distributor install JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 3 of 2198

CLASSIFICATION OF LUBRICANTS

Lubricating fluids and chassis lubricants are clas-

sified according to standards recommended by the:

²Society of Automotive Engineers (SAE)

²American Petroleum Institute (API)

²National Lubricating Grease Institute (NLGI)

ENGINE OIL

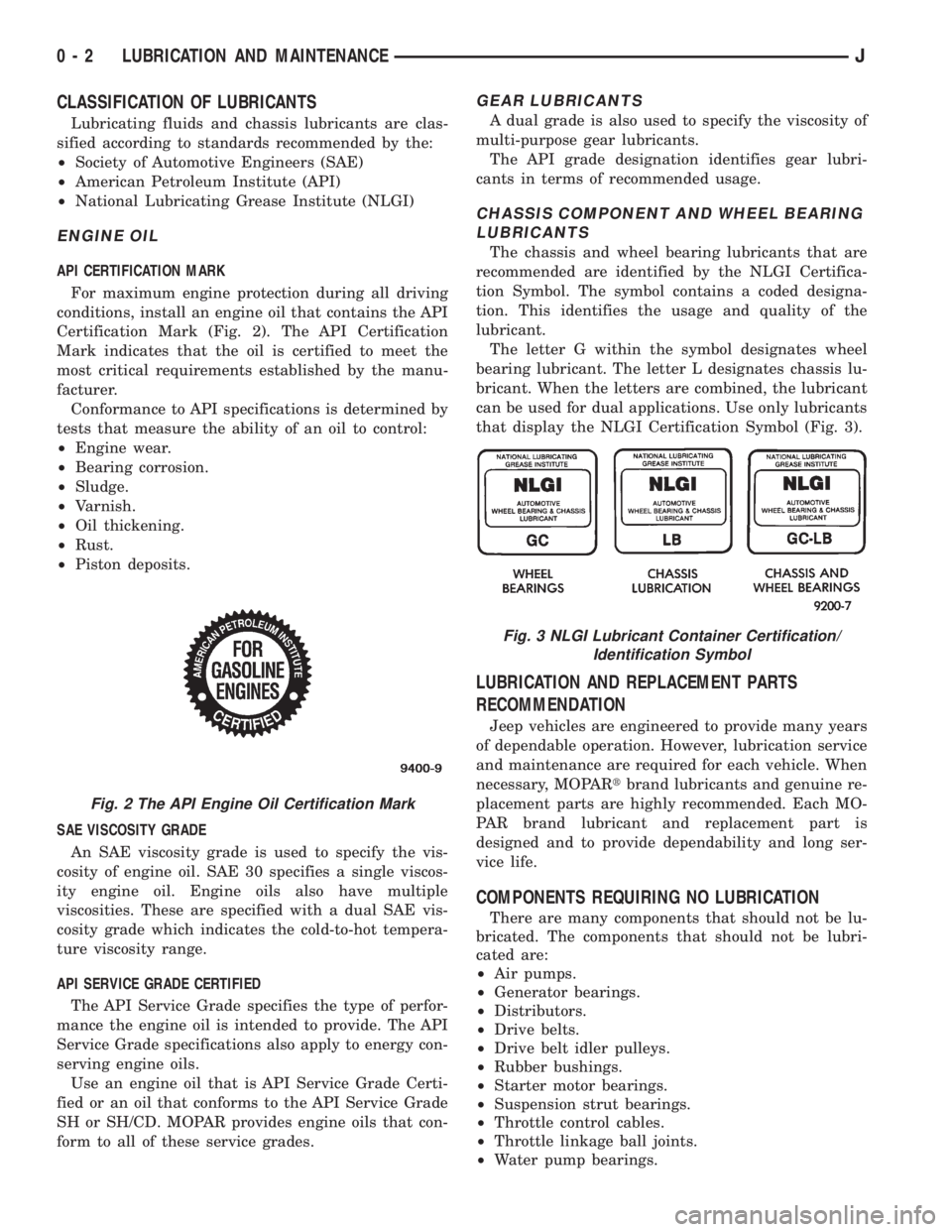

API CERTIFICATION MARK

For maximum engine protection during all driving

conditions, install an engine oil that contains the API

Certification Mark (Fig. 2). The API Certification

Mark indicates that the oil is certified to meet the

most critical requirements established by the manu-

facturer.

Conformance to API specifications is determined by

tests that measure the ability of an oil to control:

²Engine wear.

²Bearing corrosion.

²Sludge.

²Varnish.

²Oil thickening.

²Rust.

²Piston deposits.

SAE VISCOSITY GRADE

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. SAE 30 specifies a single viscos-

ity engine oil. Engine oils also have multiple

viscosities. These are specified with a dual SAE vis-

cosity grade which indicates the cold-to-hot tempera-

ture viscosity range.

API SERVICE GRADE CERTIFIED

The API Service Grade specifies the type of perfor-

mance the engine oil is intended to provide. The API

Service Grade specifications also apply to energy con-

serving engine oils.

Use an engine oil that is API Service Grade Certi-

fied or an oil that conforms to the API Service Grade

SH or SH/CD. MOPAR provides engine oils that con-

form to all of these service grades.

GEAR LUBRICANTS

A dual grade is also used to specify the viscosity of

multi-purpose gear lubricants.

The API grade designation identifies gear lubri-

cants in terms of recommended usage.

CHASSIS COMPONENT AND WHEEL BEARING

LUBRICANTS

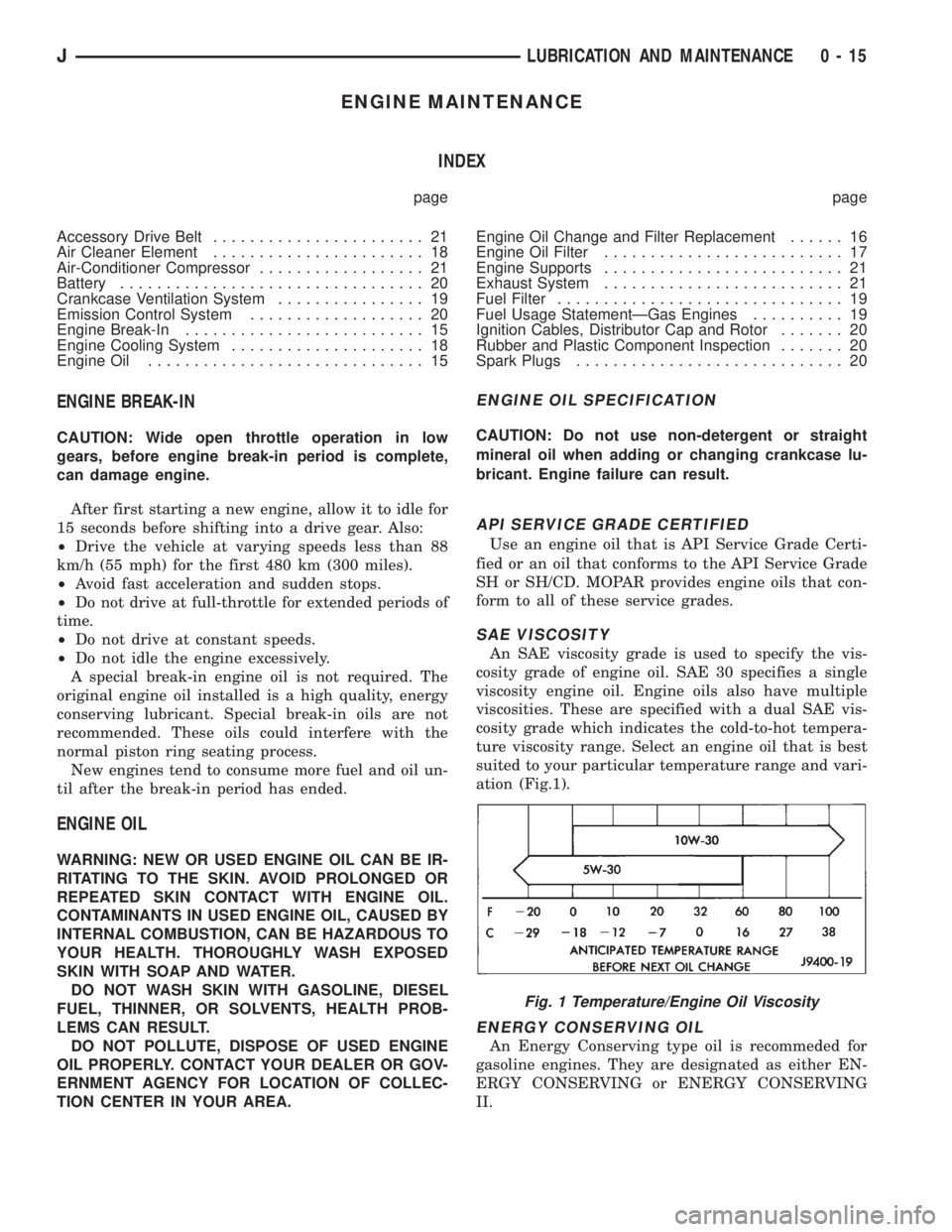

The chassis and wheel bearing lubricants that are

recommended are identified by the NLGI Certifica-

tion Symbol. The symbol contains a coded designa-

tion. This identifies the usage and quality of the

lubricant.

The letter G within the symbol designates wheel

bearing lubricant. The letter L designates chassis lu-

bricant. When the letters are combined, the lubricant

can be used for dual applications. Use only lubricants

that display the NLGI Certification Symbol (Fig. 3).

LUBRICATION AND REPLACEMENT PARTS

RECOMMENDATION

Jeep vehicles are engineered to provide many years

of dependable operation. However, lubrication service

and maintenance are required for each vehicle. When

necessary, MOPARtbrand lubricants and genuine re-

placement parts are highly recommended. Each MO-

PAR brand lubricant and replacement part is

designed and to provide dependability and long ser-

vice life.

COMPONENTS REQUIRING NO LUBRICATION

There are many components that should not be lu-

bricated. The components that should not be lubri-

cated are:

²Air pumps.

²Generator bearings.

²Distributors.

²Drive belts.

²Drive belt idler pulleys.

²Rubber bushings.

²Starter motor bearings.

²Suspension strut bearings.

²Throttle control cables.

²Throttle linkage ball joints.

²Water pump bearings.

Fig. 2 The API Engine Oil Certification Mark

Fig. 3 NLGI Lubricant Container Certification/

Identification Symbol

0 - 2 LUBRICATION AND MAINTENANCEJ

Page 16 of 2198

ENGINE MAINTENANCE

INDEX

page page

Accessory Drive Belt....................... 21

Air Cleaner Element....................... 18

Air-Conditioner Compressor.................. 21

Battery................................. 20

Crankcase Ventilation System................ 19

Emission Control System................... 20

Engine Break-In.......................... 15

Engine Cooling System..................... 18

Engine Oil.............................. 15Engine Oil Change and Filter Replacement...... 16

Engine Oil Filter.......................... 17

Engine Supports.......................... 21

Exhaust System.......................... 21

Fuel Filter............................... 19

Fuel Usage StatementÐGas Engines.......... 19

Ignition Cables, Distributor Cap and Rotor....... 20

Rubber and Plastic Component Inspection....... 20

Spark Plugs............................. 20

ENGINE BREAK-IN

CAUTION: Wide open throttle operation in low

gears, before engine break-in period is complete,

can damage engine.

After first starting a new engine, allow it to idle for

15 seconds before shifting into a drive gear. Also:

²Drive the vehicle at varying speeds less than 88

km/h (55 mph) for the first 480 km (300 miles).

²Avoid fast acceleration and sudden stops.

²Do not drive at full-throttle for extended periods of

time.

²Do not drive at constant speeds.

²Do not idle the engine excessively.

A special break-in engine oil is not required. The

original engine oil installed is a high quality, energy

conserving lubricant. Special break-in oils are not

recommended. These oils could interfere with the

normal piston ring seating process.

New engines tend to consume more fuel and oil un-

til after the break-in period has ended.

ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE IR-

RITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER.

DO NOT WASH SKIN WITH GASOLINE, DIESEL

FUEL, THINNER, OR SOLVENTS, HEALTH PROB-

LEMS CAN RESULT.

DO NOT POLLUTE, DISPOSE OF USED ENGINE

OIL PROPERLY. CONTACT YOUR DEALER OR GOV-

ERNMENT AGENCY FOR LOCATION OF COLLEC-

TION CENTER IN YOUR AREA.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase lu-

bricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied or an oil that conforms to the API Service Grade

SH or SH/CD. MOPAR provides engine oils that con-

form to all of these service grades.

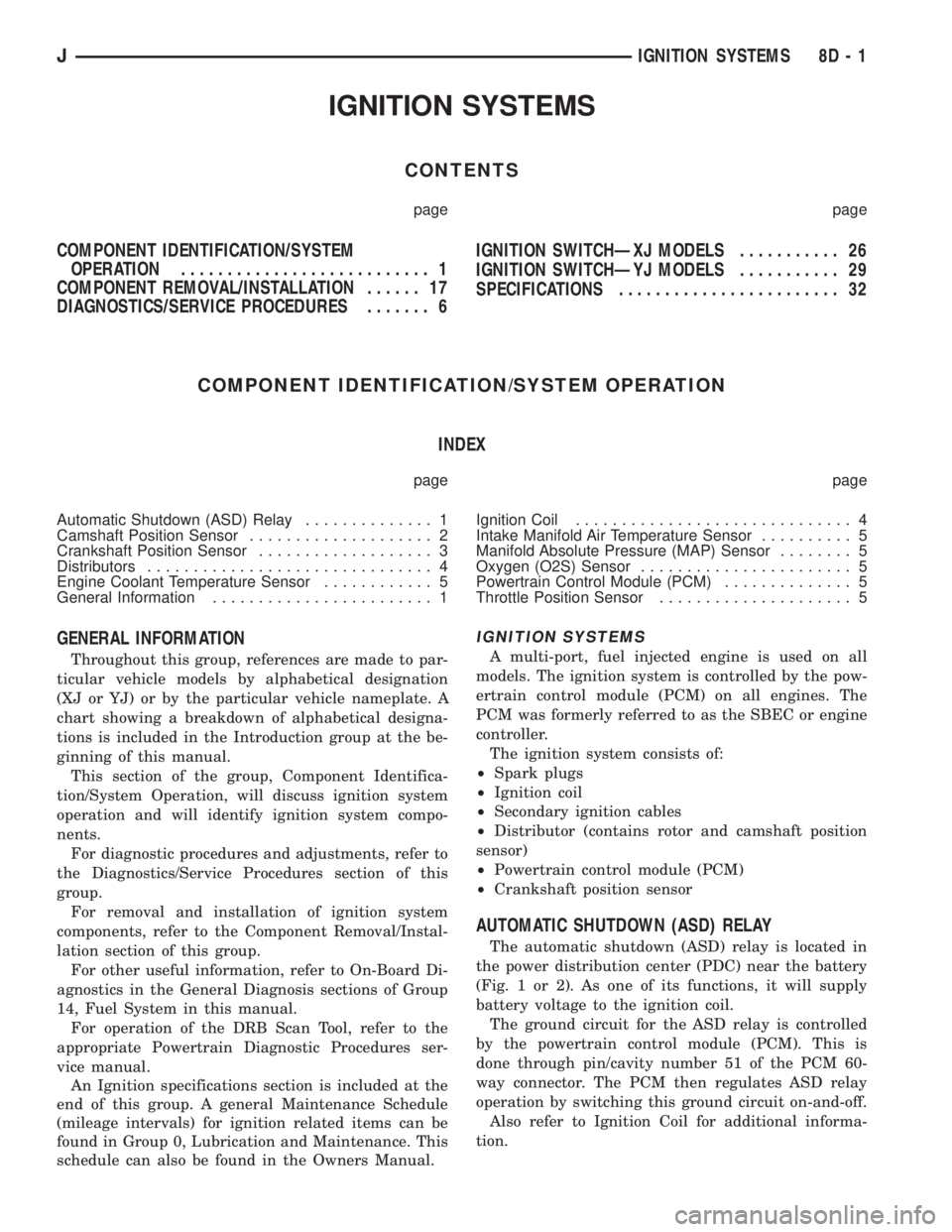

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity grade of engine oil. SAE 30 specifies a single

viscosity engine oil. Engine oils also have multiple

viscosities. These are specified with a dual SAE vis-

cosity grade which indicates the cold-to-hot tempera-

ture viscosity range. Select an engine oil that is best

suited to your particular temperature range and vari-

ation (Fig.1).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommeded for

gasoline engines. They are designated as either EN-

ERGY CONSERVING or ENERGY CONSERVING

II.

Fig. 1 Temperature/Engine Oil Viscosity

JLUBRICATION AND MAINTENANCE 0 - 15

Page 312 of 2198

IGNITION SYSTEMS

CONTENTS

page page

COMPONENT IDENTIFICATION/SYSTEM

OPERATION........................... 1

COMPONENT REMOVAL/INSTALLATION...... 17

DIAGNOSTICS/SERVICE PROCEDURES....... 6IGNITION SWITCHÐXJ MODELS........... 26

IGNITION SWITCHÐYJ MODELS........... 29

SPECIFICATIONS........................ 32

COMPONENT IDENTIFICATION/SYSTEM OPERATION

INDEX

page page

Automatic Shutdown (ASD) Relay.............. 1

Camshaft Position Sensor.................... 2

Crankshaft Position Sensor................... 3

Distributors............................... 4

Engine Coolant Temperature Sensor............ 5

General Information........................ 1Ignition Coil.............................. 4

Intake Manifold Air Temperature Sensor.......... 5

Manifold Absolute Pressure (MAP) Sensor........ 5

Oxygen (O2S) Sensor....................... 5

Powertrain Control Module (PCM).............. 5

Throttle Position Sensor..................... 5

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicle models by alphabetical designation

(XJ or YJ) or by the particular vehicle nameplate. A

chart showing a breakdown of alphabetical designa-

tions is included in the Introduction group at the be-

ginning of this manual.

This section of the group, Component Identifica-

tion/System Operation, will discuss ignition system

operation and will identify ignition system compo-

nents.

For diagnostic procedures and adjustments, refer to

the Diagnostics/Service Procedures section of this

group.

For removal and installation of ignition system

components, refer to the Component Removal/Instal-

lation section of this group.

For other useful information, refer to On-Board Di-

agnostics in the General Diagnosis sections of Group

14, Fuel System in this manual.

For operation of the DRB Scan Tool, refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice manual.

An Ignition specifications section is included at the

end of this group. A general Maintenance Schedule

(mileage intervals) for ignition related items can be

found in Group 0, Lubrication and Maintenance. This

schedule can also be found in the Owners Manual.

IGNITION SYSTEMS

A multi-port, fuel injected engine is used on all

models. The ignition system is controlled by the pow-

ertrain control module (PCM) on all engines. The

PCM was formerly referred to as the SBEC or engine

controller.

The ignition system consists of:

²Spark plugs

²Ignition coil

²Secondary ignition cables

²Distributor (contains rotor and camshaft position

sensor)

²Powertrain control module (PCM)

²Crankshaft position sensor

AUTOMATIC SHUTDOWN (ASD) RELAY

The automatic shutdown (ASD) relay is located in

the power distribution center (PDC) near the battery

(Fig. 1 or 2). As one of its functions, it will supply

battery voltage to the ignition coil.

The ground circuit for the ASD relay is controlled

by the powertrain control module (PCM). This is

done through pin/cavity number 51 of the PCM 60-

way connector. The PCM then regulates ASD relay

operation by switching this ground circuit on-and-off.

Also refer to Ignition Coil for additional informa-

tion.

JIGNITION SYSTEMS 8D - 1

Page 313 of 2198

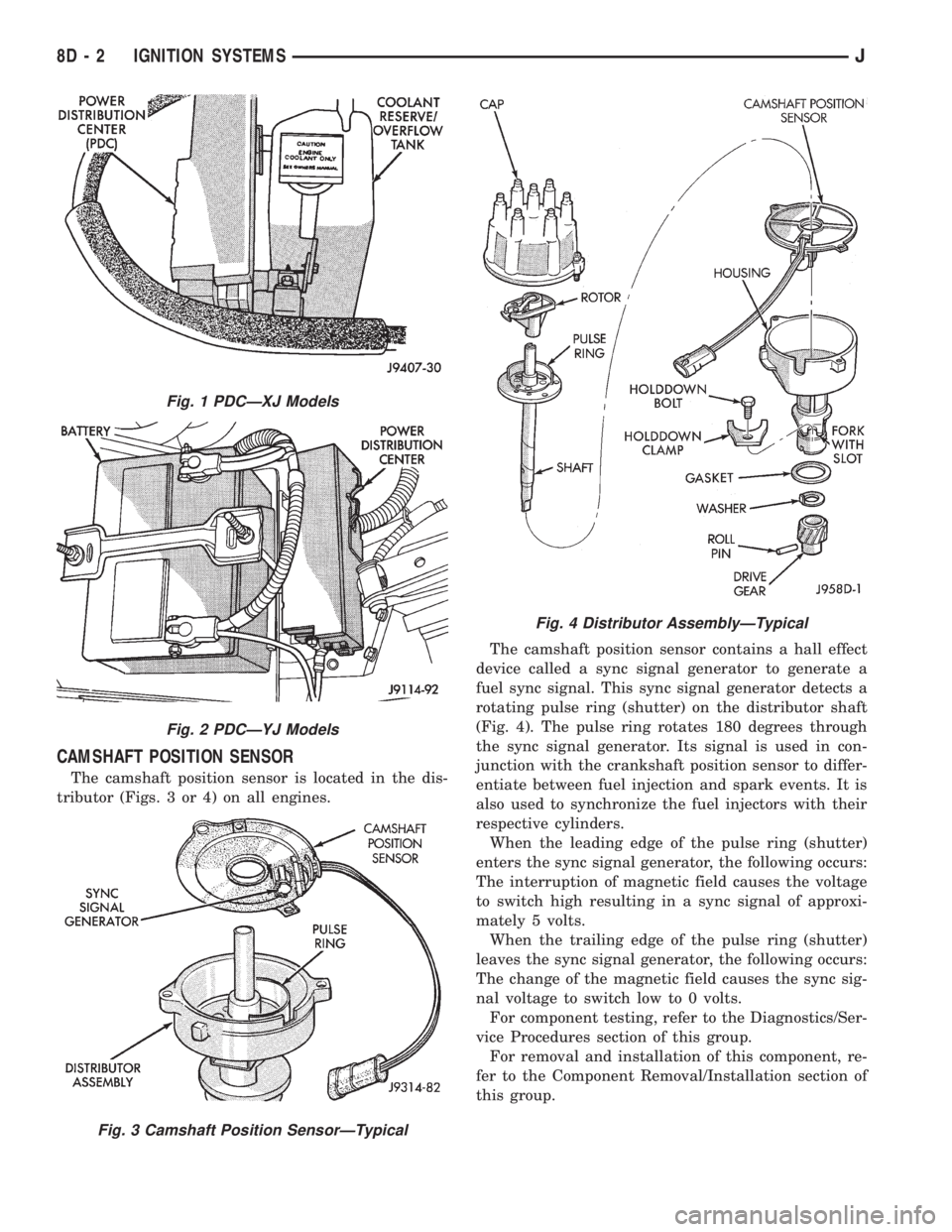

CAMSHAFT POSITION SENSOR

The camshaft position sensor is located in the dis-

tributor (Figs. 3 or 4) on all engines.The camshaft position sensor contains a hall effect

device called a sync signal generator to generate a

fuel sync signal. This sync signal generator detects a

rotating pulse ring (shutter) on the distributor shaft

(Fig. 4). The pulse ring rotates 180 degrees through

the sync signal generator. Its signal is used in con-

junction with the crankshaft position sensor to differ-

entiate between fuel injection and spark events. It is

also used to synchronize the fuel injectors with their

respective cylinders.

When the leading edge of the pulse ring (shutter)

enters the sync signal generator, the following occurs:

The interruption of magnetic field causes the voltage

to switch high resulting in a sync signal of approxi-

mately 5 volts.

When the trailing edge of the pulse ring (shutter)

leaves the sync signal generator, the following occurs:

The change of the magnetic field causes the sync sig-

nal voltage to switch low to 0 volts.

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

Fig. 1 PDCÐXJ Models

Fig. 2 PDCÐYJ Models

Fig. 3 Camshaft Position SensorÐTypical

Fig. 4 Distributor AssemblyÐTypical

8D - 2 IGNITION SYSTEMSJ

Page 315 of 2198

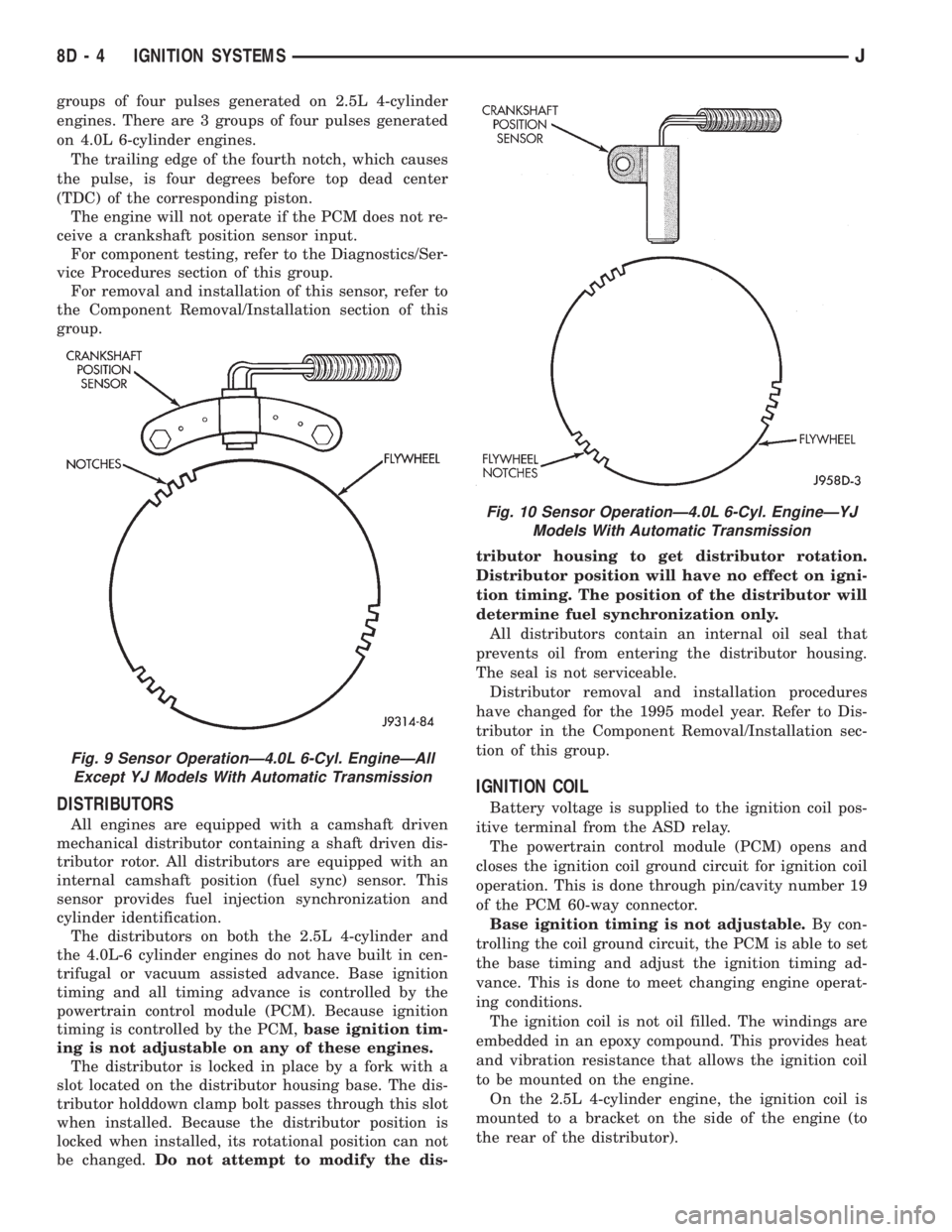

groups of four pulses generated on 2.5L 4-cylinder

engines. There are 3 groups of four pulses generated

on 4.0L 6-cylinder engines.

The trailing edge of the fourth notch, which causes

the pulse, is four degrees before top dead center

(TDC) of the corresponding piston.

The engine will not operate if the PCM does not re-

ceive a crankshaft position sensor input.

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this sensor, refer to

the Component Removal/Installation section of this

group.

DISTRIBUTORS

All engines are equipped with a camshaft driven

mechanical distributor containing a shaft driven dis-

tributor rotor. All distributors are equipped with an

internal camshaft position (fuel sync) sensor. This

sensor provides fuel injection synchronization and

cylinder identification.

The distributors on both the 2.5L 4-cylinder and

the 4.0L-6 cylinder engines do not have built in cen-

trifugal or vacuum assisted advance. Base ignition

timing and all timing advance is controlled by the

powertrain control module (PCM). Because ignition

timing is controlled by the PCM,base ignition tim-

ing is not adjustable on any of these engines.

The distributor is locked in place by a fork with a

slot located on the distributor housing base. The dis-

tributor holddown clamp bolt passes through this slot

when installed. Because the distributor position is

locked when installed, its rotational position can not

be changed.Do not attempt to modify the dis-tributor housing to get distributor rotation.

Distributor position will have no effect on igni-

tion timing. The position of the distributor will

determine fuel synchronization only.

All distributors contain an internal oil seal that

prevents oil from entering the distributor housing.

The seal is not serviceable.

Distributor removal and installation procedures

have changed for the 1995 model year. Refer to Dis-

tributor in the Component Removal/Installation sec-

tion of this group.

IGNITION COIL

Battery voltage is supplied to the ignition coil pos-

itive terminal from the ASD relay.

The powertrain control module (PCM) opens and

closes the ignition coil ground circuit for ignition coil

operation. This is done through pin/cavity number 19

of the PCM 60-way connector.

Base ignition timing is not adjustable.By con-

trolling the coil ground circuit, the PCM is able to set

the base timing and adjust the ignition timing ad-

vance. This is done to meet changing engine operat-

ing conditions.

The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the ignition coil

to be mounted on the engine.

On the 2.5L 4-cylinder engine, the ignition coil is

mounted to a bracket on the side of the engine (to

the rear of the distributor).

Fig. 9 Sensor OperationÐ4.0L 6-Cyl. EngineÐAll

Except YJ Models With Automatic Transmission

Fig. 10 Sensor OperationÐ4.0L 6-Cyl. EngineÐYJ

Models With Automatic Transmission

8D - 4 IGNITION SYSTEMSJ

Page 316 of 2198

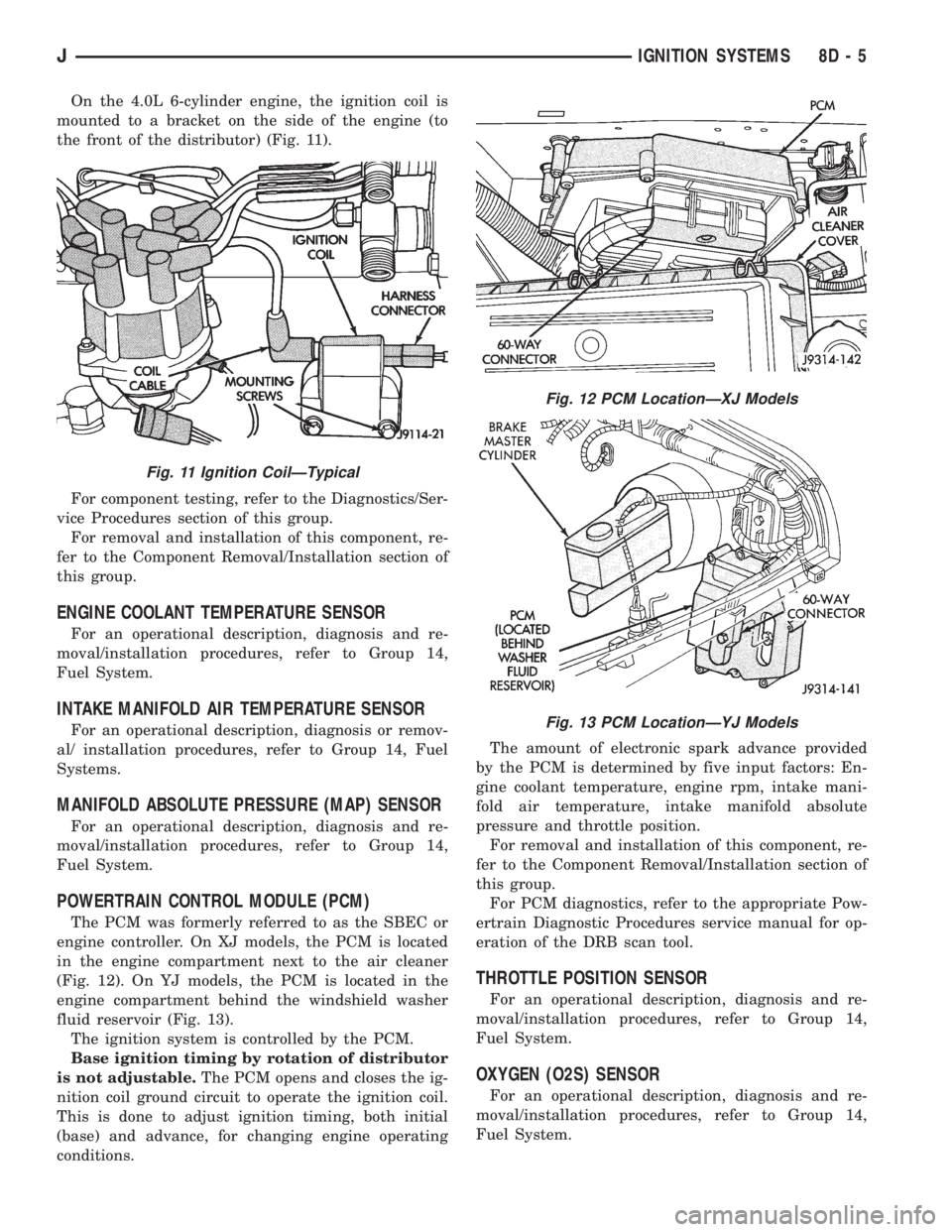

On the 4.0L 6-cylinder engine, the ignition coil is

mounted to a bracket on the side of the engine (to

the front of the distributor) (Fig. 11).

For component testing, refer to the Diagnostics/Ser-

vice Procedures section of this group.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

ENGINE COOLANT TEMPERATURE SENSOR

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

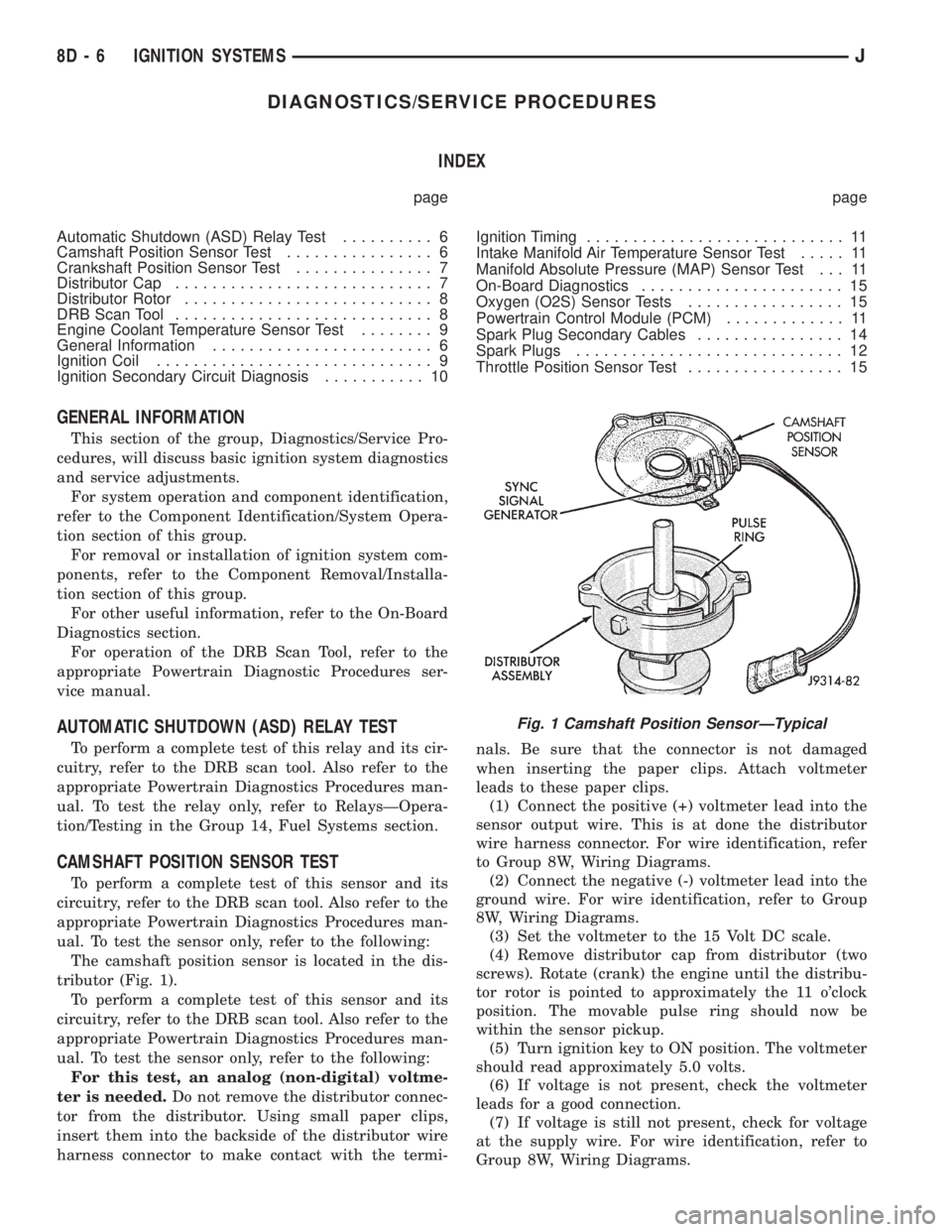

POWERTRAIN CONTROL MODULE (PCM)

The PCM was formerly referred to as the SBEC or

engine controller. On XJ models, the PCM is located

in the engine compartment next to the air cleaner

(Fig. 12). On YJ models, the PCM is located in the

engine compartment behind the windshield washer

fluid reservoir (Fig. 13).

The ignition system is controlled by the PCM.

Base ignition timing by rotation of distributor

is not adjustable.The PCM opens and closes the ig-

nition coil ground circuit to operate the ignition coil.

This is done to adjust ignition timing, both initial

(base) and advance, for changing engine operating

conditions.The amount of electronic spark advance provided

by the PCM is determined by five input factors: En-

gine coolant temperature, engine rpm, intake mani-

fold air temperature, intake manifold absolute

pressure and throttle position.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

For PCM diagnostics, refer to the appropriate Pow-

ertrain Diagnostic Procedures service manual for op-

eration of the DRB scan tool.

THROTTLE POSITION SENSOR

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

OXYGEN (O2S) SENSOR

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

Fig. 11 Ignition CoilÐTypical

Fig. 12 PCM LocationÐXJ Models

Fig. 13 PCM LocationÐYJ Models

JIGNITION SYSTEMS 8D - 5

Page 317 of 2198

DIAGNOSTICS/SERVICE PROCEDURES

INDEX

page page

Automatic Shutdown (ASD) Relay Test.......... 6

Camshaft Position Sensor Test................ 6

Crankshaft Position Sensor Test............... 7

Distributor Cap............................ 7

Distributor Rotor........................... 8

DRB Scan Tool............................ 8

Engine Coolant Temperature Sensor Test........ 9

General Information........................ 6

Ignition Coil.............................. 9

Ignition Secondary Circuit Diagnosis........... 10Ignition Timing............................ 11

Intake Manifold Air Temperature Sensor Test..... 11

Manifold Absolute Pressure (MAP) Sensor Test . . . 11

On-Board Diagnostics...................... 15

Oxygen (O2S) Sensor Tests................. 15

Powertrain Control Module (PCM)............. 11

Spark Plug Secondary Cables................ 14

Spark Plugs............................. 12

Throttle Position Sensor Test................. 15

GENERAL INFORMATION

This section of the group, Diagnostics/Service Pro-

cedures, will discuss basic ignition system diagnostics

and service adjustments.

For system operation and component identification,

refer to the Component Identification/System Opera-

tion section of this group.

For removal or installation of ignition system com-

ponents, refer to the Component Removal/Installa-

tion section of this group.

For other useful information, refer to the On-Board

Diagnostics section.

For operation of the DRB Scan Tool, refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice manual.

AUTOMATIC SHUTDOWN (ASD) RELAY TEST

To perform a complete test of this relay and its cir-

cuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the relay only, refer to RelaysÐOpera-

tion/Testing in the Group 14, Fuel Systems section.

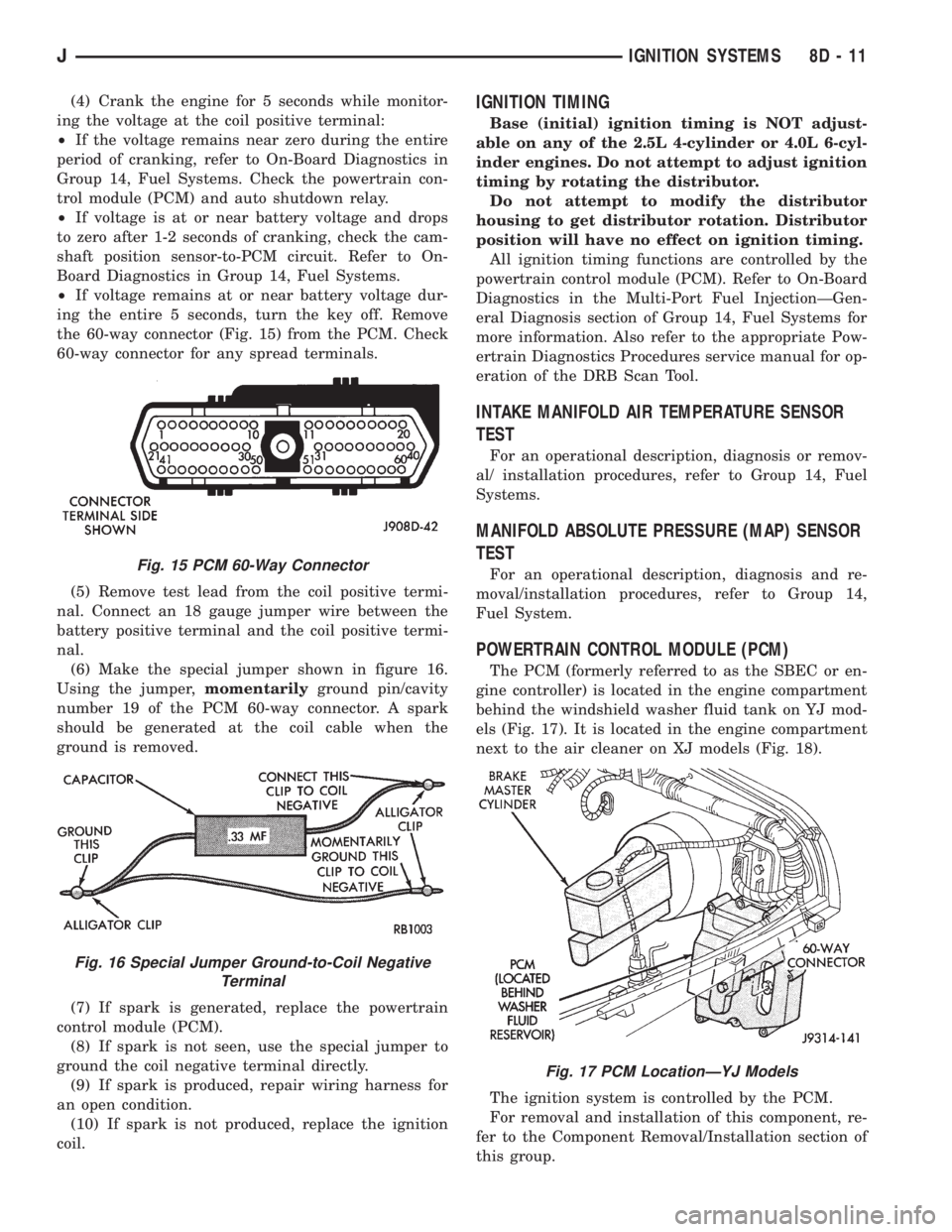

CAMSHAFT POSITION SENSOR TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

The camshaft position sensor is located in the dis-

tributor (Fig. 1).

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

For this test, an analog (non-digital) voltme-

ter is needed.Do not remove the distributor connec-

tor from the distributor. Using small paper clips,

insert them into the backside of the distributor wire

harness connector to make contact with the termi-nals. Be sure that the connector is not damaged

when inserting the paper clips. Attach voltmeter

leads to these paper clips.

(1) Connect the positive (+) voltmeter lead into the

sensor output wire. This is at done the distributor

wire harness connector. For wire identification, refer

to Group 8W, Wiring Diagrams.

(2) Connect the negative (-) voltmeter lead into the

ground wire. For wire identification, refer to Group

8W, Wiring Diagrams.

(3) Set the voltmeter to the 15 Volt DC scale.

(4) Remove distributor cap from distributor (two

screws). Rotate (crank) the engine until the distribu-

tor rotor is pointed to approximately the 11 o'clock

position. The movable pulse ring should now be

within the sensor pickup.

(5) Turn ignition key to ON position. The voltmeter

should read approximately 5.0 volts.

(6) If voltage is not present, check the voltmeter

leads for a good connection.

(7) If voltage is still not present, check for voltage

at the supply wire. For wire identification, refer to

Group 8W, Wiring Diagrams.

Fig. 1 Camshaft Position SensorÐTypical

8D - 6 IGNITION SYSTEMSJ

Page 318 of 2198

(8) If voltage is not present at supply wire, check

for voltage at pin-7 of powertrain control module

(PCM) 60-way connector. Leave the PCM connector

connected for this test.

(9) If voltage is still not present, perform vehicle

test using the DRB scan tool.

(10) If voltage is present at pin-7, but not at the

supply wire:

(a) Check continuity between the supply wire.

This is checked between the distributor connector

and pin-7 at the PCM. If continuity is not present,

repair the harness as necessary.

(b) Check for continuity between the camshaft

position sensor output wire and pin-44 at the PCM.

If continuity is not present, repair the harness as

necessary.

(c) Check for continuity between the ground cir-

cuit wire at the distributor connector and ground.

If continuity is not present, repair the harness as

necessary.

(11) While observing the voltmeter, crank the en-

gine with ignition switch. The voltmeter needle

should fluctuate between 0 and 5 volts while the en-

gine is cranking. This verifies that the camshaft po-

sition sensor in the distributor is operating properly

and a sync pulse signal is being generated.

If sync pulse signal is not present, replacement of

the camshaft position sensor is necessary.

For removal or installation of ignition system com-

ponents, refer to the Component Removal/Installa-

tion section of this group.

For system operation and component identification,

refer to the Component Identification/System Opera-

tion section of this group.

CRANKSHAFT POSITION SENSOR TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

The sensor is located on the transmission bellhous-

ing at the left/rear side of the engine block (Figs. 2, 3

or 4).

(1) Near the rear of the intake manifold, discon-

nect sensor pigtail harness connector from main wir-

ing harness.

(2) Place an ohmmeter across terminals B and C

(Fig. 5). Ohmmeter should be set to 1K-to-10K scale

for this test. The meter reading should be open (no

resistance). Replace sensor if a low resistance is indi-

cated.

For removal or installation of ignition system com-

ponents, refer to the Component Removal/Installa-

tion section of this group.DISTRIBUTOR CAP

INSPECTION

Remove the distributor cap and wipe it clean with

a dry lint free cloth. Visually inspect the cap for

cracks, carbon paths, broken towers, or damaged ro-

tor button (Figs. 6 and 7). Also check for white depos-

its on the inside (caused by condensation entering

the cap through cracks). Replace any cap that dis-

plays charred or eroded terminals. The inside flat

surface of a terminal end (faces toward rotor) will in-

dicate some evidence of erosion from normal opera-

tion. Examine the terminal ends for evidence of

mechanical interference with the rotor tip.

If replacement of the distributor cap is necessary,

transfer spark plug cables from the original cap to

the new cap. This should be done one cable at a time.

Each cable is installed onto the tower of the new cap

that corresponds to its tower position on the original

Fig. 2 Crankshaft Position SensorÐ2.5L 4-Cyl.

EngineÐTypical

Fig. 3 Crankshaft Position SensorÐ4.0L 6-Cyl.

EngineÐAll Except YJ models With Auto. Trans.

JIGNITION SYSTEMS 8D - 7

Page 322 of 2198

(4) Crank the engine for 5 seconds while monitor-

ing the voltage at the coil positive terminal:

²If the voltage remains near zero during the entire

period of cranking, refer to On-Board Diagnostics in

Group 14, Fuel Systems. Check the powertrain con-

trol module (PCM) and auto shutdown relay.

²If voltage is at or near battery voltage and drops

to zero after 1-2 seconds of cranking, check the cam-

shaft position sensor-to-PCM circuit. Refer to On-

Board Diagnostics in Group 14, Fuel Systems.

²If voltage remains at or near battery voltage dur-

ing the entire 5 seconds, turn the key off. Remove

the 60-way connector (Fig. 15) from the PCM. Check

60-way connector for any spread terminals.

(5) Remove test lead from the coil positive termi-

nal. Connect an 18 gauge jumper wire between the

battery positive terminal and the coil positive termi-

nal.

(6) Make the special jumper shown in figure 16.

Using the jumper,momentarilyground pin/cavity

number 19 of the PCM 60-way connector. A spark

should be generated at the coil cable when the

ground is removed.

(7) If spark is generated, replace the powertrain

control module (PCM).

(8) If spark is not seen, use the special jumper to

ground the coil negative terminal directly.

(9) If spark is produced, repair wiring harness for

an open condition.

(10) If spark is not produced, replace the ignition

coil.IGNITION TIMING

Base (initial) ignition timing is NOT adjust-

able on any of the 2.5L 4-cylinder or 4.0L 6-cyl-

inder engines. Do not attempt to adjust ignition

timing by rotating the distributor.

Do not attempt to modify the distributor

housing to get distributor rotation. Distributor

position will have no effect on ignition timing.

All ignition timing functions are controlled by the

powertrain control module (PCM). Refer to On-Board

Diagnostics in the Multi-Port Fuel InjectionÐGen-

eral Diagnosis section of Group 14, Fuel Systems for

more information. Also refer to the appropriate Pow-

ertrain Diagnostics Procedures service manual for op-

eration of the DRB Scan Tool.

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

TEST

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

TEST

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

POWERTRAIN CONTROL MODULE (PCM)

The PCM (formerly referred to as the SBEC or en-

gine controller) is located in the engine compartment

behind the windshield washer fluid tank on YJ mod-

els (Fig. 17). It is located in the engine compartment

next to the air cleaner on XJ models (Fig. 18).

The ignition system is controlled by the PCM.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

Fig. 15 PCM 60-Way Connector

Fig. 16 Special Jumper Ground-to-Coil Negative

Terminal

Fig. 17 PCM LocationÐYJ Models

JIGNITION SYSTEMS 8D - 11

Page 326 of 2198

To test ignition coil-to-distributor cap cable, do not

remove the cable from the cap. Connect ohmmeter to

rotor button (center contact) of distributor cap and

terminal at ignition coil end of cable. If resistance is

not within specifications as found in the Spark Plug

Cable Resistance chart, remove the cable from the

distributor cap. Connect the ohmmeter to the termi-

nal ends of the cable. If resistance is not within spec-

ifications as found in the Spark Plug Cable

Resistance chart, replace the cable. Inspect the igni-

tion coil tower for cracks, burns or corrosion.

For removal and installation of spark plug cables,

refer to Spark Plug Secondary Cables in the Compo-

nent Removal/Installation section.

THROTTLE POSITION SENSOR TEST

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

OXYGEN (O2S) SENSOR TESTS

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

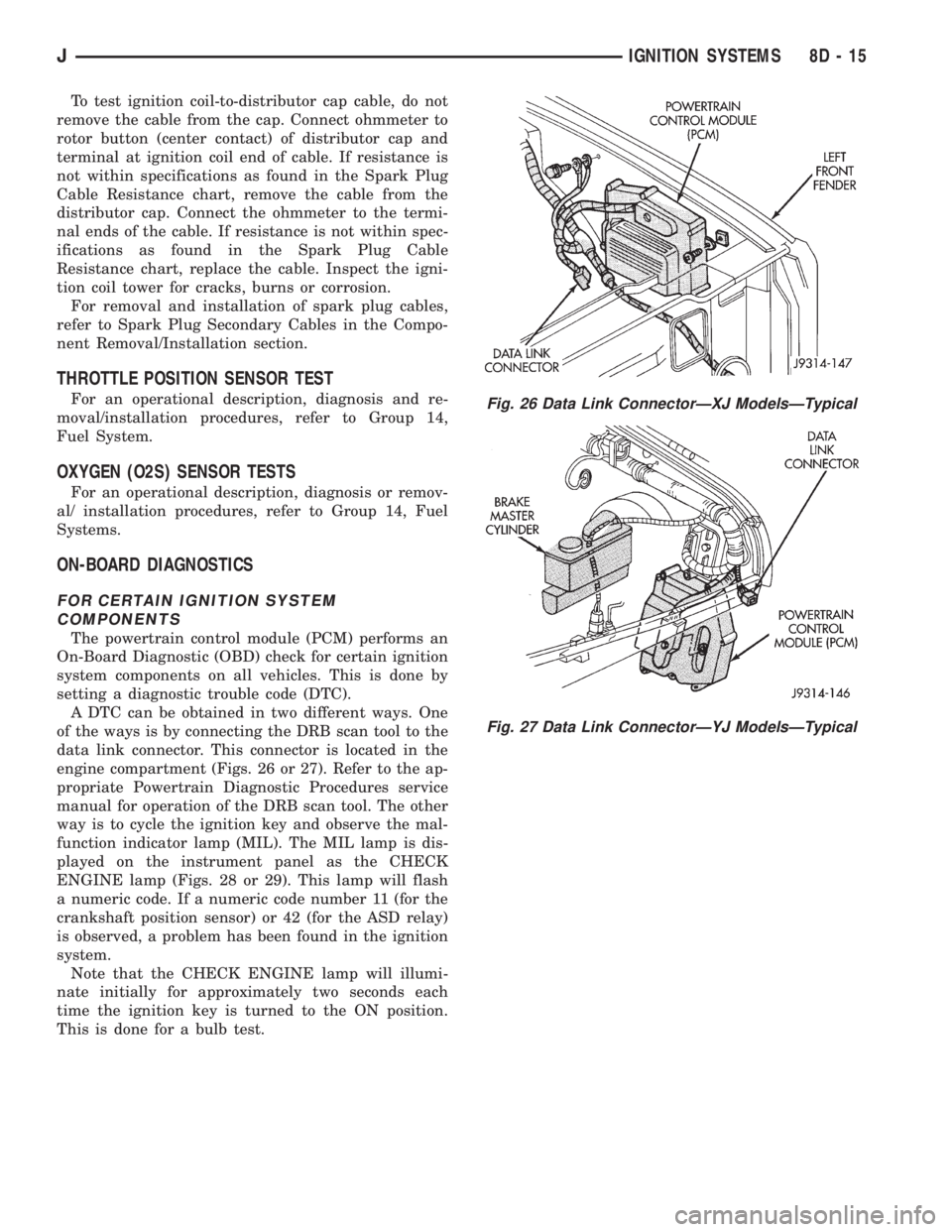

ON-BOARD DIAGNOSTICS

FOR CERTAIN IGNITION SYSTEM

COMPONENTS

The powertrain control module (PCM) performs an

On-Board Diagnostic (OBD) check for certain ignition

system components on all vehicles. This is done by

setting a diagnostic trouble code (DTC).

A DTC can be obtained in two different ways. One

of the ways is by connecting the DRB scan tool to the

data link connector. This connector is located in the

engine compartment (Figs. 26 or 27). Refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual for operation of the DRB scan tool. The other

way is to cycle the ignition key and observe the mal-

function indicator lamp (MIL). The MIL lamp is dis-

played on the instrument panel as the CHECK

ENGINE lamp (Figs. 28 or 29). This lamp will flash

a numeric code. If a numeric code number 11 (for the

crankshaft position sensor) or 42 (for the ASD relay)

is observed, a problem has been found in the ignition

system.

Note that the CHECK ENGINE lamp will illumi-

nate initially for approximately two seconds each

time the ignition key is turned to the ON position.

This is done for a bulb test.

Fig. 26 Data Link ConnectorÐXJ ModelsÐTypical

Fig. 27 Data Link ConnectorÐYJ ModelsÐTypical

JIGNITION SYSTEMS 8D - 15