battery capacity JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 274 of 2198

charged. However, even with these vents, hydrogen

gas can collect in or around the battery. If hydrogen

gas is exposed to flame or sparks, it can ignite.

If the electrolyte level is low, the battery could arc

internally and explode. If the battery is equipped

with removable cell caps, add distilled water when-

ever the electrolyte level is below the top of the

plates. If the battery cell caps cannot be removed, the

battery must be replaced when the electrolyte level is

low.

WARNING: DO NOT ATTEMPT TO ASSIST BOOST,

CHARGE, OR TEST BATTERY WHEN ELECTRO-

LYTE LEVEL IS BELOW THE TOP OF THE PLATES.

PERSONAL INJURY MAY OCCUR.

BATTERY RATINGS

Currently, there are 2 commonly accepted methods

for rating and comparing battery performance. These

ratings are called Cold Cranking Amperage (CCA),

and Reserve Capacity (RC). Be certain that a replace-

ment battery has CCA and RC ratings that equal or

exceed the original equipment specification for the

vehicle being serviced. See Battery Classifications

and Ratings charts in Specifications at the back of

this group.

COLD CRANKING AMPERAGE

The Cold Cranking Amperage (CCA) rating speci-

fies how much current (in amperes) the battery can

deliver for 30 seconds at -17.7ÉC (0ÉF). Terminal volt-

age must not fall below 7.2 volts during or after the

30 second discharge. The CCA required is generally

higher as engine displacement increases, depending

also upon the starter current draw requirements.

RESERVE CAPACITY

The Reserve Capacity (RC) rating specifies the

time (in minutes) it takes for battery terminal volt-

age to fall below 10.2 volts at a discharge rate of 25

amps. RC is determined with the battery fully-

charged at 26.7ÉC (80ÉF). This rating estimates how

long the battery might last after a charging system

failure, under minimum electrical load.

DIAGNOSIS

The battery must be completely charged and the

top, posts, and terminal clamps should be properly

cleaned before diagnostic procedures are performed.

Refer to Group 8B - Battery/Starter/Generator Ser-

vice for more information.

The condition of a battery is determined by two cri-

teria:

(1)State-Of-ChargeThis can be determined by

viewing the built-in test indicator, by checking spe-

cific gravity of the electrolyte (hydrometer test), or by

checking battery voltage (open circuit voltage test).(2)Cranking CapacityThis can be determined

by performing a battery load test, which measures

the ability of the battery to supply high-amperage

current.

If the battery has a built-in test indicator, use this

test first. If it has no test indicator, but has remov-

able cell caps, perform the hydrometer test first. If

cell caps are not removable, or a hydrometer is not

available, perform the open circuit voltage test first.

The battery must be charged before proceeding

with a load test if:

²the built-in test indicator has a black or dark color

visible

²the temperature corrected specific gravity is less

than 1.235

²the open circuit voltage is less than 12.4 volts.

A battery that will not accept a charge is faulty

and further testing is not required. A battery that is

fully-charged, but does not pass the load test is

faulty and must be replaced.

Completely discharged batteries may take

several hours to accept a charge. See Charging

Completely Discharged Battery.

A battery is fully-charged when:

²all cells are gassing freely during charging

²a green color is visible in the sight glass of the

built-in test indicator

²three corrected specific gravity tests, taken at

1-hour intervals, indicate no increase in specific grav-

ity

²open circuit voltage is 12.4 volts or greater.

ABNORMAL BATTERY DISCHARGING

Any of the following conditions can result in abnor-

mal battery discharging:

(1) Corroded battery posts and terminals.

(2) Loose or worn generator drive belt.

(3) Electrical loads that exceed the output of the

charging system, possibly due to equipment installed

after manufacture or repeated short trip use.

(4) Slow driving speeds (heavy traffic conditions) or

prolonged idling with high-amperage draw systems

in use.

(5) Faulty circuit or component causing excessive

ignition-off draw. See Ignition-Off Draw in this group

for diagnosis.

(6) Faulty charging system.

(7) Faulty or incorrect battery.

BUILT-IN TEST INDICATOR

A test indicator (hydrometer) built into the top of

the battery case, provides visual information for bat-

tery testing (Fig. 1). It is important when using the

test indicator that the battery be level and have a

clean sight glass to see correct indications. Additional

light may be required to view indicator.

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 3

Page 277 of 2198

the specific gravity for temperature variation. Test

the specific gravity of the electrolyte in each battery

cell.

Example: A battery is tested at -12.2ÉC (10ÉF) and

has a specific gravity of 1.240. Determine the actual

specific gravity as follows:

(1) Determine the number of degrees above or be-

low 26.7ÉC (80ÉF):

26.6ÉC - -12.2ÉC = 38.8ÉC (80ÉF - 10ÉF = 70ÉF)

(2) Divide the result from step 1 by 5.5 (10):

38.8ÉC/5.5 = 7 (70ÉF/10 = 7)

(3) Multiply the result from step 2 by the temper-

ature correction factor (0.004):

7 x 0.004 = 0.028

(4) The temperature at testing was below 26.7ÉC

(80ÉF); therefore, the temperature correction is sub-

tracted:

1.240 - 0.028 = 1.212

The corrected specific gravity of the battery in this

example is 1.212.

If the specific gravity of all cells is above 1.235, but

variation between cells is more than 50 points

(0.050), the battery should be replaced.

If the specific gravity of one or more cells is less

than 1.235, charge the battery at a rate of approxi-

mately 5 amperes. Continue charging until 3 consec-

utive specific gravity tests, taken at 1-hour intervals,

are constant. If the cell specific gravity variation is

more than 50 points (0.050) at the end of the charge

period, replace the battery.

When the specific gravity of all cells is above 1.235,

and cell variation is less than 50 points (0.050), the

battery may be load tested.

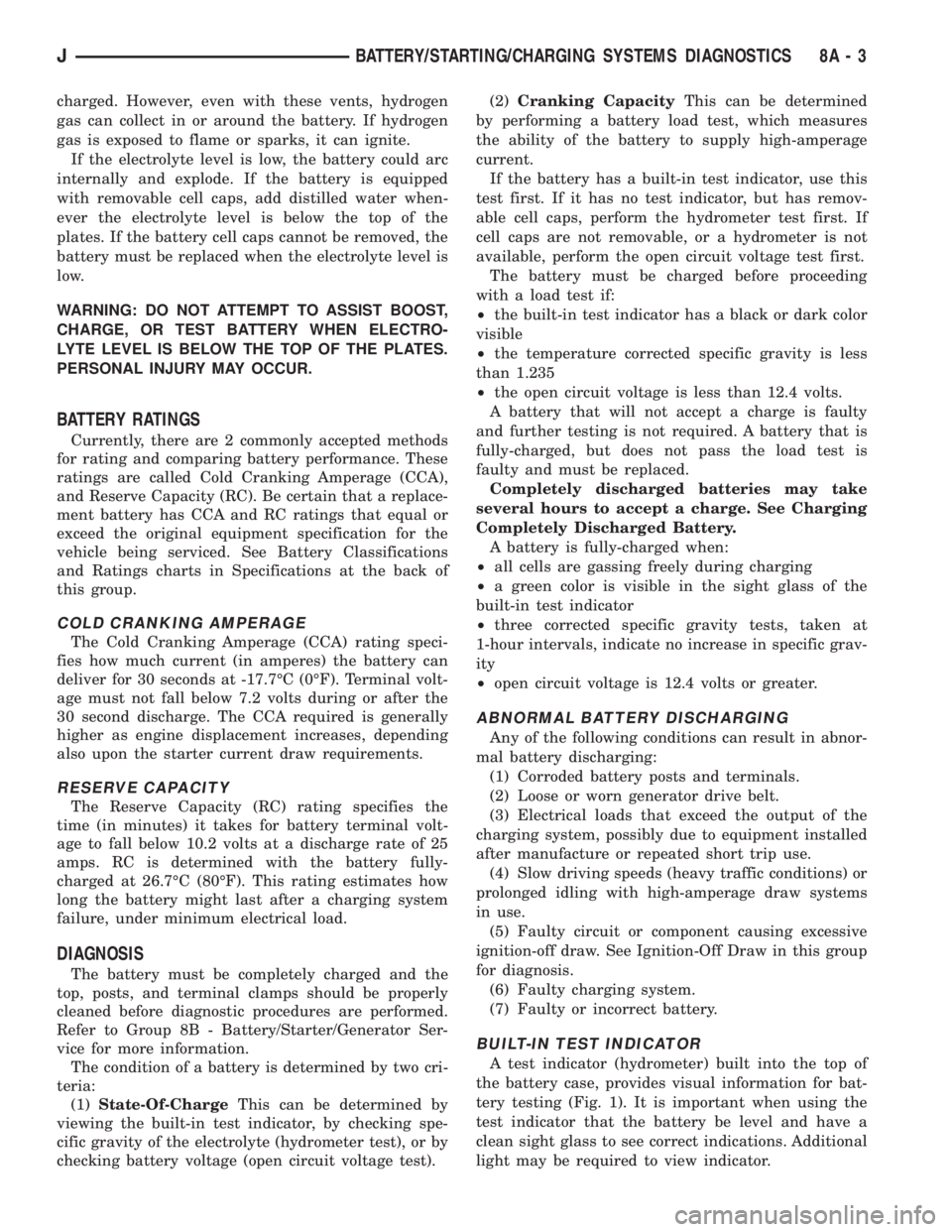

OPEN CIRCUIT VOLTAGE TEST

A battery open circuit voltage (no load) test will

show state-of-charge of a battery. This test can be

used in place of the hydrometer test if a hydrometer

is not available, or for maintenance-free batteries

with non-removable cell caps.

Before proceeding with this test or load test,

completely charge battery as described in Bat-

tery Charging in this group.

Test battery open circuit voltage as follows:

(1) Before measuring open circuit voltage the sur-

face charge must be removed from the battery. Turn

headlamps on for 15 seconds, then allow up to 5 min-

utes for voltage to stabilize.

(2) Remove both battery cables, negative first.

(3) Using a voltmeter connected to the battery

posts (refer to instructions provided with voltmeter)

measure open circuit voltage (Fig. 3).

See Open Circuit Voltage chart. This voltage read-

ing will indicate state-of-charge, but will not reveal

cranking capacity. If a battery has an open circuit

voltage reading of 12.4 volts or greater, it may be

load tested. A battery that will not endure a load test

is faulty and must be replaced.

LOAD TEST

A battery load test will verify battery cranking ca-

pacity. The test is based on the Cold Cranking Am-

perage (CCA) rating of the battery. See Battery

Classifications and Ratings chart in Specifications, at

the back of this group.

WARNING: IF BATTERY SHOWS SIGNS OF FREEZ-

ING, LEAKING, LOOSE POSTS, OR LOW ELECTRO-

LYTE LEVEL, DO NOT LOAD TEST. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

Before performing load test, the battery must

be FULLY-CHARGED.

(1) Remove both battery cables, negative first. Bat-

tery top and posts should be clean.

(2) Connect a suitable volt-ammeter-load tester

(Fig. 4) to the battery posts (Fig. 5). Refer to operat-

ing instructions provided with the tester being used.

Check the open circuit voltage (no load) of the bat-

tery. Open circuit voltage must be 12.4 volts or

greater.

(3) Rotate the load control knob (carbon pile rheo-

stat) to apply a 300 amp load for 15 seconds, then re-

turn the control knob to OFF (Fig. 6). This will

remove the surface charge from the battery.

(4) Allow the battery to stabilize to open circuit

voltage. It may take up to 5 minutes for voltage to

stabilize.

OPEN CIRCUIT VOLTAGE

Fig. 3 Testing Open Circuit Voltage

8A - 6 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 279 of 2198

WARNING: POISONOUS AND CAUSTIC. BATTERY

CONTAINS SULFURIC ACID. AVOID CONTACT WITH

SKIN, EYES, OR CLOTHING. IN EVENT OF CON-

TACT, FLUSH WITH WATER AND CALL PHYSICIAN

IMMEDIATELY. KEEP OUT OF REACH OF CHIL-

DREN.

CAUTION: Always disconnect the battery negative

cable before charging battery to avoid damage to

electrical system components. Do not exceed 16.0

volts while charging battery.

Battery electrolyte will bubble inside battery case

during normal battery charging. If the electrolyte

boils, or is discharged from the vent holes while

charging, immediately reduce charging rate or turn

OFF charger and evaluate battery condition.

Battery should not be hot to the touch. If the

battery feels hot to the touch, turn OFF

charger and let battery cool before continuing

charging operation.

Some battery chargers are equipped with polarity

sensing circuitry. This circuitry protects the charger

and/or battery from being damaged if improperly con-

nected.

If the battery state-of-charge is too low for the po-

larity sensing circuitry to detect, the charger will not

operate. This makes it appear that the battery will

not accept charging current. Refer to instructions

provided with the battery charger being used to by-

pass the polarity sensing circuitry.

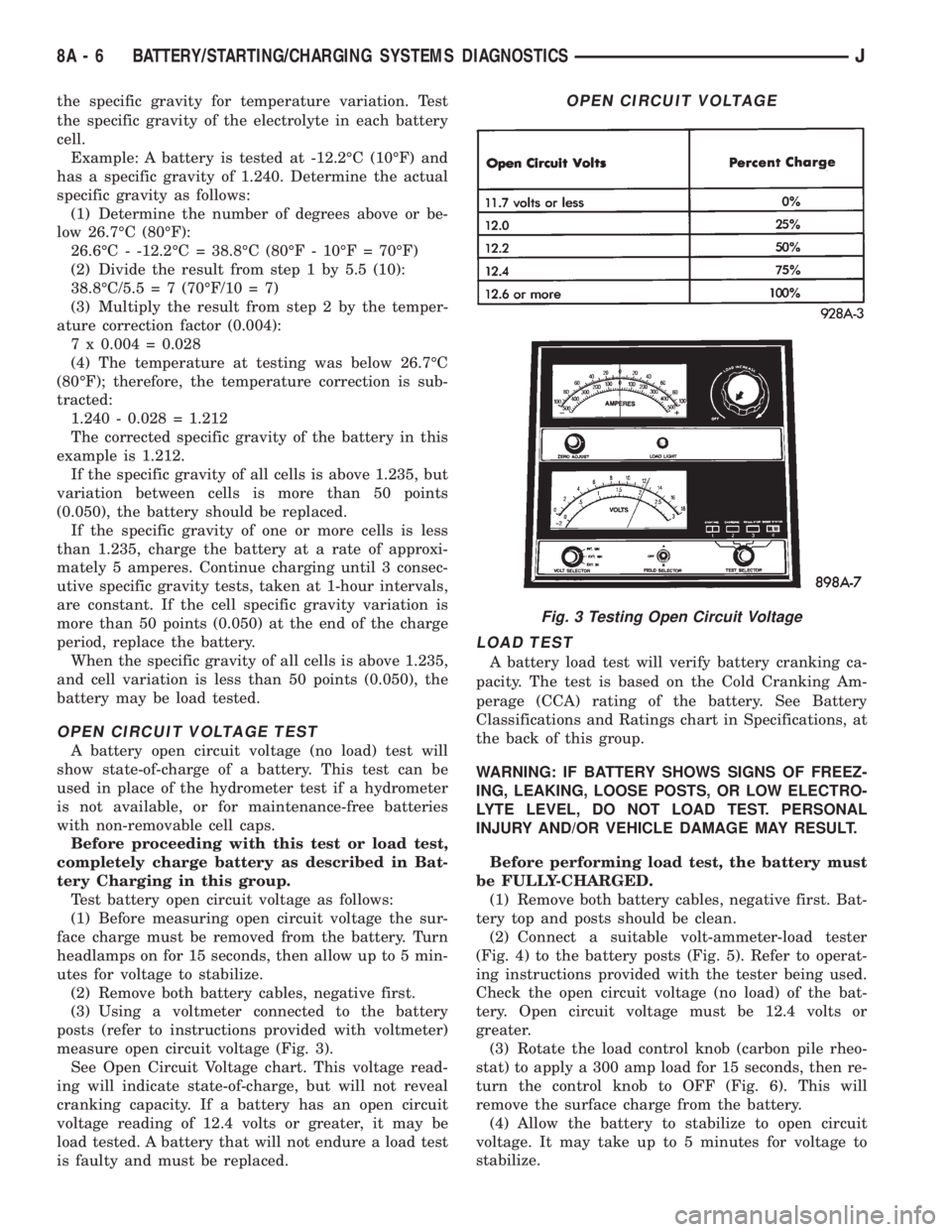

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine cranking

capacity. If the battery will endure a load test, return

the battery to use. If the battery will not endure a

load test, it must be replaced.

Clean and inspect battery holddowns, tray, termi-

nals, posts, and top before completing service. Refer

to Group 8B - Battery/Starter/Generator Service for

more information.

CHARGING TIME REQUIRED

The time required to charge a battery will vary, de-

pending upon the following factors:(1)Battery CapacityÐA completely discharged

heavy-duty battery requires twice the recharging

time of a small capacity battery.

WARNING: NEVER EXCEED 20 AMPS WHEN

CHARGING A COLD (-1ÉC/30ÉF) BATTERY. PER-

SONAL INJURY MAY RESULT.

(2)TemperatureÐA longer time will be needed to

charge a battery at -18ÉC (0ÉF) than at 27ÉC (80ÉF).

When a fast charger is connected to a cold battery,

current accepted by the battery will be very low at

first. As the battery warms, it will accept a higher

charging current rate.

(3)Charger CapacityÐA charger that supplies

only 5 amperes will require a longer charging time. A

charger that supplies 20 amperes or more requires a

shorter charging time.

(4)State-Of-ChargeÐA completely discharged

battery requires more charging time than a partially

discharged battery. Electrolyte is nearly pure water

in a completely discharged battery. At first, the

charging current (amperage) will be low. As the bat-

tery charges, the specific gravity of the electrolyte

will gradually rise.

CHARGING COMPLETELY DISCHARGED

BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless this proce-

dure is properly followed, a good battery may be

needlessly replaced.

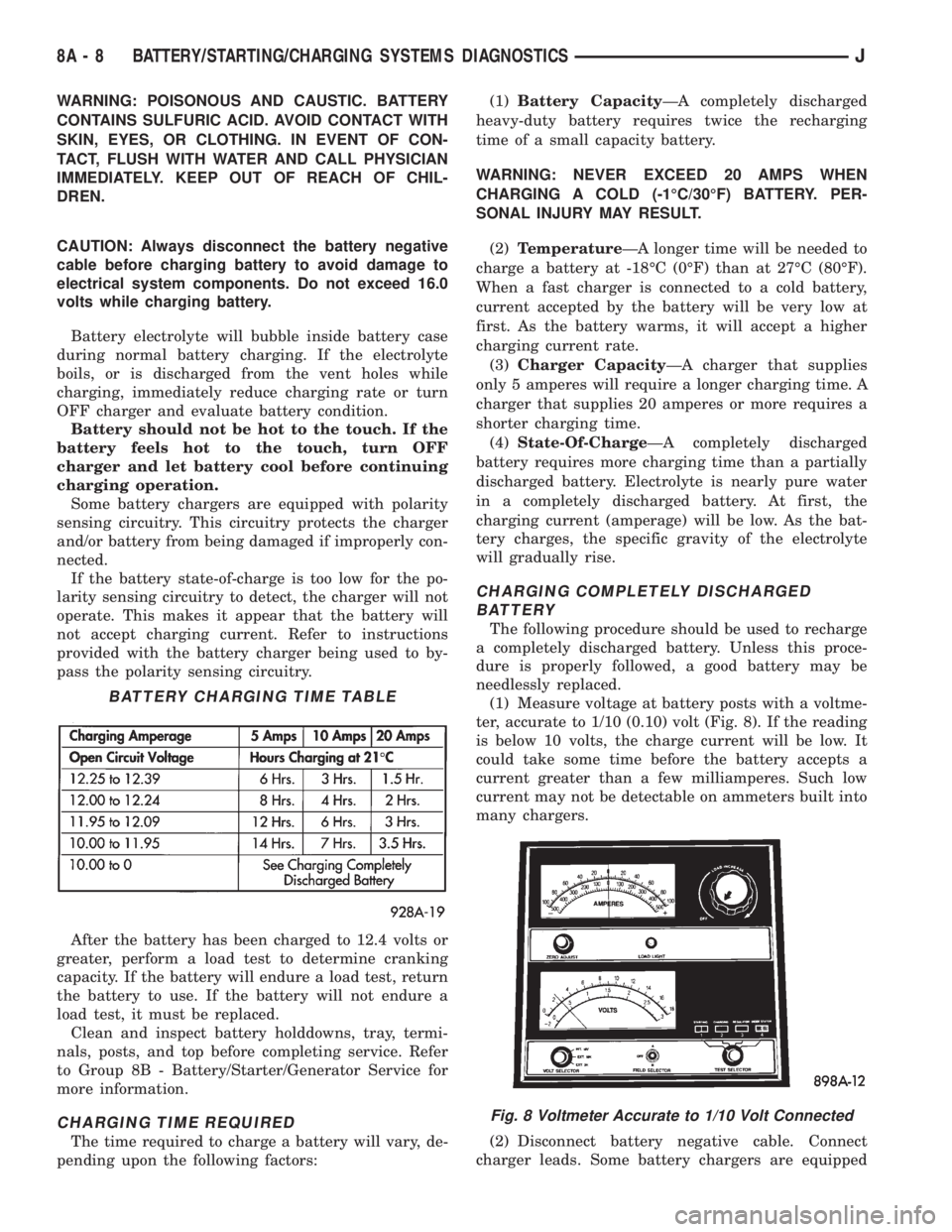

(1) Measure voltage at battery posts with a voltme-

ter, accurate to 1/10 (0.10) volt (Fig. 8). If the reading

is below 10 volts, the charge current will be low. It

could take some time before the battery accepts a

current greater than a few milliamperes. Such low

current may not be detectable on ammeters built into

many chargers.

(2) Disconnect battery negative cable. Connect

charger leads. Some battery chargers are equipped

BATTERY CHARGING TIME TABLE

Fig. 8 Voltmeter Accurate to 1/10 Volt Connected

8A - 8 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 1218 of 2198

FUEL DELIVERY SYSTEM

INDEX

page page

Fuel Filter................................ 9

Fuel Pressure Leak Down Test................ 8

Fuel Pressure Release Procedure.............. 6

Fuel Pump Capacity Test.................... 7

Fuel Pump Electrical Control.................. 5Fuel Pump Module......................... 3

Fuel System Pressure Test................... 6

Fuel Tubes/Lines/Hoses and Clamps............ 9

Quick-Connect Fittings..................... 10

FUEL PUMP MODULE

The fuel pump module is installed in the top of the

fuel tank. The fuel pump module contains the follow-

ing components:

²Electric fuel pump

²Fuel pump reservoir

²In-tank fuel filter

²Fuel gauge sending unit

²Fuel supply and return tube connections

The fuel pump used on all vehicles is a turbine

type pump. It is driven by a permanent magnet 12

volt electric motor that is immersed in the fuel tank.

The electrical pump is integral with the fuel sender

unit. The pump/sender assembly is installed inside

the fuel tank.

The fuel pump has a check valve at the outlet end

that consists of a ball held against a seat by force ap-

plied from a spring. When the pump is operating,

fuel pressure overcomes spring pressure and forces

the ball off its seat, allowing fuel to flow. When the

pump is not operating, spring pressure forces the ball

back against the seat preventing fuel backflow

through the pump.

Fuel system pressure is maintained at approxi-

mately 214 kPa (31 psi). This is when the pump is

operating and vacuum is supplied to the fuel pres-

sure regulator. If vacuum is not supplied to the pres-

sure regulator, fuel pressure will be approximately

55-69 kPa (8-10 psi) higher. This may be due to a

broken or clogged vacuum line. When the fuel pump

is not operating, fuel system pressure of 131-269 kPa

(19-39 psi) is maintained for approximately 2 to 6

hours. This is done by the fuel pump outlet check

valve and the vacuum assisted fuel pressure regula-

tor.

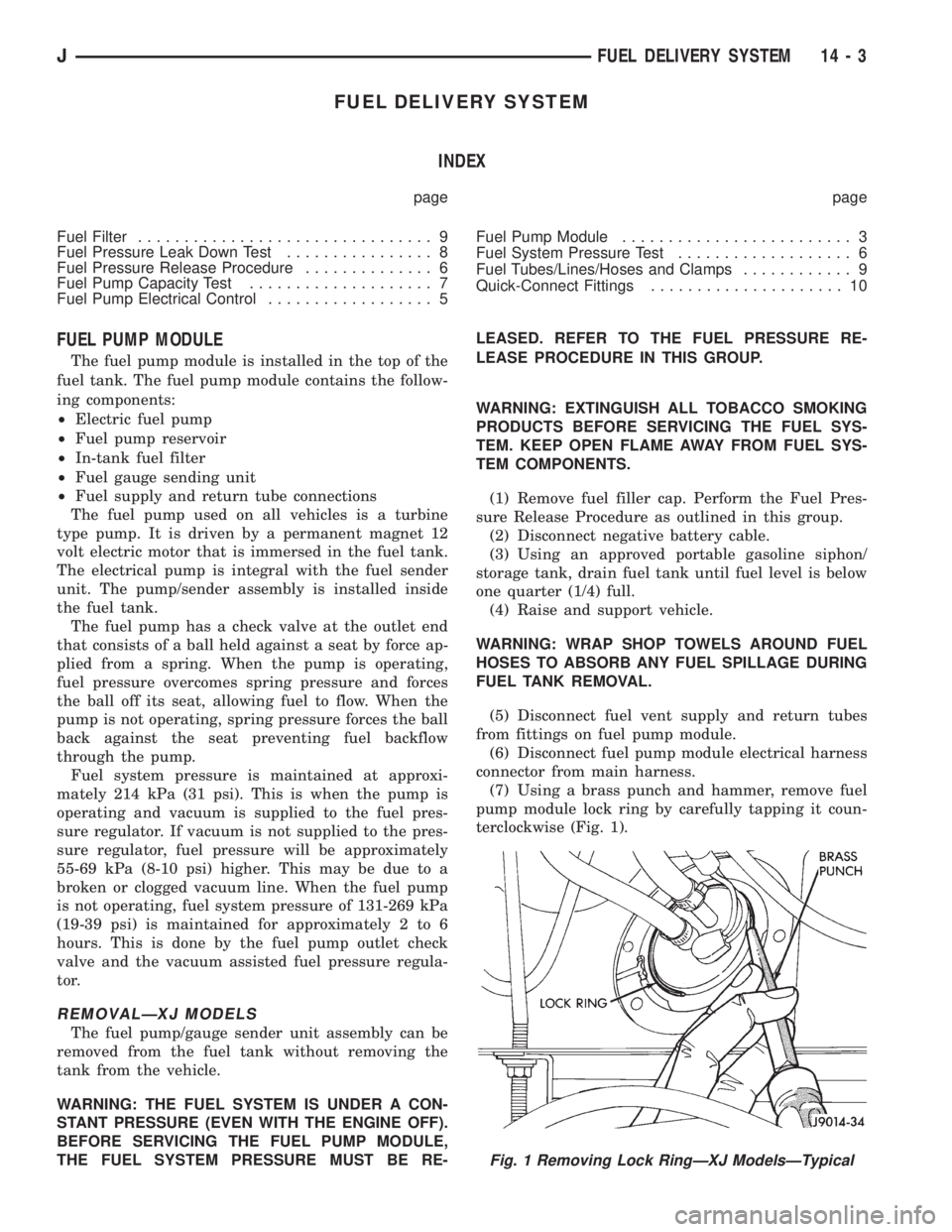

REMOVALÐXJ MODELS

The fuel pump/gauge sender unit assembly can be

removed from the fuel tank without removing the

tank from the vehicle.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING THE FUEL PUMP MODULE,

THE FUEL SYSTEM PRESSURE MUST BE RE-LEASED. REFER TO THE FUEL PRESSURE RE-

LEASE PROCEDURE IN THIS GROUP.

WARNING: EXTINGUISH ALL TOBACCO SMOKING

PRODUCTS BEFORE SERVICING THE FUEL SYS-

TEM. KEEP OPEN FLAME AWAY FROM FUEL SYS-

TEM COMPONENTS.

(1) Remove fuel filler cap. Perform the Fuel Pres-

sure Release Procedure as outlined in this group.

(2) Disconnect negative battery cable.

(3) Using an approved portable gasoline siphon/

storage tank, drain fuel tank until fuel level is below

one quarter (1/4) full.

(4) Raise and support vehicle.

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSES TO ABSORB ANY FUEL SPILLAGE DURING

FUEL TANK REMOVAL.

(5) Disconnect fuel vent supply and return tubes

from fittings on fuel pump module.

(6) Disconnect fuel pump module electrical harness

connector from main harness.

(7) Using a brass punch and hammer, remove fuel

pump module lock ring by carefully tapping it coun-

terclockwise (Fig. 1).

Fig. 1 Removing Lock RingÐXJ ModelsÐTypical

JFUEL DELIVERY SYSTEM 14 - 3

Page 1965 of 2198

BUMPERÐXJ, LIFTGATE LICENSE PLATE

SCREW ANCHOR.....................23-65

BUMPERÐXJ, REAR SEATBACK LATCH

STRIKER...........................23-84

BUMPERS......................13-16,13-5

BUS, CCD; FUEL/IGNITION (XJ).......8W-30-5

BUSHING AND PISTON CLEARANCE,

AW-4 .............................21-339

BUSHING REPLACEMENT, AXLE......2-12,2-34

BUSHING REPLACEMENT, LEAF SPRING

EYE; FRONT SUSPENSION AND AXLE.....2-17

BUSHING REPLACEMENT, LEAF SPRING

EYE; REAR SUSPENSION AND AXLES . . . 3-5,3-7

BUSHINGS, CLUTCH AND BRAKE PEDAL . . . 0-22

BUZZER, COMBINATION; INTERIOR

LIGHTING (YJ)....................8W-44-1

BUZZER MODULE.................8U-1,8U-2

BUZZER MODULE SCHEMATIC - YJ.......8U-4

CABLE, ACCELERATOR PEDAL AND

THROTTLE.....................14-17,14-58

CABLE ADJUSTMENT, PARK INTERLOCK . 21-195

CABLE ADJUSTMENT, SHIFT...........21-195

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE.........................21-194

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE VALVE....................21-71

CABLE ADJUSTMENT (XJ), PARK

INTERLOCK........................21-101

CABLE ADJUSTMENT (XJ), SHIFT.......21-100

CABLE ADJUSTMENT (XJ/YJ), THROTTLE

VALVE..............................21-101

CABLE REMOVE/INSTALL, SERVO.......8H-10

CABLE REPLACEMENT, TRANSMISSION

THROTTLE.........................21-193

CABLE REPLACEMENT (XJ), PARKING

BRAKE REAR.........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE FRONT........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE REAR.........................5-68

CABLE REPLACEMENTÐXJ, LATCH

RELEASE...........................23-11

CABLE RESISTANCE, SPARK PLUG......8D-14

CABLE, SERVO.......................8H-1

CABLE, SPEEDOMETER.................0-33

CABLE TENSIONER ADJUSTMENT

(XJ/YJ), PARKING BRAKE...............5-69

CABLE TENSIONER REPLACEMENT (XJ),

PARKING BRAKE......................5-66

CABLE, THROTTLE...................14-17

CABLE/LINKAGE ADJUSTMENT,

GEARSHIFT.........................21-71

CABLES, DISTRIBUTOR CAP AND

ROTOR, IGNITION.....................0-20

CABLES, SPARK PLUG SECONDARY.....8D-14,

8D-24

CABLES, VENT DOOR CONTROL.........24-32

CALIBRATION, COMPASS...............8C-5

CALIPER ASSEMBLY...................5-50

CALIPER CLEANING AND INSPECTION.....5-50

CALIPER DISASSEMBLY................5-48

CALIPER INSTALLATION................5-51

CALIPER OPERATION AND WEAR

COMPENSATION......................5-45

CALIPER REMOVAL....................5-48

CAMSHAFT......................9-32,9-74

CAMSHAFT PIN REPLACEMENT......9-34,9-75

CAMSHAFT POSITION SENSOR; FUEL

SYSTEM............................14-60

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (YJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

IGNITION SYSTEMS..............8D-17,8D-2

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ-RHD)............8W-30-3

CAMSHAFT POSITION SENSOR TEST;

FUEL SYSTEM.......................14-46

CAMSHAFT POSITION SENSOR TEST;

IGNITION SYSTEMS

...................8D-6

CAMSHAFT POSITION SENSORÐPCM

INPUT

.............................14-22

(CANADA ONLY)ÐXJ, DAYTIME

RUNNING LIGHTS

....................8L-15

(CANADA ONLY)ÐYJ, DAYTIME

RUNNING LIGHTS

....................8L-30

CANISTER, EVAP

..................25-4,25-7CAP AND ROTOR, IGNITION CABLES,

DISTRIBUTOR........................0-20

CAP, DISTRIBUTOR....................8D-7

CAP, FUEL TANK FILLER TUBE;

EMISSION CONTROL SYSTEMS......25-4,25-7

CAP, FUEL TANK FILLER TUBE; FUEL

SYSTEM............................14-13

CAP, RADIATOR PRESSURE.............7-25

CAPACITIES, COOLING SYSTEM..........7-45

CAPACITIES, FLUID.....................0-3

CAPACITIES, FUEL TANK..........14-13,14-67

CAPACITY TEST, FUEL PUMP............14-7

CAR REPLACEMENT, PITMAN SHAFT

SEALSÐIN.........................19-23

CARDAN (CV), DOUBLE................16-11

CARDAN, SINGLE....................16-10

CARGO BARRIERÐXJ................23-101

CARGO LAMP AND DOME LAMP;

INTERIOR LIGHTING (XJ-RHD)........8W-44-1

CARGO LAMP, COURTESY LAMPS AND

DOME LAMP; INTERIOR LIGHTING (XJ) . 8W-44-1

CARGO LAMPÐXJ...................23-94

CARPET/MATÐXJ, FRONT.............23-99

CARPET/MATÐXJ, REAR.............23-100

CARPETÐYJ.......................23-156

CARPETS AND FLOOR MATSÐXJ.......23-99

CARRIERÐYJ, EXTERNAL SPARE/

WHEEL TIRE.......................23-133

CASE (4WD VEHICLES), TRANSFER........0-24

CASE ASSEMBLY, TRANSFER....21-294,21-319

CASE CHANGES, TRANSFER...........21-307

CASE CLEANING AND INSPECTION,

TRANSMISSION.....................21-125

CASE COVER OIL SEAL REPLACEMENT,

TIMING.........................9-30,9-73

CASE COVER, TIMING..............9-31,9-72

CASE DISASSEMBLY AND OVERHAUL,

TRANSFER...................21-289,21-310

CASE IDENTIFICATION, TRANSFER.....21-284,

21-307

CASE INSTALLATION, TRANSFER . 21-288,21-309

CASE LUBRICANT AND FILL LEVEL,

TRANSFER.........................21-284

CASE, NP231 TRANSFER.......21-283,21-305

CASE, NP242 TRANSFER.......21-307,21-331

CASE OVERHAUL, FIRST-REVERSE

BRAKE PISTON AND TRANSMISSION....21-247

CASE REMOVAL, TRANSFER.....21-287,21-309

CASE SKID PLATE, TRANSFER......13-15,13-3

CASE SPECIFICATIONS, TRANSMISSION/

TRANSFER.........................21-333

CATALYTIC CONVERTER............11-1,11-4

CATALYTIC CONVERTOR................25-1

CAUTIONS, AND WARNINGS, NOTES;

WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)...................8W-1

CCD BUS; FUEL/IGNITION (XJ)........8W-30-5

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐXJ.......................8L-12

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐYJ.......................8L-28

CERTIFICATION LABEL, VEHICLE SAFETY . Intro.-4

CHAIN AND SPROCKETS, TIMING....9-31,9-73

CHANGE AND FILTER REPLACEMENT,

ENGINE OIL

..........................0-16

CHANGE, LUBRICANT; FRONT

SUSPENSION AND AXLE

................2-23

CHANGE, LUBRICANT; REAR

SUSPENSION AND AXLES

...........3-13,3-31

CHANGE, REFILLING AFTER OVERHAUL

OR FLUID/FILTER

..............21-100,21-182

CHANGES AND PARTS

INTERCHANGEABILITY, TRANSMISSION

. . . 21-67

CHANGES, TRANSFER CASE

...........21-307

CHANNEL REPLACEMENTÐYJ, DOOR

FRAME GLASS

......................23-142

CHARGING, BATTERY

..................8A-7

CHARGING REFRIGERANT SYSTEM

......24-11

CHARGING SYSTEM; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS

.......................8A-17

CHARGING SYSTEM; CHARGING

SYSTEM (XJ)

.....................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (XJ-RHD)

.................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (YJ)

.....................8W-20-1CHARGING SYSTEM INDICATOR LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-3

CHARGING SYSTEM SPECIFICATIONS....8A-23

CHARGING TIME TABLE, BATTERY........8A-8

CHART, MAIN BEARING FITTING......9-48,9-90

CHART, XJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHART, YJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHARTÐAX 15 MANUAL

TRANSMISSION, SELECTIVE SNAP

RING.............................21-334

CHARTS, BRAKELINE..................5-12

CHARTS, DIAGNOSIS GUIDES...........21-77

CHARTS, GEARTRAIN OPERATION AND

APPLICATION.......................21-169

CHARTS, INSPECTION AND DIAGNOSIS.....6-4

CHASSIS AND BODY COMPONENTS.......0-28

CHASSIS COMPONENT AND WHEEL

BEARING LUBRICANTS.................0-28

CHECK VALVE TEST, POWER BOOSTER.....5-9

CHECKING FLUID LEVEL AND

CONDITION........................21-182

CHECKS, PRELIMINARY.................7-5

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ)....................8W-44-2

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ-RHD)................8W-44-2

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ)....................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ-RHD)................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (YJ)....................8W-51-1

(CHMSL)ÐXJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-12

(CHMSL)ÐYJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-28

CIGAR LIGHTER; HORN/CIGAR LIGHTER . . . 8E-1

CIGAR LIGHTER; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

CIGAR LIGHTER; INSTRUMENT CLUSTER

(XJ).............................8W-40-1

CIRCUIT IDENTIFICATION; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-1

CIRCUIT REMOVE/INSTALL, PRINTED....8E-19,

8E-40

CIRCUIT SENSEÐPCM INPUT, IGNITION . . 14-23

CIRCUIT VOLTAGE, OPEN...............8A-6

CLAMPS, FUEL TUBES/LINES/HOSES . 14-62,14-9

CLASSIFICATION OF LUBRICANTS.........0-2

CLASSIFICATIONS AND RATINGS,

BATTERY...........................8A-23

CLEANER, AIR.......................14-29

CLEANER ELEMENT, AIR; EMISSION

CONTROL SYSTEMS...................25-7

CLEANER ELEMENT, AIR; FUEL SYSTEM . . 14-59

CLEANER ELEMENT, AIR; LUBRICATION

AND MAINTENANCE...................0-18

CLEANER HOUSING, AIR...............14-58

CLEANING AND INSPECTION, CALIPER....5-50

CLEANING AND INSPECTION, GEAR......19-42

CLEANING AND INSPECTION,

TRANSMISSION CASE................21-125

CLEANING OF TIRES...................22-2

CLEANING/INSPECTION; FRONT

SUSPENSION AND AXLE

................2-37

CLEANING/INSPECTION; REAR

SUSPENSION AND AXLES

...............3-20

CLEANING/REVERSE FLUSHING,

COOLING SYSTEM

....................7-22

CLEARANCE AND RAMP ANGLE,

GROUND

............................0-11

CLEARANCE, AW-4 BUSHING AND

PISTON

...........................21-339

CLOCKSPRING

.......................19-51

CLUSTER AND GAUGE HOUSINGSÐYJ,

INSTRUMENT

......................23-151

CLUSTER ASSEMBLY REMOVE/INSTALL

. . 8E-17,

8E-35

CLUSTER BEZELÐXJ, INSTRUMENT

.....23-80

CLUSTER BEZELÐYJ, INSTRUMENT

....23-151

CLUSTER CONNECTORS (RHD)

.........8E-11

CLUSTER, GAUGE PACKAGE

.......8E-31,8E-43

CLUSTER GROUND; INSTRUMENT

CLUSTER (XJ)

.....................8W-40-3

4 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1972 of 2198

FUEL INJECTION (MFI)ÐCOMPONENT

DESCRIPTION/SYSTEM OPERATION,

MULTI-PORT........................14-19

FUEL INJECTION (MFI)ÐCOMPONENT

REMOVAL/INSTALLATION, MULTI-PORT . . . 14-58

FUEL INJECTION (MFI)ÐGENERAL

DIAGNOSIS, MULTI-PORT..............14-35

FUEL INJECTOR......................14-60

FUEL INJECTOR TEST.................14-51

FUEL INJECTORS; FUEL/IGNITION (XJ) . 8W-30-1

FUEL INJECTORS; FUEL/IGNITION (YJ) . 8W-30-2

FUEL INJECTORS; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

FUEL INJECTORSÐPCM OUTPUT........14-27

FUEL PRESSURE LEAK DOWN TEST......14-8

FUEL PRESSURE REGULATOR.....14-33,14-61

FUEL PRESSURE RELEASE PROCEDURE . . . 14-6

FUEL PUMP CAPACITY TEST............14-7

FUEL PUMP ELECTRICAL CONTROL.......14-5

FUEL PUMP MODULE; FUEL SYSTEM....14-61,

14-3

FUEL PUMP MODULE; FUEL/IGNITION

(XJ).............................8W-30-2

FUEL PUMP MODULE; FUEL/IGNITION

(YJ).............................8W-30-2

FUEL PUMP MODULE; FUEL/IGNITION

(XJ-RHD).........................8W-30-2

FUEL PUMP RELAY; FUEL SYSTEM......14-61

FUEL PUMP RELAY; FUEL/IGNITION

(XJ).............................8W-30-2

FUEL PUMP RELAY; FUEL/IGNITION

(YJ).............................8W-30-2

FUEL PUMP RELAY; FUEL/IGNITION

(XJ-RHD).........................8W-30-2

FUEL PUMP RELAY TESTING...........14-47

FUEL PUMP RELAYÐPCM OUTPUT......14-27

FUEL RAIL..........................14-33

FUEL RAIL ASSEMBLY................14-62

FUEL REQUIREMENTS...................0-1

FUEL SYSTEM.......................14-67

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE........................14-62

FUEL SYSTEM PRESSURE TEST.....14-51,14-6

FUEL TANK.........................14-13

FUEL TANK CAPACITIES..........14-13,14-67

FUEL TANK FILLER TUBE CAP;

EMISSION CONTROL SYSTEMS......25-4,25-7

FUEL TANK FILLER TUBE CAP; FUEL

SYSTEM............................14-13

FUEL TANK FILLER TUBE, NO-LEAD......14-13

FUEL TANK PRESSURE RELIEF/

ROLLOVER VALVE...............14-16,14-62

FUEL TANK SKID PLATE...........13-15,13-3

FUEL TANK SUPPORT STRAP............13-4

FUEL TANKS...................14-13,14-62

FUEL TUBES/LINES/HOSES AND CLAMPS . 14-62,

14-9

FUEL USAGE STATEMENT...............14-1

FUEL USAGE STATEMENTÐGAS

ENGINES............................0-19

FUEL WARNING LAMP, LOW;

INSTRUMENT CLUSTER (XJ).........8W-40-1

FULL FLOOR CONSOLEÐXJ............23-95

FULL-METAL DOOR ASSIST HANDLEÐ

YJ ...............................23-136

FULL-METAL DOOR HINGESÐYJ.......23-140

FULL-METAL DOOR KEY LOCK

CYLINDERÐYJ.....................23-139

FULL-METAL DOOR LATCH EXTERNAL

RELEASE HANDLEÐYJ...............23-140

FULL-METAL DOOR LATCH INSIDE

RELEASE AND LOCK HANDLEÐYJ......23-137

FULL-METAL DOOR LATCHÐYJ........23-140

FULL-METAL DOOR SERVICEÐYJ......23-142

FULL-METAL DOOR TRIM PANELÐYJ . . . 23-137

FULL-METAL DOOR VENT WINDOW

GLASSÐYJ........................23-137

FULL-METAL DOOR WATERDAMÐYJ....23-137

FULL-METAL DOOR WEATHERSTRIP

SEALSÐYJ

........................23-141

FULL-METAL DOOR WINDOW GLASS

REGULATOR HANDLEÐYJ

............23-136

FULL-METAL DOOR WINDOW GLASS

REGULATORÐYJ

...................23-138

FULL-METAL DOOR WINDOW

GLASSÐYJ

........................23-139

FUNCTION TROUBLE DIAGNOSISÐXJ,

HEADLAMP DELAY

...................8L-14FUSE, IGNITION-OFF DRAW.............8F-1

FUSE, IN-LINE........................8F-1

GAP, SPEED SENSOR AIR...............5-37

GARAGE DOOR OPENER STORAGE,

REMOTE............................8C-1

GAS RECIRCULATION (EGR) SYSTEM,

EXHAUST............................25-1

GASKET FAILURE DIAGNOSIS, ENGINE

CYLINDER HEAD.......................9-5

GASKETS, FORM-IN-PLACE...............9-1

GAUGE CLUSTER, 9 X 3.5 ..............8E-23

GAUGE CLUSTER (LHD), HIGH-LINE.......8E-9

GAUGE CLUSTER, LOW-LINE............8E-8

GAUGE, ENGINE COOLANT

TEMPERATURE; INSTRUMENT

CLUSTER (XJ).....................8W-40-1

GAUGE, FUEL; INSTRUMENT CLUSTER

(XJ).............................8W-40-1

GAUGE, FUEL; INSTRUMENT CLUSTER

(XJ-RHD).........................8W-40-1

GAUGE HOUSINGSÐYJ, INSTRUMENT

CLUSTER..........................23-151

GAUGE, OIL PRESSURE; INSTRUMENT

CLUSTER (XJ).....................8W-40-2

GAUGE PACKAGE CLUSTER.......8E-31,8E-43

GAUGE SENDING UNIT, FUEL...........14-16

GAUGE SET, MANIFOLD................24-7

GAUGES..............8E-24,8E-27,8E-2,8E-5

GAUGES, PRESSURE...................22-2

GAUGES REMOVE/INSTALL.........8E-17,8E-39

GAUGESÐYJ, INSTRUMENT PANEL......8E-24

GEAR ADJUSTMENTS IN VEHICLE.......19-39

GEAR ADJUSTMENTS ON BENCH........19-44

GEAR ADJUSTMENTS, STEERING........19-24

GEAR AND BEARING NOISE; FRONT

SUSPENSION AND AXLE................2-18

GEAR AND BEARING NOISE; REAR

SUSPENSION AND AXLES................3-9

GEAR AND CLUTCH OVERHAUL,

OVERDRIVE PLANETARY..............21-218

GEAR AND NO. 1 ONE-WAY CLUTCH

OVERHAUL, SUN....................21-238

GEAR ASSEMBLY....................19-43

GEAR ASSEMBLY/INSTALLATION, PINION . . 2-42

GEAR CLEANING AND INSPECTION......19-42

GEAR DEPTH INFORMATION, PINION;

FRONT SUSPENSION AND AXLE..........2-39

GEAR DEPTH INFORMATION, PINION;

REAR SUSPENSION AND AXLES..........3-21

GEAR DEPTH VARIANCE, PINION; FRONT

SUSPENSION AND AXLE................2-40

GEAR DEPTH VARIANCE, PINION; REAR

SUSPENSION AND AXLES...........3-22,3-39

GEAR DISASSEMBLY..................19-39

GEAR DISASSEMBLY INFORMATION......19-26

GEAR LEAKAGE DIAGNOSIS............19-10

GEAR, MANUAL STEERING;

LUBRICATION AND MAINTENANCE........0-30

GEAR, MANUAL STEERING; STEERING . . . 19-37,

19-78

GEAR OVERDRIVE COMPONENTS,

FOURTH...........................21-167

GEAR OVERHAUL, FRONT PLANETARY . . . 21-237

GEAR OVERHAUL, GOVERNOR AND

PARK .............................21-127

GEAR, POWER STEERING..............19-78

GEAR RATIOS........................21-2

GEAR RATIOS, TRANSMISSION.........21-34

GEAR, RECIRCULATING BALL POWER

STEERING..........................19-21

GEAR REPLACEMENT, STEERING . . . 19-23,19-45

GEAR SERVICE, GOVERNOR AND PARK . . 21-105

GEAR SPECIFICATIONS, MANUAL

STEERING..........................19-46

GEAR SPECIFICATIONS, POWER

STEERING..........................19-36

GEAR, SPEED SENSOR ROTORÐ

SPEEDOMETER DRIVE...............21-193

GEAR TRAIN OVERHAUL, PLANETARY . . . 21-141

GEARS, RECIRCULATING-BALL POWER

STEERING

..........................19-74

GEARSHIFT CABLE/LINKAGE

ADJUSTMENT

.......................21-71

GEARTRAIN OPERATION AND

APPLICATION CHARTS

...............21-169

GENERAL BODY SERVICE INFORMATION

. . . 23-1

GENERAL DIAGNOSIS INFORMATION;

CLUTCH

..............................6-3GENERAL DIAGNOSIS INFORMATION;

TRANSMISSION AND TRANSFER CASE . . 21-176

GENERAL INFORMATION; AIR

CONDITIONING/HEATER (XJ).........8W-42-1

GENERAL INFORMATION; AIR

CONDITIONING/HEATER (XJ-RHD).....8W-42-1

GENERAL INFORMATION; AIR

CONDITIONING/HEATER (YJ) . . 8W-42-1,8W-42-2

GENERAL INFORMATION; ANTI-LOCK

BRAKES (XJ)......................8W-32-1

GENERAL INFORMATION; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-1

GENERAL INFORMATION; ANTI-LOCK

BRAKES (YJ)......................8W-32-1

GENERAL INFORMATION; AUDIO

SYSTEMS............................8F-1

GENERAL INFORMATION; BATTERY/

STARTER/GENERATOR SERVICE . 8B-1,8B-4,8B-6

GENERAL INFORMATION; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS . . . 8A-10,8A-11,8A-17,8A-22,8A-1,

8A-2

GENERAL INFORMATION; BRAKES . . . 5-22,5-45,

5-1,5-3,5-4

GENERAL INFORMATION; CHIME/BUZZER

WARNING SYSTEMS...................8U-1

GENERAL INFORMATION; CLUTCH.........6-1

GENERAL INFORMATION; CONNECTOR

LOCATIONS (XJ)...................8W-90-1

GENERAL INFORMATION; CONNECTOR

LOCATIONS (XJ-RHD)...............8W-90-1

GENERAL INFORMATION; CONNECTOR

LOCATIONS (YJ)...................8W-90-1

GENERAL INFORMATION; CONNECTOR

PIN OUTS (XJ)....................8W-80-1

GENERAL INFORMATION; CONNECTOR

PIN OUTS (XJ-RHD)................8W-80-1

GENERAL INFORMATION; CONNECTOR

PIN OUTS (YJ)....................8W-80-1

GENERAL INFORMATION; COOLING

SYSTEM.................7-38,7-44,7-45,7-1

GENERAL INFORMATION; EMISSION

CONTROL SYSTEMS...................25-1

GENERAL INFORMATION; ENGINES . . . 9-13,9-55,

9-5

GENERAL INFORMATION; EXHAUST

SYSTEM AND INTAKE MANIFOLD.........11-1

GENERAL INFORMATION; FRAME AND

BUMPERS......................13-10,13-1

GENERAL INFORMATION; FRONT

SUSPENSION AND AXLE..........2-18,2-1,2-5

GENERAL INFORMATION; FUEL SYSTEM . . 14-13,

14-17,14-19,14-35,14-67,14-1

GENERAL INFORMATION; FUSE/FUSE

BLOCK (XJ).......................8W-10-1

GENERAL INFORMATION; FUSE/FUSE

BLOCK (XJ-RHD)..................8W-10-1

GENERAL INFORMATION; GROUND

DISTRIBUTION (XJ)................8W-15-1

GENERAL INFORMATION; GROUND

DISTRIBUTION (XJ-RHD)............8W-15-1

GENERAL INFORMATION; GROUND

DISTRIBUTION (YJ)................8W-15-1

GENERAL INFORMATION; HEATING AND

AIR CONDITIONING....................24-1

GENERAL INFORMATION; HORNS........8G-1

GENERAL INFORMATION; IGNITION

SYSTEMS.......8D-17,8D-29,8D-32,8D-1,8D-6

GENERAL INFORMATION; INSTRUMENT

PANEL AND GAUGESÐXJ..........8E-24,8E-1

GENERAL INFORMATION; INTERIOR

LIGHTING (XJ)....................8W-44-1

GENERAL INFORMATION; INTERIOR

LIGHTING (XJ-RHD)................8W-44-1

GENERAL INFORMATION; INTERIOR

LIGHTING (YJ)....................8W-44-1

GENERAL INFORMATION; LAMPS . . 8L-18,8L-19,

8L-32,8L-1

GENERAL INFORMATION; LUBRICATION

AND MAINTENANCE

....................0-1

GENERAL INFORMATION; OVERHEAD

CONSOLE

...........................8C-1

GENERAL INFORMATION; POWER

DISTRIBUTION (XJ)

................8W-11-1

GENERAL INFORMATION; POWER

DISTRIBUTION (XJ-RHD)

............8W-11-1

GENERAL INFORMATION; POWER

DISTRIBUTION (YJ)

................8W-11-1

JINDEX 11

Description Group-Page Description Group-Page Description Group-Page

Page 1990 of 2198

TAILGATE LATCH STRIKERÐYJ........23-123

TAILGATE LOCK CYLINDERÐYJ........23-122

TAILGATE WEATHERSTRIP SEALÐYJ....23-123

TAILGATEÐYJ......................23-121

TAILPIPEÐXJ VEHICLES, MUFFLER AND

EXHAUST............................11-5

TAILPIPEÐYJ VEHICLES, MUFFLER AND

EXHAUST............................11-6

TAKE OUTS; WIRING DIAGRAMSÐ

GENERAL INFORMATION (XJ)...........8W-2

TANK CAPACITIES, FUEL..........14-13,14-67

TANK FILLER TUBE CAP, FUEL;

EMISSION CONTROL SYSTEMS......25-4,25-7

TANK FILLER TUBE CAP, FUEL; FUEL

SYSTEM............................14-13

TANK FILLER TUBE, NO-LEAD FUEL......14-13

TANK, FUEL.........................14-13

TANK PRESSURE RELIEF/ROLLOVER

VALVE, FUEL...................14-16,14-62

TANK SKID PLATE, FUEL...........13-15,13-3

TANK SUPPORT STRAP, FUEL............13-4

TANKS, FUEL...................14-13,14-62

TAPPETS, HYDRAULIC.............9-24,9-66

TELL-TALE CLUSTER (LHD)............8E-10

TEMPERATURE AND PRESSURE CHART,

XJ PERFORMANCE...................24-13

TEMPERATURE AND PRESSURE CHART,

YJ PERFORMANCE...................24-13

TEMPERATURE CONTROL THERMOSTAT . . 24-34

TEMPERATURE GAUGE, ENGINE

COOLANT; INSTRUMENT CLUSTER

(XJ).............................8W-40-1

TEMPERATURE SENSOR, COOLANT.......25-7

TEMPERATURE SENSOR, ENGINE

COOLANT; FUEL SYSTEM..............14-60

TEMPERATURE SENSOR, ENGINE

COOLANT; FUEL/IGNITION (XJ).......8W-30-3

TEMPERATURE SENSOR, ENGINE

COOLANT; FUEL/IGNITION (YJ).......8W-30-3

TEMPERATURE SENSOR, ENGINE

COOLANT; IGNITION SYSTEMS.....8D-19,8D-5

TEMPERATURE SENSOR, ENGINE

COOLANT; FUEL/IGNITION (XJ-RHD) . . . 8W-30-3

TEMPERATURE SENSOR, INTAKE AIR;

FUEL/IGNITION (XJ)................8W-30-4

TEMPERATURE SENSOR, INTAKE AIR;

FUEL/IGNITION (YJ)................8W-30-4

TEMPERATURE SENSOR, INTAKE AIR;

FUEL/IGNITION (XJ-RHD)............8W-30-4

TEMPERATURE SENSOR, INTAKE

MANIFOLD AIR; FUEL SYSTEM..........14-60

TEMPERATURE SENSOR, INTAKE

MANIFOLD AIR; IGNITION SYSTEMS . 8D-23,8D-5

TEMPERATURE, SENSOR RESISTANCE

(OHMS)ÐCOOLANT TEMPERATURE

SENSOR/MANIFOLD AIR...............14-46

TEMPERATURE SENSOR TEST, ENGINE

COOLANT; FUEL SYSTEM..............14-46

TEMPERATURE SENSOR TEST, ENGINE

COOLANT; IGNITION SYSTEMS..........8D-9

TEMPERATURE SENSOR TEST, INTAKE

MANIFOLD AIR; FUEL SYSTEM

..........14-46

TEMPERATURE SENSOR TEST, INTAKE

MANIFOLD AIR; IGNITION SYSTEMS

.....8D-11

TEMPERATURE SENSOR/MANIFOLD AIR

TEMPERATURE, SENSOR RESISTANCE

(OHMS)ÐCOOLANT

..................14-46

TEMPERATURE SENSORÐPCM INPUT,

ENGINE COOLANT

....................14-23

TEMPERATURE SENSORÐPCM INPUT,

INTAKE MANIFOLD AIR

................14-22

TEMPERATURE WARNING LAMP, ENGINE

COOLANT; INSTRUMENT CLUSTER

(XJ)

.............................8W-40-1

TEMPERATURE WARNING LAMP, ENGINE

COOLANT; INSTRUMENT CLUSTER

(XJ-RHD)

.........................8W-40-1

TENSION, DRIVE BELT

.................7-45

TENSION SPECIFICATIONS, BELT

.........7-38

TENSIONER ADJUSTMENT (XJ/YJ),

PARKING BRAKE CABLE

................5-69

TENSIONER REPLACEMENT (XJ),

PARKING BRAKE CABLE

................5-66

TENSIONERÐXJ MODELS WITH RIGHT

HAND DRIVE, AUTOMATIC BELT

..........7-42

TENSIONÐEXCEPT RIGHT HAND DRIVE

(RHD), BELT

.........................7-38TENSIONÐEXCEPT RIGHT HAND DRIVE

(RHD) MODELS, BELT..................7-45

TENSIONÐRIGHT HAND DRIVE (RHD),

BELT ...............................7-38

TERMINAL REPLACEMENT; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-8

TERMINAL REPLACEMENT, CONNECTOR;

WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)...................8W-7

TERMINAL/CONNECTOR REPAIRÐ

MOLEX CONNECTORS; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-6

TEST, AUTOMATIC SHUTDOWN (ASD)

RELAY..............................8D-6

TEST, CAMSHAFT POSITION SENSOR;

FUEL SYSTEM.......................14-46

TEST, CAMSHAFT POSITION SENSOR;

IGNITION SYSTEMS...................8D-6

TEST, COMPASS/DISPLAY SELF-

DIAGNOSTIC.........................8C-2

TEST, CONVERTER STALL..............21-74

TEST, CRANKSHAFT POSITION SENSOR;

FUEL SYSTEM.......................14-47

TEST, CRANKSHAFT POSITION SENSOR;

IGNITION SYSTEMS...................8D-7

TEST, CYLINDER COMBUSTION

PRESSURE LEAKAGE...................9-6

TEST, CYLINDER COMPRESSION

PRESSURE...........................9-5

TEST DIAGNOSIS, CYLINDER

COMBUSTION PRESSURE LEAKAGE........9-7

TEST, ENGINE COOLANT TEMPERATURE

SENSOR; FUEL SYSTEM................14-46

TEST, ENGINE COOLANT TEMPERATURE

SENSOR; IGNITION SYSTEMS...........8D-9

TEST, EXTENDED IDLE SWITCH.........14-48

TEST, FUEL INJECTOR.................14-51

TEST, FUEL PRESSURE LEAK DOWN......14-8

TEST, FUEL PUMP CAPACITY............14-7

TEST, FUEL SYSTEM PRESSURE....14-51,14-6

TEST, HYDRAULIC PRESSURE....21-177,21-72

TEST, IDLE AIR CONTROL MOTOR.......14-49

TEST, INTAKE MANIFOLD AIR

TEMPERATURE SENSOR; FUEL

SYSTEM............................14-46

TEST, INTAKE MANIFOLD AIR

TEMPERATURE SENSOR; IGNITION

SYSTEMS..........................8D-11

TEST, MANIFOLD ABSOLUTE PRESSURE

(MAP) SENSOR; FUEL SYSTEM.........14-47

TEST, MANIFOLD ABSOLUTE PRESSURE

(MAP) SENSOR; IGNITION SYSTEMS.....8D-11

TEST, MANUAL SHIFTING.............21-177

TEST, MASTER CYLINDER/POWER

BOOSTER............................5-8

TEST, OXYGEN SENSOR (O2S) HEATING

ELEMENT...........................14-48

TEST, POWER BOOSTER CHECK VALVE.....5-9

TEST, POWER BOOSTER VACUUM.........5-9

TEST PROCEDURES, HEATING AND AIR

CONDITIONING......................24-15

TEST, REFRIGERANT SERVICE AND

PERFORMANCE......................24-11

TEST, STARTER MOTOR RELAY.........14-51

TEST, THROTTLE POSITION SENSOR.....8D-15

TEST, THROTTLE POSITION SENSOR

(TPS)..............................14-48

TEST, TORQUE CONVERTER CLUTCH

RELAY

.............................14-48

TEST, TORQUE CONVERTER STALL

.....21-178

TEST, VACUUM SUPPLY

................8H-6

TEST, VEHICLE SPEED SENSOR

.........14-48

TESTING, AUTOMATIC SHUTDOWN

(ASD) RELAY

........................14-46

TESTING COOLING SYSTEM FOR LEAKS

. . . 7-22

TESTING, FUEL PUMP RELAY

...........14-47

TESTING, INTERMITTENT WIPE SWITCH

. . 8K-15

TESTING, NON-INTERMITTENT WIPE

SWITCH

............................8K-14

TESTING PROCEDURESÐXJ, MULTI-

FUNCTION SWITCH

....................8L-4

TESTING REFRIGERANT, LEAK

..........24-11

TESTING, ROAD

.......................5-5

TESTING SPECIFICATIONS, 2.5L

STARTER AND SOLENOID

..............8A-23TESTING SPECIFICATIONS, 4.0L

STARTER AND SOLENOID..............8A-23

TESTING, TRANSMISSION COOLER

FLOW.............................21-113

TESTS, AIR CONDITIONING

PERFORMANCE......................24-12

TESTS, IGNITION SWITCH CONTINUITY . . . 8D-30

TESTS, OXYGEN (O2S) SENSOR........8D-15

TESTS, SYSTEM......................8N-1

TESTS, TROUBLESHOOTING; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-4

TESTS, WATER PUMP..................7-13

THERMOMETER......................8C-1

THERMOMETER DIAGNOSIS.............8C-2

THERMOSTAT........................7-17

THERMOSTAT, TEMPERATURE CONTROL . . 24-34

THERMOSTATIC CONTROL.............24-16

THICKNESS, AW-4 CLUTCH DISC AND

PLATE ............................21-338

THICKNESS, DISC BRAKE ROTOR........5-52

THIS GROUP, HOW TO USE; WIRING

DIAGRAMS (XJ)......................8W-1

THIS GROUP, HOW TO USE; WIRING

DIAGRAMS (XJ-RHD)..................8W-1

THIS GROUP, HOW TO USE; WIRING

DIAGRAMS (YJ)......................8W-1

THREAD NOTATIONÐSAE AND METRIC . Intro.-13

THREADS, REPAIR DAMAGED OR WORN....9-4

THROTTLE BODY.................14-33,14-64

THROTTLE CABLE....................14-17

THROTTLE CABLE, ACCELERATOR

PEDAL........................14-17,14-58

THROTTLE CABLE ADJUSTMENT,

TRANSMISSION.....................21-194

THROTTLE CABLE REPLACEMENT,

TRANSMISSION.....................21-193

THROTTLE POSITION SENSOR;

FUEL/IGNITION (XJ)................8W-30-4

THROTTLE POSITION SENSOR;

FUEL/IGNITION (YJ)................8W-30-4

THROTTLE POSITION SENSOR; IGNITION

SYSTEMS...........................8D-5

THROTTLE POSITION SENSOR;

FUEL/IGNITION (XJ-RHD)............8W-30-4

THROTTLE POSITION SENSOR TEST.....8D-15

THROTTLE POSITION SENSOR (TPS);

FUEL SYSTEM.......................14-65

THROTTLE POSITION SENSOR (TPS);

IGNITION SYSTEMS..................8D-25

THROTTLE POSITION SENSOR (TPS)

SERVICE..........................21-193

THROTTLE POSITION SENSOR (TPS)

TEST..............................14-48

THROTTLE POSITION SENSOR

(TPS)ÐPCM INPUT...................14-25

THROTTLE VALVE CABLE ADJUSTMENT,

TRANSMISSION......................21-71

THROTTLE VALVE CABLE ADJUSTMENT

(XJ/YJ)............................21-101

THROUGH DEEP WATER PUDDLES,

BRAKES DO NOT HOLD AFTER

DRIVING.............................5-7

TIE ROD ......................19-16,19-19

TIGHTENING, WHEEL NUT..........5-54,5-59

TILT STEERING COLUMN..............19-66

TIME LAG TEST.....................21-178

TIME TABLE, BATTERY CHARGING........8A-8

TIMING CASE COVER..............9-31,9-72

TIMING CASE COVER OIL SEAL

REPLACEMENT...................9-30,9-73

TIMING CHAIN AND SPROCKETS.....9-31,9-73

TIMING, IGNITION....................8D-11

TIMING, VALVE...................9-30,9-71

TIPS, TRANSMISSION ASSEMBLY......21-155

TIRE AND WHEEL BALANCE.............22-6

TIRE AND WHEEL RUNOUT.............22-8

TIRE CARRIERÐYJ, EXTERNAL

SPARE/WHEEL......................23-133

TIRE INFLATION PRESSURES............22-2

TIRE NOISE OR VIBRATION.............22-4

TIRE PROBLEMS, WHEEL................5-7

TIRE WEAR PATTERNS

.................22-4

TIRES; LUBRICATION AND

MAINTENANCE

.......................0-32

TIRES; WHEELS AND TIRES

.............22-1

TIRES, CLEANING OF

..................22-2

TIRES, REPLACEMENT

.................22-2

JINDEX 29

Description Group-Page Description Group-Page Description Group-Page