check engine JEEP CHEROKEE 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: CHEROKEE, Model: JEEP CHEROKEE 2019Pages: 344, PDF Size: 6.35 MB

Page 139 of 344

Front seat belt assemblies must be replaced

after a collision. Rear seat belt assemblies

must be replaced after a collision if they have

been damaged (i.e., bent retractor, torn web-

bing, etc.). If there is any question regarding

seat belt or retractor condition, replace the

seat belt.

Air Bag Warning Light

The Air Bag warning lightwill turn on for

four to eight seconds as a bulb check when

the ignition switch is first turned to ON/RUN.

If the light is either not on during starting,

stays on, or turns on while driving, have the

system inspected at an authorized dealer as

soon as possible. After the bulb check, this

light will illuminate with a single chime when

a fault with the Air Bag System has been

detected. It will stay on until the fault is

removed. If the light comes on intermittently

or remains on while driving, have an autho-

rized dealer service the vehicle immediately.

Refer to “Occupant Restraint Systems” in

“Safety” for further information.

Defroster

Check operation by selecting the defrost

mode and place the blower control on high

speed. You should be able to feel the air

directed against the windshield. See an au-

thorized dealer for service if your defroster is

inoperable.

Floor Mat Safety Information

Always use floor mats designed to fit your

vehicle. Only use a floor mat that does not

interfere with the operation of the accelera-

tor, brake or clutch pedals. Only use a floor

mat that is securely attached using the floor

mat fasteners so it cannot slip out of position

and interfere with the accelerator, brake or

clutch pedals or impair safe operation of your

vehicle in other ways.

WARNING!

An improperly attached, damaged, folded,

or stacked floor mat, or damaged floor mat

fasteners may cause your floor mat to in-

terfere with the accelerator, brake, or

clutch pedals and cause a loss of vehicle

WARNING!

control. To prevent SERIOUS INJURY or

DEATH:

• ALWAYS securely attach

your floor

mat using the floor mat fasteners. DO

NOT install your floor mat upside down

or turn your floor mat over. Lightly pull to

confirm mat is secured using the floor

mat fasteners on a regular basis.

• ALWAYS REMOVE THE EXISTING

FLOOR MAT FROM THE VEHICLE

before installing any other floor mat.

NEVER install or stack an additional

floor mat on top of an existing floor mat.

• ONLY install floor mats designed to fit

your vehicle. NEVER install a floor mat

that cannot be properly attached and

secured to your vehicle. If a floor mat

needs to be replaced, only use a FCA

approved floor mat for the specific

make, model, and year of your vehicle.

• ONLY use the driver’s side floor mat on

the driver’s side floor area. To check for

interference, with the vehicle properly

parked with the engine off, fully depress

the accelerator, the brake, and the

137

Page 143 of 344

Normal Starting Procedure — Keyless

Enter-N-Go

Observe the instrument panel cluster lights

when starting the engine.

NOTE:

Normal starting of either a cold or a warm

engine is obtained without pumping or press-

ing the accelerator pedal.

1. Always apply the parking brake.

2. Press and hold the brake pedal while

pushing the ENGINE START/STOP button

once.

NOTE:

A delay of the start of up to five seconds is

possible under very cold conditions. The

“Wait to Start” telltale will be illuminated

during the pre-heat process, When the

engine Wait To Start light goes off the

engine will automatically crank.

CAUTION!

If the “Water in Fuel Indicator Light” re-

mains on, DO NOT START the engine be-

CAUTION!

fore the water is drained from the fuel

filters to avoid engine damage.

3. The system will automatically engage the

starter to crank the engine. If the vehicle

fails to start, the starter will disengage

automatically after 30 seconds.

4. If you wish to stop the cranking of the

engine prior to the engine starting, push

the button again.

5. Check that the oil pressure warning light

has turned off.

6. Release the parking brake.

Engine Warm Up

Avoid full throttle operation when the engine

is cold. When starting a cold engine, bring the

engine up to operating speed slowly to allow

the oil pressure to stabilize as the engine

warms up.NOTE:

High-speed, no-load running of a cold engine

can result in excessive white smoke and poor

engine performance. No-load engine speeds

should be kept under 1,200 RPM during the

warm-up period, especially in cold ambient

temperature conditions.

ENGINE BREAK-IN

RECOMMENDATIONS

A long break-in period is not required for the

engine and drivetrain (transmission and axle)

in your vehicle.

Drive moderately during the first 300 miles

(500 km). After the initial 60 miles

(100 km), speeds up to 50 or 55 mph (80 or

90 km/h) are desirable.

While cruising, brief full-throttle acceleration

within the limits of local traffic laws contrib-

utes to a good break-in. Wide-open throttle

acceleration in low gear can be detrimental

and should be avoided.

141

Page 149 of 344

WARNING!

in the LOCK/OFF (key removal) position,

(or, with Keyless Enter-N-Go, when the

ignition is in the OFF mode) the trans-

mission is locked in PARK, securing the

vehicle against unwanted movement.

• When leaving the vehicle, always make

sure the ignition is in the OFF mode,

remove the key fob from the vehicle, and

lock the vehicle.

• Never use the PARK position as a sub-

stitute for the parking brake. Always

apply the parking brake fully when exit-

ing the vehicle to guard against vehicle

movement and possible injury or dam-

age.

• Your vehicle could move and injure you

and others if it is not in PARK. Check by

trying to move the gear selector out of

PARK with the brake pedal released.

Make sure the transmission is in PARK

before exiting the vehicle.

• Never leave children alone in a vehicle,

or with access to an unlocked vehicle.

Allowing children to be in a vehicle un-

attended is dangerous for a number of

WARNING!

reasons. A child or others could be seri-

ously or fatally injured. Children should

be warned not to touch the parking

brake, brake pedal or the transmission

gear selector.

• Do not leave the key fob in or near the

vehicle (or in a location accessible to

children), and do not leave the ignition

(in a vehicle equipped with Keyless

Enter-N-Go) in the ACC or ON/RUN

mode. A child could operate power win-

dows, other controls, or move the ve-

hicle.

CAUTION!

Damage to the transmission may occur if

the following precautions are not ob-

served:

• Shift into or out of PARK or REVERSE

only after the vehicle has come to a

complete stop.

CAUTION!

• Do not shift between PARK, REVERSE,

NEUTRAL, or DRIVE when the engine is

above idle speed.

• Before shifting into any gear, make sure

your foot is firmly pressing the brake

pedal.

NOTE:

You must press and hold the brake pedal

while shifting out of PARK.

Key Ignition Park Interlock

This vehicle is equipped with a Key Ignition

Park Interlock which requires the transmis-

sion to be in PARK before the ignition can be

turned to the LOCK/OFF (key removal) posi-

tion. The key fob can only be removed from

the ignition when the ignition is in the LOCK/

OFF position, and the transmission is locked

in PARK whenever the ignition is in the

LOCK/OFF position.

147

Page 159 of 344

Refer to the “Stop/Start System” in the

“Starting And Operating” in your Owner’s

Manual.

Possible Reasons The Engine Does Not

Autostop

Prior to engine shut down, the system will

check many safety and comfort conditions to

see if they are fulfilled. Detailed information

about the operation of the Stop/Start system

may be viewed in the instrument cluster dis-

play Stop/Start Screen. In the following situ-

ations the engine will not stop:

• Driver’s seat belt is not buckled.

• Driver’s door is not closed.

• Battery temperature is too warm or cold.

• Battery charge is low.

• The vehicle is on a steep grade.

• Cabin heating or cooling is in process and

an acceptable cabin temperature has not

been achieved.

• HVAC is set to full defrost mode at a high

blower speed.

• HVAC set to MAX A/C.• Engine has not reached normal operating

temperature.

• The transmission is not in a forward or

reverse gear.

• Hood is open.

• Vehicle is in 4LO transfer case mode (if

equipped with 4WD).

• Brake pedal is not pressed with sufficient

pressure with vehicle in DRIVE position.

Other Factors Which Can Inhibit Autostop In-

clude:

• Accelerator pedal input.

• Engine temp too high.

• 5 mph threshold not achieved from previ-

ous AUTOSTOP.

• Steering angle beyond threshold.

• ACC is on and speed is set.

It may be possible for the vehicle to be driven

several times without the STOP/START sys-

tem going into a STOP/START READY state

under more extreme conditions of the items

listed above.

To Start The Engine While In Autostop

Mode

While in a forward gear, the engine will start

when the brake pedal is released or the

throttle pedal is depressed. The transmission

will automatically re-engage upon engine re-

start.

Conditions That Will Cause The Engine To Start

Automatically While In Autostop Mode:

• The transmission gear selector is moved out

of DRIVE except in the PARK position.

• To maintain cabin temperature comfort.

• HVAC is set to full defrost mode.

• HVAC system temperature or fan speed is

manually adjusted.

• Battery voltage drops too low.

• Low brake vacuum (e.g. after several brake

pedal applications).

• STOP/START OFF switch is pushed.

• A STOP/START system error occurs.

• 4WD system is put into 4LO mode (if

equipped with 4WD).

157

Page 161 of 344

Automatic Mode

The Stop/Start feature is enabled after every

normal customer engine start. It will remain

in STOP/START NOT READY until you drive

forward with a vehicle speed greater than

4 mph (7 km/h). At that time, the system will

go into STOP/START READY and if all other

conditions are met, can go into a STOP/

START AUTOSTOP ACTIVE “Autostop”

mode.

To Activate The Autostop Mode, The Following

Must Occur:

• The system must be in STOP/START

READY state. A STOP/START READY mes-

sage will be displayed in the instrument

cluster display within the Stop/Start sec-

tion. Refer to “Instrument Cluster Display”

in “Getting To Know Your Instrument

Panel” in your Owner’s information for fur-

ther details.

• The vehicle must be completely stopped.

• The gear selector must be in DRIVE and the

brake pedal depressed (automatic trans-

mission) or the gear selector must be in

NEUTRAL and the clutch pedal must be

fully released (manual transmission).The engine will shut down, the tachometer

will move to the zero position and the Stop/

Start telltale will illuminate indicating you

are in Autostop. While in Autostop, the Cli-

mate Controls system may automatically ad-

just airflow to maintain cabin comfort. Cus-

tomer settings will be maintained upon return

to an engine running condition.

Possible Reasons The Engine Does Not

Autostop

Prior to engine shut down, the system will

check many safety and comfort conditions to

see if they are fulfilled. Detailed information

about the operation of the Stop/Start system

may be viewed in the instrument cluster

Stop/Start Screen. In the following situations

the engine will not stop:

• Driver’s seat belt is not buckled.

• Driver’s door is not closed.

• Battery temperature is too warm or cold.

• The vehicle is on a steep grade.

• Cabin heating or cooling is in process and

an acceptable cabin temperature has not

been achieved.• HVAC is set to full defrost mode at a high

blower speed.

• Engine has not reached normal operating

temperature.

• Battery charge is low.

• The transmission is not in DRIVE (auto-

matic transmission) or NEUTRAL (manual

transmission).

• Hood is open.

• Vehicle is in 4LO transfer case mode.

• Exhaust system regeneration in process.

Other Factors Which Can Inhibit Autostop In-

clude:

• Fuel level.

• Accelerator pedal input (automatic trans-

mission only).

• Engine temperature too high.

It may be possible for the vehicle to be driven

several times without the STOP/START sys-

tem going into a STOP/START READY state

under more extreme conditions of the items

listed above.

159

Page 188 of 344

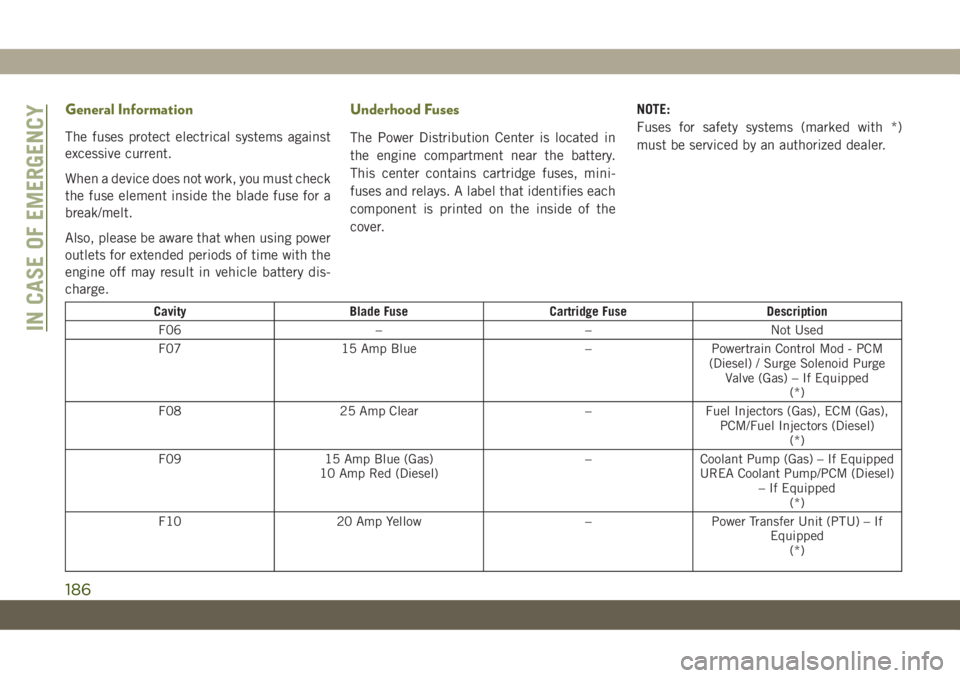

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check

the fuse element inside the blade fuse for a

break/melt.

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery dis-

charge.

Underhood Fuses

The Power Distribution Center is located in

the engine compartment near the battery.

This center contains cartridge fuses, mini-

fuses and relays. A label that identifies each

component is printed on the inside of the

cover.NOTE:

Fuses for safety systems (marked with *)

must be serviced by an authorized dealer.

Cavity Blade Fuse Cartridge Fuse Description

F06 – – Not Used

F07 15 Amp Blue – Powertrain Control Mod - PCM

(Diesel) / Surge Solenoid Purge

Valve (Gas) – If Equipped

(*)

F08 25 Amp Clear – Fuel Injectors (Gas), ECM (Gas),

PCM/Fuel Injectors (Diesel)

(*)

F09 15 Amp Blue (Gas)

10 Amp Red (Diesel)– Coolant Pump (Gas) – If Equipped

UREA Coolant Pump/PCM (Diesel)

– If Equipped

(*)

F10 20 Amp Yellow – Power Transfer Unit (PTU) – If

Equipped

(*)IN CASE OF EMERGENCY

186

Page 209 of 344

If the sealant (white fluid) does not flow within 0

– 10 seconds through the Sealant Hose (6):

1. Push the Power Button (4) to turn Off the

Tire Service Kit. Disconnect the Sealant

Hose (6) from the valve stem. Make sure

the valve stem is free of debris. Reconnect

the Sealant Hose (6) to the valve stem.

Check that the Mode Select Knob (5) is in

the Sealant Mode position and not Air

Mode. Push the Power Button (4) to turn

On the Tire Service Kit.

2. Connect the Power Plug (8) to a different

12 Volt power outlet in your vehicle or

another vehicle, if available. Make sure

the engine is running before turning ON

the Tire Service Kit.

3. The Sealant Bottle (1) may be empty due

to previous use. Call for assistance.

NOTE:

If the Mode Select Knob (5) is on Air Mode

and the pump is operating, air will dispense

from the Air Pump Hose (7) only, not the

Sealant Hose (6).If the sealant (white fluid) does flow through the

Sealant Hose (6):

1. Continue to operate the pump until seal-

ant is no longer flowing through the hose

(typically takes 30 - 70 seconds). As the

sealant flows through the Sealant Hose

(6), the Pressure Gauge (3) can read as

high as 70 psi (4.8 Bar). The Pressure

Gauge (3) will decrease quickly from ap-

proximately 70 psi (4.8 Bar) to the actual

tire pressure when the Sealant Bottle (1)

is empty.

2. The pump will start to inject air into the

tire immediately after the Sealant Bottle

(1) is empty. Continue to operate the

pump and inflate the tire to the pressure

indicated on the tire pressure label on the

driver-side latch pillar (recommended

pressure). Check the tire pressure by look-

ing at the Pressure Gauge (3).

If the tire does not inflate to at least 26 psi

(1.8 Bar) pressure within 15 minutes:

• The tire is too badly damaged. Do not at-

tempt to drive the vehicle further. Call for

assistance.NOTE:

If the tire becomes overinflated, push the

Deflation Button to reduce the tire pressure

to the recommended inflation pressure be-

fore continuing.

If the tire inflates to the recommended pressure

or is at least 26 psi (1.8 Bar) pressure within

15 minutes:

1. Push the Power Button (4) to turn off the

Tire Service Kit.

2. Remove the Speed Limit sticker from the

top of the Sealant Bottle (1) and place the

sticker on the instrument panel.

3. Immediately disconnect the Sealant Hose

(6) from the valve stem, reinstall the cap

on the fitting at the end of the hose, and

place the Tire Service Kit in the vehicle

storage location. Quickly proceed to (D)

“Drive Vehicle.”

CAUTION!

• The metal end fitting from Power Plug

(8) may get hot after use, so it should be

handled carefully.

207

Page 220 of 344

SCHEDULED SERVICING

Correct servicing is crucial for guaranteeing a

long life for the car under the best conditions.

For this reason, Jeep has planned a series of

checks and services at fixed distance inter-

vals and, where provided, at fixed time inter-

vals, as described in the Scheduled Servicing

plan. To keep the car’s efficiency in tip-top

condition, in the following Scheduled Service

plan pages a few additional checks are listed

that should be carried out more frequently

with respect to the normal coupon redemp-

tion schedule. Scheduled Servicing is offered

by all authorized dealerships according to

fixed time or mileage intervals. If, during

each operation, in addition to the ones

scheduled, the need arises for further re-

placements or repairs, these may be carried

out with the owner's explicit agreement only.

The technicians at your dealership know your

vehicle best, and have access to factory

trained information, genuine Mopar parts,

and specially designed electronic and me-

chanical tools that can help prevent future

costly repairs. If your car is used frequently

for towing, the interval between one sched-uled servicing operation and the next should

be reduced. More frequent maintenance may

be needed for vehicles in severe operating

conditions, such as dusty areas and very

short trip driving.

NOTE:

Scheduled Servicing interventions are set out

by the Manufacturer. Failure to have them

carried out may invalidate the warranty. It is

advised to inform an authorized dealership of

any small operating irregularities without

waiting for the next service.

Scheduled Servicing — Gasoline Engine

The oil change indicator system will remind

you that it is time to take your vehicle in for

engine oil replacement.

An “Oil Change Required” will be displayed

in the instrument cluster and a single chime

will sound, indicating that an oil change is

necessary.

The oil change indicator message will illumi-

nate approximately 7,000 miles

(11,200 km) after the most recent oil change

was performed. Have your vehicle serviced assoon as possible, within 500 miles (800 km)

(except for 2.0L gasoline engine with GPF –

Gasoline Particulate Filter).

NOTE:

• The oil change indicator message will not

monitor the time since the last oil change.

Change your vehicle’s oil if it has been

12 months since your last oil change even

if the oil change indicator message is NOT

illuminated.

• Change your engine oil more often if you

drive your vehicle off-road for an extended

period of time (refer to the “Heavy Duty

Use” section).

• Under no circumstances should oil change

intervals exceed 7,500 miles (12,000 km)

or 12 months, whichever comes first (ex-

cept for 2.0L gasoline engine with GPF –

Gasoline Particulate Filter).

Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change.

SERVICING AND MAINTENANCE

218

Page 221 of 344

Once A Month Or Before A Long Trip

• Check engine oil level.

• Check windshield washer fluid level.

• Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.

• Check the fluid levels of the coolant reser-

voir and brake master cylinder, fill as

needed.

• Check function of all interior and exterior

lights.

At Each Oil Change

• Change oil and filter.

• Rotate the tires.Rotate at the first sign of

irregular wear, even if it occurs before the oil

indicator system turns on.

• Inspect battery and clean and tighten ter-

minals as required.• Inspect brake pads, shoes, rotors, drums,

hoses and park brake.

• Inspect engine cooling system protection

and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty

or off-road conditions.

CAUTION!

Failure to perform the required mainte-

nance items may result in damage to the

vehicle.Maintenance Plan — Gasoline Engine

NOTE:

Once you have carried out the last interven-

tion in the table, continue with the scheduled

servicing, maintaining the frequency indi-

cated in the plan by marking each operation

with a dot or dedicated note. Simply restart-

ing the maintenance from the start of the

plan may cause the allowed interval to be

exceeded for some operations.

219

Page 225 of 344

The manufacturer recommends that these

maintenance intervals be performed at your

selling dealer. The technicians at your deal-

ership know your vehicle best, and have ac-

cess to factory trained information, genuine

Mopar parts, and specially designed elec-

tronic and mechanical tools that can help

prevent future costly repairs.

NOTE:

•The actual interval for changing engine oil

and replacing the engine oil filter depends on

the vehicle usage conditions, and is signaled

by the warning light or message in the instru-

ment cluster. In any case, it must never ex-

ceed two years. If the vehicle is used mainly

for city driving, change the engine oil and

filter every year.

•Flush and replace the engine coolant at

120 months or 150,000 miles (240,000 km)

whichever comes first.

•The timing and accessory belts must be

changed every 37,500 miles (60,000 km) or

3 years for particularly demanding use (dusty

areas, severe weather conditions, very low orvery high temperatures for extended periods,

city driving, long periods of idling). Under no

circumstances should these intervals be

exceeded.

Once A Month Or Before A Long Trip

• Check engine oil level.

• Check windshield washer fluid level.

• Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.

• Check the fluid levels of the coolant reser-

voir and brake master cylinder, fill as

needed.

• Check function of all interior and exterior

lights.

• Control and recovery of additive level for

AdBlue Diesel emissions (UREA) (if

equipped)

At Each Oil Change

• Change the engine oil filter.

• Inspect the brake hoses and lines.• Inspect for the presence of water in the fuel

filter/water separator unit.

Demanding Vehicle Use

• Restore additive level for AdBlue Diesel

emissions (UREA) (if equipped), when the

lamp is illuminated or the message on the

instrument panel.

CAUTION!

Failure to perform the required mainte-

nance items may result in damage to the

vehicle.

Maintenance Plan — Diesel Engine

NOTE:

Once you have carried out the last interven-

tion in the table, continue with the scheduled

servicing, maintaining the frequency indi-

cated in the plan by marking each operation

with a dot or dedicated note. Simply restart-

ing the maintenance from the start of the

plan may cause the allowed interval to be

exceeded for some operations.

223