seats JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 105 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

Dl-104.

SERVICE

DIAGNOSIS

Poor Fuel Economy

Ignition Timing Late or Spark Advance Inoperative

Carburetor

Float Setting Too High

Accelerator Pump Improperly Adjusted

Fuel

Pump Pressure High

Fuel

Line

Leakage

Fuel

Pump Diaphragm Leakage

Cylinder

Compression Low

Valves Do Not Seat Properly

Spark

Plugs

Defective

Spark

Plug Cables

Defective

Ignition

Coil

or Capacitor

Defective

Carburetor

Air Cleaner Dirty

Brakes

Drag

Wheel Alignment Incorrect

Tire

Pressure Incorrect Odometer Inaccurate

Fuel

Tank

Cap Clogged or

Defective

Muffler or Exhaust Pipe Clogged or Bent

Lack

of

Power

Cylinder

Compression Low

Ingitdon Timing Late

Carburetor

or

Fuel

Pump Clogged or

Defective

Fuel

Lines Clogged

Air

Cleaner Restricted

Engine Temperature High Valves Do Not Seat Property

Valve

Timing Late Intake Manifold or Cylinder Head

Gasket Leaks

Muffler or Exhaust Pipe Clogged or Bent

Spark

Plugs Dirty or

Defective

Breaker

Point Gap Incorrect

Breaker

Points

Defective

Ignition

Coil

or Capacitor

Defective

Electrical

Connection Loose

Broken

Valve Spring

Broken

Piston Ring or Piston

Cylinder

Head Gasket

Defective

Distributor Cap Cracked

Low

Compression

Valves Not Seating Properly Piston Rings Seal Poorly

Valve

Spring Weak or Broken

Cylinder

Scored or Worn

Piston Clearance Too Great

Cylinder

Head Gasket Leaks

Burned

Valves and

Seats

Valves Stick or Are Too Loose in Guides

Valve

Timing Incorrect

Valve

Head and Seat Have Excessive Carbon

Engine Overheats

Valve

Spring Weak or Broken

Valve

Lifter Seized or Collapsed

Exhaust

System Clogged

Valves Sticking

Valve

Stem Warped

Valve

Stem Carbonized or Scored

Valve

Stem Clearance Insufficient in Guide

Valve

Spring Weak or Broken

Valve

Spring Distorted

Oil

Contaminated

Overheating

Cooling System Inoperative

Thermostat Inoperative Ignition Timing Incorrect

Valve

Timing Incorrect

Carbon

Accumulation Excessive

Fan

Belt Loose

Muffler or Exhaust Pipe Clogged or Bent

Oil

System Failure

Piston Rings Worn or Scored

Popping,

Spitting,

Detonation

Ignition Timing Incorrect

Carburetion

Improper

Carbon

Deposit

in Combustion

Chambers Excessive

Valves Not Seating Properly

Valve

Spring Broken

Spark

Plug Electrodes Burned

Water or Dirt in

Fuel

Fuel

Line

Clogged

Valve

Timing Incorrect

Excessive

Oil

Consumption

Piston Rings Stuck in Grooves, Weak,

Worn,

Broken, or Incorrectly Fitted

Crankshaft

Main Bearings or

Connecting Rod Bearings Have

Excessive Clearance

Gaskets or Oil Seals

Leak

Cylinder

Bores Worn, Scored,

Out-of-Round or Tapered

Pistons Have Too Great Clearance to Cylinder Bores

Connecting Rods Misaligned High Road Speed

High Temperature

Crankcase

Ventilation System Inoperative

Bearing Failure

Crankshaft

Bearing Journal Rough or Out-of-Round

Oil

Level Low

Oil

Leakage

Oil

Dirty

Oil

Pressure Low or Lacking

(Oil

Pump Failure)

Drilled

Passages

in Crankshaft or

Crankcase

Clogged

Oil

Screen Dirty

Connecting Rod Bent 105

Page 116 of 376

E

FUEL

SYSTEM

pressing downward on metering rod) or

seats

be

fore the metering rod arm makes flat contact with the pump lifter link, make adjustment by bending

the lip on the metering rod arm.

E-17.

Choke System

The

choke system consists of a manually-operated

choke valve, a fast-idle connecting rod, and a fast-

idle arm. The choke valve is offset-spring loaded to prevent over-choking during the starting warm-

up period. When the choke valve is moved to a closed position for starting, the fast idle connector

rod

in Fig. E-ll revolves the fast idle link.

This

action increases the

engine

idle speed to prevent stalling during the warm-up period. A fast-idle

connector rod return spring prevents partial closing

of the choke valve. pump lifter which is connected to the throttle.

This

movement forces fuel from the chamber

above the diaphragm through discharge pump check valve and discharge pump jet.

This

auxiliary discharge of fuel supplies

engine

requirements for

quick

acceleration and heavy loads. When the

throttle is closed, the diaphragm is again pulled

down by high vacuum and another measured

charge of fuel enters the chamber above the

diaphragm

through the intake passage to be

available for the next cycle of operation.

Note:

The pump jet (see insert drawing in Fig.

E-12)

projecting into the air stream is permanently pressed into the carburetor body and should not

be removed. Also, carburetor design makes it im possible to adjust the pump stroke.

FIG.

E-ll—FAST

IDLE

ADJUSTMENT

1—Fast

Idle

Connector Rod

2—Fast

Idle

Link

E-18.

Fast

Idle Adjustment

With

the choke held in wide open position, lip (No. 1) (Fig.

E-ll)

on the fast-idle rod should con

tact the

boss

on the body casting. Adjust by bend

ing the fast-idle link at

offset

as shown by (No. 2).

E-19.

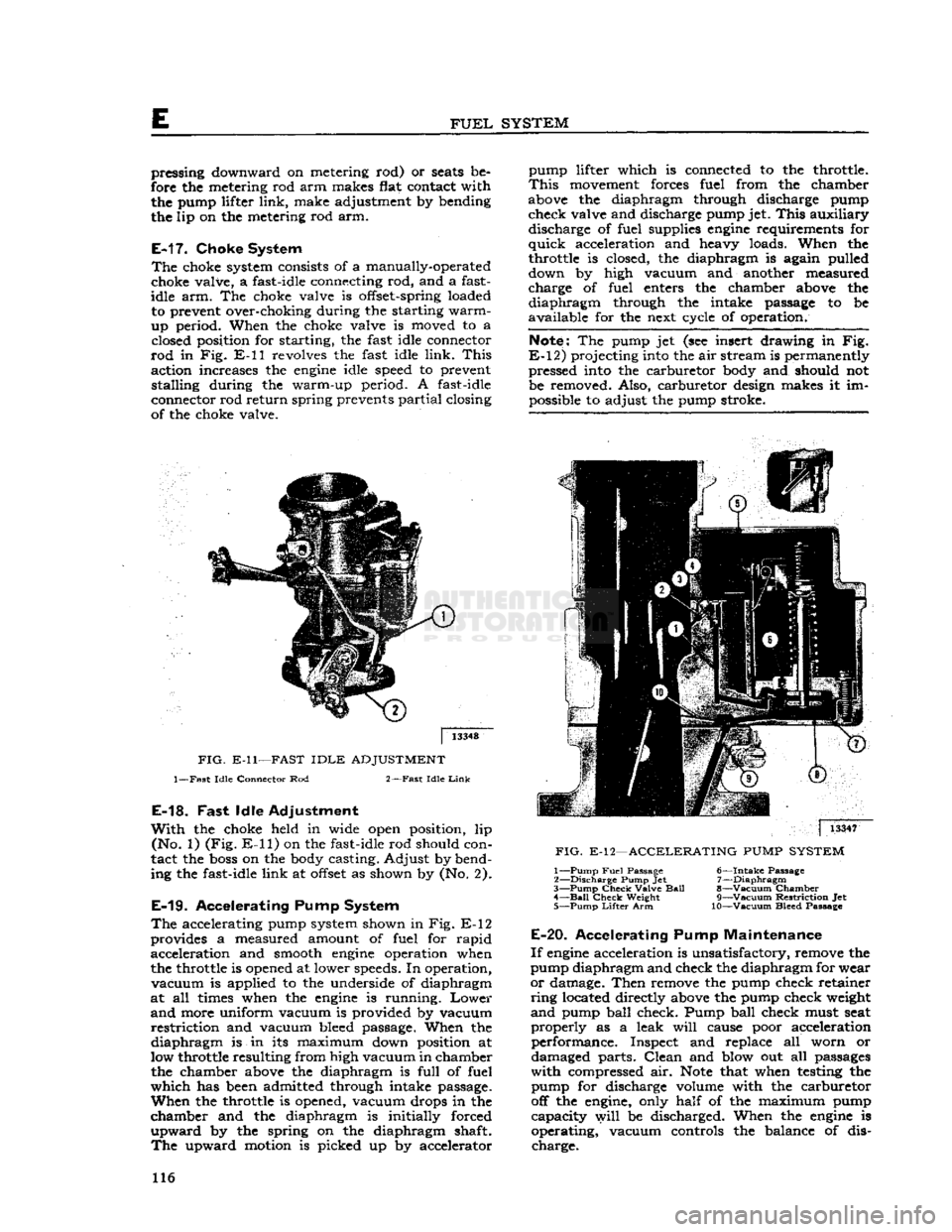

Accelerating Pump System

The

accelerating pump system shown in Fig. E-12

provides a measured amount of fuel for rapid acceleration and smooth

engine

operation when

the throttle is opened at lower speeds. In operation,

vacuum

is applied to the underside of diaphragm

at all times when the

engine

is running.

Lower

and

more uniform vacuum is provided by vacuum

restriction

and vacuum bleed passage. When the

diaphragm

is in its maximum down position at

low throttle resulting from high vacuum in chamber the chamber above the diaphragm is full of fuel

which

has been admitted through intake passage.

When

the throttle is opened, vacuum drops in the

chamber and the diaphragm is initially forced

upward

by the spring on the diaphragm shaft.

The

upward motion is picked up by accelerator

|

13347

FIG.

E-12—ACCELERATING

PUMP

SYSTEM

1—

Pump

Fuel

Passage

6—Intake

Passage

2—

Discharge

Pump Jet 7—Diaphragm

3—

Pump

Check

Valve

Ball

8—Vacuum Chamber 4—

Bail

Check

Weight

9—Vacuum

Restriction

Jet

5—

Pump

Lifter

Arm 10—Vacuum Bleed Passage

E-20.

Accelerating Pump Maintenance

If

engine

acceleration is unsatisfactory, remove the

pump diaphragm and check the diaphragm for wear

or

damage. Then remove the pump check retainer

ring

located directly above the pump check weight

and

pump ball check. Pump ball check must seat

properly

as a leak

will

cause poor acceleration performance. Inspect and replace all worn or

damaged parts.

Clean

and blow out all passages

with

compressed air.

Note

that when testing the pump for discharge volume with the carburetor

off the engine, only half of the maximum pump capacity

will

be discharged. When the

engine

is

operating, vacuum controls the balance of dis charge. 116

Page 121 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

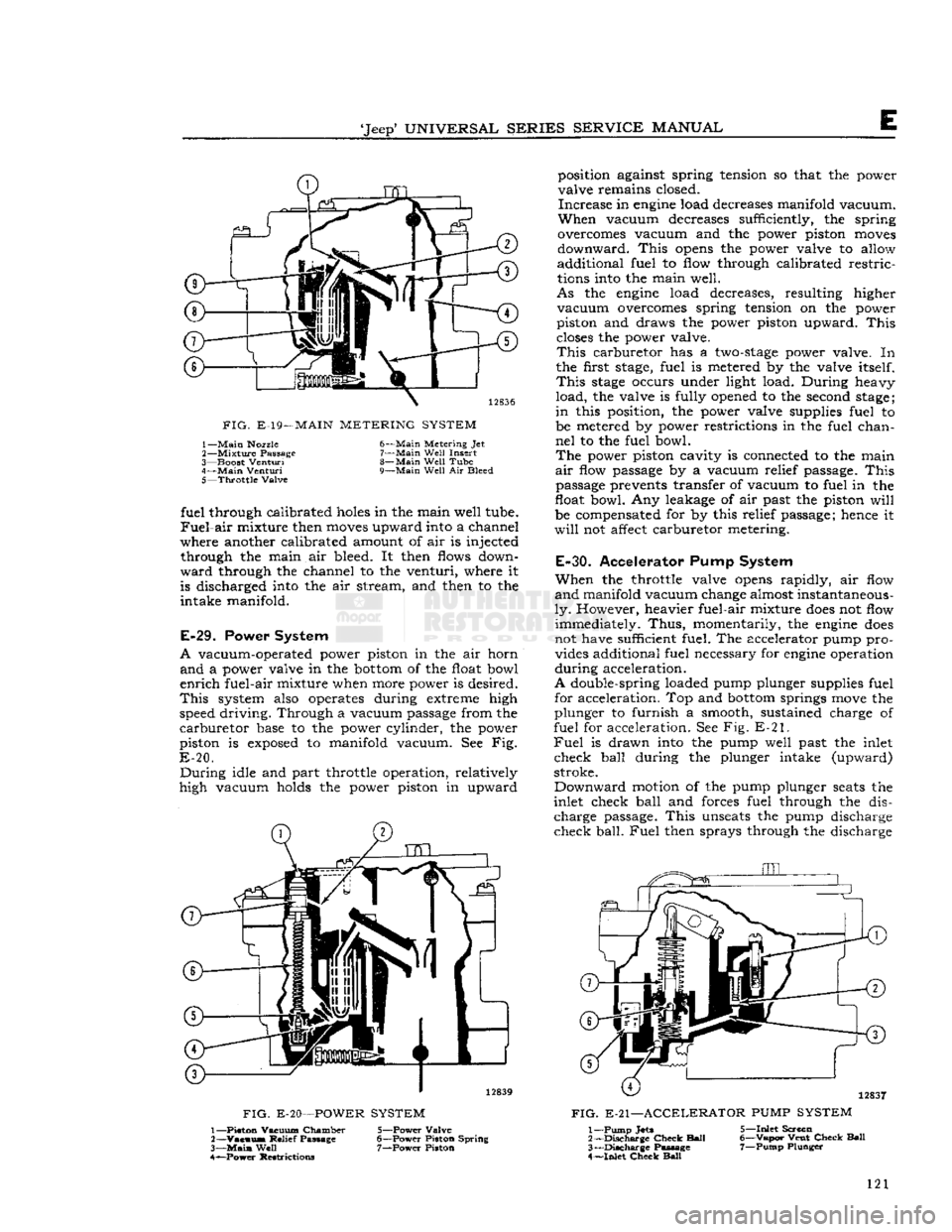

FIG.

E-19—

MAIN

METERING SYSTEM

1—

Main

Nozzle

2—

Mixture

Passage

3—

Boost

Venturi

4—

Main

Venturi

5—

Throttle

Valve 6—

Main

Metering Jet

7—

Main

Well

Insert

8—

Main

Well

Tube

9—

Main

Well

Air Bleed fuel through calibrated

holes

in the main well tube.

Fuel-air

mixture then

moves

upward into a channel

where another calibrated amount of air is injected through the main air bleed. It then flows down

ward

through the channel to the venturi, where it is discharged into the air stream, and then to the

intake manifold.

E-29.

Power System

A

vacuum-operated power piston in the air horn

and

a power valve in the

bottom

of the float bowl

enrich

fuel-air mixture when more power is desired.

This

system also operates during extreme high

speed driving. Through a vacuum passage from the

carburetor

base to the power cylinder, the power

piston is

exposed

to manifold vacuum. See Fig.

E-20.

During

idle and part throttle operation, relatively

high vacuum holds the power piston in upward

FIG.

E-20—POWER

SYSTEM

position against spring tension so that the power

valve remains closed.

Increase

in

engine

load decreases manifold vacuum.

When

vacuum decreases sufficiently, the spring

overcomes vacuum and the power piston

moves

downward.

This

opens

the power valve to allow

additional fuel to flow through calibrated restric

tions into the main well.

As

the

engine

load decreases, resulting higher

vacuum

overcomes spring tension on the power

piston and draws the power piston upward.

This

closes

the power valve.

This

carburetor has a

two-stage

power valve. In

the first

stage,

fuel is metered by the valve itself.

This

stage

occurs under light load. During heavy

load,

the valve is fully opened to the second

stage;

in

this position, the power valve supplies fuel to

be metered by power restrictions in the fuel chan

nel

to the fuel bowl.

The

power piston cavity is connected to the main

air

flow passage by a vacuum relief passage.

This

passage prevents transfer of vacuum to fuel in the

float bowl. Any leakage of air past the piston

will

be compensated for by this relief passage; hence it

will

not affect carburetor metering.

E-30.

Accelerator Pump System

When

the throttle valve

opens

rapidly, air flow

and

manifold vacuum change almost instantaneous

ly.

However, heavier fuel-air mixture

does

not flow immediately.

Thus,

momentarily, the

engine

does

not have sufficient fuel. The accelerator pump pro vides additional fuel necessary for

engine

operation

during

acceleration.

A

double-spring loaded pump plunger supplies fuel for acceleration. Top and

bottom

springs

move

the

plunger to furnish a smooth, sustained charge of

fuel for acceleration. See Fig. E-21.

Fuel

is drawn into the pump well past the inlet

check ball during the plunger intake (upward)

stroke.

Downward

motion of the pump plunger

seats

the

inlet check ball and forces fuel through the dis charge

passage.

This

unseats

the pump discharge

check

ball.

Fuel

then sprays through the discharge

12837

FIG.

E-21—ACCELERATOR

PUMP

SYSTEM

1— Piston Vacuum Chamber

2—

Vacuus*

Relief Passage

3—

Main

Well

4— ^Power Restrictions 5— Power Valve

6— Power Piston Spring 7— Power Piston 1— Pump

Jets

2—

Discharge

Check

Ball

3—

Discharge

Passage

4—

Inlet

Check

Ball

5—

Inlet

Screen

6—

Vapor

Vent

Check

Ball

7—

Pump

Plunger

121

Page 123 of 376

'Jeep9

UNIVERSAL

SERIES

SERVICE

MANUAL

E

exterior moving parts of a carburetor are

often

responsible for unsatisfactory performance.

For

this

reason,

efficient carburetion depends upon careful cleaning and inspection while servicing.

a.

Thoroughly clean carburetor castings and metal

parts

in carburetor cleaning solvent.

Caution:

Accelerator pump plunger and any fiber

or

rubber parts should never be immersed in

car

buretor

cleaner. Wash pump plunger in cleaning

solvent.

b.

Blow out all passages in the castings with com

pressed air. Dry all parts with compressed air.

Make

sure all jets and passages are clean. Do

not use wire to clean fuel passages or air bleeds.

c.

Check

inlet valve

needle

and seat for wear. If

wear

is noted, the assembly must be replaced.

d.

Check

float hinge pin for wear and check float

for damage.

e.

Check

throttle and choke shaft bores for wear

and

out-of-round.

f. Inspect idle mixture adjustment

needles

for

burrs

or

grooves; replace if damaged.

g. Inspect cup of accelerator pump plunger; re

place if damaged, worn, or hardened. Inspect pump

well

in bowl for wear or scoring.

h.

Check

filter screens for

dirt

or lint.

Clean,

and

if

they remain

clogged,

replace.

i.

If for any reason parts have

become

loose

or

damaged in the cluster assembly, the assembly

must be replaced.

Note:

Use ijew gaskets whenever the carburetor

is disassembled.

E-37.

Throttle Body Assembly

a.

Install

idle mixture adjustment

needles

and

springs in throttle body. Tighten finger-tight, then

unthread

one

turn

as a preliminary adjustment

setting.

Caution:

Do not force idle mixture adjustment

needles

against

seats

or damage may result.

b.

Invert

fuel bowl body and place new throttle

body gasket on bowl. Fasten throttle body to bowl

body with three screws and lockwashers; tighten

securely.

E-38.

Fuel

Bowl Body Assembly

a.

Drop steel discharge check

tall

of accelerator

pump into discharge hole.

Install

pump discharge

spring

and T-shaped retainer. Stake retainer in

place.

Note:

Top of retainer must be flush with flat

surface

of fuel bowl body.

b.

Install

two inserts in main well. Align surface

on lip of insert with flat surface in recess on top

of main well.

Install

venturi cluster with gasket,

and

tighten mounting screws evenly and securely.

Be

certain that center screw is fitted with fiber gasket, and that a special smooth shank screw is

used.

c.

Install

two main metering jets, power valve

gasket and power valve.

d.

Install

small aluminum inlet check

ball

in ac

celerator

pump inlet at

bottom

of pump well. In

sert

pump return spring into well, and center by

pressing spring downward with finger.

e.

Install

pump inlet screen in

bottom

of fuel

bowl.

E-39.

Air

Horn Body

Assembly

a.

Install

choke lever and collar on choke shaft.

Prong

on choke lever must face away from air

horn

body and be on top of choke trip lever.

b.

Install

choke shaft and lever assembly into the

air

horn. Choke rod

hole

in the choke lever must

face fuel inlet side of carburetor.

c.

Install

choke valve plate in choke shaft so that

letters RP

will

face upward in finished carburetor.

Install

two new valve plate attaching screws, but

do not tighten securely until valve plate is centered.

To

center choke valve plate on choke shaft, hold

choke valve tightly closed, then slide choke shaft

inward

to obtain approximately .020" [0,508 mm.]

clearance

between

choke trip lever and choke lever

and

collar assembly. Tighten choke valve screws

securely,

and stake lightly in place. Choke valve

will

be perfectly free in all positions when installed

correctly.

d.

Insert

outer accelerator pump lever and shaft as sembly into air horn body, with lever pointing to

ward

choke shaft.

Install

inner pump arm, with plunger

hole

inward,

and tighten set screw securely.

Position pump plunger assembly on inner pump

arm,

with pump shaft pointing

inward,

and install

retainer.

e.

Install

needle

seat screen on inlet valve seat. In

stall

seat and gasket in air horn body. Tighten seat

securely with a wide-blade screwdriver.

f.

Install

power piston into vacuum cavity.

Lightly

stake piston retainer washer in place. Piston should

travel

freely in cavity.

g.

Install

air horn gasket on air horn body, fitting

gasket over guide pin.

h.

Attach inlet valve

needle

to float.

Carefully

position float and insert float hinge pin. Drop tang

at

rear

of float arm downward toward air horn.

i.

Install

fuel inlet fitting, if removed.

j.

With

air horn assembly inverted, measure the distance from the air horn gasket to top of float

at toe \%£f [27,78 mm.] for standard carburetors

and

\%i [29,36 mm.] for exhaust emission control

equipped carburetors, as shown in Fig. E-23. Use

float level

gauge

J-5127-2. Bend float arm as re

quired

to adjust float level.

k.

With

air horn body held upright, measure dis

tance from gasket to

bottom

of float

pontoon

at outer end. Use a l7/s" [47,625 mm.] float drop

gauge.

Bend float tang, as required, to adjust float

drop.

See Fig. E-24.

I.

Carefully

place air horn body on fuel bowl

body, making certain that the accelerator pump

plunger is properly positioned in the pump well.

Lower

the cover gently, straight down; install air 123

Page 161 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

COOLING

SYSTEM

Contents

SUBJECT

PAR.

GENERAL

.G-l Antifreeze Solutions. .G-l6

Cylinder

Block.

..................

.G-8

Draining

Cooling System............... G-3

Engine

Overheating..

.................

.G-19

Fan

Belt.

......... .........

.G-18

Filling

Cooling System.................

G-2

Inhibited

Coolant Solution .G-l7

Temperature

Sending Unit.

...........

.G-l0

Thermostat

.........................

G-9

RADIATOR

.G-5

Radiator

and Heater Hoses.............

G-7

SUBJECT

PAR.

Radiator

Pressure

Cap.................

G-4

Radiator

Removal and Replacement..... G-6

WATER

PUMP.

. . .G-ll

Water

Pump Disassembly. .............G-13

Water

Pump Inspection.

..............

.G-12

Water

Pump Reassembly.

.............

.G-14

Water

Pump Removal and Replacement. .G-l5

SERVICE

DIAGNOSIS.

.G-20

SPECIFICATIONS

. .G-21

ANTIFREEZE

CHART.

..... ... .G-22

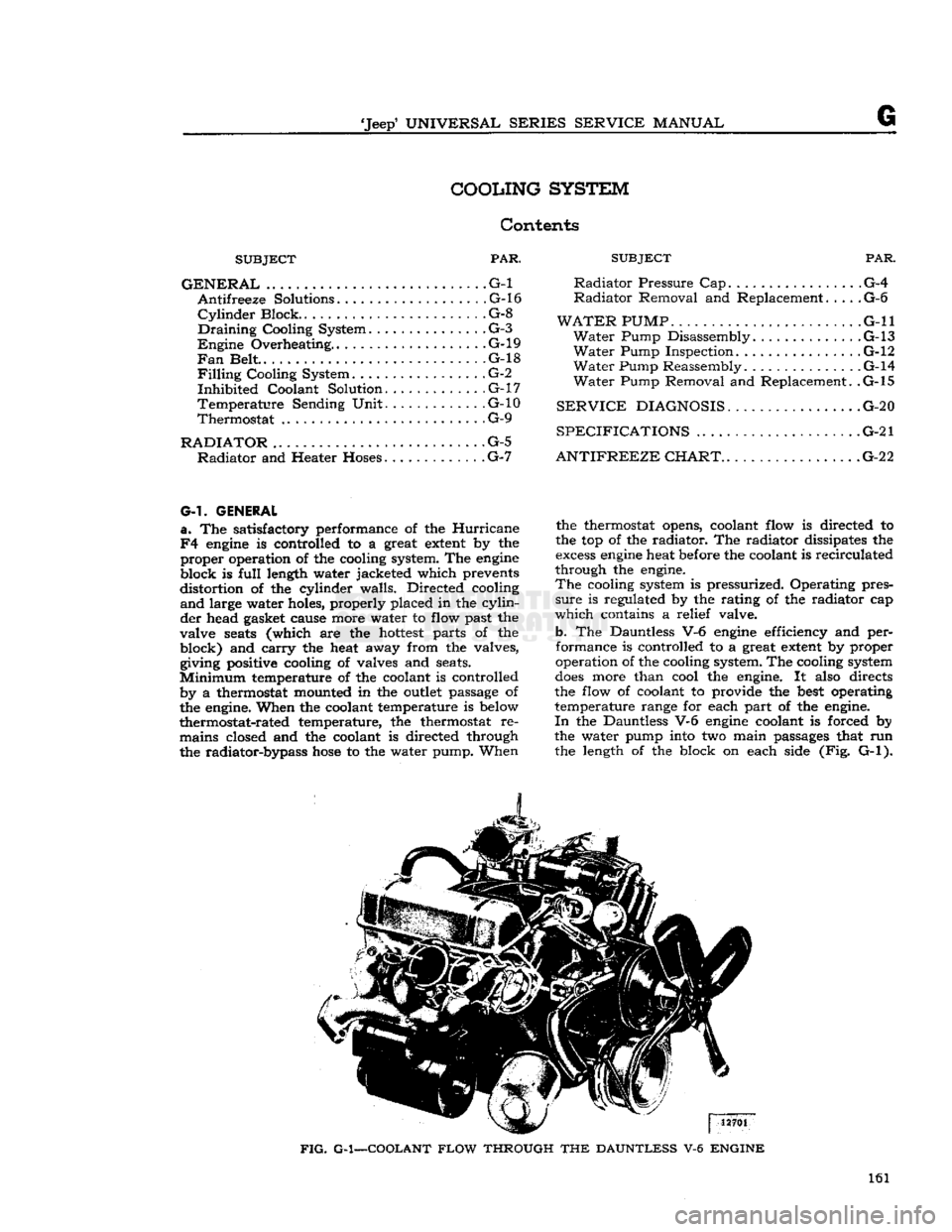

G-l. GENERAL

a.

The satisfactory performance of the Hurricane

F4

engine

is controlled to a great

extent

by the proper operation of the cooling system. The

engine

block is full length water jacketed which prevents

distortion of the cylinder walls. Directed cooling

and

large water holes, properly placed in the cylin

der head gasket cause more water to flow past the

valve

seats

(which are the

hottest

parts of the

block)

and

carry

the heat away from the valves, giving positive cooling of valves and seats.

Minimum

temperature of the coolant is controlled by a thermostat mounted in the

outlet

passage of

the engine. When the coolant temperature is below

thermostat-rated temperature, the thermostat re mains closed and the coolant is directed through

the radiator-bypass

hose

to the water pump. When the thermostat opens, coolant flow is directed to

the top of the radiator. The radiator dissipates the

excess

engine

heat before the coolant is recirculated

through the engine.

The

cooling system is pressurized. Operating pres

sure

is regulated by the rating of the radiator cap

which

contains a relief valve, b. The Dauntless V-6

engine

efficiency and performance is controlled to a great

extent

by proper

operation of the cooling system. The cooling system

does

more than cool the engine. It also directs

the flow of coolant to provide the

best

operating

temperature range for each part of the engine.

In

the Dauntless V-6

engine

coolant is forced by

the water pump into two main passages that run the length of the block on each side (Fig. G-l).

FIG.

G-1—COOLANT

FLOW

THROUGH

THE

DAUNTLESS

V-6

ENGINE

161

Page 205 of 376

SERIES

SERVICE

MANUAL

H

t

^

12956

FIG.

H-41—PRESTOLITE

STARTING

MOTOR—V-6

ENGINE

1—

End

Plate

2—

Oiling

Pad

3—

Thrust

Washer

4—

Brush

Plate Assembly 5—

Screw

6—

Lock

Washer 7—

Insulating

Washer

8—

Terminal

9—

Field

Coil

and Pole Shoe

10—Frame

11—

Insulating

Washer

12—

Washer

13— Nut

14

—Lockwasher

15—

Insulating

Bushing

16— Pole Shoe Screw

17—

Bearing,

Outer

18—

Drive

End

Frame

Pinion Housing

19— Intermediate Bearing Housing

20—

Lock

Washer 21—

Screw

22— Bendix Drive

23—

Thrust

Washer

24—Pin

25—

Armature

2 6—Commutator

27—

Thru

Bolt

28—

Insulator

29—

Bearing,

Intermediate

and

the armature rotated slowly by hand. If a

shorted coil is present, the steel strip

will

become

magnetized and

will

then vibrate.

H-101-

Field

Coils

Using

test

probes, check the field coils for both

ground and

open

circuits.

a.

To

test

for ground, place one probe on the motor frame or

pole

piece

and touch the other probe to the field coil terminals. If a ground is present, the

lamp

will

light.

b.

To

test

for

open

circuits, place the probes on

the field coil terminal and on an insulated brush.

If

the light,

does

not light, the coil is

open

circuited.

H-102.

Brush

Holder Inspection

Using

test

probes, touch the insulated brush holder with one probe and a convenient ground on the commutator end head with the other probe. If the

lamp lights, it indicates a grounded brush holder.

H-103.

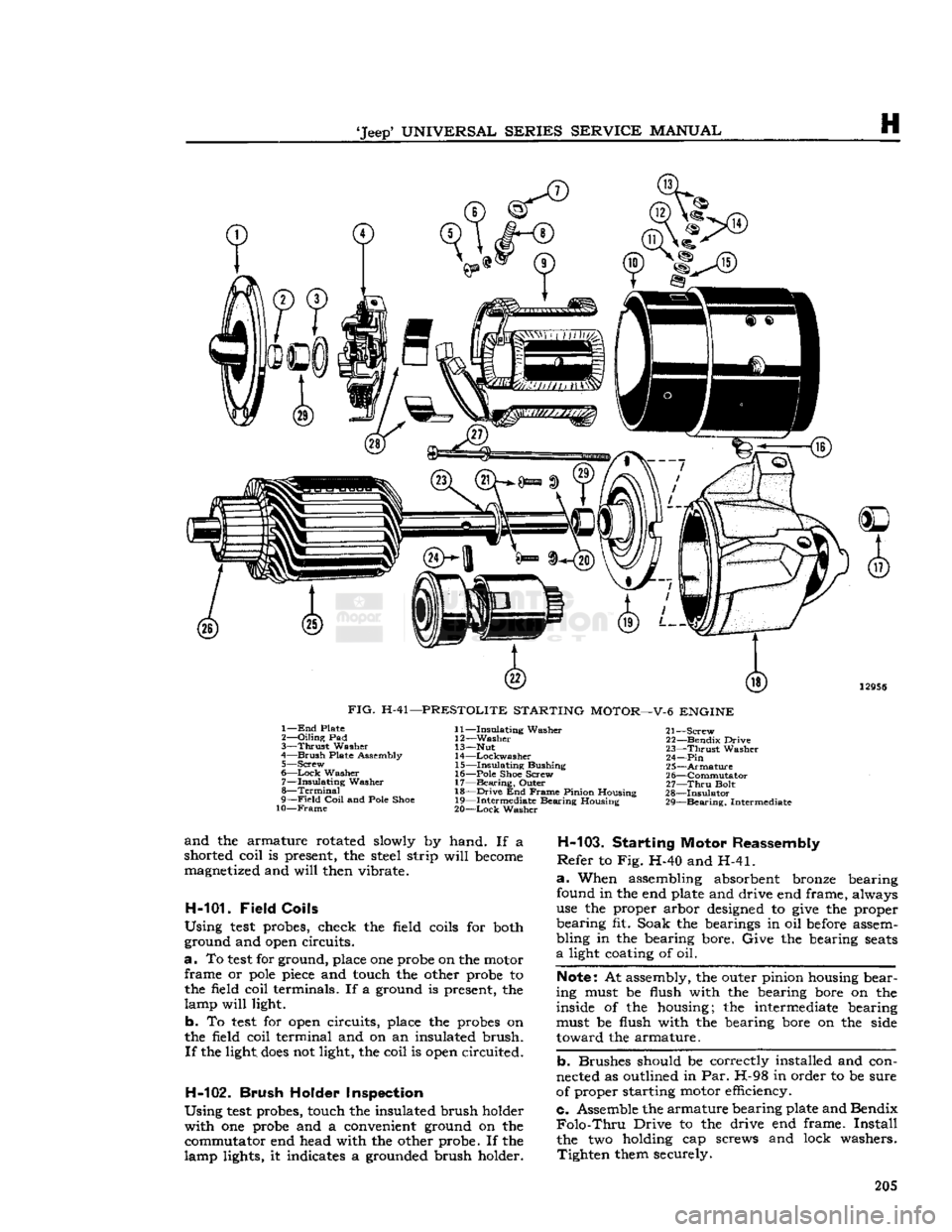

Starting Motor Reassembly

Refer

to Fig. H-40 and H-41.

a.

When assembling absorbent bronze bearing

found in the end plate and drive end frame, always

use the proper arbor

designed

to

give

the proper

bearing fit. Soak the bearings in oil

before

assem

bling in the bearing bore. Give the bearing

seats

a

light coating of oil.

Note:

At assembly, the outer pinion housing bear

ing must be flush with the bearing bore on the inside of the housing; the intermediate bearing

must be flush with the bearing bore on the side

toward the armature.

b.

Brushes should be correctly installed and con

nected as outlined in Par. H-98 in order to be sure

of proper starting motor efficiency.

c. Assemble the armature bearing plate and Bendix

Folo-Thru

Drive to the drive end frame.

Install

the two holding cap screws and lock washers. Tighten them securely. 205

Page 278 of 376

M

FRONT

AXLE

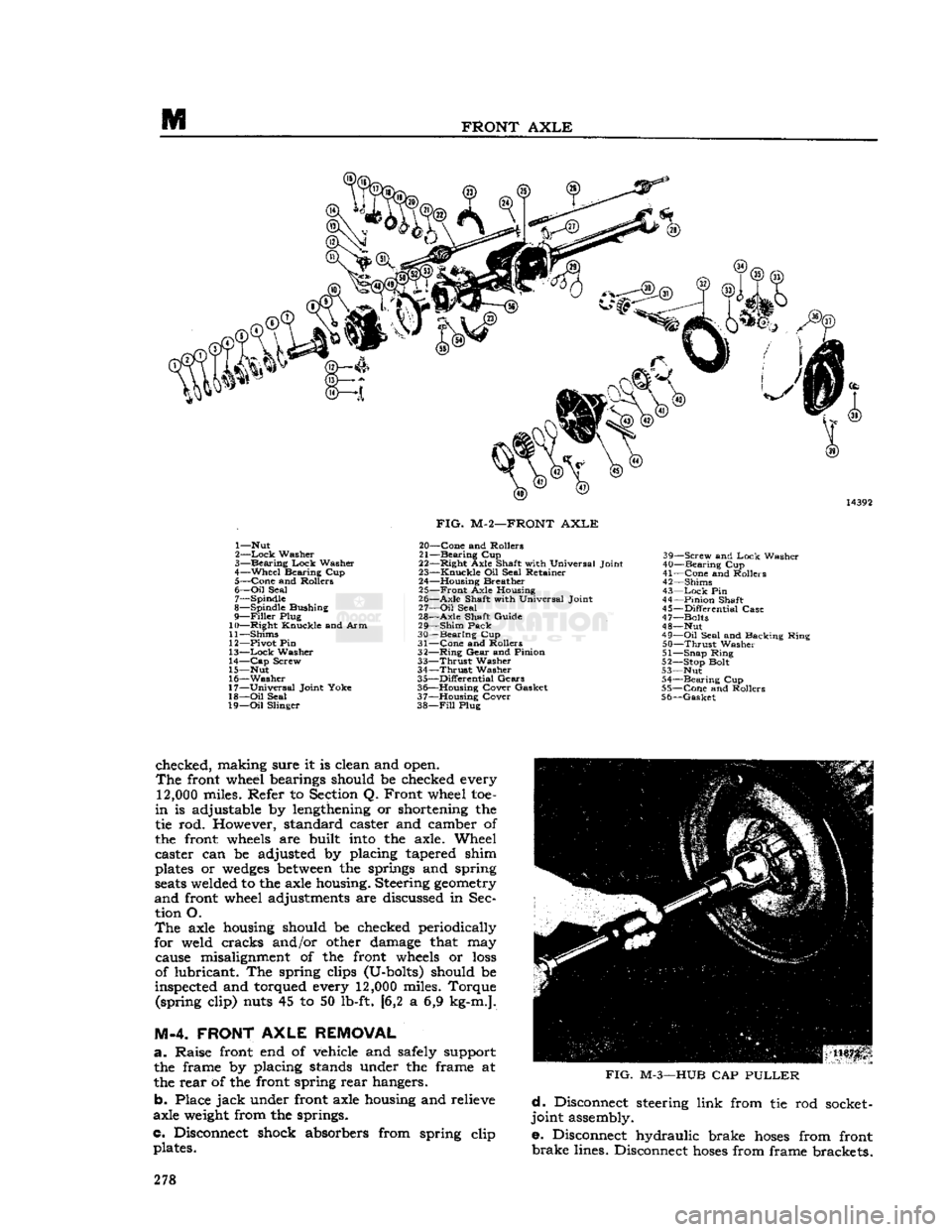

1— Nut

2—

Lock

Washer

3—

Bearing

Lock

Washer

4—

Wheel

Bearing Cup 5—

Cone

and Rollers

6—

Oil

Seal 7— Spindle

8— Spindle Bushing

9—

Filler

Plug

10—

Right

Knuckle and Arm

11— Shims

12— Pivot Pin

13—

Lock

Washer

14—

Cap

Screw

15— Nut

16—

Washer

17—

Universal

Joint Yoke

18—

Oil

Seal

19—

Oil

Slinger

FIG.

M-2—FRONT

AXLE

20—

Cone

and Rollers

21—

Bearing

Cup

22—

Right

Axle Shaft with Universal Joint

23—

Knuckle

Oil Seal Retainer

24— Housing Breather 25—

Front

Axle Housing

26—

Axle

Shaft with Universal Joint

27—

Oil

Seal

28—

Axle

Shaft Guide

29—

Shim

Pack

30—

Bearing

Cup

31—

Cone

and Rollers

32—

Ring

Gear

and Pinion

33—

Thrust

Washer

34—

Thrust

Washer

35—

Differential

Gears

36— Housing Cover Gasket

37— Housing Cover

38—

Fill

Plug 39—

Screw

and

Lock

Washer

40—

Bearing

Cup

41—

Cone

and Rollers

42— Shims

43—

Lock

Pin

44—

Pinion

Shaft

45—

Differential

Case

47— Bolts

48— Nut

49—

Oil

Seal and Backing Ring

50—

Thrust

Washer

51— Snap Ring

52— Stop Bolt

53— Nut 54—

Bearing

Cup

55—

Cone

and Rollers

56—

Gasket

checked, making sure it is clean and open.

The

front wheel bearings should be checked every

12,000

miles. Refer to Section Q. Front wheel toe-

in

is adjustable by lengthening or shortening the

tie rod. However, standard caster and camber of

the front

wheels

are built

into

the axle. Wheel

caster can be adjusted by placing tapered shim

plates or

wedges

between

the springs and spring

seats

welded to the axle housing. Steering

geometry

and

front wheel adjustments are discussed in Sec tion O.

The

axle housing should be checked periodically

for weld cracks and/or other damage that may cause misalignment of the front

wheels

or

loss

of lubricant. The spring clips (U-bolts) should be

inspected and torqued every

12,000

miles. Torque (spring clip) nuts 45 to 50 lb-ft. [6,2 a 6,9 kg-m.].

M-4. FRONT

AXLE

REMOVAL

a.

Raise front end of vehicle

arid

safely support the frame by placing stands under the frame at

the rear of the front spring rear hangers.

b. Place

jack

under front axle housing and relieve

axle

weight

from the springs.

c. Disconnect shock absorbers from spring clip plates.

FIG.

M-3—HUB

CAP

PULLER

d.

Disconnect steering link from tie rod socket-

joint assembly.

e. Disconnect hydraulic brake

hoses

from front

brake

lines. Disconnect

hoses

from frame brackets. 278

Page 282 of 376

FRONT

AXLE

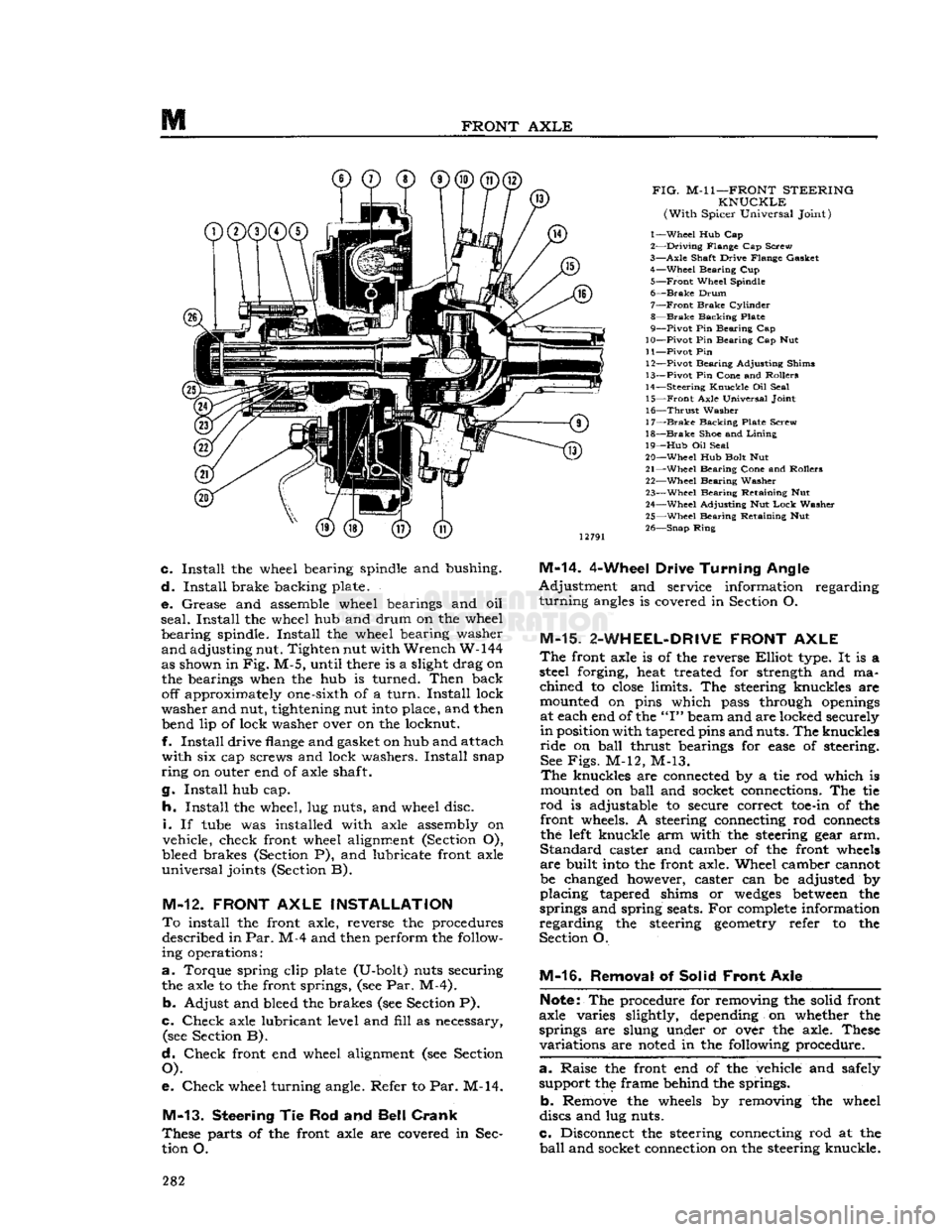

FIG.

M-l

1—FRONT

STEERING

KNUCKLE

(With

Spicer Universal Joint)

1—

Wheel

Hub Cap

2—

Driving

Flange Cap Screw

3—

Axle

Shaft Drive Flange Gasket 4—

Wheel

Bearing Cup

5—

Front

Wheel Spindle

6—

Brake

Drum

7—

Front

Brake

Cylinder

8—

Brake

Backing Plate

9—

Pivot

Pin Bearing Cap

10—

Pivot

Pin Bearing Cap Nut

11—

Pivot

Pin 12—

Pivot

Bearing Adjusting Shims

13—

Pivot

Pin Cone and Rollers

14—

Steering

Knuckle

Oil Seal 15—

Front

Axle Universal Joint

16—

Thrust

Washer

17—

Brake

Backing Plate Screw

18—

Brake

Shoe and

Lining

19—

Hub

Oil Seal

20—

Wheel

Hub Bolt Nut

21—

Wheel

Bearing Cone and Rollers 22—

Wheel

Bearing Washer

23—

Wheel

Bearing Retaining Nut

24—

Wheel

Adjusting Nut

Lock

Washer

25—

Wheel

Bearing Retaining Nut

26—

Snap

Ring

c.

Install

the wheel bearing spindle and bushing.

d.

Install

brake backing plate.

e.

Grease and assemble wheel bearings and oil

seal.

Install

the wheel hub and drum on the wheel

bearing

spindle.

Install

the wheel bearing washer

and

adjusting nut. Tighten nut with

Wrench

W-144

as shown in

Fig.

M-5, until there is a slight drag on the bearings when the hub is turned.

Then

back off approximately one-sixth of a

turn.

Install

lock

washer

and nut, tightening nut

into

place, and then bend lip of lock washer over on the locknut.

f.

Install

drive

flange

and gasket on hub and attach

with

six cap screws and lock washers.

Install

snap

ring

on outer end of axle shaft.

g.

Install

hub cap.

h.

Install

the wheel, lug nuts, and wheel disc.

i.

If

tube

was installed with axle assembly on

vehicle, check front wheel alignment (Section O),

bleed brakes (Section P), and lubricate front axle

universal

joints (Section B).

M-12.

FRONT

AXLE

INSTALLATION

To

install the front axle, reverse the procedures described in

Par.

M-4 and then perform the follow

ing operations:

a.

Torque spring clip plate (U-bolt) nuts securing the axle to the front springs, (see Par. M-4).

b.

Adjust and bleed the brakes (see Section P).

c.

Check

axle lubricant level and

fill

as necessary, (see Section B).

d.

Check

front end wheel alignment (see Section

O).

e.

Check

wheel turning angle. Refer to Par. M-14.

M-13.

Steering

Tie Rod and

Bell Crank

These

parts of the front axle are covered in Sec

tion O.

M-14.

4-Wheel Drive

Turning

Angle

Adjustment

and service information regarding

turning

angles

is covered in Section O.

M-15.

2-WHEEL-DRIVE

FRONT

AXLE

The

front axle is of the reverse

Elliot

type. It is a

steel forging, heat treated for strength and ma

chined

to

close

limits. The steering knuckles are

mounted on pins which pass through

openings

at each end of the

"I"

beam and are locked securely

in

position with tapered pins and nuts. The knuckles

ride

on

ball

thrust bearings for

ease

of steering. See

Figs.

M-12, M-13.

The

knuckles are connected by a tie rod which is

mounted on

ball

and socket connections. The tie

rod

is adjustable to secure correct

toe-in

of the front wheels. A steering connecting rod

connects

the

left

knuckle arm with the steering gear arm.

Standard

caster and camber of the front

wheels

are

built

into

the front axle. Wheel camber cannot

be changed however, caster can be adjusted by

placing

tapered shims or

wedges

between

the

springs and spring seats. For

complete

information

regarding

the steering

geometry

refer to the

Section O.

M-16.

Removal of Solid

Front

Axle

Note:

The procedure for removing the solid front

axle varies slightly, depending on whether the

springs are slung under or over the axle. These

variations

are

noted

in the following procedure.

a. -

Raise the front end of the vehicle and safely support the frame behind the springs.

b.

Remove the

wheels

by removing the wheel

discs and lug nuts.

c.

Disconnect the steering connecting rod at the

ball

and socket connection on the steering knuckle. 282

Page 318 of 376

o

STEERING

SYSTEM

10

FIG.

0-7—STEERING

CONNECTING

ROD

(DRAG

LINK)

10696

1—Cotter Pin

2>—Large

Plug

3—

Ball

Seat

4—

Ball

Seat Spring 5—

Spring

Plug

shaft,

tightness

of the steering gear in the frame,

tightness

of steering gear arm, adjustment of the

steering connecting rod and condition of the steer ing tie rod

ball

joint ends. Adjust the steering con

necting rod (drag

link)

to maximum safe

tightness

at both ends. Examine the steering beilcrank bearings, the shaft in the mounting bracket, and

the mounting bracket on the frame cross member,

k.

Check

front axle caster.

This

should be the same

on both sides, otherwise a locking brake may be

indicated

causing a twisting action of the axle.

Correct

caster is shown in specifications at the end

of this section.

I.

Check

the front wheel toe-in. See Specifications,

m.

Check

wheel

toe-out

on turns.

This

gives

you

an

indication of the proper angularity of the steer

ing knuckle arms and tells whether or not they have been bent and require replacing. These may be checked by comparing them with new parts. If

an

arm is bent, check for a bent tie rod.

n.

Check

wheel camber.

This

should be the same

on both wheels as shown on the Specifications,

o.

Check

the king pin inclination. See Specifica tions.

p.

Check

the tracking of the front axle and frame

alignment, which may be incorrect due to an accident.

0-14.

STEERING

LINKAGE

SERVICE

The

steering linkage must maintain constant toe-

in

and

good

steering control under all driving

conditions.

This

requires

ball

joints at each end

of the tie rods and steering connecting rod. All

joints in the steering linkage must be kept well

lubricated

for easy operation and long life. Should

the joints be worn, allowing excessive free motion

in

the linkage, the joints must be replaced. When

ever

ball

joints are replaced, toe-in must be reset. Because

some

members of the steering system may

have

become

bent or distorted, a periodic inspection

should be made.

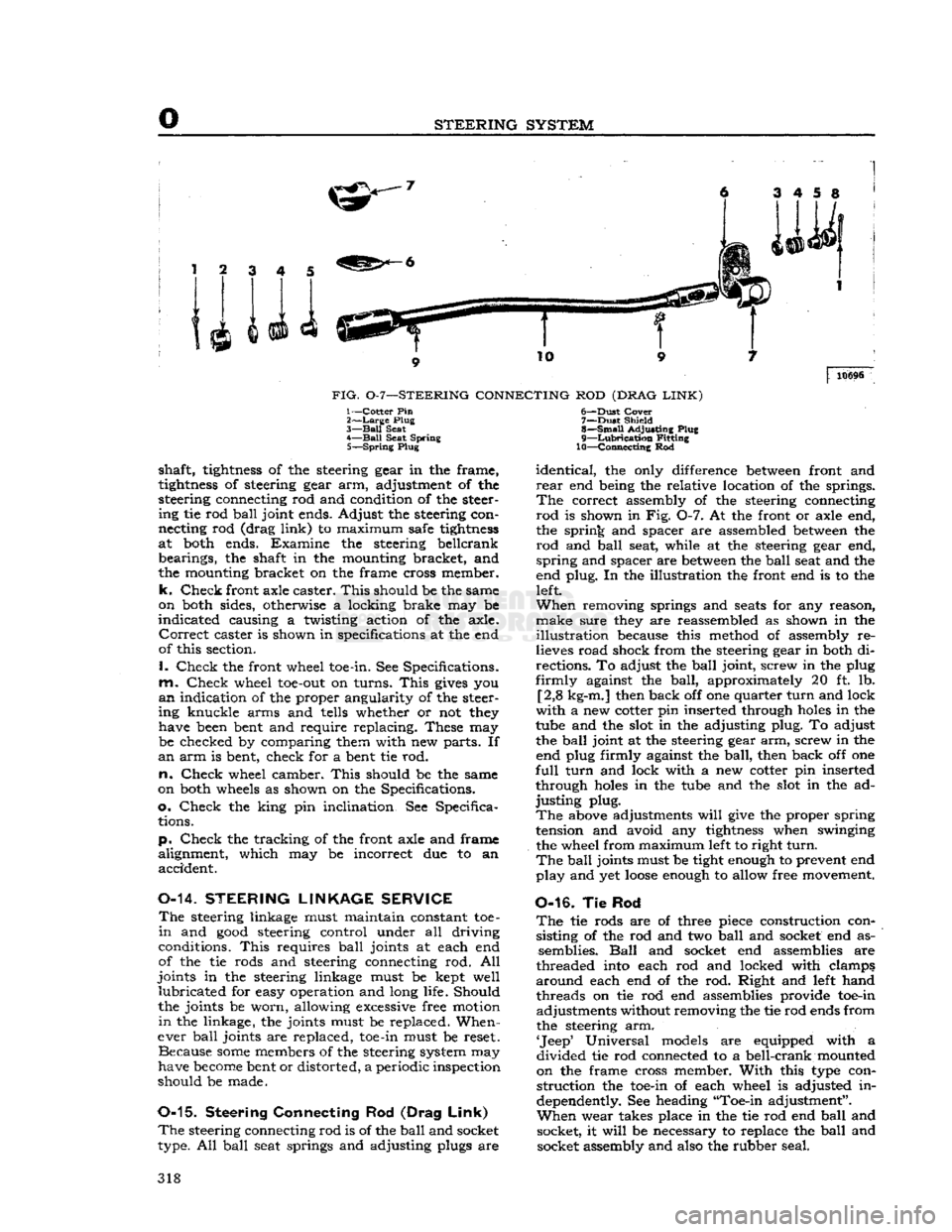

0-15.

Steering Connecting

Rod

(Drag

Link)

The

steering connecting rod is of the

ball

and socket

type. All

ball

seat springs and adjusting plugs are 6—

-Dust

Cover

7—

Dust

Shield

8—

Small

Adjusting Plug

9—

Lubrication

Fitting

10—Connecting Rod

identical,

the only difference

between

front and

rear

end being the relative location of the springs.

The

correct assembly of the steering connecting

rod

is shown in Fig. 0-7. At the front or axle end,

the spring and spacer are assembled

between

the

rod

and

ball

seat, while at the steering gear end,

spring

and spacer are

between

the

ball

seat and the

end plug. In the illustration the front end is to the left.

When

removing springs and

seats

for any reason,

make

sure they are reassembled as shown in the

illustration

because this method of assembly re

lieves road shock from the steering gear in both di

rections. To adjust the

ball

joint, screw in the plug

firmly

against the

ball,

approximately 20 ft. lb. [2,8 kg-m.] then back off one quarter

turn

and lock

with

a new cotter pin inserted through

holes

in the

tube and the slot in the adjusting plug. To adjust the

ball

joint at the steering gear arm, screw in the end plug firmly against the

ball,

then back off one

full

turn

and lock with a new cotter pin inserted

through

holes

in the tube and the slot in the ad

justing

plug.

The

above adjustments

will

give

the proper spring

tension and avoid any

tightness

when swinging

the wheel from maximum left to right

turn.

The

ball

joints must be tight enough to prevent end

play

and yet

loose

enough to allow free movement.

0-16. Tie Rod

The

tie rods are of three piece construction consisting of the rod and two

ball

and socket end as semblies.

Ball

and socket end assemblies are

threaded into each rod and locked with clamps,

around

each end of the rod. Right and left hand threads on tie rod end assemblies provide toe-in adjustments without removing the tie rod ends from

the steering arm.

'Jeep'

Universal models are equipped with a

divided

tie rod connected to a bell-crank mounted

on the frame cross member.

With

this type con

struction

the toe-in of each wheel is adjusted in

dependently. See heading "Toe-in adjustment".

When

wear takes place in the tie rod end

ball

and socket, it

will

be necessary to replace the

ball

and socket assembly and also the rubber seal. 318

Page 331 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

P

f. On vehicles without a transmission brake hold

the brake

shoes

in their relative position and

engage

the parking brake cable

into

the parking

brake

lever.

g. On vehicles without a transmission brake in

stall

the parking brake strut and spring

between

the parking brake lever and the primary

shoe.

h.

Place the brake

shoes

on the backing plate and

install

the retainer pins, springs and retainers.

i.

Install the anchor pin plate.

j.

Install the lever and

sleeve

on the primary

shoe

then install the secondary return spring, then the

primary

return spring.

Important:

A

"L"

or "R" is located on the hex

agon

side of the lever crank for identification. The

lever crank marked "R" applies to the primary

shoe

on the

left

rear brake assembly. The lever

crank

marked

"L"

applies to the primary

shoe

on

the right rear brake assembly.

k. Place the upper linkage rod in the

groove

of the

anchor pin and

engage

the hook of the link rod

into

the adjusting lever.

I.

Install the brake drum. Install the wheel and

tire

assembly.

m. Adjust the brakes as described

below.

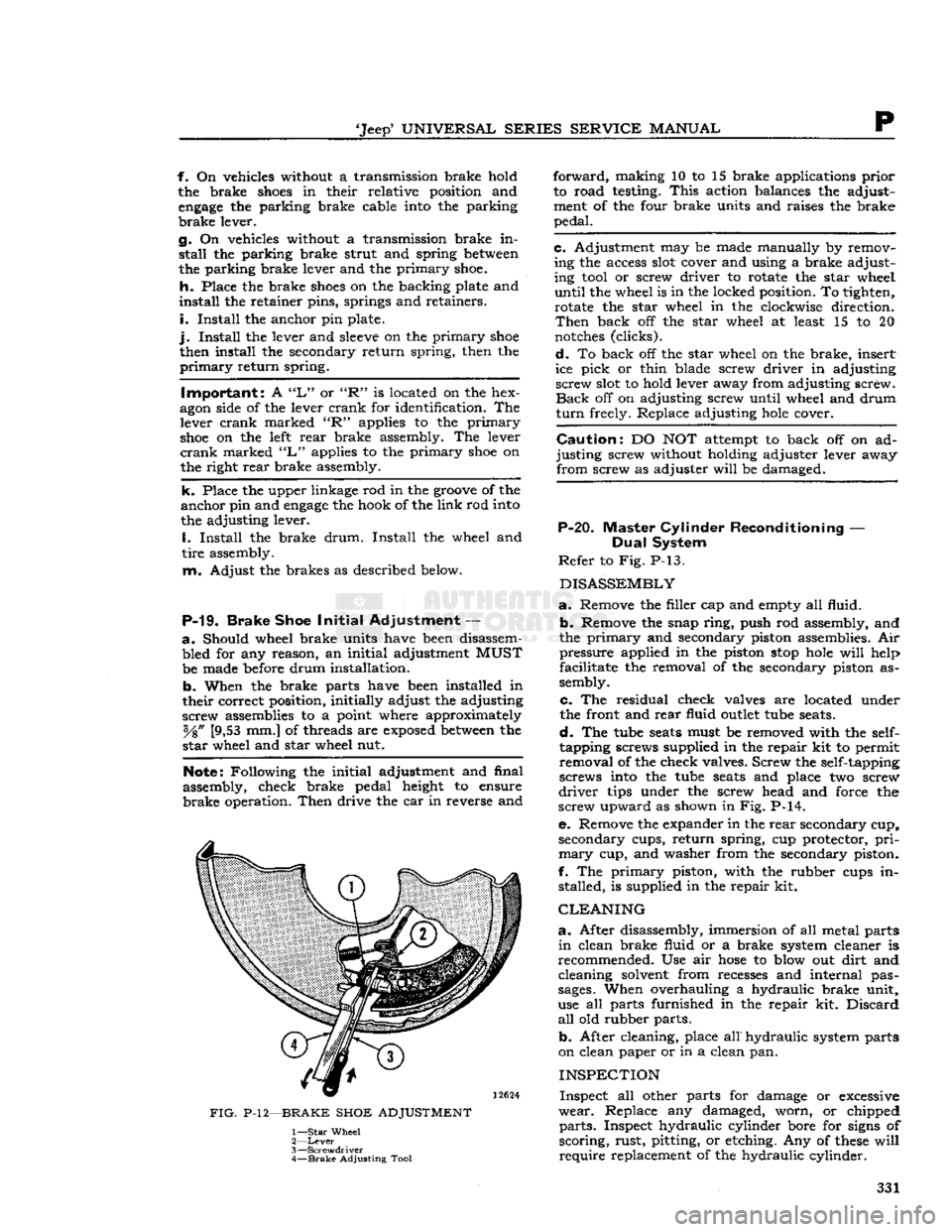

P-19.

Brake

Shoe

Initial

Adjustment —

a.

Should wheel brake units have

been

disassem bled for any reason, an initial adjustment

MUST

be made

before

drum installation.

b.

When the brake parts have

been

installed in

their correct position, initially adjust the adjusting

screw assemblies to a point where approximately Y% [9,53 mm.] of threads are

exposed

between

the

star

wheel and star wheel nut.

Note:

Following the initial adjustment and final

assembly, check brake pedal height to ensure

brake

operation. Then drive the car in reverse and

FIG.

P-12—BRAKE SHOE ADJUSTMENT

1—

Star

Wheel

2—

Lever

3—

Screwdriver

4—

Brake

Adjusting Tool

forward,

making 10 to 15 brake applications prior

to road testing.

This

action balances the adjust

ment of the four brake units and raises the brake

pedal.

c. Adjustment may be made manually by removing the access

slot

cover and using a brake adjust

ing

tool

or screw driver to rotate the star wheel

until

the wheel is in the locked position. To tighten, rotate the star wheel in the clockwise direction.

Then

back off the star wheel at least 15 to 20

notches

(clicks).

d.

To back off the star wheel on the brake, insert

ice pick or thin blade screw driver in adjusting screw

slot

to hold lever away from adjusting screw.

Back

off on adjusting screw until wheel and drum

turn

freely. Replace adjusting

hole

cover.

Caution:

DO NOT attempt to back off on ad

justing screw without holding adjuster lever away from screw as adjuster

will

be damaged.

P-20. Master Cylinder Reconditioning —

Dual

System

Refer

to Fig. P-13.

DISASSEMBLY

a.

Remove the filler cap and empty all fluid.

b.

Remove the snap ring, push rod assembly, and

the primary and secondary piston assemblies. Air pressure applied in the piston

stop

hole

will

help

facilitate the removal of the secondary piston as

sembly.

c. The residual check valves are located under

the front and rear fluid

outlet

tube

seats.

d.

The

tube

seats

must be removed with the

self-

tapping screws supplied in the repair kit to permit removal of the check valves. Screw the self-tapping

screws

into

the

tube

seats

and place two screw

driver

tips under the screw head and force the

screw upward as shown in Fig. P-14.

e. Remove the expander in the rear secondary cup, secondary cups, return spring, cup protector,

pri

mary

cup, and washer from the secondary piston.

f. The primary piston, with the rubber cups in stalled, is supplied in the repair kit.

CLEANING

a.

After disassembly, immersion of all metal parts

in

clean brake fluid or a brake system cleaner is

recommended. Use air

hose

to blow out dirt and cleaning solvent from recesses and internal pas

sages.

When overhauling a hydraulic brake unit,

use all parts furnished in the repair kit. Discard

all

old rubber parts.

b.

After cleaning, place

all"

hydraulic

system parts

on clean paper or in a clean pan.

INSPECTION

Inspect all other parts for damage or

excessive

wear.

Replace any damaged, worn, or chipped

parts.

Inspect hydraulic cylinder bore for

signs

of

scoring, rust, pitting, or etching. Any of

these

will

require

replacement of the hydraulic cylinder. 331