seats JEEP CJ 1953 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 332 of 376

BRAKES

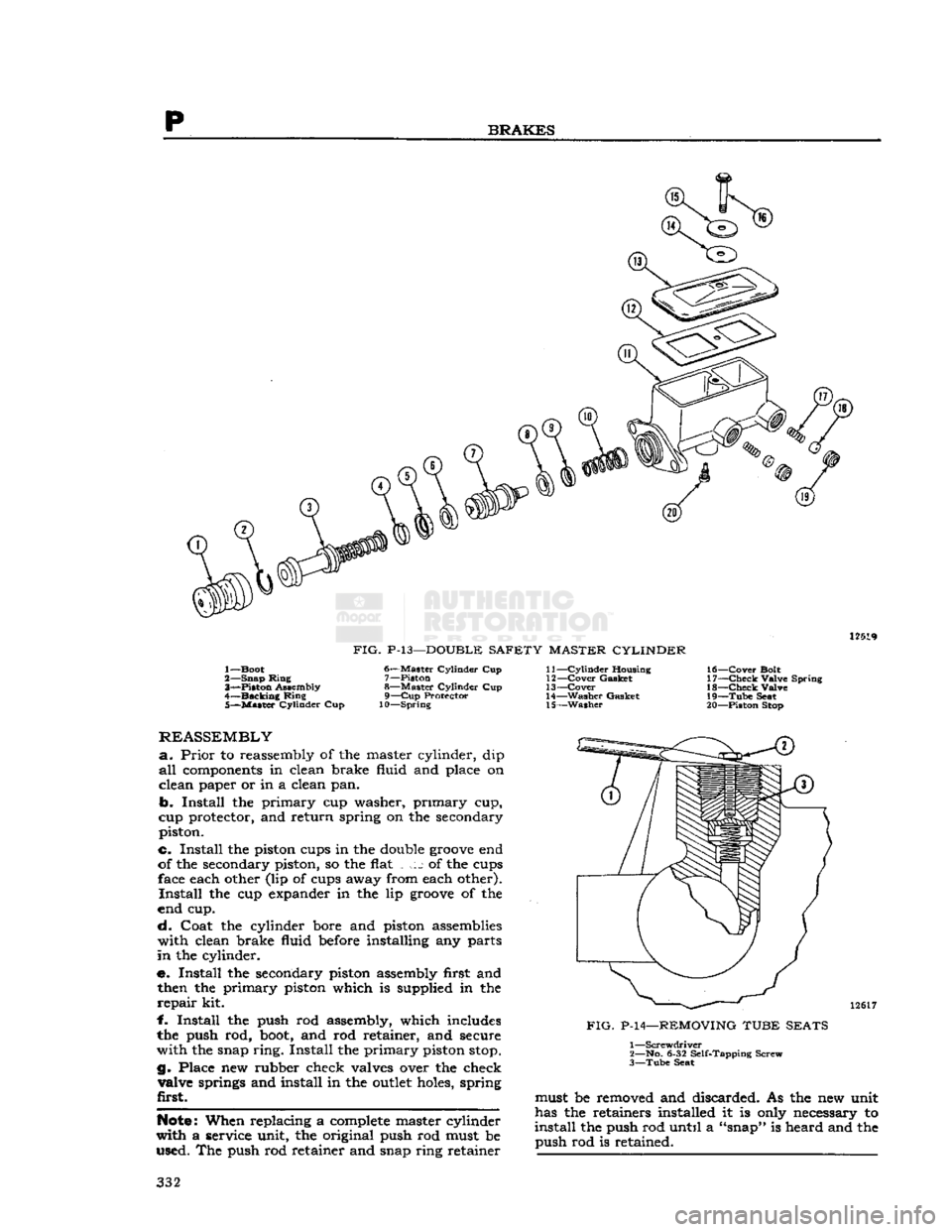

12519

FIG.

P-13—DOUBLE

SAFETY MASTER CYLINDER

1— Boot

2— Snap Ming 3"*—Piston Assembly

4—

Backing

Ring 5—

Master

Cylinder Cup 6—

Master

Cylinder Cup

7— Piston

8—

Master

Cylinder Cup 9—

Cup

Protector

10—Spring 11—

Cylinder

Housing

12—

Cover

Gasket

13—

Cover

14—

Washer

Gasket 15—

Washer

16—

Cover

Bolt

17—

Check

Valve Spring 18—

Check

Valve

19—

Tube

Seat

20— Piston Stop

REASSEMBLY

a.

Prior

to reassembly of the master cylinder, dip

all

components

in clean brake fluid and place on

clean paper or in a clean pan.

b.

Install the primary cup washer, primary cup,

cup protector, and return spring on the secondary piston.

c. Install the piston cups in the double

groove

end

of the secondary piston, so the flat j of the cups face each other (lip of cups away from each other).

Install

the cup expander in the lip

groove

of the

end cup.

cL

Coat the cylinder bore and piston assemblies with clean brake fluid

before

installing any parts

in

the cylinder.

e. Install the secondary piston assembly first and then the primary piston which is supplied in the

repair

kit.

f.

Install the push rod assembly, which includes

the push rod,

boot,

and rod retainer, and secure

with the snap ring. Install the primary piston

stop.

g. Place new rubber check valves over the check valve springs and install in the

outlet

holes, spring

first.

Note:

When replacing a

complete

master cylinder

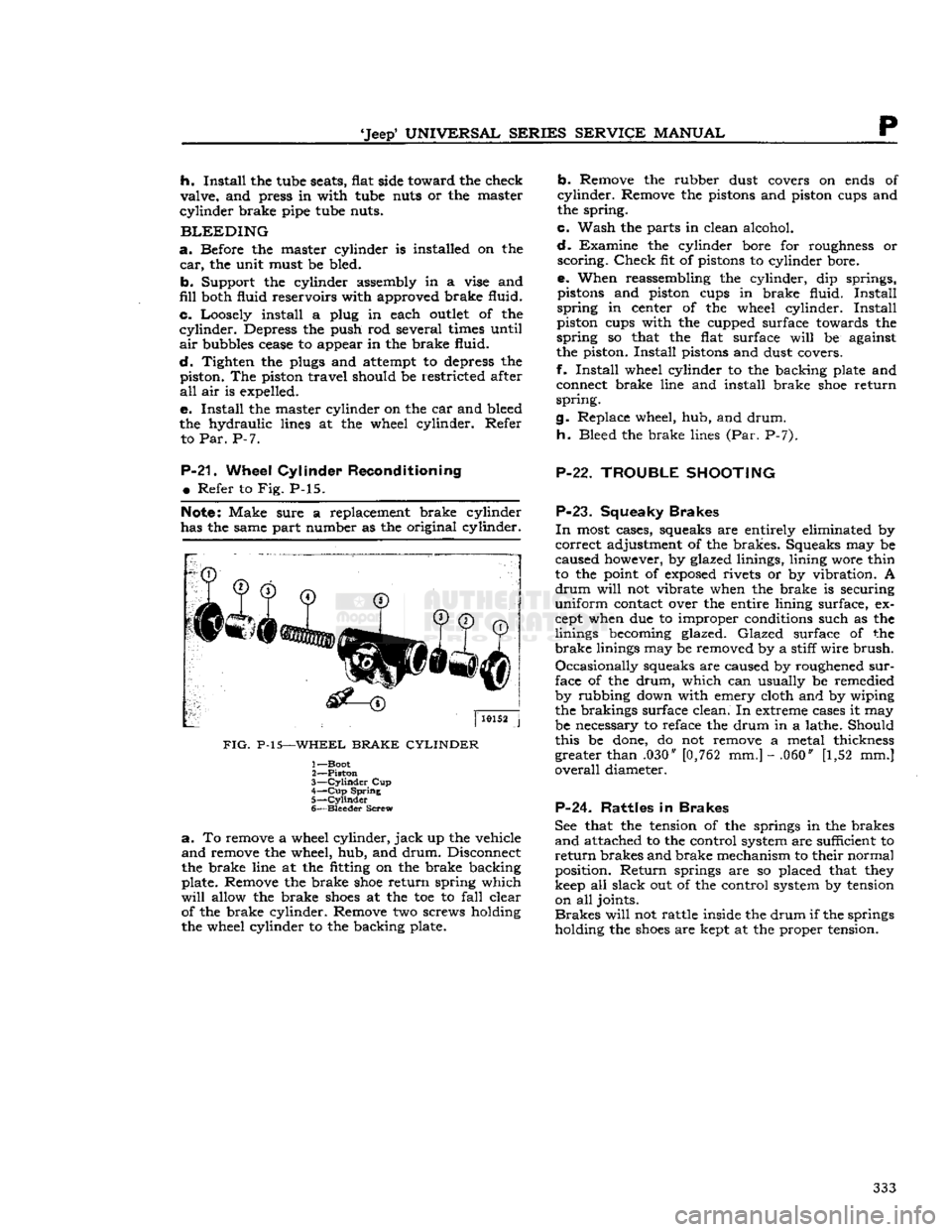

with a service unit, the original push rod must be used. The push rod retainer and snap ring retainer 12617

FIG.

P-14—REMOVING TUBE SEATS 1

—Screwdriver

2— No. 6-32 Self-Tapping Screw

3—

Tube

Seat must be removed and discarded. As the new unit

has the retainers installed it is only necessary to

install

the push rod until a "snap" is heard and the push rod is retained. 332

Page 333 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

P h.

Install

the tube seats, flat side toward the check

valve,

and press in with tube nuts or the master

cylinder

brake pipe tube nuts.

BLEEDING

a.

Before the master cylinder is installed on the

car,

the unit must be bled.

b.

Support the cylinder assembly in a vise and

fill

both fluid reservoirs with approved brake fluid,

e.

Loosely install a plug in each

outlet

of the

cylinder.

Depress the push rod several times until

air

bubbles cease to appear in the brake fluid.

d.

Tighten the plugs and attempt to depress the piston. The piston travel should be restricted after

all

air is expelled.

e.

Install

the master cylinder on the car and bleed

the hydraulic lines at the wheel cylinder. Refer to

Par.

P-7.

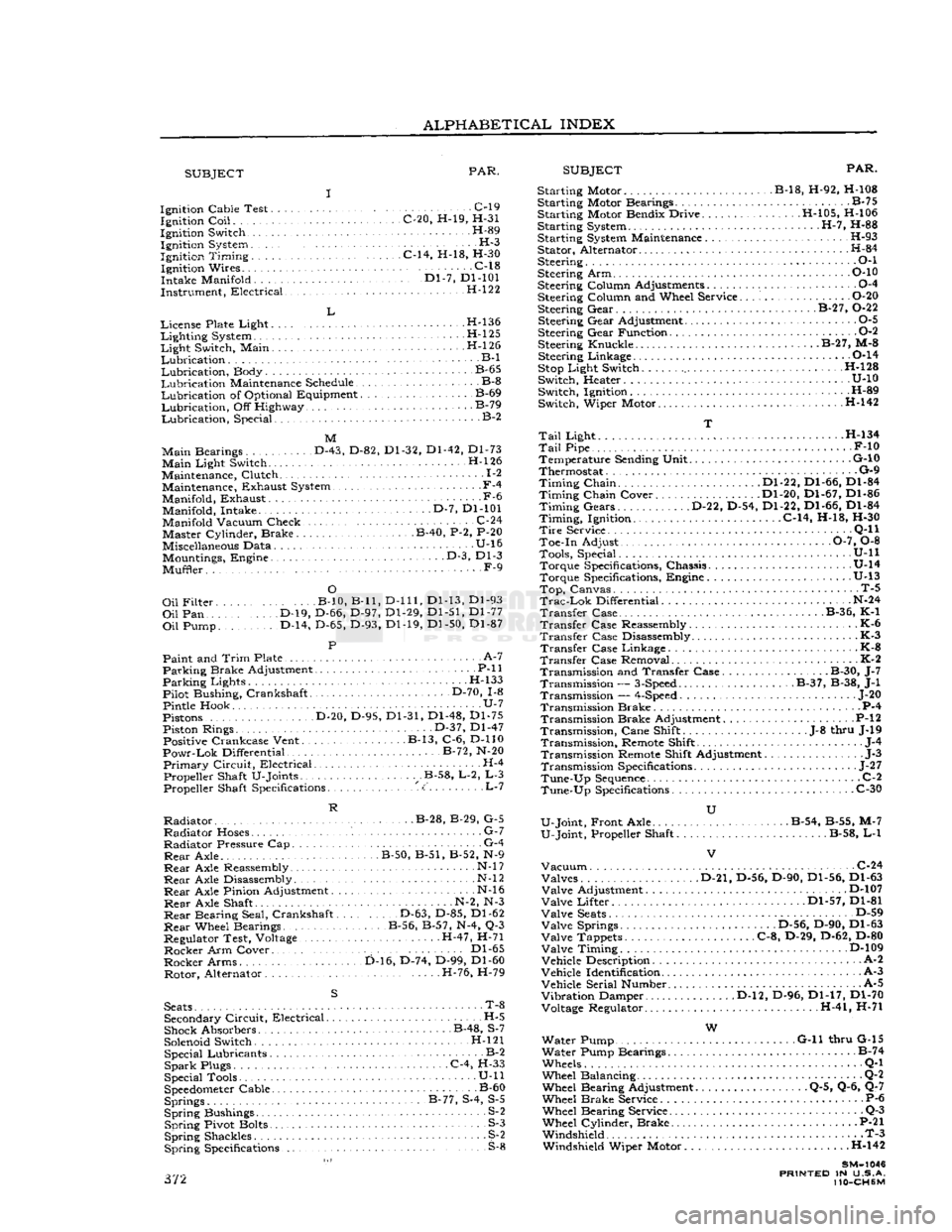

P-21.

Wheel

Cylinder

Reconditioning

•

Refer to Fig. P-15.

Note:

Make sure a replacement brake cylinder

has the same part number as the original cylinder.

FIG.

P-15—WHEEL

BRAKE CYLINDER

1— Boot

2—

Piston

3—

Cylinder

Cup

4—

Cup

Spring

5—

Cylinder

6—

Bleeder

Screw

a.

To remove a wheel cylinder,

jack

up the vehicle

and

remove the wheel, hub, and

drum.

Disconnect

the brake line at the fitting on the brake backing

plate. Remove the brake

shoe

return spring which

will

allow the brake

shoes

at the toe to

fall

clear of the brake cylinder. Remove two screws holding

the wheel cylinder to the backing plate.

b.

Remove the rubber dust covers on ends of

cylinder.

Remove the pistons and piston cups and

the spring.

c.

Wash the parts in clean alcohol.

d.

Examine the cylinder bore for roughness or

scoring.

Check

fit of pistons to cylinder bore.

e. When reassembling the cylinder, dip springs, pistons and piston cups in brake fluid.

Install

spring

in center of the wheel cylinder.

Install

piston cups with the cupped surface towards the

spring

so that the flat surface

will

be against

the piston.

Install

pistons and dust covers.

f.

Install

wheel cylinder to the backing plate and connect brake line and install brake

shoe

return

spring.

g. Replace wheel, hub, and

drum.

h.

Bleed the brake lines (Par. P-7).

P-22. TROUBLE

SHOOTING

P-23.

Squeaky

Brakes

In

most cases, squeaks are entirely eliminated by

correct

adjustment of the brakes. Squeaks may be

caused however, by glazed linings, lining wore thin

to the point of

exposed

rivets or by vibration. A

drum

will

not vibrate when the brake is securing

uniform

contact over the entire lining surface, ex

cept when due to improper conditions such as the

linings becoming glazed.

Glazed

surface of the

brake

linings may be removed by a stiff

wire

brush.

Occasionally

squeaks are caused by roughened

sur

face of the

drum,

which can usually be remedied

by rubbing down with emery cloth and by wiping

the brakings surface clean. In extreme cases it may

be necessary to reface the drum in a lathe. Should

this be done, do not remove a metal thickness greater than .030" [0,762 mm.] - .060" [1,52 mm.]

overall

diameter.

P-24. Rattles

in

Brakes

See that the tension of the springs in the brakes

and

attached to the control system are sufficient to

return

brakes and brake mechanism to their normal

position.

Return

springs are so placed that they

keep all slack out of the control system by tension on all joints.

Brakes

will

not rattle inside the

drum

if the springs

holding the

shoes

are kept at the proper tension. 333

Page 372 of 376

ALPHABETICAL

INDEX

SUBJECT

PAR.

SUBJECT

PAR.

Ignition Cable Test C-l9 Ignition

Coil

C-20, H-19, H-31

Ignition Switch H-89 Ignition System H-3

Ignition

Timing

C-14, H-18, H-30 Ignition Wires C-18

Intake Manifold '." Dl-7, Dl-101

Instrument, Electrical H-122

L

License Plate Light H-l36

Lighting

System H-l25

Light

Switch, Main . H-l 26

Lubrication

B-l

Lubrication,

Body B-65

Lubrication

Maintenance Schedule B-8

Lubrication

of Optional Equipment B-69

Lubrication,

Off Highway B-79

Lubrication,

Special. B-2

M

Main

Bearings D-43, D-82, Dl-32, Dl-42, Dl-73

Main

Light Switch. H-l26

Maintenance, Clutch 1-2 Maintenance, Exhaust System.,

-

F-4

Manifold, Exhaust -F-6 Manifold, Intake D-7, Dl-101

Manifold Vacuum Check. .C-24 Master Cylinder, Brake B-40, P-2, P-20

Miscellaneous Data U-16 Mountings, Engine • • •

-

D-3, Dl-3

Muffler. F-9

O

Oil

Filter B-10, B-ll,

D-lll,

Dl-13, Dl-93

Oil

Pan D-19, D-66, D-97, Dl-29, Dl-51, Dl-77

Oil

Pump. D-14, D-65, D-93, Dl-19, Dl-50, Dl-87

P

Paint and

Trim

Plate • • A-7

Parking

Brake Adjustment P-ll

Parking

Lights H-133

Pilot Bushing, Crankshaft D-70, 1-8

Pintle Hook U-7

Pistons D-20, D-95, Dl-31, Dl-48, Dl-75 Piston Rings. • • •

•

D-37, Dl-47 Positive Crankcase Vent. B-13, C-6, D-110

Powr-Lok

Differential B-72, N-20

Primary

Circuit,

Electrical H-4 Propeller Shaft U-Joints .B-58, L-2, L-3 Propeller Shaft Specifications <:' L-7

R

Radiator

B-28, B-29, G-5

Radiator

Hoses. G-7

Radiator

Pressure Cap G-4

Rear

Axle. B-50, B-51, B-52, N-9

Rear

Axle Reassembly • N-l

7

Rear

Axle Disassembly N-l

2

Rear

Axle Pinion Adjustment N-l6

Rear

Axle Shaft N-2, N-3

Rear

Bearing Seal, Crankshaft D-63, D-85, Dl-62

Rear

Wheel Bearings B-56, B-57, N-4, Q-3

Regulator Test, Voltage H-47, H-71

Rocker

Arm Cover.. . Dl-65

Rocker

Arms D-16, D-74, D-99, Dl-60 Rotor, Alternator H-76, H-79

S

Seats

• T-8 Secondary

Circuit,

Electrical H-5

Shock Absorbers B-48, S-7

Solenoid Switch. H-l21 Special Lubricants B-2

Spark

Plugs C-4, H-33

Special Tools • U-ll

Speedometer

Cable B-60 Springs B-77, S-4, S-5

Spring

Bushings S-2

Spring

Pivot Bolts S-3

Spring

Shackles S^2

Spring

Specifications S-8 372 Starting Motor B-18, H-92, H-108

Starting Motor Bearings B-75

Starting Motor Bendix Drive H-105, H-106

Starting System H-7, H-88

Starting System Maintenance H-93 Stator, Alternator H-84

Steering • • •

•

O-l

Steering Arm P-10

Steering Column Adjustments 0-4

Steering Column and Wheel Service O-20 Steering Gear. . B-27, 0-22

Steering Gear Adjustment 0-5

Steering Gear Function 0-2

Steering Knuckle. B-27, M-8 Steering Linkage 0-14

Stop

Light Switch H-128

Switch, Heater U-10 Switch, Ignition H-89

Switch, Wiper Motor H-142

T

Tail

Light . H-134

Tail

Pipe F-10 Temperature Sending Unit G-10

Thermostat G-9

Timing

Chain Dl-22, Dl-66, Dl-84

Timing

Chain Cover Dl-20, Dl-67, Dl-86

Timing

Gears D-22, D-54, Dl-22, Dl-66, Dl-84

Timing,

Ignition. C-14, H-18, H-30

Tire

Service . •

•

Q-l

1

Toe-in Adjust 0-7, 0-8 Tools, Special. . .

........

U-ll Torque Specifications, Chassis U-14

Torque Specifications, Engine .U-13

Top,

Canvas. T-5

Trac-Lok

Differential N-24

Transfer

Case B-36, K-1

Transfer

Case Reassembly K-6

Transfer

Case Disassembly K-3

Transfer

Case Linkage - K-8

Transfer

Case Removal K-2 Transmission and Transfer Case. B-30, J-7 Transmission —

3-Speed

B-37, B-38, J-l

Transmission —

4-Speed

... J-20

Transmission Brake P-4 Transmission Brake Adjustment P-l

2

Transmission,

Cane Shift .J-8 thru J-19

Transmission,

Remote Shift J-4

Transmission Remote Shift Adjustment J-3

Transmission Specifications

-

J-27

Tune-Up

Sequence

C-2

Tune-Up

Specifications C-30

U

U-Joint, Front Axle . . B-54, B-55, M-7

U-Joint, Propeller Shaft B-58, L-l

Vacuum

C-24 Valves D-21, D-56, D-90, Dl-56, Dl-63

Valve

Adjustment D-107

Valve

Lifter Dl-57, Dl-81

Valve

Seats

D-59

Valve

Springs .D-56, D-90, Dl-63

Valve

Tappets C-8, D-29, D-62, D-80

Valve

Timing D-109

Vehicle Description A-2

Vehicle Identification A-3

Vehicle Serial Number. A-5

Vibration

Damper D-l2, D-96, Dl-17, Dl-70 Voltage Regulator. H-41, H-71

W

Water Pump G-ll thru G-15

Water Pump Bearings B-74

Wheels Q-l

Wheel Balancing Q-2 Wheel Bearing Adjustment Q-5, Q-6, Q-7

Wheel Brake Service P-6 Wheel Bearing Service Q-3

Wheel Cylinder, Brake P-21 Windshield T-3 Windshield Wiper Motor . .H-142

SM-1046

PRINTED

IN U.S.A.

110-CH6M