heating JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 290 of 376

N

REAR

AXLE

14153

FIG.

N-8—REMOVING FLANGED

AXLE

SHAFT

1—

Flange

Adapter Tool W-343

2—

Tool

C-637

3—

Axle

Flange nuts attaching backing plate and retainer to axle

tube flange.

e. Attach axle shaft adapter tool W-343 and slide

hammer

handle C-637 to axle shaft flange and re

move

axle shaft, as shown in Fig. N-8.

Caution:

Should a bearing disintegrate on the

axle shaft because of inadequate lubrication, the axle shaft and housing assembly must be carefully inspected for possible damage before new parts are

installed.

If

the bearing

cone

(inner race) is seized (cold

welded)

onto

the axle shaft due to excessive over heating, the axle shaft must be discarded and a new

axle shaft and bearing assembly installed.

Note:

Make certain the bearing cup has been

removed from the axle housing.

f. Remove axle shaft oil seal from axle housing tube using tool C-637.

g. Wipe axle housing tube seal bore clean and in

stall

a new oil seal using driver tool W-186, as shown in Fig. N-l7.

N-4.

UNIT BEARING

Basically,

there are five parts to a Unit Bearing assembly: the cup, or outer race, the cup

ring,

the cone, or inner race, the tapered rollers which

roll

freely

between

the cup and cone, and the

cage

which

serves as a retainer to maintain the proper spacing

between

the tapered rollers grouped around

the cone.

When

the bearing is manufactured, the cup and

rib

ring are bonded

together

with an adhesive to

facilitate bearing handling and installation. Since the cup and rib ring are clamped

together

in the axle housing, there is no need for a permanent

bond. When the bearing is serviced the cup

will

usually

be separated from the rib

ring.

The

bearing is held on the shaft by the press fit of the

cone

plus the press fit of the retainer

ring.

The

cup and rib ring are clamped

together

in the axle housing through the outboard seal by the re

tainer

plate. The outboard seal wipes on the rotat ing axle shaft and at the same time functions as a

static seal to prevent lubricant from escaping be

tween the housing and the seal outside diameter.

It's

important to

note

that the seal serves also as

a

"spacer" or "filler" in the clamp-up of the bearing

in

the axle housing.

Note:

All Unit Bearings are manufactured with

built-in

adjustment for axle shaft end play. No adjustment shims are necessary when installing a

flange type axle shaft.

N-5.

Servicing Unit Bearing

The

Unit

Bearing

assembly should be serviced each

12,000

miles [

19,200

km.] with bearing cleaning,

inspection and relubrication. The Unit Bearing re

quires

little attention while in service if the bear

ings have been properly installed and are ade

quately lubricated.

•

Cleaning and Inspection

a.

The Unit Bearing assembly should not be re moved from the axle shaft unless the outer seal is defective, the retainer plate is distorted or damaged,

or

the Unit Bearing is defective.

Should

it be necessary to remove the Unit Bearing

from

the axle shaft for any of

these

reasons, refer

to Par. N-7 for proper Unit Bearing removal.

b.

Clean

bearing cup with solvent and inspect cup

for any possible wear, nicks or damage.

c.

The bearing assembly can be cleaned in place

on the axle shaft. Use cleaning solvent and a stiff

bristle

brush to

loosen

the old grease. To assure

removal

of old grease and any contamination that

might be present, use compressed air. Air should be directed at the bearing assembly so that it

goes

through the bearing from one end of the rollers to the other. It is important not to "spin dry" the

bearing

with compressed

air.

Spinning the dry bearing may score the raceways and rollers due to

lack

of lubricant.

d.

Use cleaning solvent to clean out the bearing

and

oil seal bore in the housing. Wipe the area

clean

making sure it is free from old grease or other

contamination that might be present.

FIG.

N-9—LUBRICATING BEARING

290

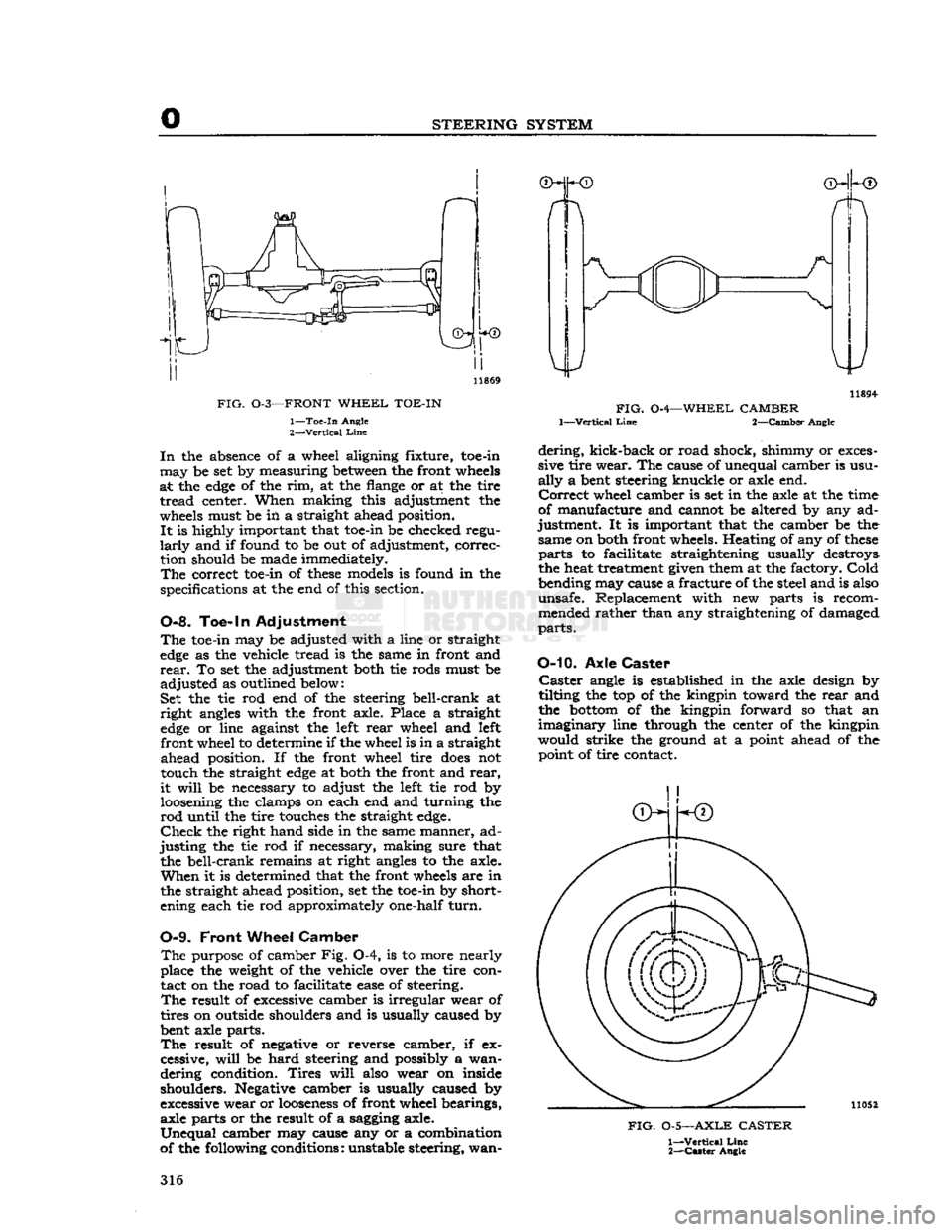

Page 316 of 376

o

STEERING SYSTEM

FIG.

0-3—FRONT

WHEEL

TOE-IN

1—

Toe-in

Angle

2—

Vertical

Line

In

the absence of a wheel aligning fixture, toe-in

may

be set by measuring

between

the front wheels

at the

edge

of the rim, at the flange or at the tire

tread

center. When making this adjustment the

wheels must be in a straight ahead position.

It

is highly important that toe-in be checked regu

larly

and if found to be out of adjustment, correc tion should be made immediately.

The

correct toe-in of

these

models is found in the

specifications at the end of this section.

0-8. Toe-in Adjustment

The

toe-in may be adjusted with a line or straight

edge

as the vehicle tread is the same in front and

rear.

To set the adjustment both tie rods must be

adjusted

as outlined below:

Set the tie rod end of the steering bell-crank at

right

angles with the front axle. Place a straight

edge

or line against the left

rear

wheel and left front wheel to determine if the wheel is in a straight

ahead

position. If the front wheel tire

does

not touch the straight

edge

at both the front and

rear,

it

will

be necessary to adjust the left tie rod by loosening the clamps on each end and turning the

rod

until the tire touches the straight

edge.

Check

the right hand side in the same manner, ad

justing

the tie rod if necessary, making sure that the bell-crank remains at right angles to the axle.

When

it is determined that the front wheels are in the straight ahead position, set the toe-in by short

ening each tie rod approximately one-half

turn.

0-9.

Front

Wheel

Camber

The

purpose of camber Fig. 0-4, is to more nearly

place the weight of the vehicle over the tire con tact on the road to facilitate

ease

of steering.

The

result of excessive camber is irregular wear of

tires on outside shoulders and is usually caused by

bent axle parts.

The

result of negative or reverse camber, if ex

cessive,

will

be

hard

steering and possibly a wan

dering

condition.

Tires

will

also wear on inside shoulders. Negative camber is usually caused by

excessive wear or

looseness

of front wheel bearings, axle parts or the result of a sagging axle.

Unequal

camber may cause any or a combination

of the following conditions: unstable steering, wan- 11894-

FIG.

0-4—WHEEL CAMBER

1—Vertical

Line

2—Camber Angle

dering,

kick-back or road shock, shimmy or exces

sive tire wear. The cause of unequal camber is usu

ally

a bent steering knuckle or axle end.

Correct

wheel camber is set in the axle at the time

of manufacture and cannot be altered by any ad

justment. It is important that the camber be the same on both front wheels. Heating of any of

these

parts

to facilitate straightening usually destroys

the heat treatment given them at the factory.

Cold

bending may cause a fracture of the steel and is also

unsafe. Replacement with new parts is recom mended rather than any straightening of damaged

parts.

O-10.

Axle

Caster Caster

angle is established in the axle design by

tilting the top of the kingpin toward the

rear

and

the

bottom

of the kingpin forward so that an

imaginary

line through the center of the kingpin

would strike the ground at a point ahead of the point of tire contact.

FIG.

0-5—AXLE

CASTER

1—

Vertical

Line

2—

Caster

Angle

316

Page 371 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

ALPHABETICAL INDEX

SUBJECT PAR.

SUBJECT

PAR.

Abbreviations,

List

U-17 Accelerator Linkage E-70

Air

Cleaner B-25, B-26, B-82, C-21, E-69

Air

Delivery Manifold Fl-4, F2-12

Air

Filter, Pump • F2-3, F2-11

Air

Injection Tubes Fl-5, F2-13

Air

Pump Fl-2, F2-10

Alternator Bearings B-76, H-80

Alternator Brushes H-74, H-75

Alternator Charging System •

•

H-63

Alternator

Diodes

H-69, H-85

Alternator Precautions H-64 Alternator Rotor H-76, H-79

Alternator Tests H-67, H-77 Alternator Specifications H-l 52

Alternator Stator H-84

Anti-Backfire

Valve Fl-6, F2-14

Antifreeze

Chart

• G-22 Antifreeze

Solutions

- G-16

Axle Camber O-l

Axle Caster 0-8

Back-Up

Lights H-135

Ballast

Resistor. H-32 Battery C-3, H-2 Bendix Folo-Thru Drive H-105, H-106

Bleeding Brakes P-7

Body T-l Body Lubrication. B-65 Body Name Plates ' A-7

Brake

Adjustment P-14

Brake

Drums. • .P-17

Brake

Hoses

P-8

Brake

Maintenance . P-5

Brake

Master Cylinder B-40, P-2, P-20

Brake

Service P-6

Brake

Wheel Cylinder • P-21

Camber

Adjustment 0-7

Camshaft D-6, D-51, D-52, D-53, D-81, Dl-26, Dl-33, Dl-55, Dl-80

Carburetor

E-10, E-25

Carburetor

Adjustment C-25, E-14, E-40,

Fl-13,

F2-16

Carburetor

Specifications .Fl-38, F2-34, E-79

Caster

Adjustment 0-8

Charging

System Service. .H-34, H-63

Chassis

Lubrication B-7, B-83

Chassis

Torque Specifications U-14

Clutch

1-4, MO

Clutch

Adjustment 1-3

Clutch

Linkage B-44, 1-3

Clutch

Maintenance .. 1-2

Clutch

Release Bearing B-74, 1-25

Coil

C-20, H-19, H-31 Connecting Rod Bearings D-47, D-48, D-49, Dl-49 Connecting Rod

Crank

Pins D-42

Connecting Rods... .D-20, D-50, D-95, Dl-31, Dl-45, Dl-75

Controls B-59, B-62

Cooling System B-28, G-l Cooling System Filling G-2

Core

Hole Expansion Plugs D-72

Crankcase

Ventilating System B-13, C-6, D-110

Crankshaft

D-26, D-38, D-39, Dl-38, Dl-73

Crankshaft

End Play. D-83, Dl-74

Crankshaft

Main Bearing D-43, D-44, Dl-32, Dl-40, Dl-73

Crankshaft

Oil Seal, Front Dl-21, Dl-85

Crankshaft

Oil Seal, Rear D-63, D-85, Dl-72

Cylinder

Block D-32, Dl-34

Cylinder

Bores D-35, Dl-36

Cylinder

Head D-17, D-73, D-98, Dl-24, Dl-63, Dl-82

Cylinder

Head Torque. C-5

Dash Pot Adjustment C-26, E-44

Differential B-51 thru B-53, N-9 Differential Adjustments N-16, N-18

Differential, Powr-Lok N-20

Differential,

Trac-Lok

N-24

Directional Signal Lights. . H-138

Distributor B-14, B-15, C-10, D-13, Dl-9, H-9, H-20 Distributor Check H-l7, H-28

Distributor Point Dwell C-17 Distributor Resistance Test C-16

Drawbar

.R-6, U-16

Dual

Brake System P-l thru P-26

Electrical

Instruments H-l22

Electrical

Specifications .H-l52

Electrical

System H-l Engine .

..D-l,

Dl-1

Engine Code Number A-6

Engine Compression .

.

C-9 Engine Disassembly . • .D-6, Dl-5 Engine Installation D-105, Dl-102

Engine Lubrication System B-4, B-6 Engine Mountings D-3, Dl-3

Engine Oil B-9

Engine Oil Filter B-10, B-ll,

D-lll,

Dl-13, Dl-93

Engine Oil Pan D-l9, D-66, D-97, Dl-29, Dl-51, Dl-77 Engine Oil Pump. . .D-14, D-65, D-93, Dl-19, Dl-50, Dl-87

Engine Overheating. G-l9 Engine Removal D-5, Dl-4.

Exhaust

Emission Control — F4 Fl-1 thru Fl-30

Exhaust

Emission Control — V6 F2-1 thru F2-36

Exhaust

Manifold, Install F-6

Exhaust

Pipe -

•

F-8

Exhaust

System F-2, F-3

Exhaust

System Maintenance F-4

Fan

Belt C-27, Dl-11, Dl-96, G-18

Floating Oil Intake. D-64, Dl-30, Dl-50, Dl-76 Flywheel D-25, D-67, D-87, Dl-28, Dl-52, Dl-78

Flywheel Housing. D-71, D-88, Dl-27, Dl-54, Dl-79

Flywheel Pilot Bushing D-70, 1-8

Frame

R-l

Frame

Alignment. R-2

Frame

Dimensions R-3

Frame

Straightening R-4

Front

Bumper Weight. • U-9

Front

Axle B-50, M-2

Front

Axle Alignment R-5

Front

Axle Installation • M-12

Front

Axle Maintenance M-3

Front

Axle Shaft Removal M-5

Front

Axle U-Joint B-54, B-55, M-7

Front

Axle Steering Knuckle M-&

Front

Wheel Alignment 0-4

Front

Wheel Bearings B-56, B-57, Q-4

Front

Wheel Toe-in 0-5, 0-6

Front

Wheel Turning Angle 0-9

Fuel

Gauge Float Unit F-76

Fuel

Lines - E-77

Fuel

Pump E-45, E-54, E-60, E-67

Fuel

Pump Check C-23

Fuel

Tank

E-72

G

Gauges, Testing H-l24

General

Specifications A-8

Generator B-16, H-34 thru H-40

Glass

Replacement • T-4

Governor. . .

•.

• U-3

Guides, Valve D"61

H

Hazard

Warning Lights H-139

Head Lamp Aiming H-131, H-132 Head Lamp Replacement H-130

Headlight Dimmer Switch H-l

2

7

Heat Control Valve C-7, F-7 Heated Air System • •

•

F2-2

Heater U-10

Horns.....

....H-137 371