dash JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 32 of 2198

(5) Inspect the reservoir rubber diaphragm seal for

cracks, cuts and distortion.

(6) Inspect the brake fluid tubing fittings and the

master cylinder housing for indications of fluid leak-

age. Repair as necessary.

(7) Install the brake fluid reservoir cover.

ANTI-LOCK BRAKE SYSTEMÐXJ VEHICLES

The anti-lock brake system fluid reservoir for XJ

Vehicles is located in the engine compartment at the

left side of the dash panel.

(1) Turn the ignition switch ON and allow the

pump motor to operate until it automatically de-en-

ergizes.

(2) Clean the cover before removing it.

CAUTION: Over-filling could cause fluid overflow

and possible reservoir damage when the pump mo-

tor energizes.

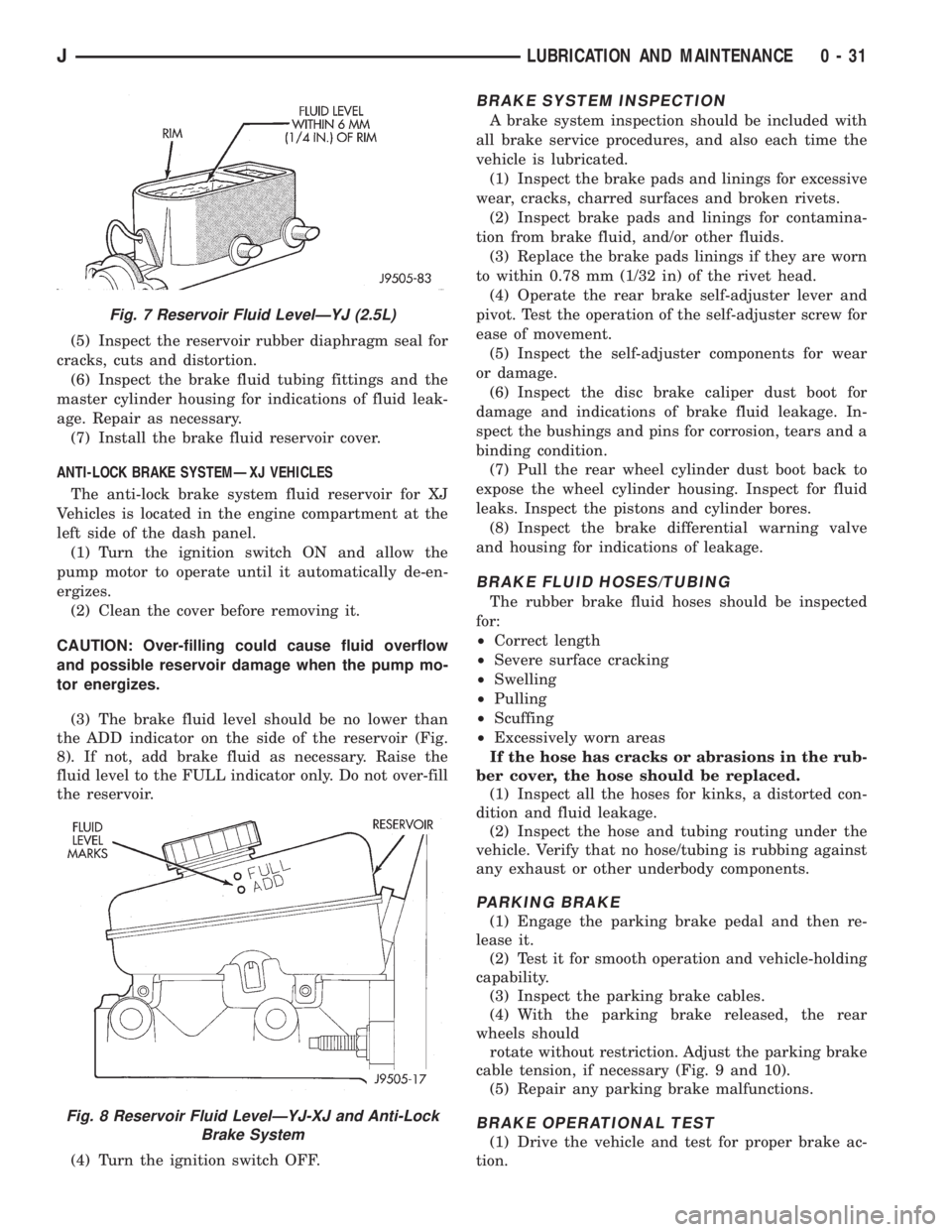

(3) The brake fluid level should be no lower than

the ADD indicator on the side of the reservoir (Fig.

8). If not, add brake fluid as necessary. Raise the

fluid level to the FULL indicator only. Do not over-fill

the reservoir.

(4) Turn the ignition switch OFF.

BRAKE SYSTEM INSPECTION

A brake system inspection should be included with

all brake service procedures, and also each time the

vehicle is lubricated.

(1) Inspect the brake pads and linings for excessive

wear, cracks, charred surfaces and broken rivets.

(2) Inspect brake pads and linings for contamina-

tion from brake fluid, and/or other fluids.

(3) Replace the brake pads linings if they are worn

to within 0.78 mm (1/32 in) of the rivet head.

(4) Operate the rear brake self-adjuster lever and

pivot. Test the operation of the self-adjuster screw for

ease of movement.

(5) Inspect the self-adjuster components for wear

or damage.

(6) Inspect the disc brake caliper dust boot for

damage and indications of brake fluid leakage. In-

spect the bushings and pins for corrosion, tears and a

binding condition.

(7) Pull the rear wheel cylinder dust boot back to

expose the wheel cylinder housing. Inspect for fluid

leaks. Inspect the pistons and cylinder bores.

(8) Inspect the brake differential warning valve

and housing for indications of leakage.

BRAKE FLUID HOSES/TUBING

The rubber brake fluid hoses should be inspected

for:

²Correct length

²Severe surface cracking

²Swelling

²Pulling

²Scuffing

²Excessively worn areas

If the hose has cracks or abrasions in the rub-

ber cover, the hose should be replaced.

(1) Inspect all the hoses for kinks, a distorted con-

dition and fluid leakage.

(2) Inspect the hose and tubing routing under the

vehicle. Verify that no hose/tubing is rubbing against

any exhaust or other underbody components.

PARKING BRAKE

(1) Engage the parking brake pedal and then re-

lease it.

(2) Test it for smooth operation and vehicle-holding

capability.

(3) Inspect the parking brake cables.

(4) With the parking brake released, the rear

wheels should

rotate without restriction. Adjust the parking brake

cable tension, if necessary (Fig. 9 and 10).

(5) Repair any parking brake malfunctions.

BRAKE OPERATIONAL TEST

(1) Drive the vehicle and test for proper brake ac-

tion.

Fig. 7 Reservoir Fluid LevelÐYJ (2.5L)

Fig. 8 Reservoir Fluid LevelÐYJ-XJ and Anti-Lock

Brake System

JLUBRICATION AND MAINTENANCE 0 - 31

Page 159 of 2198

POWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCH

INDEX

page page

Brake Pedal Installation..................... 31

Brake Pedal Removal...................... 31

Brakelight Switch Adjustment................. 32

Brakelight Switch Installation................. 32

Brakelight Switch Removal.................. 32

General Information....................... 22

Power Brake Booster Installation (XJ with ABS) . . . 27

Power Brake Booster Installation (XJ Without ABS).. 30

Power Brake Booster Installation (YJ).......... 30

Power Brake Booster Operation.............. 23

Power Brake Booster Removal (XJ with ABS).... 24

Power Brake Booster Removal (XJ Without ABS) . . 29

Power Brake Booster Removal (YJ)............ 30

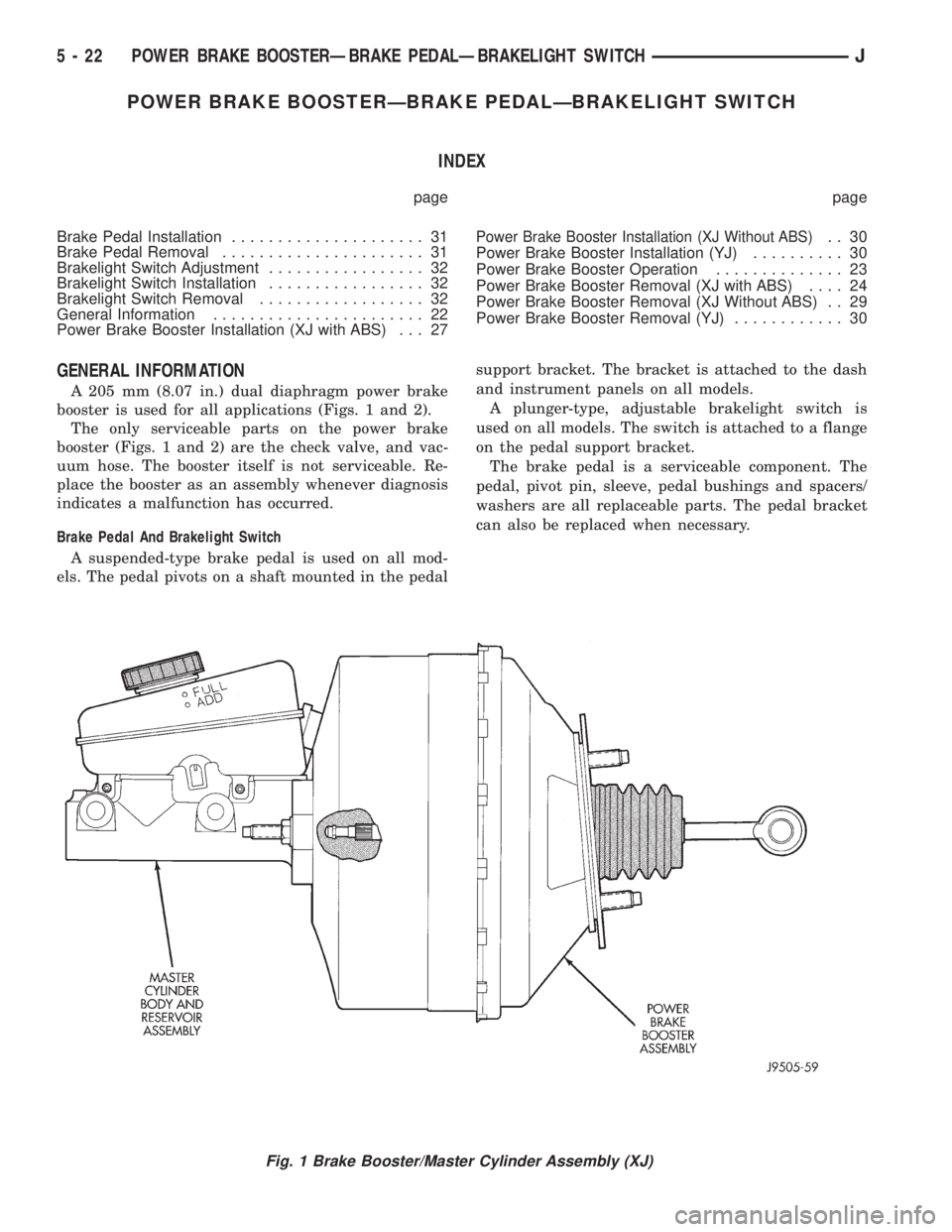

GENERAL INFORMATION

A 205 mm (8.07 in.) dual diaphragm power brake

booster is used for all applications (Figs. 1 and 2).

The only serviceable parts on the power brake

booster (Figs. 1 and 2) are the check valve, and vac-

uum hose. The booster itself is not serviceable. Re-

place the booster as an assembly whenever diagnosis

indicates a malfunction has occurred.

Brake Pedal And Brakelight Switch

A suspended-type brake pedal is used on all mod-

els. The pedal pivots on a shaft mounted in the pedalsupport bracket. The bracket is attached to the dash

and instrument panels on all models.

A plunger-type, adjustable brakelight switch is

used on all models. The switch is attached to a flange

on the pedal support bracket.

The brake pedal is a serviceable component. The

pedal, pivot pin, sleeve, pedal bushings and spacers/

washers are all replaceable parts. The pedal bracket

can also be replaced when necessary.

Fig. 1 Brake Booster/Master Cylinder Assembly (XJ)

5 - 22 POWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCHJ

Page 163 of 2198

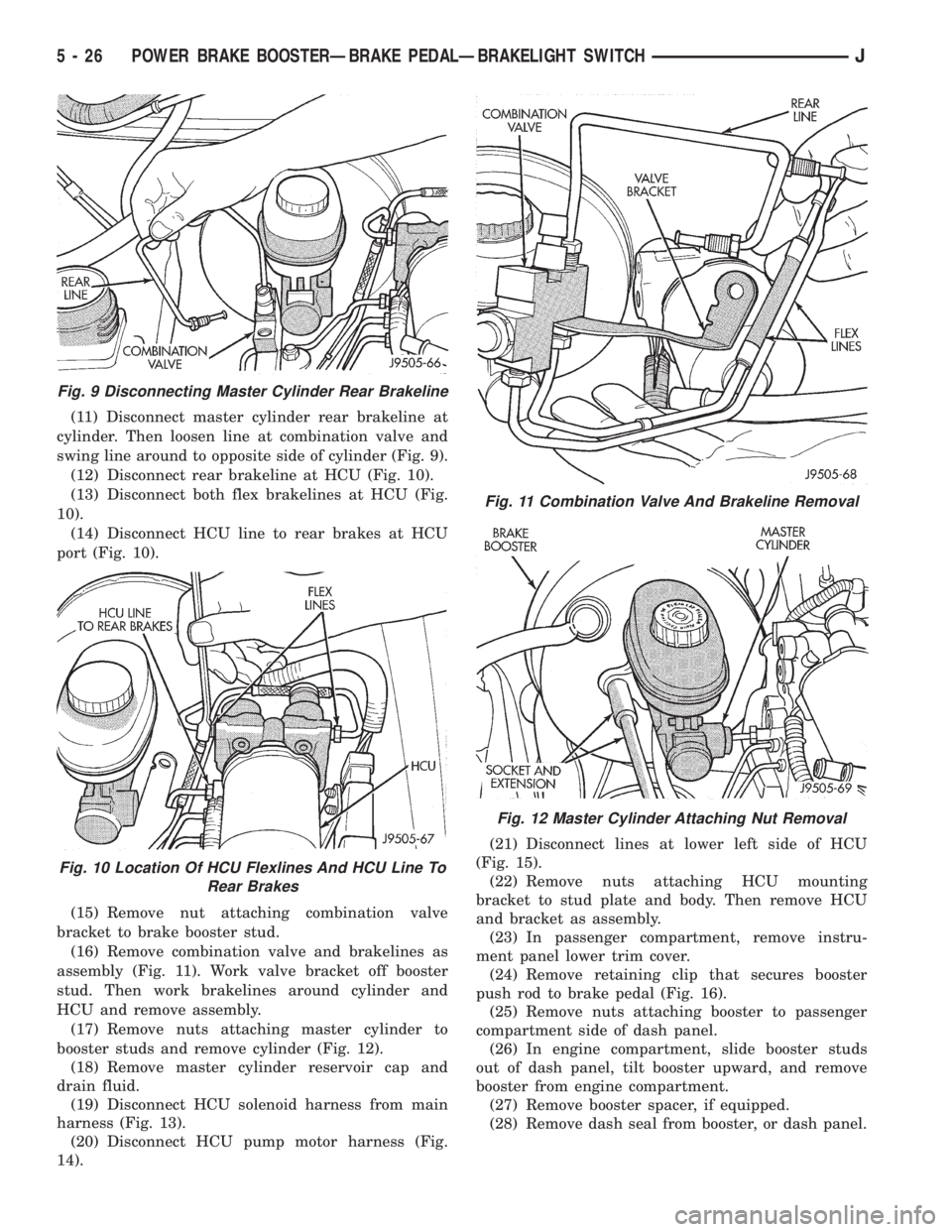

(11) Disconnect master cylinder rear brakeline at

cylinder. Then loosen line at combination valve and

swing line around to opposite side of cylinder (Fig. 9).

(12) Disconnect rear brakeline at HCU (Fig. 10).

(13) Disconnect both flex brakelines at HCU (Fig.

10).

(14) Disconnect HCU line to rear brakes at HCU

port (Fig. 10).

(15) Remove nut attaching combination valve

bracket to brake booster stud.

(16) Remove combination valve and brakelines as

assembly (Fig. 11). Work valve bracket off booster

stud. Then work brakelines around cylinder and

HCU and remove assembly.

(17) Remove nuts attaching master cylinder to

booster studs and remove cylinder (Fig. 12).

(18) Remove master cylinder reservoir cap and

drain fluid.

(19) Disconnect HCU solenoid harness from main

harness (Fig. 13).

(20) Disconnect HCU pump motor harness (Fig.

14).(21) Disconnect lines at lower left side of HCU

(Fig. 15).

(22) Remove nuts attaching HCU mounting

bracket to stud plate and body. Then remove HCU

and bracket as assembly.

(23) In passenger compartment, remove instru-

ment panel lower trim cover.

(24) Remove retaining clip that secures booster

push rod to brake pedal (Fig. 16).

(25) Remove nuts attaching booster to passenger

compartment side of dash panel.

(26) In engine compartment, slide booster studs

out of dash panel, tilt booster upward, and remove

booster from engine compartment.

(27) Remove booster spacer, if equipped.

(28) Remove dash seal from booster, or dash panel.

Fig. 9 Disconnecting Master Cylinder Rear Brakeline

Fig. 10 Location Of HCU Flexlines And HCU Line To

Rear Brakes

Fig. 11 Combination Valve And Brakeline Removal

Fig. 12 Master Cylinder Attaching Nut Removal

5 - 26 POWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCHJ

Page 164 of 2198

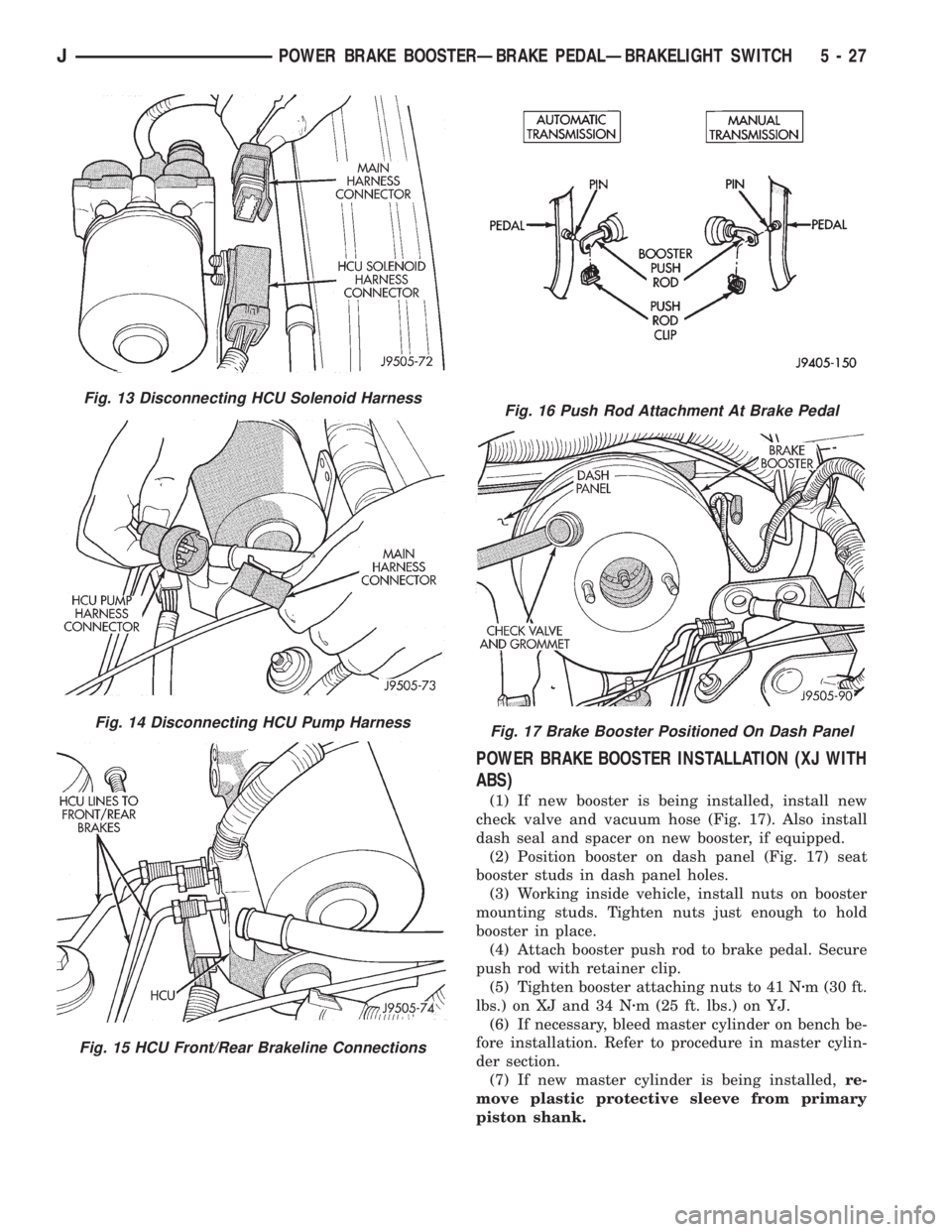

POWER BRAKE BOOSTER INSTALLATION (XJ WITH

ABS)

(1) If new booster is being installed, install new

check valve and vacuum hose (Fig. 17). Also install

dash seal and spacer on new booster, if equipped.

(2) Position booster on dash panel (Fig. 17) seat

booster studs in dash panel holes.

(3) Working inside vehicle, install nuts on booster

mounting studs. Tighten nuts just enough to hold

booster in place.

(4) Attach booster push rod to brake pedal. Secure

push rod with retainer clip.

(5) Tighten booster attaching nuts to 41 Nzm (30 ft.

lbs.) on XJ and 34 Nzm (25 ft. lbs.) on YJ.

(6) If necessary, bleed master cylinder on bench be-

fore installation. Refer to procedure in master cylin-

der section.

(7) If new master cylinder is being installed,re-

move plastic protective sleeve from primary

piston shank.

Fig. 13 Disconnecting HCU Solenoid Harness

Fig. 14 Disconnecting HCU Pump Harness

Fig. 15 HCU Front/Rear Brakeline Connections

Fig. 16 Push Rod Attachment At Brake Pedal

Fig. 17 Brake Booster Positioned On Dash Panel

JPOWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCH 5 - 27

Page 167 of 2198

(11) Remove nuts attaching booster to passenger

compartment side of dash panel.

(12) In engine compartment, slide booster studs

out of dash panel, tilt booster upward, and remove

booster from engine compartment.

(13) Remove dash seal from booster.

(14) If booster is only being removed for access to

other components, cover booster front opening with

clean shop towel.

POWER BRAKE BOOSTER INSTALLATION (XJ

WITHOUT ABS)

(1) If original booster is being installed, test check

valve with vacuum tool before booster installation.

Replace check valve if it will not hold vacuum.

(2) Install dash seal on booster.

(3) Align and position booster on dash panel (Fig.

17).

(4) In passenger compartment, install nuts that at-

tach booster to dash panel. Tighten nuts just enough

to hold booster in place.

(5) Slide booster push rod onto brake pedal. Then

secure push rod to pedal pin with retaining clip.

(6) Tighten booster attaching nuts to 41 Nzm (30 ft.

lbs.) on XJ and 34 Nzm (25 ft. lbs.) on YJ.

(7) Install instrument panel lower trim cover.

(8) If original master cylinder is being installed,

check condition of seal at rear of master cylinder

(Fig. 18). Clean and reposition seal if dislodged. Re-

place seal if cut, or torn.

(9) Clean cylinder mounting surface of brake

booster. Use shop towel wetted with brake cleaner for

this purpose. Dirt, grease, or similar materials will

prevent proper cylinder seating and could result in

vacuum leak.

(10) Align and install master cylinder on booster

studs. Tighten cylinder attaching nuts to 13-25 Nzm

(115-220 in. lbs.) torque.

(11) Connect vacuum hose to booster check valve.

(12) Connect and secure brakelines to combination

valve and master cylinder. Start all brakeline fittings

by hand to avoid cross threading.

(13) If combination valve has integral bracket, po-

sition bracket on booster studs. Then install and

tighten bracket attaching nuts to 13-25 Nzm (115-220

in. lbs.) torque.

(14) Connect wire to combination valve switch.

(15) Top off master cylinder fluid level.

(16) Bleed brakes. Refer to procedures in section

on brake bleeding.

(17) Install engine air cleaner and hoses.

(18) Verify proper brake operation before moving

vehicle.

POWER BRAKE BOOSTER REMOVAL (YJ)

(1) Disconnect brakelines at master cylinder. Then

loosen lines at combination valve and move lines

away from cylinder.

(2) Remove nuts master cylinder to booster studs.

(3) If combination valve has integral bracket, slide

bracket off studs and move valve aside.

(4) Remove master cylinder. Slide cylinder off

studs and remove it from engine compartment.

(5) Working under instrument panel, remove re-

tainer clip that secures booster push rod to brake

pedal.

(6) Disconnect vacuum hose at booster check valve.

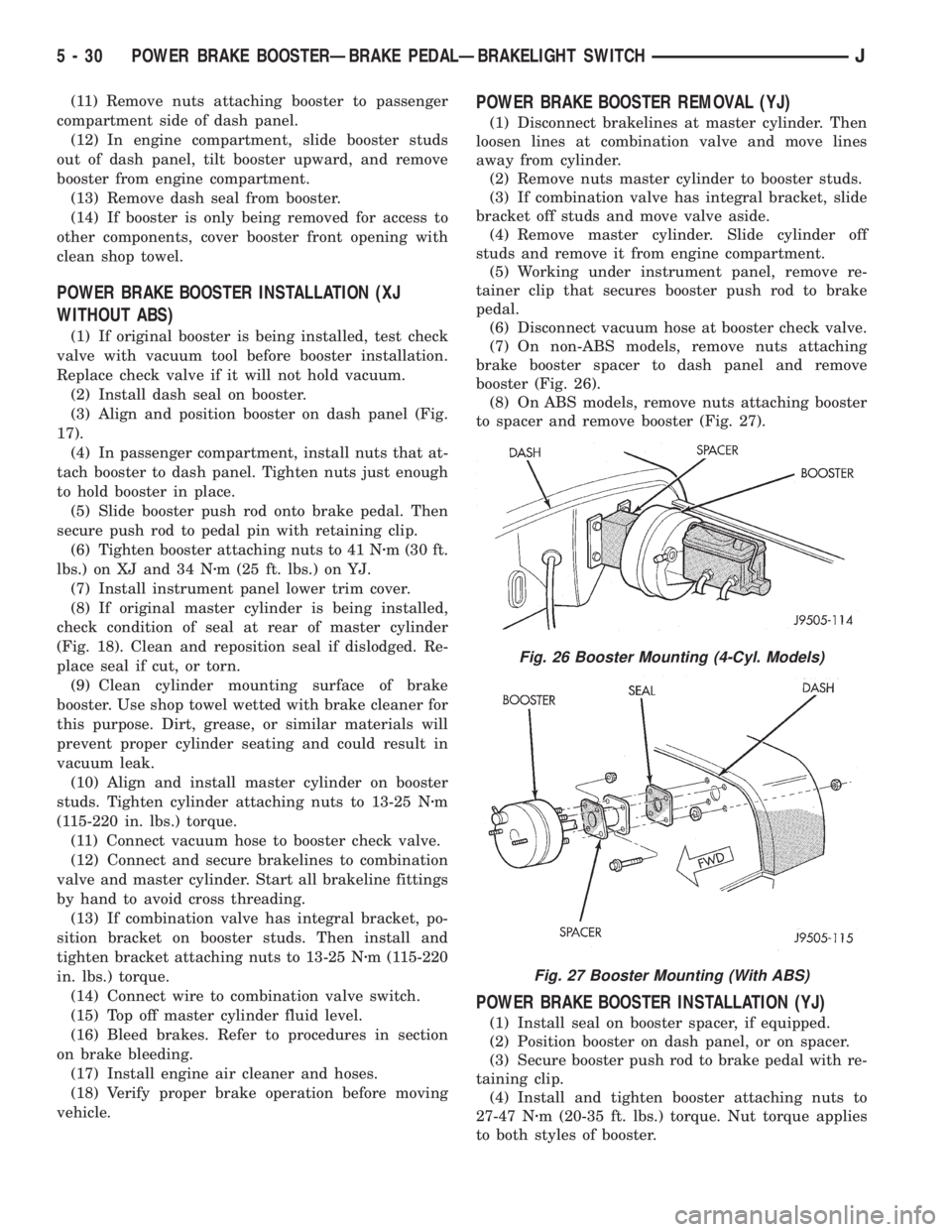

(7) On non-ABS models, remove nuts attaching

brake booster spacer to dash panel and remove

booster (Fig. 26).

(8) On ABS models, remove nuts attaching booster

to spacer and remove booster (Fig. 27).

POWER BRAKE BOOSTER INSTALLATION (YJ)

(1) Install seal on booster spacer, if equipped.

(2) Position booster on dash panel, or on spacer.

(3) Secure booster push rod to brake pedal with re-

taining clip.

(4) Install and tighten booster attaching nuts to

27-47 Nzm (20-35 ft. lbs.) torque. Nut torque applies

to both styles of booster.

Fig. 26 Booster Mounting (4-Cyl. Models)

Fig. 27 Booster Mounting (With ABS)

5 - 30 POWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCHJ

Page 168 of 2198

(5) Connect vacuum hose to brake booster check

valve.

(6) Install master cylinder and combination valve.

(7) Bleed brakes. Then tighten brakeline fittings to

15-18 Nzm (130-160 in. lbs.) at master cylinder and

18-24 Nzm (160-210 in. lbs.) at combination valve.

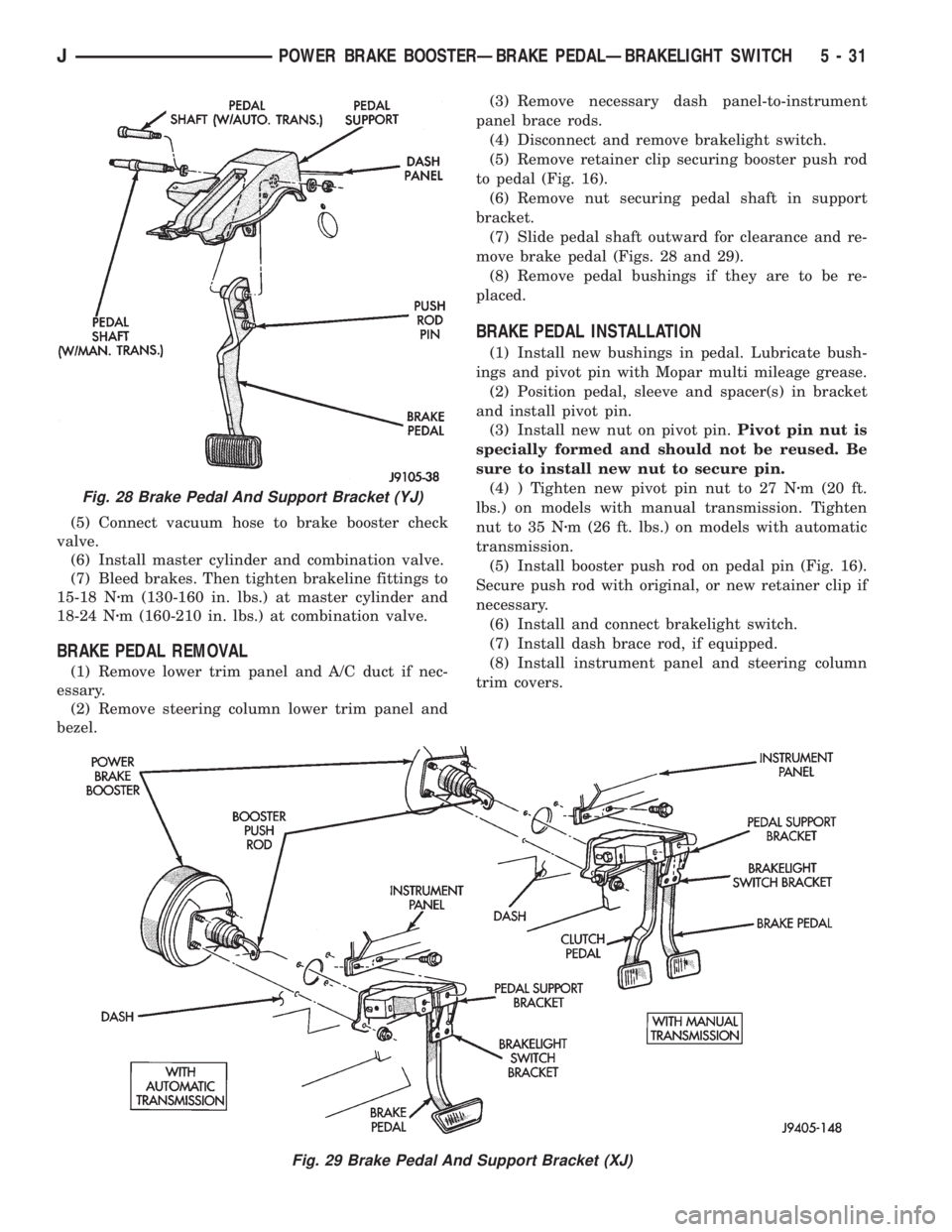

BRAKE PEDAL REMOVAL

(1) Remove lower trim panel and A/C duct if nec-

essary.

(2) Remove steering column lower trim panel and

bezel.(3) Remove necessary dash panel-to-instrument

panel brace rods.

(4) Disconnect and remove brakelight switch.

(5) Remove retainer clip securing booster push rod

to pedal (Fig. 16).

(6) Remove nut securing pedal shaft in support

bracket.

(7) Slide pedal shaft outward for clearance and re-

move brake pedal (Figs. 28 and 29).

(8) Remove pedal bushings if they are to be re-

placed.

BRAKE PEDAL INSTALLATION

(1) Install new bushings in pedal. Lubricate bush-

ings and pivot pin with Mopar multi mileage grease.

(2) Position pedal, sleeve and spacer(s) in bracket

and install pivot pin.

(3) Install new nut on pivot pin.Pivot pin nut is

specially formed and should not be reused. Be

sure to install new nut to secure pin.

(4) ) Tighten new pivot pin nut to 27 Nzm (20 ft.

lbs.) on models with manual transmission. Tighten

nut to 35 Nzm (26 ft. lbs.) on models with automatic

transmission.

(5) Install booster push rod on pedal pin (Fig. 16).

Secure push rod with original, or new retainer clip if

necessary.

(6) Install and connect brakelight switch.

(7) Install dash brace rod, if equipped.

(8) Install instrument panel and steering column

trim covers.

Fig. 28 Brake Pedal And Support Bracket (YJ)

Fig. 29 Brake Pedal And Support Bracket (XJ)

JPOWER BRAKE BOOSTERÐBRAKE PEDALÐBRAKELIGHT SWITCH 5 - 31

Page 177 of 2198

CAUTION: The mercury switch (inside the accelera-

tion switch), will not function properly if the switch

is mispositioned. Verify that the switch locating ar-

row is pointing to the front of the vehicle.

(2) Position switch in mounting bracket.

(3) Install and tighten switch attaching screws to

2-4 Nzm (17-32 in. lbs.) torque.

(4) Connect harness to switch. Be sure harness

connecter is firmly seated.

(5) Move seat back to normal position.

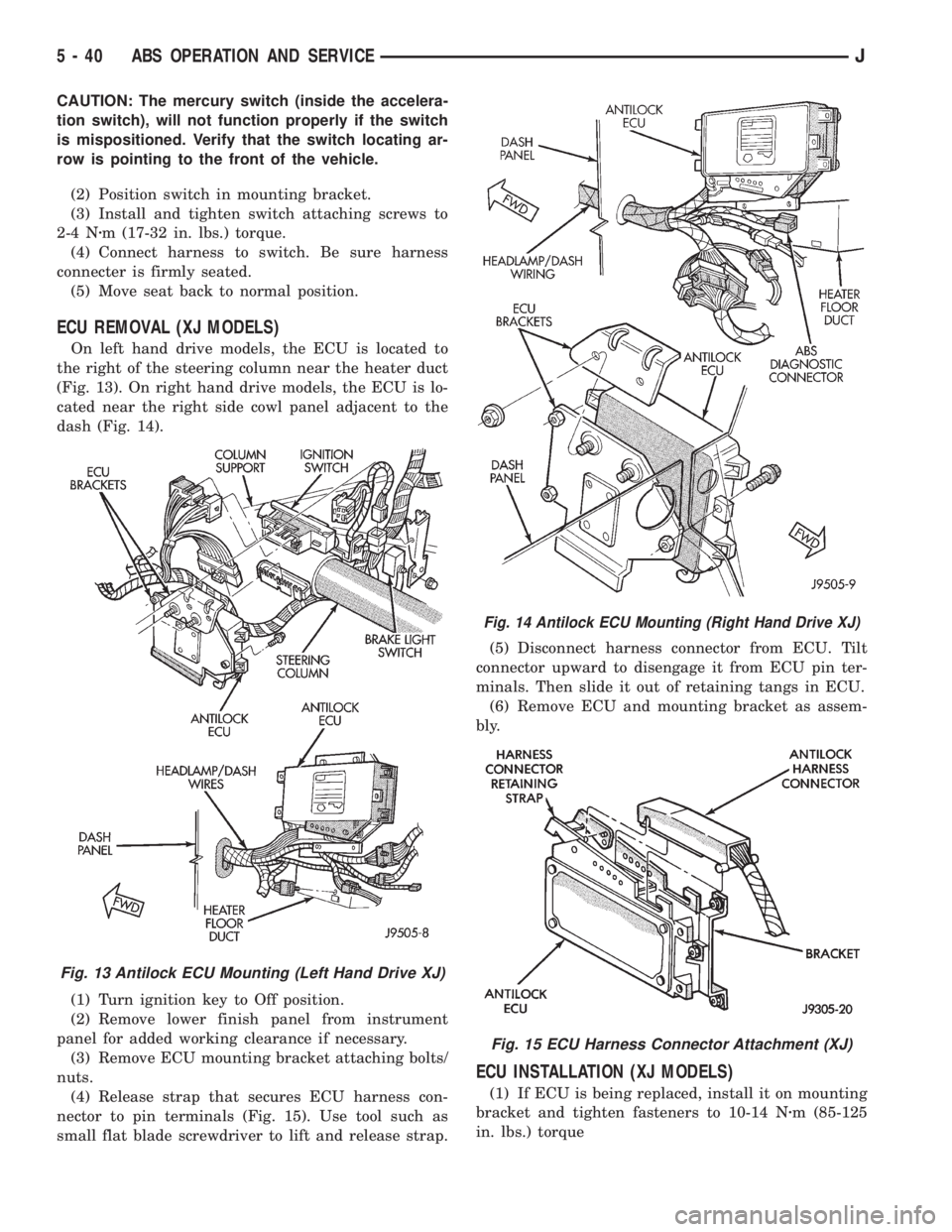

ECU REMOVAL (XJ MODELS)

On left hand drive models, the ECU is located to

the right of the steering column near the heater duct

(Fig. 13). On right hand drive models, the ECU is lo-

cated near the right side cowl panel adjacent to the

dash (Fig. 14).

(1) Turn ignition key to Off position.

(2) Remove lower finish panel from instrument

panel for added working clearance if necessary.

(3) Remove ECU mounting bracket attaching bolts/

nuts.

(4) Release strap that secures ECU harness con-

nector to pin terminals (Fig. 15). Use tool such as

small flat blade screwdriver to lift and release strap.(5) Disconnect harness connector from ECU. Tilt

connector upward to disengage it from ECU pin ter-

minals. Then slide it out of retaining tangs in ECU.

(6) Remove ECU and mounting bracket as assem-

bly.

ECU INSTALLATION (XJ MODELS)

(1) If ECU is being replaced, install it on mounting

bracket and tighten fasteners to 10-14 Nzm (85-125

in. lbs.) torque

Fig. 13 Antilock ECU Mounting (Left Hand Drive XJ)

Fig. 14 Antilock ECU Mounting (Right Hand Drive XJ)

Fig. 15 ECU Harness Connector Attachment (XJ)

5 - 40 ABS OPERATION AND SERVICEJ

Page 178 of 2198

(2) Align and attach harness connector to ECU.

Slide connector into engagement with tangs on ECU.

Then tilt connector downward and into engagement

with ECU pin terminals. Exercise care as pin termi-

nals can be damaged if connector is forced into place.

(3) Connect harness to security alarm module, if

equipped.

(4) Position ECU bracket under instrument panel.

(5) Install and tighten ECU mounting bracket

bolts/nuts to 8-14 Nzm (75- 125 in. lbs.) torque.

(6) Install trim panel on instrument panel, if re-

moved.

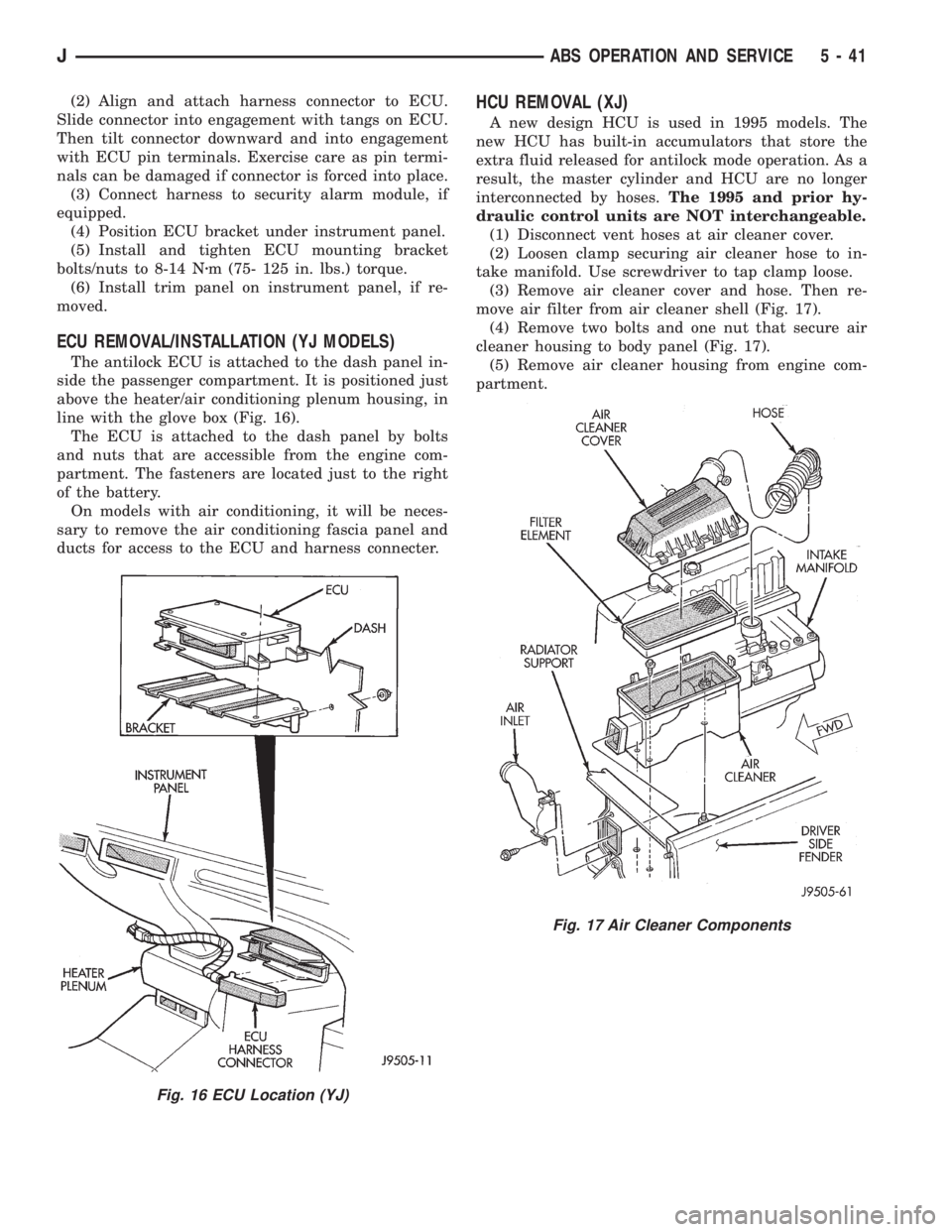

ECU REMOVAL/INSTALLATION (YJ MODELS)

The antilock ECU is attached to the dash panel in-

side the passenger compartment. It is positioned just

above the heater/air conditioning plenum housing, in

line with the glove box (Fig. 16).

The ECU is attached to the dash panel by bolts

and nuts that are accessible from the engine com-

partment. The fasteners are located just to the right

of the battery.

On models with air conditioning, it will be neces-

sary to remove the air conditioning fascia panel and

ducts for access to the ECU and harness connecter.

HCU REMOVAL (XJ)

A new design HCU is used in 1995 models. The

new HCU has built-in accumulators that store the

extra fluid released for antilock mode operation. As a

result, the master cylinder and HCU are no longer

interconnected by hoses.The 1995 and prior hy-

draulic control units are NOT interchangeable.

(1) Disconnect vent hoses at air cleaner cover.

(2) Loosen clamp securing air cleaner hose to in-

take manifold. Use screwdriver to tap clamp loose.

(3) Remove air cleaner cover and hose. Then re-

move air filter from air cleaner shell (Fig. 17).

(4) Remove two bolts and one nut that secure air

cleaner housing to body panel (Fig. 17).

(5) Remove air cleaner housing from engine com-

partment.

Fig. 16 ECU Location (YJ)

Fig. 17 Air Cleaner Components

JABS OPERATION AND SERVICE 5 - 41

Page 198 of 2198

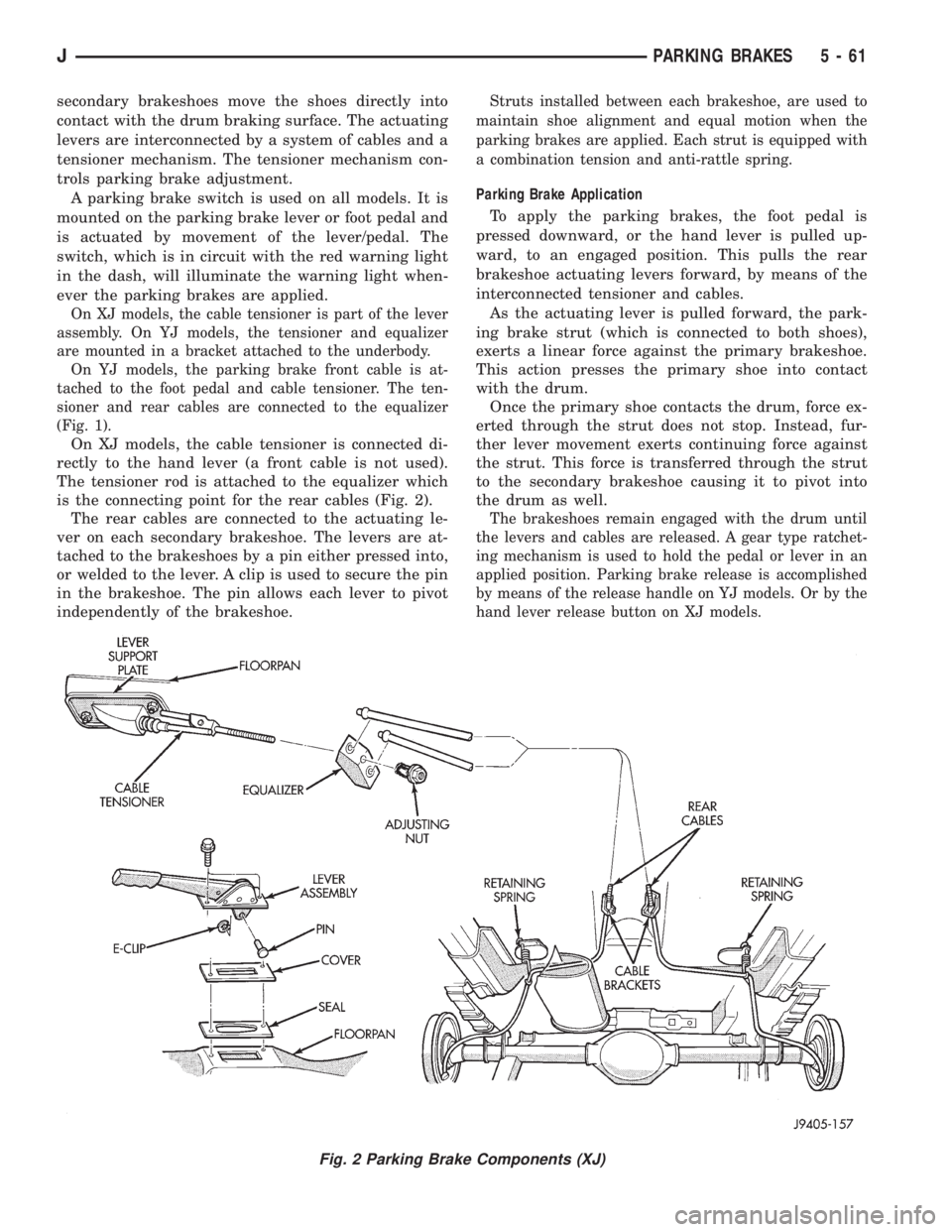

secondary brakeshoes move the shoes directly into

contact with the drum braking surface. The actuating

levers are interconnected by a system of cables and a

tensioner mechanism. The tensioner mechanism con-

trols parking brake adjustment.

A parking brake switch is used on all models. It is

mounted on the parking brake lever or foot pedal and

is actuated by movement of the lever/pedal. The

switch, which is in circuit with the red warning light

in the dash, will illuminate the warning light when-

ever the parking brakes are applied.

On XJ models, the cable tensioner is part of the lever

assembly. On YJ models, the tensioner and equalizer

are mounted in a bracket attached to the underbody.

On YJ models, the parking brake front cable is at-

tached to the foot pedal and cable tensioner. The ten-

sioner and rear cables are connected to the equalizer

(Fig. 1).

On XJ models, the cable tensioner is connected di-

rectly to the hand lever (a front cable is not used).

The tensioner rod is attached to the equalizer which

is the connecting point for the rear cables (Fig. 2).

The rear cables are connected to the actuating le-

ver on each secondary brakeshoe. The levers are at-

tached to the brakeshoes by a pin either pressed into,

or welded to the lever. A clip is used to secure the pin

in the brakeshoe. The pin allows each lever to pivot

independently of the brakeshoe.

Struts installed between each brakeshoe, are used to

maintain shoe alignment and equal motion when the

parking brakes are applied. Each strut is equipped with

a combination tension and anti-rattle spring.

Parking Brake Application

To apply the parking brakes, the foot pedal is

pressed downward, or the hand lever is pulled up-

ward, to an engaged position. This pulls the rear

brakeshoe actuating levers forward, by means of the

interconnected tensioner and cables.

As the actuating lever is pulled forward, the park-

ing brake strut (which is connected to both shoes),

exerts a linear force against the primary brakeshoe.

This action presses the primary shoe into contact

with the drum.

Once the primary shoe contacts the drum, force ex-

erted through the strut does not stop. Instead, fur-

ther lever movement exerts continuing force against

the strut. This force is transferred through the strut

to the secondary brakeshoe causing it to pivot into

the drum as well.

The brakeshoes remain engaged with the drum until

the levers and cables are released. A gear type ratchet-

ing mechanism is used to hold the pedal or lever in an

applied position. Parking brake release is accomplished

by means of the release handle on YJ models. Or by the

hand lever release button on XJ models.

Fig. 2 Parking Brake Components (XJ)

JPARKING BRAKES 5 - 61

Page 203 of 2198

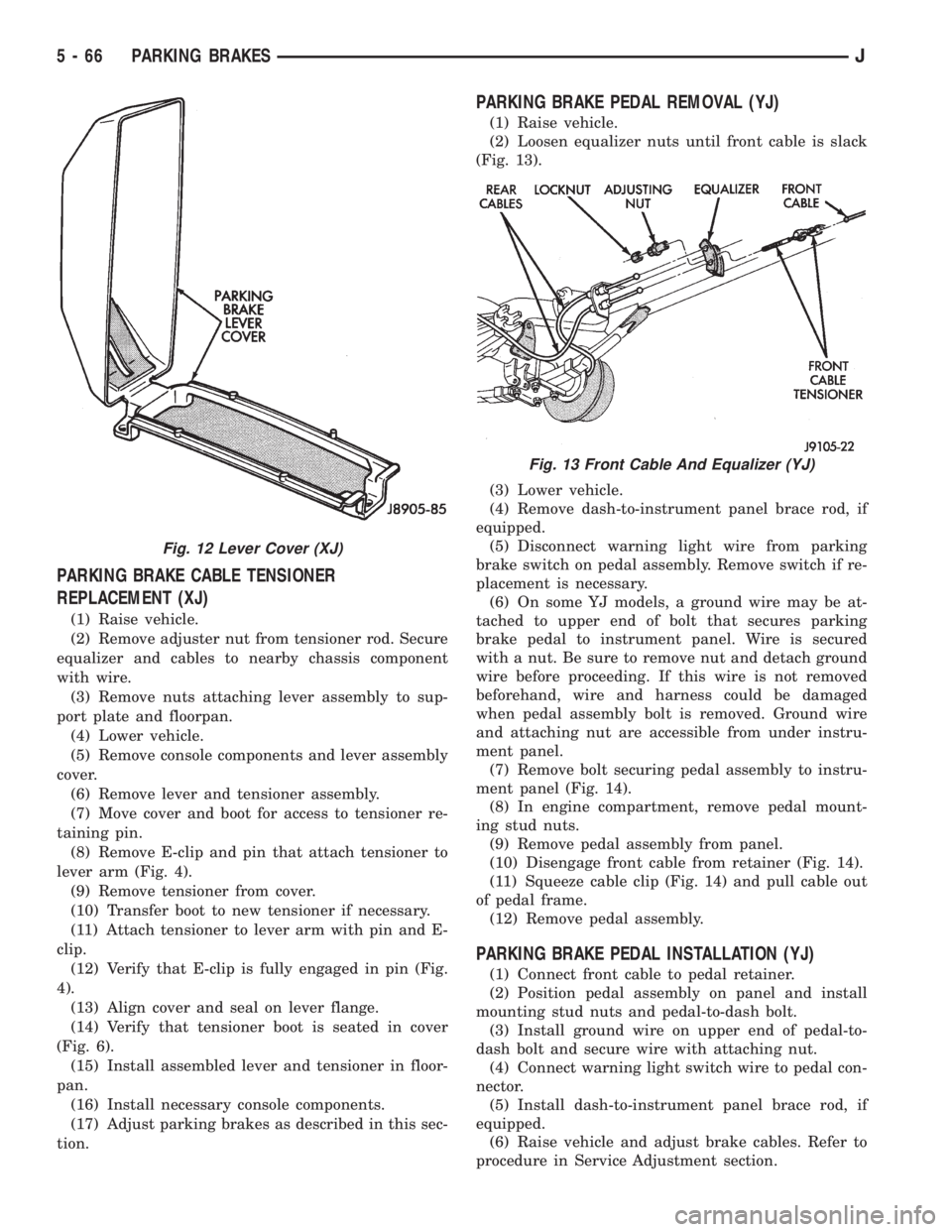

PARKING BRAKE CABLE TENSIONER

REPLACEMENT (XJ)

(1) Raise vehicle.

(2) Remove adjuster nut from tensioner rod. Secure

equalizer and cables to nearby chassis component

with wire.

(3) Remove nuts attaching lever assembly to sup-

port plate and floorpan.

(4) Lower vehicle.

(5) Remove console components and lever assembly

cover.

(6) Remove lever and tensioner assembly.

(7) Move cover and boot for access to tensioner re-

taining pin.

(8) Remove E-clip and pin that attach tensioner to

lever arm (Fig. 4).

(9) Remove tensioner from cover.

(10) Transfer boot to new tensioner if necessary.

(11) Attach tensioner to lever arm with pin and E-

clip.

(12) Verify that E-clip is fully engaged in pin (Fig.

4).

(13) Align cover and seal on lever flange.

(14) Verify that tensioner boot is seated in cover

(Fig. 6).

(15) Install assembled lever and tensioner in floor-

pan.

(16) Install necessary console components.

(17) Adjust parking brakes as described in this sec-

tion.

PARKING BRAKE PEDAL REMOVAL (YJ)

(1) Raise vehicle.

(2) Loosen equalizer nuts until front cable is slack

(Fig. 13).

(3) Lower vehicle.

(4) Remove dash-to-instrument panel brace rod, if

equipped.

(5) Disconnect warning light wire from parking

brake switch on pedal assembly. Remove switch if re-

placement is necessary.

(6) On some YJ models, a ground wire may be at-

tached to upper end of bolt that secures parking

brake pedal to instrument panel. Wire is secured

with a nut. Be sure to remove nut and detach ground

wire before proceeding. If this wire is not removed

beforehand, wire and harness could be damaged

when pedal assembly bolt is removed. Ground wire

and attaching nut are accessible from under instru-

ment panel.

(7) Remove bolt securing pedal assembly to instru-

ment panel (Fig. 14).

(8) In engine compartment, remove pedal mount-

ing stud nuts.

(9) Remove pedal assembly from panel.

(10) Disengage front cable from retainer (Fig. 14).

(11) Squeeze cable clip (Fig. 14) and pull cable out

of pedal frame.

(12) Remove pedal assembly.

PARKING BRAKE PEDAL INSTALLATION (YJ)

(1) Connect front cable to pedal retainer.

(2) Position pedal assembly on panel and install

mounting stud nuts and pedal-to-dash bolt.

(3) Install ground wire on upper end of pedal-to-

dash bolt and secure wire with attaching nut.

(4) Connect warning light switch wire to pedal con-

nector.

(5) Install dash-to-instrument panel brace rod, if

equipped.

(6) Raise vehicle and adjust brake cables. Refer to

procedure in Service Adjustment section.

Fig. 12 Lever Cover (XJ)

Fig. 13 Front Cable And Equalizer (YJ)

5 - 66 PARKING BRAKESJ