warning JEEP CHEROKEE 1995 Service Manual Online

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 415 of 2198

allowing current flow to the lamps. As the bimetal

strip cools, the contact points are pushed open and

the cycle repeats.

COMBINATION FLASHER (XJ ONLY)

The combination flasher functions as both the turn

signal and hazard warning flasher on XJ models. The

combination flasher is a smart relay that is located in

the relay center under the lower instrument panel

and inboard of the steering column. The combination

flasher can not be repaired. If faulty, it must be

replaced.

The combination flasher is designed to handle the

current flow requirements of the factory installed

lighting. If supplemental lighting is added to the turn

signal circuits such as when towing a trailer with

lights, the combination flasher will automatically

compensate. This allows the flash rate to remain the

same, regardless of electrical load increases. However,

if a bulb fails in the turn signal or hazard warning

circuits, the flash rate of the remaining bulbs in that

circuit will increase to 120 flashes per minute or

higher.

TURN SIGNAL/HAZARD WARNING SWITCH

(YJ ONLY)

The turn signal and hazard warning switches are

combined into a single unit mounted within the upper

steering column bowl and beneath the steering wheel.

The turn signal lever on the left side of the steering

column is moved up or down to select the right or left

turn signal switch position. The turn signals will only

operate with the ignition switch in the ACCESSORY

or ON position.

The hazard warning button on the right side of the

steering column is pushed in to turn the hazard

warning system on, or pulled out to turn the system

off. The hazard warning system will operate regard-

less of ignition switch position. The turn signal/haz-

ard warning switch can not be repaired. If faulty, the

entire unit must be replaced.

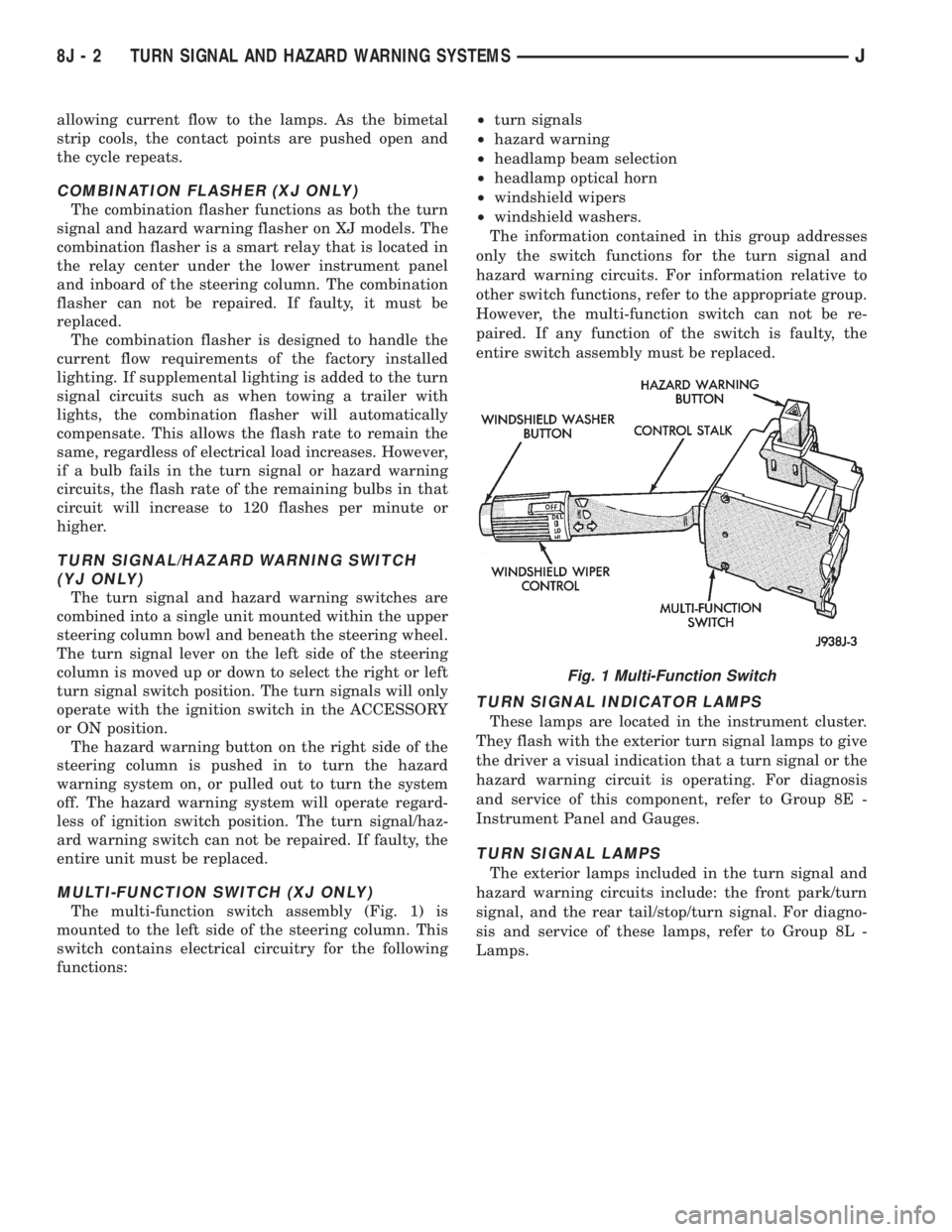

MULTI-FUNCTION SWITCH (XJ ONLY)

The multi-function switch assembly (Fig. 1) is

mounted to the left side of the steering column. This

switch contains electrical circuitry for the following

functions:²turn signals

²hazard warning

²headlamp beam selection

²headlamp optical horn

²windshield wipers

²windshield washers.

The information contained in this group addresses

only the switch functions for the turn signal and

hazard warning circuits. For information relative to

other switch functions, refer to the appropriate group.

However, the multi-function switch can not be re-

paired. If any function of the switch is faulty, the

entire switch assembly must be replaced.

TURN SIGNAL INDICATOR LAMPS

These lamps are located in the instrument cluster.

They flash with the exterior turn signal lamps to give

the driver a visual indication that a turn signal or the

hazard warning circuit is operating. For diagnosis

and service of this component, refer to Group 8E -

Instrument Panel and Gauges.

TURN SIGNAL LAMPS

The exterior lamps included in the turn signal and

hazard warning circuits include: the front park/turn

signal, and the rear tail/stop/turn signal. For diagno-

sis and service of these lamps, refer to Group 8L -

Lamps.

Fig. 1 Multi-Function Switch

8J - 2 TURN SIGNAL AND HAZARD WARNING SYSTEMSJ

Page 416 of 2198

DIAGNOSIS

When diagnosing the turn signal or hazard warning

circuits, remember that high generator output can

burn out bulbs rapidly and repeatedly. If this is a

problem on the vehicle being diagnosed, refer to

Group 8A - Battery/Starting/Charging Systems Diag-

nostics to test charging system.

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

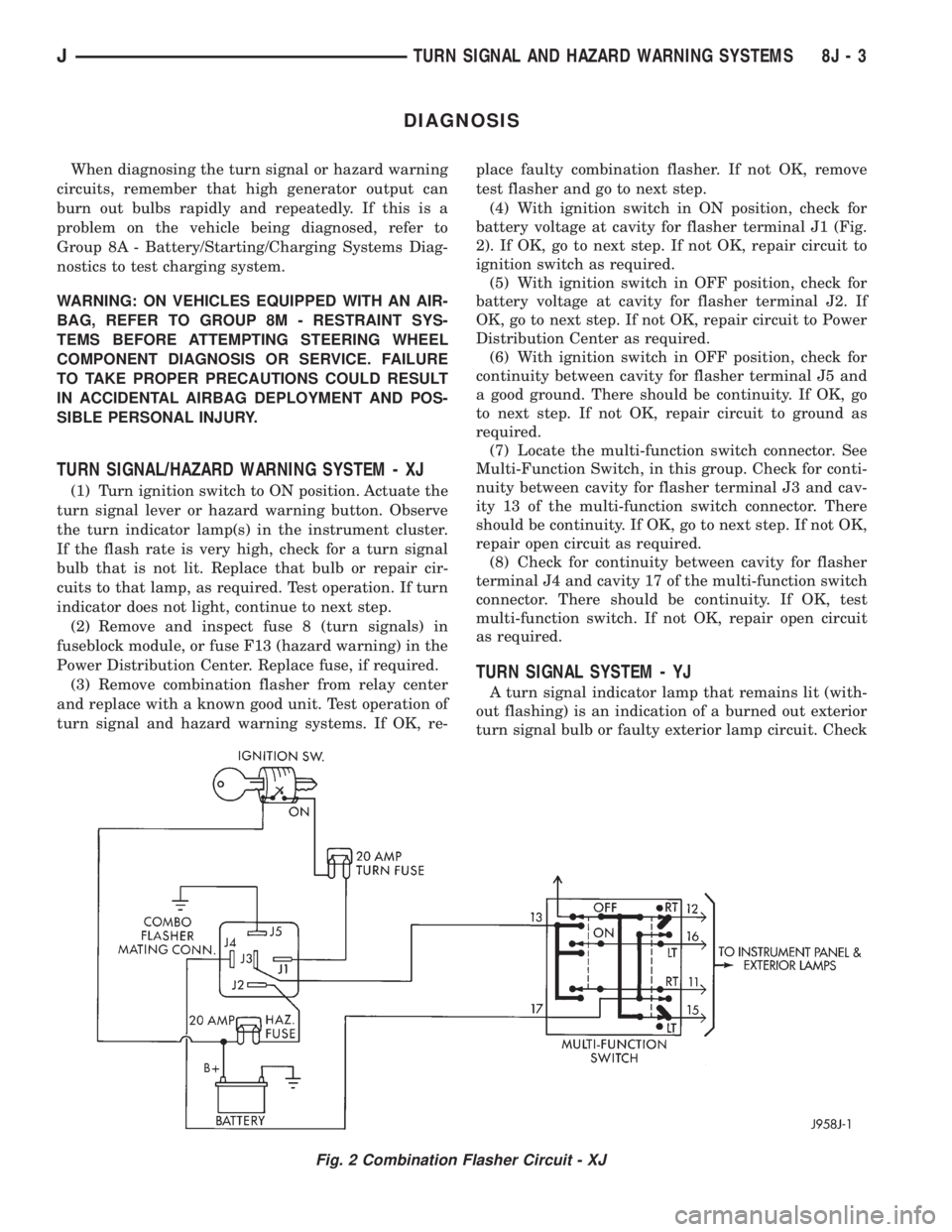

TURN SIGNAL/HAZARD WARNING SYSTEM - XJ

(1) Turn ignition switch to ON position. Actuate the

turn signal lever or hazard warning button. Observe

the turn indicator lamp(s) in the instrument cluster.

If the flash rate is very high, check for a turn signal

bulb that is not lit. Replace that bulb or repair cir-

cuits to that lamp, as required. Test operation. If turn

indicator does not light, continue to next step.

(2) Remove and inspect fuse 8 (turn signals) in

fuseblock module, or fuse F13 (hazard warning) in the

Power Distribution Center. Replace fuse, if required.

(3) Remove combination flasher from relay center

and replace with a known good unit. Test operation of

turn signal and hazard warning systems. If OK, re-place faulty combination flasher. If not OK, remove

test flasher and go to next step.

(4) With ignition switch in ON position, check for

battery voltage at cavity for flasher terminal J1 (Fig.

2). If OK, go to next step. If not OK, repair circuit to

ignition switch as required.

(5) With ignition switch in OFF position, check for

battery voltage at cavity for flasher terminal J2. If

OK, go to next step. If not OK, repair circuit to Power

Distribution Center as required.

(6) With ignition switch in OFF position, check for

continuity between cavity for flasher terminal J5 and

a good ground. There should be continuity. If OK, go

to next step. If not OK, repair circuit to ground as

required.

(7) Locate the multi-function switch connector. See

Multi-Function Switch, in this group. Check for conti-

nuity between cavity for flasher terminal J3 and cav-

ity 13 of the multi-function switch connector. There

should be continuity. If OK, go to next step. If not OK,

repair open circuit as required.

(8) Check for continuity between cavity for flasher

terminal J4 and cavity 17 of the multi-function switch

connector. There should be continuity. If OK, test

multi-function switch. If not OK, repair open circuit

as required.

TURN SIGNAL SYSTEM - YJ

A turn signal indicator lamp that remains lit (with-

out flashing) is an indication of a burned out exterior

turn signal bulb or faulty exterior lamp circuit. Check

Fig. 2 Combination Flasher Circuit - XJ

JTURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 3

Page 417 of 2198

lamps and repair circuits or replace bulbs as re-

quired. If system still does not function properly, pro-

ceed as follows.

(1) Locate fuseblock module under driver's side of

instrument panel. Remove and inspect fuse 4. If OK,

go to next step. If not OK, replace fuse as required.

(2) Replace turn signal flasher (light blue can in

fuseblock module) with a known good unit. Test op-

eration. If OK, replace faulty turn signal flasher. If

not OK, remove test flasher and go to next step.

(3) Turn ignition switch to ACCESSORY position.

Check for battery voltage at flasher cavity on left

(closest to hazard flasher). If OK, go to next step. If

not OK, repair circuit to fuse 4 as required.

(4) Turn ignition switch to OFF position. See Turn

Signal/Hazard Warning Switch Remove/Install to lo-

cate steering column connector. Unplug connector.

(5) Turn ignition switch to ACCESSORY position.

Check for battery voltage at connector terminal L. If

OK, replace turn signal/hazard warning switch. If not

OK, repair circuit between turn signal flasher and

steering column connector.

HAZARD WARNING SYSTEM - YJ

(1) Locate Power Distribution Center (PDC) near

battery tray in engine compartment. Remove and in-

spect fuse F5. If OK, go to next step. If not OK,

replace fuse as required.(2) Replace hazard warning flasher (metal can in

fuseblock module) with a known good unit. Test op-

eration. If OK, replace faulty hazard warning flasher.

If not OK, remove test flasher and go to next step.

(3) Check for battery voltage at flasher cavity on

left (closest to hazard flasher). If OK, go to next step.

If not OK, repair circuit to fuse F5 in PDC as re-

quired.

(4) See Turn Signal/Hazard Warning Switch Re-

move/Install to locate steering column connector. Un-

plug connector.

(5) Check for battery voltage at connector terminal

K. If OK, replace turn signal/hazard warning switch.

If not OK, repair circuit between hazard warning

flasher and steering column connector.

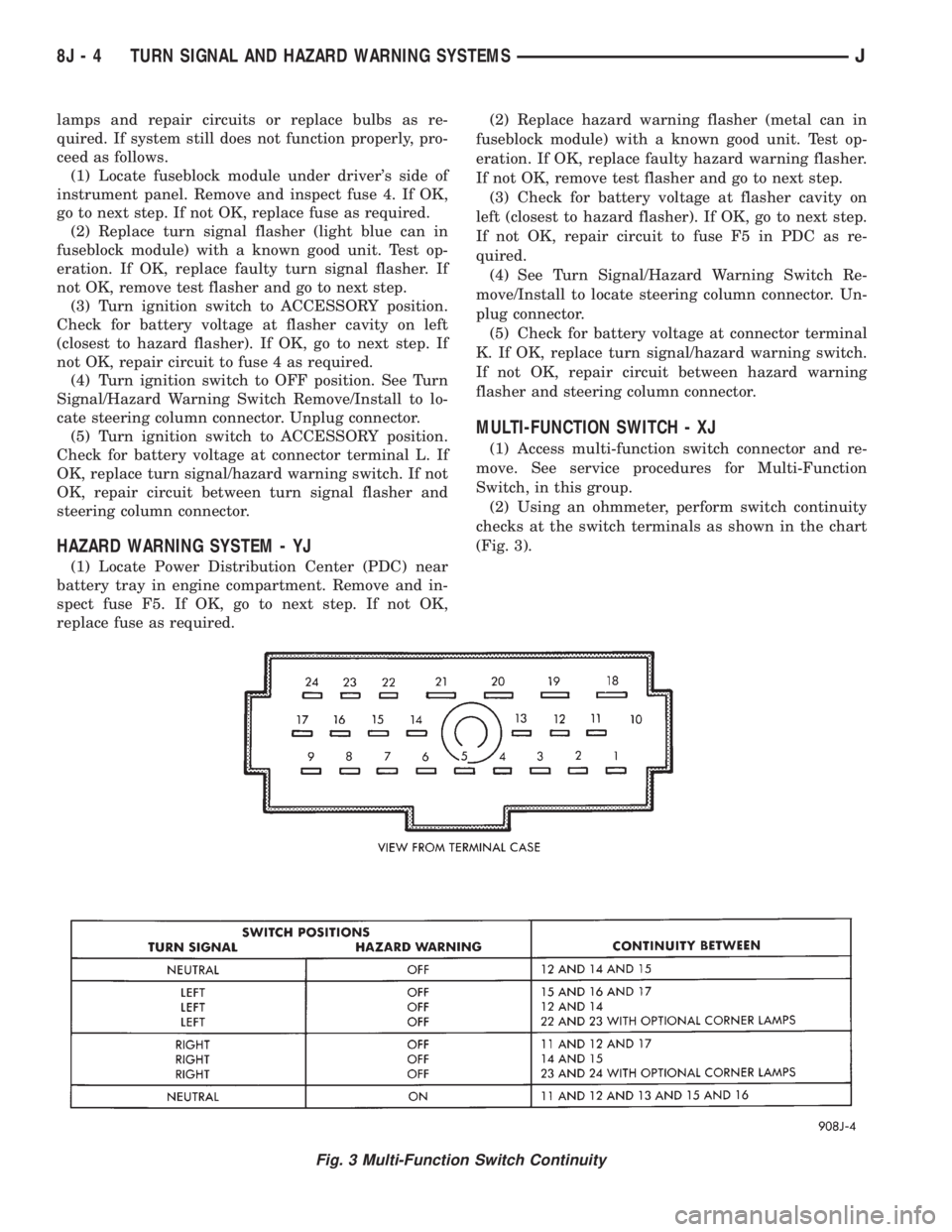

MULTI-FUNCTION SWITCH - XJ

(1) Access multi-function switch connector and re-

move. See service procedures for Multi-Function

Switch, in this group.

(2) Using an ohmmeter, perform switch continuity

checks at the switch terminals as shown in the chart

(Fig. 3).

Fig. 3 Multi-Function Switch Continuity

8J - 4 TURN SIGNAL AND HAZARD WARNING SYSTEMSJ

Page 418 of 2198

SERVICE PROCEDURES

WARNING: ON VEHICLES EQUIPPED WITH AN AIRBAG,

REFER TO GROUP 8M - RESTRAINT SYSTEMS BEFORE

ATTEMPTING STEERING WHEEL COMPONENT DIAGNO-

SIS OR SERVICE. FAILURE TO TAKE PROPER PRECAU-

TIONS COULD RESULT IN ACCIDENTAL AIRBAG DE-

PLOYMENT AND POSSIBLE PERSONAL INJURY.

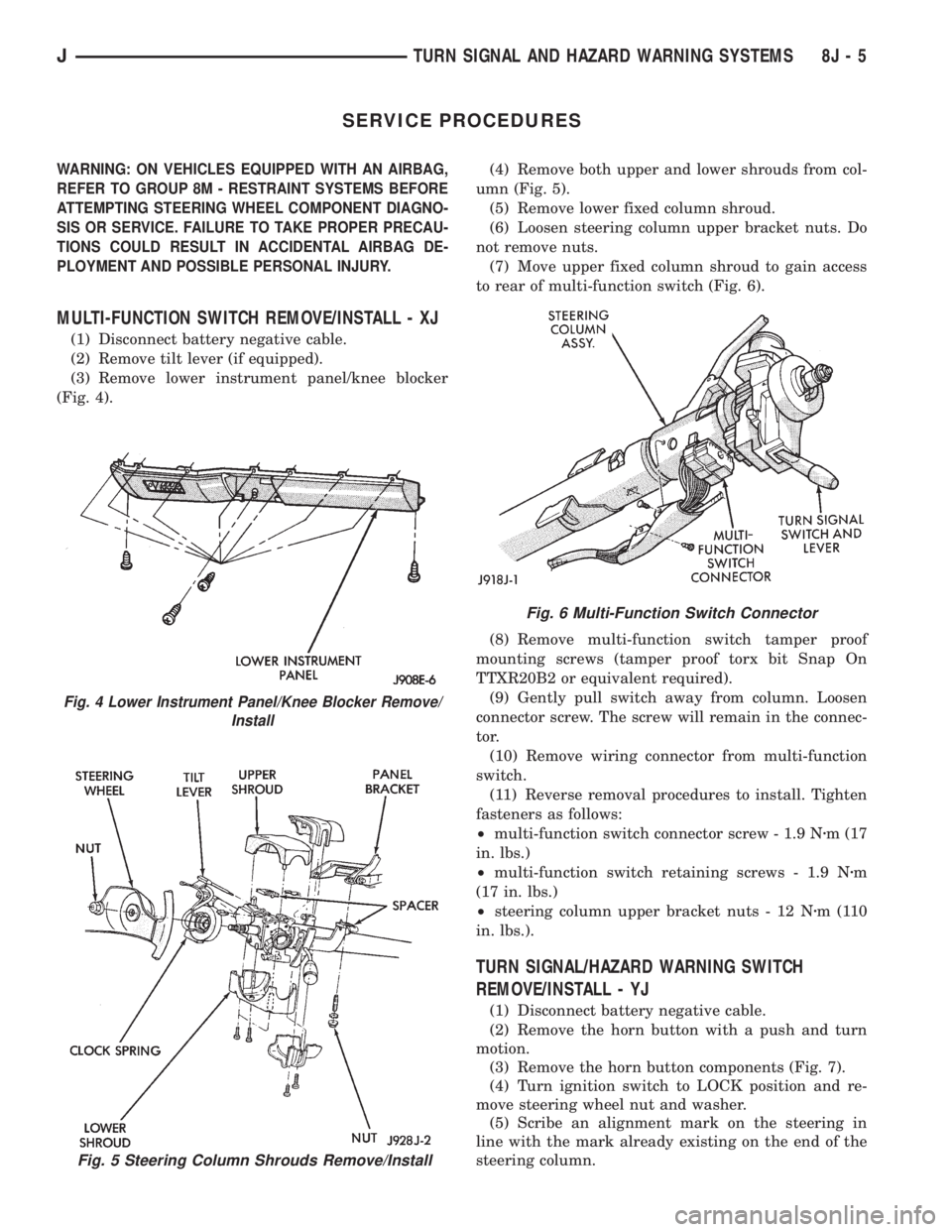

MULTI-FUNCTION SWITCH REMOVE/INSTALL - XJ

(1) Disconnect battery negative cable.

(2) Remove tilt lever (if equipped).

(3) Remove lower instrument panel/knee blocker

(Fig. 4).(4) Remove both upper and lower shrouds from col-

umn (Fig. 5).

(5) Remove lower fixed column shroud.

(6) Loosen steering column upper bracket nuts. Do

not remove nuts.

(7) Move upper fixed column shroud to gain access

to rear of multi-function switch (Fig. 6).

(8) Remove multi-function switch tamper proof

mounting screws (tamper proof torx bit Snap On

TTXR20B2 or equivalent required).

(9) Gently pull switch away from column. Loosen

connector screw. The screw will remain in the connec-

tor.

(10) Remove wiring connector from multi-function

switch.

(11) Reverse removal procedures to install. Tighten

fasteners as follows:

²multi-function switch connector screw - 1.9 Nzm (17

in. lbs.)

²multi-function switch retaining screws - 1.9 Nzm

(17 in. lbs.)

²steering column upper bracket nuts - 12 Nzm(110

in. lbs.).

TURN SIGNAL/HAZARD WARNING SWITCH

REMOVE/INSTALL - YJ

(1) Disconnect battery negative cable.

(2) Remove the horn button with a push and turn

motion.

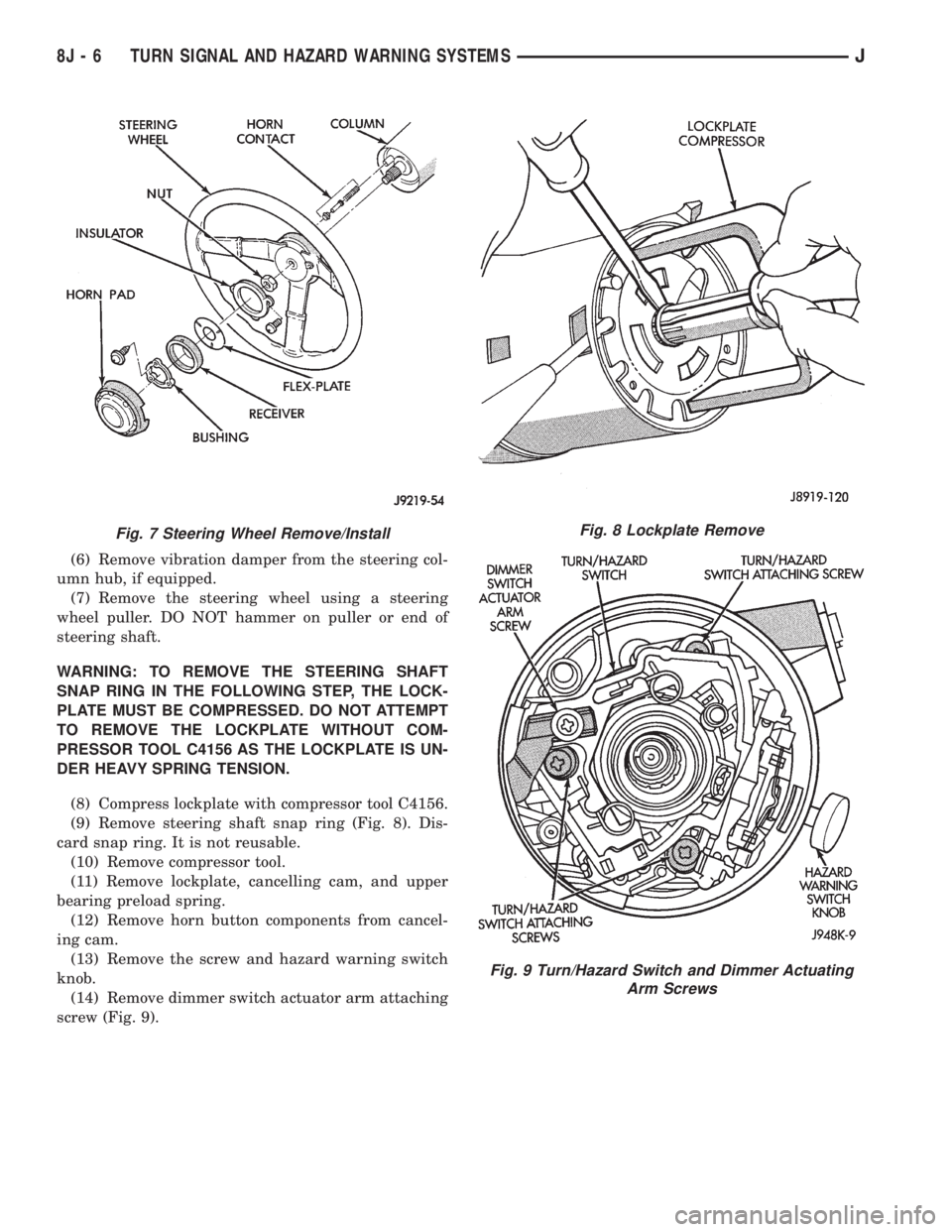

(3) Remove the horn button components (Fig. 7).

(4) Turn ignition switch to LOCK position and re-

move steering wheel nut and washer.

(5) Scribe an alignment mark on the steering in

line with the mark already existing on the end of the

steering column.

Fig. 5 Steering Column Shrouds Remove/Install

Fig. 4 Lower Instrument Panel/Knee Blocker Remove/

Install

Fig. 6 Multi-Function Switch Connector

JTURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 5

Page 419 of 2198

(6) Remove vibration damper from the steering col-

umn hub, if equipped.

(7) Remove the steering wheel using a steering

wheel puller. DO NOT hammer on puller or end of

steering shaft.

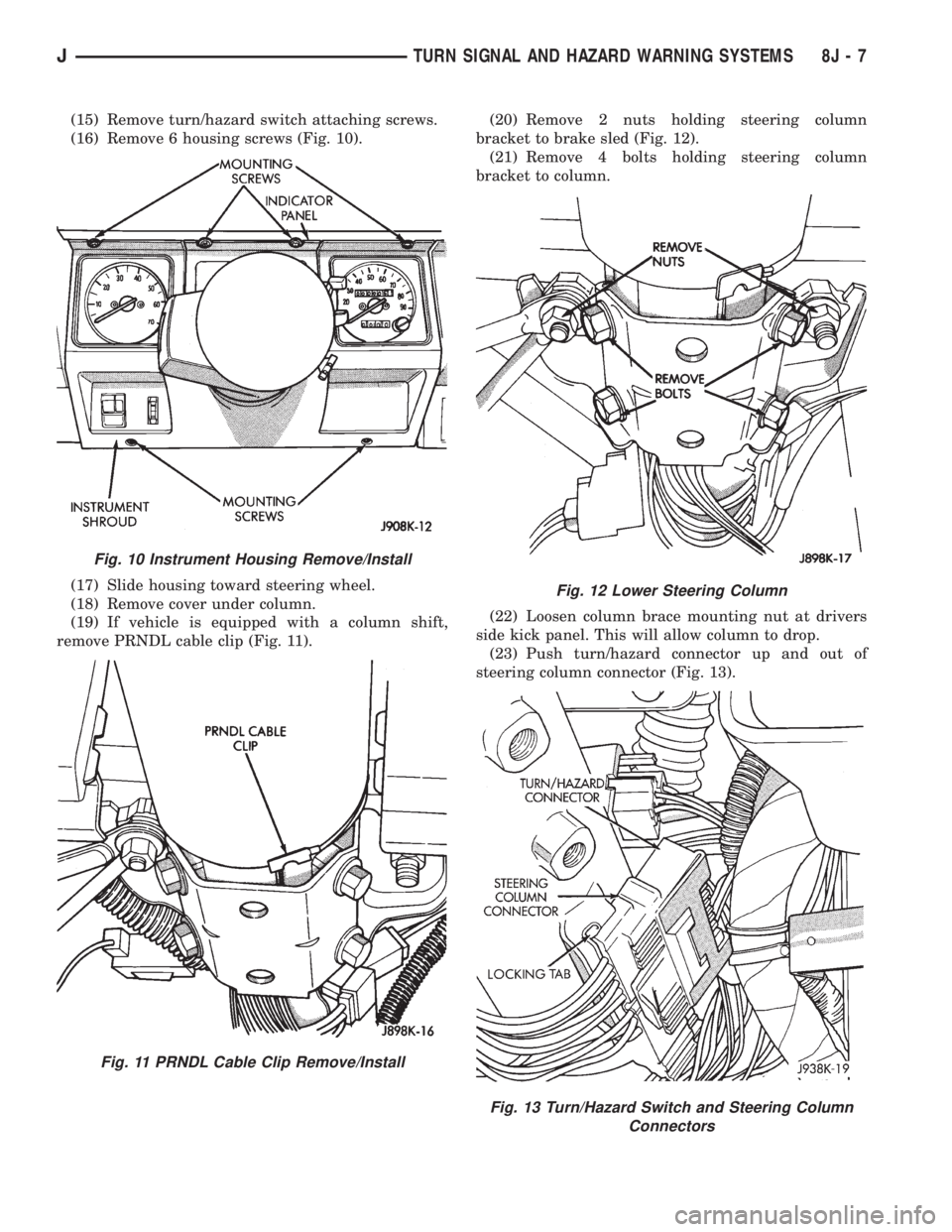

WARNING: TO REMOVE THE STEERING SHAFT

SNAP RING IN THE FOLLOWING STEP, THE LOCK-

PLATE MUST BE COMPRESSED. DO NOT ATTEMPT

TO REMOVE THE LOCKPLATE WITHOUT COM-

PRESSOR TOOL C4156 AS THE LOCKPLATE IS UN-

DER HEAVY SPRING TENSION.

(8) Compress lockplate with compressor tool C4156.

(9) Remove steering shaft snap ring (Fig. 8). Dis-

card snap ring. It is not reusable.

(10) Remove compressor tool.

(11) Remove lockplate, cancelling cam, and upper

bearing preload spring.

(12) Remove horn button components from cancel-

ing cam.

(13) Remove the screw and hazard warning switch

knob.

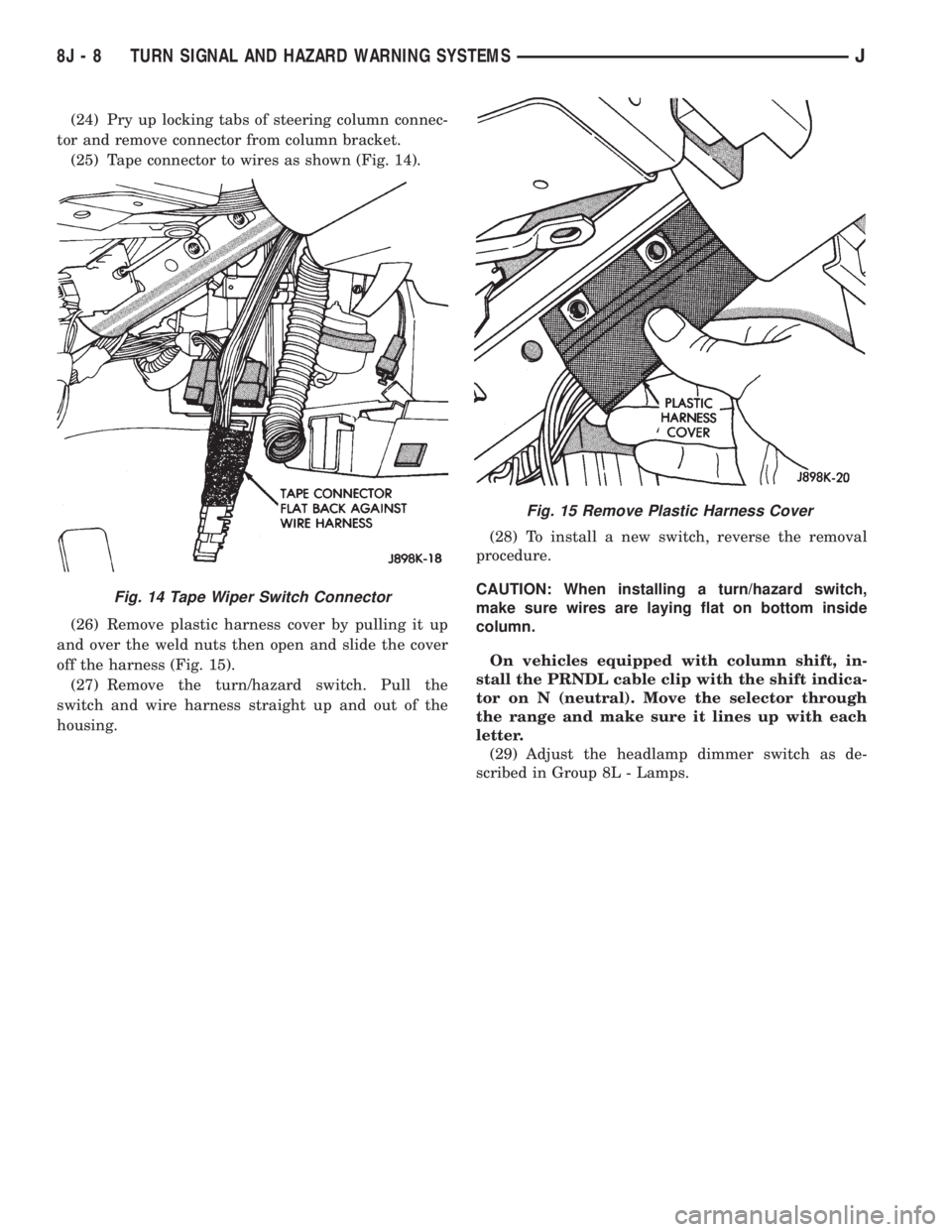

(14) Remove dimmer switch actuator arm attaching

screw (Fig. 9).

Fig. 7 Steering Wheel Remove/InstallFig. 8 Lockplate Remove

Fig. 9 Turn/Hazard Switch and Dimmer Actuating

Arm Screws

8J - 6 TURN SIGNAL AND HAZARD WARNING SYSTEMSJ

Page 420 of 2198

(15) Remove turn/hazard switch attaching screws.

(16) Remove 6 housing screws (Fig. 10).

(17) Slide housing toward steering wheel.

(18) Remove cover under column.

(19) If vehicle is equipped with a column shift,

remove PRNDL cable clip (Fig. 11).(20) Remove 2 nuts holding steering column

bracket to brake sled (Fig. 12).

(21) Remove 4 bolts holding steering column

bracket to column.

(22) Loosen column brace mounting nut at drivers

side kick panel. This will allow column to drop.

(23) Push turn/hazard connector up and out of

steering column connector (Fig. 13).

Fig. 10 Instrument Housing Remove/Install

Fig. 11 PRNDL Cable Clip Remove/Install

Fig. 12 Lower Steering Column

Fig. 13 Turn/Hazard Switch and Steering Column

Connectors

JTURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 7

Page 421 of 2198

(24) Pry up locking tabs of steering column connec-

tor and remove connector from column bracket.

(25) Tape connector to wires as shown (Fig. 14).

(26) Remove plastic harness cover by pulling it up

and over the weld nuts then open and slide the cover

off the harness (Fig. 15).

(27) Remove the turn/hazard switch. Pull the

switch and wire harness straight up and out of the

housing.(28) To install a new switch, reverse the removal

procedure.

CAUTION: When installing a turn/hazard switch,

make sure wires are laying flat on bottom inside

column.

On vehicles equipped with column shift, in-

stall the PRNDL cable clip with the shift indica-

tor on N (neutral). Move the selector through

the range and make sure it lines up with each

letter.

(29) Adjust the headlamp dimmer switch as de-

scribed in Group 8L - Lamps.

Fig. 15 Remove Plastic Harness Cover

Fig. 14 Tape Wiper Switch Connector

8J - 8 TURN SIGNAL AND HAZARD WARNING SYSTEMSJ

Page 441 of 2198

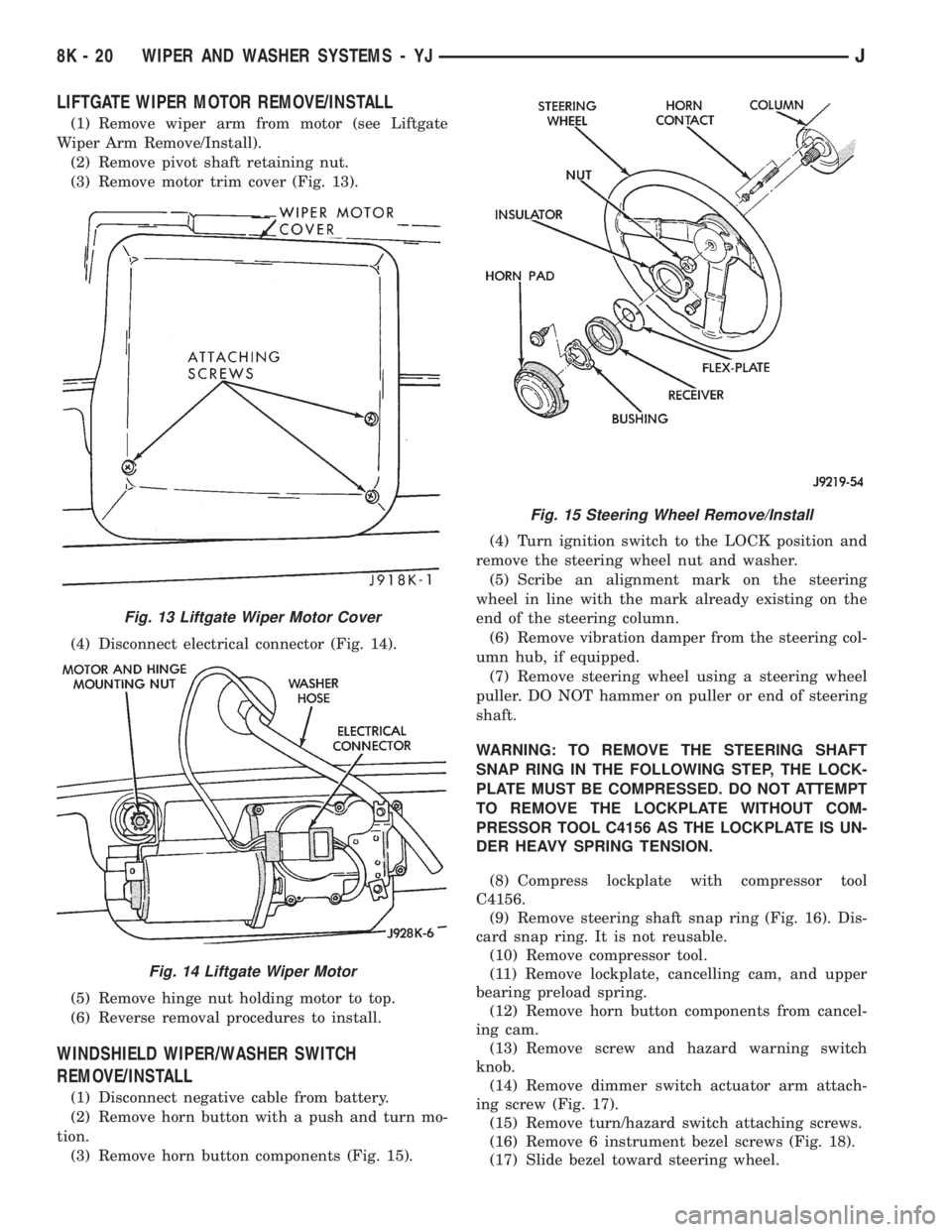

LIFTGATE WIPER MOTOR REMOVE/INSTALL

(1) Remove wiper arm from motor (see Liftgate

Wiper Arm Remove/Install).

(2) Remove pivot shaft retaining nut.

(3) Remove motor trim cover (Fig. 13).

(4) Disconnect electrical connector (Fig. 14).

(5) Remove hinge nut holding motor to top.

(6) Reverse removal procedures to install.

WINDSHIELD WIPER/WASHER SWITCH

REMOVE/INSTALL

(1) Disconnect negative cable from battery.

(2) Remove horn button with a push and turn mo-

tion.

(3) Remove horn button components (Fig. 15).(4) Turn ignition switch to the LOCK position and

remove the steering wheel nut and washer.

(5) Scribe an alignment mark on the steering

wheel in line with the mark already existing on the

end of the steering column.

(6) Remove vibration damper from the steering col-

umn hub, if equipped.

(7) Remove steering wheel using a steering wheel

puller. DO NOT hammer on puller or end of steering

shaft.

WARNING: TO REMOVE THE STEERING SHAFT

SNAP RING IN THE FOLLOWING STEP, THE LOCK-

PLATE MUST BE COMPRESSED. DO NOT ATTEMPT

TO REMOVE THE LOCKPLATE WITHOUT COM-

PRESSOR TOOL C4156 AS THE LOCKPLATE IS UN-

DER HEAVY SPRING TENSION.

(8) Compress lockplate with compressor tool

C4156.

(9) Remove steering shaft snap ring (Fig. 16). Dis-

card snap ring. It is not reusable.

(10) Remove compressor tool.

(11) Remove lockplate, cancelling cam, and upper

bearing preload spring.

(12) Remove horn button components from cancel-

ing cam.

(13) Remove screw and hazard warning switch

knob.

(14) Remove dimmer switch actuator arm attach-

ing screw (Fig. 17).

(15) Remove turn/hazard switch attaching screws.

(16) Remove 6 instrument bezel screws (Fig. 18).

(17) Slide bezel toward steering wheel.

Fig. 13 Liftgate Wiper Motor Cover

Fig. 14 Liftgate Wiper Motor

Fig. 15 Steering Wheel Remove/Install

8K - 20 WIPER AND WASHER SYSTEMS - YJJ

Page 444 of 2198

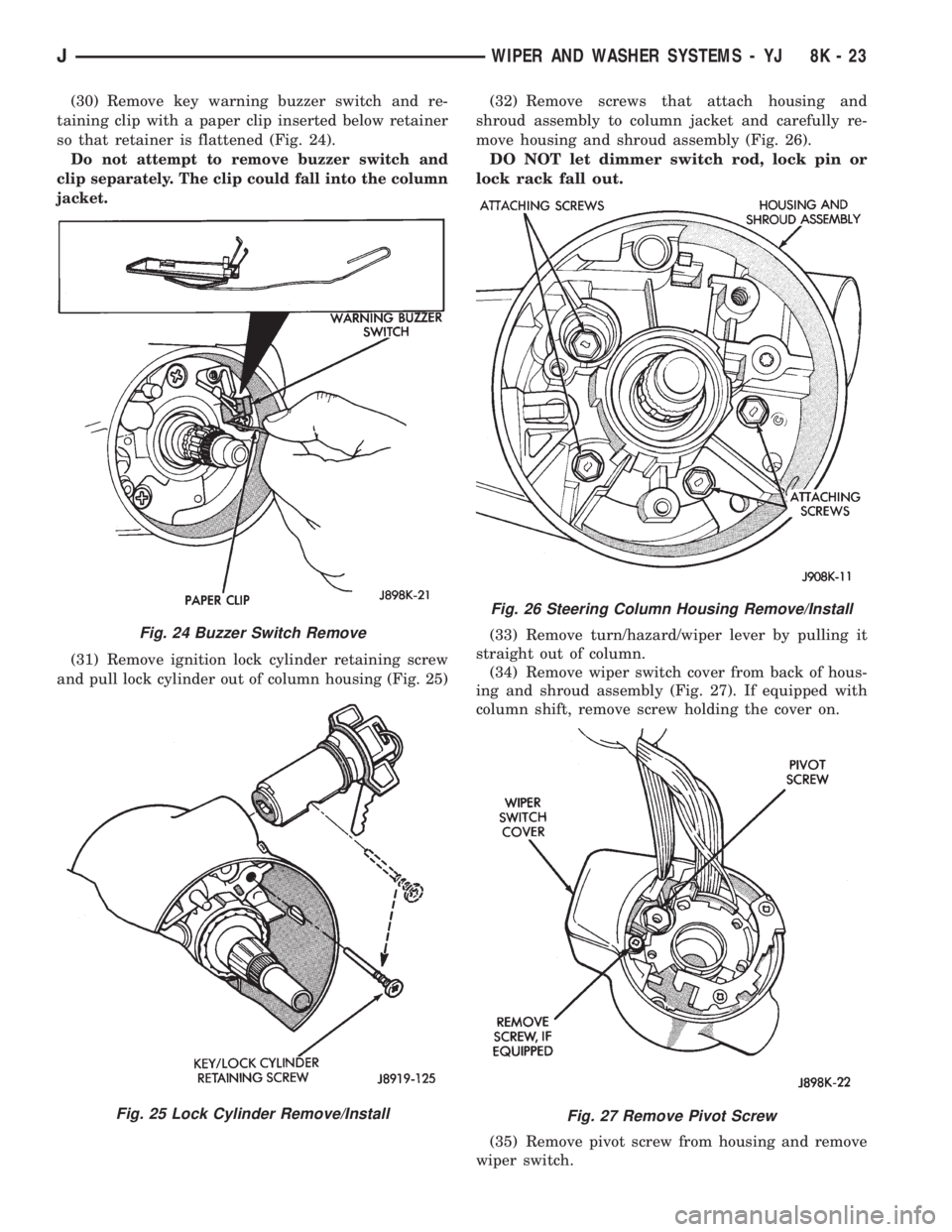

(30) Remove key warning buzzer switch and re-

taining clip with a paper clip inserted below retainer

so that retainer is flattened (Fig. 24).

Do not attempt to remove buzzer switch and

clip separately. The clip could fall into the column

jacket.

(31) Remove ignition lock cylinder retaining screw

and pull lock cylinder out of column housing (Fig. 25)(32) Remove screws that attach housing and

shroud assembly to column jacket and carefully re-

move housing and shroud assembly (Fig. 26).

DO NOT let dimmer switch rod, lock pin or

lock rack fall out.

(33) Remove turn/hazard/wiper lever by pulling it

straight out of column.

(34) Remove wiper switch cover from back of hous-

ing and shroud assembly (Fig. 27). If equipped with

column shift, remove screw holding the cover on.

(35) Remove pivot screw from housing and remove

wiper switch.

Fig. 24 Buzzer Switch Remove

Fig. 25 Lock Cylinder Remove/Install

Fig. 26 Steering Column Housing Remove/Install

Fig. 27 Remove Pivot Screw

JWIPER AND WASHER SYSTEMS - YJ 8K - 23

Page 451 of 2198

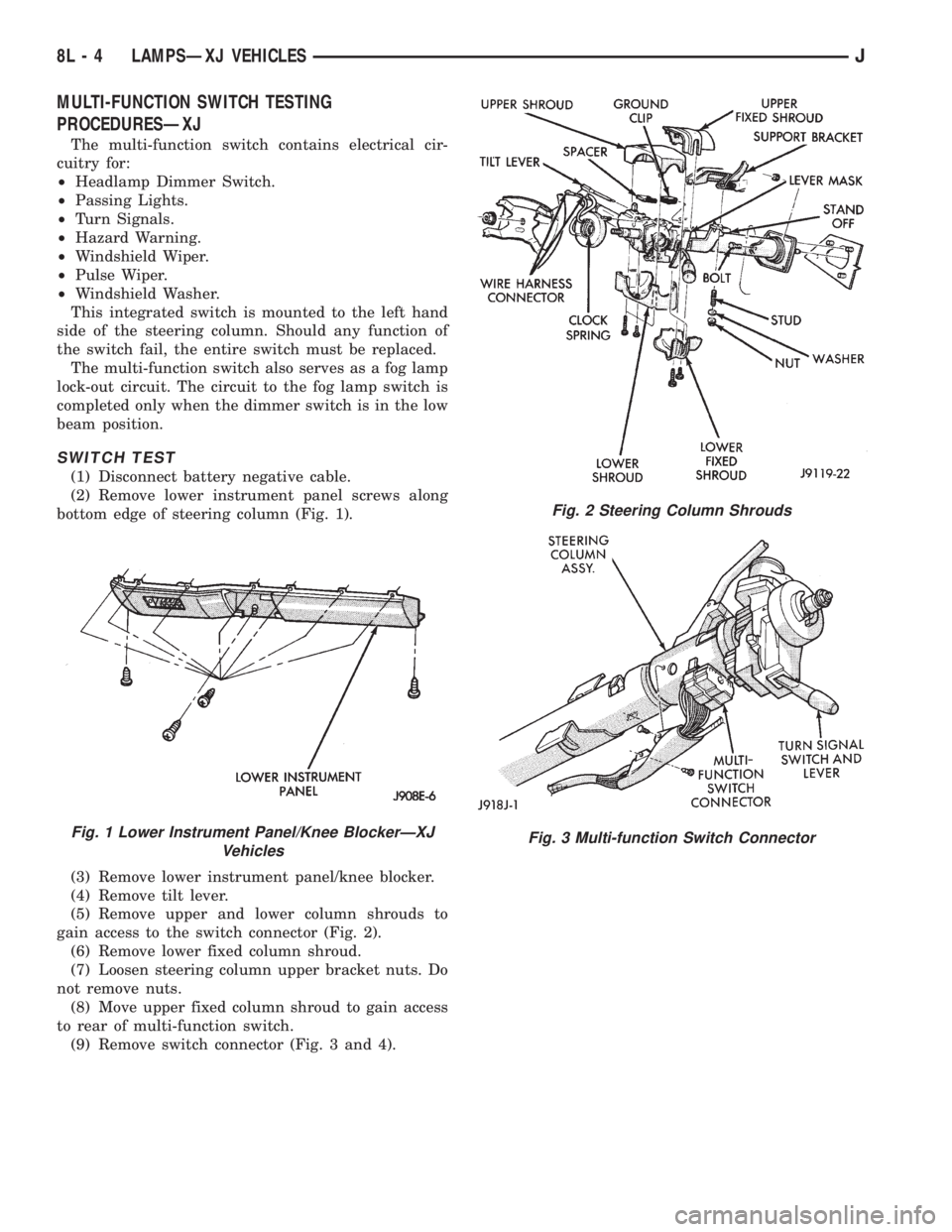

MULTI-FUNCTION SWITCH TESTING

PROCEDURESÐXJ

The multi-function switch contains electrical cir-

cuitry for:

²Headlamp Dimmer Switch.

²Passing Lights.

²Turn Signals.

²Hazard Warning.

²Windshield Wiper.

²Pulse Wiper.

²Windshield Washer.

This integrated switch is mounted to the left hand

side of the steering column. Should any function of

the switch fail, the entire switch must be replaced.

The multi-function switch also serves as a fog lamp

lock-out circuit. The circuit to the fog lamp switch is

completed only when the dimmer switch is in the low

beam position.

SWITCH TEST

(1) Disconnect battery negative cable.

(2) Remove lower instrument panel screws along

bottom edge of steering column (Fig. 1).

(3) Remove lower instrument panel/knee blocker.

(4) Remove tilt lever.

(5) Remove upper and lower column shrouds to

gain access to the switch connector (Fig. 2).

(6) Remove lower fixed column shroud.

(7) Loosen steering column upper bracket nuts. Do

not remove nuts.

(8) Move upper fixed column shroud to gain access

to rear of multi-function switch.

(9) Remove switch connector (Fig. 3 and 4).

Fig. 1 Lower Instrument Panel/Knee BlockerÐXJ

Vehicles

Fig. 2 Steering Column Shrouds

Fig. 3 Multi-function Switch Connector

8L - 4 LAMPSÐXJ VEHICLESJ