lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1330 of 2198

DISASSEMBLE

(1) Remove adjuster plug, refer to Adjuster Plug

Assembly Replacement.

(2) Remove stub shaft and valve assembly (Fig.

25).

(3) Remove stub shaft from valve assembly, if nec-

essary.

²Tap stub shaft lightly on a block of wood to loosen

shaft cap

²Pull cap and valve body and disengage stub shaft

pin from hole in valve body (Fig. 26).

(4) Remove valve assembly if necessary.

²Remove valve spool by pulling and rotating from

valve body (Fig. 27).

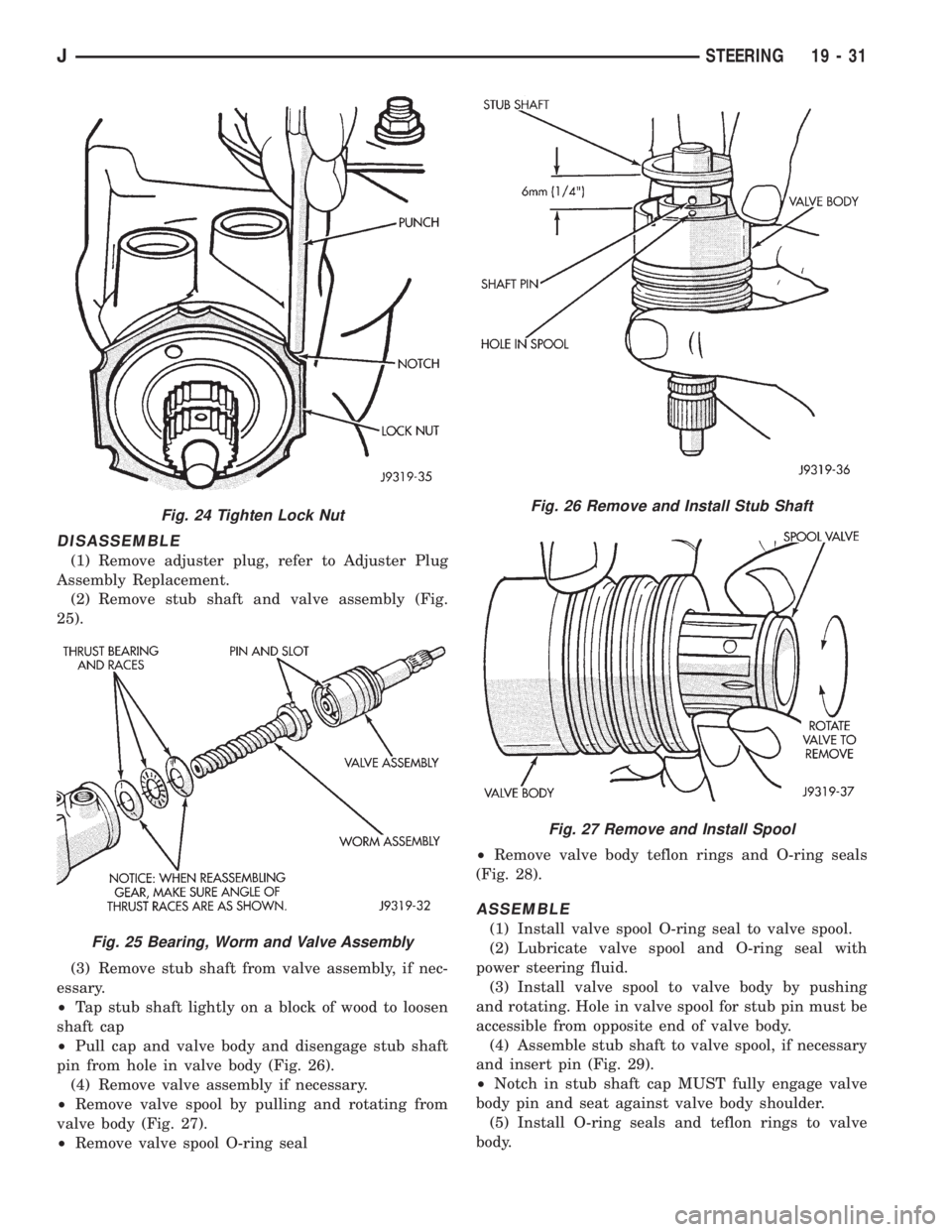

²Remove valve spool O-ring seal²Remove valve body teflon rings and O-ring seals

(Fig. 28).

ASSEMBLE

(1) Install valve spool O-ring seal to valve spool.

(2) Lubricate valve spool and O-ring seal with

power steering fluid.

(3) Install valve spool to valve body by pushing

and rotating. Hole in valve spool for stub pin must be

accessible from opposite end of valve body.

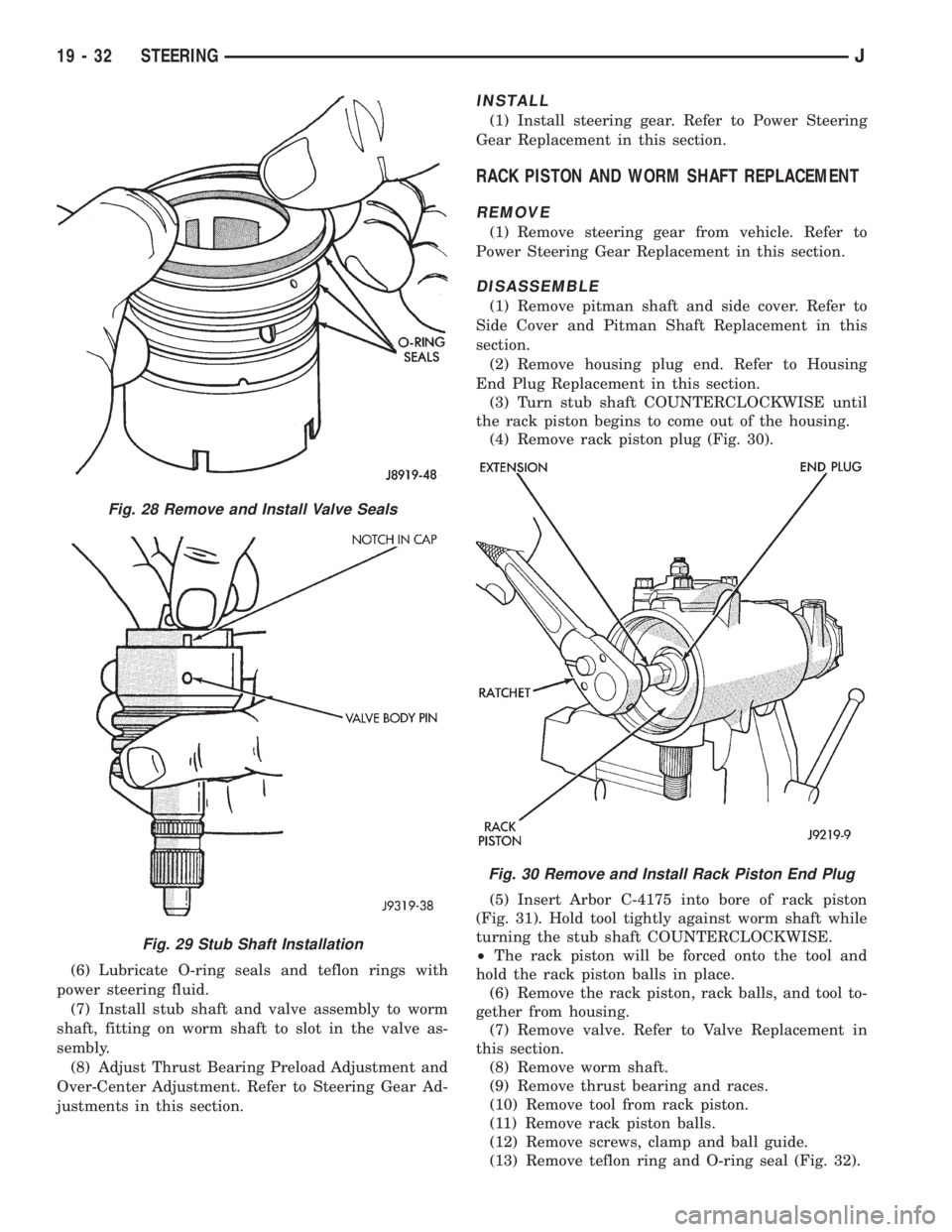

(4) Assemble stub shaft to valve spool, if necessary

and insert pin (Fig. 29).

²Notch in stub shaft cap MUST fully engage valve

body pin and seat against valve body shoulder.

(5) Install O-ring seals and teflon rings to valve

body.

Fig. 24 Tighten Lock Nut

Fig. 25 Bearing, Worm and Valve Assembly

Fig. 26 Remove and Install Stub Shaft

Fig. 27 Remove and Install Spool

JSTEERING 19 - 31

Page 1331 of 2198

(6) Lubricate O-ring seals and teflon rings with

power steering fluid.

(7) Install stub shaft and valve assembly to worm

shaft, fitting on worm shaft to slot in the valve as-

sembly.

(8) Adjust Thrust Bearing Preload Adjustment and

Over-Center Adjustment. Refer to Steering Gear Ad-

justments in this section.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

RACK PISTON AND WORM SHAFT REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

DISASSEMBLE

(1) Remove pitman shaft and side cover. Refer to

Side Cover and Pitman Shaft Replacement in this

section.

(2) Remove housing plug end. Refer to Housing

End Plug Replacement in this section.

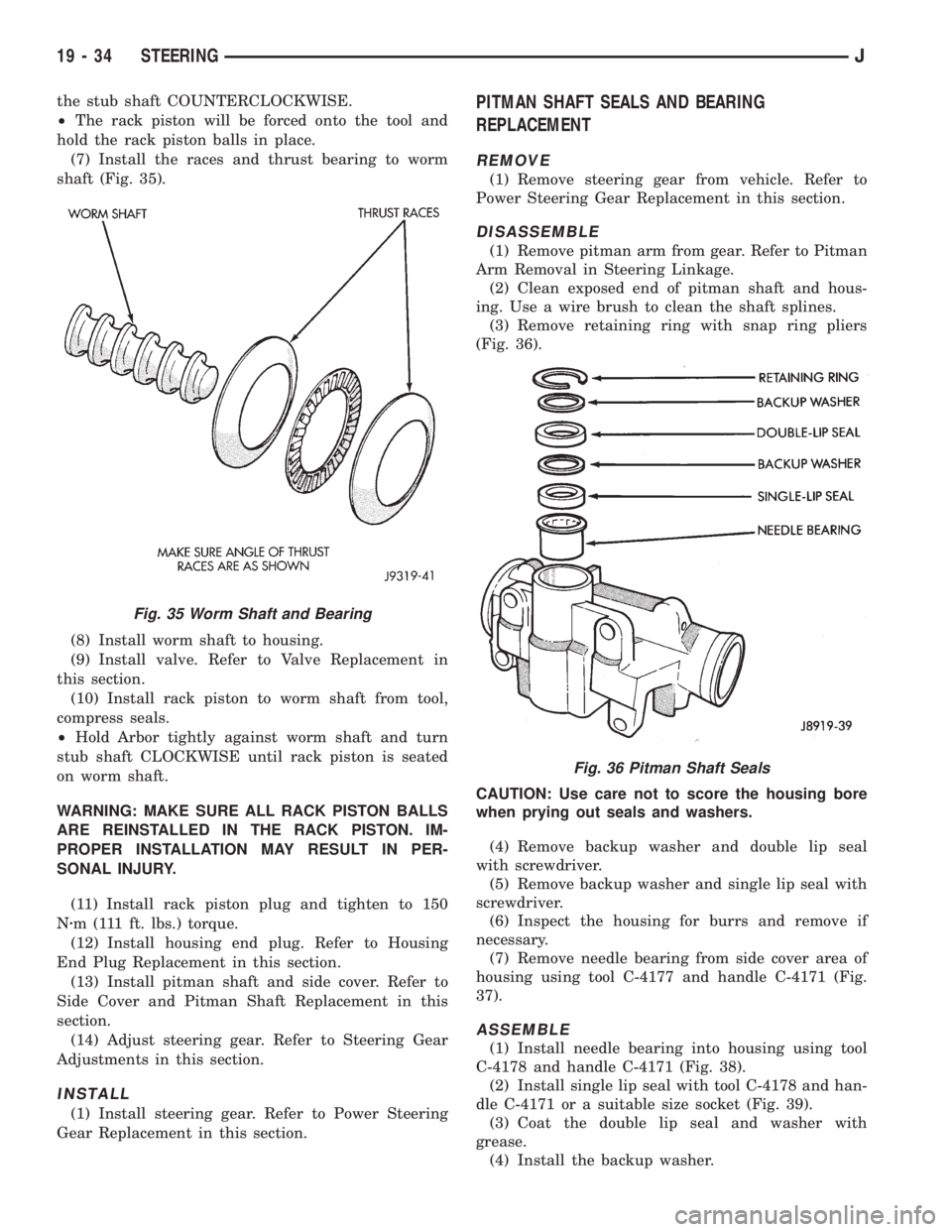

(3) Turn stub shaft COUNTERCLOCKWISE until

the rack piston begins to come out of the housing.

(4) Remove rack piston plug (Fig. 30).

(5) Insert Arbor C-4175 into bore of rack piston

(Fig. 31). Hold tool tightly against worm shaft while

turning the stub shaft COUNTERCLOCKWISE.

²The rack piston will be forced onto the tool and

hold the rack piston balls in place.

(6) Remove the rack piston, rack balls, and tool to-

gether from housing.

(7) Remove valve. Refer to Valve Replacement in

this section.

(8) Remove worm shaft.

(9) Remove thrust bearing and races.

(10) Remove tool from rack piston.

(11) Remove rack piston balls.

(12) Remove screws, clamp and ball guide.

(13) Remove teflon ring and O-ring seal (Fig. 32).

Fig. 28 Remove and Install Valve Seals

Fig. 29 Stub Shaft Installation

Fig. 30 Remove and Install Rack Piston End Plug

19 - 32 STEERINGJ

Page 1332 of 2198

CLEAN AND INSPECTION

(1) Wash all components in clean solvent and dry

with compressed air.

(2) Check for scores, nicks or burrs on the rack pis-

ton finished surface. Slight wear is normal on the

worm gear surfaces.

ASSEMBLE

(1) Install O-ring seal and teflon ring and lubricate

with power steering fluid.

(2) Install worm shaft to rack piston outside of

housing. Fully seat worm shaft to rack piston and

align worm shaft spiral groove with rack piston ball

guide hole (Fig. 33).

WARNING: MAKE SURE ALL RACK PISTON BALLS

ARE REINSTALLED IN THE RACK PISTON. IM-

PROPER INSTALLATION MAY RESULT IN PER-

SONAL INJURY.There are 24 balls in the rack piston circuit,

12 are black and 12 are silver (Chrome). The

black rack piston balls are smaller than the sil-

ver balls. THE BLACK AND SILVER BALLS

MUST BE INSTALLED ALTERNATELY INTO

THE RACK PISTON AND BALL GUIDE. This

procedure will maintain worm shaft preload.

(3) Lubricate and install rack piston balls through

return guide hole while turning wormshaft COUN-

TERCLOCKWISE.

(4) Install remaining balls to guide using grease or

petroleum jelly at each end to hold in place (Fig. 34).

(5) Install guide onto rack piston and return with

clamp and screws. Tighten screws to 58 Nzm (43 in.

lbs.) torque.

(6) Insert Arbor C-4175 into bore of rack piston.

Hold tool tightly against worm shaft while turning

Fig. 31 Remove and Install Rack Piston

Fig. 32 Remove and Install Seal on Rack Piston

Fig. 33 Installing Balls in Rack Piston

Fig. 34 Balls in the Return Guide

JSTEERING 19 - 33

Page 1333 of 2198

the stub shaft COUNTERCLOCKWISE.

²The rack piston will be forced onto the tool and

hold the rack piston balls in place.

(7) Install the races and thrust bearing to worm

shaft (Fig. 35).

(8) Install worm shaft to housing.

(9) Install valve. Refer to Valve Replacement in

this section.

(10) Install rack piston to worm shaft from tool,

compress seals.

²Hold Arbor tightly against worm shaft and turn

stub shaft CLOCKWISE until rack piston is seated

on worm shaft.

WARNING: MAKE SURE ALL RACK PISTON BALLS

ARE REINSTALLED IN THE RACK PISTON. IM-

PROPER INSTALLATION MAY RESULT IN PER-

SONAL INJURY.

(11) Install rack piston plug and tighten to 150

Nzm (111 ft. lbs.) torque.

(12) Install housing end plug. Refer to Housing

End Plug Replacement in this section.

(13) Install pitman shaft and side cover. Refer to

Side Cover and Pitman Shaft Replacement in this

section.

(14) Adjust steering gear. Refer to Steering Gear

Adjustments in this section.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

PITMAN SHAFT SEALS AND BEARING

REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

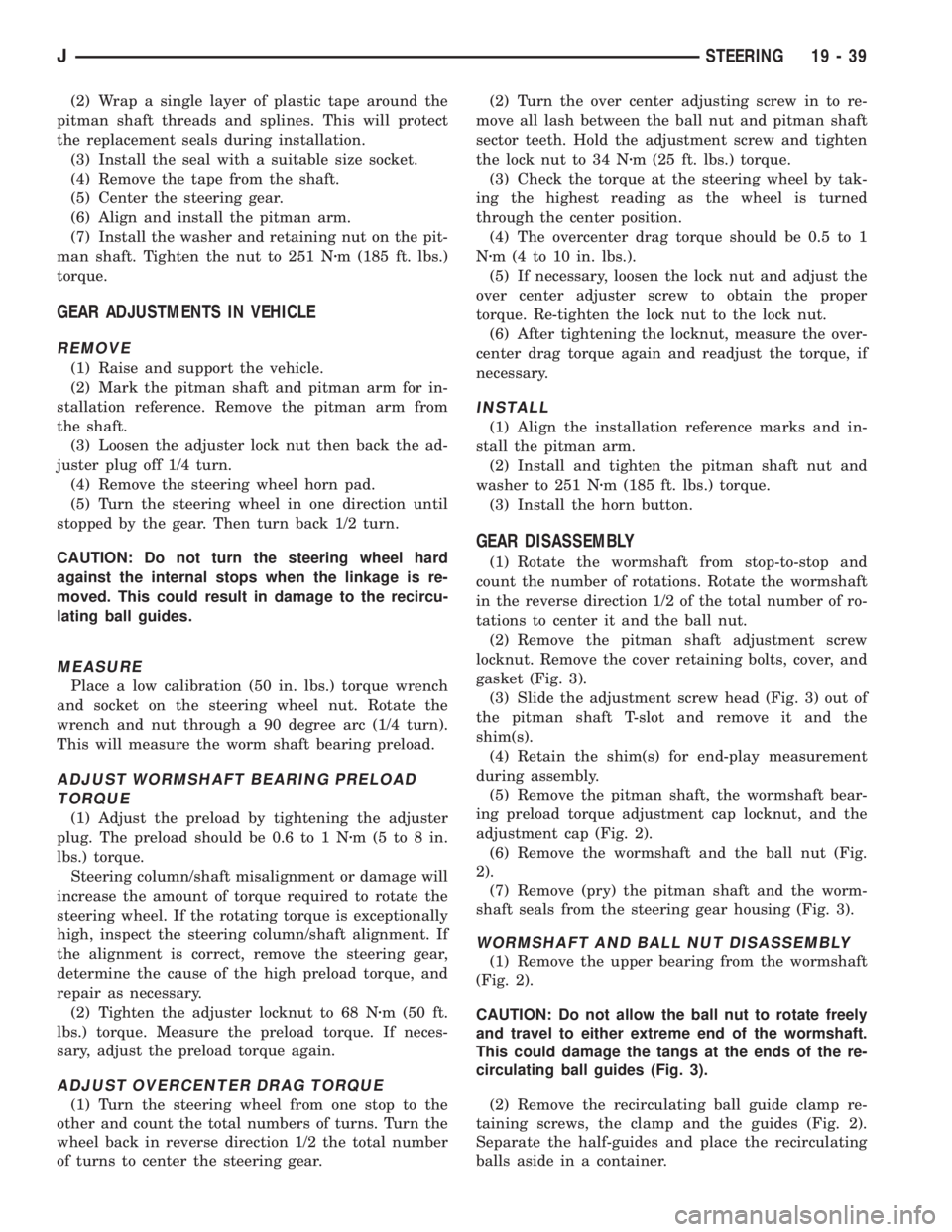

DISASSEMBLE

(1) Remove pitman arm from gear. Refer to Pitman

Arm Removal in Steering Linkage.

(2) Clean exposed end of pitman shaft and hous-

ing. Use a wire brush to clean the shaft splines.

(3) Remove retaining ring with snap ring pliers

(Fig. 36).

CAUTION: Use care not to score the housing bore

when prying out seals and washers.

(4) Remove backup washer and double lip seal

with screwdriver.

(5) Remove backup washer and single lip seal with

screwdriver.

(6) Inspect the housing for burrs and remove if

necessary.

(7) Remove needle bearing from side cover area of

housing using tool C-4177 and handle C-4171 (Fig.

37).

ASSEMBLE

(1) Install needle bearing into housing using tool

C-4178 and handle C-4171 (Fig. 38).

(2) Install single lip seal with tool C-4178 and han-

dle C-4171 or a suitable size socket (Fig. 39).

(3) Coat the double lip seal and washer with

grease.

(4) Install the backup washer.

Fig. 35 Worm Shaft and Bearing

Fig. 36 Pitman Shaft Seals

19 - 34 STEERINGJ

Page 1338 of 2198

(2) Wrap a single layer of plastic tape around the

pitman shaft threads and splines. This will protect

the replacement seals during installation.

(3) Install the seal with a suitable size socket.

(4) Remove the tape from the shaft.

(5) Center the steering gear.

(6) Align and install the pitman arm.

(7) Install the washer and retaining nut on the pit-

man shaft. Tighten the nut to 251 Nzm (185 ft. lbs.)

torque.

GEAR ADJUSTMENTS IN VEHICLE

REMOVE

(1) Raise and support the vehicle.

(2) Mark the pitman shaft and pitman arm for in-

stallation reference. Remove the pitman arm from

the shaft.

(3) Loosen the adjuster lock nut then back the ad-

juster plug off 1/4 turn.

(4) Remove the steering wheel horn pad.

(5) Turn the steering wheel in one direction until

stopped by the gear. Then turn back 1/2 turn.

CAUTION: Do not turn the steering wheel hard

against the internal stops when the linkage is re-

moved. This could result in damage to the recircu-

lating ball guides.

MEASURE

Place a low calibration (50 in. lbs.) torque wrench

and socket on the steering wheel nut. Rotate the

wrench and nut through a 90 degree arc (1/4 turn).

This will measure the worm shaft bearing preload.

ADJUST WORMSHAFT BEARING PRELOAD

TORQUE

(1) Adjust the preload by tightening the adjuster

plug. The preload should be 0.6 to 1 Nzm(5to8in.

lbs.) torque.

Steering column/shaft misalignment or damage will

increase the amount of torque required to rotate the

steering wheel. If the rotating torque is exceptionally

high, inspect the steering column/shaft alignment. If

the alignment is correct, remove the steering gear,

determine the cause of the high preload torque, and

repair as necessary.

(2) Tighten the adjuster locknut to 68 Nzm (50 ft.

lbs.) torque. Measure the preload torque. If neces-

sary, adjust the preload torque again.

ADJUST OVERCENTER DRAG TORQUE

(1) Turn the steering wheel from one stop to the

other and count the total numbers of turns. Turn the

wheel back in reverse direction 1/2 the total number

of turns to center the steering gear.(2) Turn the over center adjusting screw in to re-

move all lash between the ball nut and pitman shaft

sector teeth. Hold the adjustment screw and tighten

the lock nut to 34 Nzm (25 ft. lbs.) torque.

(3) Check the torque at the steering wheel by tak-

ing the highest reading as the wheel is turned

through the center position.

(4) The overcenter drag torque should be 0.5 to 1

Nzm (4 to 10 in. lbs.).

(5) If necessary, loosen the lock nut and adjust the

over center adjuster screw to obtain the proper

torque. Re-tighten the lock nut to the lock nut.

(6) After tightening the locknut, measure the over-

center drag torque again and readjust the torque, if

necessary.

INSTALL

(1) Align the installation reference marks and in-

stall the pitman arm.

(2) Install and tighten the pitman shaft nut and

washer to 251 Nzm (185 ft. lbs.) torque.

(3) Install the horn button.

GEAR DISASSEMBLY

(1) Rotate the wormshaft from stop-to-stop and

count the number of rotations. Rotate the wormshaft

in the reverse direction 1/2 of the total number of ro-

tations to center it and the ball nut.

(2) Remove the pitman shaft adjustment screw

locknut. Remove the cover retaining bolts, cover, and

gasket (Fig. 3).

(3) Slide the adjustment screw head (Fig. 3) out of

the pitman shaft T-slot and remove it and the

shim(s).

(4) Retain the shim(s) for end-play measurement

during assembly.

(5) Remove the pitman shaft, the wormshaft bear-

ing preload torque adjustment cap locknut, and the

adjustment cap (Fig. 2).

(6) Remove the wormshaft and the ball nut (Fig.

2).

(7) Remove (pry) the pitman shaft and the worm-

shaft seals from the steering gear housing (Fig. 3).

WORMSHAFT AND BALL NUT DISASSEMBLY

(1) Remove the upper bearing from the wormshaft

(Fig. 2).

CAUTION: Do not allow the ball nut to rotate freely

and travel to either extreme end of the wormshaft.

This could damage the tangs at the ends of the re-

circulating ball guides (Fig. 3).

(2) Remove the recirculating ball guide clamp re-

taining screws, the clamp and the guides (Fig. 2).

Separate the half-guides and place the recirculating

balls aside in a container.

JSTEERING 19 - 39

Page 1343 of 2198

(6) Install the wormshaft bearing adjustment cap

in the housing and tighten it only enough to remove

the wormshaft end-play.

(7) Install the locknut on the wormshaft bearing

adjustment cap but do not tighten it at this time.

(8) Pack the steering gear housing with as much

chassis lubricant as possible.

Rotate the wormshaft in one direction until

the ball nut ceases. Pack the end of the housing

full of lubricant, rotate the shaft in the opposite

direction and repeat the packing procedure.

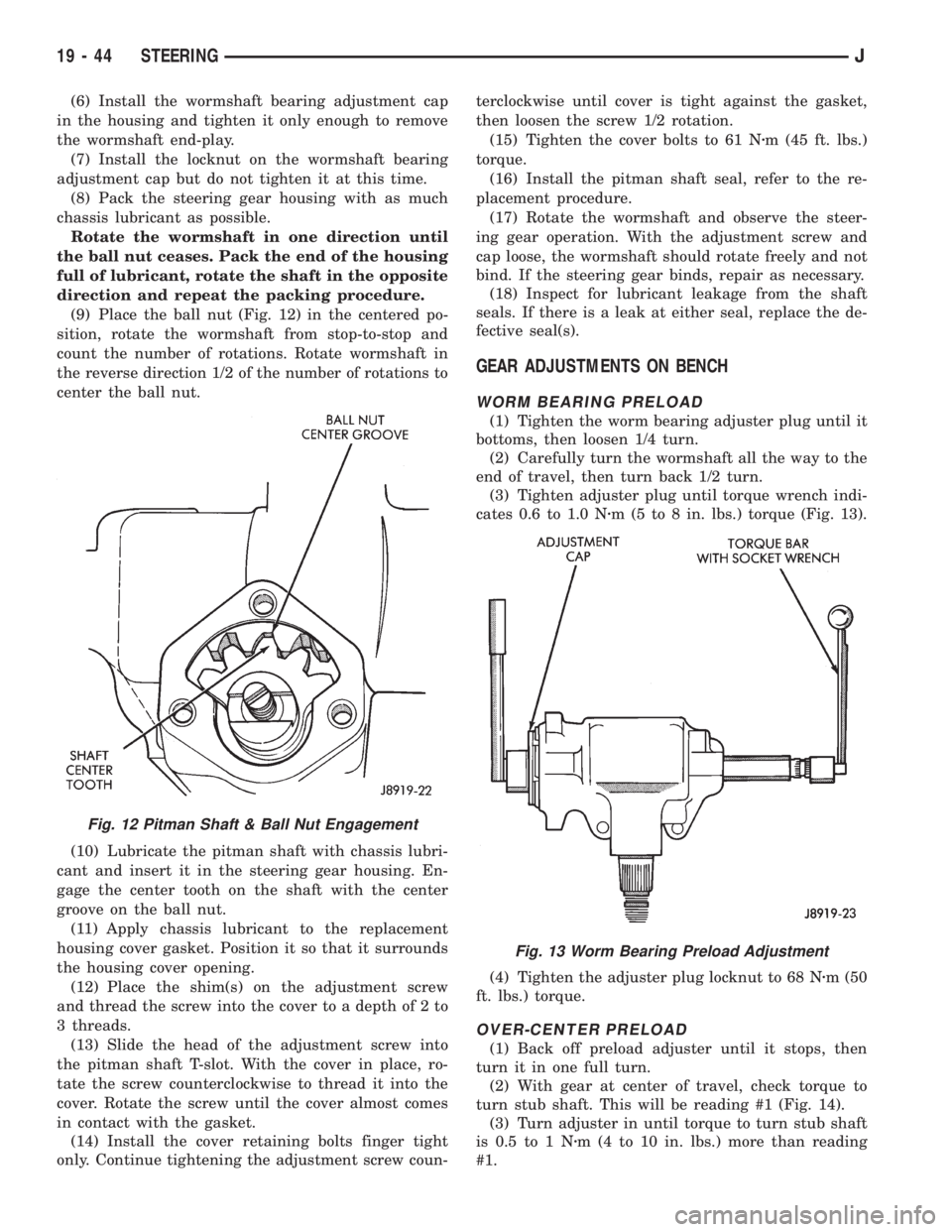

(9) Place the ball nut (Fig. 12) in the centered po-

sition, rotate the wormshaft from stop-to-stop and

count the number of rotations. Rotate wormshaft in

the reverse direction 1/2 of the number of rotations to

center the ball nut.

(10) Lubricate the pitman shaft with chassis lubri-

cant and insert it in the steering gear housing. En-

gage the center tooth on the shaft with the center

groove on the ball nut.

(11) Apply chassis lubricant to the replacement

housing cover gasket. Position it so that it surrounds

the housing cover opening.

(12) Place the shim(s) on the adjustment screw

and thread the screw into the cover to a depth of 2 to

3 threads.

(13) Slide the head of the adjustment screw into

the pitman shaft T-slot. With the cover in place, ro-

tate the screw counterclockwise to thread it into the

cover. Rotate the screw until the cover almost comes

in contact with the gasket.

(14) Install the cover retaining bolts finger tight

only. Continue tightening the adjustment screw coun-terclockwise until cover is tight against the gasket,

then loosen the screw 1/2 rotation.

(15) Tighten the cover bolts to 61 Nzm (45 ft. lbs.)

torque.

(16) Install the pitman shaft seal, refer to the re-

placement procedure.

(17) Rotate the wormshaft and observe the steer-

ing gear operation. With the adjustment screw and

cap loose, the wormshaft should rotate freely and not

bind. If the steering gear binds, repair as necessary.

(18) Inspect for lubricant leakage from the shaft

seals. If there is a leak at either seal, replace the de-

fective seal(s).

GEAR ADJUSTMENTS ON BENCH

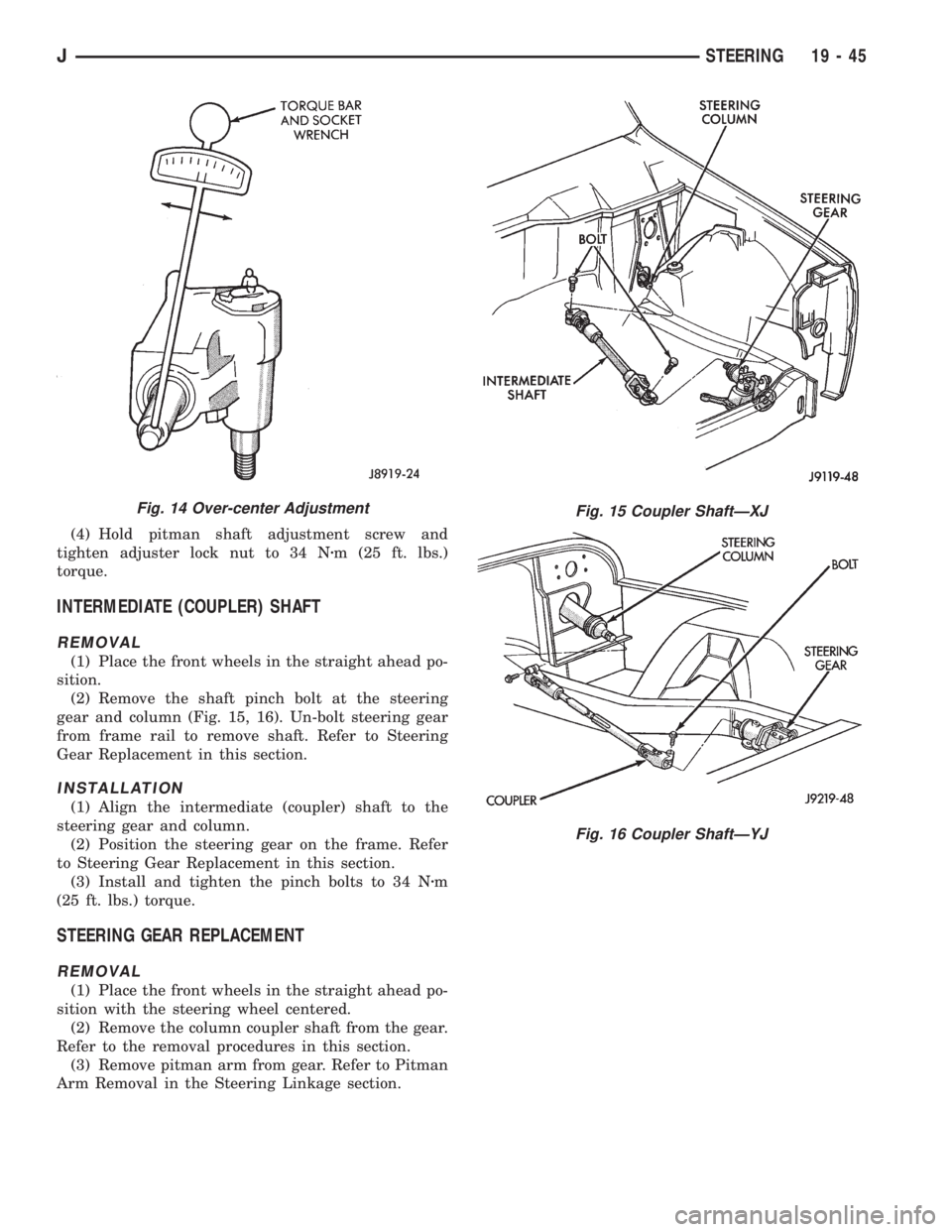

WORM BEARING PRELOAD

(1) Tighten the worm bearing adjuster plug until it

bottoms, then loosen 1/4 turn.

(2) Carefully turn the wormshaft all the way to the

end of travel, then turn back 1/2 turn.

(3) Tighten adjuster plug until torque wrench indi-

cates 0.6 to 1.0 Nzm (5 to 8 in. lbs.) torque (Fig. 13).

(4) Tighten the adjuster plug locknut to 68 Nzm (50

ft. lbs.) torque.

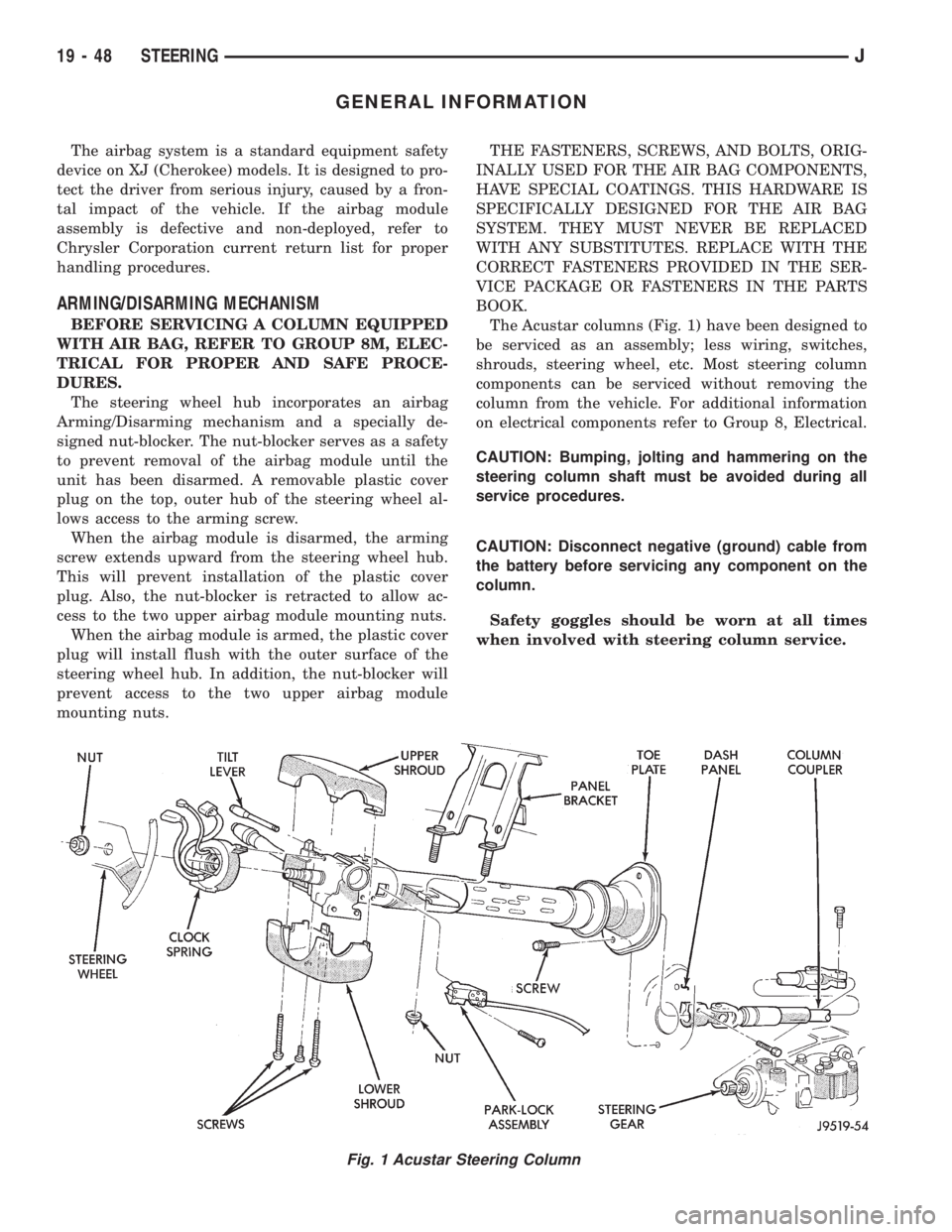

OVER-CENTER PRELOAD

(1) Back off preload adjuster until it stops, then

turn it in one full turn.

(2) With gear at center of travel, check torque to

turn stub shaft. This will be reading #1 (Fig. 14).

(3) Turn adjuster in until torque to turn stub shaft

is 0.5 to 1 Nzm (4 to 10 in. lbs.) more than reading

#1.

Fig. 12 Pitman Shaft & Ball Nut Engagement

Fig. 13 Worm Bearing Preload Adjustment

19 - 44 STEERINGJ

Page 1344 of 2198

(4) Hold pitman shaft adjustment screw and

tighten adjuster lock nut to 34 Nzm (25 ft. lbs.)

torque.

INTERMEDIATE (COUPLER) SHAFT

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition.

(2) Remove the shaft pinch bolt at the steering

gear and column (Fig. 15, 16). Un-bolt steering gear

from frame rail to remove shaft. Refer to Steering

Gear Replacement in this section.

INSTALLATION

(1) Align the intermediate (coupler) shaft to the

steering gear and column.

(2) Position the steering gear on the frame. Refer

to Steering Gear Replacement in this section.

(3) Install and tighten the pinch bolts to 34 Nzm

(25 ft. lbs.) torque.

STEERING GEAR REPLACEMENT

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition with the steering wheel centered.

(2) Remove the column coupler shaft from the gear.

Refer to the removal procedures in this section.

(3) Remove pitman arm from gear. Refer to Pitman

Arm Removal in the Steering Linkage section.

Fig. 14 Over-center AdjustmentFig. 15 Coupler ShaftÐXJ

Fig. 16 Coupler ShaftÐYJ

JSTEERING 19 - 45

Page 1347 of 2198

GENERAL INFORMATION

The airbag system is a standard equipment safety

device on XJ (Cherokee) models. It is designed to pro-

tect the driver from serious injury, caused by a fron-

tal impact of the vehicle. If the airbag module

assembly is defective and non-deployed, refer to

Chrysler Corporation current return list for proper

handling procedures.

ARMING/DISARMING MECHANISM

BEFORE SERVICING A COLUMN EQUIPPED

WITH AIR BAG, REFER TO GROUP 8M, ELEC-

TRICAL FOR PROPER AND SAFE PROCE-

DURES.

The steering wheel hub incorporates an airbag

Arming/Disarming mechanism and a specially de-

signed nut-blocker. The nut-blocker serves as a safety

to prevent removal of the airbag module until the

unit has been disarmed. A removable plastic cover

plug on the top, outer hub of the steering wheel al-

lows access to the arming screw.

When the airbag module is disarmed, the arming

screw extends upward from the steering wheel hub.

This will prevent installation of the plastic cover

plug. Also, the nut-blocker is retracted to allow ac-

cess to the two upper airbag module mounting nuts.

When the airbag module is armed, the plastic cover

plug will install flush with the outer surface of the

steering wheel hub. In addition, the nut-blocker will

prevent access to the two upper airbag module

mounting nuts.THE FASTENERS, SCREWS, AND BOLTS, ORIG-

INALLY USED FOR THE AIR BAG COMPONENTS,

HAVE SPECIAL COATINGS. THIS HARDWARE IS

SPECIFICALLY DESIGNED FOR THE AIR BAG

SYSTEM. THEY MUST NEVER BE REPLACED

WITH ANY SUBSTITUTES. REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SER-

VICE PACKAGE OR FASTENERS IN THE PARTS

BOOK.

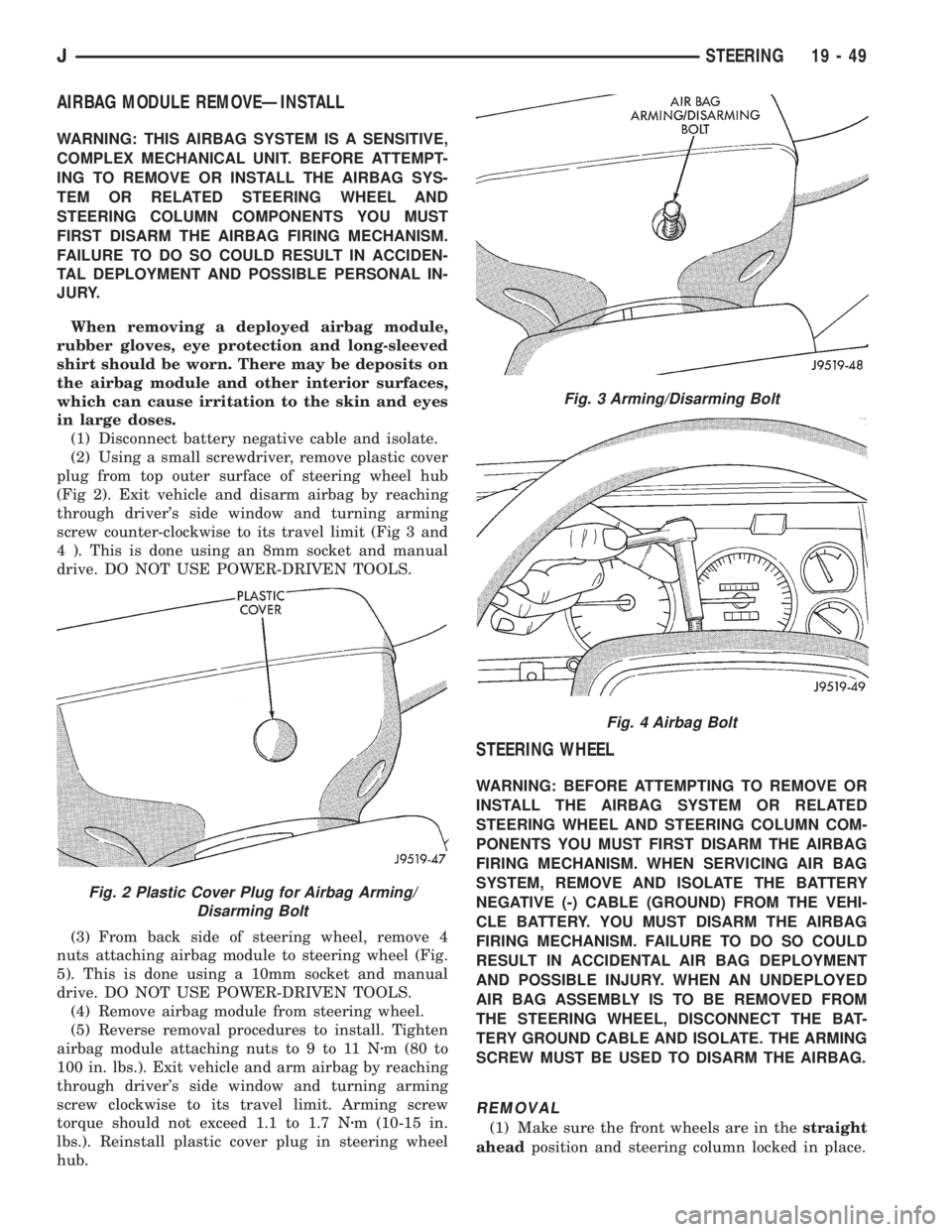

The Acustar columns (Fig. 1) have been designed to

be serviced as an assembly; less wiring, switches,

shrouds, steering wheel, etc. Most steering column

components can be serviced without removing the

column from the vehicle. For additional information

on electrical components refer to Group 8, Electrical.

CAUTION: Bumping, jolting and hammering on the

steering column shaft must be avoided during all

service procedures.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any component on the

column.

Safety goggles should be worn at all times

when involved with steering column service.

Fig. 1 Acustar Steering Column

19 - 48 STEERINGJ

Page 1348 of 2198

AIRBAG MODULE REMOVEÐINSTALL

WARNING: THIS AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX MECHANICAL UNIT. BEFORE ATTEMPT-

ING TO REMOVE OR INSTALL THE AIRBAG SYS-

TEM OR RELATED STEERING WHEEL AND

STEERING COLUMN COMPONENTS YOU MUST

FIRST DISARM THE AIRBAG FIRING MECHANISM.

FAILURE TO DO SO COULD RESULT IN ACCIDEN-

TAL DEPLOYMENT AND POSSIBLE PERSONAL IN-

JURY.

When removing a deployed airbag module,

rubber gloves, eye protection and long-sleeved

shirt should be worn. There may be deposits on

the airbag module and other interior surfaces,

which can cause irritation to the skin and eyes

in large doses.

(1) Disconnect battery negative cable and isolate.

(2) Using a small screwdriver, remove plastic cover

plug from top outer surface of steering wheel hub

(Fig 2). Exit vehicle and disarm airbag by reaching

through driver's side window and turning arming

screw counter-clockwise to its travel limit (Fig 3 and

4 ). This is done using an 8mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(3) From back side of steering wheel, remove 4

nuts attaching airbag module to steering wheel (Fig.

5). This is done using a 10mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(4) Remove airbag module from steering wheel.

(5) Reverse removal procedures to install. Tighten

airbag module attaching nuts to 9 to 11 Nzm (80 to

100 in. lbs.). Exit vehicle and arm airbag by reaching

through driver's side window and turning arming

screw clockwise to its travel limit. Arming screw

torque should not exceed 1.1 to 1.7 Nzm (10-15 in.

lbs.). Reinstall plastic cover plug in steering wheel

hub.

STEERING WHEEL

WARNING: BEFORE ATTEMPTING TO REMOVE OR

INSTALL THE AIRBAG SYSTEM OR RELATED

STEERING WHEEL AND STEERING COLUMN COM-

PONENTS YOU MUST FIRST DISARM THE AIRBAG

FIRING MECHANISM. WHEN SERVICING AIR BAG

SYSTEM, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. YOU MUST DISARM THE AIRBAG

FIRING MECHANISM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIR BAG DEPLOYMENT

AND POSSIBLE INJURY. WHEN AN UNDEPLOYED

AIR BAG ASSEMBLY IS TO BE REMOVED FROM

THE STEERING WHEEL, DISCONNECT THE BAT-

TERY GROUND CABLE AND ISOLATE. THE ARMING

SCREW MUST BE USED TO DISARM THE AIRBAG.

REMOVAL

(1) Make sure the front wheels are in thestraight

aheadposition and steering column locked in place.

Fig. 2 Plastic Cover Plug for Airbag Arming/

Disarming Bolt

Fig. 3 Arming/Disarming Bolt

Fig. 4 Airbag Bolt

JSTEERING 19 - 49

Page 1349 of 2198

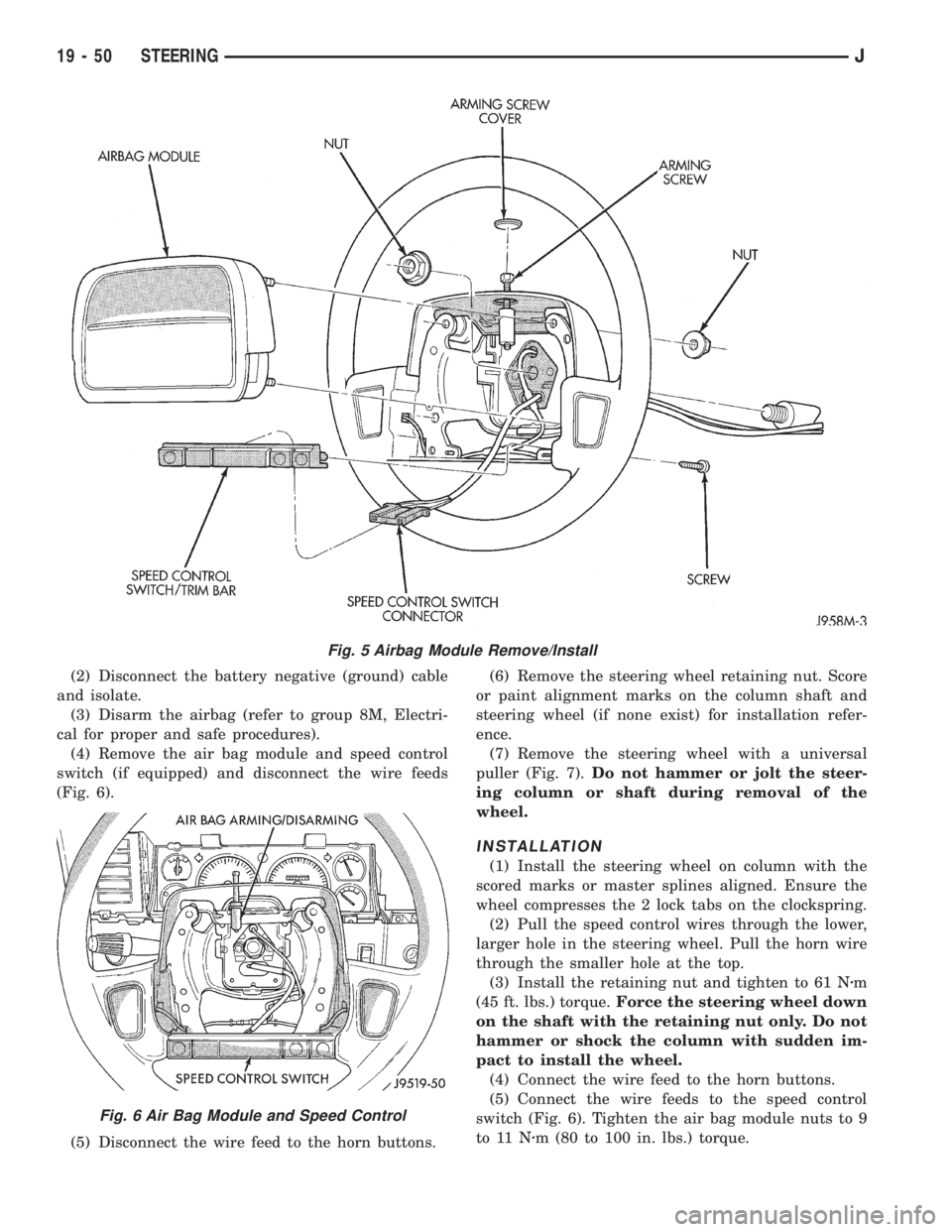

(2) Disconnect the battery negative (ground) cable

and isolate.

(3) Disarm the airbag (refer to group 8M, Electri-

cal for proper and safe procedures).

(4) Remove the air bag module and speed control

switch (if equipped) and disconnect the wire feeds

(Fig. 6).

(5) Disconnect the wire feed to the horn buttons.(6) Remove the steering wheel retaining nut. Score

or paint alignment marks on the column shaft and

steering wheel (if none exist) for installation refer-

ence.

(7) Remove the steering wheel with a universal

puller (Fig. 7).Do not hammer or jolt the steer-

ing column or shaft during removal of the

wheel.

INSTALLATION

(1) Install the steering wheel on column with the

scored marks or master splines aligned. Ensure the

wheel compresses the 2 lock tabs on the clockspring.

(2) Pull the speed control wires through the lower,

larger hole in the steering wheel. Pull the horn wire

through the smaller hole at the top.

(3) Install the retaining nut and tighten to 61 Nzm

(45 ft. lbs.) torque.Force the steering wheel down

on the shaft with the retaining nut only. Do not

hammer or shock the column with sudden im-

pact to install the wheel.

(4) Connect the wire feed to the horn buttons.

(5) Connect the wire feeds to the speed control

switch (Fig. 6). Tighten the air bag module nuts to 9

to 11 Nzm (80 to 100 in. lbs.) torque.

Fig. 5 Airbag Module Remove/Install

Fig. 6 Air Bag Module and Speed Control

19 - 50 STEERINGJ