Compressor JEEP CHEROKEE 1995 Service Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1512 of 2198

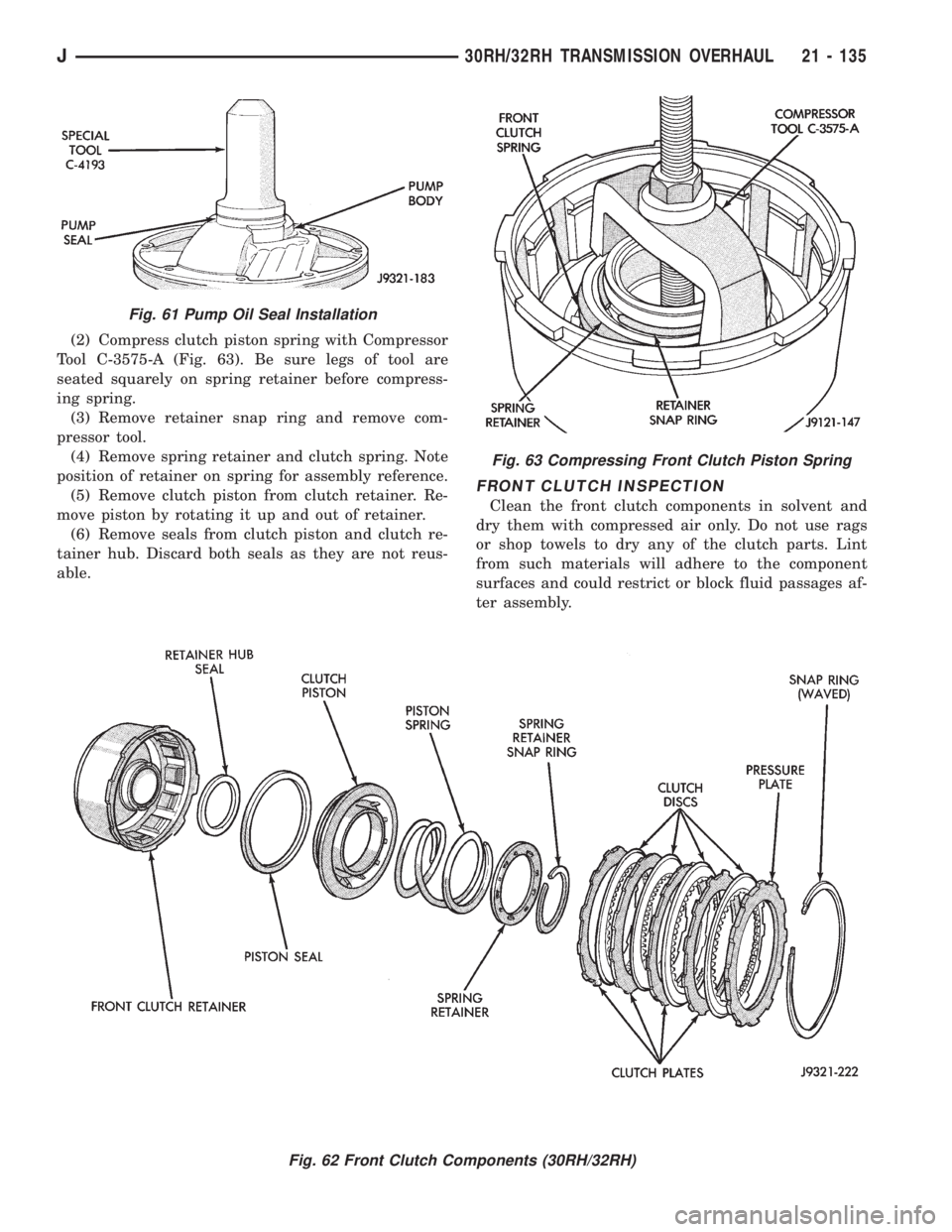

(2) Compress clutch piston spring with Compressor

Tool C-3575-A (Fig. 63). Be sure legs of tool are

seated squarely on spring retainer before compress-

ing spring.

(3) Remove retainer snap ring and remove com-

pressor tool.

(4) Remove spring retainer and clutch spring. Note

position of retainer on spring for assembly reference.

(5) Remove clutch piston from clutch retainer. Re-

move piston by rotating it up and out of retainer.

(6) Remove seals from clutch piston and clutch re-

tainer hub. Discard both seals as they are not reus-

able.

FRONT CLUTCH INSPECTION

Clean the front clutch components in solvent and

dry them with compressed air only. Do not use rags

or shop towels to dry any of the clutch parts. Lint

from such materials will adhere to the component

surfaces and could restrict or block fluid passages af-

ter assembly.

Fig. 63 Compressing Front Clutch Piston Spring

Fig. 62 Front Clutch Components (30RH/32RH)

Fig. 61 Pump Oil Seal Installation

J30RH/32RH TRANSMISSION OVERHAUL 21 - 135

Page 1532 of 2198

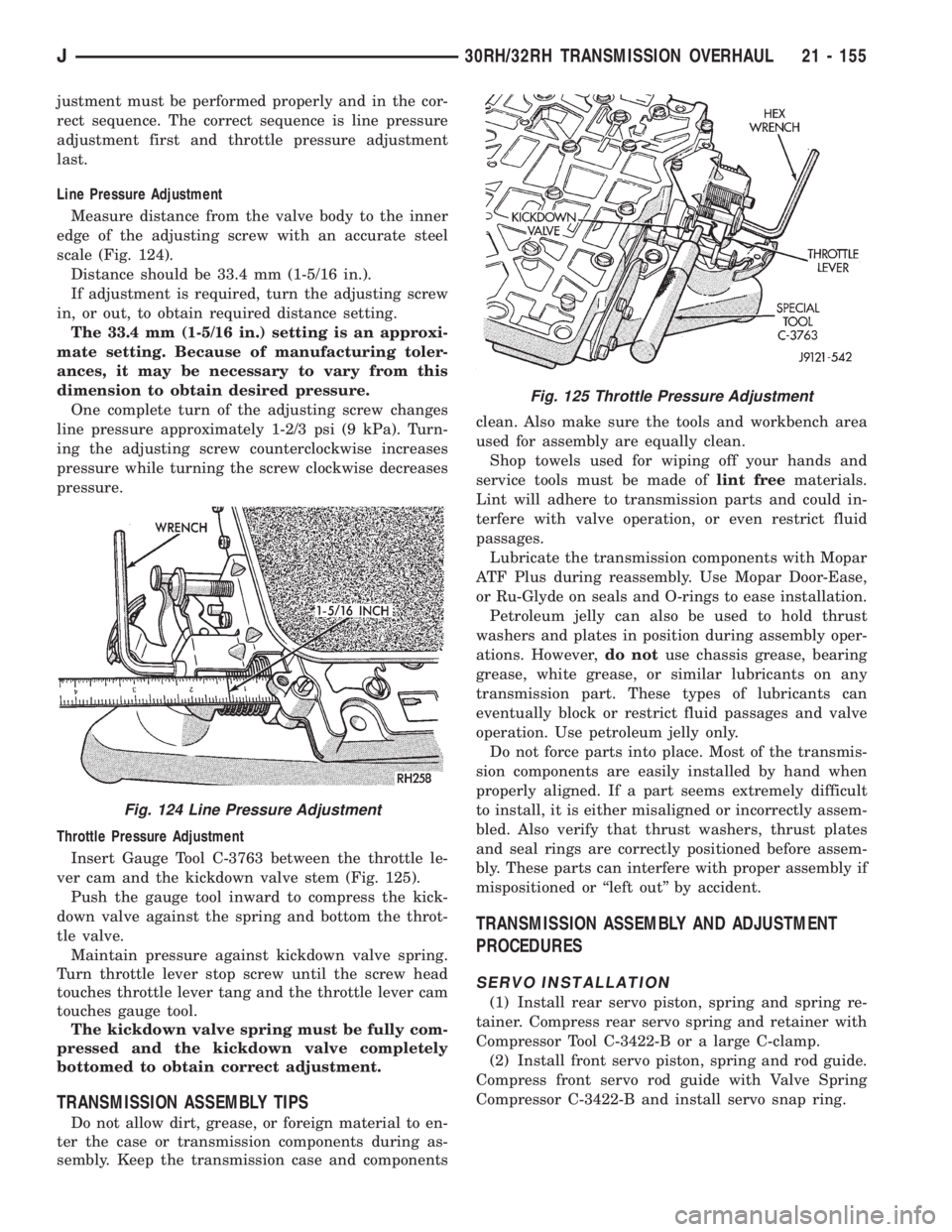

justment must be performed properly and in the cor-

rect sequence. The correct sequence is line pressure

adjustment first and throttle pressure adjustment

last.

Line Pressure Adjustment

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 124).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

The 33.4 mm (1-5/16 in.) setting is an approxi-

mate setting. Because of manufacturing toler-

ances, it may be necessary to vary from this

dimension to obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa). Turn-

ing the adjusting screw counterclockwise increases

pressure while turning the screw clockwise decreases

pressure.

Throttle Pressure Adjustment

Insert Gauge Tool C-3763 between the throttle le-

ver cam and the kickdown valve stem (Fig. 125).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

The kickdown valve spring must be fully com-

pressed and the kickdown valve completely

bottomed to obtain correct adjustment.

TRANSMISSION ASSEMBLY TIPS

Do not allow dirt, grease, or foreign material to en-

ter the case or transmission components during as-

sembly. Keep the transmission case and componentsclean. Also make sure the tools and workbench area

used for assembly are equally clean.

Shop towels used for wiping off your hands and

service tools must be made oflint freematerials.

Lint will adhere to transmission parts and could in-

terfere with valve operation, or even restrict fluid

passages.

Lubricate the transmission components with Mopar

ATF Plus during reassembly. Use Mopar Door-Ease,

or Ru-Glyde on seals and O-rings to ease installation.

Petroleum jelly can also be used to hold thrust

washers and plates in position during assembly oper-

ations. However,do notuse chassis grease, bearing

grease, white grease, or similar lubricants on any

transmission part. These types of lubricants can

eventually block or restrict fluid passages and valve

operation. Use petroleum jelly only.

Do not force parts into place. Most of the transmis-

sion components are easily installed by hand when

properly aligned. If a part seems extremely difficult

to install, it is either misaligned or incorrectly assem-

bled. Also verify that thrust washers, thrust plates

and seal rings are correctly positioned before assem-

bly. These parts can interfere with proper assembly if

mispositioned or ``left out'' by accident.

TRANSMISSION ASSEMBLY AND ADJUSTMENT

PROCEDURES

SERVO INSTALLATION

(1) Install rear servo piston, spring and spring re-

tainer. Compress rear servo spring and retainer with

Compressor Tool C-3422-B or a large C-clamp.

(2) Install front servo piston, spring and rod guide.

Compress front servo rod guide with Valve Spring

Compressor C-3422-B and install servo snap ring.

Fig. 124 Line Pressure Adjustment

Fig. 125 Throttle Pressure Adjustment

J30RH/32RH TRANSMISSION OVERHAUL 21 - 155

Page 1597 of 2198

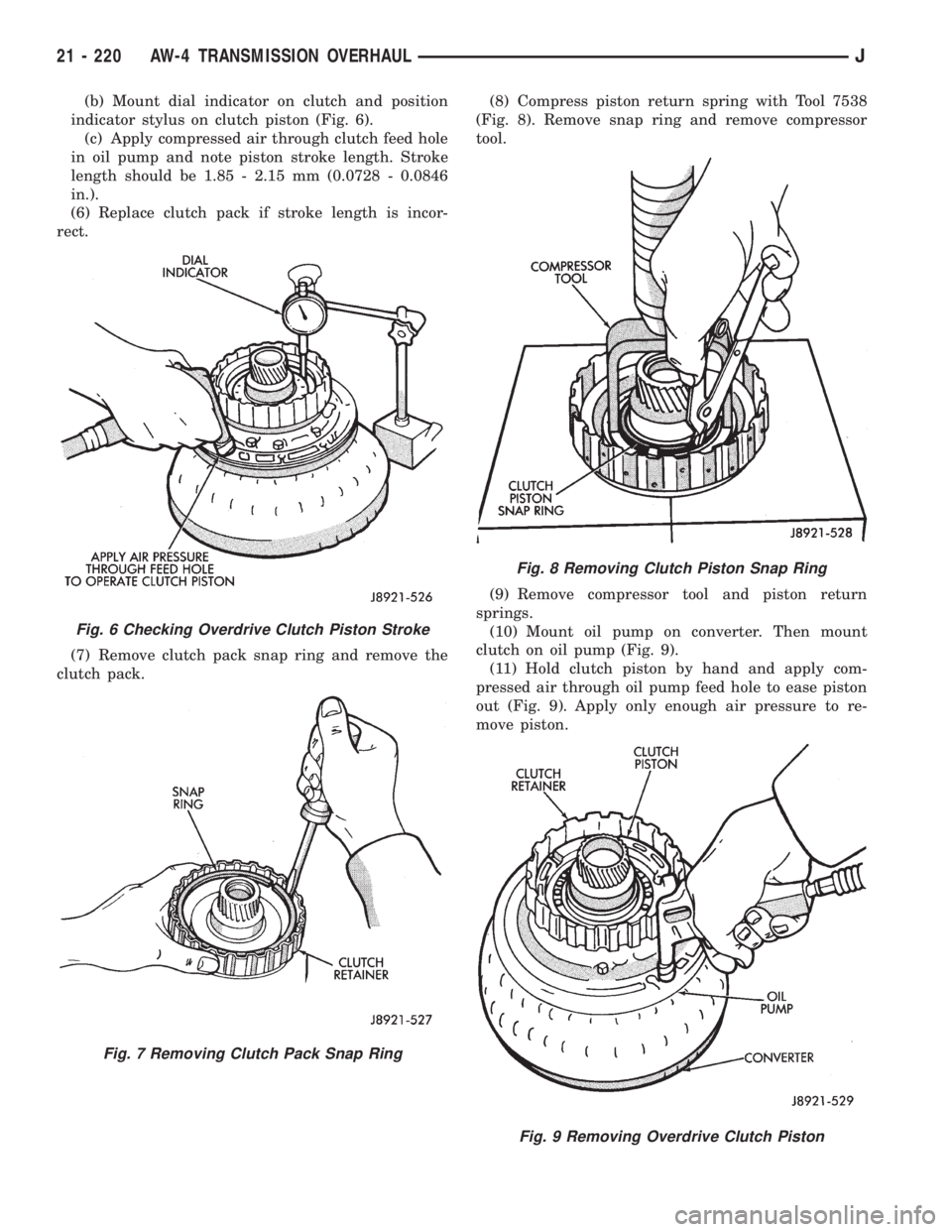

(b) Mount dial indicator on clutch and position

indicator stylus on clutch piston (Fig. 6).

(c) Apply compressed air through clutch feed hole

in oil pump and note piston stroke length. Stroke

length should be 1.85 - 2.15 mm (0.0728 - 0.0846

in.).

(6) Replace clutch pack if stroke length is incor-

rect.

(7) Remove clutch pack snap ring and remove the

clutch pack.(8) Compress piston return spring with Tool 7538

(Fig. 8). Remove snap ring and remove compressor

tool.

(9) Remove compressor tool and piston return

springs.

(10) Mount oil pump on converter. Then mount

clutch on oil pump (Fig. 9).

(11) Hold clutch piston by hand and apply com-

pressed air through oil pump feed hole to ease piston

out (Fig. 9). Apply only enough air pressure to re-

move piston.

Fig. 6 Checking Overdrive Clutch Piston Stroke

Fig. 7 Removing Clutch Pack Snap Ring

Fig. 8 Removing Clutch Piston Snap Ring

Fig. 9 Removing Overdrive Clutch Piston

21 - 220 AW-4 TRANSMISSION OVERHAULJ

Page 1606 of 2198

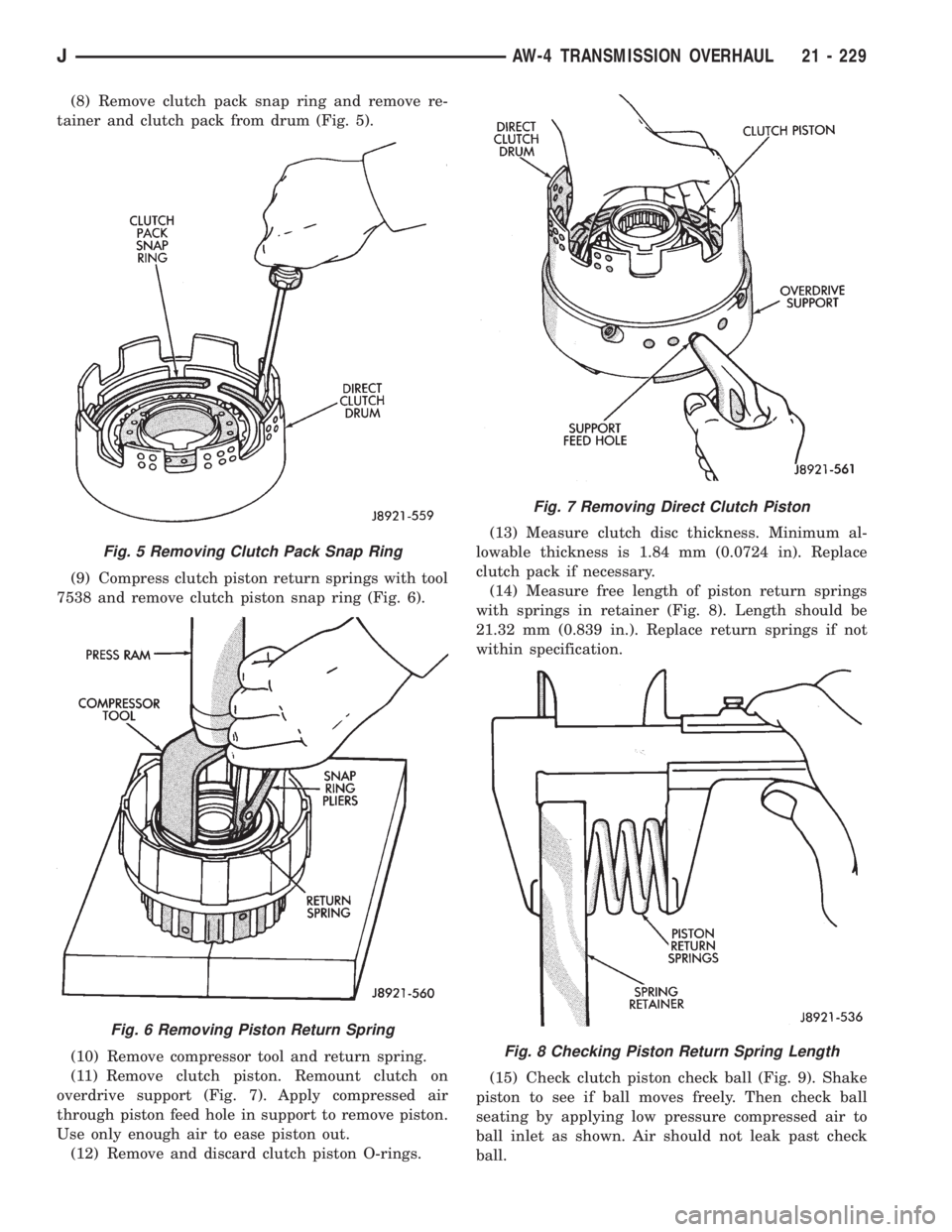

(8) Remove clutch pack snap ring and remove re-

tainer and clutch pack from drum (Fig. 5).

(9) Compress clutch piston return springs with tool

7538 and remove clutch piston snap ring (Fig. 6).

(10) Remove compressor tool and return spring.

(11) Remove clutch piston. Remount clutch on

overdrive support (Fig. 7). Apply compressed air

through piston feed hole in support to remove piston.

Use only enough air to ease piston out.

(12) Remove and discard clutch piston O-rings.(13) Measure clutch disc thickness. Minimum al-

lowable thickness is 1.84 mm (0.0724 in). Replace

clutch pack if necessary.

(14) Measure free length of piston return springs

with springs in retainer (Fig. 8). Length should be

21.32 mm (0.839 in.). Replace return springs if not

within specification.

(15) Check clutch piston check ball (Fig. 9). Shake

piston to see if ball moves freely. Then check ball

seating by applying low pressure compressed air to

ball inlet as shown. Air should not leak past check

ball.

Fig. 5 Removing Clutch Pack Snap Ring

Fig. 6 Removing Piston Return Spring

Fig. 7 Removing Direct Clutch Piston

Fig. 8 Checking Piston Return Spring Length

JAW-4 TRANSMISSION OVERHAUL 21 - 229

Page 1611 of 2198

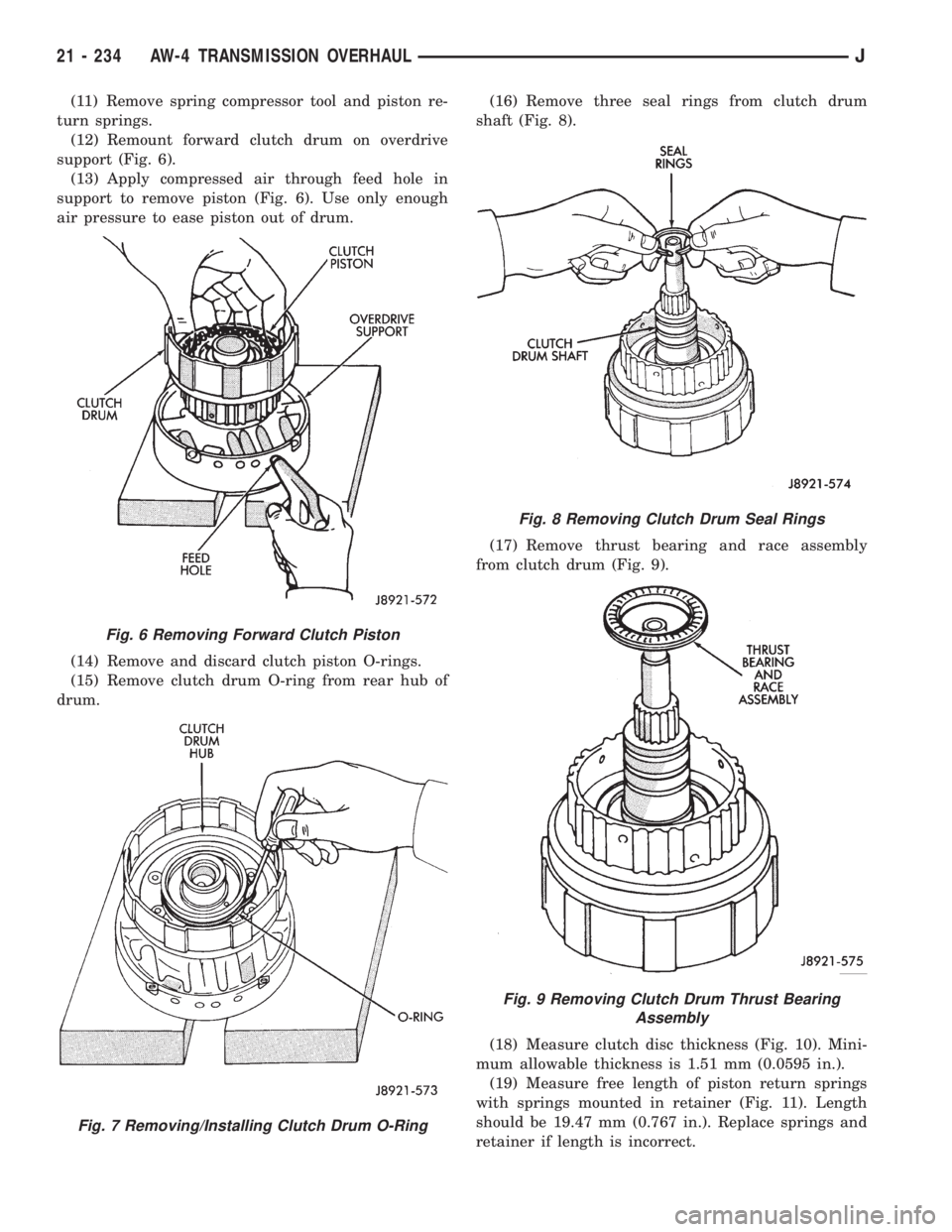

(11) Remove spring compressor tool and piston re-

turn springs.

(12) Remount forward clutch drum on overdrive

support (Fig. 6).

(13) Apply compressed air through feed hole in

support to remove piston (Fig. 6). Use only enough

air pressure to ease piston out of drum.

(14) Remove and discard clutch piston O-rings.

(15) Remove clutch drum O-ring from rear hub of

drum.(16) Remove three seal rings from clutch drum

shaft (Fig. 8).

(17) Remove thrust bearing and race assembly

from clutch drum (Fig. 9).

(18) Measure clutch disc thickness (Fig. 10). Mini-

mum allowable thickness is 1.51 mm (0.0595 in.).

(19) Measure free length of piston return springs

with springs mounted in retainer (Fig. 11). Length

should be 19.47 mm (0.767 in.). Replace springs and

retainer if length is incorrect.

Fig. 6 Removing Forward Clutch Piston

Fig. 7 Removing/Installing Clutch Drum O-Ring

Fig. 8 Removing Clutch Drum Seal Rings

Fig. 9 Removing Clutch Drum Thrust Bearing

Assembly

21 - 234 AW-4 TRANSMISSION OVERHAULJ

Page 1619 of 2198

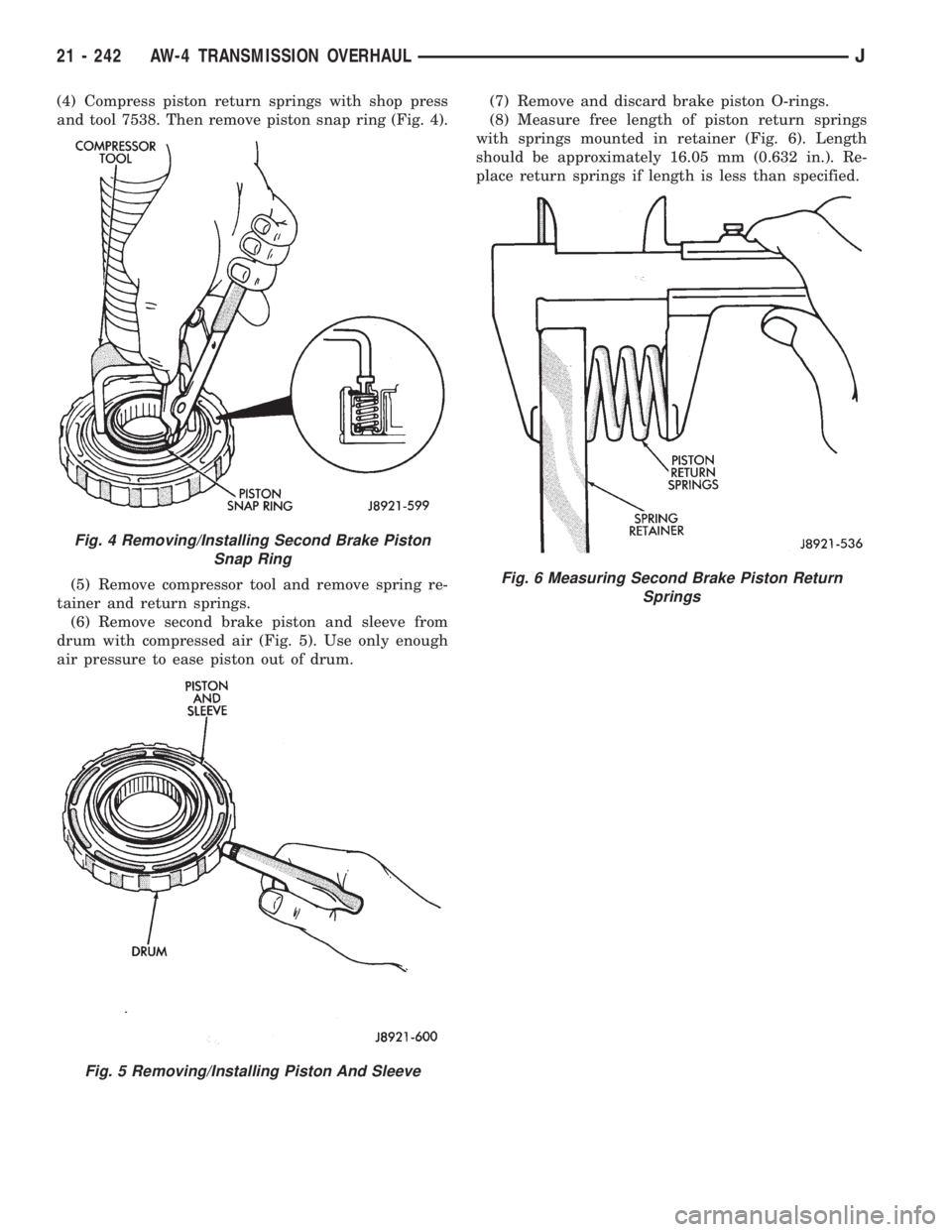

(4) Compress piston return springs with shop press

and tool 7538. Then remove piston snap ring (Fig. 4).

(5) Remove compressor tool and remove spring re-

tainer and return springs.

(6) Remove second brake piston and sleeve from

drum with compressed air (Fig. 5). Use only enough

air pressure to ease piston out of drum.(7) Remove and discard brake piston O-rings.

(8) Measure free length of piston return springs

with springs mounted in retainer (Fig. 6). Length

should be approximately 16.05 mm (0.632 in.). Re-

place return springs if length is less than specified.

Fig. 4 Removing/Installing Second Brake Piston

Snap Ring

Fig. 5 Removing/Installing Piston And Sleeve

Fig. 6 Measuring Second Brake Piston Return

Springs

21 - 242 AW-4 TRANSMISSION OVERHAULJ

Page 1620 of 2198

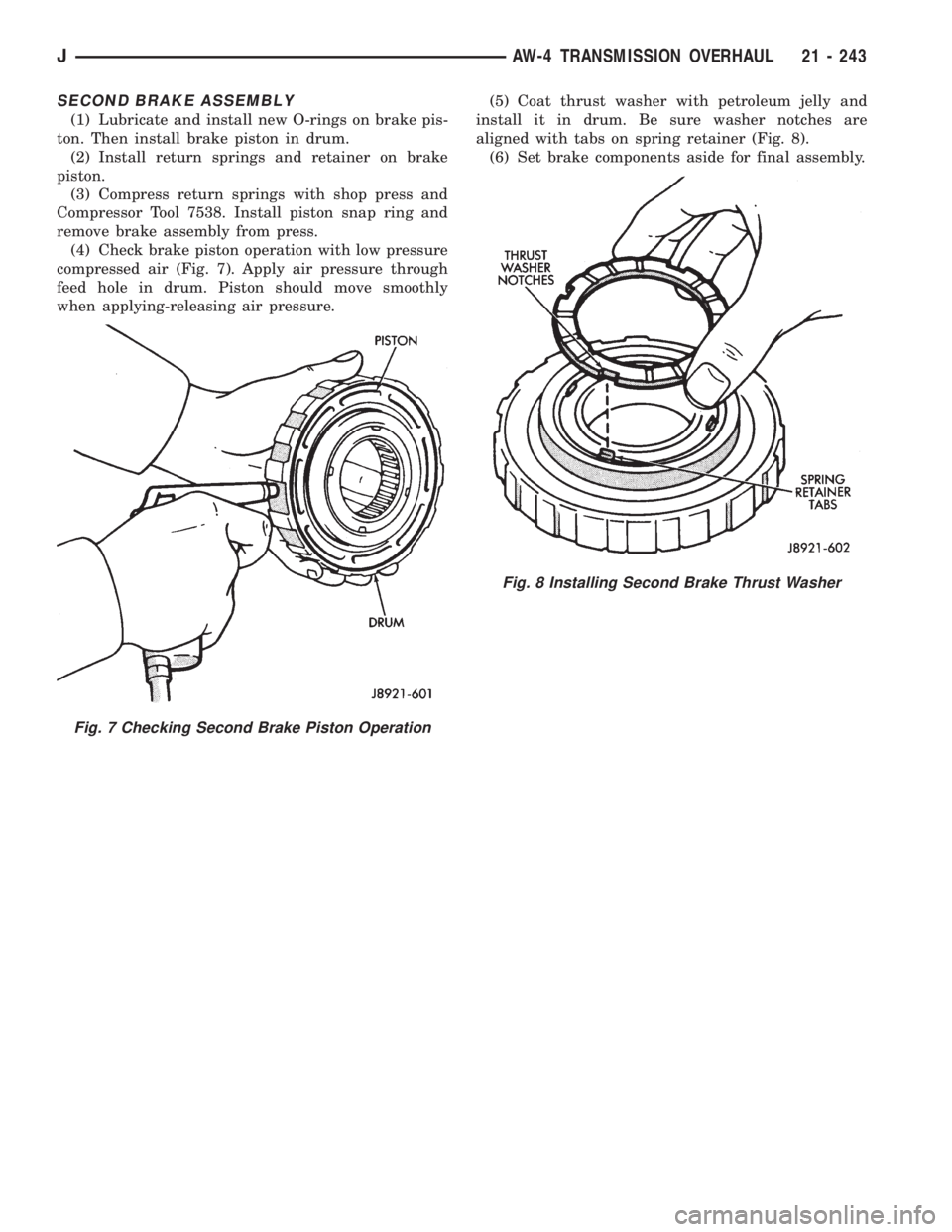

SECOND BRAKE ASSEMBLY

(1) Lubricate and install new O-rings on brake pis-

ton. Then install brake piston in drum.

(2) Install return springs and retainer on brake

piston.

(3) Compress return springs with shop press and

Compressor Tool 7538. Install piston snap ring and

remove brake assembly from press.

(4) Check brake piston operation with low pressure

compressed air (Fig. 7). Apply air pressure through

feed hole in drum. Piston should move smoothly

when applying-releasing air pressure.(5) Coat thrust washer with petroleum jelly and

install it in drum. Be sure washer notches are

aligned with tabs on spring retainer (Fig. 8).

(6) Set brake components aside for final assembly.

Fig. 7 Checking Second Brake Piston Operation

Fig. 8 Installing Second Brake Thrust Washer

JAW-4 TRANSMISSION OVERHAUL 21 - 243

Page 1732 of 2198

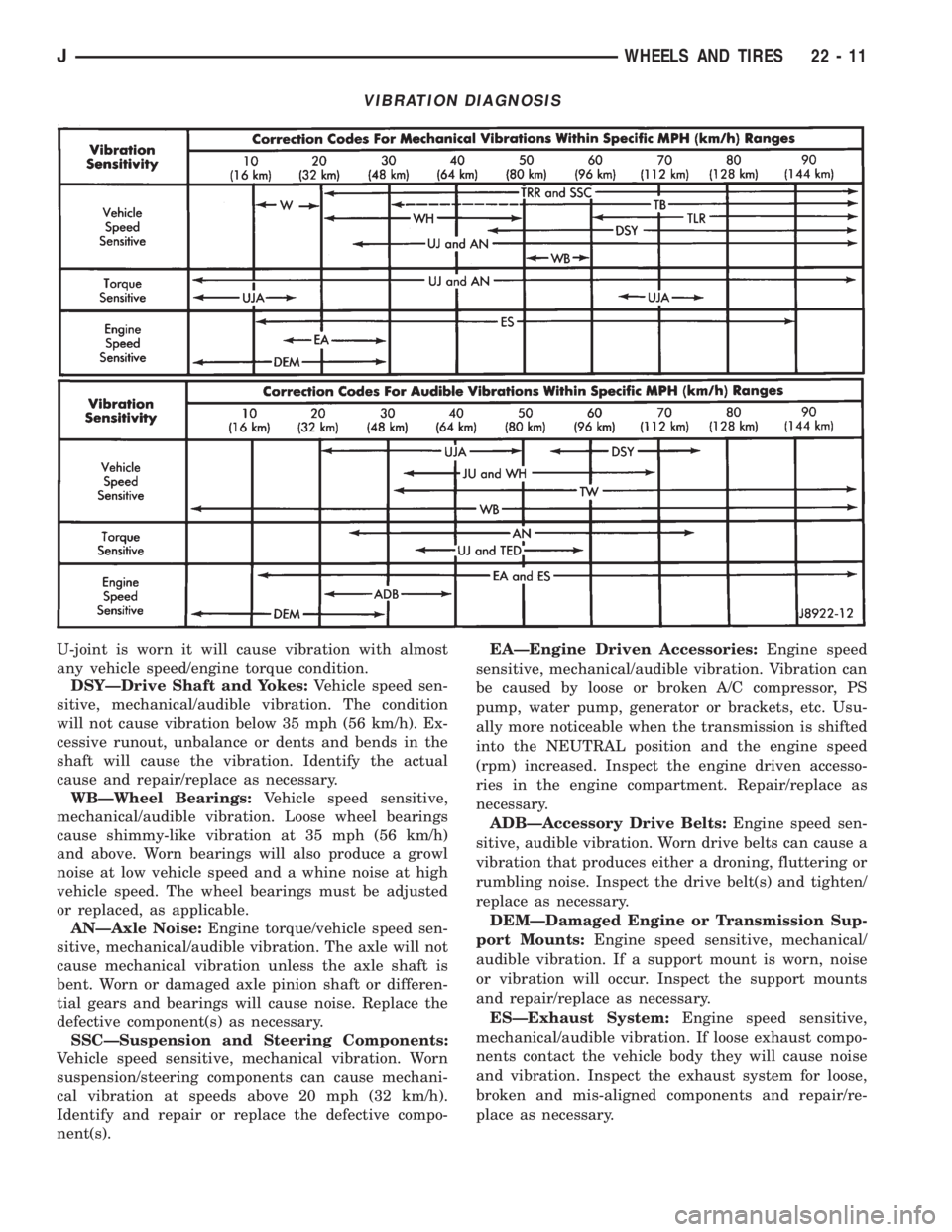

U-joint is worn it will cause vibration with almost

any vehicle speed/engine torque condition.

DSYÐDrive Shaft and Yokes:Vehicle speed sen-

sitive, mechanical/audible vibration. The condition

will not cause vibration below 35 mph (56 km/h). Ex-

cessive runout, unbalance or dents and bends in the

shaft will cause the vibration. Identify the actual

cause and repair/replace as necessary.

WBÐWheel Bearings:Vehicle speed sensitive,

mechanical/audible vibration. Loose wheel bearings

cause shimmy-like vibration at 35 mph (56 km/h)

and above. Worn bearings will also produce a growl

noise at low vehicle speed and a whine noise at high

vehicle speed. The wheel bearings must be adjusted

or replaced, as applicable.

ANÐAxle Noise:Engine torque/vehicle speed sen-

sitive, mechanical/audible vibration. The axle will not

cause mechanical vibration unless the axle shaft is

bent. Worn or damaged axle pinion shaft or differen-

tial gears and bearings will cause noise. Replace the

defective component(s) as necessary.

SSCÐSuspension and Steering Components:

Vehicle speed sensitive, mechanical vibration. Worn

suspension/steering components can cause mechani-

cal vibration at speeds above 20 mph (32 km/h).

Identify and repair or replace the defective compo-

nent(s).EAÐEngine Driven Accessories:Engine speed

sensitive, mechanical/audible vibration. Vibration can

be caused by loose or broken A/C compressor, PS

pump, water pump, generator or brackets, etc. Usu-

ally more noticeable when the transmission is shifted

into the NEUTRAL position and the engine speed

(rpm) increased. Inspect the engine driven accesso-

ries in the engine compartment. Repair/replace as

necessary.

ADBÐAccessory Drive Belts:Engine speed sen-

sitive, audible vibration. Worn drive belts can cause a

vibration that produces either a droning, fluttering or

rumbling noise. Inspect the drive belt(s) and tighten/

replace as necessary.

DEMÐDamaged Engine or Transmission Sup-

port Mounts:Engine speed sensitive, mechanical/

audible vibration. If a support mount is worn, noise

or vibration will occur. Inspect the support mounts

and repair/replace as necessary.

ESÐExhaust System:Engine speed sensitive,

mechanical/audible vibration. If loose exhaust compo-

nents contact the vehicle body they will cause noise

and vibration. Inspect the exhaust system for loose,

broken and mis-aligned components and repair/re-

place as necessary.

VIBRATION DIAGNOSIS

JWHEELS AND TIRES 22 - 11

Page 1839 of 2198

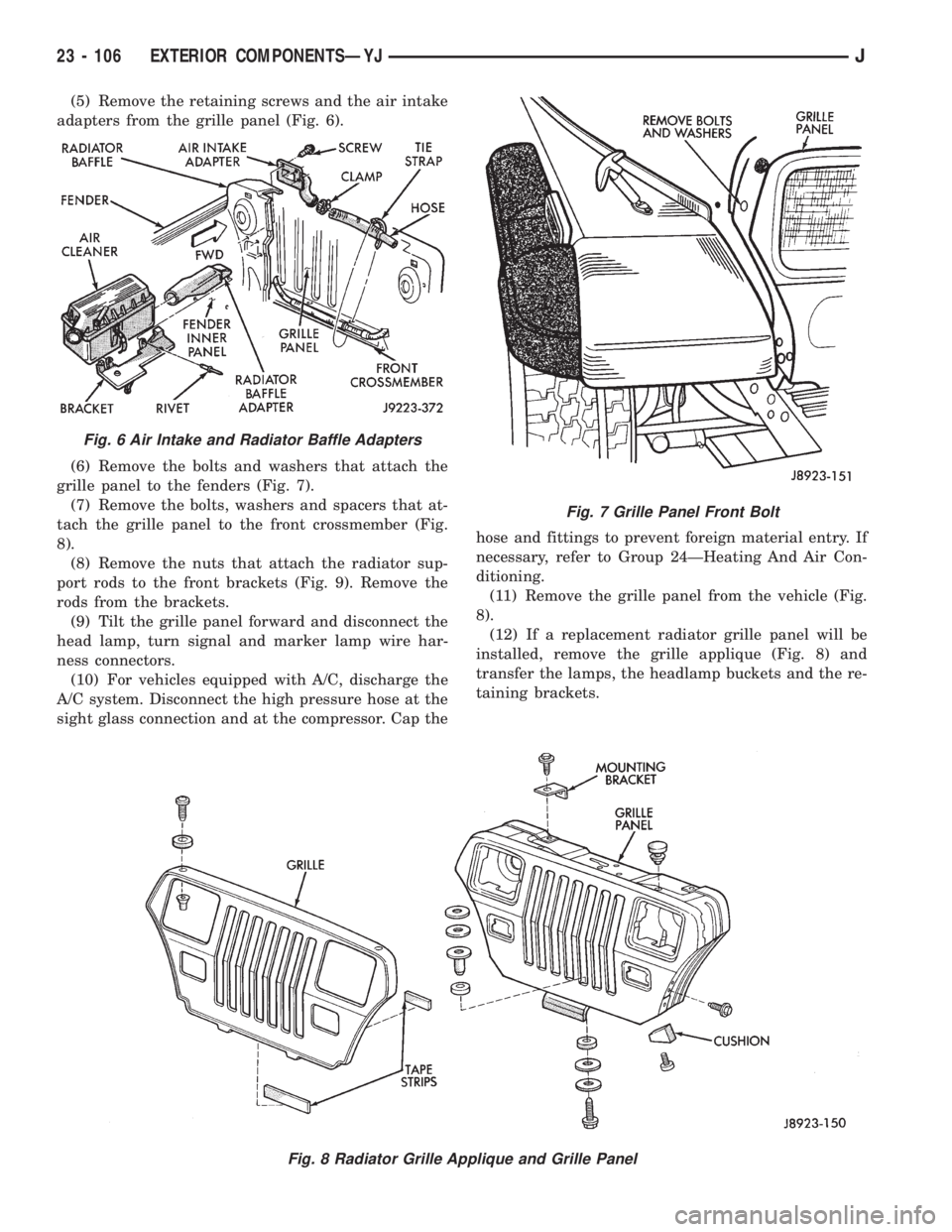

(5) Remove the retaining screws and the air intake

adapters from the grille panel (Fig. 6).

(6) Remove the bolts and washers that attach the

grille panel to the fenders (Fig. 7).

(7) Remove the bolts, washers and spacers that at-

tach the grille panel to the front crossmember (Fig.

8).

(8) Remove the nuts that attach the radiator sup-

port rods to the front brackets (Fig. 9). Remove the

rods from the brackets.

(9) Tilt the grille panel forward and disconnect the

head lamp, turn signal and marker lamp wire har-

ness connectors.

(10) For vehicles equipped with A/C, discharge the

A/C system. Disconnect the high pressure hose at the

sight glass connection and at the compressor. Cap thehose and fittings to prevent foreign material entry. If

necessary, refer to Group 24ÐHeating And Air Con-

ditioning.

(11) Remove the grille panel from the vehicle (Fig.

8).

(12) If a replacement radiator grille panel will be

installed, remove the grille applique (Fig. 8) and

transfer the lamps, the headlamp buckets and the re-

taining brackets.

Fig. 7 Grille Panel Front Bolt

Fig. 8 Radiator Grille Applique and Grille Panel

Fig. 6 Air Intake and Radiator Baffle Adapters

23 - 106 EXTERIOR COMPONENTSÐYJJ

Page 1896 of 2198

HEATING AND AIR CONDITIONING

CONTENTS

page page

COMPONENT SERVICEÐXJ VEHICLES...... 23

COMPONENT SERVICEÐYJ VEHICLES...... 32

COMPRESSOR SERVICE.................. 19

GENERAL INFORMATION.................. 1

HEATING AND AIR CONDITIONING TEST

PROCEDURES......................... 15REFRIGERANT SERVICE AND PERFORMANCE

TEST................................ 11

TORQUE SPECIFICATIONS................ 37

WARNINGS, CAUTIONS AND SERVICE

PRECAUTIONS......................... 9

GENERAL INFORMATION

INDEX

page page

A/C Components.......................... 4

Heater and A/C Operation.................... 1

Manifold Gauge Set........................ 7Refrigerant............................... 7

Refrigerant Equipment...................... 7

HEATER AND A/C OPERATION

HEATERÐXJ

A blend-air heating system is used in XJ vehicles.

The temperature of heated air is controlled by regu-

lating the quantity of air flow through the heater

core. This is accomplished by blending outside air

with heated air from the heater core to obtain the de-

sired discharge temperature. A temperature control

lever on the heater control determines air flow

through the heater core. The lever uses a cable to op-erate the blend-air door. This door controls air flow

through the core. Vacuum motors are used to actuate

and position the remaining door in the system.

On left hand drive (LHD) XJ vehicles a water valve

controls coolant flow to the heater core. The valve is

vacuum operated. When vacuum is applied, the valve

opens and coolant is directed through the heater core

and back to the engine. When the water valve is

closed (no vacuum applied) coolant flow bypasses the

heater core back to the engine.

JHEATING AND AIR CONDITIONING 24 - 1