display JEEP CHEROKEE 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 918 of 2198

RADIO

RADIO

When the ignition switch is in the ACCESSORY or

RUN position, it connects circuit A1 from fuse 6 in

the Power Distribution Center (PDC) to circuit A48.

Circuit A48 powers circuit F85 through fuse 13 in the

fuse block. Circuit F85 powers the radio.

Circuit Z1 provides ground for the radio. The an-

tenna connects to the rear of the radio.

RADIO MEMORY

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power for the radio memory.

Circuit A7 from fuse 3 in the PDC supplies voltage

to fuse 16. Circuits A7 and M1 are HOT at all times.

RADIO ILLUMINATION

Circuit E2 supplies battery voltage to the radio il-

lumination lamps when the headlamps or parking

lamps are on and the dimmer switch is in the Low or

On positions.

Circuit X5 supplies battery voltage for the radio

clock and station frequency display. Circuit X5 origi-

nates at the radio illumination relay and is fed by ei-

ther circuit F85 or circuit E2 depending on the

switch position inside the relay.

When the headlamps and parking lamps are off,

the radio illumination relay is in its normal At Rest

position. In the At Rest position, the relay connects

circuit F85 from fuse 13 in the fuse block to circuit

X5.

When the headlamps or parking lamps are on, cir-

cuit L90 from the headlamp switch supplies battery

voltage to the coil side of the radio illumination relay.

Circuit Z1 provides ground for the coil side of the re-

lay.

When voltage is present on circuit L90, the radio

illumination relay switches from its At Rest position

to connect circuit E2 to circuit X5.

HELPFUL INFORMATION

²Circuit A48 supplies voltage to fuse 13 in the fuse

block for circuit F85 when the ignition switch is in

the ACCESSORY or RUN positions. In these posi-

tions, the ignition switch connects circuit A1 from

fuse 6 in the PDC to circuit A48.²Circuit A3 from fuse 5 in the PDC supplies power

to the fuse block for fuse 9. Fuse 9 protects circuit

L7. When the headlamps or parking lamps are ON,

the headlamp switch connects circuit L7 to circuit

L90. When the adjustable dimmer switch is in the

LOW to ON positions, it internally connects circuit

L7 to circuit E2. Circuit E2 powers fuse 25 in the

fuse block. Circuit E2 continues through fuse 25.

POWER ANTENNA

The Power Antenna Relay supplies power to raise

and lower the antenna. Circuit F60 from fuse 7 in

the fuse block powers the relay. Circuit Z1 provides

ground for the relay.

When the radio is turned on, circuit X60 from the

radio energizes the relay to raise the antenna.

SPEAKERS

Circuit X53 feeds the left front speakers. Circuit

X55 is the return from the speakers to the radio.

Circuit X54 feeds the right front speakers. Circuit

X56 is the return from the speakers to the radio.

Circuit X51 feeds the left rear speaker. Circuit X57

is the return from the speaker to the radio.

Circuit X52 feeds the right rear speaker. Circuit

X58 is the return from the speaker to the radio.

DIAGRAM INDEX

Component Page

Fuse 3 (PDC).........................8W-47-2, 4

Fuse 5 (PDC).......................8W-47-2, 4, 5

Fuse 6 (PDC).........................8W-47-2, 4

Fuse 7 (PDC).........................8W-47-2, 4

Fuse 9 (Fuse Block)...................8W-47-2, 4, 5

Fuse 13 (Fuse Block)....................8W-47-2, 4

Fuse 16 (PDC)........................8W-47-2, 4

Fuse 25 (Fuse Block)....................8W-47-2, 4

Headlamp Switch.......................8W-47-2, 4

Ignition Switch..........................8W-47-2

LCD Relay...........................8W-47-3, 5

Power Antenna..........................8W-47-6

Power Antenna Relay......................8W-47-6

Radio...........................8W-47-2 thru 8

Speakers............................8W-47-7, 8

J8W-47 AUDIO SYSTEMÐXJ-RHD 8W - 47 - 1

Page 1119 of 2198

(2) Use Valve Spring Compressor Tool

MD-998772A and compress each valve spring.

(3) Remove the valve locks, retainers, springs and

valve stem oil seals. Discard the oil seals.

(4) Use an Arkansas smooth stone or a jewelers

file to remove any burrs on the top of the valve stem,

especially around the groove for the locks.

(5) Remove the valves, and place them in a rack in

the same order as removed.

VALVE CLEANING

Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

Clean all grime and gasket material from the en-

gine cylinder head machined gasket surface.

INSPECTION

Inspect for cracks in the combustion chambers and

valve ports.

Inspect for cracks on the exhaust seat.

Inspect for cracks in the gasket surface at each

coolant passage.

Inspect valves for burned, cracked or warped

heads.

Inspect for scuffed or bent valve stems.

Replace valves displaying any damage.

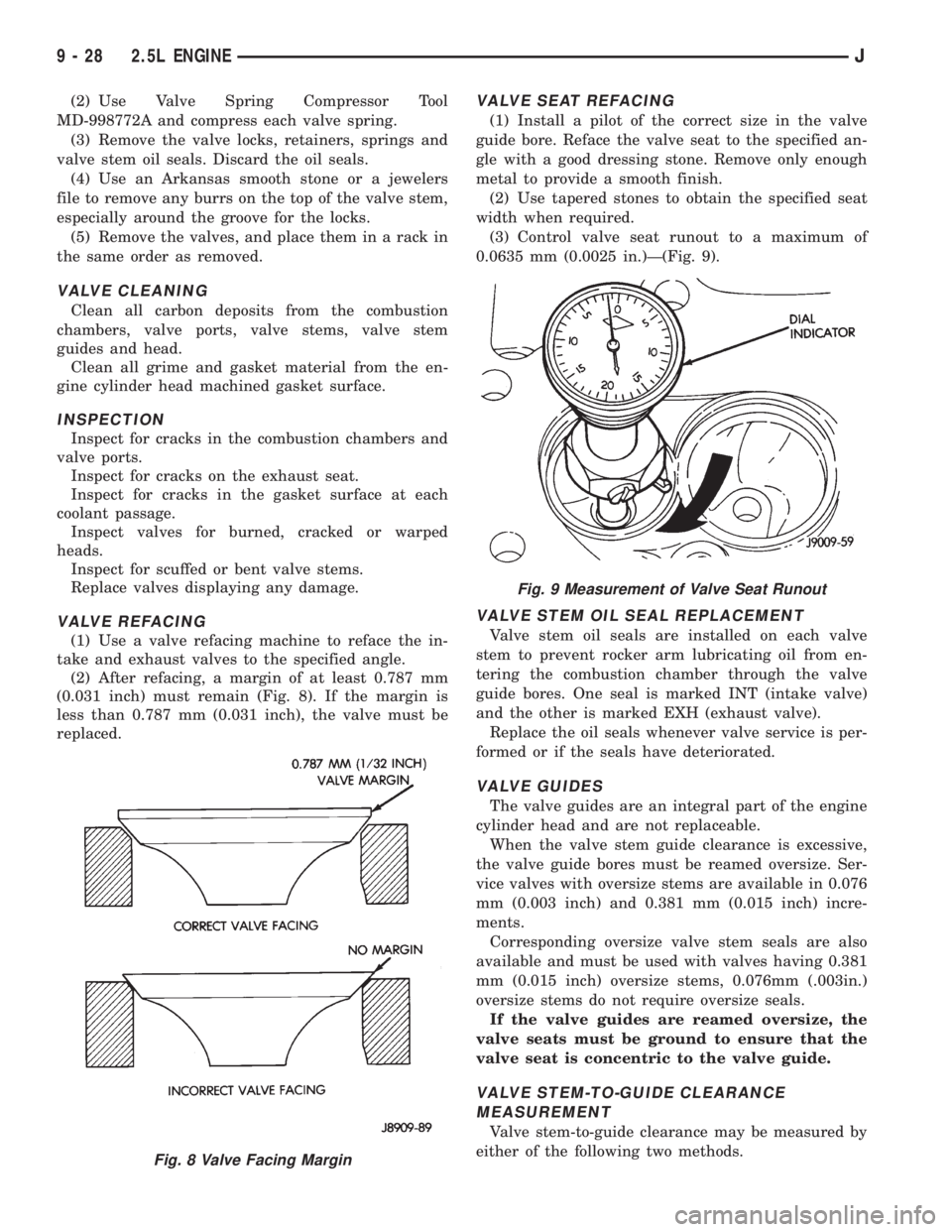

VALVE REFACING

(1) Use a valve refacing machine to reface the in-

take and exhaust valves to the specified angle.

(2) After refacing, a margin of at least 0.787 mm

(0.031 inch) must remain (Fig. 8). If the margin is

less than 0.787 mm (0.031 inch), the valve must be

replaced.

VALVE SEAT REFACING

(1) Install a pilot of the correct size in the valve

guide bore. Reface the valve seat to the specified an-

gle with a good dressing stone. Remove only enough

metal to provide a smooth finish.

(2) Use tapered stones to obtain the specified seat

width when required.

(3) Control valve seat runout to a maximum of

0.0635 mm (0.0025 in.)Ð(Fig. 9).

VALVE STEM OIL SEAL REPLACEMENT

Valve stem oil seals are installed on each valve

stem to prevent rocker arm lubricating oil from en-

tering the combustion chamber through the valve

guide bores. One seal is marked INT (intake valve)

and the other is marked EXH (exhaust valve).

Replace the oil seals whenever valve service is per-

formed or if the seals have deteriorated.

VALVE GUIDES

The valve guides are an integral part of the engine

cylinder head and are not replaceable.

When the valve stem guide clearance is excessive,

the valve guide bores must be reamed oversize. Ser-

vice valves with oversize stems are available in 0.076

mm (0.003 inch) and 0.381 mm (0.015 inch) incre-

ments.

Corresponding oversize valve stem seals are also

available and must be used with valves having 0.381

mm (0.015 inch) oversize stems, 0.076mm (.003in.)

oversize stems do not require oversize seals.

If the valve guides are reamed oversize, the

valve seats must be ground to ensure that the

valve seat is concentric to the valve guide.

VALVE STEM-TO-GUIDE CLEARANCE

MEASUREMENT

Valve stem-to-guide clearance may be measured by

either of the following two methods.

Fig. 8 Valve Facing Margin

Fig. 9 Measurement of Valve Seat Runout

9 - 28 2.5L ENGINEJ

Page 1160 of 2198

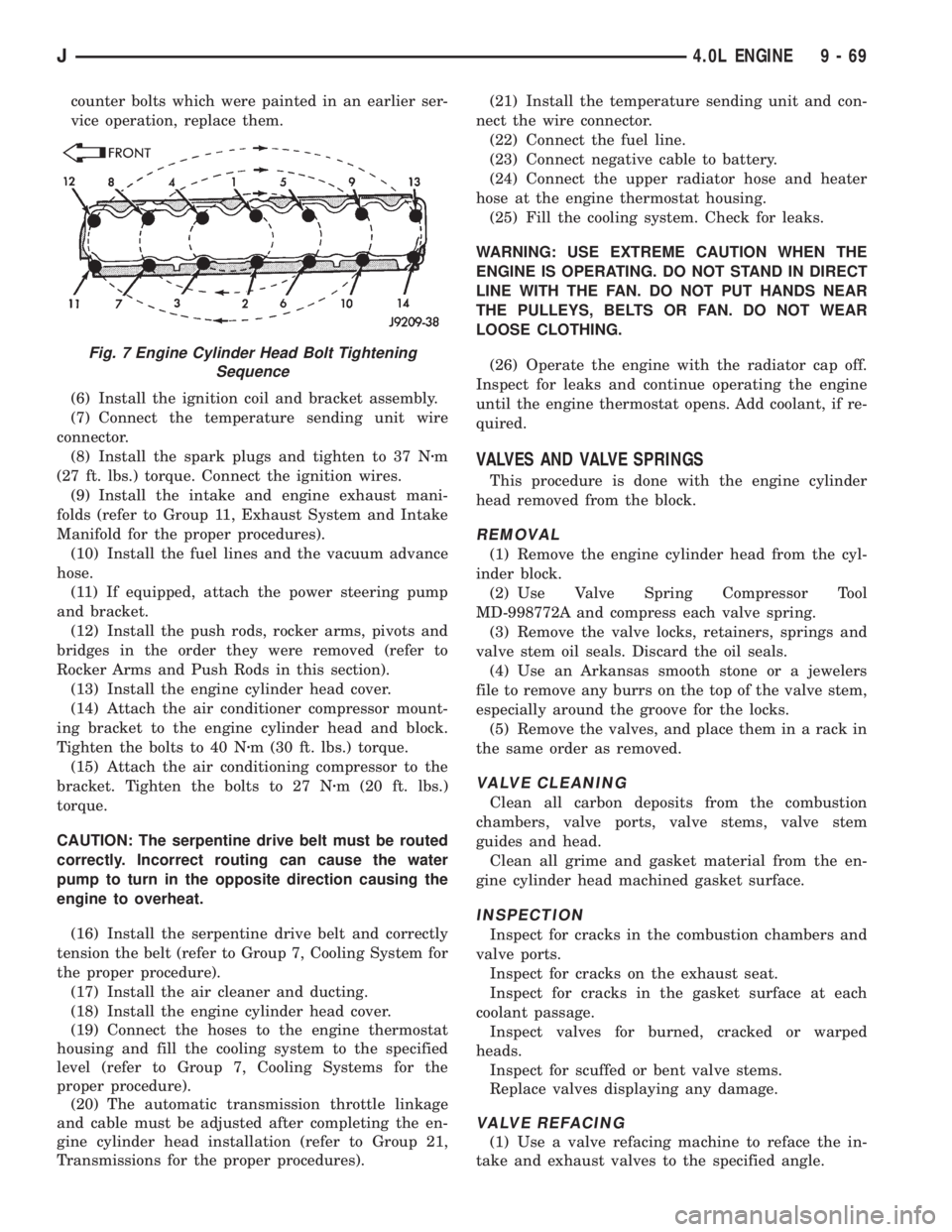

counter bolts which were painted in an earlier ser-

vice operation, replace them.

(6) Install the ignition coil and bracket assembly.

(7) Connect the temperature sending unit wire

connector.

(8) Install the spark plugs and tighten to 37 Nzm

(27 ft. lbs.) torque. Connect the ignition wires.

(9) Install the intake and engine exhaust mani-

folds (refer to Group 11, Exhaust System and Intake

Manifold for the proper procedures).

(10) Install the fuel lines and the vacuum advance

hose.

(11) If equipped, attach the power steering pump

and bracket.

(12) Install the push rods, rocker arms, pivots and

bridges in the order they were removed (refer to

Rocker Arms and Push Rods in this section).

(13) Install the engine cylinder head cover.

(14) Attach the air conditioner compressor mount-

ing bracket to the engine cylinder head and block.

Tighten the bolts to 40 Nzm (30 ft. lbs.) torque.

(15) Attach the air conditioning compressor to the

bracket. Tighten the bolts to 27 Nzm (20 ft. lbs.)

torque.

CAUTION: The serpentine drive belt must be routed

correctly. Incorrect routing can cause the water

pump to turn in the opposite direction causing the

engine to overheat.

(16) Install the serpentine drive belt and correctly

tension the belt (refer to Group 7, Cooling System for

the proper procedure).

(17) Install the air cleaner and ducting.

(18) Install the engine cylinder head cover.

(19) Connect the hoses to the engine thermostat

housing and fill the cooling system to the specified

level (refer to Group 7, Cooling Systems for the

proper procedure).

(20) The automatic transmission throttle linkage

and cable must be adjusted after completing the en-

gine cylinder head installation (refer to Group 21,

Transmissions for the proper procedures).(21) Install the temperature sending unit and con-

nect the wire connector.

(22) Connect the fuel line.

(23) Connect negative cable to battery.

(24) Connect the upper radiator hose and heater

hose at the engine thermostat housing.

(25) Fill the cooling system. Check for leaks.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN DIRECT

LINE WITH THE FAN. DO NOT PUT HANDS NEAR

THE PULLEYS, BELTS OR FAN. DO NOT WEAR

LOOSE CLOTHING.

(26) Operate the engine with the radiator cap off.

Inspect for leaks and continue operating the engine

until the engine thermostat opens. Add coolant, if re-

quired.

VALVES AND VALVE SPRINGS

This procedure is done with the engine cylinder

head removed from the block.

REMOVAL

(1) Remove the engine cylinder head from the cyl-

inder block.

(2) Use Valve Spring Compressor Tool

MD-998772A and compress each valve spring.

(3) Remove the valve locks, retainers, springs and

valve stem oil seals. Discard the oil seals.

(4) Use an Arkansas smooth stone or a jewelers

file to remove any burrs on the top of the valve stem,

especially around the groove for the locks.

(5) Remove the valves, and place them in a rack in

the same order as removed.

VALVE CLEANING

Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

Clean all grime and gasket material from the en-

gine cylinder head machined gasket surface.

INSPECTION

Inspect for cracks in the combustion chambers and

valve ports.

Inspect for cracks on the exhaust seat.

Inspect for cracks in the gasket surface at each

coolant passage.

Inspect valves for burned, cracked or warped

heads.

Inspect for scuffed or bent valve stems.

Replace valves displaying any damage.

VALVE REFACING

(1) Use a valve refacing machine to reface the in-

take and exhaust valves to the specified angle.

Fig. 7 Engine Cylinder Head Bolt Tightening

Sequence

J4.0L ENGINE 9 - 69

Page 1224 of 2198

codes are not displayed, the problem may be mechan-

ical rather than electronic.

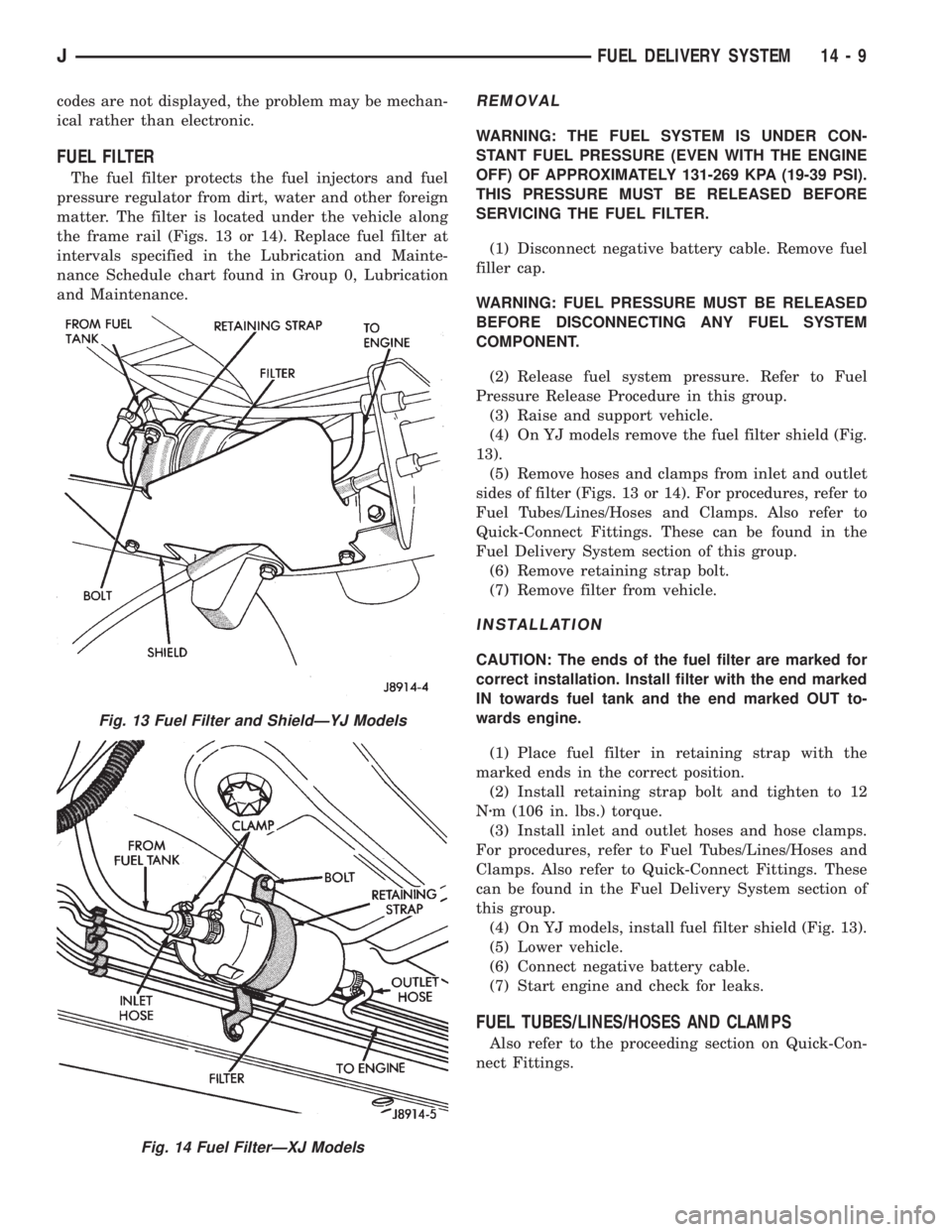

FUEL FILTER

The fuel filter protects the fuel injectors and fuel

pressure regulator from dirt, water and other foreign

matter. The filter is located under the vehicle along

the frame rail (Figs. 13 or 14). Replace fuel filter at

intervals specified in the Lubrication and Mainte-

nance Schedule chart found in Group 0, Lubrication

and Maintenance.

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE (EVEN WITH THE ENGINE

OFF) OF APPROXIMATELY 131-269 KPA (19-39 PSI).

THIS PRESSURE MUST BE RELEASED BEFORE

SERVICING THE FUEL FILTER.

(1) Disconnect negative battery cable. Remove fuel

filler cap.

WARNING: FUEL PRESSURE MUST BE RELEASED

BEFORE DISCONNECTING ANY FUEL SYSTEM

COMPONENT.

(2) Release fuel system pressure. Refer to Fuel

Pressure Release Procedure in this group.

(3) Raise and support vehicle.

(4) On YJ models remove the fuel filter shield (Fig.

13).

(5) Remove hoses and clamps from inlet and outlet

sides of filter (Figs. 13 or 14). For procedures, refer to

Fuel Tubes/Lines/Hoses and Clamps. Also refer to

Quick-Connect Fittings. These can be found in the

Fuel Delivery System section of this group.

(6) Remove retaining strap bolt.

(7) Remove filter from vehicle.

INSTALLATION

CAUTION: The ends of the fuel filter are marked for

correct installation. Install filter with the end marked

IN towards fuel tank and the end marked OUT to-

wards engine.

(1) Place fuel filter in retaining strap with the

marked ends in the correct position.

(2) Install retaining strap bolt and tighten to 12

Nzm (106 in. lbs.) torque.

(3) Install inlet and outlet hoses and hose clamps.

For procedures, refer to Fuel Tubes/Lines/Hoses and

Clamps. Also refer to Quick-Connect Fittings. These

can be found in the Fuel Delivery System section of

this group.

(4) On YJ models, install fuel filter shield (Fig. 13).

(5) Lower vehicle.

(6) Connect negative battery cable.

(7) Start engine and check for leaks.

FUEL TUBES/LINES/HOSES AND CLAMPS

Also refer to the proceeding section on Quick-Con-

nect Fittings.

Fig. 13 Fuel Filter and ShieldÐYJ Models

Fig. 14 Fuel FilterÐXJ Models

JFUEL DELIVERY SYSTEM 14 - 9

Page 1243 of 2198

The throttle body has an air control passage that

provides air for the engine at idle (the throttle plate

is closed). The IAC motor pintle protrudes into the

air control passage and regulates air flow through it.

Based on various sensor inputs, the powertrain con-

trol module (PCM) adjusts engine idle speed by mov-

ing the IAC motor pintle in and out of the air control

passage. The IAC motor is positioned when the igni-

tion key is turned to the On position.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

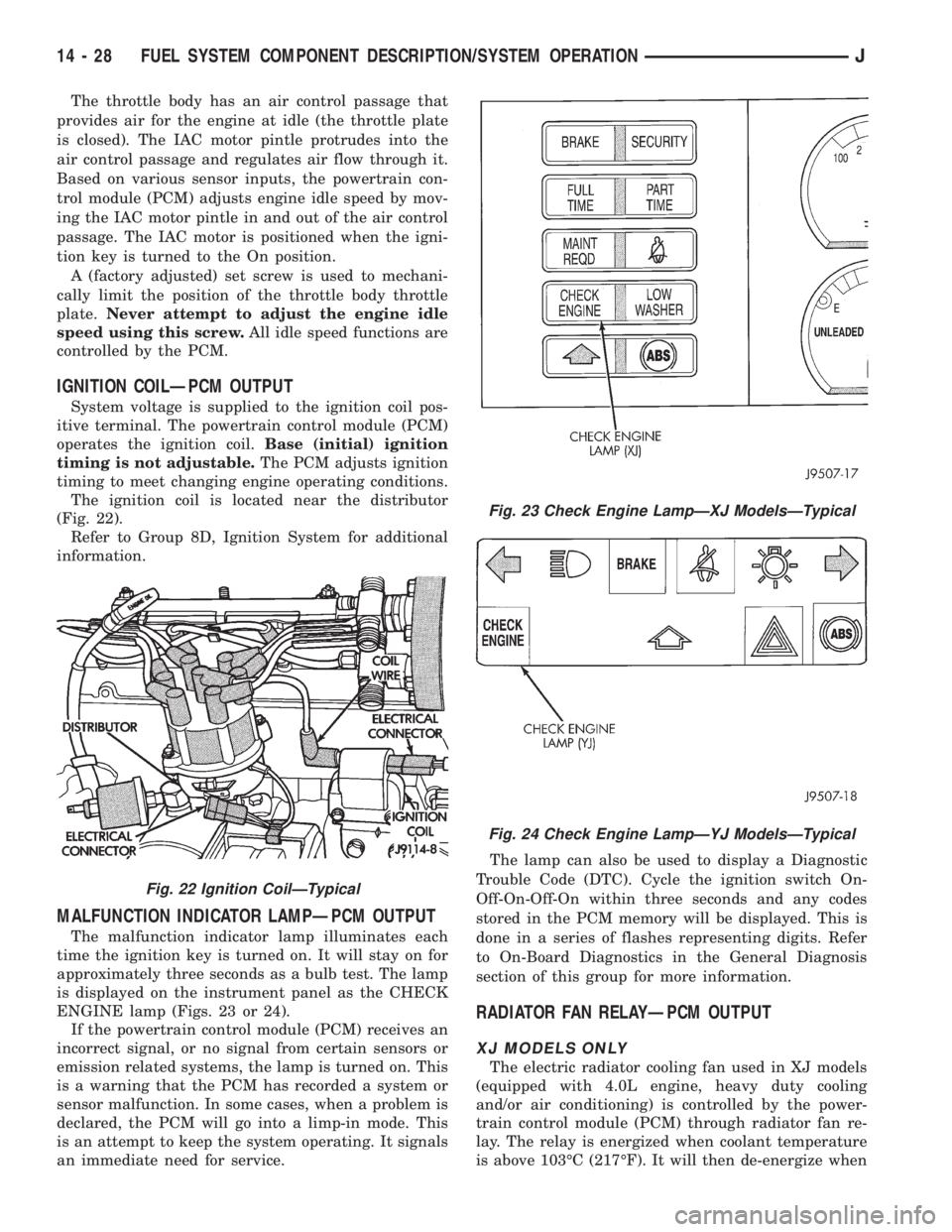

IGNITION COILÐPCM OUTPUT

System voltage is supplied to the ignition coil pos-

itive terminal. The powertrain control module (PCM)

operates the ignition coil.Base (initial) ignition

timing is not adjustable.The PCM adjusts ignition

timing to meet changing engine operating conditions.

The ignition coil is located near the distributor

(Fig. 22).

Refer to Group 8D, Ignition System for additional

information.

MALFUNCTION INDICATOR LAMPÐPCM OUTPUT

The malfunction indicator lamp illuminates each

time the ignition key is turned on. It will stay on for

approximately three seconds as a bulb test. The lamp

is displayed on the instrument panel as the CHECK

ENGINE lamp (Figs. 23 or 24).

If the powertrain control module (PCM) receives an

incorrect signal, or no signal from certain sensors or

emission related systems, the lamp is turned on. This

is a warning that the PCM has recorded a system or

sensor malfunction. In some cases, when a problem is

declared, the PCM will go into a limp-in mode. This

is an attempt to keep the system operating. It signals

an immediate need for service.The lamp can also be used to display a Diagnostic

Trouble Code (DTC). Cycle the ignition switch On-

Off-On-Off-On within three seconds and any codes

stored in the PCM memory will be displayed. This is

done in a series of flashes representing digits. Refer

to On-Board Diagnostics in the General Diagnosis

section of this group for more information.

RADIATOR FAN RELAYÐPCM OUTPUT

XJ MODELS ONLY

The electric radiator cooling fan used in XJ models

(equipped with 4.0L engine, heavy duty cooling

and/or air conditioning) is controlled by the power-

train control module (PCM) through radiator fan re-

lay. The relay is energized when coolant temperature

is above 103ÉC (217ÉF). It will then de-energize when

Fig. 22 Ignition CoilÐTypical

Fig. 23 Check Engine LampÐXJ ModelsÐTypical

Fig. 24 Check Engine LampÐYJ ModelsÐTypical

14 - 28 FUEL SYSTEM COMPONENT DESCRIPTION/SYSTEM OPERATIONJ

Page 1256 of 2198

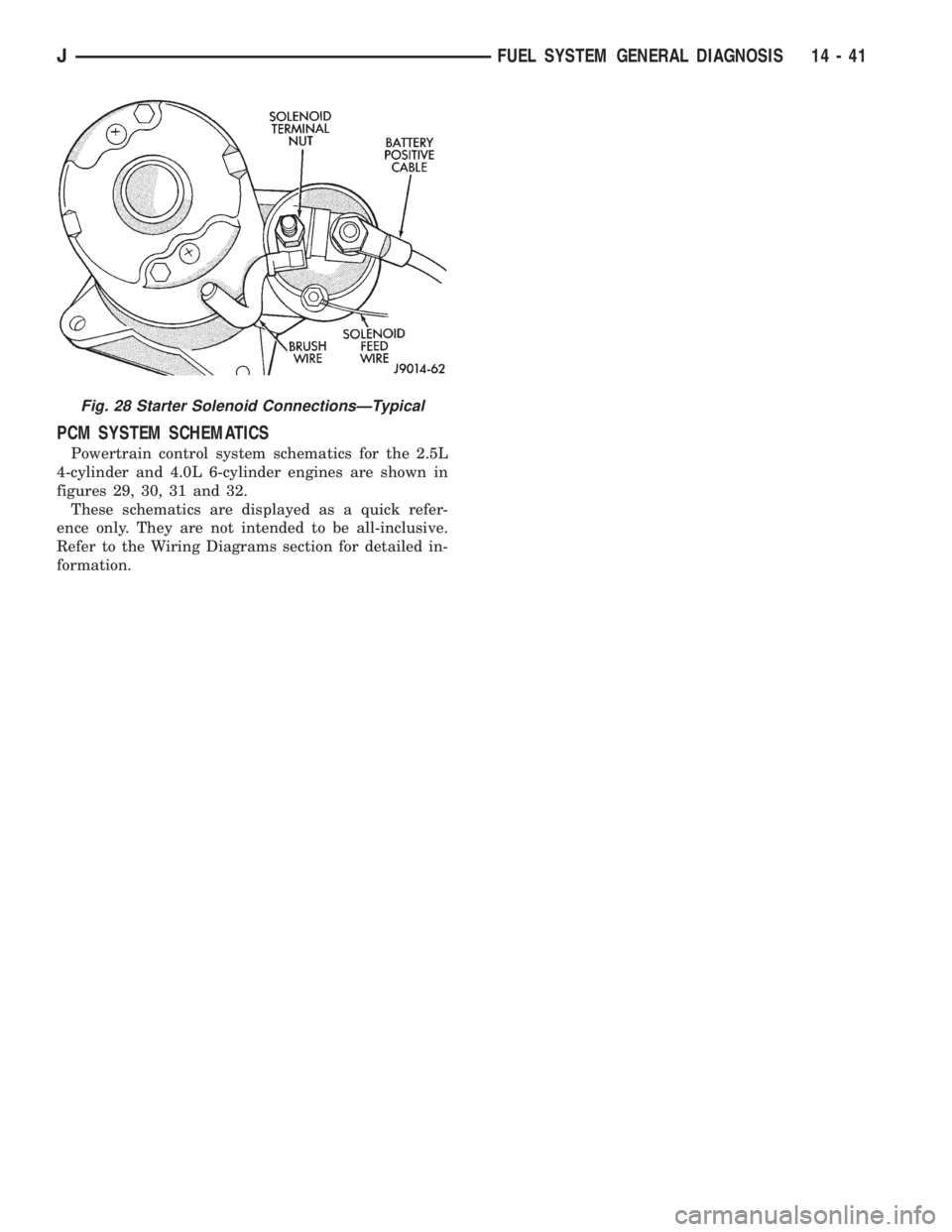

PCM SYSTEM SCHEMATICS

Powertrain control system schematics for the 2.5L

4-cylinder and 4.0L 6-cylinder engines are shown in

figures 29, 30, 31 and 32.

These schematics are displayed as a quick refer-

ence only. They are not intended to be all-inclusive.

Refer to the Wiring Diagrams section for detailed in-

formation.

Fig. 28 Starter Solenoid ConnectionsÐTypical

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 41

Page 1263 of 2198

EXTENDED IDLE SWITCH TEST

OPTIONAL POLICE PACKAGE ONLY

OPERATION

The extended idle switch is used to raise the en-

gine idle speed to approximately 1000 rpm when the

shifter is in either the Park or Neutral position. A

rocker-type 2-wire switch (extended idle switch) is

mounted to the instrument panel.This switch is

available only with 4.0L engine when supplied

with the optional police package.

TESTING

The extended idle switch will control a ground cir-

cuit going to the powertrain control module (PCM).

When a ground signal (through this switch) has been

received at pin number 10 in the PCM, engine idle

speed will increase.

Bring the engine to normal operating temperature

and turn the extended idle switch to the ON position.

Engine speed should now increase to approximately

1000 rpm when the shifter is in either the Park or

Neutral position. If engine speed does not increase,

apply a good ground to pin number 10 at the PCM

using a small paper clip. Be careful not to damage

the wiring with the paper clip. If the engine speed

now increases, it can be assumed that the PCM is

functioning correctly. Check the instrument panel

mounted switch for a closed ground circuit when in

the ON position. If the engine speed will not increase

after applying a ground to pin number 10, replace

the PCM. Refer to Group 8W, Wiring Diagrams for

circuit and wiring information.

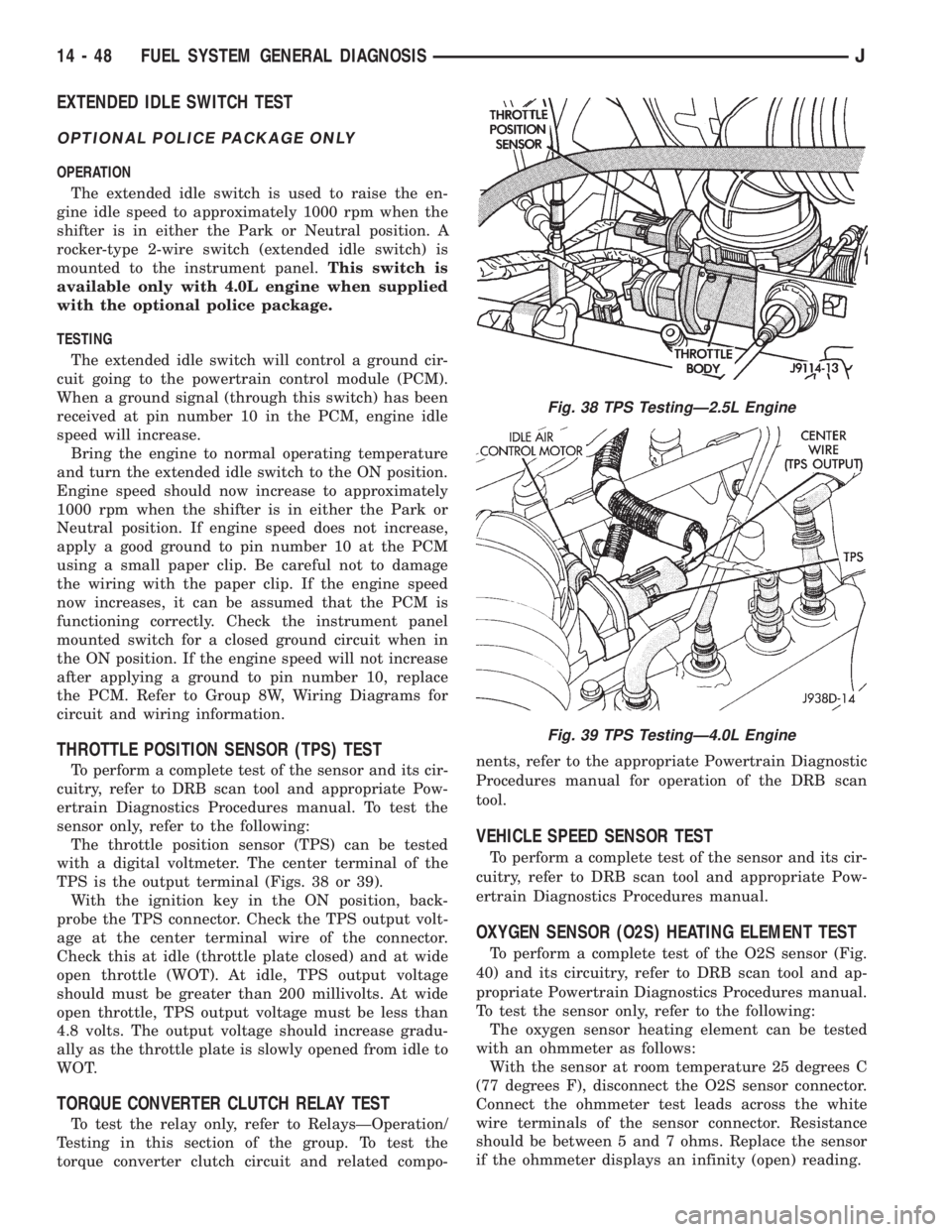

THROTTLE POSITION SENSOR (TPS) TEST

To perform a complete test of the sensor and its cir-

cuitry, refer to DRB scan tool and appropriate Pow-

ertrain Diagnostics Procedures manual. To test the

sensor only, refer to the following:

The throttle position sensor (TPS) can be tested

with a digital voltmeter. The center terminal of the

TPS is the output terminal (Figs. 38 or 39).

With the ignition key in the ON position, back-

probe the TPS connector. Check the TPS output volt-

age at the center terminal wire of the connector.

Check this at idle (throttle plate closed) and at wide

open throttle (WOT). At idle, TPS output voltage

should must be greater than 200 millivolts. At wide

open throttle, TPS output voltage must be less than

4.8 volts. The output voltage should increase gradu-

ally as the throttle plate is slowly opened from idle to

WOT.

TORQUE CONVERTER CLUTCH RELAY TEST

To test the relay only, refer to RelaysÐOperation/

Testing in this section of the group. To test the

torque converter clutch circuit and related compo-nents, refer to the appropriate Powertrain Diagnostic

Procedures manual for operation of the DRB scan

tool.

VEHICLE SPEED SENSOR TEST

To perform a complete test of the sensor and its cir-

cuitry, refer to DRB scan tool and appropriate Pow-

ertrain Diagnostics Procedures manual.

OXYGEN SENSOR (O2S) HEATING ELEMENT TEST

To perform a complete test of the O2S sensor (Fig.

40) and its circuitry, refer to DRB scan tool and ap-

propriate Powertrain Diagnostics Procedures manual.

To test the sensor only, refer to the following:

The oxygen sensor heating element can be tested

with an ohmmeter as follows:

With the sensor at room temperature 25 degrees C

(77 degrees F), disconnect the O2S sensor connector.

Connect the ohmmeter test leads across the white

wire terminals of the sensor connector. Resistance

should be between 5 and 7 ohms. Replace the sensor

if the ohmmeter displays an infinity (open) reading.

Fig. 38 TPS TestingÐ2.5L Engine

Fig. 39 TPS TestingÐ4.0L Engine

14 - 48 FUEL SYSTEM GENERAL DIAGNOSISJ

Page 1266 of 2198

(8) Disconnect jumper wires from relay and 12 Volt

power source.

If continuity or resistance tests did not pass, re-

place relay. If tests passed, refer to Group 8W, Wiring

Diagrams for additional circuit information. Also re-

fer to the appropriate Powertrain Diagnostic Proce-

dures manual for operation of the DRB scan tool.

STARTER MOTOR RELAY TEST

Refer to Group 8A, Battery/Starting/Charging/Sys-

tem Diagnostics, for starter motor relay testing.

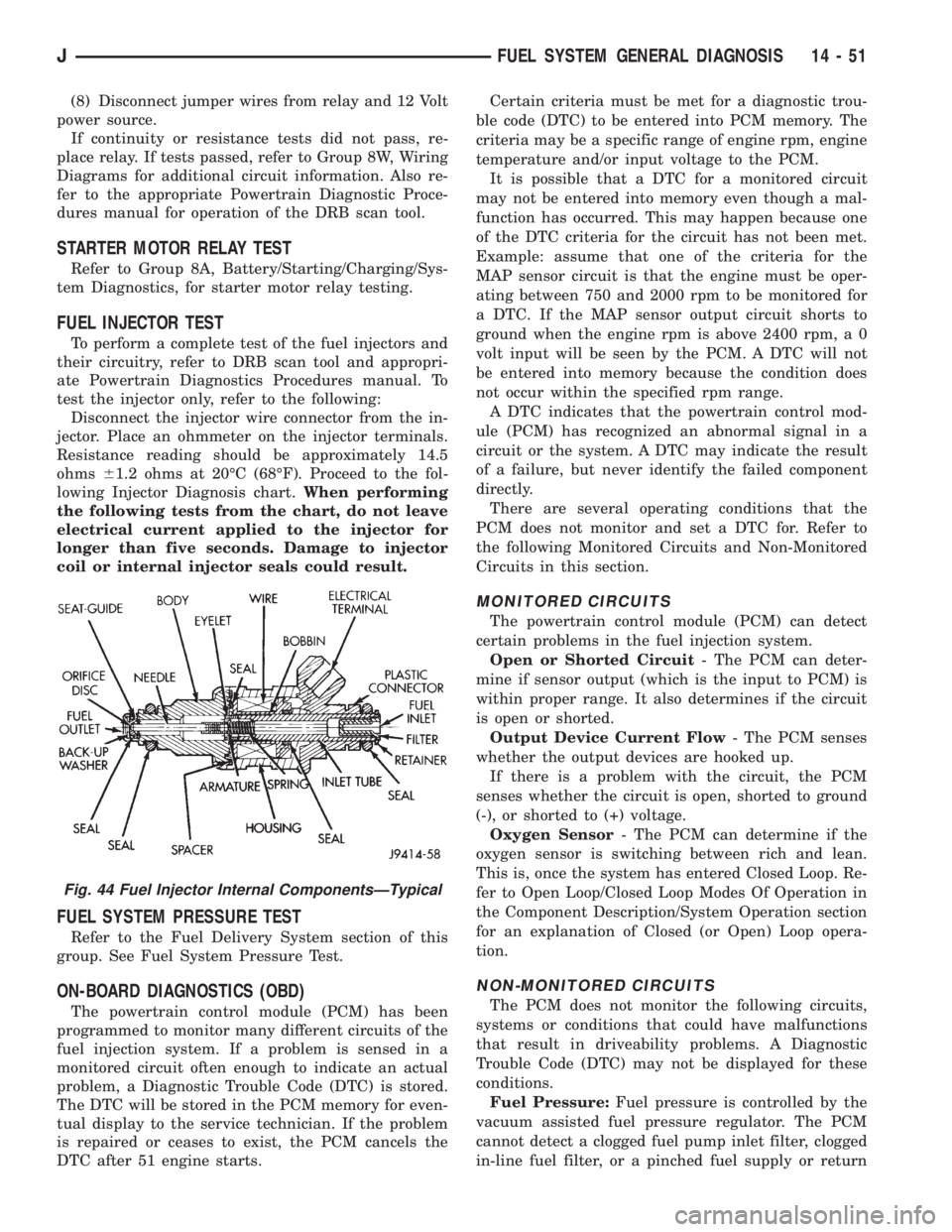

FUEL INJECTOR TEST

To perform a complete test of the fuel injectors and

their circuitry, refer to DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the injector only, refer to the following:

Disconnect the injector wire connector from the in-

jector. Place an ohmmeter on the injector terminals.

Resistance reading should be approximately 14.5

ohms61.2 ohms at 20ÉC (68ÉF). Proceed to the fol-

lowing Injector Diagnosis chart.When performing

the following tests from the chart, do not leave

electrical current applied to the injector for

longer than five seconds. Damage to injector

coil or internal injector seals could result.

FUEL SYSTEM PRESSURE TEST

Refer to the Fuel Delivery System section of this

group. See Fuel System Pressure Test.

ON-BOARD DIAGNOSTICS (OBD)

The powertrain control module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed in a

monitored circuit often enough to indicate an actual

problem, a Diagnostic Trouble Code (DTC) is stored.

The DTC will be stored in the PCM memory for even-

tual display to the service technician. If the problem

is repaired or ceases to exist, the PCM cancels the

DTC after 51 engine starts.Certain criteria must be met for a diagnostic trou-

ble code (DTC) to be entered into PCM memory. The

criteria may be a specific range of engine rpm, engine

temperature and/or input voltage to the PCM.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. This may happen because one

of the DTC criteria for the circuit has not been met.

Example: assume that one of the criteria for the

MAP sensor circuit is that the engine must be oper-

ating between 750 and 2000 rpm to be monitored for

a DTC. If the MAP sensor output circuit shorts to

ground when the engine rpm is above 2400 rpm, a 0

volt input will be seen by the PCM. A DTC will not

be entered into memory because the condition does

not occur within the specified rpm range.

A DTC indicates that the powertrain control mod-

ule (PCM) has recognized an abnormal signal in a

circuit or the system. A DTC may indicate the result

of a failure, but never identify the failed component

directly.

There are several operating conditions that the

PCM does not monitor and set a DTC for. Refer to

the following Monitored Circuits and Non-Monitored

Circuits in this section.

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain problems in the fuel injection system.

Open or Shorted Circuit- The PCM can deter-

mine if sensor output (which is the input to PCM) is

within proper range. It also determines if the circuit

is open or shorted.

Output Device Current Flow- The PCM senses

whether the output devices are hooked up.

If there is a problem with the circuit, the PCM

senses whether the circuit is open, shorted to ground

(-), or shorted to (+) voltage.

Oxygen Sensor- The PCM can determine if the

oxygen sensor is switching between rich and lean.

This is, once the system has entered Closed Loop. Re-

fer to Open Loop/Closed Loop Modes Of Operation in

the Component Description/System Operation section

for an explanation of Closed (or Open) Loop opera-

tion.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems or conditions that could have malfunctions

that result in driveability problems. A Diagnostic

Trouble Code (DTC) may not be displayed for these

conditions.

Fuel Pressure:Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

Fig. 44 Fuel Injector Internal ComponentsÐTypical

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 51

Page 1268 of 2198

line. However, these could result in a rich or lean

condition causing an oxygen sensor DTC to be stored

in the PCM.

Secondary Ignition Circuit:The PCM cannot

detect an inoperative ignition coil, fouled or worn

spark plugs, ignition cross firing, or open circuited

spark plug cables.

Engine Timing:The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket or

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor DTC to be stored in the PCM.

Cylinder Compression:The PCM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System:The PCM cannot detect a

plugged, restricted or leaking exhaust system.

Fuel Injector Malfunctions:The PCM cannot de-

termine if the fuel injector is clogged, or the wrong

injector is installed. However, these could result in a

rich or lean condition causing an oxygen sensor DTC

to be stored in the PCM.

Excessive Oil Consumption:Although the PCM

monitors exhaust stream oxygen content through ox-

ygen sensor (closed loop), it cannot determine exces-

sive oil consumption.

Throttle Body Air Flow:The PCM cannot detect

a clogged or restricted air cleaner inlet or air cleaner

element.

Evaporative System:The PCM will not detect a

restricted, plugged or loaded EVAP canister.

Vacuum Assist:Leaks or restrictions in the vac-

uum circuits of vacuum assisted engine control sys-

tem devices are not monitored by the PCM. However,

a vacuum leak at the MAP sensor will be monitored

and a diagnostic trouble code (DTC) will be gener-

ated by the PCM.

Powertrain Control Module (PCM) System

Ground:The PCM cannot determine a poor system

ground. However, a DTC may be generated as a re-

sult of this condition.

Powertrain Control Module (PCM) Connector

Engagement:The PCM cannot determine spread or

damaged connector pins. However, a DTC may be

generated as a result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device. It will es-

tablish high and low limits that are programmed into

it for that device. If the input voltage is not within

specifications and other Diagnostic Trouble Code

(DTC) criteria are met, a DTC will be stored in mem-

ory. Other DTC criteria might include engine rpm

limits or input voltages from other sensors or

switches. The other inputs might have to be sensed

by the PCM when it senses a high or low input volt-

age from the control system device in question.

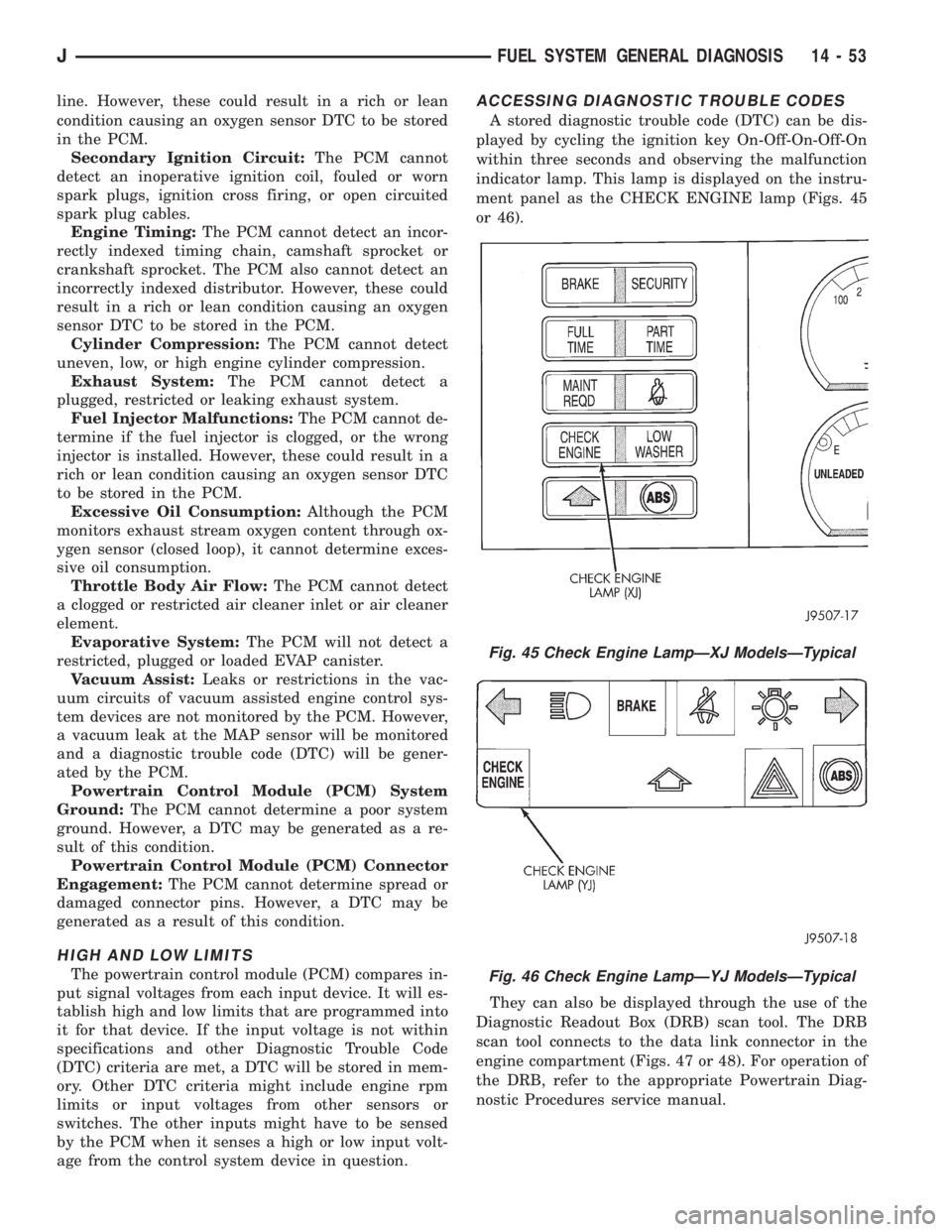

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored diagnostic trouble code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the malfunction

indicator lamp. This lamp is displayed on the instru-

ment panel as the CHECK ENGINE lamp (Figs. 45

or 46).

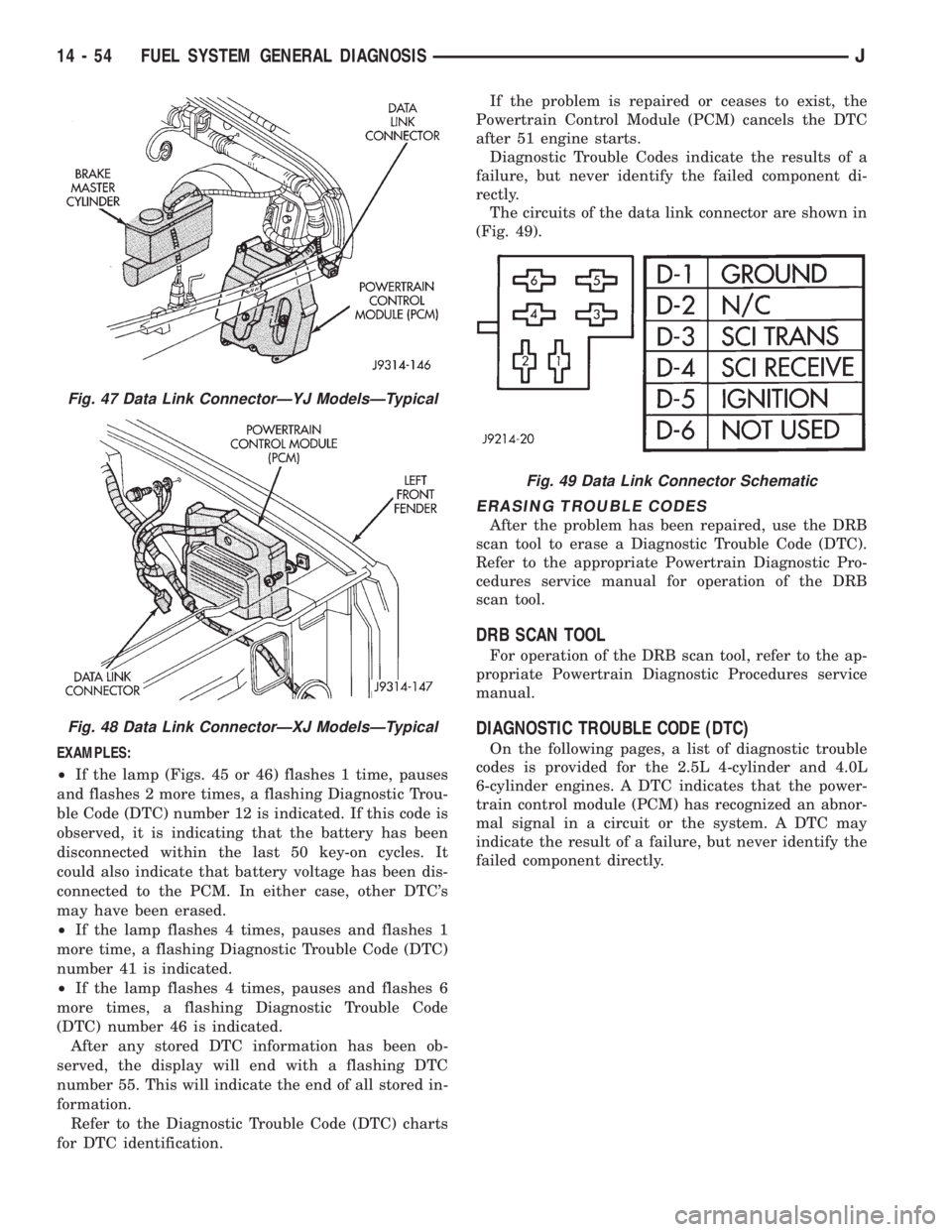

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

scan tool connects to the data link connector in the

engine compartment (Figs. 47 or 48). For operation of

the DRB, refer to the appropriate Powertrain Diag-

nostic Procedures service manual.

Fig. 45 Check Engine LampÐXJ ModelsÐTypical

Fig. 46 Check Engine LampÐYJ ModelsÐTypical

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 53

Page 1269 of 2198

EXAMPLES:

²If the lamp (Figs. 45 or 46) flashes 1 time, pauses

and flashes 2 more times, a flashing Diagnostic Trou-

ble Code (DTC) number 12 is indicated. If this code is

observed, it is indicating that the battery has been

disconnected within the last 50 key-on cycles. It

could also indicate that battery voltage has been dis-

connected to the PCM. In either case, other DTC's

may have been erased.

²If the lamp flashes 4 times, pauses and flashes 1

more time, a flashing Diagnostic Trouble Code (DTC)

number 41 is indicated.

²If the lamp flashes 4 times, pauses and flashes 6

more times, a flashing Diagnostic Trouble Code

(DTC) number 46 is indicated.

After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored in-

formation.

Refer to the Diagnostic Trouble Code (DTC) charts

for DTC identification.If the problem is repaired or ceases to exist, the

Powertrain Control Module (PCM) cancels the DTC

after 51 engine starts.

Diagnostic Trouble Codes indicate the results of a

failure, but never identify the failed component di-

rectly.

The circuits of the data link connector are shown in

(Fig. 49).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a Diagnostic Trouble Code (DTC).

Refer to the appropriate Powertrain Diagnostic Pro-

cedures service manual for operation of the DRB

scan tool.

DRB SCAN TOOL

For operation of the DRB scan tool, refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual.

DIAGNOSTIC TROUBLE CODE (DTC)

On the following pages, a list of diagnostic trouble

codes is provided for the 2.5L 4-cylinder and 4.0L

6-cylinder engines. A DTC indicates that the power-

train control module (PCM) has recognized an abnor-

mal signal in a circuit or the system. A DTC may

indicate the result of a failure, but never identify the

failed component directly.

Fig. 47 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 48 Data Link ConnectorÐXJ ModelsÐTypical

Fig. 49 Data Link Connector Schematic

14 - 54 FUEL SYSTEM GENERAL DIAGNOSISJ