technical specifications JEEP CHEROKEE 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: CHEROKEE, Model: JEEP CHEROKEE 2019Pages: 344, PDF Size: 6.35 MB

Page 7 of 344

GRAPHICAL TABLE OF CONTENTS

GETTING TO KNOW YOUR VEHICLE

GETTING TO KNOW YOUR INSTRUMENT PANEL

SAFETY

STARTING AND OPERATING

IN CASE OF EMERGENCY

SERVICING AND MAINTENANCE

TECHNICAL SPECIFICATIONS

MULTIMEDIA

CUSTOMER ASSISTANCE

INDEX

Page 11 of 344

RAISING THE VEHICLE................. 239

TIRES.......................... 239

Tires — General Information......... 239

Tire Types..................... 244

Spare Tires — If Equipped........... 244

Wheel And Wheel Trim Care.......... 246

Tire Chains (Traction Devices)......... 247

Tire Rotation Recommendations........ 248

STORING THE VEHICLE................ 249

BODYWORK....................... 250

Preserving The Bodywork............ 250

INTERIORS....................... 251Seats And Fabric Parts............. 251

Plastic And Coated Parts............ 251

Leather Parts................... 252

Glass Surfaces.................. 252

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER.......... 253

WHEEL AND TIRE TORQUE SPECIFICATIONS.... 253

Torque Specifications.............. 254

FUEL REQUIREMENTS — GASOLINE ENGINE.... 254Methanol..................... 255

Ethanol....................... 255

Clean Air Gasoline................ 255

CNG And LP Fuel System Modifications . . . 255

MMT In Gasoline................. 256

Materials Added To Fuel............ 256

Fuel Icon Identification Compliant To

EN16942..................... 256

FUEL REQUIREMENTS — DIESEL ENGINE...... 258Fuel Icon Identification Compliant To

EN16942..................... 259

FLUID CAPACITIES................... 260

FLUIDS AND LUBRICANTS............... 262

Engine....................... 262

Chassis....................... 265

FUEL CONSUMPTION AND CO2EMISSIONS..... 265

MOPAR ACCESSORIES................. 265

Authentic Accessories By Mopar........ 265

MULTIMEDIA

CYBERSECURITY................... 267

UCONNECT 3 WITH 5–INCH DISPLAY — IF

EQUIPPED....................... 268

Uconnect 3 With 5–inch Display At A

Glance....................... 268

Clock Setting................... 269

Audio Setting................... 269

Radio Operation................. 270

Voice Text Reply

(Not Compatible With iPhone)........ 270

Apps — If Equipped............... 271

UCONNECT 4 WITH 7-INCH DISPLAY......... 272Uconnect 4 At A Glance............ 272

Drag & Drop Menu Bar............. 273

Radio....................... 274

Android Auto — If Equipped.......... 275

Apple CarPlay Integration — If Equipped . . 276

Apps — If Equipped............... 277

UCONNECT 4C/4C NAV WITH 8.4-INCH DISPLAY . . 278Uconnect 4C/4C NAV At A Glance...... 278

Drag & Drop Menu Bar............. 279

Radio....................... 280

Android Auto — If Equipped.......... 281

Apple CarPlay Integration — If Equipped . . 285

Apps — If Equipped............... 287

UCONNECT SETTINGS................ 288

TIPS CONTROLS AND GENERAL INFORMATION . . . 288

Steering Wheel Audio Controls........ 288

AUX/USB/MP3 CONTROL — IF EQUIPPED...... 289

NAVIGATION — IF EQUIPPED............. 290

Changing The Navigation Voice Prompt

Volume....................... 290

Finding Points Of Interest........... 292

Finding A Place By Spelling The Name . . . 292

One-Step Voice Destination Entry....... 292

Setting Your Home Location.......... 292

Home........................ 292

Adding A Stop.................. 294

Taking A Detour.................. 294

Map Update.................... 294

UCONNECT PHONE.................. 295Uconnect Phone (Bluetooth Hands Free

Calling)...................... 295

Pairing (Wirelessly Connecting) Your Mobile

Phone To The Uconnect System....... 298

Common Phone Commands (Examples) . . . 301

Mute (Or Unmute) Microphone During Call . 302

Transfer Ongoing Call Between Handset And

Vehicle...................... 302

Phonebook.................... 302

Voice Command Tips.............. 302

Changing The Volume.............. 302

Using Do Not Disturb.............. 302

Incoming Text Messages............ 303

Helpful Tips And Common Questions To Improve

Bluetooth Performance With Your Uconnect

System...................... 304

9

Page 144 of 344

The engine oil installed in the engine at the

factory is a high-quality energy conserving

type lubricant. Oil changes should be consis-

tent with anticipated climate conditions un-

der which vehicle operations will occur.

For the recommended viscosity and quality

grades, refer to “Fluids And Lubricants” in

“Technical Specifications”.

CAUTION!

Never use Non-Detergent Oil or Straight

Mineral Oil in the engine or damage may

result.

NOTE:

A new engine may consume some oil during

its first few thousand miles (kilometers) of

operation. This should be considered a nor-

mal part of the break-in and not interpreted

as a problem.

PARKING BRAKE

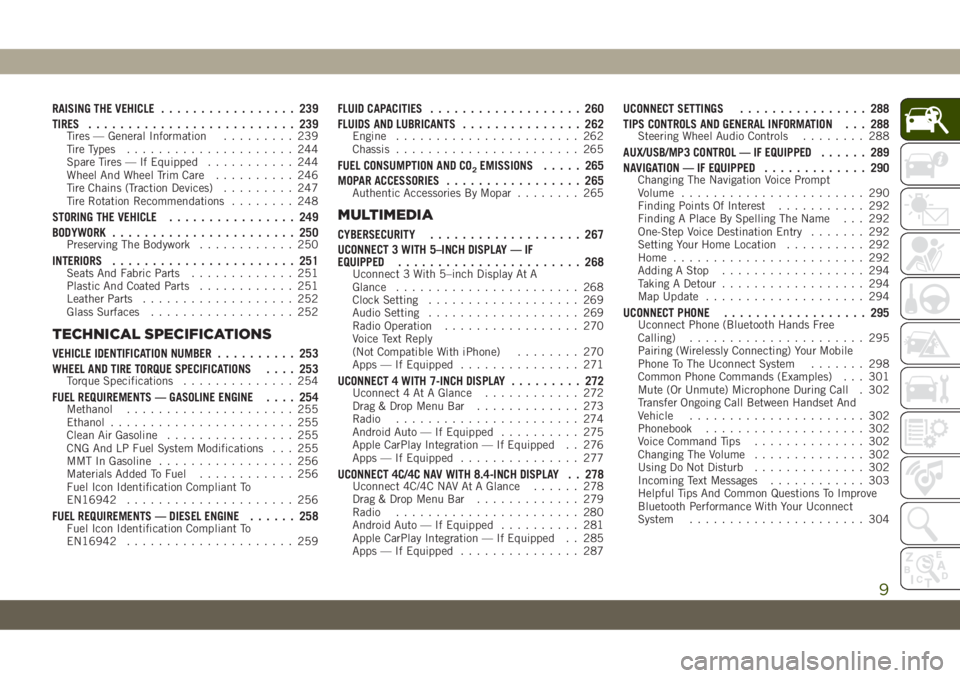

Electric Park Brake (EPB)

Your vehicle is equipped with a new Electric

Park Brake System (EPB) that offers greater

convenience. The park brake switch is lo-

cated in the center console.

To apply the park brake manually, pull up on

the switch momentarily. The BRAKE telltale

light in the instrument cluster and an indica-

tor on the switch will illuminate.To release the park brake manually, the igni-

tion must be in ON/RUN. Then put your foot

on the brake pedal and push the park brake

switch down momentarily. Once the park

brake is fully disengaged, the BRAKE telltale

light and the switch indicator will extinguish.

The park brake can also be automatically

released. With the engine running and the

transmission in gear, release the brake pedal

and depress the throttle pedal. For safety

reasons, your seat belt must also be fastened.

NOTE:

• You may hear a slight whirring sound from

the back of the vehicle while the parking

brake engages or disengages.

• If your foot is on the brake pedal while you

are engaging or disengaging the parking

brake, you may notice a small amount of

brake pedal movement.

• The new Auto Park Brake feature can be

used to apply the park brake automatically

every time you park the vehicle. Auto Park

Brake can be enabled and disabled in the

Settings menu in Uconnect.

Parking Brake Switch

STARTING AND OPERATING

142

Page 180 of 344

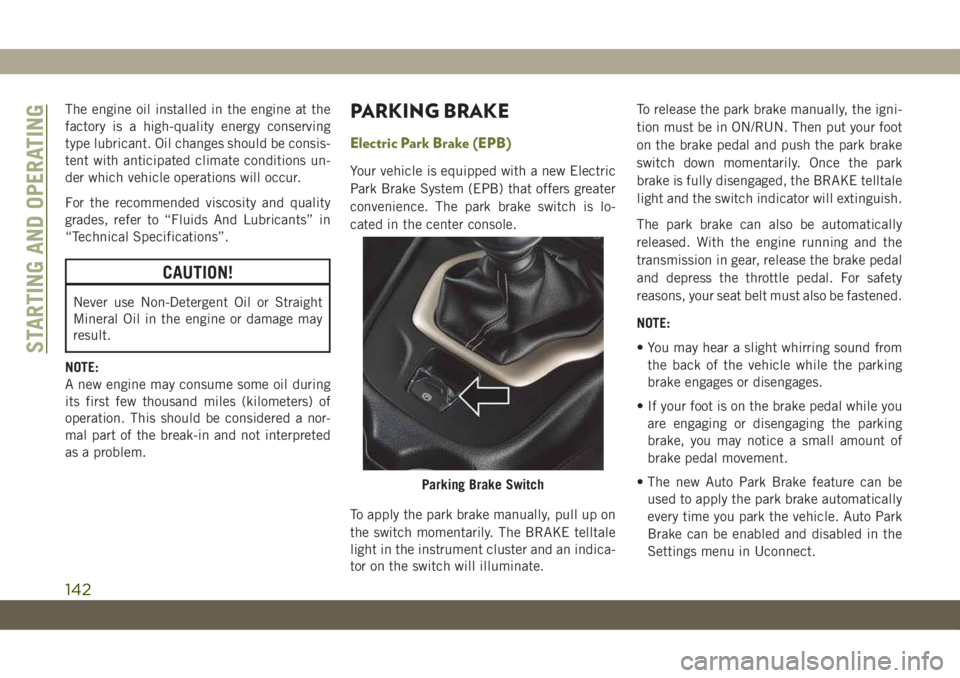

Adding AdBlue (UREA)

NOTE:

Driving conditions (altitude, vehicle speed,

load, etc.) will effect the amount of AdBlue

(UREA) that is used in your vehicle.

AdBlue (UREA) Fill Procedure With Pump

Nozzle

NOTE:

Refer to “Fluids And Lubricants” in the

“Technical Specifications” section for the

correct fluid type.

1. Park the vehicle on level ground. Turn off

the engine by cycling the ignition to the

OFF position. Open the fuel filler and then

unscrew and remove the cap from the

AdBlue (UREA) filler.2. Insert AdBlue (UREA) fill adapter/nozzle

into AdBlue (UREA) fill inlet.

CAUTION!

•To avoid AdBlue (UREA) spillage, and

possible damage to the AdBlue (UREA)

tank from overfilling, do not “top off” the

AdBlue (UREA) tank after filling.

CAUTION!

• DO NOT OVERFILL. AdBlue (UREA) will

freeze below 12ºF (-11ºC). The AdBlue

(UREA) system is designed to work in

temperatures below the AdBlue (UREA)

freezing point, however, if the tank is

overfilled and freezes, the system could

be damaged.

• When AdBlue (UREA) is spilled, clean

the area immediately with water and use

an absorbent material to soak up the

spills on the ground.

• Do not attempt to start your engine if

AdBlue (UREA) is accidentally added to

the diesel fuel tank as it can result in

severe damage to your engine, including

but not limited to failure of the fuel

pump and injectors.

Fuel Filler

1 — AdBlue (UREA) Filler Cap

2 — Fuel Filler

STARTING AND OPERATING

178

Page 201 of 344

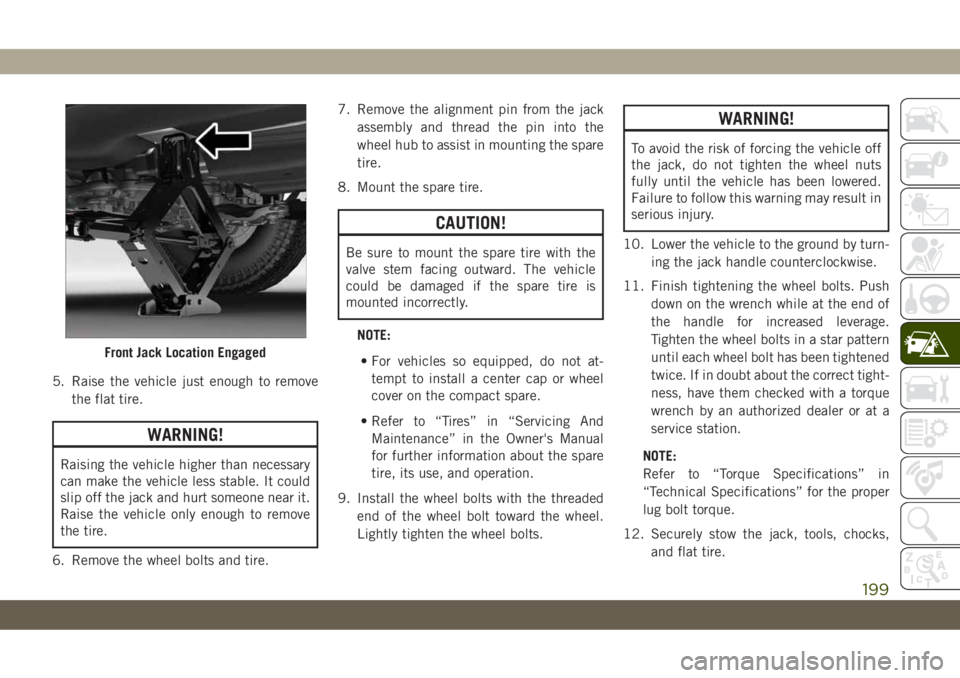

5. Raise the vehicle just enough to remove

the flat tire.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the wheel bolts and tire.7. Remove the alignment pin from the jack

assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

8. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

NOTE:

• For vehicles so equipped, do not at-

tempt to install a center cap or wheel

cover on the compact spare.

• Refer to “Tires” in “Servicing And

Maintenance” in the Owner's Manual

for further information about the spare

tire, its use, and operation.

9. Install the wheel bolts with the threaded

end of the wheel bolt toward the wheel.

Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

10. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. If in doubt about the correct tight-

ness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

NOTE:

Refer to “Torque Specifications” in

“Technical Specifications” for the proper

lug bolt torque.

12. Securely stow the jack, tools, chocks,

and flat tire.

Front Jack Location Engaged

199

Page 202 of 344

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the

threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.4. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage. Tighten

the wheel bolts in a star pattern until each

wheel bolt has been tightened twice. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.

Refer to “Torque Specifications” in

“Technical Specifications” for the proper

lug bolt torque.

5. Lower the jack until it is free. Remove the

wheel chocks. Reassemble the lug wrench

to the jack assembly and stow it in the

spare tire area. Secure the assembly using

the means provided. Release the parking

brake before driving the vehicle.

6. After 25 miles (40 km), check the wheel

bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

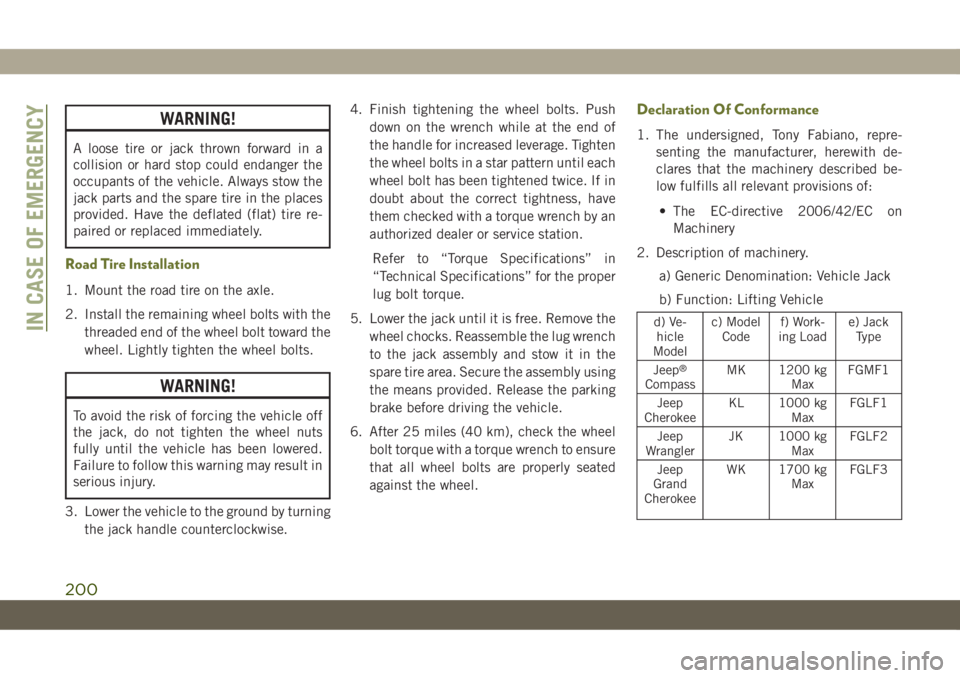

Declaration Of Conformance

1. The undersigned, Tony Fabiano, repre-

senting the manufacturer, herewith de-

clares that the machinery described be-

low fulfills all relevant provisions of:

• The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d) Ve-

hicle

Modelc) Model

Codef) Work-

ing Loade) Jack

Type

Jeep

®

CompassMK 1200 kg

MaxFGMF1

Jeep

CherokeeKL 1000 kg

MaxFGLF1

Jeep

WranglerJK 1000 kg

MaxFGLF2

Jeep

Grand

CherokeeWK 1700 kg

MaxFGLF3

IN CASE OF EMERGENCY

200

Page 235 of 344

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake tem-

peratures, excessive lining wear, and pos-

sible brake damage. You would not have

your full braking capacity in an emergency.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should

be checked whenever the vehicle is serviced,

or immediately if the brake system warning

light is on. If necessary, add fluid to bring

level within the designated marks on the side

of the reservoir of the brake master cylinder.

Be sure to clean the top of the master cylin-

der area before removing cap. With disc

brakes, fluid level can be expected to fall as

the brake pads wear. Brake fluid level should

be checked when pads are replaced. If the

brake fluid is abnormally low, check the sys-

tem for leaks.

Refer to “Fluids And Lubricants” in “Techni-

cal Specifications” for further information.

WARNING!

• Brake fluid is poisonous and highly cor-

rosive. In the event of accidental con-

tact, immediately wash the affected

parts with water and neutral soap. Then

rinse thoroughly. Call a doctor immedi-

ately if swallowed.

• Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri-

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its per-

formance. The proper type of brake fluid

for your vehicle is also identified on the

original factory installed hydraulic mas-

ter cylinder reservoir.

• To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master cylin-

der reservoir cap secured at all times.

Brake fluid in a open container absorbs

moisture from the air resulting in a lower

boiling point. This may cause it to boil

WARNING!

unexpectedly during hard or prolonged

braking, resulting in sudden brake fail-

ure. This could result in a collision.

• Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot en-

gine parts, causing the brake fluid to

catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should

be taken to avoid its contact with these

surfaces.

• Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This

could result in a collision.

Manual Transmission — If Equipped

Fluid Level Check

Check the fluid level by removing the fill

plug. The fluid level should be between the

bottom of the fill hole and a point not more

than 3/16 inch (4.7 mm) below the bottom of

the hole.

233

Page 256 of 344

nuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

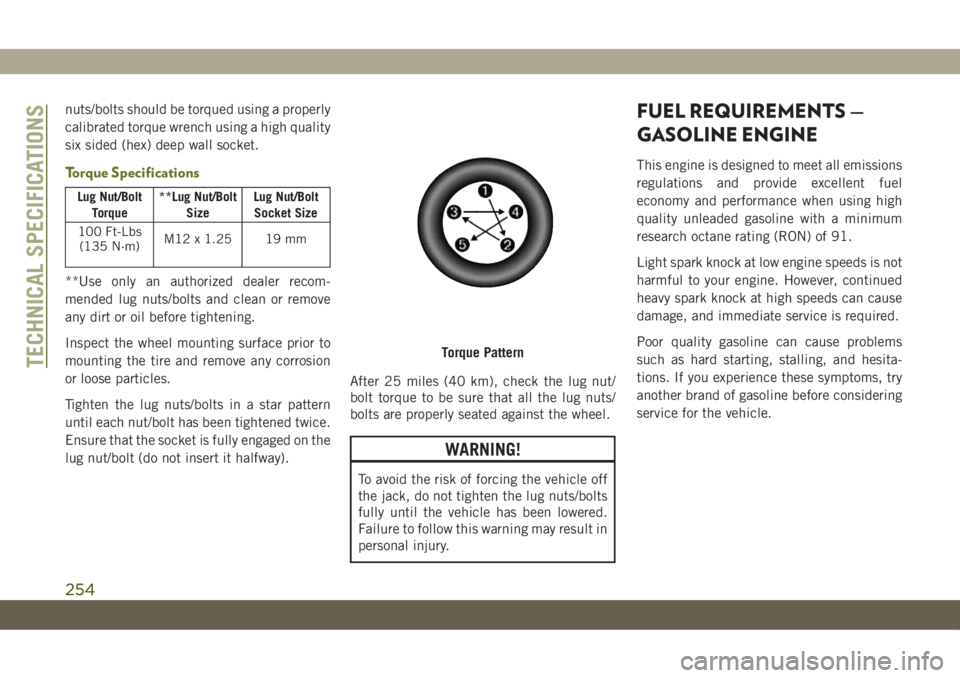

Torque Specifications

Lug Nut/Bolt

Torque**Lug Nut/Bolt

SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs

(135 N·m)M12 x 1.25 19 mm

**Use only an authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it halfway).After 25 miles (40 km), check the lug nut/

bolt torque to be sure that all the lug nuts/

bolts are properly seated against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts/bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

personal injury.

FUEL REQUIREMENTS —

GASOLINE ENGINE

This engine is designed to meet all emissions

regulations and provide excellent fuel

economy and performance when using high

quality unleaded gasoline with a minimum

research octane rating (RON) of 91.

Light spark knock at low engine speeds is not

harmful to your engine. However, continued

heavy spark knock at high speeds can cause

damage, and immediate service is required.

Poor quality gasoline can cause problems

such as hard starting, stalling, and hesita-

tions. If you experience these symptoms, try

another brand of gasoline before considering

service for the vehicle.

Torque PatternTECHNICAL SPECIFICATIONS

254

Page 258 of 344

MMT In Gasoline

Methylcyclopentadienyl Manganese Tricar-

bonyl (MMT) is a manganese containing me-

tallic additive that is blended into some gaso-

line to increase octane. Gasoline blended

with MMT provides no performance advan-

tage beyond gasoline of the same octane

number without MMT. Gasoline blended with

MMT reduces spark plug life and reduces

emission system performance in some ve-

hicles. The manufacturer recommends that

gasoline without MMT be used in your ve-

hicle. The MMT content of gasoline may not

be indicated on the gasoline pump; there-

fore, you should ask your gasoline retailer

whether or not his/her gasoline contains

MMT.

Materials Added To Fuel

Indiscriminate use of fuel system cleaning

agents should be avoided. Many of these

materials intended for gum and varnish re-

moval may contain active solvents or similar

ingredients. These can harm fuel system gas-

ket and diaphragm materials.

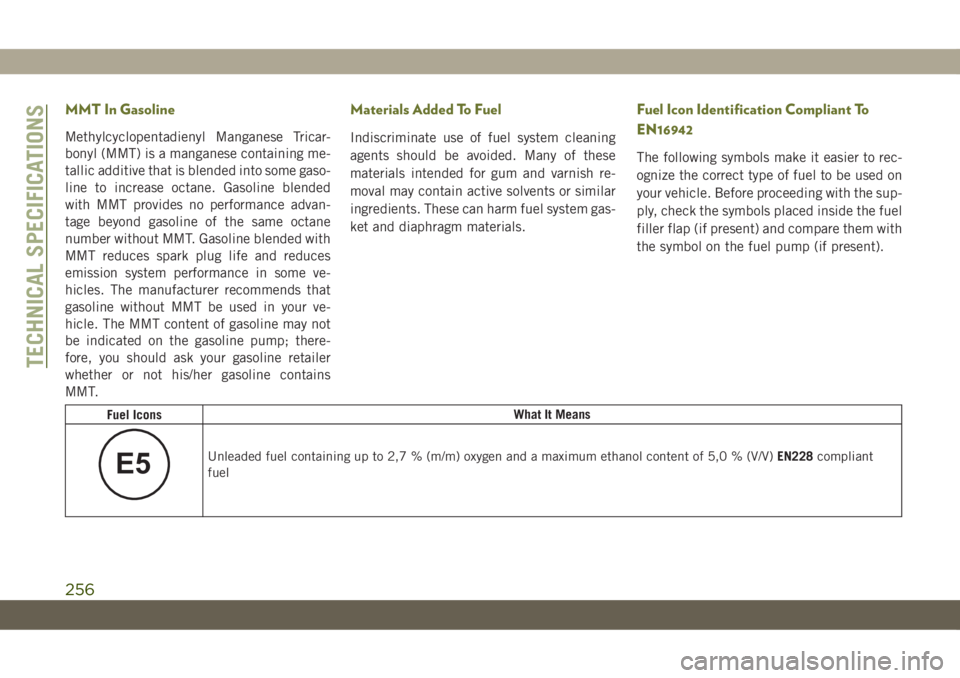

Fuel Icon Identification Compliant To

EN16942

The following symbols make it easier to rec-

ognize the correct type of fuel to be used on

your vehicle. Before proceeding with the sup-

ply, check the symbols placed inside the fuel

filler flap (if present) and compare them with

the symbol on the fuel pump (if present).

Fuel IconsWhat It Means

E5Unleaded fuel containing up to 2,7 % (m/m) oxygen and a maximum ethanol content of 5,0 % (V/V)EN228compliant

fuel

TECHNICAL SPECIFICATIONS

256

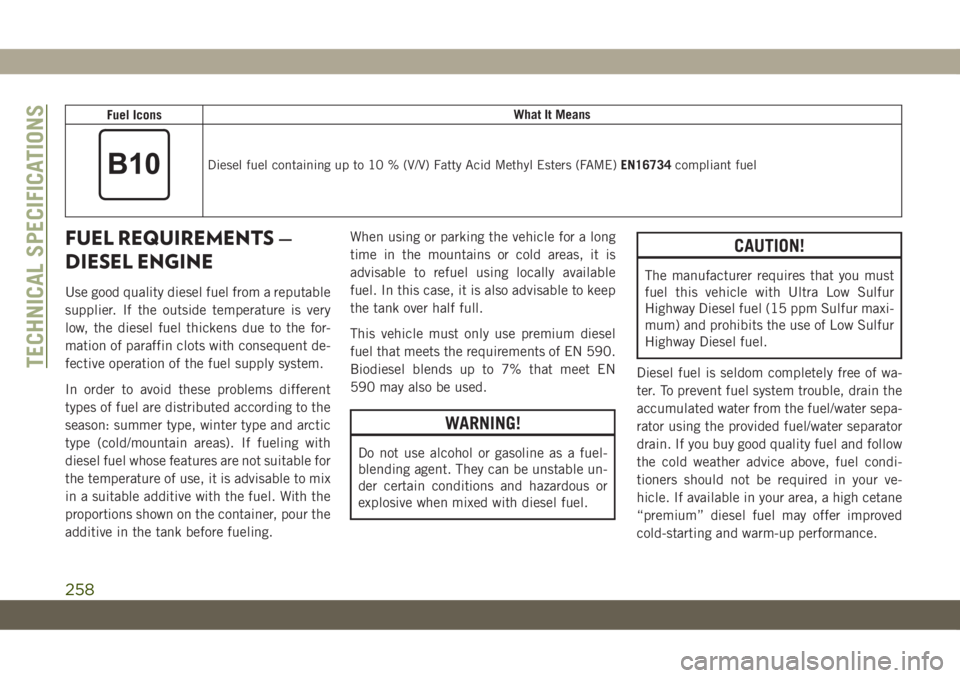

Page 260 of 344

Fuel IconsWhat It Means

Diesel fuel containing up to 10 % (V/V) Fatty Acid Methyl Esters (FAME)EN16734compliant fuel

FUEL REQUIREMENTS —

DIESEL ENGINE

Use good quality diesel fuel from a reputable

supplier. If the outside temperature is very

low, the diesel fuel thickens due to the for-

mation of paraffin clots with consequent de-

fective operation of the fuel supply system.

In order to avoid these problems different

types of fuel are distributed according to the

season: summer type, winter type and arctic

type (cold/mountain areas). If fueling with

diesel fuel whose features are not suitable for

the temperature of use, it is advisable to mix

in a suitable additive with the fuel. With the

proportions shown on the container, pour the

additive in the tank before fueling.When using or parking the vehicle for a long

time in the mountains or cold areas, it is

advisable to refuel using locally available

fuel. In this case, it is also advisable to keep

the tank over half full.

This vehicle must only use premium diesel

fuel that meets the requirements of EN 590.

Biodiesel blends up to 7% that meet EN

590 may also be used.

WARNING!

Do not use alcohol or gasoline as a fuel-

blending agent. They can be unstable un-

der certain conditions and hazardous or

explosive when mixed with diesel fuel.

CAUTION!

The manufacturer requires that you must

fuel this vehicle with Ultra Low Sulfur

Highway Diesel fuel (15 ppm Sulfur maxi-

mum) and prohibits the use of Low Sulfur

Highway Diesel fuel.

Diesel fuel is seldom completely free of wa-

ter. To prevent fuel system trouble, drain the

accumulated water from the fuel/water sepa-

rator using the provided fuel/water separator

drain. If you buy good quality fuel and follow

the cold weather advice above, fuel condi-

tioners should not be required in your ve-

hicle. If available in your area, a high cetane

“premium” diesel fuel may offer improved

cold-starting and warm-up performance.

TECHNICAL SPECIFICATIONS

258