lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1273 of 2198

MULTI-PORT FUEL INJECTION (MFI)ÐCOMPONENT REMOVAL/INSTALLATION

INDEX

page page

Accelerator Pedal and Throttle Cable........... 58

Air Cleaner Element....................... 59

Air Cleaner Housing....................... 58

Air Conditioning (A/C) Clutch Relay............ 58

Automatic Shutdown (ASD) Relay............. 59

Brake Switch............................ 59

Camshaft Position Sensor................... 60

Crankshaft Position Sensor.................. 60

Engine Coolant Temperature Sensor........... 60

Fuel Filter............................... 60

Fuel Injector............................. 60

Fuel Pressure Regulator.................... 61

Fuel Pump Module........................ 61

Fuel Pump Relay......................... 61

Fuel Rail Assembly........................ 62

Fuel System Pressure Release Procedure....... 62

Fuel Tank Pressure Relief/Rollover Valve........ 62Fuel Tanks.............................. 62

Fuel Tubes/Lines/Hoses and Clamps........... 62

Idle Air Control (IAC) Motor.................. 62

Ignition Coil............................. 62

Intake Manifold........................... 63

Intake Manifold Air Temperature Sensor......... 60

Manifold Absolute Pressure (Map) Sensor....... 63

Oxygen (O2S) Sensor...................... 63

Park Neutral Switch....................... 63

Power Steering Pressure SwitchÐ2.5L

Engine Only............................ 63

Powertrain Control Module (PCM)............. 64

Quick-Connect Fittings..................... 64

Throttle Body............................ 64

Throttle Position Sensor (TPS)............... 65

Torque Converter Clutch Relay............... 65

Vehicle Speed Sensor...................... 66

ACCELERATOR PEDAL AND THROTTLE CABLE

Refer to the Accelerator Pedal and Throttle Cable

section of this group for removal/installation proce-

dures.

AIR CONDITIONING (A/C) CLUTCH RELAY

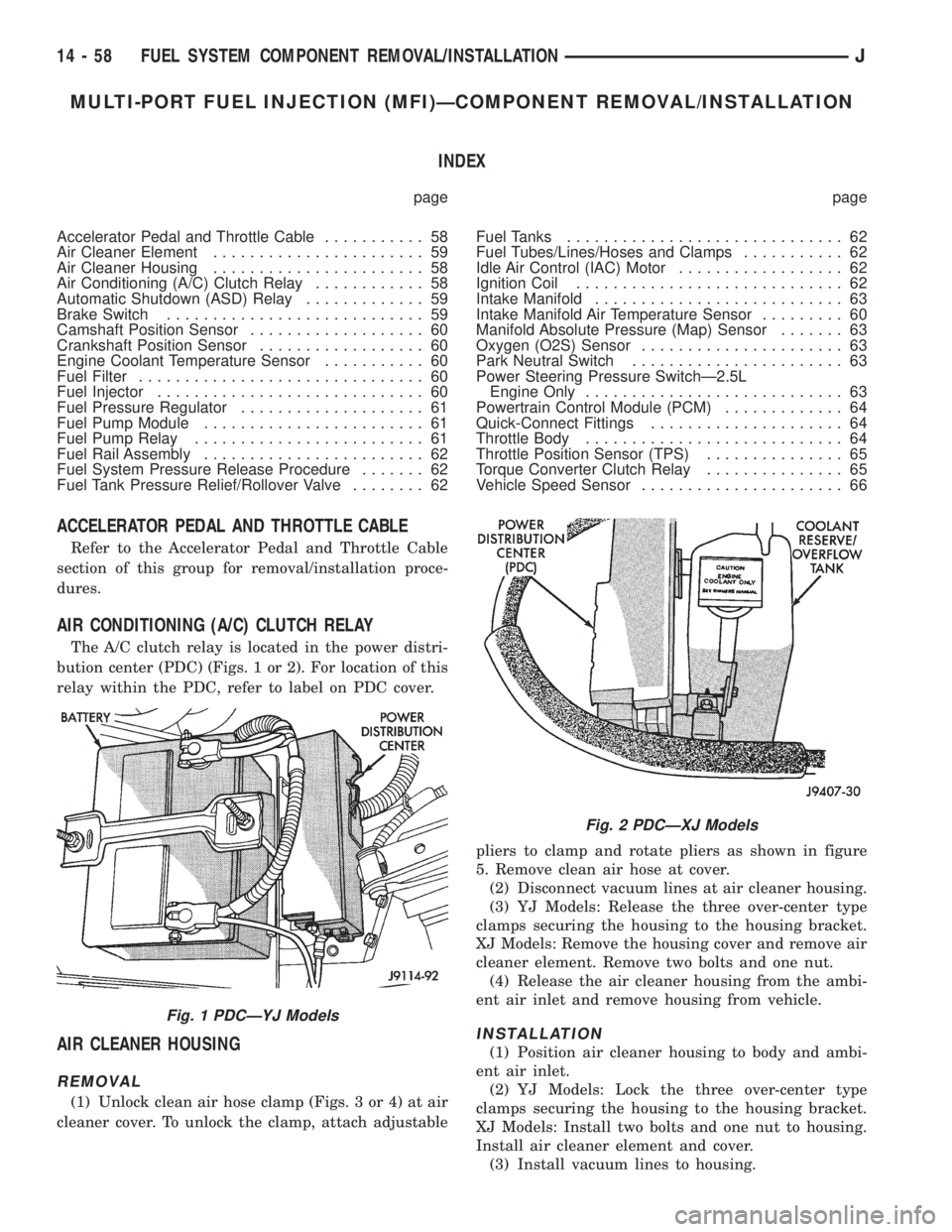

The A/C clutch relay is located in the power distri-

bution center (PDC) (Figs. 1 or 2). For location of this

relay within the PDC, refer to label on PDC cover.

AIR CLEANER HOUSING

REMOVAL

(1) Unlock clean air hose clamp (Figs. 3 or 4) at air

cleaner cover. To unlock the clamp, attach adjustablepliers to clamp and rotate pliers as shown in figure

5. Remove clean air hose at cover.

(2) Disconnect vacuum lines at air cleaner housing.

(3) YJ Models: Release the three over-center type

clamps securing the housing to the housing bracket.

XJ Models: Remove the housing cover and remove air

cleaner element. Remove two bolts and one nut.

(4) Release the air cleaner housing from the ambi-

ent air inlet and remove housing from vehicle.

INSTALLATION

(1) Position air cleaner housing to body and ambi-

ent air inlet.

(2) YJ Models: Lock the three over-center type

clamps securing the housing to the housing bracket.

XJ Models: Install two bolts and one nut to housing.

Install air cleaner element and cover.

(3) Install vacuum lines to housing.

Fig. 1 PDCÐYJ Models

Fig. 2 PDCÐXJ Models

14 - 58 FUEL SYSTEM COMPONENT REMOVAL/INSTALLATIONJ

Page 1275 of 2198

CAMSHAFT POSITION SENSOR

For removal/installation procedures, refer to Group

8D, Ignition System. See Camshaft Position Sensor.

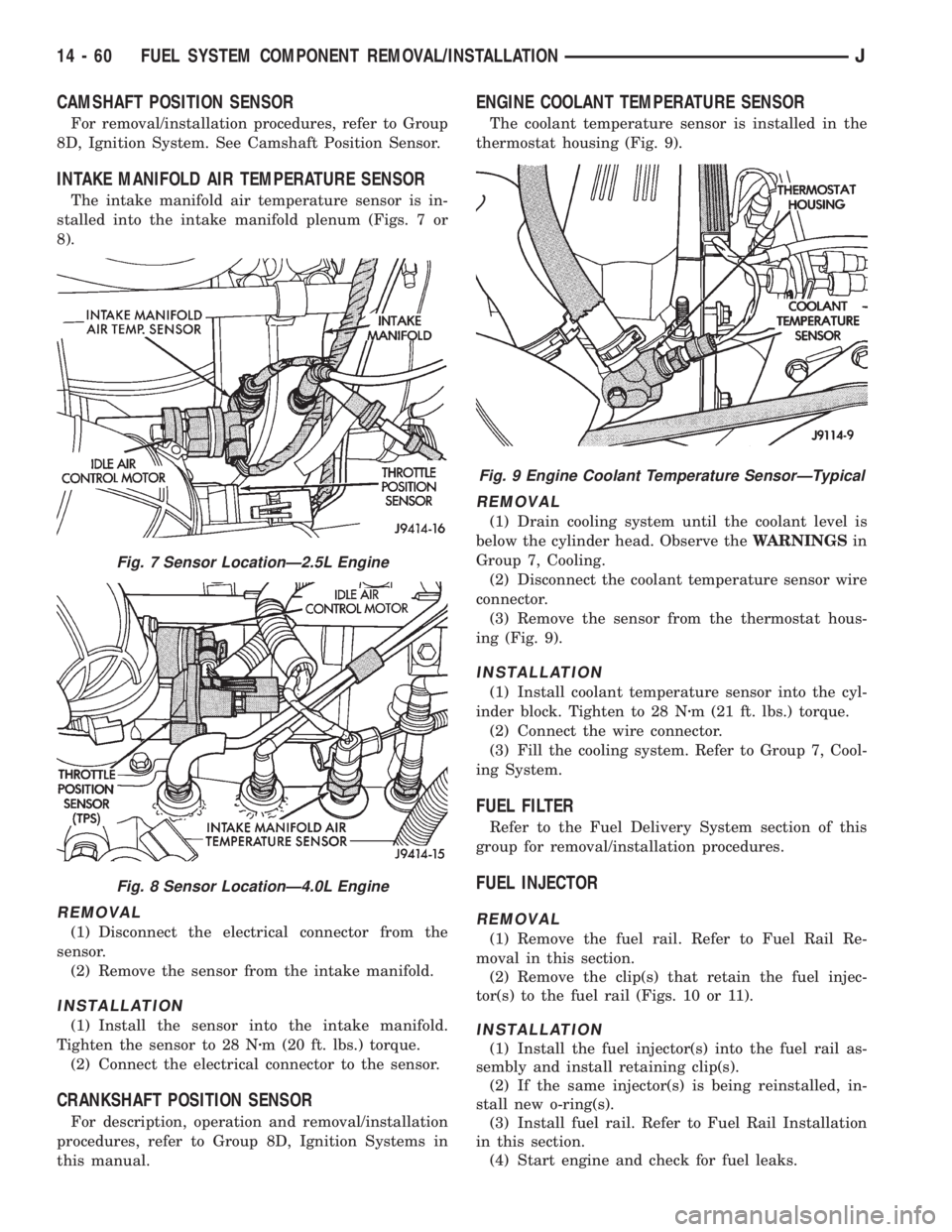

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

The intake manifold air temperature sensor is in-

stalled into the intake manifold plenum (Figs. 7 or

8).

REMOVAL

(1) Disconnect the electrical connector from the

sensor.

(2) Remove the sensor from the intake manifold.

INSTALLATION

(1) Install the sensor into the intake manifold.

Tighten the sensor to 28 Nzm (20 ft. lbs.) torque.

(2) Connect the electrical connector to the sensor.

CRANKSHAFT POSITION SENSOR

For description, operation and removal/installation

procedures, refer to Group 8D, Ignition Systems in

this manual.

ENGINE COOLANT TEMPERATURE SENSOR

The coolant temperature sensor is installed in the

thermostat housing (Fig. 9).

REMOVAL

(1) Drain cooling system until the coolant level is

below the cylinder head. Observe theWARNINGSin

Group 7, Cooling.

(2) Disconnect the coolant temperature sensor wire

connector.

(3) Remove the sensor from the thermostat hous-

ing (Fig. 9).

INSTALLATION

(1) Install coolant temperature sensor into the cyl-

inder block. Tighten to 28 Nzm (21 ft. lbs.) torque.

(2) Connect the wire connector.

(3) Fill the cooling system. Refer to Group 7, Cool-

ing System.

FUEL FILTER

Refer to the Fuel Delivery System section of this

group for removal/installation procedures.

FUEL INJECTOR

REMOVAL

(1) Remove the fuel rail. Refer to Fuel Rail Re-

moval in this section.

(2) Remove the clip(s) that retain the fuel injec-

tor(s) to the fuel rail (Figs. 10 or 11).

INSTALLATION

(1) Install the fuel injector(s) into the fuel rail as-

sembly and install retaining clip(s).

(2) If the same injector(s) is being reinstalled, in-

stall new o-ring(s).

(3) Install fuel rail. Refer to Fuel Rail Installation

in this section.

(4) Start engine and check for fuel leaks.

Fig. 7 Sensor LocationÐ2.5L Engine

Fig. 8 Sensor LocationÐ4.0L Engine

Fig. 9 Engine Coolant Temperature SensorÐTypical

14 - 60 FUEL SYSTEM COMPONENT REMOVAL/INSTALLATIONJ

Page 1301 of 2198

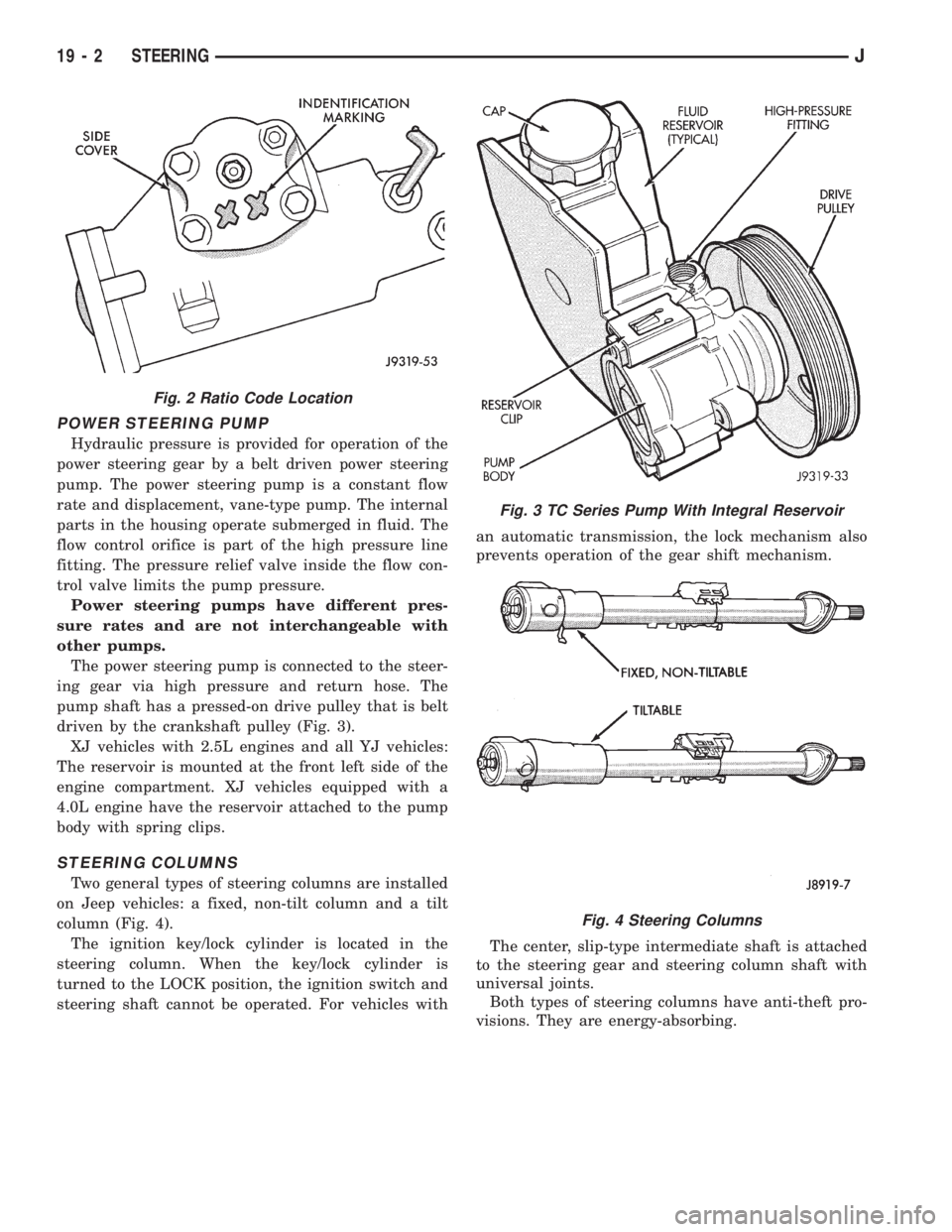

POWER STEERING PUMP

Hydraulic pressure is provided for operation of the

power steering gear by a belt driven power steering

pump. The power steering pump is a constant flow

rate and displacement, vane-type pump. The internal

parts in the housing operate submerged in fluid. The

flow control orifice is part of the high pressure line

fitting. The pressure relief valve inside the flow con-

trol valve limits the pump pressure.

Power steering pumps have different pres-

sure rates and are not interchangeable with

other pumps.

The power steering pump is connected to the steer-

ing gear via high pressure and return hose. The

pump shaft has a pressed-on drive pulley that is belt

driven by the crankshaft pulley (Fig. 3).

XJ vehicles with 2.5L engines and all YJ vehicles:

The reservoir is mounted at the front left side of the

engine compartment. XJ vehicles equipped with a

4.0L engine have the reservoir attached to the pump

body with spring clips.

STEERING COLUMNS

Two general types of steering columns are installed

on Jeep vehicles: a fixed, non-tilt column and a tilt

column (Fig. 4).

The ignition key/lock cylinder is located in the

steering column. When the key/lock cylinder is

turned to the LOCK position, the ignition switch and

steering shaft cannot be operated. For vehicles withan automatic transmission, the lock mechanism also

prevents operation of the gear shift mechanism.

The center, slip-type intermediate shaft is attached

to the steering gear and steering column shaft with

universal joints.

Both types of steering columns have anti-theft pro-

visions. They are energy-absorbing.

Fig. 2 Ratio Code Location

Fig. 3 TC Series Pump With Integral Reservoir

Fig. 4 Steering Columns

19 - 2 STEERINGJ

Page 1313 of 2198

(2) Be sure tool and pulley remain aligned and

NOT cocked with the pump shaft.

(3) Press the pulley on flush with end of pump

shaft (Fig. 7).

(4) Install power steering pump. Refer to Pump

Replacement in this section.

With Serpentine Belts; Run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If

noise increases, press on 1.0 mm (0.040 in.).Be

careful that pulley does not contact mounting

bolts.

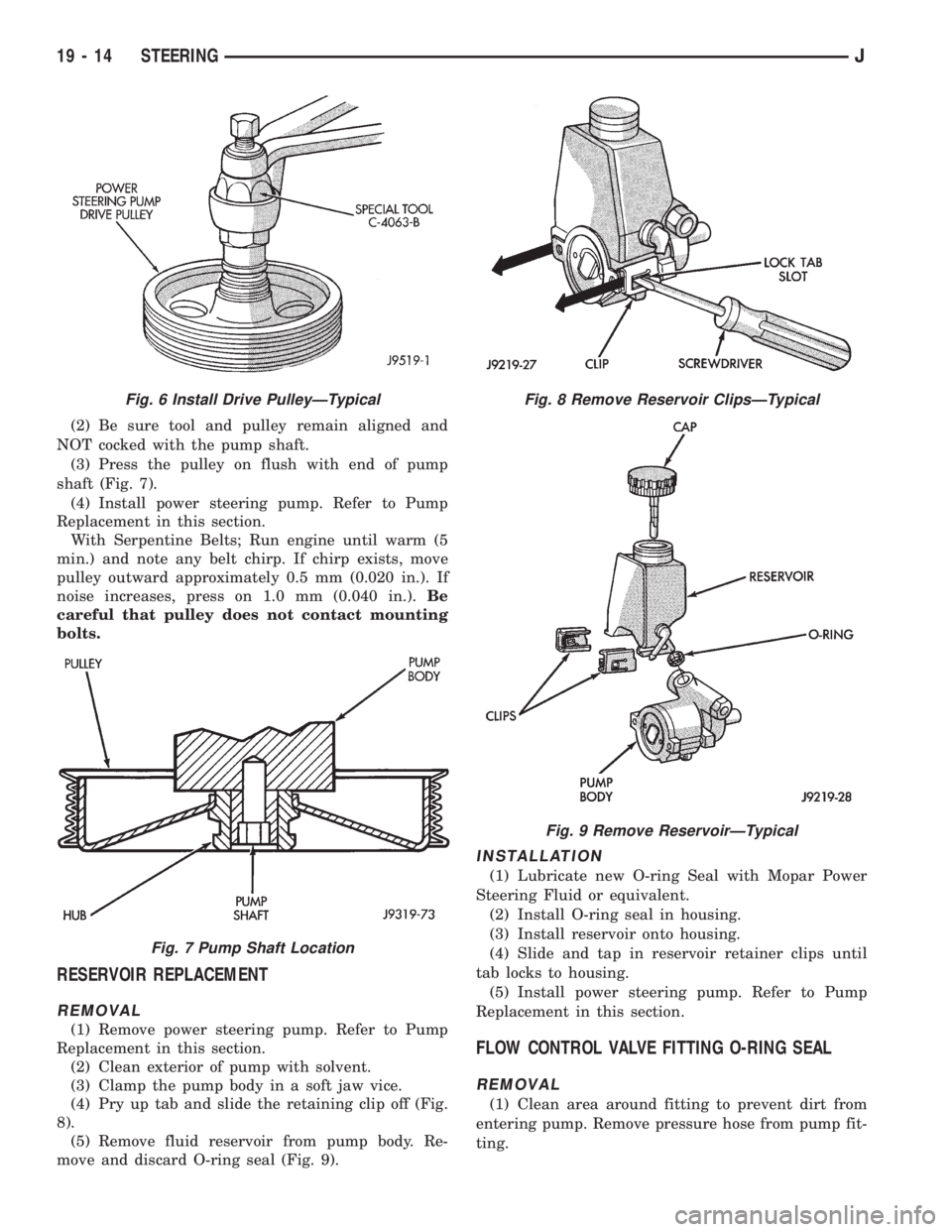

RESERVOIR REPLACEMENT

REMOVAL

(1) Remove power steering pump. Refer to Pump

Replacement in this section.

(2) Clean exterior of pump with solvent.

(3) Clamp the pump body in a soft jaw vice.

(4) Pry up tab and slide the retaining clip off (Fig.

8).

(5) Remove fluid reservoir from pump body. Re-

move and discard O-ring seal (Fig. 9).

INSTALLATION

(1) Lubricate new O-ring Seal with Mopar Power

Steering Fluid or equivalent.

(2) Install O-ring seal in housing.

(3) Install reservoir onto housing.

(4) Slide and tap in reservoir retainer clips until

tab locks to housing.

(5) Install power steering pump. Refer to Pump

Replacement in this section.

FLOW CONTROL VALVE FITTING O-RING SEAL

REMOVAL

(1) Clean area around fitting to prevent dirt from

entering pump. Remove pressure hose from pump fit-

ting.

Fig. 6 Install Drive PulleyÐTypical

Fig. 7 Pump Shaft Location

Fig. 8 Remove Reservoir ClipsÐTypical

Fig. 9 Remove ReservoirÐTypical

19 - 14 STEERINGJ

Page 1314 of 2198

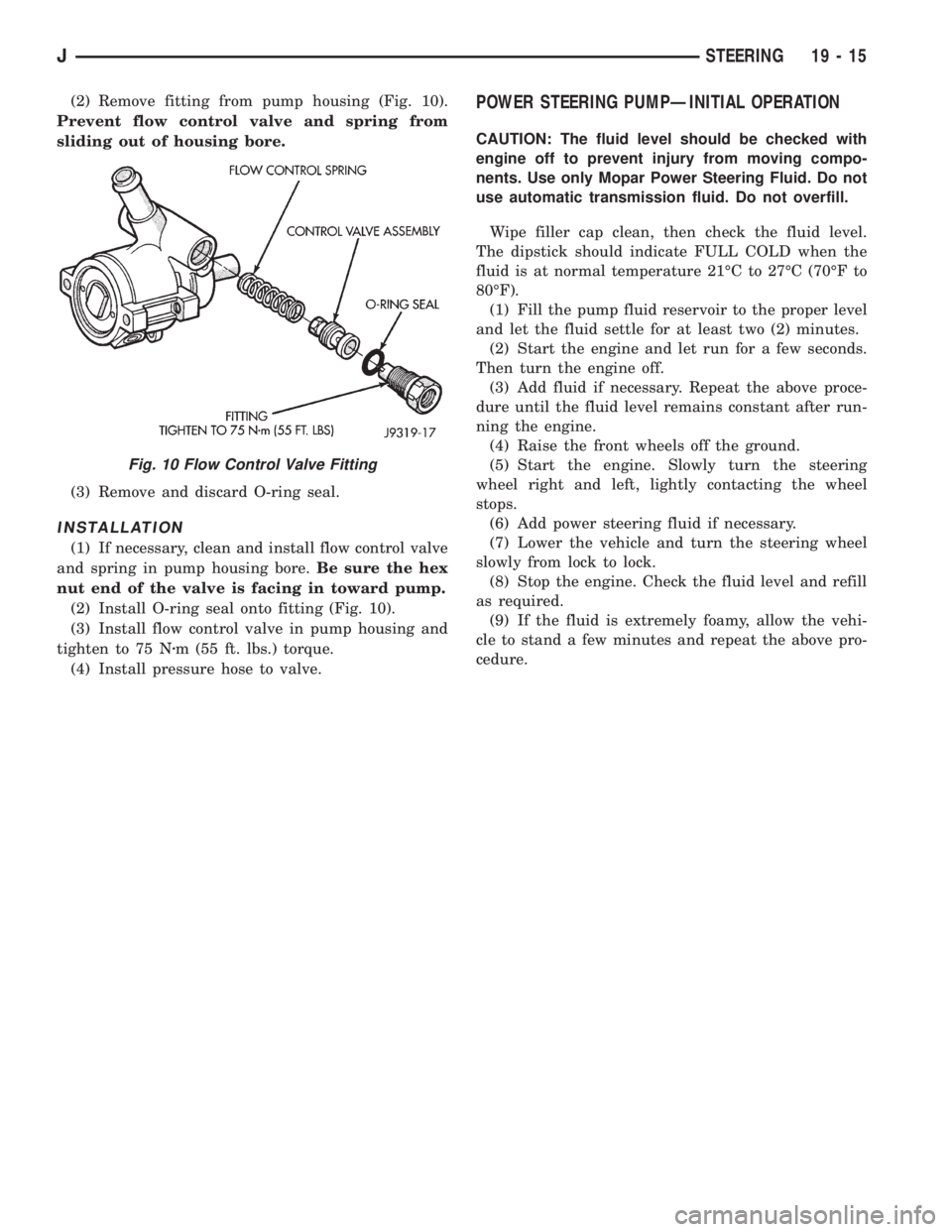

(2) Remove fitting from pump housing (Fig. 10).

Prevent flow control valve and spring from

sliding out of housing bore.

(3) Remove and discard O-ring seal.

INSTALLATION

(1) If necessary, clean and install flow control valve

and spring in pump housing bore.Be sure the hex

nut end of the valve is facing in toward pump.

(2) Install O-ring seal onto fitting (Fig. 10).

(3) Install flow control valve in pump housing and

tighten to 75 Nzm (55 ft. lbs.) torque.

(4) Install pressure hose to valve.

POWER STEERING PUMPÐINITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only Mopar Power Steering Fluid. Do not

use automatic transmission fluid. Do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicate FULL COLD when the

fluid is at normal temperature 21ÉC to 27ÉC (70ÉF to

80ÉF).

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two (2) minutes.

(2) Start the engine and let run for a few seconds.

Then turn the engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops.

(6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(8) Stop the engine. Check the fluid level and refill

as required.

(9) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

Fig. 10 Flow Control Valve Fitting

JSTEERING 19 - 15

Page 1324 of 2198

²SECOND - over-center preload adjustment

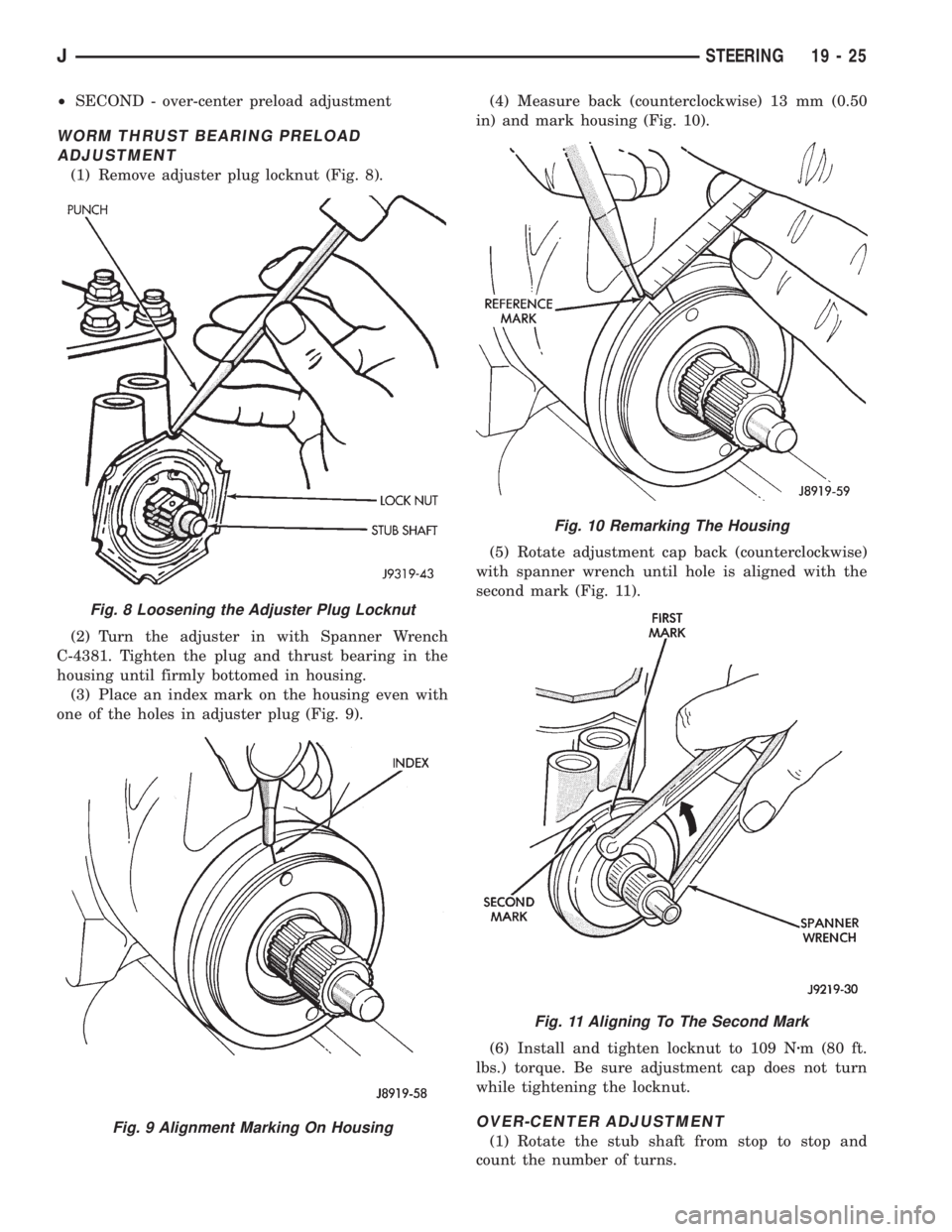

WORM THRUST BEARING PRELOAD

ADJUSTMENT

(1) Remove adjuster plug locknut (Fig. 8).

(2) Turn the adjuster in with Spanner Wrench

C-4381. Tighten the plug and thrust bearing in the

housing until firmly bottomed in housing.

(3) Place an index mark on the housing even with

one of the holes in adjuster plug (Fig. 9).(4) Measure back (counterclockwise) 13 mm (0.50

in) and mark housing (Fig. 10).

(5) Rotate adjustment cap back (counterclockwise)

with spanner wrench until hole is aligned with the

second mark (Fig. 11).

(6) Install and tighten locknut to 109 Nzm (80 ft.

lbs.) torque. Be sure adjustment cap does not turn

while tightening the locknut.

OVER-CENTER ADJUSTMENT

(1) Rotate the stub shaft from stop to stop and

count the number of turns.

Fig. 10 Remarking The Housing

Fig. 11 Aligning To The Second Mark

Fig. 8 Loosening the Adjuster Plug Locknut

Fig. 9 Alignment Marking On Housing

JSTEERING 19 - 25

Page 1325 of 2198

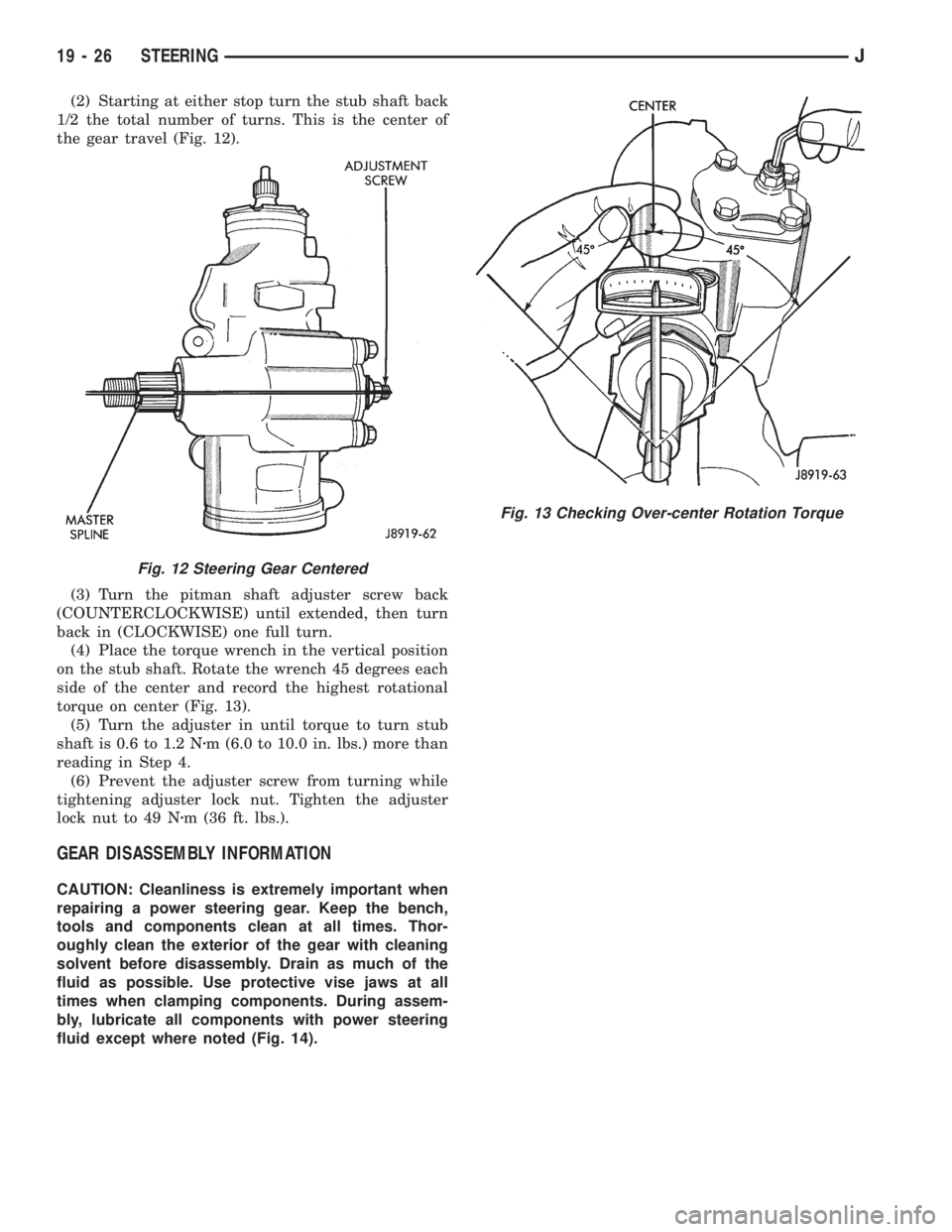

(2) Starting at either stop turn the stub shaft back

1/2 the total number of turns. This is the center of

the gear travel (Fig. 12).

(3) Turn the pitman shaft adjuster screw back

(COUNTERCLOCKWISE) until extended, then turn

back in (CLOCKWISE) one full turn.

(4) Place the torque wrench in the vertical position

on the stub shaft. Rotate the wrench 45 degrees each

side of the center and record the highest rotational

torque on center (Fig. 13).

(5) Turn the adjuster in until torque to turn stub

shaft is 0.6 to 1.2 Nzm (6.0 to 10.0 in. lbs.) more than

reading in Step 4.

(6) Prevent the adjuster screw from turning while

tightening adjuster lock nut. Tighten the adjuster

lock nut to 49 Nzm (36 ft. lbs.).

GEAR DISASSEMBLY INFORMATION

CAUTION: Cleanliness is extremely important when

repairing a power steering gear. Keep the bench,

tools and components clean at all times. Thor-

oughly clean the exterior of the gear with cleaning

solvent before disassembly. Drain as much of the

fluid as possible. Use protective vise jaws at all

times when clamping components. During assem-

bly, lubricate all components with power steering

fluid except where noted (Fig. 14).

Fig. 12 Steering Gear Centered

Fig. 13 Checking Over-center Rotation Torque

19 - 26 STEERINGJ

Page 1327 of 2198

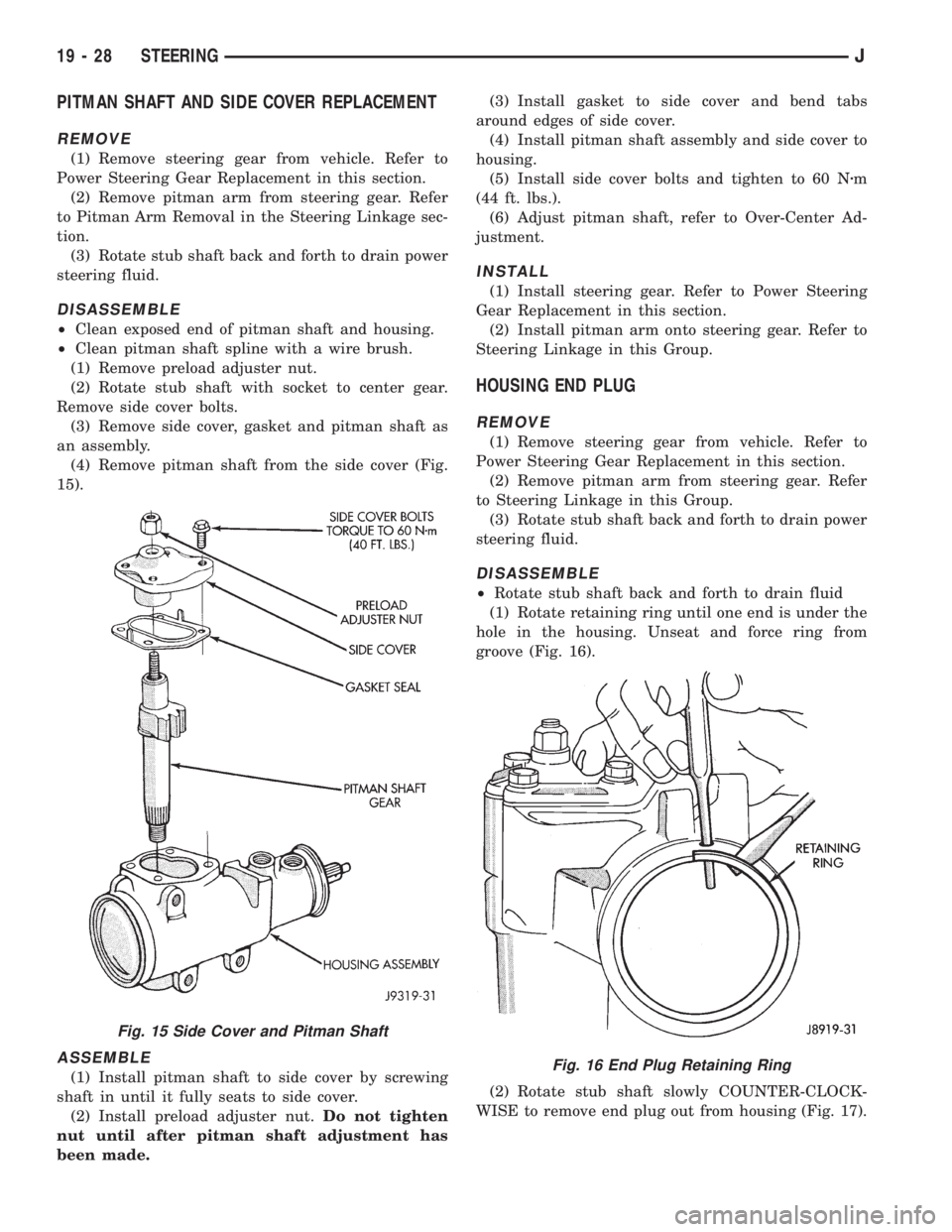

PITMAN SHAFT AND SIDE COVER REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

(2) Remove pitman arm from steering gear. Refer

to Pitman Arm Removal in the Steering Linkage sec-

tion.

(3) Rotate stub shaft back and forth to drain power

steering fluid.

DISASSEMBLE

²Clean exposed end of pitman shaft and housing.

²Clean pitman shaft spline with a wire brush.

(1) Remove preload adjuster nut.

(2) Rotate stub shaft with socket to center gear.

Remove side cover bolts.

(3) Remove side cover, gasket and pitman shaft as

an assembly.

(4) Remove pitman shaft from the side cover (Fig.

15).

ASSEMBLE

(1) Install pitman shaft to side cover by screwing

shaft in until it fully seats to side cover.

(2) Install preload adjuster nut.Do not tighten

nut until after pitman shaft adjustment has

been made.(3) Install gasket to side cover and bend tabs

around edges of side cover.

(4) Install pitman shaft assembly and side cover to

housing.

(5) Install side cover bolts and tighten to 60 Nzm

(44 ft. lbs.).

(6) Adjust pitman shaft, refer to Over-Center Ad-

justment.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

(2) Install pitman arm onto steering gear. Refer to

Steering Linkage in this Group.

HOUSING END PLUG

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

(2) Remove pitman arm from steering gear. Refer

to Steering Linkage in this Group.

(3) Rotate stub shaft back and forth to drain power

steering fluid.

DISASSEMBLE

²Rotate stub shaft back and forth to drain fluid

(1) Rotate retaining ring until one end is under the

hole in the housing. Unseat and force ring from

groove (Fig. 16).

(2) Rotate stub shaft slowly COUNTER-CLOCK-

WISE to remove end plug out from housing (Fig. 17).

Fig. 15 Side Cover and Pitman Shaft

Fig. 16 End Plug Retaining Ring

19 - 28 STEERINGJ

Page 1328 of 2198

CAUTION: Do not turn stub shaft any farther than

necessary. The recirculating balls will drop out of

the rack piston circuit and fall inside the rack pis-

ton chamber.

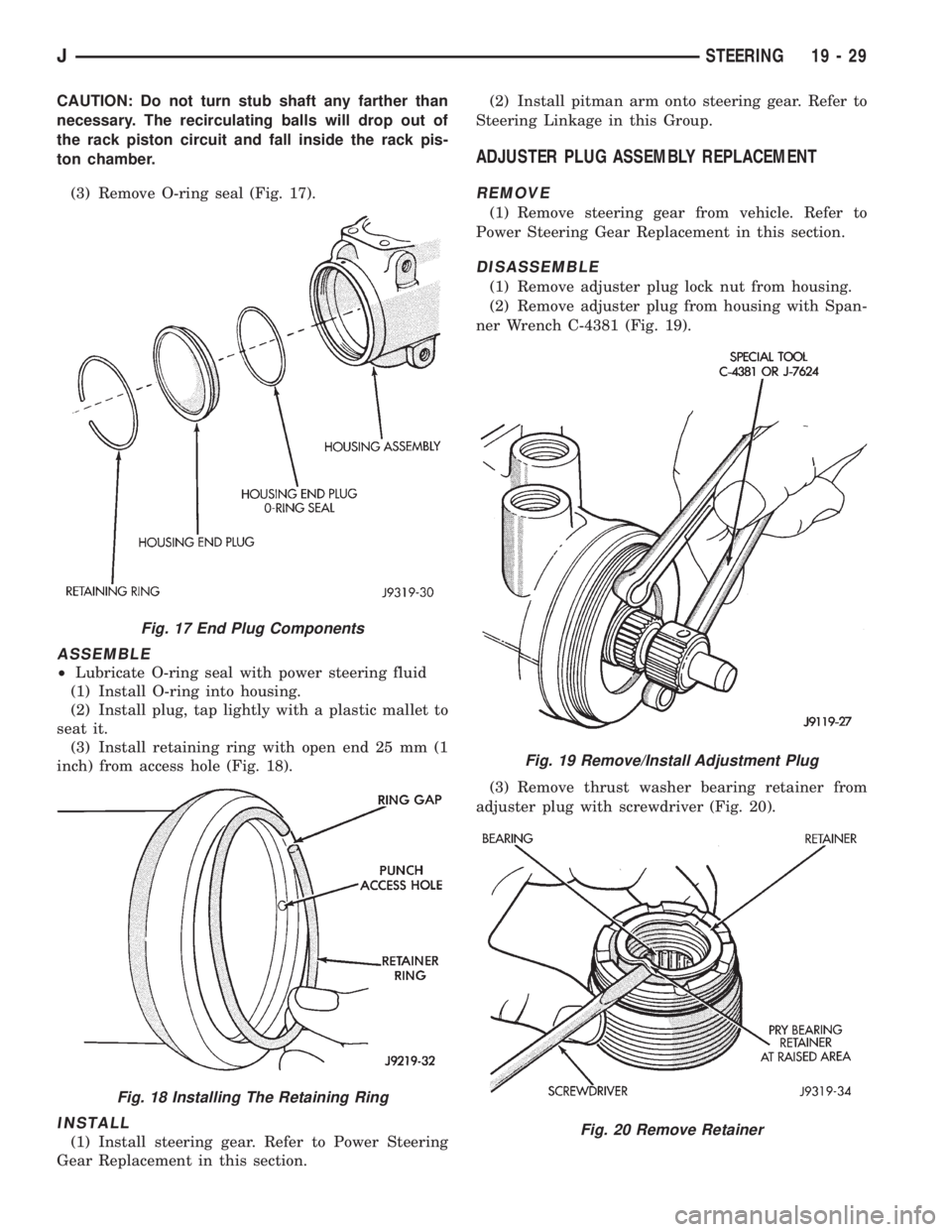

(3) Remove O-ring seal (Fig. 17).

ASSEMBLE

²Lubricate O-ring seal with power steering fluid

(1) Install O-ring into housing.

(2) Install plug, tap lightly with a plastic mallet to

seat it.

(3) Install retaining ring with open end 25 mm (1

inch) from access hole (Fig. 18).

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.(2) Install pitman arm onto steering gear. Refer to

Steering Linkage in this Group.

ADJUSTER PLUG ASSEMBLY REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

DISASSEMBLE

(1) Remove adjuster plug lock nut from housing.

(2) Remove adjuster plug from housing with Span-

ner Wrench C-4381 (Fig. 19).

(3) Remove thrust washer bearing retainer from

adjuster plug with screwdriver (Fig. 20).

Fig. 17 End Plug Components

Fig. 18 Installing The Retaining Ring

Fig. 19 Remove/Install Adjustment Plug

Fig. 20 Remove Retainer

JSTEERING 19 - 29

Page 1329 of 2198

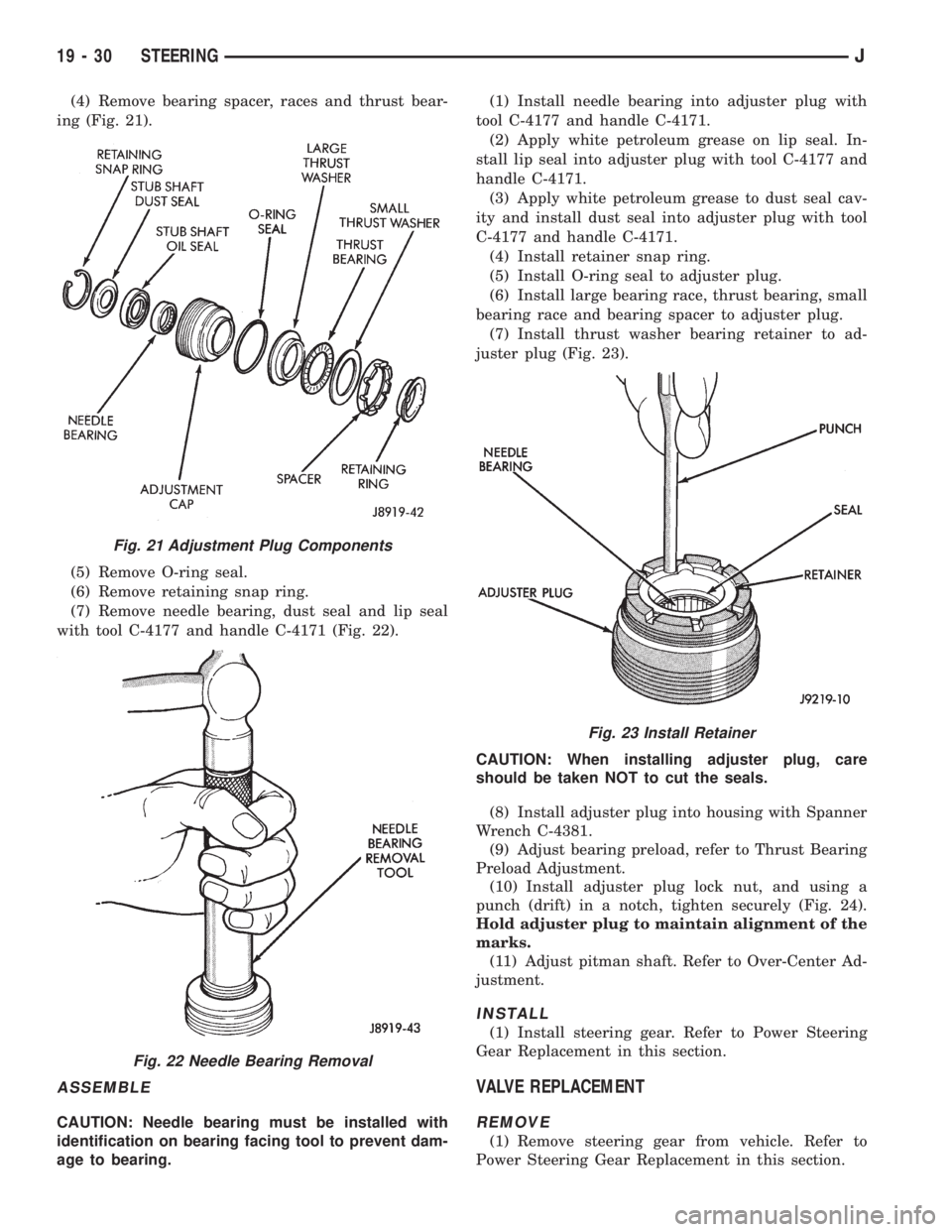

(4) Remove bearing spacer, races and thrust bear-

ing (Fig. 21).

(5) Remove O-ring seal.

(6) Remove retaining snap ring.

(7) Remove needle bearing, dust seal and lip seal

with tool C-4177 and handle C-4171 (Fig. 22).

ASSEMBLE

CAUTION: Needle bearing must be installed with

identification on bearing facing tool to prevent dam-

age to bearing.(1) Install needle bearing into adjuster plug with

tool C-4177 and handle C-4171.

(2) Apply white petroleum grease on lip seal. In-

stall lip seal into adjuster plug with tool C-4177 and

handle C-4171.

(3) Apply white petroleum grease to dust seal cav-

ity and install dust seal into adjuster plug with tool

C-4177 and handle C-4171.

(4) Install retainer snap ring.

(5) Install O-ring seal to adjuster plug.

(6) Install large bearing race, thrust bearing, small

bearing race and bearing spacer to adjuster plug.

(7) Install thrust washer bearing retainer to ad-

juster plug (Fig. 23).

CAUTION: When installing adjuster plug, care

should be taken NOT to cut the seals.

(8) Install adjuster plug into housing with Spanner

Wrench C-4381.

(9) Adjust bearing preload, refer to Thrust Bearing

Preload Adjustment.

(10) Install adjuster plug lock nut, and using a

punch (drift) in a notch, tighten securely (Fig. 24).

Hold adjuster plug to maintain alignment of the

marks.

(11) Adjust pitman shaft. Refer to Over-Center Ad-

justment.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

VALVE REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

Fig. 21 Adjustment Plug Components

Fig. 22 Needle Bearing Removal

Fig. 23 Install Retainer

19 - 30 STEERINGJ