, adjust the preload torque again.

ADJUST OVERCENTER DRAG TORQUE

(1) Turn the steering wheel from one stop to the

other and count the total numbers of turns. Turn the

wheel back in reverse direction 1/2 the total number

of turns to center the steering gear.(2) Turn the over center adjusting screw in to re-

move all lash between the ball nut and pitman shaft

sector teeth. Hold the adjustment screw and tighten

the lock nut to 34 Nzm (25 ft. lbs.) torque.

(3) Check the torque at the steering wheel by tak-

ing the highest reading as the wheel is turned

through the center position.

(4) The overcenter drag torque should be 0.5 to 1

Nzm (4 to 10 in. lbs.).

(5) If necessary, loosen the lock nut and adjust the

over center adjuster screw to obtain the proper

torque. Re-tighten the lock nut to the lock nut.

(6) After tightening the locknut, measure the over-

center drag torque again and readjust the torque, if

necessary.

INSTALL

(1) Align the installation reference marks and in-

stall the pitman arm.

(2) Install and tighten the pitman shaft nut and

washer to 251 Nzm (185 ft. lbs.) torque.

(3) Install the horn button.

GEAR DISASSEMBLY

(1) Rotate the wormshaft from stop-to-stop and

count the number of rotations. Rotate the wormshaft

in the reverse direction 1/2 of the total number of ro-

tations to center it and the ball nut.

(2) Remove the pitman shaft adjustment screw

locknut. Remove the cover retaining bolts, cover, and

gasket (Fig. 3).

(3) Slide the adjustment screw head (Fig. 3) out of

the pitman shaft T-slot and remove it and the

shim(s).

(4) Retain the shim(s) for end-play measurement

during assembly.

(5) Remove the pitman shaft, the wormshaft bear-

ing preload torque adjustment cap locknut, and the

adjustment cap (Fig. 2).

(6) Remove the wormshaft and the ball nut (Fig.

2).

(7) Remove (pry) the pitman shaft and the worm-

shaft seals from the steering gear housing (Fig. 3).

WORMSHAFT AND BALL NUT DISASSEMBLY

(1) Remove the upper bearing from the wormshaft

(Fig. 2).

CAUTION: Do not allow the ball nut to rotate freely

and travel to either extreme end of the wormshaft.

This could damage the tangs at the ends of the re-

circulating ball guides (Fig. 3).

(2) Remove the recirculating ball guide clamp re-

taining screws, the clamp and the guides (Fig. 2).

Separate the half-guides and place the recirculating

balls aside in a container.

JSTEERING 19 - 39

Page 1349 of 2198

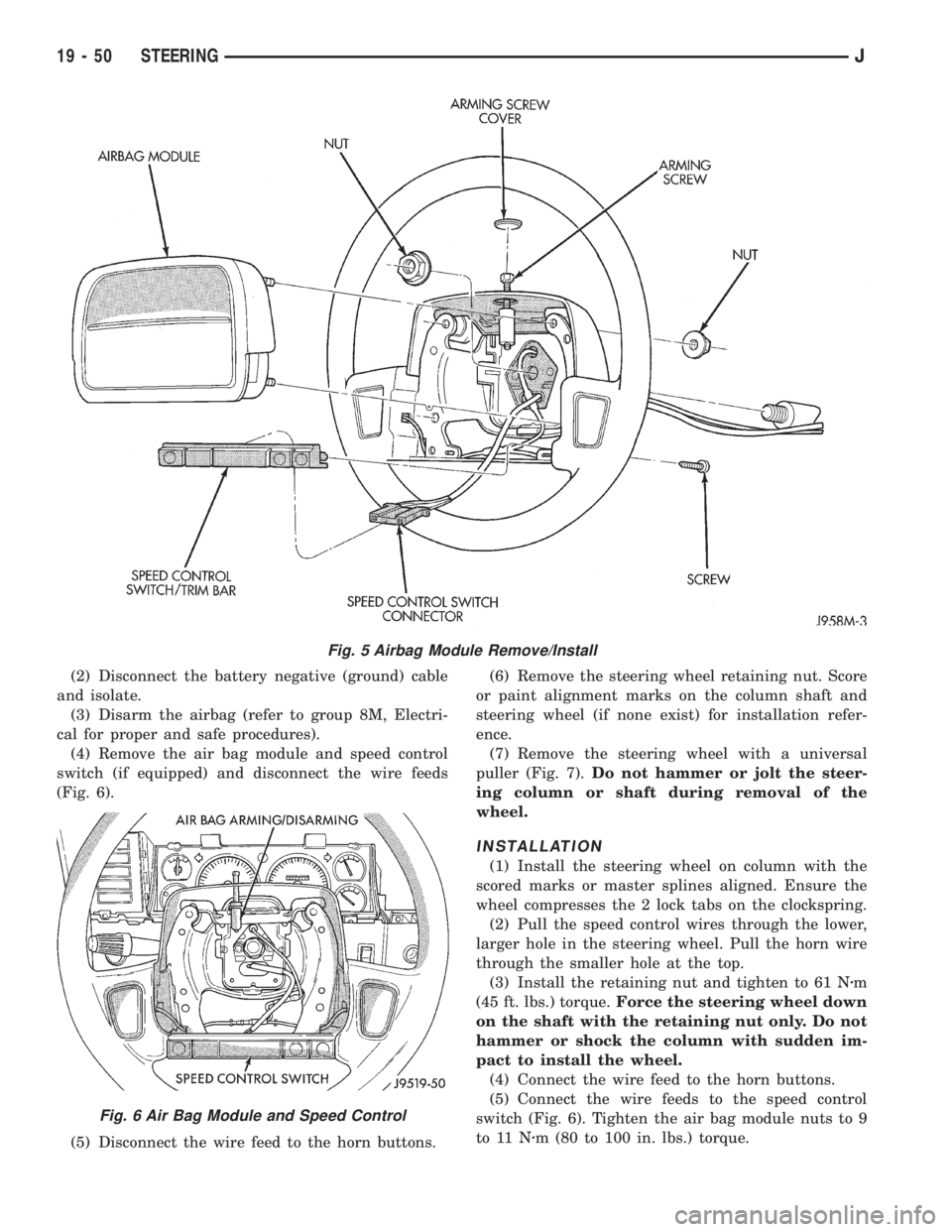

(2) Disconnect the battery negative (ground) cable

and isolate.

(3) Disarm the airbag (refer to group 8M, Electri-

cal for proper and safe procedures).

(4) Remove the air bag module and speed control

switch (if equipped) and disconnect the wire feeds

(Fig. 6).

(5) Disconnect the wire feed to the horn buttons.(6) Remove the steering wheel retaining nut. Score

or paint alignment marks on the column shaft and

steering wheel (if none exist) for installation refer-

ence.

(7) Remove the steering wheel with a universal

puller (Fig. 7).Do not hammer or jolt the steer-

ing column or shaft during removal of the

wheel.

INSTALLATION

(1) Install the steering wheel on column with the

scored marks or master splines aligned. Ensure the

wheel compresses the 2 lock tabs on the clockspring.

(2) Pull the speed control wires through the lower,

larger hole in the steering wheel. Pull the horn wire

through the smaller hole at the top.

(3) Install the retaining nut and tighten to 61 Nzm

(45 ft. lbs.) torque.Force the steering wheel down

on the shaft with the retaining nut only. Do not

hammer or shock the column with sudden im-

pact to install the wheel.

(4) Connect the wire feed to the horn buttons.

(5) Connect the wire feeds to the speed control

switch (Fig. 6). Tighten the air bag module nuts to 9

to 11 Nzm (80 to 100 in. lbs.) torque.

Fig. 5 Airbag Module Remove/Install

Fig. 6 Air Bag Module and Speed Control

19 - 50 STEERINGJ

Page 1356 of 2198

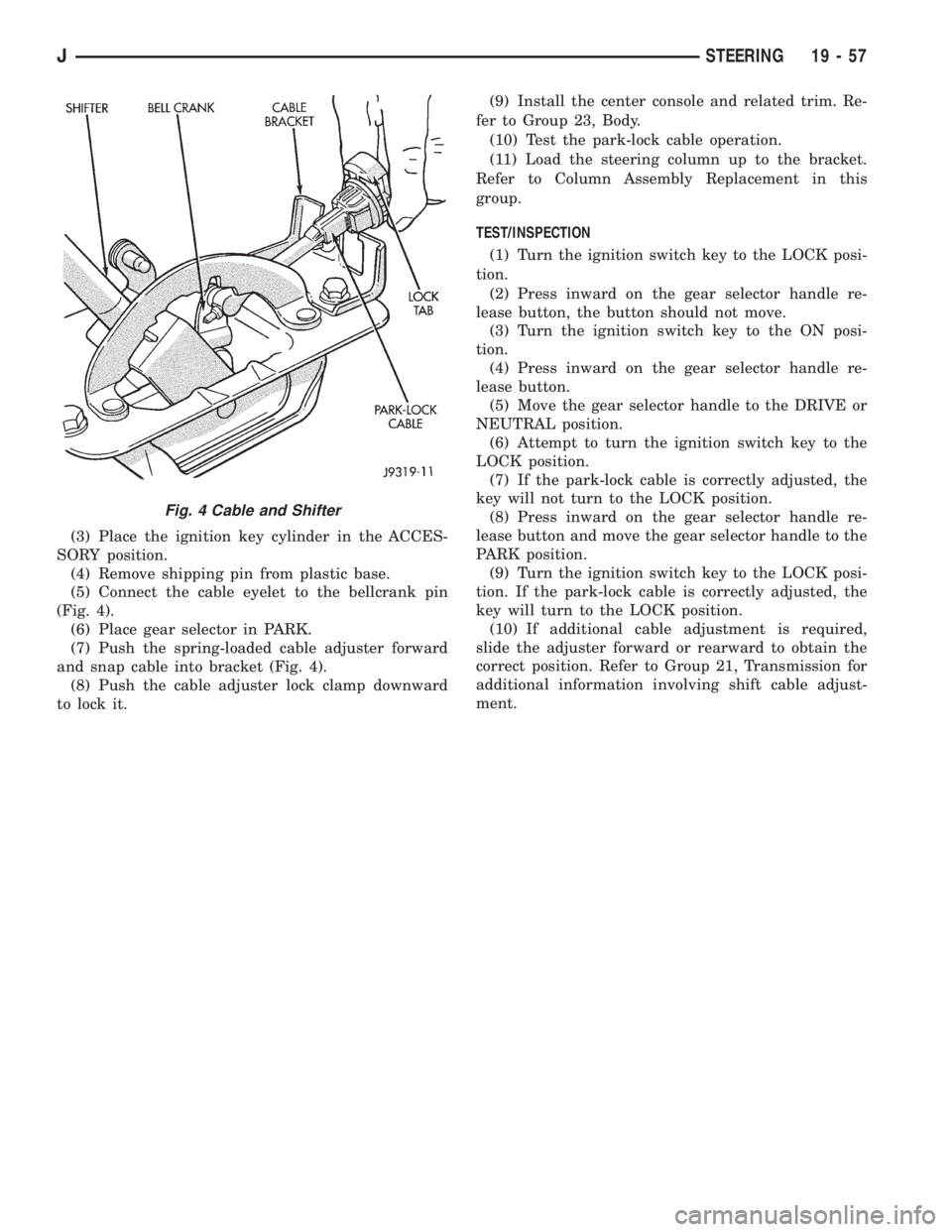

(3) Place the ignition key cylinder in the ACCES-

SORY position.

(4) Remove shipping pin from plastic base.

(5) Connect the cable eyelet to the bellcrank pin

(Fig. 4).

(6) Place gear selector in PARK.

(7) Push the spring-loaded cable adjuster forward

and snap cable into bracket (Fig. 4).

(8) Push the cable adjuster lock clamp downward

to lock it.(9) Install the center console and related trim. Re-

fer to Group 23, Body.

(10) Test the park-lock cable operation.

(11) Load the steering column up to the bracket.

Refer to Column Assembly Replacement in this

group.

TEST/INSPECTION

(1) Turn the ignition switch key to the LOCK posi-

tion.

(2) Press inward on the gear selector handle re-

lease button, the button should not move.

(3) Turn the ignition switch key to the ON posi-

tion.

(4) Press inward on the gear selector handle re-

lease button.

(5) Move the gear selector handle to the DRIVE or

NEUTRAL position.

(6) Attempt to turn the ignition switch key to the

LOCK position.

(7) If the park-lock cable is correctly adjusted, the

key will not turn to the LOCK position.

(8) Press inward on the gear selector handle re-

lease button and move the gear selector handle to the

PARK position.

(9) Turn the ignition switch key to the LOCK posi-

tion. If the park-lock cable is correctly adjusted, the

key will turn to the LOCK position.

(10) If additional cable adjustment is required,

slide the adjuster forward or rearward to obtain the

correct position. Refer to Group 21, Transmission for

additional information involving shift cable adjust-

ment.

Fig. 4 Cable and Shifter

JSTEERING 19 - 57

Page 1478 of 2198

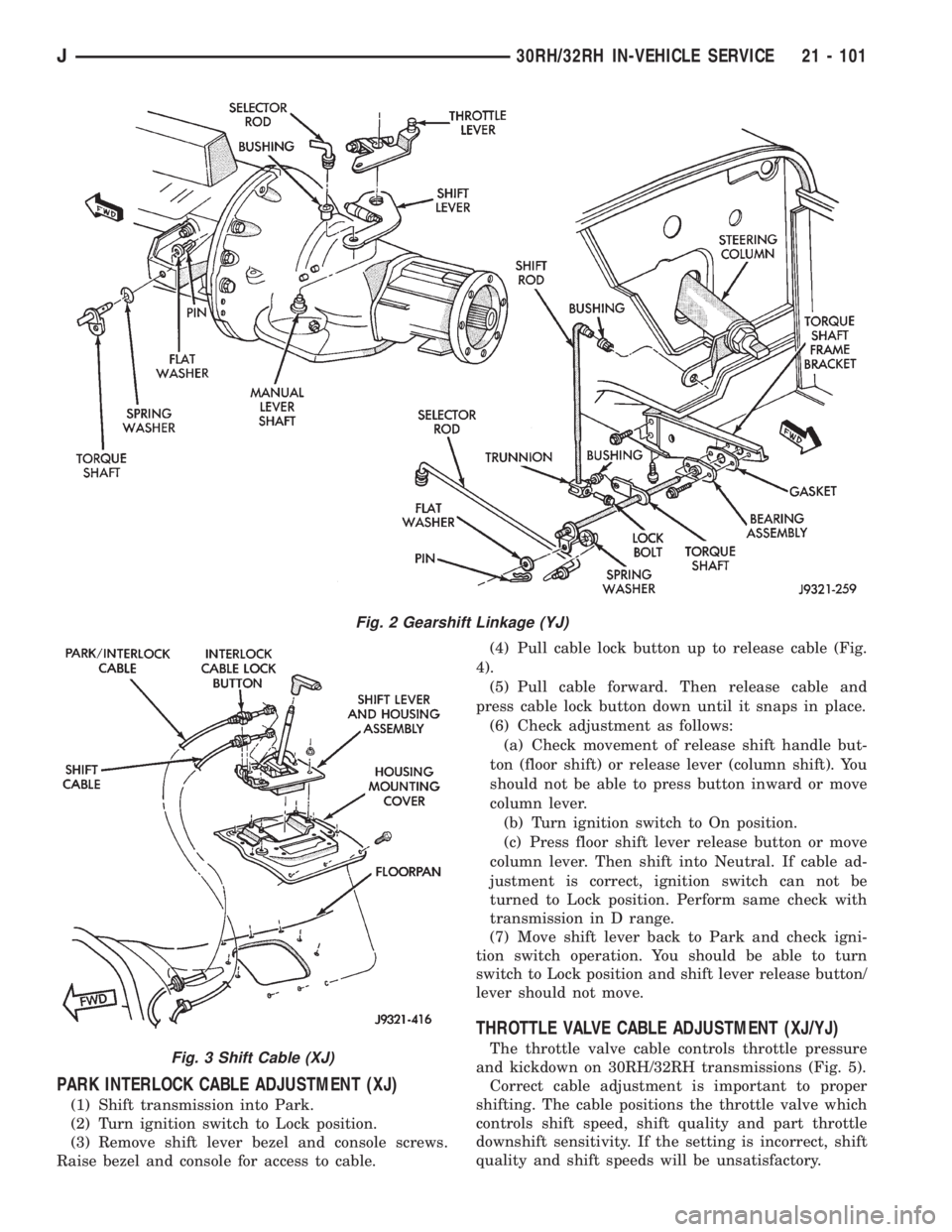

PARK INTERLOCK CABLE ADJUSTMENT (XJ)

(1) Shift transmission into Park.

(2) Turn ignition switch to Lock position.

(3) Remove shift lever bezel and console screws.

Raise bezel and console for access to cable.(4) Pull cable lock button up to release cable (Fig.

4).

(5) Pull cable forward. Then release cable and

press cable lock button down until it snaps in place.

(6) Check adjustment as follows:

(a) Check movement of release shift handle but-

ton (floor shift) or release lever (column shift). You

should not be able to press button inward or move

column lever.

(b) Turn ignition switch to On position.

(c) Press floor shift lever release button or move

column lever. Then shift into Neutral. If cable ad-

justment is correct, ignition switch can not be

turned to Lock position. Perform same check with

transmission in D range.

(7) Move shift lever back to Park and check igni-

tion switch operation. You should be able to turn

switch to Lock position and shift lever release button/

lever should not move.

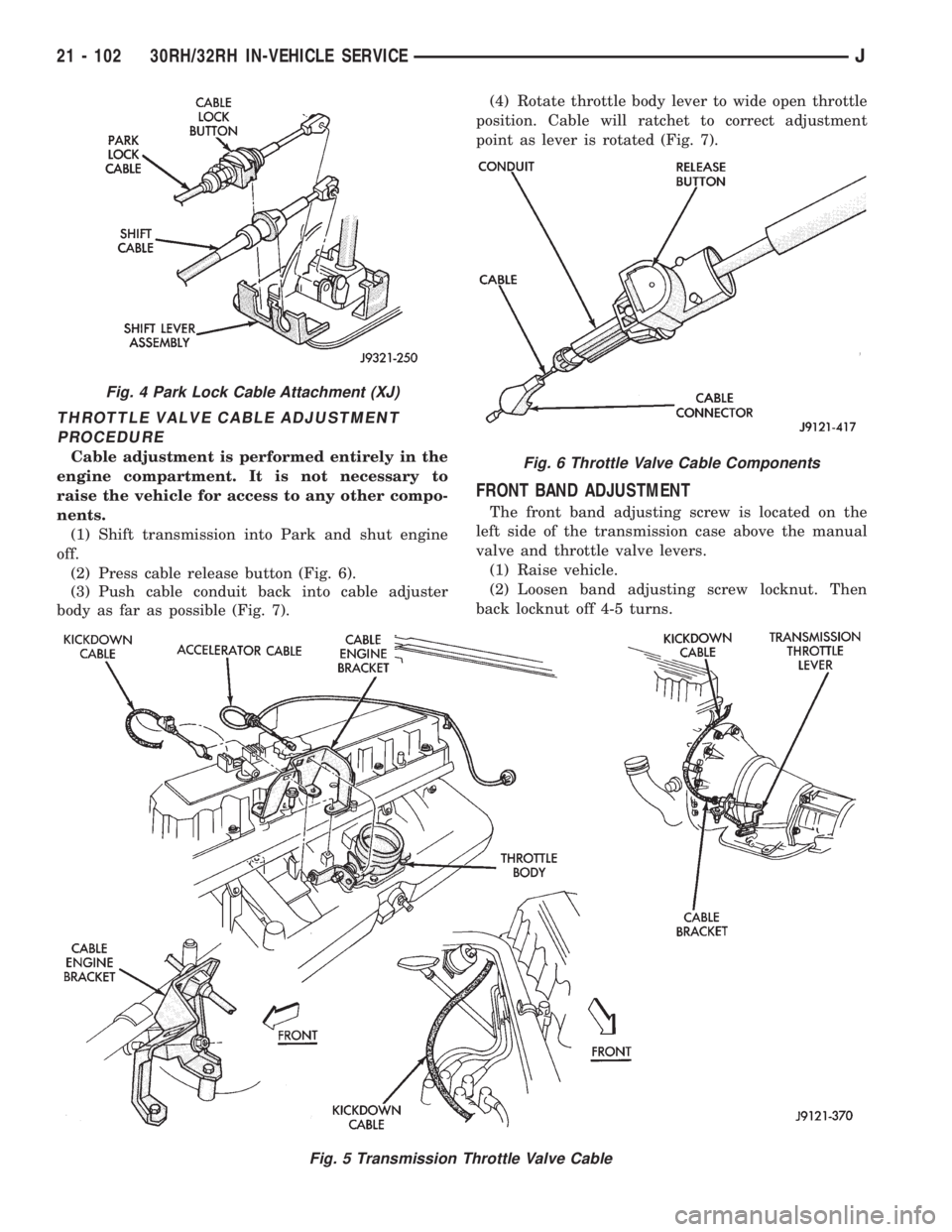

THROTTLE VALVE CABLE ADJUSTMENT (XJ/YJ)

The throttle valve cable controls throttle pressure

and kickdown on 30RH/32RH transmissions (Fig. 5).

Correct cable adjustment is important to proper

shifting. The cable positions the throttle valve which

controls shift speed, shift quality and part throttle

downshift sensitivity. If the setting is incorrect, shift

quality and shift speeds will be unsatisfactory.

Fig. 2 Gearshift Linkage (YJ)

Fig. 3 Shift Cable (XJ)

J30RH/32RH IN-VEHICLE SERVICE 21 - 101

Page 1479 of 2198

THROTTLE VALVE CABLE ADJUSTMENT

PROCEDURE

Cable adjustment is performed entirely in the

engine compartment. It is not necessary to

raise the vehicle for access to any other compo-

nents.

(1) Shift transmission into Park and shut engine

off.

(2) Press cable release button (Fig. 6).

(3) Push cable conduit back into cable adjuster

body as far as possible (Fig. 7).(4) Rotate throttle body lever to wide open throttle

position. Cable will ratchet to correct adjustment

point as lever is rotated (Fig. 7).

FRONT BAND ADJUSTMENT

The front band adjusting screw is located on the

left side of the transmission case above the manual

valve and throttle valve levers.

(1) Raise vehicle.

(2) Loosen band adjusting screw locknut. Then

back locknut off 4-5 turns.

Fig. 5 Transmission Throttle Valve Cable

Fig. 4 Park Lock Cable Attachment (XJ)

Fig. 6 Throttle Valve Cable Components

21 - 102 30RH/32RH IN-VEHICLE SERVICEJ

Page 1571 of 2198

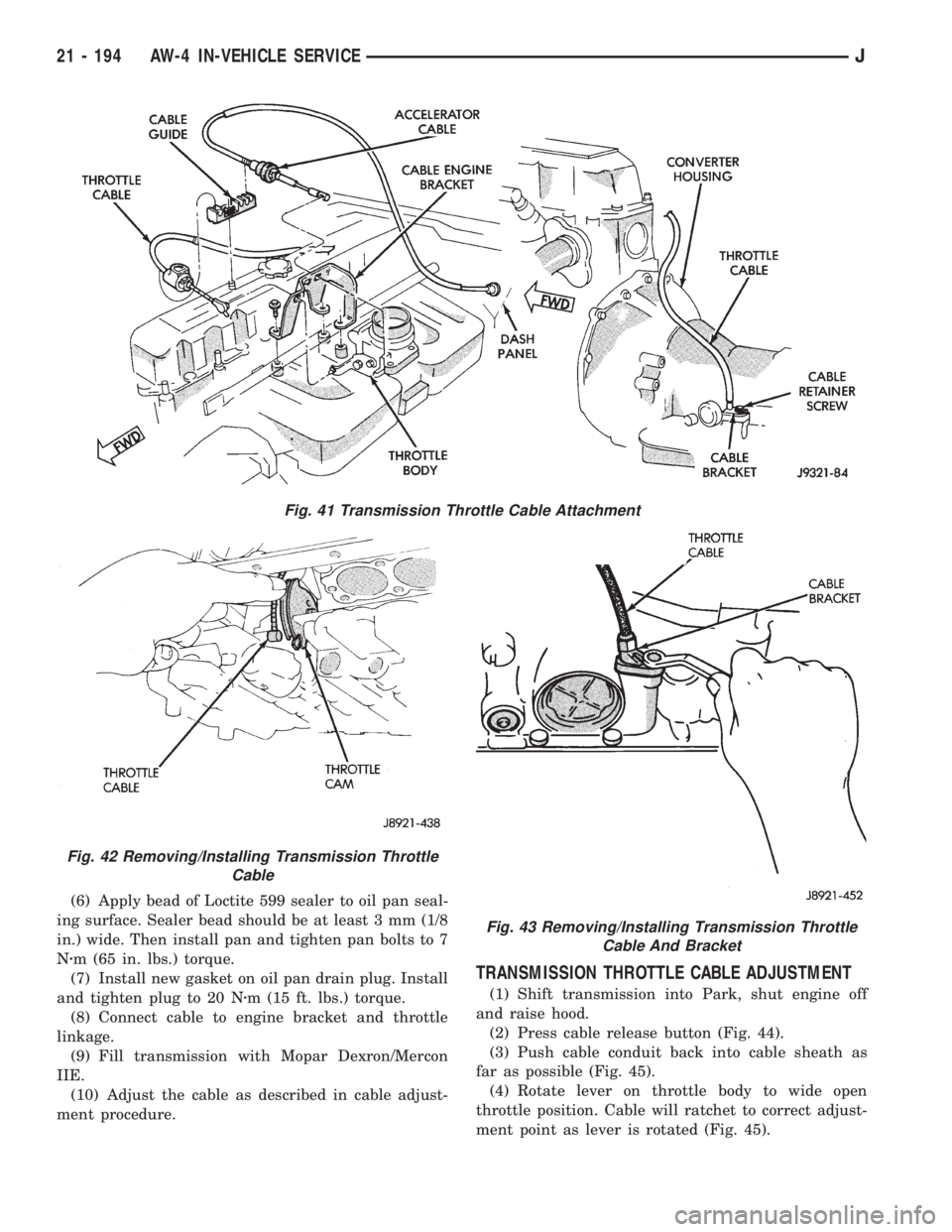

(6) Apply bead of Loctite 599 sealer to oil pan seal-

ing surface. Sealer bead should be at least 3 mm (1/8

in.) wide. Then install pan and tighten pan bolts to 7

Nzm (65 in. lbs.) torque.

(7) Install new gasket on oil pan drain plug. Install

and tighten plug to 20 Nzm (15 ft. lbs.) torque.

(8) Connect cable to engine bracket and throttle

linkage.

(9) Fill transmission with Mopar Dexron/Mercon

IIE.

(10) Adjust the cable as described in cable adjust-

ment procedure.

TRANSMISSION THROTTLE CABLE ADJUSTMENT

(1) Shift transmission into Park, shut engine off

and raise hood.

(2) Press cable release button (Fig. 44).

(3) Push cable conduit back into cable sheath as

far as possible (Fig. 45).

(4) Rotate lever on throttle body to wide open

throttle position. Cable will ratchet to correct adjust-

ment point as lever is rotated (Fig. 45).

Fig. 43 Removing/Installing Transmission Throttle

Cable And Bracket

Fig. 41 Transmission Throttle Cable Attachment

Fig. 42 Removing/Installing Transmission Throttle

Cable

21 - 194 AW-4 IN-VEHICLE SERVICEJ