engine JEEP CJ 1953 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 1 of 376

1953-71

SERVICE MANUAL

JeeP

UNIVERSAL

4-WHEEL DRIVE

CJ-3B CJ-5A

CJ-5

CJ-6

CJ-6A

2-WHEEL DRIVE DJ-5

DJ-6

Copyright®

1977

FI Jeep Corporation Corporate Publications

Printed

in USA

Reprinted

6-77

SM-1046

SECTION

INDEX

NAME

Section

General

Data

A

Lubrication

B

Tune-Up

C

Hurricane

F4 Engine

D

Dauntless V-6 Engine

Dl

Fuel

System

E

Exhaust

System

F

Exhaust

Emission Control System F4 Engine

Fl

Exhaust

Emission Control System V6-225 Engine

F2

Cooling System

G

Electrical

H

Clutch

I

3-Speed

Transmission

J

4-Speed

Transmission

Jl

Transfer

Case

K

Propeller Shafts

L

Front

Axle

M

Rear

Axle

N

Steering 0

Brakes

P

Wheels 0

Frame

R

Springs

Shock Absorbers

S

Body

T

Miscellaneous

U

Page 2 of 376

IMPORTANT

DEALER

INFORMATION

This

manual, SM-1046, covers current 'Jeep' Universal Series vehicles, and

past models,

except

as

noted

hereinafter:

SM-1037 should be retained in your service

library

for

information related to the

6-volt

electrical system, or the

single brake system.

SM-1002-R5

(no longer available) should be retained

for information related to the

CJ-2A, CJ-3A

or

DJ-3A

models

equipped with the L4-134

engine.

The

above

three manuals provide

full

service coverage since inception of the

'Jeep' Universal and

1

Jeep' Dispatcher model vehicles.

Page 3 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

A

GENERAL

DHTfl

Contents

SUBJECT

PAR.

General

A-l

Vehicle

Description .A-2

Vehicle

Identification A-3

Identification

Number Location A-4

Serial

Number Location A-5

Engine

Code Number A-6

Plate-And-Trim

Option Plate A-7

General

Specifications A-8

A-1.

GENERAL

This

manual is provided for the guidance of all

automotive service men, vehicle owners, and service salesmen who

repair,

maintain, or adjust

the 'Jeep' Universal Series vehicles. The information herein was prepared from the service man's

viewpoint to

give

him the accurate and concise

data

he may need to service the entire vehicle.

The

information is not elementary as it is intended

for automotive service men who are familiar with

automotive construction and repair in general. It is not intended, nor would it be possible in such

limited

space, to cover every possible repair that he may encounter. All specifications are in accord

with

Engineering Specifications and should be

adhered

to in all work on the vehicle.

The

manual sections follow logical division into

major

components of the vehicles. The first

page

of each section has a detailed index of the

contents

of that section. Subject matter covers all models

included

in this manual unless an exception for a

particular

model is specifically mentioned.

Specifications and components covered were for

standard

production models of 'Jeep' vehicles

current

at the time the manual was approved for

printing.

'Jeep' Corporation reserves the right to

discontinue models at any time or change specifi

cations or design of any of its models without

notice and without

incurring

any obligation.

A-2.

Vehicle Description

This

manual covers all standard production 'Jeep'

Universal

models currently being produced at the time this manual was approved for publication.

Significant

changes made in each model since it

was first produced are included in the manual.

A

description of each model follows.

General

specifications for each model are listed in Par. A-8. Detailed specifications covering major vehicle units

are

listed at the end of each section of the manual.

CJ-3B

—

This

is a 4-wheel-drive 'Jeep' Universal

model, equipped with the four-cylinder

Hurricane

F4-134 engine. Wheelbase is 80".

CJ-5

CJ-5A

— These are 4-wheel-drive 'Jeep' Universal models, equipped with either the Daunt

less

V-6 engine, or the four-cylinder

Hurricane

F4-134 engine. Wheelbase is 81".

CJ-6

CJ-6A

— These are 4-wheel-drive 'Jeep' Universal models, equipped with either the Daunt

less

V-6 engine, or the four-cylinder

Hurricane

F4-134 engine. Wheelbase is 101".

DJ-5

DJ-6

— These are 2-wheel-drive 'Jeep' Universal models, equipped with the four-cylinder

Hurricane

F4-134 engine. DJ-5 wheel- base is 81". DJ-6 wheelbase is 101".

A-3.

Vehicle Identification

Each

'Jeep' vehicle model series has one or more

serial

number prefixes to identify it. Complete

identification of a specific vehicle requires the

prefix

plus the

serial

number.

Serial

numbers are

consecutive for each prefix grouping. Prefix infor

mation following

will

identify the 'Jeep' models

shown by

serial

number prefix from model inception to date.-.

••

' . -

Note:

Vehicles with a

serial

number prefix of five

(5) or more digits that have an S, 5, or 7 as the last

digit are equipped with

Exhaust

Emission

Control.

A

number 1 in the sixth (6th) digit within a seven (7) digit vehicle

serial

number prefix indicates

Left

Hand

Drive;

a 2 indicates Right

Hand

Drive;

a

3 indicates

Left

Hand

Drive

California

Exhaust

Emission

Control

Engine;

a 4 indicates Right

Hand

Drive

California

Exhaust

Emission

Control

Engine.

3

Page 4 of 376

A

GENERAL

DATA

'Jeep'

Serial

No.

'Jeep'

Serial

No.

Model

Prefix

Model

Prefix

CJ-3B

453-GB2

CJ-3B

454-GB2

57348

8105

8105014

CJ-5

57548

CJ-6

57648

8305 8405

8305A 8405A

8305S 8405S

8305AS 8405AS

8305014 8405014

8305015 8405015

8305016 8405016

8305017 8405017

CJ-5A

8322

CJ-6A

8422

8322A 8422A

8322S 8422S

83

2 2AS

8422AS

.

DJ-5

8505

DJ-6

8605

8505A 8605A

8505S 8605S

8505AS 8605AS

8505014

8505015

8505016

8505017

Any

prefix not given here for one of the listed models indicates a special vehicle whose differences

from

standard are not covered in this manual.

A-4. IDENTIFICATION

NUMBER

LOCATION

All

'Jeep* vehicles and

some

of their major com

ponents have identifying numbers.

Paragraphs

fol lowing

will

describe the location of identifying

numbers.

A-5.

Vehicle

Serial

Number

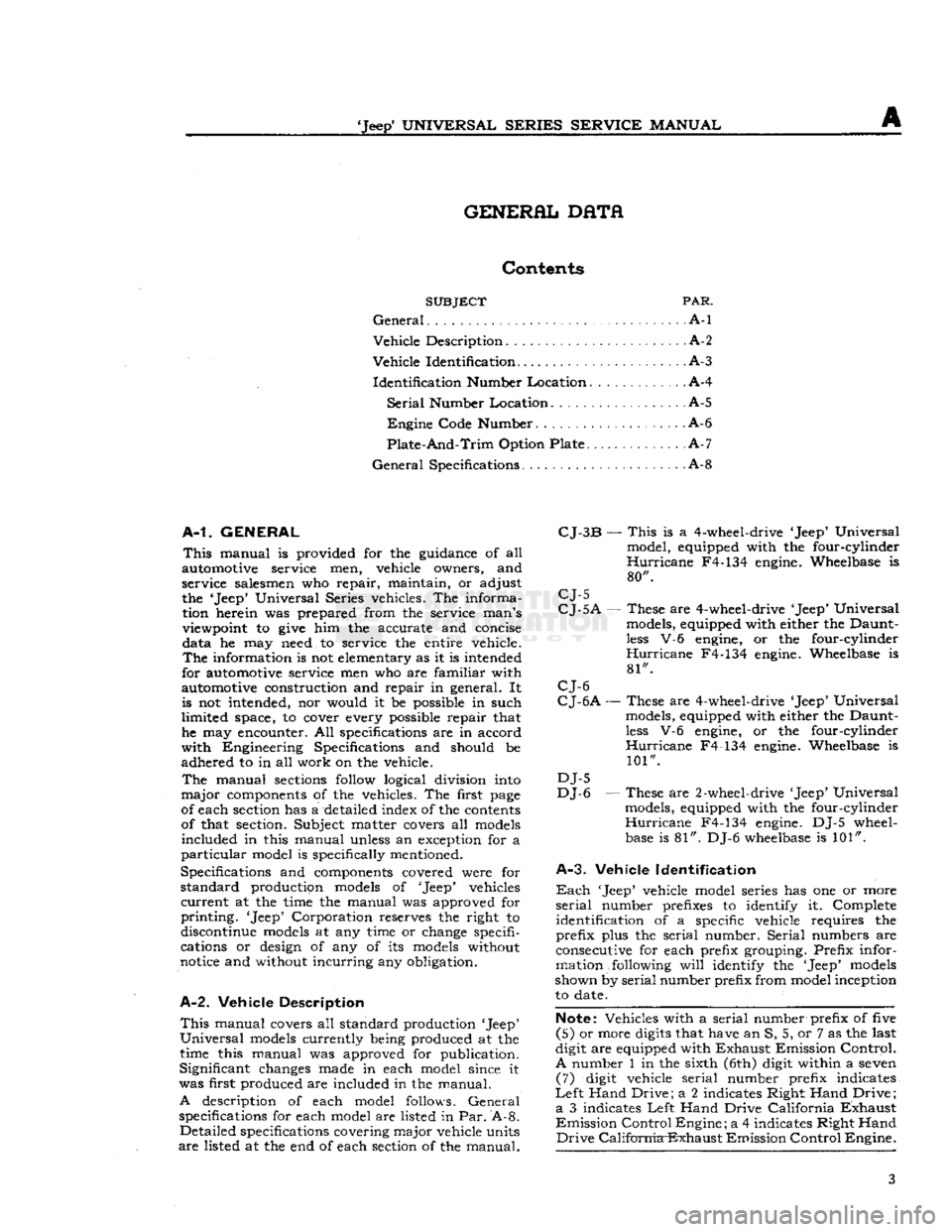

The

vehicle

serial

number is stamped on a metal

plate located on the dash under the hood. It is on

the left side of the vehicle for models

CJ-5, CJ-5A,

CJ-6,

CJ-6A,

DJ-5 and DJ-6 as shown in Fig.

A-l.

It

is on the right side of the vehicle for model

CJ-3B,

as shown in

Fig.

A-2. Refer to Par. A-3 for

specific information on codes.

FIG.

A-l—CJ-5, CJ-5A, CJ-6, CJ-6A,

DJ-5, DJ-6

VEHICLE

SERIAL

NUMBER LOCATION

FIG.

A-2

CJ-3B

VEHICLE

SERIAL

NUMBER LOCATION A-6.

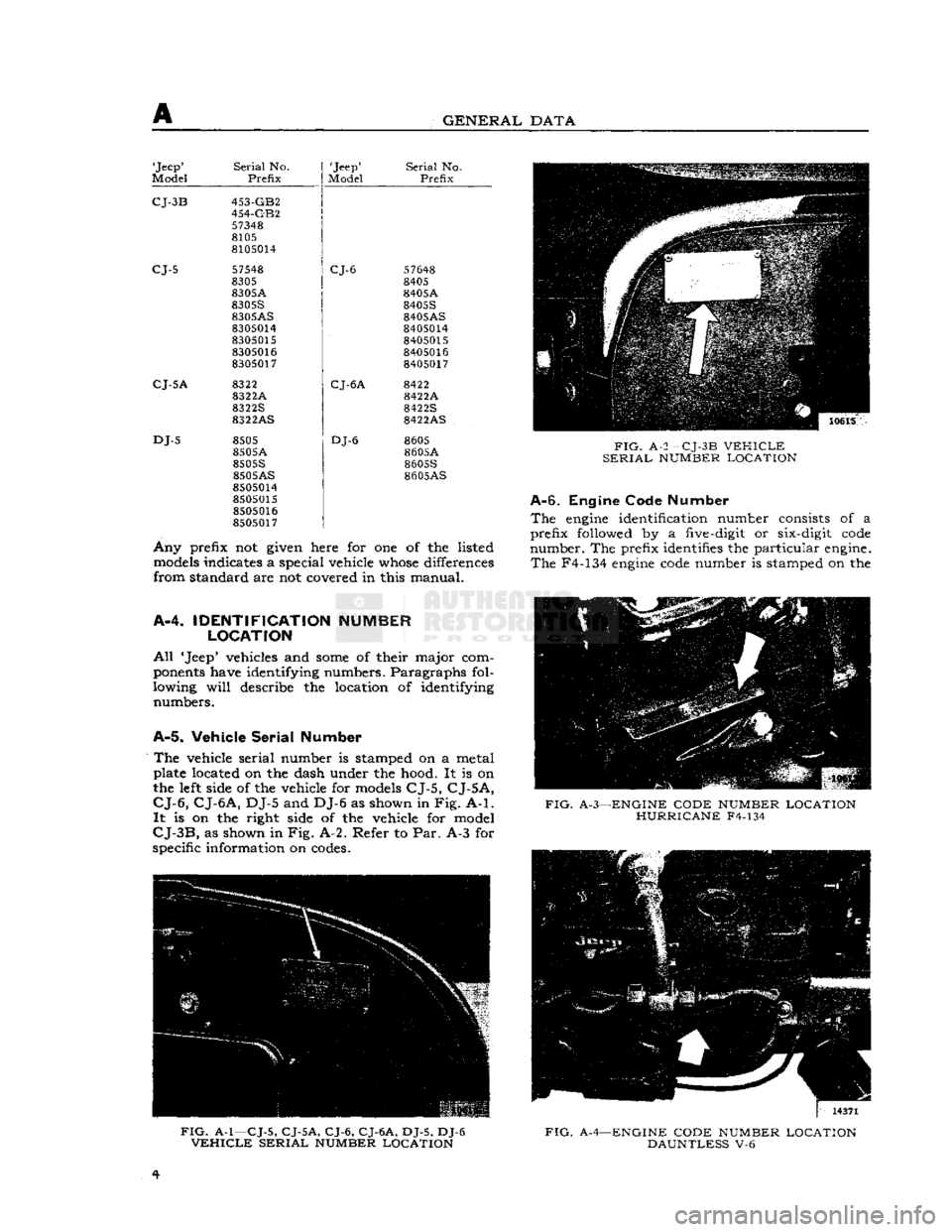

Engine Code Number

The

engine identification number consists of a

prefix

followed by a five-digit or six-digit

code

number.

The prefix identifies the

particular

engine.

The

F4-134 engine

code

number is stamped on the

FIG.

A-3—ENGINE CODE NUMBER LOCATION

HURRICANE

F4-134

FIG.

A-4—ENGINE CODE NUMBER LOCATION DAUNTLESS

V-6

4

Page 5 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

A

water pump

boss

at the front of the

engine,

as

shown in Fig. A-3. The Dauntless V-6

code

number is stamped on the right front face of the cylinder

block, just

below

the rocker arm cover as shown in

Fig.

A-4.

A-7.

Paint-and-Trim Option Plate

A

Paint-and-Trim

Option Plate is installed on late

production 'Jeep' vehicles. The paint

code

on the plate identifies the paint colors. The trim

code

on

the plate identifies the color of all trim parts in the

interior

of the vehicle.

To

identify paint or trim on vehicles manufactured

before

the Paint-and-Trim Option Plate was in

stalled, see your 'Jeep' dealer.

'Jeep' Universals have the plate located on the

right hand side of the dash under the hood, as shown in Fig. A-5.

FIG.

A-5—PAINT

AND

TRIM

OPTION

PLATE LOCATION

5

Page 6 of 376

GENERAL

DATA

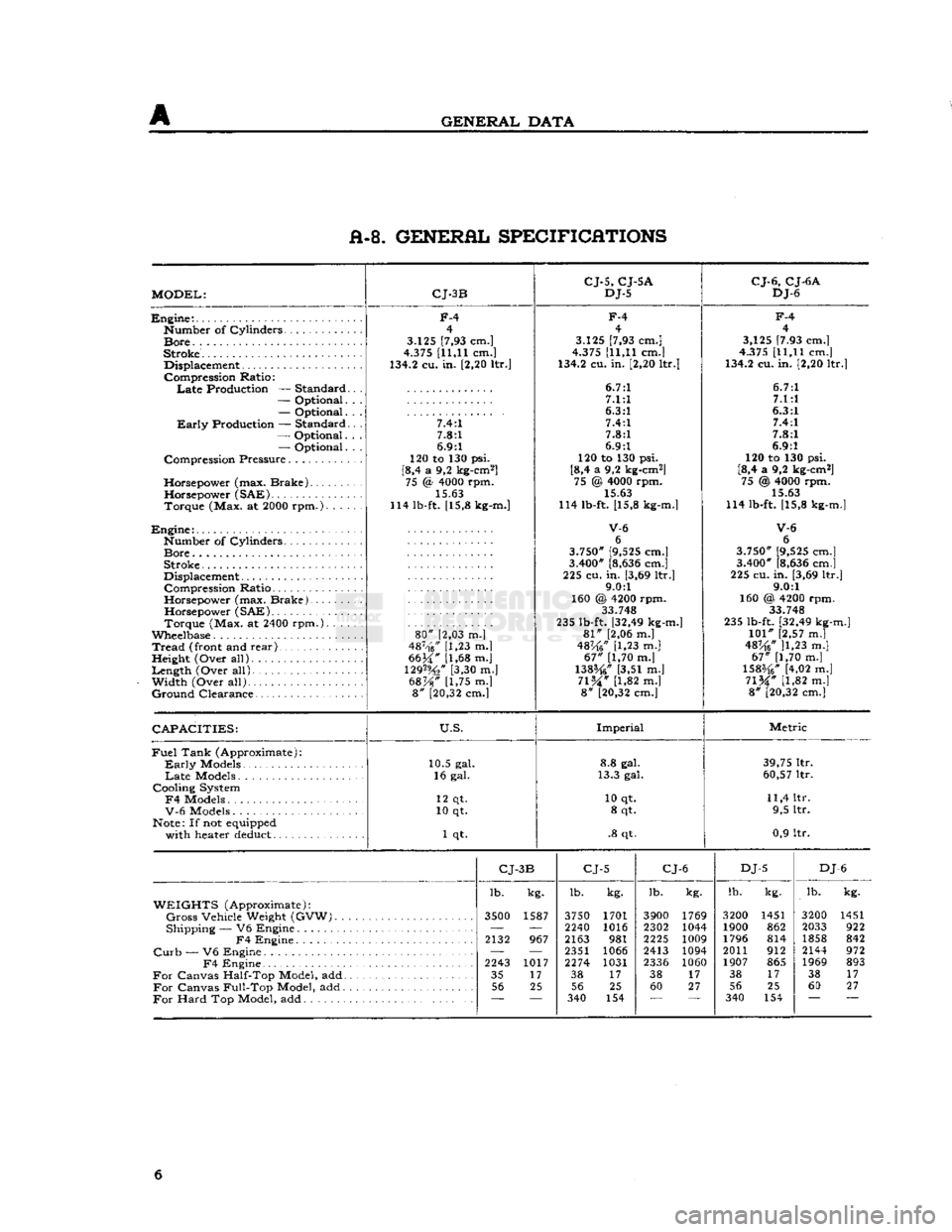

A-8. GENERAL SPECIFICATIONS

MODEL:

CJ-3B

CJ-5,

CJ-5A

DJ-5

CJ-6,

CJ-6A

DJ-6

Engine:.

Number

of

Cylinders

Bore.

.

Stroke.

Displacement

Compression

Ratio:

Late

Production —

Standard

—

Optional.

—

Optional.

Early

Production —

Standard

—

Optional.

—

Optional.

Compression

Pressure

Horsepower

(max.

Brake)

Horsepower

(SAE)

Torque

(Max. at 2000

rpm.).

. . .

Engine:

Number

of

Cylinders

Bore

Stroke

Displacement

Compression

Ratio

Horsepower

(max.

Brake).

Horsepower

(SAE)

Torque

(Max. at 2400

rpm.).

. . .

Wheelbase

Tread

(front and

rear)

,

Height

(Over

all)

Length

(Over

all).

Width

(Over

all)

Ground

Clearance

F-4

4

3.125 [7,93 cm.]

4.375 [11,11 cm.]

134.2 cu. in. [2,20 ltr.]

7.4:1 7.8:1

6.9:1

120 to 130 psi.

[8,4 a 9,2 kg-cm2] 75 <§ 4000 rpm.

15.63

114 lb-ft. [15,8 kg-m.]

80"

[2,03 m.]

487-'f6/' [1,23 m.|

6634" [1,68 m.j

129%"

[3,30 m.]

68%"

[1,75 m.] 8" [20,32 cm.]

F-4

4

3.125 [7,93 cm.]

4.375 [11,11 cm.]

134.2 cu. in. [2,20 ltr.]

6.7:1 7.1:1

6.3:1 7.4:1

7.8:1

6.9:1

120 to 130 psi.

[8,4 a 9,2 kg-cm2] 75 @ 4000 rpm. 15.63

114 lb-ft. [15,8 kg-m.]

V-6

6

3.750" [9,525 cm.]

3.400" [8,636 cm.]

225 cu.

in.

[3,69 ltr.] 9.0:1

160 @ 4200 rpm. 33.748

235 lb-ft. [32,49 kg-m.]

81"

[2,06 m.]

48K6"

[1,23 m.]

67"

[1,70 m.]

138%"

[3,51 m.]

71%"

[1,82 m.] 8" [20,32 cm.]

F-4

4

3,125 [7.93 cm.]

4.375 [11,11 cm.]

134.2 cu. in. [2,20 ltr.]

6.7:1 7.1:1

6.3:1 7.4:1

7.8:1

6.9:1

120 to 130 psi.

[8,4 a 9,2 kg-cm2] 75 @ 4000 rpm.

15.63

114 lb-ft. [15,8 kg-m.]

V-6

6

3.750" [9,525 cm.]

3.400" [8,636 cm.]

225 cu. in. [3,69 ltr.] 9.0:1

160 @, 4200 rpm. 33 748

235 lb-ft. [32,49 kg-m.]

101"

[2,57 m.]

48^6* ]1,23 m.]

67"

[1,70 m.]

1583/4" [4,02 m.]

71%"

[1,82 m.] 8" [20,32 cm.]

CAPACITIES:

U.S.

Imperial

Metric

Fuel

Tank

(Approximate):

Early

Models

Late

Models

Cooling

System

F4

Models

V-6

Models

Note: If not equipped

with

heater deduct 10.5 gal.

16 gal.

12 qt.

10 qt.

1 qt. 8.8 gal.

13.3 gal.

10 qt. 8 qt.

.8 qt. 39,75 ltr.

60,57 ltr.

11,4 ltr. 9,5 ltr.

0,9 ltr.

CJ-

3B

CJ-5

CJ-6

DJ-5

DJ

-6

lb. kg. lb.

kg. lb.

kg. lb.

kg. lb.

kg.

WEIGHTS

(Approximate):

Gross

Vehicle

Weight

(GVW).

3500

1587 3750 1701 3900 1769 3200 1451 3200 1451

Shipping

— V6

Engine

—

'—

2240 1016 2302 1044 1900 862 2033 922

F4

Engine

2132

967 2163

981 2225

1009 1796 814 1858 842

Curb

— V6

Engine

— —

2351 1066 2413 1094 2011 912 2144 972

F4

Engine

2243

1017 2274 1031

2336 1060 1907 865 1969 893

For

Canvas

Half-Top

Model, add 35

17 38

17 38

17 38

17 38 17

For

Canvas

Full-Top

Model, add 56

25 56 25 60 27 56 25 60 27

For

Hard

Top Model, add

~~

340

154 340 154 6

Page 7 of 376

'Jeep*

UNIVERSAL SERIES

SERVICE

MANUAL

B

LUBRICATION

AND

PERIODIC SERVICES

Contents

PAR. SUBJECT

PAR.

SUBJECT

GENERAL

.B-l

Chassis

Lubrication

B-7

Engine

Lubrication System B-4, B-6

Special

Lubricants B-2

Fresh

Lubricant.

.B-3

LUBRICATION CHARTS

. Pages 8, 9

SERVICE

MAINTENANCE SCHEDULE.

.B-8

Air

Cleaner

B-2

5,

B-2

6

Air

Filter

—

F.E.E.C.

System Canister

B-2

4

Axle

U-Bolts B-49 Body

Lube

Points: B-65 Hood Hinge Pivot Points B-66

Glove

Compartment Door

Latch

B-6

7

Tailgate Hinges .B-68

Brakes,

Adjust .B-41

Brake

Linings .B-42

Brake

Master Cylinder B-40

Charging

Circuit

B-l9

Clutch

. B-43, B-44

Cooling System—Radiator. B-28, B-29 Differentials

........

.B-50, B-51, B-52, B-53

Distributor

B-14, B-l5

Engine

Oil B-9

Engine

Oil

Filter

B-10, B-ll

Engine

Tune-Up B-20

Exhaust

Emission Control System

B-2

2

Exhaust

Manifold Heat Control Valve. . . .B-l2

Exhaust

System

B-2 3

Fan

Belt . .B-21

Front

Axle U-Joint B-54, B-55

Generator

.B-16

Headlights B-61

Heater Controls B-62

Lights

and Controls B-59 Positive Crankcase Ventilation Valve. . . .B-l3

Shock Absorbers B-48

Spark

Plugs. B-17

Speedometer Cable. .B-60

Spring

Bushings.. . .B-46

Spring

Shackles .B-47

Steering

Gear

B-2 7

B-l. GENERAL

All

'Jeep' Universal vehicles require periodic

lubri

cation and other maintenance services for normal

vehicle

usage

and application to promote satis factory operation and prevent

excessive

wear. Un

der severe operating or atmospheric conditions

these

services should be performed more

often

than

under normal conditions. It should also be remem

bered that common short trips and

stop-and-go

driving

are more severe on lubrication

points

than

Starting

Circuit

B-l8

Tie

Rod and Drag

Link

Sockets

.

B-45

Tires

B-64

Transmission

and Transfer Case—

Lubricant

Level

Check B-30

General

B-31

Transfer

Case B-32

Transmission

.B-33

Transmission

and Transfer

Case

—

Lubricant

Change .B-34

General

.B-35

Transfer

Case B-36

Transmission

B-3

7, B-38

Transfer

Case Linkage B-39

Universal

Joints and Slip Joints.

.......

.B-58

Wheel

Bearings..

.........

. . .B-56, B-57

Windshield

Wiper and Washer B-63

LUBRICATION

OF

OPTIONAL EQUIPMENT

B-69

Centrifugal

Governor. .B-71

Pintle Hook .B-70

Powr-Lok

or

Trac-Lok

Differential B-72

PARTS REQUIRING

NO LUBRICATION.

. . .B-73

Alternator

Bearings. B-76

Clutch

Release Bearings.

.............

.B-74

Shock Absorbers B-78

Springs

B-7

7

Starter

Motor Bearings B-75

Water

Pump Bearings B-74

LUBRICATION REQUIREMENTS FOR OFF-HIGHWAY OPERATIONS

B-79

Air

Cleaner B-82

Chassis

Lubrication

B-83

Engine

Oil B-80

Engine

Oil

Filter

B-81

Differentials .B-86

Front

Axle U-Joints. B-84

Transfer

Case and Transmission .B-85

constant

speed

driving on highways, and even more

intensified in extreme cold or hot weather; there fore, vehicles driven under

these

conditions must

be lubricated and serviced more

often

than nor mally operated vehicles. The specifications of

types

and

amounts of lubricant given in the Lubrication

Chart

and

text

of this section should be closely

followed. The off-highway operation lubrication

notes,

given in the last part of the section, should

be followed when applicable. 7

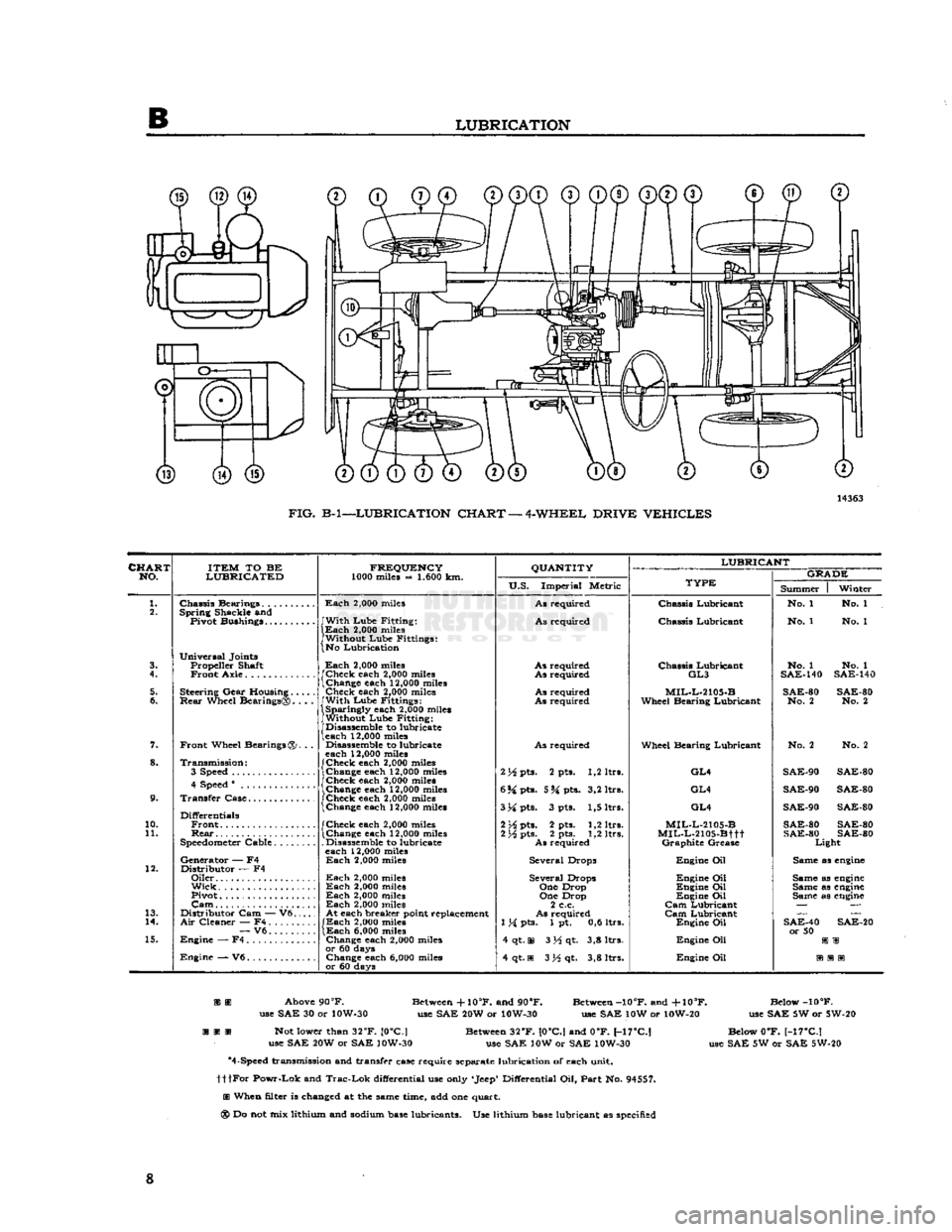

Page 8 of 376

B

LUBRICATION D0®

® ® ®

FIG.

B-l—-LUBRICATION CHART

—

4-WHEEL DRIVE

VEHICLES

CHART NO.

ITEM

TO BE

LUBRICATED

10.

11.

13.

14.

Chassis

Bearings. . .

Spring

Shackle and Pivot Bushings...

Universal

Joints Propeller Shaft

Front

Axle

Steering

Gear

Housing

Rear

Wheel BearingstS

Front

Wheel Bearings

.

Transmission:

3

Speed

4 Speed °

Transfer

Case

Differentials

Front.

Rear

Speedometer Cable

Generator

— F4

Distributor

— F4

Oiler

Wick

Pivot.

Gam

Distributor

Cam — V6.

Air

Cleaner — F4

—

V6

Engine

— F4

Engine

— V6.

FREQUENCY

1000 miles — 1.600 km.

Each

2,000

miles

/With

Lube

Fitting;

(Each

2,000

miles [Without

Lube

Fittings:

\No Lubrication

Each

2,000

miles

f

Check

each

2,000

miles

\

Change each

12,000

miles

Check

each

2,000

miles

fWith

Lube

Fittings:

1

Sparingly each

2,000

miles

J

Without

Lube

Fitting:

|

Disassemble to lubricate

\each

12,000

miles

Disassemble to lubricate

each

12,000

miles

I

Check

each

2,000

miles

l

Change each

12,000

miles

/Check

each

2,000

miles

l

Change each

12,000

miles

!Check

each

2,000

miles

\

Change each

12,000

miles

f

Check

each

2,000

miles

\

Change each

12,000

miles

.

Disassemble to lubricate each

12,000

miles

Each

2,000

miles

Each

2,000

miles

Each

2,000

miles

Each

2,000

miles

Each

2,000

miles

At

each breaker point replacement

/Each

2,000

miles

\Each

6,000

miles

Change each

2,000

miles

or 60 days

Change each

6,000

miles

or 60 days

QUANTITY

U.S.

Imperial Metric

As

required

As

required

As

required

As

required

As

required

As

required

As

required

2H

Pts. 2 pts. 1,2 ltrs.

6 H pts. 5

M

pts. 3,2 ltrs.

3Mpti«

3 pts. 1,5 ltrs. 2

M

pts. 2 pts. 1,2 ltrs.

2

Yi

pts. 2 pts. 1,2 ltrs.

As

required

Several

Drops

Several

Drops

One

Drop

One

Drop

2 c.c.

As

required

1 H pts. 1 pt. 0,6 ltrs.

4 qt. m 314 qt. 3,8 ltrs.

4 qt.

11

3 34 qt. 3,8 ltrs.

LUBRICANT

TYPE

Chassis

Lubricant

Chassis

Lubricant

Chassis

Lubricant

GL3

MIL-L-2105-B

Wheel

Bearing

Lubricant

Wheel

Bearing

Lubricant

GL4

GL4 GL4

MIL-L-2105-B

MIL-L-2105-Bttt

Graphite

Grease

Engine

Oil

Engine

Oil

Engine

Oil

Engine

Oil

Cam

Lubricant

Cam

Lubricant

Engine

Oil

Engine

Oil

Engine

Oil

GRADE

No. 1 No.

1

No. 1 No. 1

No. 1

SAE-140

No. 1

SAE-140

SAE-80

No. 2

SAE-

No. 80

2

No. 2 No. 2

SAE-90

SAE

80

SAE-90

SAE

80

SAE-90

SAE

80

SAE-80

SAE-80

SAE

SAE

80

80

Light

Same as

engine

Same as

engine

Same as

engine

Same as

engine

SAE-40

or 50

SAE-20

Above 90

°F.

use SAE 30 or 10W-30

Not lower than

32°F.

[0°C.|

use SAE 20W or SAE 10W-30 Between

-f-10°F.

and 90

8F.

use SAE 20W or 10W-30 Between

-10°F.

and

+10°F.

use SAE 10W or 10W-20 Between

32eF.

[0°C.]

and 0°F.

l-17°Cl

use SAE 10W or SAE 10W-30

*4-Speed transmission and transfer case require separate lubrication of each unit.

tttFor

Powr-Lok

and

Trac-Lok

differential use only 'Jeep* Differential Oil,

Part

No. 94557.

SI

When filter is changed at the same time, add one quart.

®

Do not mix lithium and sodium base lubricants. Use lithium base lubricant as specified Below

-10°F.

use SAE 5W or 5W-20

Below 0°F. [-17°C.J

use SAE 5W or SAE 5W-20 8

Page 9 of 376

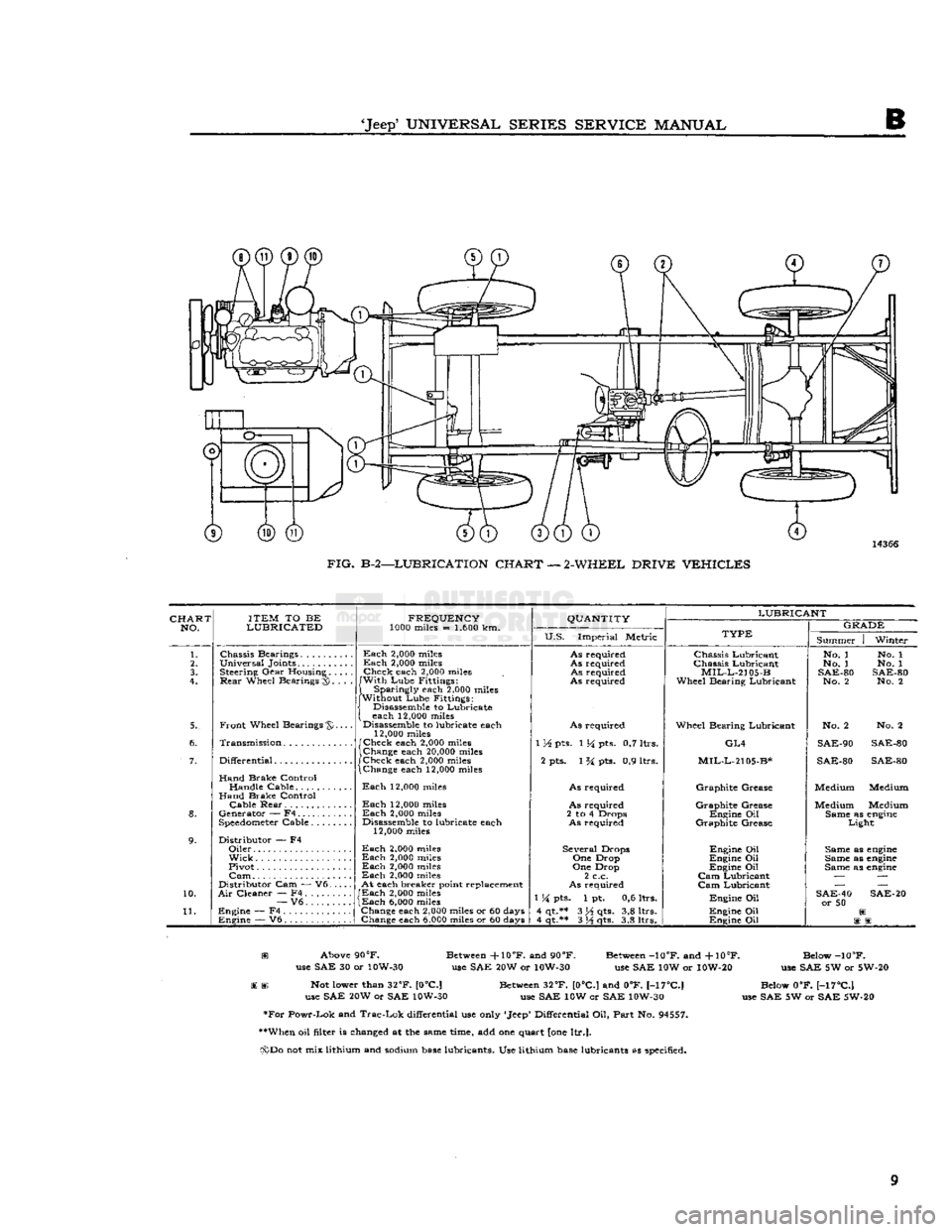

*Jeep?

UNIVERSAL

SERIES

SERVICE

MANUAL

FIG.

B-2—LUBRICATION

CHART

—

2-WHEEL

DRIVE

VEHICLES

CHART

NO

ITEM

TO BE

LUBRICATED

FREQUENCY

1000 miles = 1.600 km.

QUANTITY

U.S.

Imperial Metric

LUBRICANT

TYPE

Summer I Winter

Chassis

Bearings.....

Universal

Joints...... Steering

Gear

Housing

Rear

Wheel Bearings fx

Front

Wheel

Bearings®

Transmission

Differential

Hand

Brake Control Handle Cable

Hand

Brake Control

Cable

Rear

Generator — F4

Speedometer

Cable....

Distributor — F4

Oiler

Wick

Pivot

Cam

Distributor Cam — V6.

Air

Cleaner — F4

—

V6.

....

Engine

— F4

Engine

— V6

Each

2,000

miles

Each

2,000

miles

Check

each

2,000

miles

With

Lube Fittings;

Sparingly each

2.000

miles

Without Lube Fittings: Disassemble to Lubricate

each

12,000

miles

Disassemble to lubricate each

12,000

miles

Check

each

2,000

miles

Change each

20,000

miles

Check

each

2,000

miles Change each

12,000

miles

Each

12,000

miles

Each

12,000

miles

Each

2,000

miles Disassemble to lubricate each

12,000

miles

Each

2,000

miles

Each

2,000

miles

Each

2,000

miles

Each

2,000

miles

At

each breaker point replacement

Each

2,000

miles

Each

6,000

miles

Change each

2,000

miles or 60 days Change each

6.000

miles or 60 days

As

required

As

required

As

required

As

required

As

required

1 XA pts. 114 pts. 0,7 ltrs. 2 pts. 1 % pts. 0,9 ltrs.

As

required

As

required

2 to 4 Drops

As

required

Several

Drops One Drop

One Drop

2 c.c.

As

required

1

M

pts. 1 pt. 0,6 ltrs.

4 qt.** 3 H qts. 3,8 ltrs. 4 qt.** 3

}A

qts. 3,8 ltrs.

Chassis

Lubricant

Chassis

Lubricant

MIL-L-2105-B

Wheel Bearing Lubricant

Wheel Bearing Lubricant

GL4

MIL-L-2105-B*

Graphite

Grease

Graphite

Grease

Engine

Oil

Graphite

Grease

Engine

Oil

Engine

Oil

Engine

Oil

Cam

Lubricant

Cam

Lubricant

Engine

Oil

Engine

Oil

Engine

Oil No. 1 No. 1

No. 1 No. 1

SAE-80 SAE-80

No. 2 No. 2

No. 2 No. 2

SAE-90 SAE-80

SAE-80 SAE-80

Medium Medium

Medium Medium Same as

engine

Light

Same as

engine

Same as

engine

Same as

engine

SAE-40

or 50

®

Above

90°F.

Between -f

10°F.

and

90°F.

Between

-10°F.

and

-fl0°F.

Below

-10°F.

use SAE 30 or 10W-30 use SAE 20W or 10W-30 use SAE 10W or 10W-20 use SAE 5W or 5W-20

BE

St

Not lower than

32°F.

[08C] Between

32°F.

10°C] and 0°F.

l-17°CI

Below 0°F. [-17°C] use SAE 20W or SAE 10W-30 use SAE 10W or SAE 10W-30 use SAE 5W or SAE 5W-20

•For

Powr-Lok and

Trac-Lok

differential use only 'Jeep' Differential Oil, Part No.

94557.

**When oil filter is changed at the same time, add one quart {one

ltr.].

(x)Do not mix lithium and sodium

base

lubricants. Use lithium

base

lubricants as specified. 9

Page 10 of 376

B

LUBRICATION

B-2.

Special Lubricants

Special

lubricants are required for certain

lubri

cation points on the 'Jeep' Universal vehicles. The

special

lubricants are necessary for proper function ing and maintenance of the vehicle. The

Lubrica

tion

Chart

(Fig. B-l and B-2)

designates

the spe

cial

lubricating points and identifies them by type

or

part number.

B-3.

Applying

Fresh

Lubricant

When

servicing or lubricating the vehicle, it is important that all old lubricant and

dirt

be re moved from the fitting and/or plugs before servic

ing and that the recommended type of lubricant be used for the particular item being serviced.

Force

lubricant through the lube fittings until the lubricant being forced out of the joint is fresh

lubricant,

indicating that all old lubricant has

been removed.

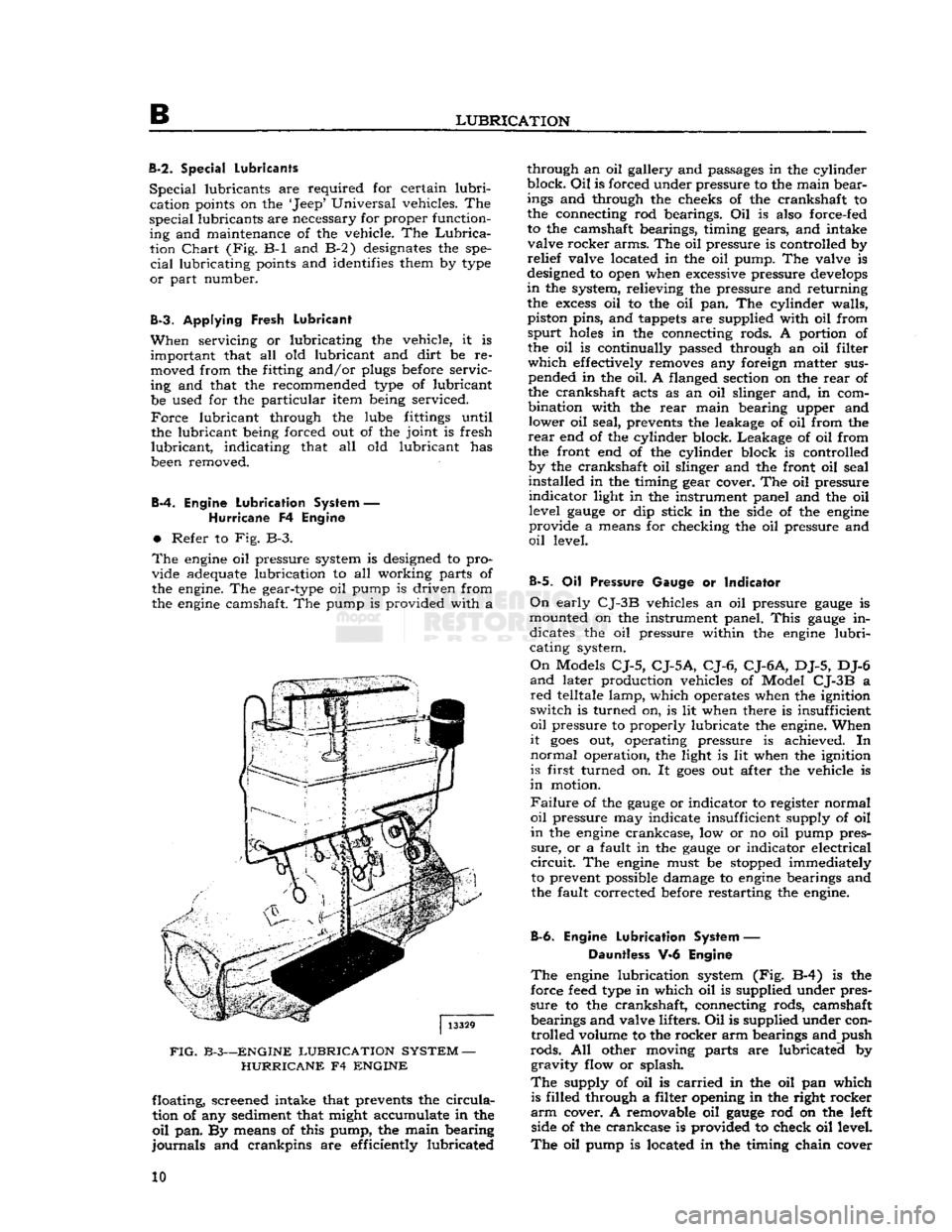

B-4.

Engine

Lubrication

System —

Hurricane

F4 Engine

•

Refer to Fig. B-3.

The

engine

oil pressure system is designed to pro

vide adequate lubrication to all working parts of

the engine. The gear-type oil pump is driven from

the

engine

camshaft. The pump is provided with a

FIG.

B-3—ENGINE

LUBRICATION

SYSTEM

—

HURRICANE

F4

ENGINE

floating, screened intake that prevents the

circula

tion of any sediment that might accumulate in the

oil

pan. By means of this pump, the main bearing

journals

and crankpins are efficiently lubricated through an oil gallery and passages in the cylinder

block.

Oil

is forced under pressure to the main bear

ings and through the cheeks of the crankshaft to

the connecting rod bearings. Oil is also force-fed

to the camshaft bearings, timing gears, and intake valve rocker arms. The oil pressure is controlled by

relief

valve located in the oil pump. The valve is

designed to open when excessive pressure

develops

in

the system, relieving the pressure and returning the

excess

oil to the oil pan. The cylinder walls,

piston pins, and tappets are supplied with oil from

spurt

holes

in the connecting rods. A portion of the oil is continually passed through an oil filter

which

effectively removes any foreign matter sus pended in the oil. A flanged section on the

rear

of

the crankshaft acts as an oil slinger and, in com

bination with the

rear

main bearing upper and lower oil seal, prevents the leakage of oil from the

rear

end of the cylinder block. Leakage of oil from

the front end of the cylinder block is controlled by the crankshaft oil slinger and the front oil seal

installed in the timing gear cover. The oil pressure

indicator

light in the instrument panel and the oil level

gauge

or dip stick in the side of the

engine

provide a means for checking the oil pressure and

oil

level.

B-5.

Oil Pressure Gauge or Indicator

On

early

CJ-3B

vehicles an oil pressure

gauge

is

mounted on the instrument panel.

This

gauge

in dicates the oil pressure within the

engine

lubri

cating system.

On

Models

CJ-5,

CJ-5A,

CJ-6,

CJ-6A,

DJ-5, DJ-6

and

later production vehicles of Model

CJ-3B

a

red

telltale lamp, which operates when the ignition

switch is turned on, is lit when there is insufficient

oil

pressure to properly lubricate the engine. When

it

goes

out, operating pressure is achieved. In

normal

operation, the light is lit when the ignition

is first turned on. It

goes

out after the vehicle is

in

motion.

Failure

of the

gauge

or indicator to register normal

oil

pressure may indicate insufficient supply of oil

in

the

engine

crankcase, low or no oil pump pres

sure,

or a fault in the

gauge

or indicator electrical

circuit.

The

engine

must be stopped immediately to prevent possible damage to

engine

bearings and

the fault corrected before restarting the engine.

B-6.

Engine

Lubrication

System — Dauntless V-6 Engine

The

engine

lubrication system (Fig. B-4) is the

force

feed

type in which oil is supplied under pres

sure

to the crankshaft, connecting rods, camshaft bearings and valve lifters. Oil is supplied under controlled volume to the rocker arm bearings and push

rods.

All other moving parts are lubricated by gravity flow or splash.

The

supply of oil is

carried

in the oil pan which is filled through a filter opening in the right rocker

arm

cover. A removable oil

gauge

rod on the left side of the crankcase is provided to check oil level.

The

oil pump is located in the timing chain cover 10