engine JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1286 of 2198

SERVICE DIAGNOSIS

INDEX

page page

Runout.................................. 4

Unbalance............................... 3Universal Joint Angle Measurement............. 4

Vibration................................. 3

VIBRATION

Tires that are out-of-round or wheels that are un-

balanced will cause a low frequency vibration. Refer

to Group 22, Wheels and Tires for additional infor-

mation.

Brake drums that are unbalanced will cause a

harsh, low frequency vibration. Refer to Group 5,

Brakes for additional information.

Driveline vibration can also result from loose or

damaged engine mounts. Refer to Group 21, Trans-

missions for additional information.

Propeller shaft vibration will increase as the vehi-

cle speed is increased. A vibration that occurs within

a specific speed range is not caused by propeller

shaft unbalance. Defective universal joints or an in-

correct propeller shaft angle are usually the cause.

UNBALANCE

If propeller shaft unbalance is suspected, it can be

verified with the following procedure.

Removing and re-indexing the propeller shaft

180É may eliminate some vibrations.

²Clean all the foreign material from the propeller

shaft and the universal joints.²Inspect the propeller shaft for missing balance

weights, broken welds, and bent areas.If the pro-

peller shaft is bent, it must be replaced.

²Ensure the universal joints are not worn, are prop-

erly installed, and are correctly aligned with the

shaft.

²Check the universal joint clamp screws torque

(1) Raise the vehicle.

(2) Remove the wheel and tires assembly. Install

the wheel lug nuts to retain the brake drums.

(3) Mark and number the shaft six inches from the

yoke end at four positions 90É apart.

(4) Run and accelerate the vehicle until vibration

occurs. Note the intensity and speed the vibration oc-

curred. Stop the engine.

(5) Install a screw clamp at position 1 (Fig. 1).

(6) Start the engine and re-check for vibration. If

there is little or no change in vibration, move the

clamp to one of the other three positions. Repeat the

vibration test.

(7) If there is no difference in vibration at the

other positions, the vibration may not be propshaft

unbalance.

DRIVELINE VIBRATION

JPROPELLER SHAFTS 16 - 3

Page 1288 of 2198

²Have at least a 1/2 degree continuous operating

(propeller shaft) angle

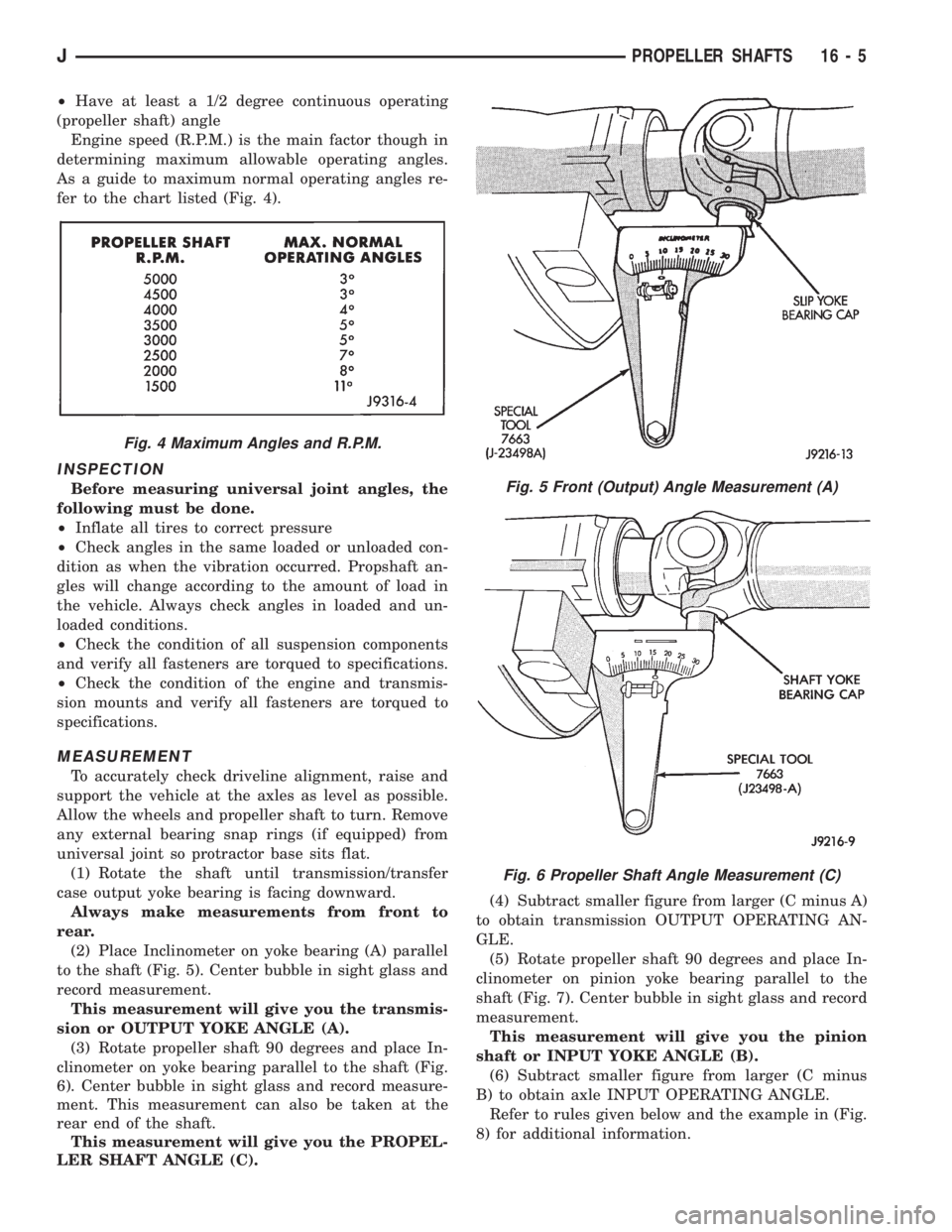

Engine speed (R.P.M.) is the main factor though in

determining maximum allowable operating angles.

As a guide to maximum normal operating angles re-

fer to the chart listed (Fig. 4).

INSPECTION

Before measuring universal joint angles, the

following must be done.

²Inflate all tires to correct pressure

²Check angles in the same loaded or unloaded con-

dition as when the vibration occurred. Propshaft an-

gles will change according to the amount of load in

the vehicle. Always check angles in loaded and un-

loaded conditions.

²Check the condition of all suspension components

and verify all fasteners are torqued to specifications.

²Check the condition of the engine and transmis-

sion mounts and verify all fasteners are torqued to

specifications.

MEASUREMENT

To accurately check driveline alignment, raise and

support the vehicle at the axles as level as possible.

Allow the wheels and propeller shaft to turn. Remove

any external bearing snap rings (if equipped) from

universal joint so protractor base sits flat.

(1) Rotate the shaft until transmission/transfer

case output yoke bearing is facing downward.

Always make measurements from front to

rear.

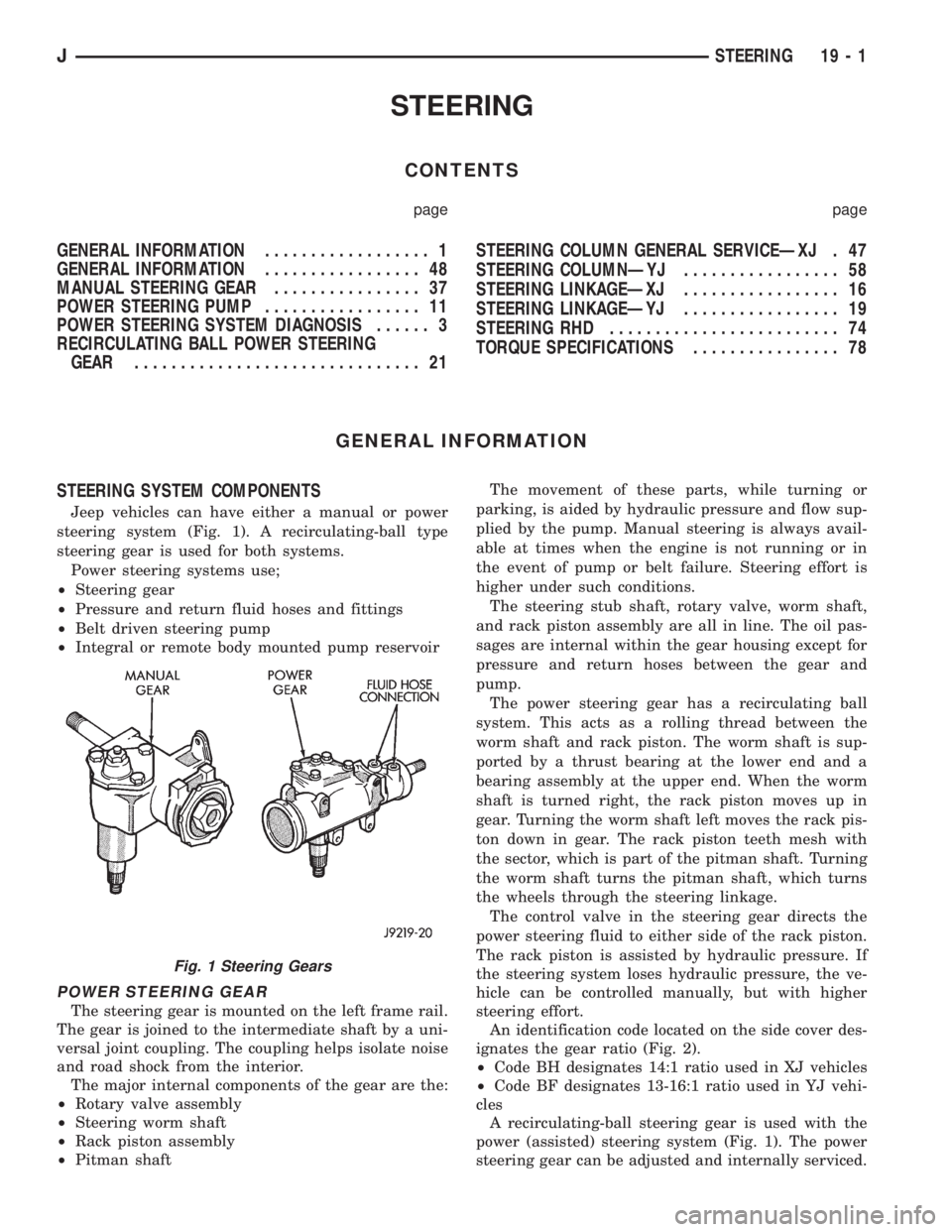

(2) Place Inclinometer on yoke bearing (A) parallel

to the shaft (Fig. 5). Center bubble in sight glass and

record measurement.

This measurement will give you the transmis-

sion or OUTPUT YOKE ANGLE (A).

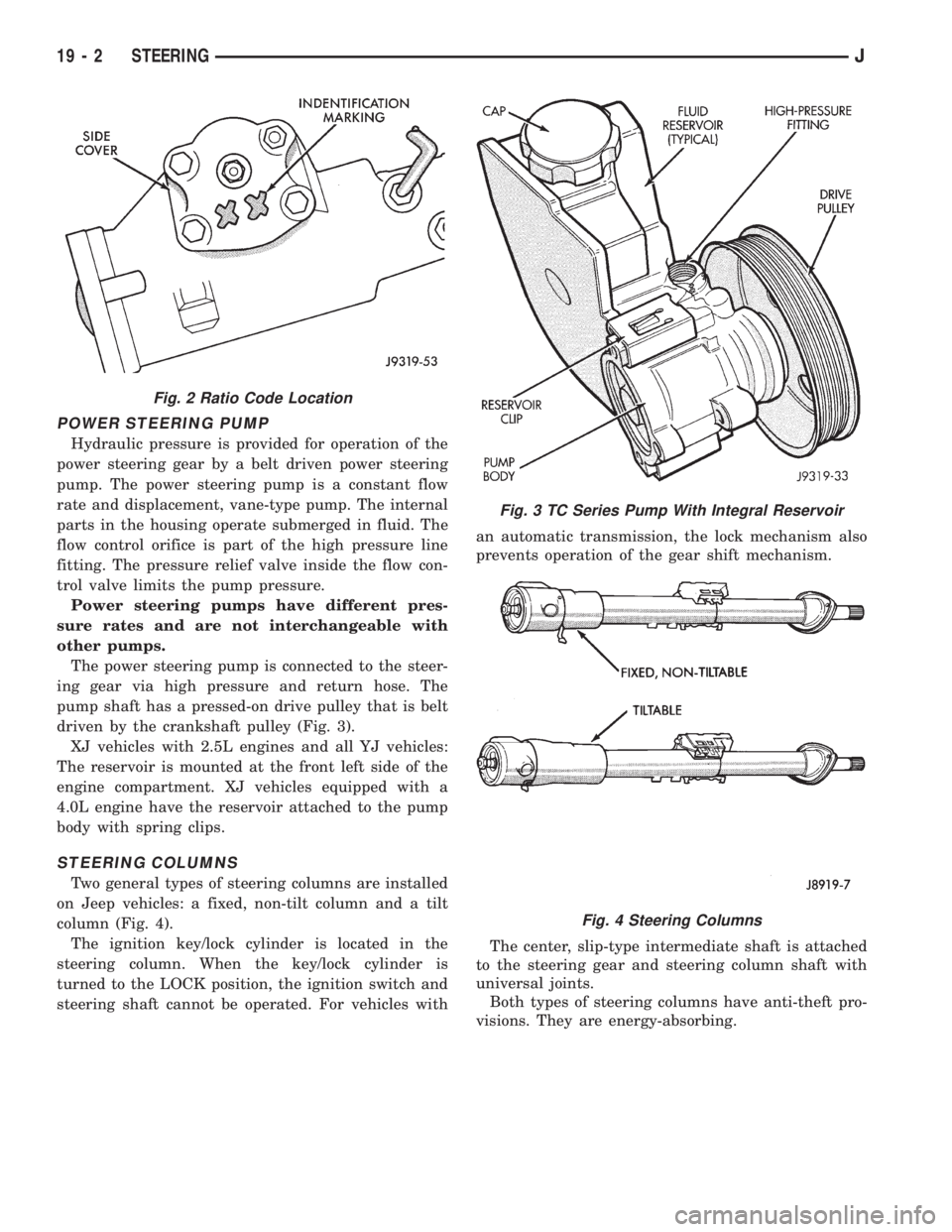

(3) Rotate propeller shaft 90 degrees and place In-

clinometer on yoke bearing parallel to the shaft (Fig.

6). Center bubble in sight glass and record measure-

ment. This measurement can also be taken at the

rear end of the shaft.

This measurement will give you the PROPEL-

LER SHAFT ANGLE (C).(4) Subtract smaller figure from larger (C minus A)

to obtain transmission OUTPUT OPERATING AN-

GLE.

(5) Rotate propeller shaft 90 degrees and place In-

clinometer on pinion yoke bearing parallel to the

shaft (Fig. 7). Center bubble in sight glass and record

measurement.

This measurement will give you the pinion

shaft or INPUT YOKE ANGLE (B).

(6) Subtract smaller figure from larger (C minus

B) to obtain axle INPUT OPERATING ANGLE.

Refer to rules given below and the example in (Fig.

8) for additional information.

Fig. 4 Maximum Angles and R.P.M.

Fig. 5 Front (Output) Angle Measurement (A)

Fig. 6 Propeller Shaft Angle Measurement (C)

JPROPELLER SHAFTS 16 - 5

Page 1300 of 2198

STEERING

CONTENTS

page page

GENERAL INFORMATION.................. 1

GENERAL INFORMATION................. 48

MANUAL STEERING GEAR................ 37

POWER STEERING PUMP................. 11

POWER STEERING SYSTEM DIAGNOSIS...... 3

RECIRCULATING BALL POWER STEERING

GEAR............................... 21STEERING COLUMN GENERAL SERVICEÐXJ . 47

STEERING COLUMNÐYJ................. 58

STEERING LINKAGEÐXJ................. 16

STEERING LINKAGEÐYJ................. 19

STEERING RHD......................... 74

TORQUE SPECIFICATIONS................ 78

GENERAL INFORMATION

STEERING SYSTEM COMPONENTS

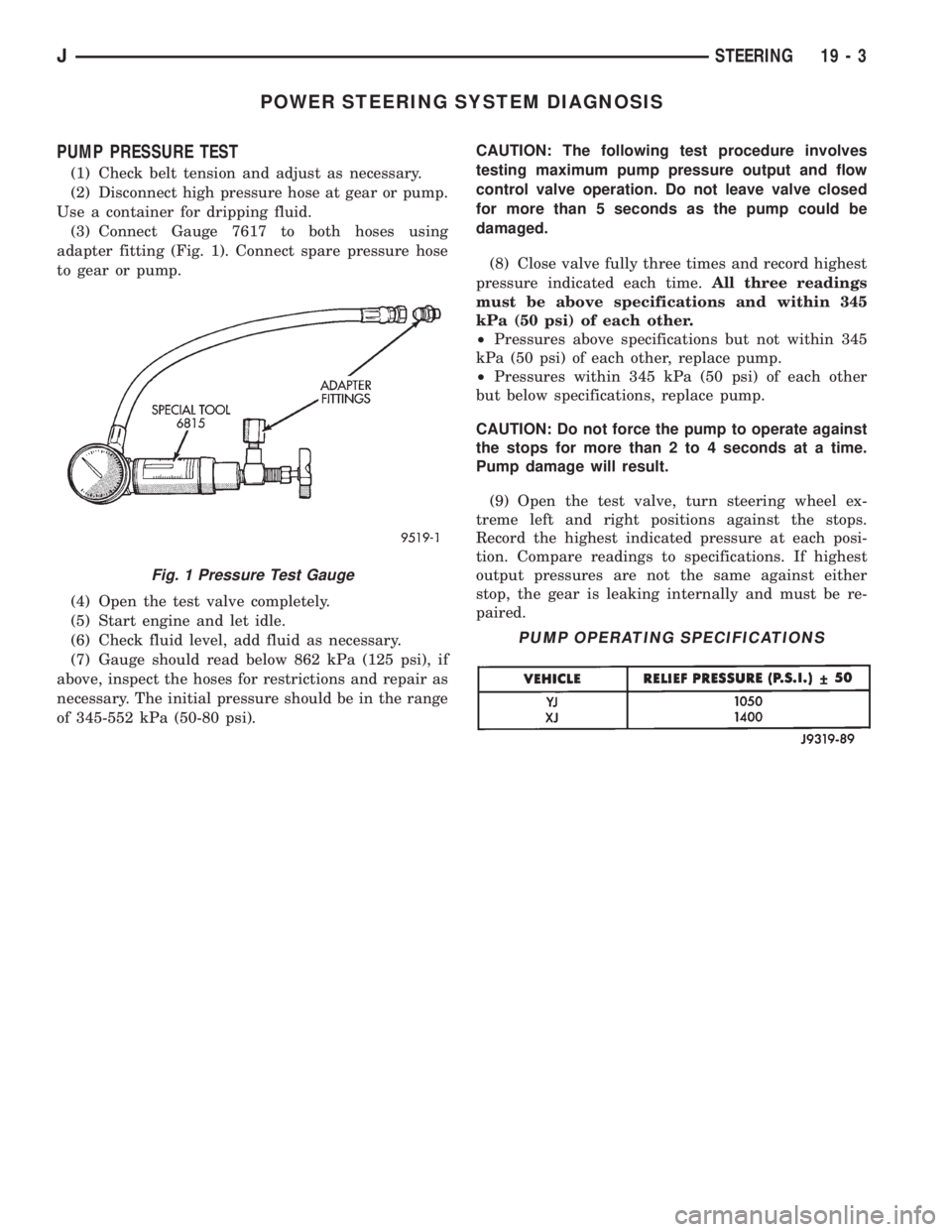

Jeep vehicles can have either a manual or power

steering system (Fig. 1). A recirculating-ball type

steering gear is used for both systems.

Power steering systems use;

²Steering gear

²Pressure and return fluid hoses and fittings

²Belt driven steering pump

²Integral or remote body mounted pump reservoir

POWER STEERING GEAR

The steering gear is mounted on the left frame rail.

The gear is joined to the intermediate shaft by a uni-

versal joint coupling. The coupling helps isolate noise

and road shock from the interior.

The major internal components of the gear are the:

²Rotary valve assembly

²Steering worm shaft

²Rack piston assembly

²Pitman shaftThe movement of these parts, while turning or

parking, is aided by hydraulic pressure and flow sup-

plied by the pump. Manual steering is always avail-

able at times when the engine is not running or in

the event of pump or belt failure. Steering effort is

higher under such conditions.

The steering stub shaft, rotary valve, worm shaft,

and rack piston assembly are all in line. The oil pas-

sages are internal within the gear housing except for

pressure and return hoses between the gear and

pump.

The power steering gear has a recirculating ball

system. This acts as a rolling thread between the

worm shaft and rack piston. The worm shaft is sup-

ported by a thrust bearing at the lower end and a

bearing assembly at the upper end. When the worm

shaft is turned right, the rack piston moves up in

gear. Turning the worm shaft left moves the rack pis-

ton down in gear. The rack piston teeth mesh with

the sector, which is part of the pitman shaft. Turning

the worm shaft turns the pitman shaft, which turns

the wheels through the steering linkage.

The control valve in the steering gear directs the

power steering fluid to either side of the rack piston.

The rack piston is assisted by hydraulic pressure. If

the steering system loses hydraulic pressure, the ve-

hicle can be controlled manually, but with higher

steering effort.

An identification code located on the side cover des-

ignates the gear ratio (Fig. 2).

²Code BH designates 14:1 ratio used in XJ vehicles

²Code BF designates 13-16:1 ratio used in YJ vehi-

cles

A recirculating-ball steering gear is used with the

power (assisted) steering system (Fig. 1). The power

steering gear can be adjusted and internally serviced.

Fig. 1 Steering Gears

JSTEERING 19 - 1

Page 1301 of 2198

POWER STEERING PUMP

Hydraulic pressure is provided for operation of the

power steering gear by a belt driven power steering

pump. The power steering pump is a constant flow

rate and displacement, vane-type pump. The internal

parts in the housing operate submerged in fluid. The

flow control orifice is part of the high pressure line

fitting. The pressure relief valve inside the flow con-

trol valve limits the pump pressure.

Power steering pumps have different pres-

sure rates and are not interchangeable with

other pumps.

The power steering pump is connected to the steer-

ing gear via high pressure and return hose. The

pump shaft has a pressed-on drive pulley that is belt

driven by the crankshaft pulley (Fig. 3).

XJ vehicles with 2.5L engines and all YJ vehicles:

The reservoir is mounted at the front left side of the

engine compartment. XJ vehicles equipped with a

4.0L engine have the reservoir attached to the pump

body with spring clips.

STEERING COLUMNS

Two general types of steering columns are installed

on Jeep vehicles: a fixed, non-tilt column and a tilt

column (Fig. 4).

The ignition key/lock cylinder is located in the

steering column. When the key/lock cylinder is

turned to the LOCK position, the ignition switch and

steering shaft cannot be operated. For vehicles withan automatic transmission, the lock mechanism also

prevents operation of the gear shift mechanism.

The center, slip-type intermediate shaft is attached

to the steering gear and steering column shaft with

universal joints.

Both types of steering columns have anti-theft pro-

visions. They are energy-absorbing.

Fig. 2 Ratio Code Location

Fig. 3 TC Series Pump With Integral Reservoir

Fig. 4 Steering Columns

19 - 2 STEERINGJ

Page 1302 of 2198

POWER STEERING SYSTEM DIAGNOSIS

PUMP PRESSURE TEST

(1) Check belt tension and adjust as necessary.

(2) Disconnect high pressure hose at gear or pump.

Use a container for dripping fluid.

(3) Connect Gauge 7617 to both hoses using

adapter fitting (Fig. 1). Connect spare pressure hose

to gear or pump.

(4) Open the test valve completely.

(5) Start engine and let idle.

(6) Check fluid level, add fluid as necessary.

(7) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the range

of 345-552 kPa (50-80 psi).CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than 5 seconds as the pump could be

damaged.

(8) Close valve fully three times and record highest

pressure indicated each time.All three readings

must be above specifications and within 345

kPa (50 psi) of each other.

²Pressures above specifications but not within 345

kPa (50 psi) of each other, replace pump.

²Pressures within 345 kPa (50 psi) of each other

but below specifications, replace pump.

CAUTION: Do not force the pump to operate against

the stops for more than 2 to 4 seconds at a time.

Pump damage will result.

(9) Open the test valve, turn steering wheel ex-

treme left and right positions against the stops.

Record the highest indicated pressure at each posi-

tion. Compare readings to specifications. If highest

output pressures are not the same against either

stop, the gear is leaking internally and must be re-

paired.

Fig. 1 Pressure Test Gauge

PUMP OPERATING SPECIFICATIONS

JSTEERING 19 - 3

Page 1310 of 2198

POWER STEERING PUMP

INDEX

page page

Drive Pulley Replacement................... 13

Flow Control Valve Fitting O-Ring Seal......... 14

Power Steering PumpÐInitial Operation........ 15

Pressure and Return Hose Replacement........ 11Pump Replacement........................ 12

Reservoir Replacement..................... 14

Service Information........................ 11

SERVICE INFORMATION

The power steering pump internal components are

not serviced or adjusted. If a malfunction or an inter-

nal fluid leak occurs, the complete unit must be re-

placed. A reservoir, cap, and O-ring seal kit are the

only service components available.

PRESSURE AND RETURN HOSE REPLACEMENT

Cap hose open ends and pump/steering gear fit-

tings to prevent entry of foreign material.

WARNING: POWER STEERING FLUID (AND PUMP

COMPONENTS) AND THE EXHAUST SYSTEM CAN

BE EXTREMELY HOT IF THE ENGINE HAS BEEN

RECENTLY OPERATING. DO NOT START THE EN-

GINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW THE HOSES TO TOUCH A

HOT EXHAUST MANIFOLD OR THE CATALYTIC

CONVERTER.

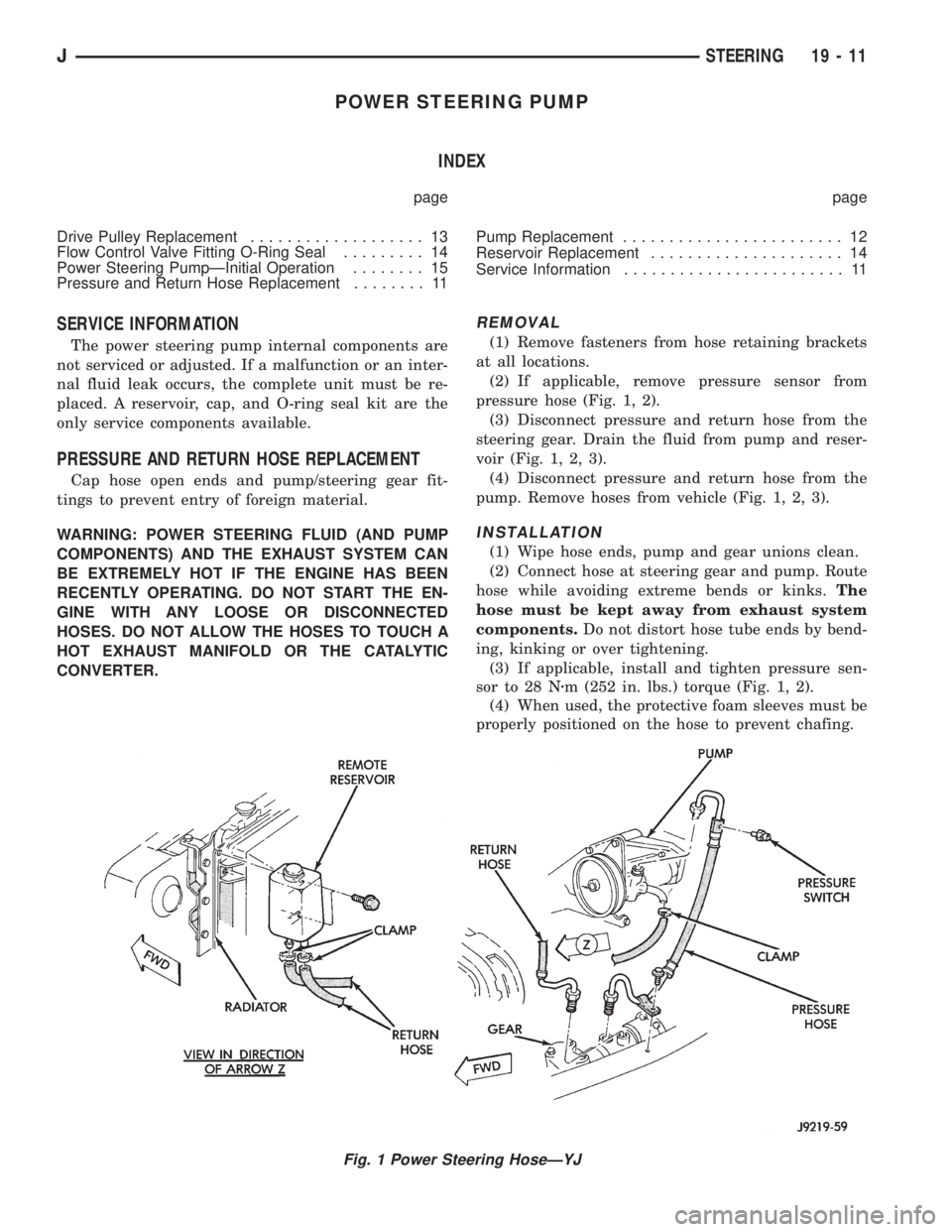

REMOVAL

(1) Remove fasteners from hose retaining brackets

at all locations.

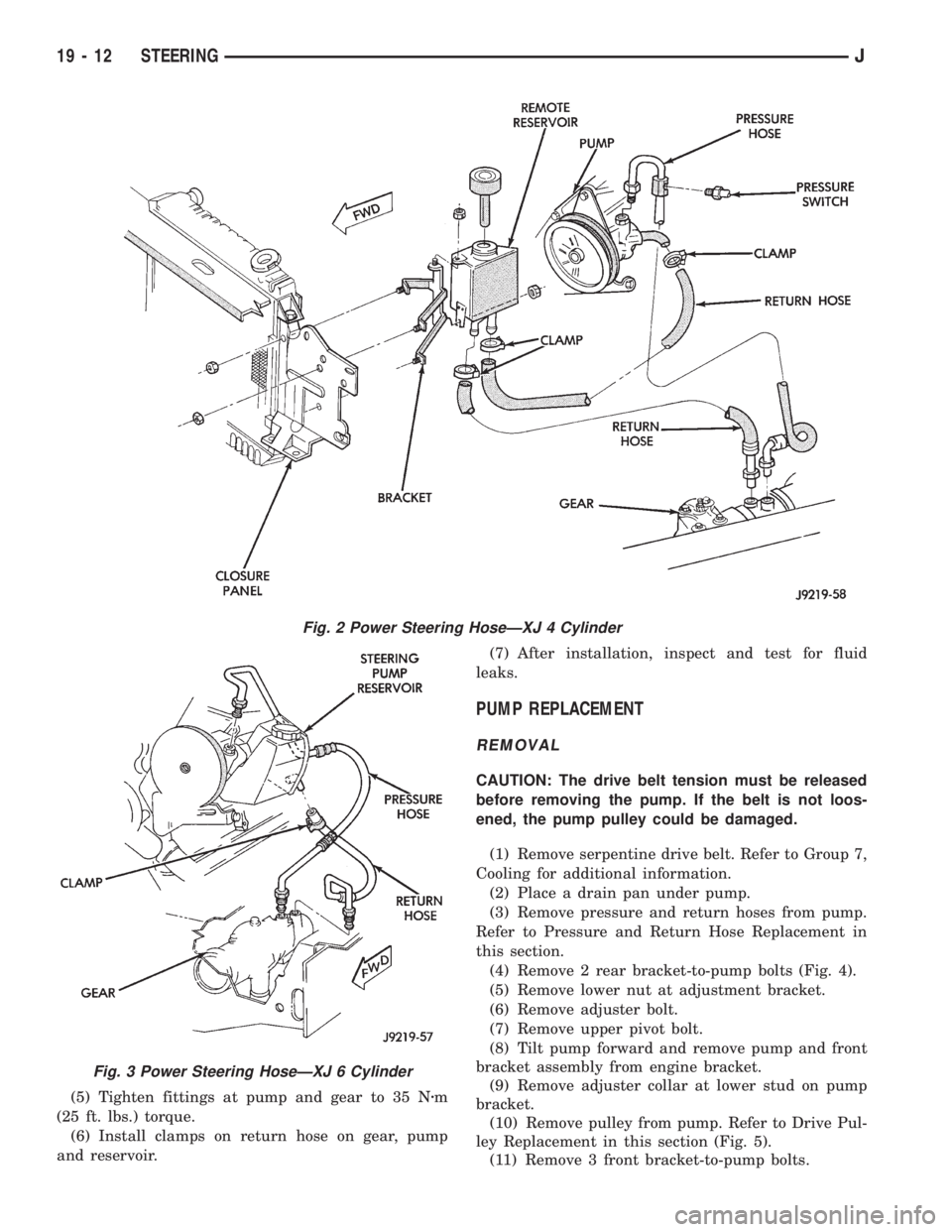

(2) If applicable, remove pressure sensor from

pressure hose (Fig. 1, 2).

(3) Disconnect pressure and return hose from the

steering gear. Drain the fluid from pump and reser-

voir (Fig. 1, 2, 3).

(4) Disconnect pressure and return hose from the

pump. Remove hoses from vehicle (Fig. 1, 2, 3).

INSTALLATION

(1) Wipe hose ends, pump and gear unions clean.

(2) Connect hose at steering gear and pump. Route

hose while avoiding extreme bends or kinks.The

hose must be kept away from exhaust system

components.Do not distort hose tube ends by bend-

ing, kinking or over tightening.

(3) If applicable, install and tighten pressure sen-

sor to 28 Nzm (252 in. lbs.) torque (Fig. 1, 2).

(4) When used, the protective foam sleeves must be

properly positioned on the hose to prevent chafing.

Fig. 1 Power Steering HoseÐYJ

JSTEERING 19 - 11

Page 1311 of 2198

(5) Tighten fittings at pump and gear to 35 Nzm

(25 ft. lbs.) torque.

(6) Install clamps on return hose on gear, pump

and reservoir.(7) After installation, inspect and test for fluid

leaks.

PUMP REPLACEMENT

REMOVAL

CAUTION: The drive belt tension must be released

before removing the pump. If the belt is not loos-

ened, the pump pulley could be damaged.

(1) Remove serpentine drive belt. Refer to Group 7,

Cooling for additional information.

(2) Place a drain pan under pump.

(3) Remove pressure and return hoses from pump.

Refer to Pressure and Return Hose Replacement in

this section.

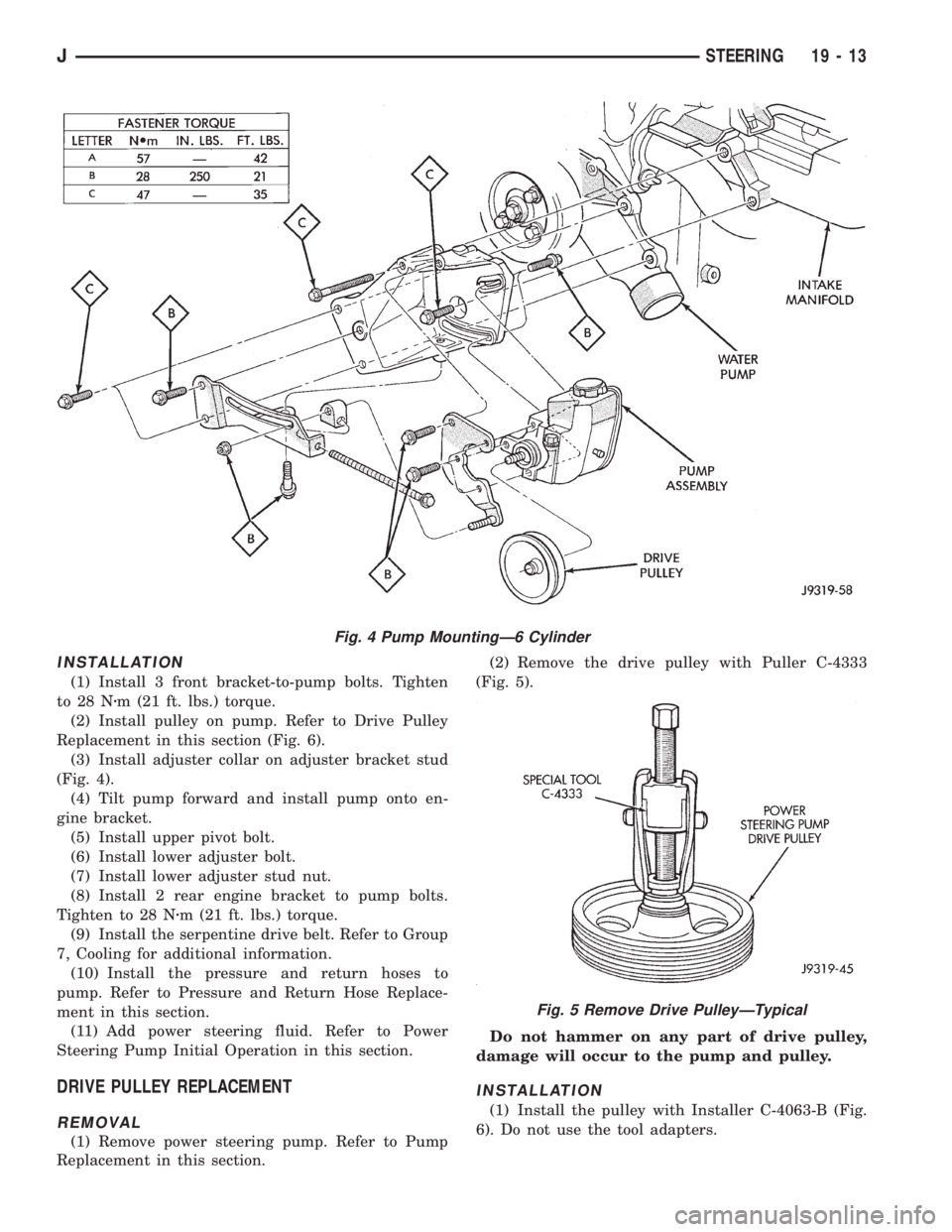

(4) Remove 2 rear bracket-to-pump bolts (Fig. 4).

(5) Remove lower nut at adjustment bracket.

(6) Remove adjuster bolt.

(7) Remove upper pivot bolt.

(8) Tilt pump forward and remove pump and front

bracket assembly from engine bracket.

(9) Remove adjuster collar at lower stud on pump

bracket.

(10) Remove pulley from pump. Refer to Drive Pul-

ley Replacement in this section (Fig. 5).

(11) Remove 3 front bracket-to-pump bolts.

Fig. 2 Power Steering HoseÐXJ 4 Cylinder

Fig. 3 Power Steering HoseÐXJ 6 Cylinder

19 - 12 STEERINGJ

Page 1312 of 2198

INSTALLATION

(1) Install 3 front bracket-to-pump bolts. Tighten

to 28 Nzm (21 ft. lbs.) torque.

(2) Install pulley on pump. Refer to Drive Pulley

Replacement in this section (Fig. 6).

(3) Install adjuster collar on adjuster bracket stud

(Fig. 4).

(4) Tilt pump forward and install pump onto en-

gine bracket.

(5) Install upper pivot bolt.

(6) Install lower adjuster bolt.

(7) Install lower adjuster stud nut.

(8) Install 2 rear engine bracket to pump bolts.

Tighten to 28 Nzm (21 ft. lbs.) torque.

(9) Install the serpentine drive belt. Refer to Group

7, Cooling for additional information.

(10) Install the pressure and return hoses to

pump. Refer to Pressure and Return Hose Replace-

ment in this section.

(11) Add power steering fluid. Refer to Power

Steering Pump Initial Operation in this section.

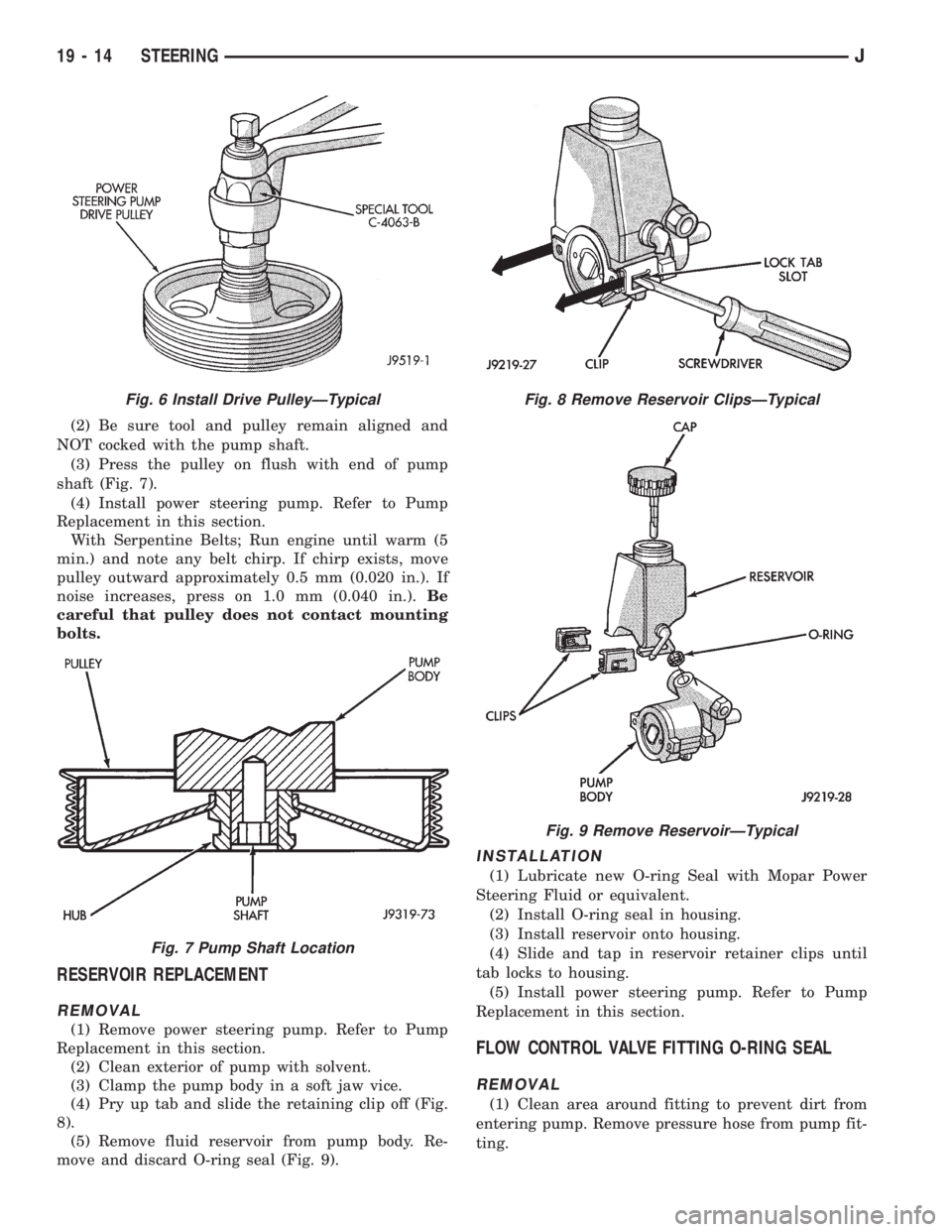

DRIVE PULLEY REPLACEMENT

REMOVAL

(1) Remove power steering pump. Refer to Pump

Replacement in this section.(2) Remove the drive pulley with Puller C-4333

(Fig. 5).

Do not hammer on any part of drive pulley,

damage will occur to the pump and pulley.

INSTALLATION

(1) Install the pulley with Installer C-4063-B (Fig.

6). Do not use the tool adapters.

Fig. 4 Pump MountingÐ6 Cylinder

Fig. 5 Remove Drive PulleyÐTypical

JSTEERING 19 - 13

Page 1313 of 2198

(2) Be sure tool and pulley remain aligned and

NOT cocked with the pump shaft.

(3) Press the pulley on flush with end of pump

shaft (Fig. 7).

(4) Install power steering pump. Refer to Pump

Replacement in this section.

With Serpentine Belts; Run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If

noise increases, press on 1.0 mm (0.040 in.).Be

careful that pulley does not contact mounting

bolts.

RESERVOIR REPLACEMENT

REMOVAL

(1) Remove power steering pump. Refer to Pump

Replacement in this section.

(2) Clean exterior of pump with solvent.

(3) Clamp the pump body in a soft jaw vice.

(4) Pry up tab and slide the retaining clip off (Fig.

8).

(5) Remove fluid reservoir from pump body. Re-

move and discard O-ring seal (Fig. 9).

INSTALLATION

(1) Lubricate new O-ring Seal with Mopar Power

Steering Fluid or equivalent.

(2) Install O-ring seal in housing.

(3) Install reservoir onto housing.

(4) Slide and tap in reservoir retainer clips until

tab locks to housing.

(5) Install power steering pump. Refer to Pump

Replacement in this section.

FLOW CONTROL VALVE FITTING O-RING SEAL

REMOVAL

(1) Clean area around fitting to prevent dirt from

entering pump. Remove pressure hose from pump fit-

ting.

Fig. 6 Install Drive PulleyÐTypical

Fig. 7 Pump Shaft Location

Fig. 8 Remove Reservoir ClipsÐTypical

Fig. 9 Remove ReservoirÐTypical

19 - 14 STEERINGJ

Page 1314 of 2198

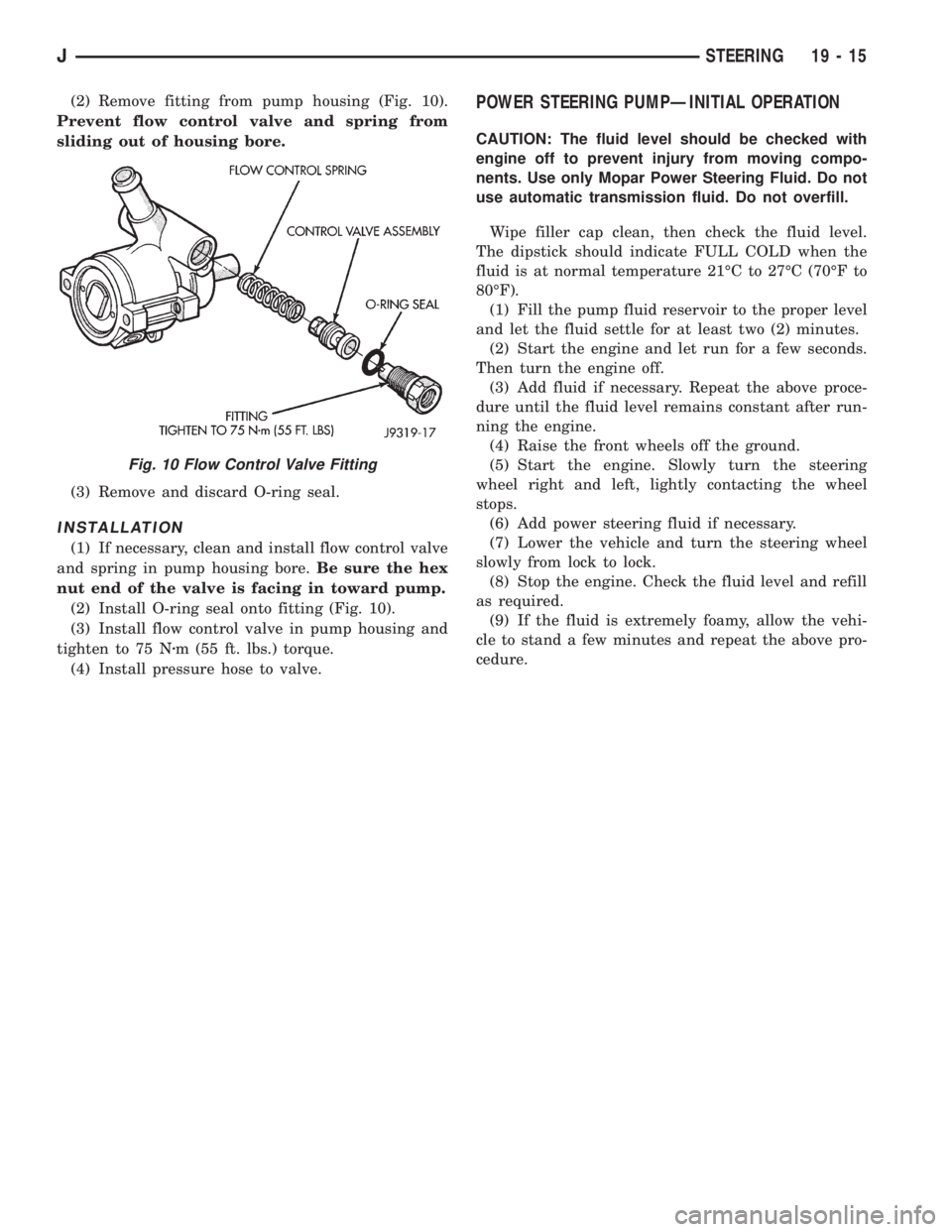

(2) Remove fitting from pump housing (Fig. 10).

Prevent flow control valve and spring from

sliding out of housing bore.

(3) Remove and discard O-ring seal.

INSTALLATION

(1) If necessary, clean and install flow control valve

and spring in pump housing bore.Be sure the hex

nut end of the valve is facing in toward pump.

(2) Install O-ring seal onto fitting (Fig. 10).

(3) Install flow control valve in pump housing and

tighten to 75 Nzm (55 ft. lbs.) torque.

(4) Install pressure hose to valve.

POWER STEERING PUMPÐINITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only Mopar Power Steering Fluid. Do not

use automatic transmission fluid. Do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicate FULL COLD when the

fluid is at normal temperature 21ÉC to 27ÉC (70ÉF to

80ÉF).

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two (2) minutes.

(2) Start the engine and let run for a few seconds.

Then turn the engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops.

(6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(8) Stop the engine. Check the fluid level and refill

as required.

(9) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

Fig. 10 Flow Control Valve Fitting

JSTEERING 19 - 15