weight JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 62 of 376

D

HURRICANE

F4

ENGINE d.

Remove the intake valve adjusting screw lock-

nuts from each of the rocker arm valve lash ad

justing

screws. Remove the screws from the rocker

arms.

D-76.

Inspection and

Repair

Run

a round wire brush through the bore of the

rocker

arm shaft and clean out the drilled oil holes.

Clean

out the oil

holes

in the rocker arm shaft

brackets,

and the oil

holes

and

grooves

in the bores

of the rocker arm.

Inspect

the diameter of the shaft at the rocker arm

bearing

areas. Replace the shaft if there are scores

or

abrasion marks along the length of the shaft.

Check

the shaft for alignment by rolling it across

a

smooth level surface. If the shaft

will

not

roll

freely, or if it rolls with a bumping motion, the

shaft is out of alignment and must be replaced.

Inspect

the threads of the adjusting screw

hole

in

the rocker arms and if necessary clean with a

proper

size tap. Replace the adjusting screw lock-

nut or the adjusting screw if either part is damaged

or

deformed.

Inspect

the threads in the tapped

hole

in the top

of the rocker arm shaft brackets and if necessary

clean

with a proper size tap. Replace the bracket

if

either side is worn or scored.

D-77.

Reassembly

a.

Install

two rocker arm shaft plugs, one in each

end of the shaft. Slide two

rocker

arm

shaft brackets

onto

the center of the shaft. Align the tapped

holes

in

the brackets with the drilled

holes

in the top of

the shaft and install the rocker arm shaft lock

screws,

making sure the points of the screws enter

the drilled

holes

in the shaft.

b.

Screw the intake valve adjusting screws into

the rocker arms and install the locknuts.

c.

The rocker arms are paired; that is, two of the

arms

are angled to the right and two are angled to

the left. One of each type is used on each end of

the rocker arm shaft. Slide a rocker arm with the

adjusting

screw end of the rocker arm angling

away

from the bracket

onto

the shaft so that the

adjusting

screw is on the same side of the shaft

as the mounting

hole

in the bracket.

d.

Temporarily

secure the end bracket in place by

installing

a rocker arm cover stud in the tapped

opening in the top of the support.

e. Assemble the parts on the

opposite

end of the

rocker

arm shaft repeating

steps

c and d above.

D-78. ENGINE REASSEMBLY

The

engine

reassembly procedure in the following

paragraphs

is given in the sequence to be followed

when the

engine

is being completely overhauled.

Individual

inspection,

repair,

and fitting operations

previously covered in detail are made throughout

the reassembly procedure. The reassembly pro

cedure

does

not cover accessories. If a new cylinder

block

fitted with pistons is used, many of the

operations

will

not be required.

Mount

the cylinder block in an

engine

repair stand.

If

an

engine

stand is not available, perform the fol

lowing reassembly operation in a manner designed to protect personnel against an accident and the

engine

and its parts against damage.

Note:

During

engine

reassembly, use Perfect Seal

Aerosol

Spray

Sealer

Part

No.

994757

on all

engine

gaskets to ensure against vacuum, oil, gasoline and

water

leaks. Apply to head gaskets, valve covers,

water

pumps, oil pan gaskets, radiator and heater

hose

connections, felt gaskets, gasoline and oil line

connections, stud bolts,

spark

plug threads, and

grease retainer washers. Refer to manufacturer's in

structions on container for proper application pro

cedure.

D-79.

Install

Oil

Gallery

Plug

Coat

plug threads with a suitable sealing compound

and

install the plugs in the front and

rear

ends of

the oil gallery in the cylinder block and the

rear

end of the cylinder head. Torque the plugs 20 to 25 lb-ft. [2,8 a 3,4 kg-m.].

There

is also a pipe plug

(}/g,f

[3,2 mm.] slotted, headless) in the opening in the main oil gallery inside the cylinder block at No. 2 cylinder and another pipe plug

(}/g

"

square-head) in the opening

in

the oil passage directly below the oil pump intake

passage. If

these

two pipe plugs were removed,

make

certain they are reinstalled in the locations

described above or the counterweight of the

crankshaft

might strike the projecting head of the

square-head

plug.

D-80.

Install

Tappets

Turn

the block upside down. Beginning at the

rear

end of the cylinder block, install the intake

and

exhaust valve tappets in the tappet bores in the cylinder block in the following order: one

exhaust, two intake, two exhaust, two intake, and

finally

one exhaust valve tappet.

Check

the tappet to bore fit of each tappet as it

is installed in the block. If the stem-to-block

clearance

tolerance of .0005" to .002" [0,0127 a

0,051 mm.] is

exceeded

install a new tappet fitting

within

this tolerance or ream the bore to accomo date the next oversize tappet which is available

in

.004" oversize.

D-81.

Install

Camshaft and

Thrust

Plate

Lubricate

all camshaft bearings and cam surfaces generously with clean, light

engine

oil.

Carefully,

so not to damage or score the camshaft front bear

ing,

install the camshaft, locating it properly in the bearings. Do not allow the

rear

end of the camshaft to strike sharply against the expansion plug

installed

in the

rear

end of the bore.

Install

the camshaft thrust plate. Slide the thrust

plate spacer

onto

the end of the camshaft with the

beveled inner

edge

of the spacer facing the cam

shaft. If the same camshaft is being reinstalled,

install

any shims previously removed. These shims

are

placed

between

the camshaft shoulder and the

spacer.

Torque the thrust plate attaching

bolts

20

to 26 lb-ft. [2,8 a 3,6 kg-m.].

End

play of the camshaft is determined by running

clearance

between

the

rear

face of the camshaft

gear and the thrust plate. The standard clearance 62

Page 67 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

D

Lubricate

the connecting rod bearing surfaces

generously with

engine

oil and install the bearing

cap with the numbered side matched to the num

bered side of the connecting rod. Torque the nuts

evenly 35 to 45 lb-ft. [4,8 a 6,2 kg-m.]. The con

necting rod cap nuts are locked with stamped nuts.

Used

stamped nuts should be discarded and re

placed with new

ones.

These locking stamped nuts

should be installed with the flat face toward the

connecting rod nut.

Turn

the locking nut finger

tight and then 34

turn

more with a wrench. Refer

to Par. D-36 for detailed information on fitting pistons and rings in the cylinder bores.

D-96.

Install

Crankshaft

Pulley

Align

the keyway in the pulley with the woodruff key installed in the crankshaft. Drive the pulley

onto

the crankshaft and secure it in place with

the crankshaft pulley nut. Insert a block of wood

between

one of the counterweights on the

crank

shaft and the side of the cylinder block to prevent the crankshaft from turning, then tighten the nut.

D-97.

Install

Oil Pan

Before installing the oil pan, make a final internal

inspection particularly making certain that the

inside of the cylinder block is clean. Apply a thin

coat of gasket paste on the oil pan. Place the new

oil

pan gasket in position. Set the oil pan in posi

tion on the cylinder block and install the oil pan.

Torque

the attaching

bolts

12 to 15 lb-ft. [1,7 a 2,1

kg-m.].

Install

the oil pan

drain

plug and gasket

and

tighten the plug securely.

D-98.

Install

Cylinder

Head

Make

certain that the entire top of the cylinder

block

assembly, the lower surface of the cylinder

head,

and the cylinder head gasket are clean. Blow

all

dirt

or carbon out of the blind tapped bolt

holes

in

the cylinder block before the cylinder head and gasket are installed. Using aerosol spray sealer

Part

No. 994757, spray a thincoat on both surfaces

of the head gasket, position the new cylinder head gasket with the crimped

edges

of the gasket metal down (See Fig. D-31).

This

gasket position allows a

positive seal along the narrow surfaces of the

cylin

der

head

between

the combustion chambers and

eliminates the possibility of burning combustion

10102

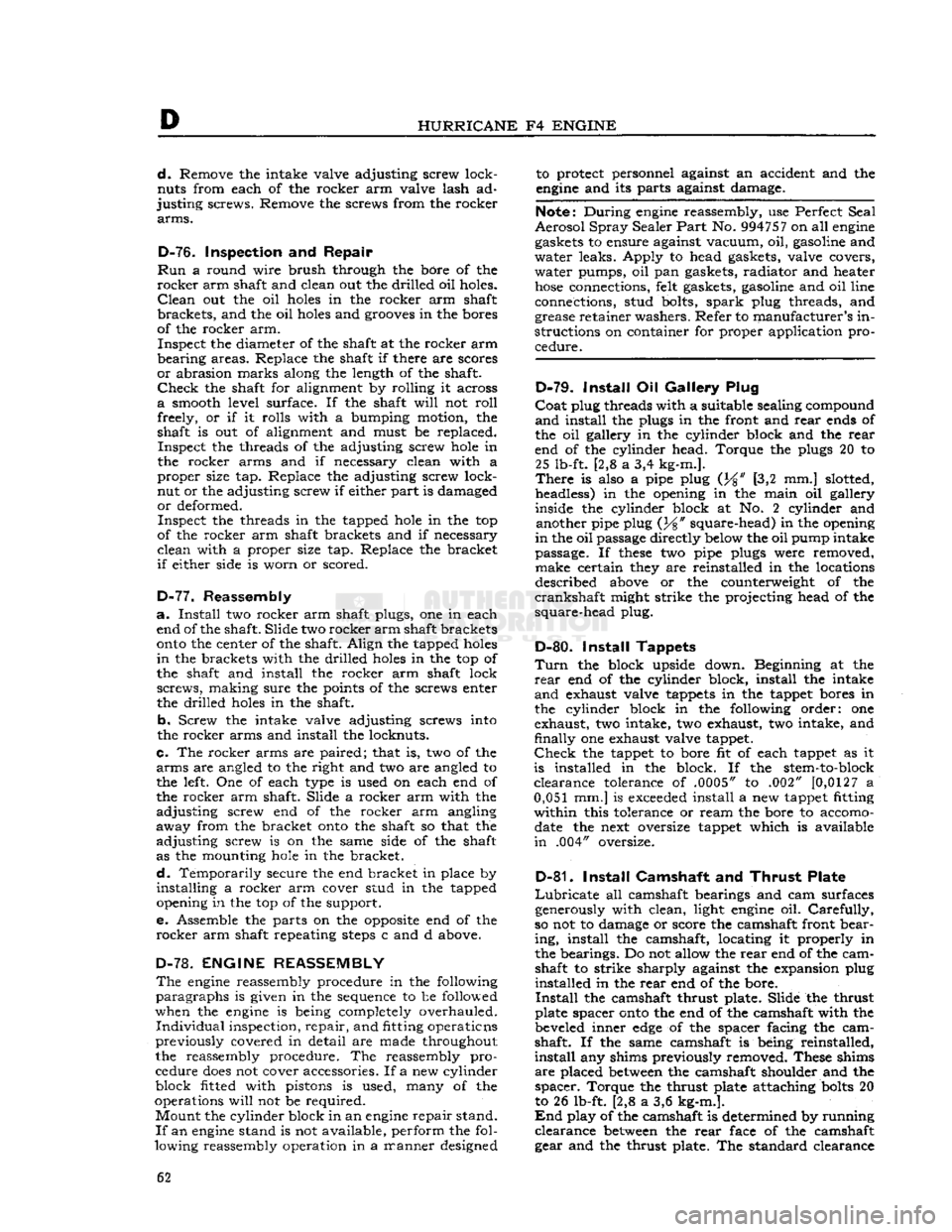

FIG.

D-41—CYLINDER

HEAD

BOLT

TIGHTENING

SEQUENCE

gases

reaching

an

asbestos

portion of the cylinder

head gasket.

Install

the cylinder head bolts. Tighten

the

bolts

with a torque wrench to 60 to 70 lb-ft. 8,3 a 9,7

kg-m.]

in the sequence shown in

Fig.

D-41.

Do not overlook installing the cylinder head bolt

in

the intake

manifold

directly under the

car

buretor

opening.

D-99.

Install

Rocker Arm Assembly

a.

Insert

ball

ends of the intake valve push rods through the cylinder head and cylinder block and

seat them in the cupped head of the intake valve

tappets.

b.

Install

the

rocker-arm

assembly on the 'four

rocker-arm-mounting

studs. Align the rocker arms

so that the

ball

ends of the intake valve tappet

adjusting

screws fit into the cup ends of the push

rods.

c.

Install

the four rocker-arm-attaching nuts.

Thread

each nut down evenly in sequence, one

turn

at a time, until the torque is 30 to 36 lb-ft. [4,1 a 5,0 kg-m.].

d.

Cement a new gasket on the rocker arm cover.

Install

the cover placing an oil seal then a flat

washer

and nut on each cover stud. Cement a new gasket on the exhaust valve cover.

Install

the cover and crankcase ventilation fittings using a

new gasket back of the vent cover and new copper

ring

gaskets under the attaching screw heads.

Torque

the valve tappet cover nuts 7 to 10 lb-ft. [1,0 a 1,4 kg-m.].

D-100.

Install

Distributor and

Spark

Plugs

To

correctly install the distributor, it

will

be neces

sary

to place No. 1 piston in the firing position.

To

locate the firing position of No. 1 piston, first

turn

the

engine

until No. 1 piston is moving up on

the compression stroke as indicated by compression

pressure

being forced through the

spark

plug open

ing.

Turn

the

engine

slowly until the 5° before top

center

mark

on the timing gear cover is in align

ment with the

mark

on the crankshaft pulley. Oil

the distributor housing where it bears on the

cylin

der

block and install the distributor. Mount the

rotor

on distributor shaft and

turn

the shaft until

the rotor points towards No. 1

spark

plug terminal

tower position (when cap is installed, about 5

o'clock) with the contact points just breaking.

Move the rotor back and forth slightly until the

driving

lug on the end of the shaft enters the slot cut in the oil pump gear and slide the distributor

assembly down into place. Rotate the distributor body until the contact points are just breaking.

Install

the hold down screw.

Connect

the core

primary

wire to the distributor.

Clean

and adjust the

spark

plugs, setting the elec

trode

gaps

at .030" [0,762 mm.].

Install

the plugs

to prevent any foreign matter entering the com

bustion chambers during the remaining operations.

Torque

the

spark

plugs 25 to 30 lb-ft. [3,5 a 4,6

kg-m.].

Install

spark

plug cables, placing them in the dis

tributor

cap terminal towers starting with No. 1

and

installing in a counter clockwise direction of

the firing order sequence (1-3-4-2). 67

Page 71 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

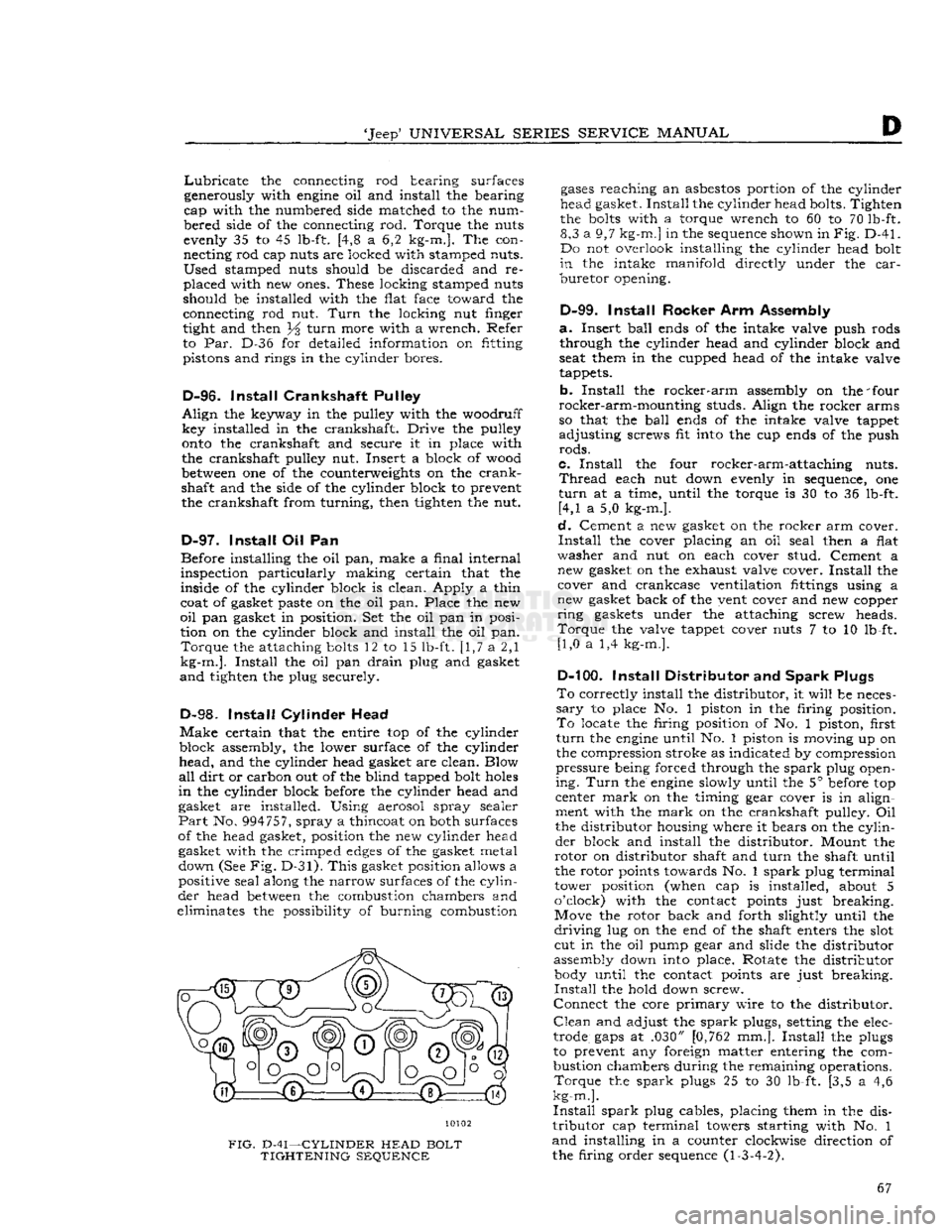

D D-l 13. HURRICANE

F4

ENGINE SPECIFICATIONS

MODEL:

ENGLISH

ENGINE:

Type

Number of Cylinders

Bore

Stroke

Piston Displacement...........

Bore

Spacing (center to center): 1 and 2, 3 and 4

2 and 3

Firing

Order Compression Ratio Compression Pressure... .

Number of Mounting Points:

Front

Rear

Horsepower (SAE)

Horsepower (Max Brake) Maximum Torque @

2000

rpm.

PISTONS:

Material

Description

Length

,.

Diameter (near

bottom

of

skirt).

Weight.

Clearance

Limits:

Piston-To-Cylindcr

Bore

Ring

Groove Depth:

No. 1 and 2 Ring No. 3 Ring

Ring

Groove Width:

No. 1 Ring No. 2 Ring

No. 3 Ring

Piston Pin Hole Bore

Cylinder

Bore — Standard.....

—

max. out of round

F-Head

4

W

134.2 cu. in.

3.437"

4.938"

1-3-4-2

6.7:1

120 to 130 psi.

2

1

15.63

@

4000

rpm. 114 lb-ft. 75

-

max. taper..

-

max. rebore.

PISTON RINGS:

Function:

No. 1 and 2 No. 3. .

Material:

No. 1. .

No. 2 and 3

Width;

No. 1 and 2

No. 3. . . .

Gap

(Std. to .009 Cyl. Bore).

Thickness:

No. 1 and No. 2 Rings....

No. 3 Ring

Side Clearance in Groove:

No. 1 Ring No. 2 Ring

No. 3 Ring

PISTON

PINS:

Material

Length

Diameter

Type

Clearance

in Piston

(selective

fit).

Aluminum

Alloy

Gam

Ground, T-slot, Tin Plated

3.1225*

to

3.1245*

13.5 oz.

Selective Feeler Fit

.1593" to .1655"

.1693" to .1755"

.0955" to .0965" .095" to .096"

1875" to .1885" .760" to .770"

3.125"

to

3.127"

.005" .005" .040"

Compression

Oil

Cast

Iron,

Chrome-plated Face

Cast

Iron

.007" to .017"

.134" to .144" .115" to .125"

.002" to .004"

.0015" to .0035" .001" to .0025"

SAE

1016 Steel

2.781"

.8119"

Locked

in Rod

.0001"

to .0003"

METRIC

7,937

cm.

11,112

cm. 2199 cm*

8,729

cm.

12,542

cm.

8,4 a 9,2 kg-cm2

15,77 kg-m.

9,525

cm.

7,9311

a

7,9362

cm.

382,7

gr.

4,046

a

4,203

mm.

4,300

a

4,457

mm.

2,4257

a

2,4511

mm. 2,413 a

2,438

mm.

4,7625

a

4,7879

mm.

19,304

a

19,558

mm.

7,9375

a

7,9425

cm.

0,1270

mm.

0,1270

mm.

1,0160

mm.

2,38 mm.

4,76 mm.

0,178 a

0,432

mm.

3,403

a

3,657

mm. 2,821 a 3,175 mm.

0,051 a 0,102 mm.

0,038

a

0,088

mm.

0,025

a

0,063

mm.

70,637

mm.

20,6223

mm.

0,0025

a

0,0076

mm. 71

Page 72 of 376

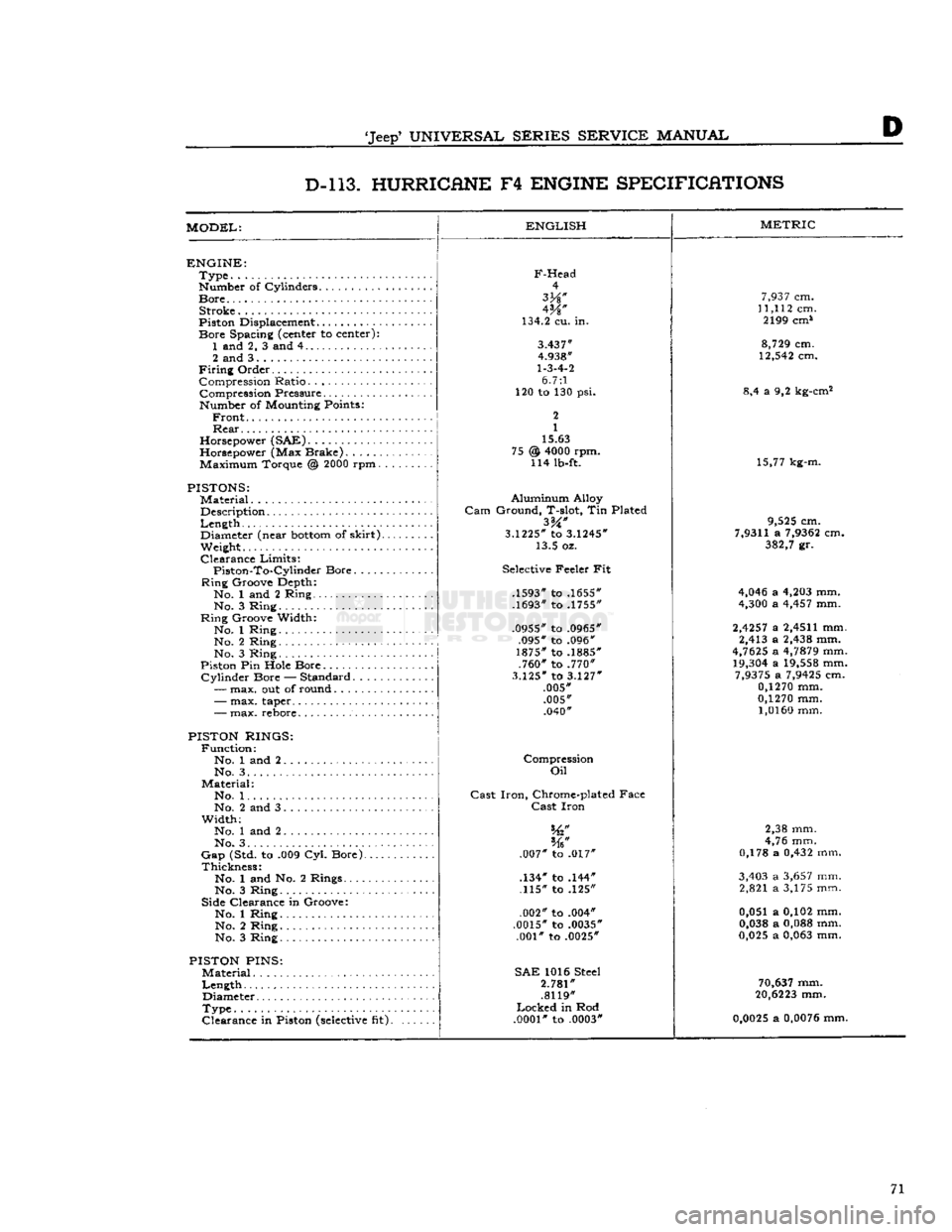

D

HURRICANE

F4

ENGINE

D-l

13

HURRICHNE

F4

ENGINE

SPECIFICATIONS

(Continued)

MODEL:

CONNECTING

RODS:

Material.

Weight

Length

(center to

center)......

Bearing:

Type.

Material

Length

Over

All

Clearance

Limits.

..........

Undersize

Bearings

Available

End

Play

Installation

Bore:

Upper

Lower

CRANKSHAFT:

Material....................

End

Thrust

End

Play

Main

Bearings:

Type.

Material

Clearance

Undersize

Bearings

Available

Journal

Diameter

Bearing

Length:

Front.

No.

2. . .

No.

3

Out

of

round

and out of taper

limits

Direction

of

Cylinder

Offset..........

Amount

of

Cylinder

Offset

Crankpin

Journal

Diameter

Flywheel

Run Out

(max.)

ENGLISH

CAMSHAFT:

Bearings:

Material..........

Number

Clearance.

Journal

Diameter:

Front Front

Intermediate.

Rear

Intermediate..

Rear

Bearing

Diameter:

Front Front

Intermediate.

Rear

Intermediate..

Rear

End

Play

Drive:

Type.............

Crankshaft

Gear.

. .

Camshaft

Gear

VALVE

SYSTEM:

Valve

Rotators

Tappets:

Clearance

—

Cold:

Intake

Exhaust

Clearance

for

Timing

(intake).

SAE

1141

Forged

Steel

32 oz.

9.187"

Removable

Steel-backed

Babbitt

1.089" to 1.099"

.001"

to .0019"

.001" .002"

.010"

.012" .020" .030"

.004"

to .010"

From

Above

.8115"

to .8125"

2.0432"

to 2.0440"

SAE

1040

Forged

Steel

Front

Bearing

.004*

to .006*

Removable

Steel-backed

Babbitt

.0003"

to .0029*

.001"

.002" .010"

.012" .020"

.030"

2.333"

to 2.334"

1.64"

1.72"

1.66"

.001"

Right

.125"

1.9375" to

1,9383

.005"

Steel-backed

Babbitt

(Front

only) 4

.001"

to .0025"

2.1860" to 2.1855"

2.1225"

to 2.1215"

2.0600" to 2.0590" 1.6230" to 1.6225"

2.1870" to 2.1890"

2.125"

to 2.126"

2.0625"

to 2.0635"

1.625" to 1.626"

.004*

to .007"

Helical

Gear

Cast

Iron

Pressed

Fiber-Steel

Hub

On

Exhaust

Valve

.018*

.016* .026"

METRIC

907

gr.

23,33 cm.

2,766 a 2,791 cm.

0,025 a 0,0483 mm.

0,025 mm. 0,051 mm.

0,254

mm.

0,305 mm. 0,508 mm.

0,762 mm.

0,102 a

0,254

mm.

20,612 a 20,637 mm. 5,1897 a 5,1917 cm.

0,102 a 0,152 mm,

0,0076 a 0,0736 mm. 0,025 mm.

0,051 mm.

0,254

mm.

0,305 mm.

0,508 mm.

0,762 mm.

5,9261

a 5,9286 cm.

4,16 cm.

4,36 cm.

4,21 cm.

0,025 mm.

3,175 mm.

4,9213 a 4,9233 cm. 0,127 mm.

0,025 a

0,063

mm.

5,5524 a

5,5511

cm.

5,3911

a 5,3886 cm.

5,2324 a 5,2298 cm.

4,1224 a

4,1211

cm.

5,5549 a 5,5600 cm.

5,3975 a 5,4000 cm. 5,2387 a 5,2412 cm.

4,1275 a 4,1300 cm. 0,101 a 0,178 mm.

0,461 mm. 0,406 mm.

0,660

mm. 72

Page 76 of 376

Dl

DAUNTLESS

V-6

ENGINE

DM.

GENERAL

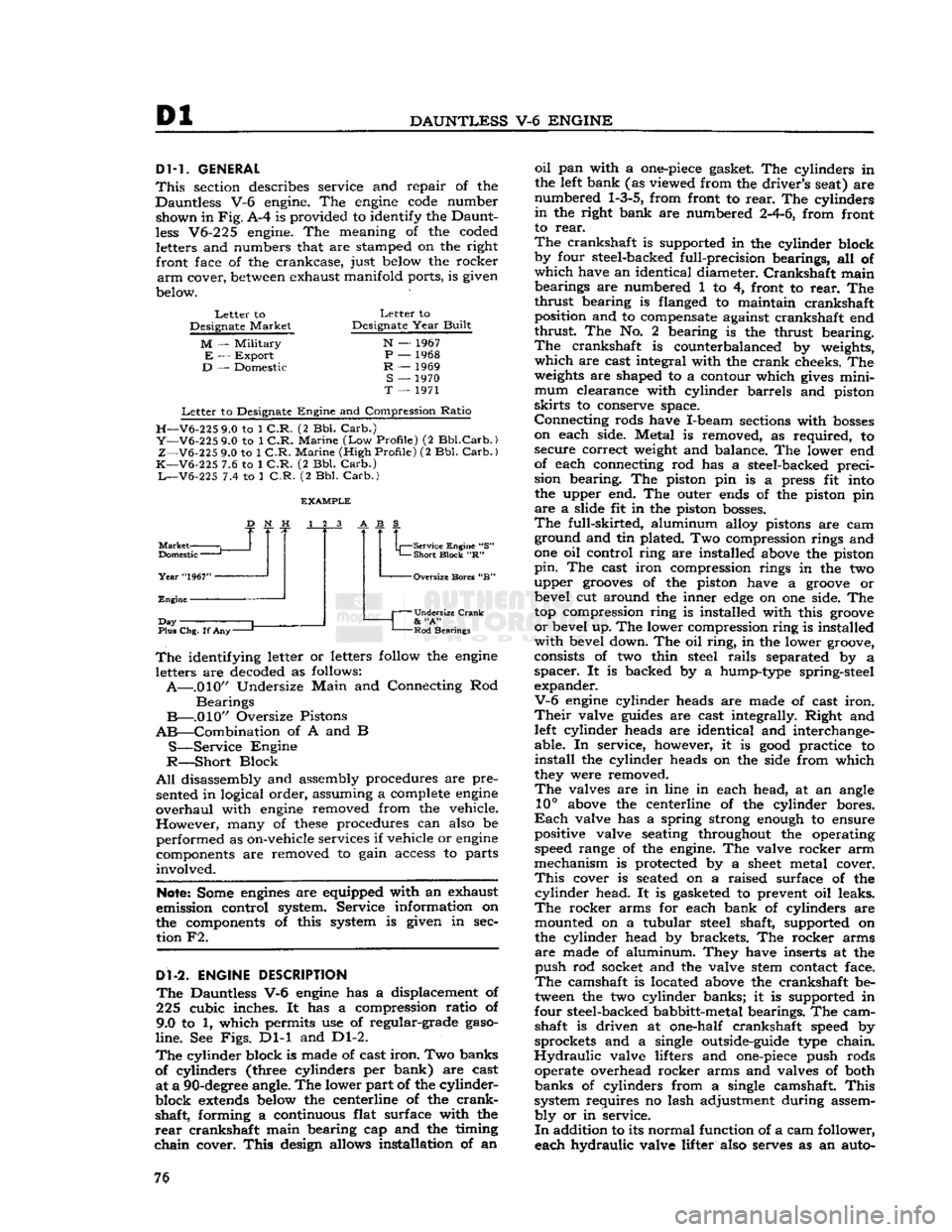

This

section describes service and repair of the

Dauntless V-6 engine. The

engine

code

number shown in

Fig.

A-4 is provided to identify the Daunt

less

V6-225 engine. The meaning of the coded letters and numbers that are stamped on the right front face of the crankcase, just below the rocker

arm

cover,

between

exhaust manifold ports, is given

below.

Letter

to

Designate

Market

M

—

Military

E

—

Export

D

— Domestic

Letter

to

Designate

Year

Built

N

— 1967

P

— 1968

R

— 1969

S

— 1970

T

— 1971

Letter

to Designate

Engine

and Compression

Ratio

H—V6-225

9.0 to 1

C.R.

(2 Bbl.

Carb.)

Y—V6-225

9.0 to 1

C.R.

Marine

(Low

Profile)

(2

Bbl.Carb.)

Z—V6-225

9.0 to 1

C.R.

Marine

(High

Profile)

(2 Bbl.

Carb.)

K—V6-225

7.6 to 1

C.R.

(2 Bbl.

Carb.)

L—V6-225

7.4 to 1

C.R.

(2 Bbl.

Carb.)

Market

Domestic

—

Year

"1967"

Engine

J

Day

Plus Chg. If

Any-

Service Engine "S"

Short

Block

"R" -Oversize Bores "B"

Undersize Crank

&

"A"

Rod

Bearings

The

identifying letter or letters follow the

engine

letters are decoded as follows:

A—.010"

Undersize

Main

and Connecting Rod

Bearings

B—.010"

Oversize Pistons

AB—Combination

of A and B

S—Service

Engine

R—Short

Block

All

disassembly and assembly procedures are pre sented in logical order, assuming a complete

engine

overhaul

with

engine

removed from the vehicle.

However,

many of

these

procedures can also be

performed as on-vehicle services if vehicle or

engine

components are removed to gain access to parts

involved.

Note:

Some

engines

are equipped with an exhaust

emission control system. Service information on

the components of this system is given in sec tion F2.

Dl-2.

ENGINE

DESCRIPTION

The

Dauntless V-6

engine

has a displacement of

225 cubic inches. It has a compression ratio of

9.0 to 1, which permits use of regular-grade

gaso

line.

See

Figs.

Dl-1 and Dl-2.

The

cylinder block is made of cast

iron.

Two banks

of cylinders (three cylinders per bank) are cast at a

90-degree

angle. The lower part of the cylinder-

block

extends

below the centerline of the

crank

shaft, forming a continuous flat surface with the

rear

crankshaft main bearing cap and the timing

chain

cover.

This

design allows installation of an

oil

pan with a

one-piece

gasket. The cylinders in

the left bank (as viewed from the driver's seat) are

numbered

1-3-5,

from front to

rear.

The cylinders

in

the right bank are numbered

2-4-6,

from front

to

rear.

The

crankshaft is supported in the cylinder block

by four steel-backed full-precision bearings, all of

which

have an identical diameter.

Crankshaft

main bearings are numbered 1 to 4, front to

rear.

The

thrust

bearing is flanged to maintain crankshaft position and to compensate against crankshaft end

thrust

The No. 2 bearing is the thrust bearing.

The

crankshaft is counterbalanced by weights,

which

are cast integral with the

crank

cheeks. The

weights

are shaped to a contour which

gives

mini

mum

clearance with cylinder barrels and piston

skirts

to conserve space.

Connecting

rods have I-beam sections with

bosses

on each side. Metal is removed, as required, to secure correct weight and balance. The lower end

of each connecting rod has a steel-backed preci

sion bearing. The piston pin is a press fit into the upper end. The outer ends of the piston pin

are

a slide fit in the piston

bosses.

The

full-skirted, aluminum alloy pistons are cam ground and tin plated. Two compression rings and

one oil control ring are installed above the piston

pin.

The cast iron compression rings in the two

upper

grooves

of the piston have a

groove

or bevel cut around the inner

edge

on one side. The

top compression ring is installed with this

groove

or

bevel up. The lower compression ring is installed

with

bevel down. The oil

ring,

in the lower groove,

consists of two thin steel

rails

separated by a

spacer.

It is backed by a hump-type spring-steel

expander.

V-6

engine

cylinder heads are made of cast

iron.

Their

valve

guides

are cast integrally. Right and left cylinder heads are identical and interchange

able. In service, however, it is

good

practice to

install

the cylinder heads on the side from which

they were removed.

The

valves are in line in each head, at an angle

10°

above the centerline of the cylinder bores.

Each

valve has a spring strong enough to ensure

positive valve seating throughout the operating speed range of the engine. The valve rocker arm

mechanism is protected by a

sheet

metal cover.

This

cover is seated on a raised surface of the

cylinder

head. It is gasketed to prevent oil leaks.

The

rocker arms for each bank of cylinders are mounted on a tubular steel shaft, supported on

the cylinder head by brackets. The rocker arms

are

made of aluminum. They have inserts at the

push

rod socket and the valve stem contact face.

The

camshaft is located above the crankshaft be

tween the two cylinder banks; it is supported in

four steel-backed babbitt-metal bearings. The cam shaft is driven at one-half crankshaft speed by

sprockets and a single outside-guide type chain.

Hydraulic

valve lifters and

one-piece

push rods operate overhead rocker arms and valves of both

banks

of cylinders from a single camshaft.

This

system requires no lash adjustment during assem

bly

or in service.

In

addition to its normal function of a cam follower,

each hydraulic valve lifter also serves as an auto- 76

Page 79 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

Dl

12710

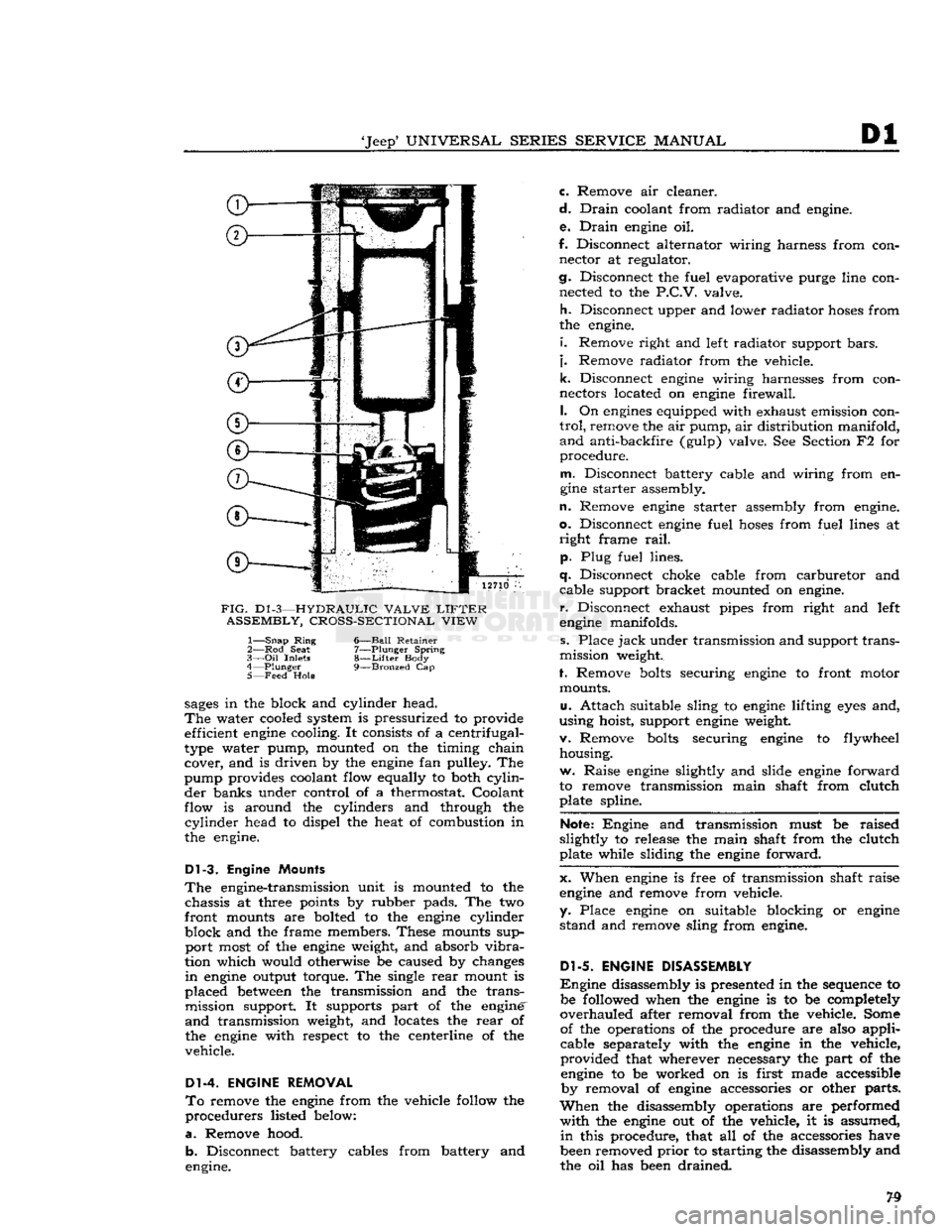

FIG.

D1

-3—HYDRAULIC VALVE

LIFTER

ASSEMBLY, CROSS-SECTIONAL VIEW

1—

Snap

Ring

6—Ball Retainer

2— Rod

Seat

7—Plunger Spring

3—

Oil

Inlets

8—Lifter

Body

4—

Plunger

9—Bronzed

Cap

5— Feed

Hole

sages

in the block and cylinder head.

The

water cooled system is pressurized to provide efficient

engine

cooling. It consists of a centrifugal-

type water pump, mounted on the timing chain cover, and is driven by the

engine

fan pulley. The

pump provides coolant flow equally to both

cylin

der banks under control of a thermostat. Coolant

flow is around the cylinders and through the

cylinder

head to dispel the heat of combustion in

the engine.

Dl-3.

Engine Mounts

The

engine-transmission unit is mounted to the chassis at three points by rubber pads. The two

front mounts are bolted to the

engine

cylinder

block and the frame members. These mounts sup port most of the

engine

weight, and absorb

vibra

tion which would otherwise be caused by changes

in

engine

output torque. The single

rear

mount is

placed

between

the transmission and the trans mission support. It supports part of the engine'

and

transmission weight, and locates the

rear

of

the

engine

with respect to the centerline of the

vehicle.

Dl-4. ENGINE REMOVAL

To

remove the

engine

from the vehicle follow the

procedurers listed below:

a.

Remove hood. b. Disconnect battery cables from battery and

engine. c. Remove air cleaner.

d.

Drain

coolant from radiator and engine.

e.

Drain

engine

oil.

f. Disconnect alternator wiring harness from con nector at regulator.

cj.

Disconnect the fuel evaporative purge line con nected to the

P.C.V.

valve.

h.

Disconnect upper and lower radiator

hoses

from

the engine.

i.

Remove right and left radiator support

bars,

j.

Remove radiator from the vehicle.

k.

Disconnect

engine

wiring harnesses from con

nectors located on

engine

firewall.

I.

On

engines

equipped with exhaust emission con

trol,

remove the air pump, air distribution manifold,

and

anti-backfire (gulp) valve. See Section F2 for

procedure.

m.

Disconnect battery cable and wiring from en

gine

starter assembly.

n.

Remove

engine

starter assembly from engine,

o.

Disconnect

engine

fuel

hoses

from fuel lines at

right

frame

rail,

p. Plug fuel lines.

q.

Disconnect choke cable from carburetor and cable support bracket mounted on engine,

r.

Disconnect exhaust pipes from right and left

engine

manifolds.

s. Place

jack

under transmission and support trans

mission weight.

f. Remove

bolts

securing

engine

to front motor mounts.

u.

Attach suitable sling to

engine

lifting

eyes

and,

using hoist, support

engine

weight.

v. Remove

bolts

securing

engine

to flywheel housing.

w. Raise

engine

slightly and slide

engine

forward

to remove transmission main shaft from clutch plate spline.

Note:

Engine and transmission must be raised

slightly to release the main shaft from the clutch

plate while sliding the

engine

forward.

x. When

engine

is free of transmission shaft raise

engine

and remove from vehicle,

y. Place

engine

on suitable blocking or

engine

stand and remove sling from engine.

Dl-5.

ENGINE DISASSEMBLY

Engine

disassembly is presented in the sequence to be followed when the

engine

is to be completely

overhauled after removal from the vehicle. Some of the operations of the procedure are also applicable separately with the

engine

in the vehicle,

provided that wherever necessary the part of the

engine

to be worked on is first made accessible by removal of

engine

accessories or other parts.

When

the disassembly operations are performed

with

the

engine

out of the vehicle, it is assumed,

in

this procedure, that all of the accessories have

been removed

prior

to starting the disassembly and

the oil has been drained.

Page 85 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

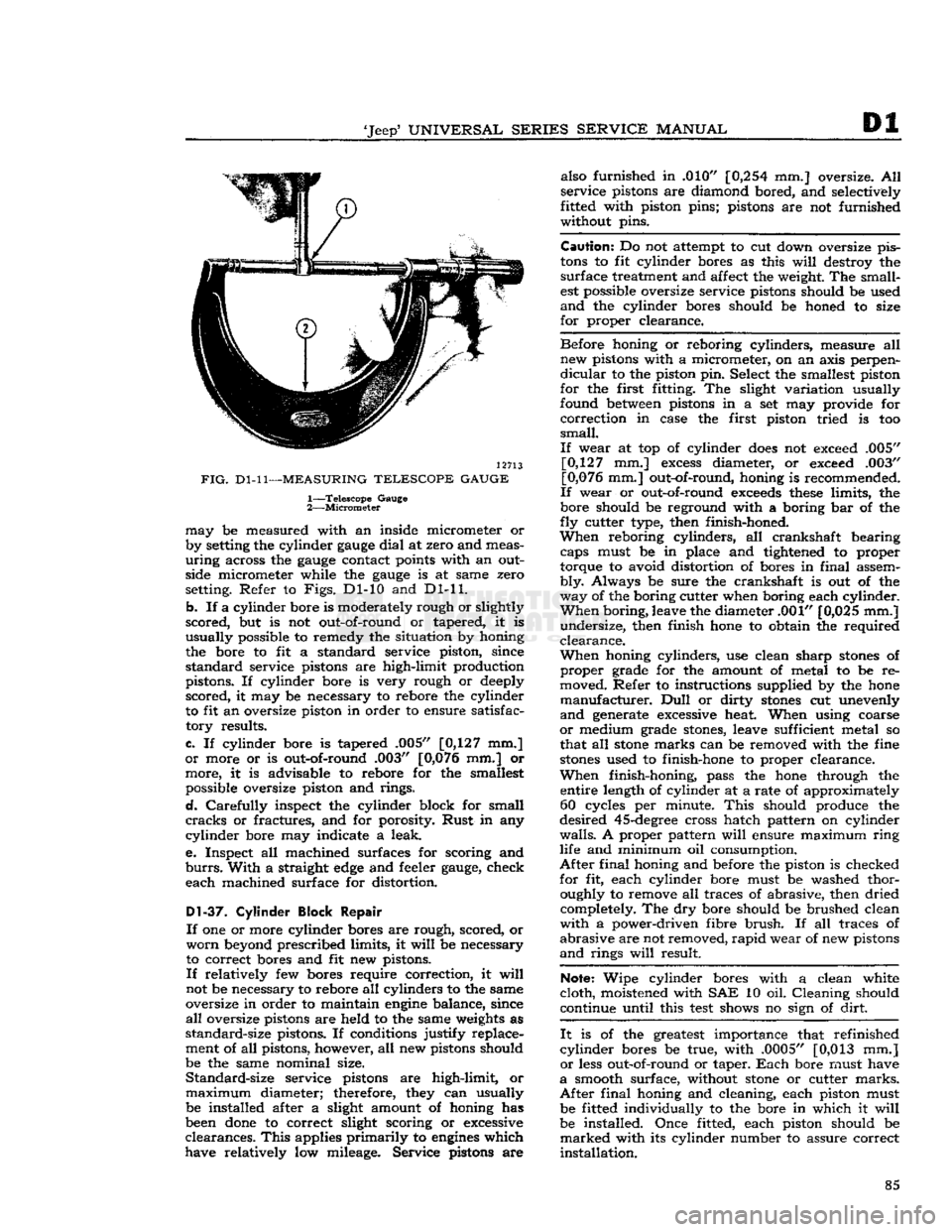

12713

FIG.

Dl-11—MEASURING

TELESCOPE GAUGE

1—

Telescope

Gauge

2—

Micrometer

may

be measured with an inside micrometer or

by setting the cylinder

gauge

dial

at zero and meas

uring

across the

gauge

contact points with an outside micrometer while the

gauge

is at same zero

setting. Refer to

Figs.

Dl-10 and Dl-11.

b.

If a cylinder bore is moderately rough or slightly

scored,

but is not out-of-round or tapered, it is

usually

possible to remedy the situation by honing

the bore to fit a standard service piston, since

standard

service pistons are high-limit production

pistons. If cylinder bore is very rough or deeply

scored,

it may be necessary to rebore the cylinder

to fit an oversize piston in order to ensure satisfac

tory

results.

c.

If cylinder bore is tapered .005" [0,127 mm.]

or

more or is out-of-round .003" [0,076 mm.] or

more,

it is advisable to rebore for the smallest possible oversize piston and rings.

d.

Carefully

inspect the cylinder block for small

cracks

or fractures, and for porosity.

Rust

in any

cylinder

bore may indicate a leak.

e.

Inspect all machined surfaces for scoring and

burrs.

With

a straight

edge

and feeler

gauge,

check

each

machined surface for distortion.

D1-37.

Cylinder Block Repair

If

one or more cylinder bores are rough, scored, or

worn

beyond prescribed limits, it

will

be necessary

to correct bores and fit new pistons.

If

relatively few bores require correction, it

will

not be necessary to rebore all cylinders to the same

oversize in order to maintain

engine

balance, since

all

oversize pistons are held to the same weights as

standard-size

pistons. If conditions justify replace

ment of all pistons, however, all new pistons should

be the same nominal size.

Standard-size

service pistons are high-limit, or

maximum

diameter; therefore, they can usually be installed after a slight amount of honing has

been

done

to correct slight scoring or excessive

clearances.

This

applies

primarily

to

engines

which

have relatively low mileage. Service pistons are also furnished in .010"

[0,254

mm.] oversize. All

service

pistons are diamond bored, and selectively

fitted with piston pins; pistons are not furnished

without pins.

Caution:

Do not attempt to cut down oversize pis

tons

to fit cylinder bores as this

will

destroy the

surface

treatment and affect the weight. The small

est possible oversize service pistons should be used

and

the cylinder bores should be honed to size

for

proper clearance.

Before

honing or reboring cylinders, measure all new pistons with a micrometer, on an axis perpen

dicular

to the piston pin. Select the smallest piston

for

the first fitting. The slight variation usually

found between pistons in a set may provide for

correction

in case the first piston tried is too

small.

If

wear at top of cylinder

does

not exceed .005" [0,127 mm.]

excess

diameter, or exceed .003"

[0,076 mm.] out-of-round, honing is recommended.

If

wear or out-of-round

exceeds

these

limits, the

bore should be reground with a boring bar of the

fly

cutter type, then finish-honed.

When

reboring cylinders, all crankshaft bearing caps must be in place and tightened to proper

torque to avoid distortion of bores in

final

assem

bly.

Always be sure the crankshaft is out of the

way

of the boring cutter when boring each cylinder.

When

boring, leave the diameter .001" [0,025 mm.]

undersize,

then finish hone to obtain the required

clearance.

When

honing cylinders, use clean sharp

stones

of

proper

grade for the amount of metal to be re

moved. Refer to instructions supplied by the hone

manufacturer.

Dull

or dirty

stones

cut unevenly

and

generate excessive heat. When using coarse

or

medium grade

stones,

leave sufficient metal so

that all

stone

marks can be removed with the fine

stones

used to finish-hone to proper clearance.

When

finish-honing, pass the hone through the entire length of cylinder at a rate of approximately 60 cycles per minute.

This

should produce the

desired

45-degree

cross hatch pattern on cylinder

walls.

A proper pattern

will

ensure maximum

ring

life and minimum oil consumption.

After

final

honing and before the piston is checked

for

fit, each cylinder bore must be washed thor oughly to remove all traces of abrasive, then dried completely. The dry bore should be brushed clean

with

a power-driven fibre

brush.

If all traces of

abrasive

are not removed,

rapid

wear of new pistons

and

rings

will

result.

Note:

Wipe cylinder bores with a clean white

cloth,

moistened with SAE 10 oil. Cleaning should

continue until this

test

shows no sign of

dirt.

It

is of the greatest importance that refinished

cylinder

bores be true, with .0005" [0,013 mm.]

or

less out-of-round or taper.

Each

bore must have

a

smooth surface, without

stone

or cutter

marks.

After

final

honing and cleaning, each piston must be fitted individually to the bore in which it

will

be installed. Once fitted, each piston should be

marked

with its cylinder number to assure correct

installation.

85

Page 96 of 376

Dl

DAUNTLESS

V-6

ENGINE

Note:

During

engine

reassembly, use Perfect Seal

Aerosol

Spray Sealer

Part

No.

994757

on all en

gine

gaskets to ensure against vacuum, oil, gasoline

and

water leaks. Apply to head gaskets, valve covers, water pumps, oil pan gaskets, radiator and

heater

hose

connections, felt gaskets, gasoline and

oil

line connections, stud bolts, spark plug threads,

and

grease retainer washers. Refer to manufac

turer's

instructions on container for proper appli

cation procedure.

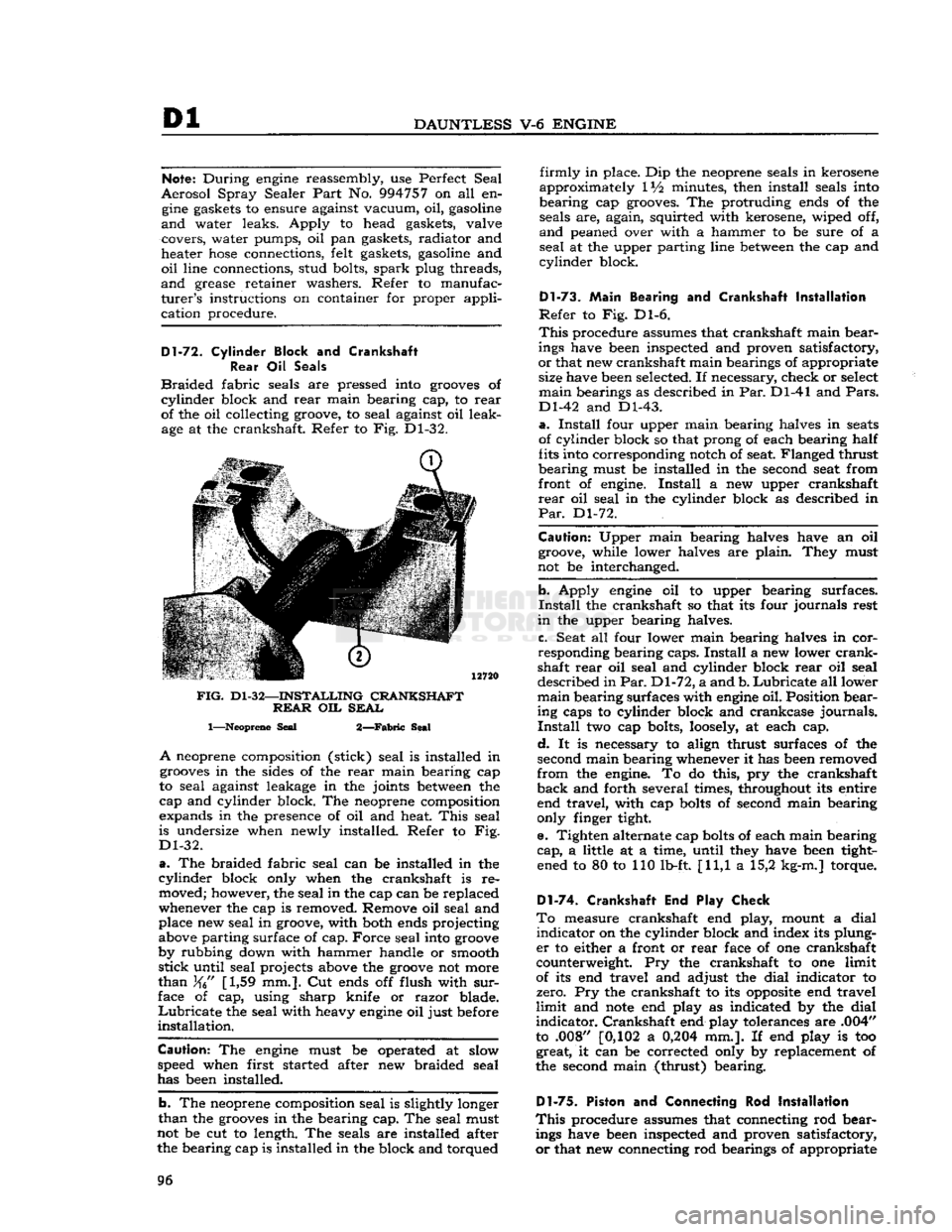

Dl-72.

Cylinder

Block

and Crankshaft

Rear

Oil Seals

Braided

fabric seals are pressed into

grooves

of

cylinder

block and

rear

main bearing cap, to

rear

of the oil collecting groove, to seal against oil leak age at the crankshaft. Refer to Fig. Dl-32.

FIG.

Dl-32—INSTALLING

CRANKSHAFT REAR

OIL

SEAL

1—Neoprene

Seal

2—Fabric

Seal

A

neoprene composition (stick) seal is installed in

grooves

in the sides of the

rear

main bearing cap

to seal against leakage in the joints

between

the

cap and cylinder block. The neoprene composition

expands in the presence of oil and heat.

This

seal

is undersize when newly installed. Refer to Fig.

Dl-32.

a.

The braided fabric seal can be installed in the

cylinder

block only when the crankshaft is re moved; however, the seal in the cap can be replaced

whenever the cap is removed. Remove oil seal and place new seal in groove, with both ends projecting

above parting surface of cap. Force seal into

groove

by rubbing down with hammer handle or smooth

stick

until seal projects above the

groove

not more

than

[1,59 mm.]. Cut ends off flush with

sur

face of cap, using sharp knife or razor blade.

Lubricate

the seal with heavy

engine

oil just before

installation.

Caution:

The

engine

must be operated at slow

speed when first started after new braided seal

has been installed.

b. The neoprene composition seal is slightly longer

than

the

grooves

in the bearing cap. The seal must

not be cut to length. The seals are installed after the bearing cap is installed in the block and torqued

firmly

in place. Dip the neoprene seals in kerosene

approximately IV2 minutes, then install seals into

bearing cap grooves. The protruding ends of the seals are, again, squirted with kerosene, wiped off,

and

peaned over with a hammer to be sure of a

seal

at the upper parting line

between

the cap and

cylinder

block.

Dl-73.

Main

Bearing and Crankshaft

Installation

Refer

to Fig. Dl-6.

This

procedure assumes that crankshaft main bear

ings have been inspected and proven satisfactory,

or

that new crankshaft main bearings of appropriate size have been selected. If necessary, check or select

main

bearings as described in Par. Dl-41 and

Pars.

Dl-42 and Dl-43.

a.

Install

four upper main bearing halves in

seats

of cylinder block so that prong of each bearing half

fits into corresponding notch of seat. Flanged thrust

bearing must be installed in the second seat from

front of engine.

Install

a new upper crankshaft

rear

oil seal in the cylinder block as described in

Par.

Dl-72.

Caution:

Upper main bearing halves have an oil groove, while lower halves are plain. They must

not be interchanged.

b. Apply

engine

oil to upper bearing surfaces.

Install

the crankshaft so that its four journals rest

in

the upper bearing halves.

c. Seat all four lower main bearing halves in cor

responding bearing caps.

Install

a new lower

crank

shaft

rear

oil seal and cylinder block

rear

oil seal

described in

Par.

Dl-72, a and b.

Lubricate

all lower

main

bearing surfaces with

engine

oil. Position bear ing caps to cylinder block and crankcase journals.

Install

two cap bolts,

loosely,

at each cap.

d.

It is necessary to align thrust surfaces of the

second main bearing whenever it has been removed

from

the engine. To do this, pry the crankshaft

back

and forth several times, throughout its entire end travel, with cap

bolts

of second main bearing

only finger tight.

e. Tighten alternate cap

bolts

of each main bearing

cap,

a little at a time, until they have been tight ened to 80 to 110 lb-ft. [11,1 a 15,2 kg-m.] torque.

D1-74. Crankshaft End Play Check

To

measure crankshaft end play, mount a dial

indicator

on the cylinder block and index its plung

er

to either a front or

rear

face of one crankshaft

counterweight. Pry the crankshaft to one limit

of its end travel and adjust the dial indicator to

zero. Pry the crankshaft to its

opposite

end travel

limit

and

note

end play as indicated by the dial

indicator.

Crankshaft end play tolerances are .004"

to .008" [0,102 a

0,204

mm.]. If end play is too great, it can be corrected only by replacement of

the second main (thrust) bearing.

Dl-75.

Piston and Connecting Rod

Installation

This

procedure assumes that connecting rod bear ings have been inspected and proven satisfactory,

or

that new connecting rod bearings of appropriate 96

Page 114 of 376

FUEL

SYSTEM

14261

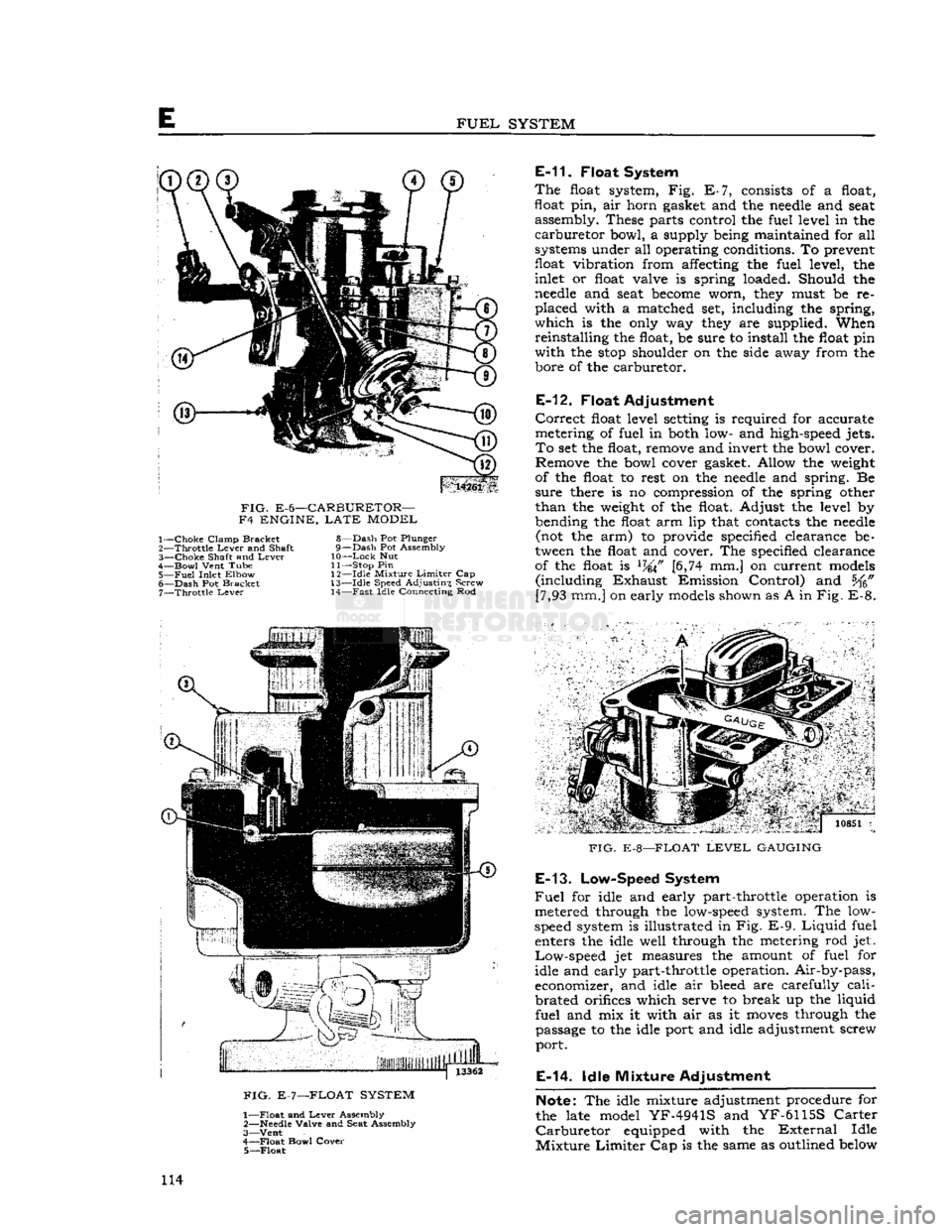

FIG.

E-6—CARBURETOR—

F4 ENGINE,

LATE

MODEL 1—

Choke

Clamp Bracket

2—

Throttle

Lever

and Shaft

3—

Choke

Shaft and

Lever

4—

Bowl

Vent Tube

5—

Fuel

Inlet Elbow

6—

Dash

Pot Bracket 7—

Throttle

Lever

8—

Dash

Pot Plunger

9—

Dash

Pot Assembly

10—

Lock

Nut

11— Stop Pin

1

2—Idle Mixture

Limiter

Cap

13—

Idle

Speed Adjusting Screw 14—

Fast

Idle Connecting Rod

E-11.

Float System

The

float system, Fig. E-7, consists of a float,

float

pin,

air horn gasket and the

needle

and seat assembly. These parts control the fuel level in the

carburetor

bowl, a supply being maintained for all

systems under all operating conditions. To prevent

float

vibration

from affecting the fuel level, the

inlet or float valve is spring loaded. Should the

needle

and seat

become

worn, they must be re

placed

with a matched set, including the spring,

which

is the only way they are supplied. When

reinstalling

the float, be sure to install the float pin

with

the

stop

shoulder on the side away from the bore of the carburetor.

E-12.

Float Adjustment

Correct

float level setting is required for accurate

metering of fuel in both low- and high-speed jets.

To

set the float, remove and invert the bowl cover. Remove the bowl cover gasket. Allow the weight

of the float to rest on the

needle

and spring. Be

sure

there is no compression of the spring other

than

the weight of the float. Adjust the level by

bending the float arm lip that contacts the

needle

(not the arm) to provide specified clearance be

tween the float and cover. The specified clearance of the float is

L74\F

[6,74 mm.] on current models

(including

Exhaust

Emission Control) and [7,93 mm.] on early models shown as A in

Fig.

E-8.

FIG.

E-7—FLOAT SYSTEM

1—

Float

and

Lever

Assembly

2—

Needle

Valve and Seat Assembly

3—

Vent

4—

Float

Bowl Cover 5—

Float

7 '.. j

io8Si

i

FIG.

E-8—FLOAT

LEVEL

GAUGING

E-13.

Low-Speed System

Fuel

for idle and early part-throttle operation is

metered through the low-speed system. The low-

speed system is illustrated in Fig.

E-9.

Liquid

fuel enters the idle well through the metering rod jet.

Low-speed

jet measures the amount of fuel for

idle and early part-throttle operation. Air-by-pass,

economizer, and idle air bleed are carefully

cali

brated

orifices which serve to break up the liquid

fuel

and mix it with air as it

moves

through the passage to the idle port and idle adjustment screw

port.

E-14.

Idle Mixture Adjustment

Note:

The idle mixture adjustment procedure for

the late model

YF-4941S

and

YF-6115S

Carter

Carburetor

equipped with the

External

Idle

Mixture

Limiter

Cap is the same as outlined below 114

Page 116 of 376

E

FUEL

SYSTEM

pressing downward on metering rod) or

seats

be

fore the metering rod arm makes flat contact with the pump lifter link, make adjustment by bending

the lip on the metering rod arm.

E-17.

Choke System

The

choke system consists of a manually-operated

choke valve, a fast-idle connecting rod, and a fast-

idle arm. The choke valve is offset-spring loaded to prevent over-choking during the starting warm-

up period. When the choke valve is moved to a closed position for starting, the fast idle connector

rod

in Fig. E-ll revolves the fast idle link.

This

action increases the

engine

idle speed to prevent stalling during the warm-up period. A fast-idle

connector rod return spring prevents partial closing

of the choke valve. pump lifter which is connected to the throttle.

This

movement forces fuel from the chamber

above the diaphragm through discharge pump check valve and discharge pump jet.

This

auxiliary discharge of fuel supplies

engine

requirements for

quick

acceleration and heavy loads. When the

throttle is closed, the diaphragm is again pulled

down by high vacuum and another measured

charge of fuel enters the chamber above the

diaphragm

through the intake passage to be

available for the next cycle of operation.

Note:

The pump jet (see insert drawing in Fig.

E-12)

projecting into the air stream is permanently pressed into the carburetor body and should not

be removed. Also, carburetor design makes it im possible to adjust the pump stroke.

FIG.

E-ll—FAST

IDLE

ADJUSTMENT

1—Fast

Idle

Connector Rod

2—Fast

Idle

Link

E-18.

Fast

Idle Adjustment

With

the choke held in wide open position, lip (No. 1) (Fig.

E-ll)

on the fast-idle rod should con

tact the

boss

on the body casting. Adjust by bend

ing the fast-idle link at

offset

as shown by (No. 2).

E-19.

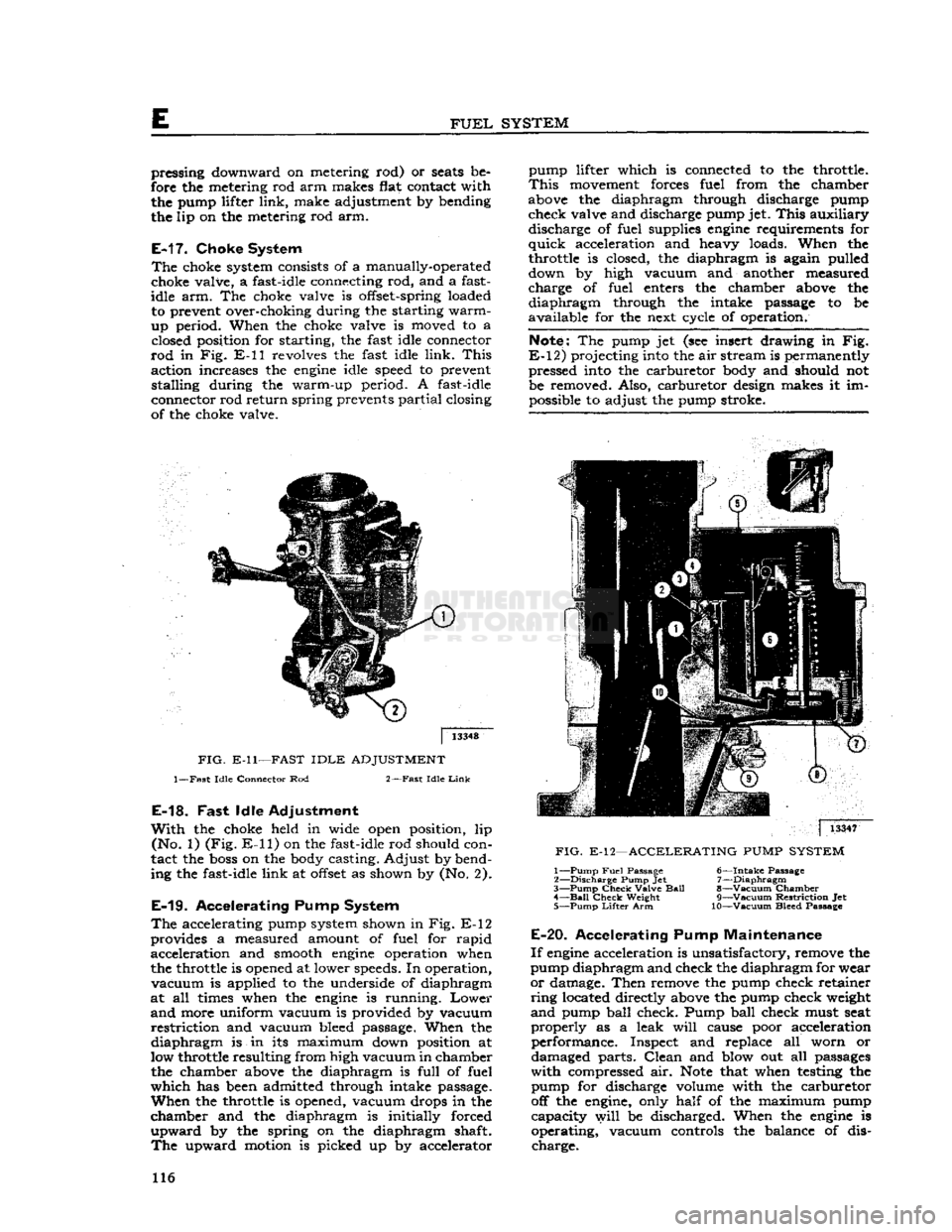

Accelerating Pump System

The

accelerating pump system shown in Fig. E-12

provides a measured amount of fuel for rapid acceleration and smooth

engine

operation when

the throttle is opened at lower speeds. In operation,

vacuum

is applied to the underside of diaphragm

at all times when the

engine

is running.

Lower

and

more uniform vacuum is provided by vacuum

restriction

and vacuum bleed passage. When the

diaphragm

is in its maximum down position at

low throttle resulting from high vacuum in chamber the chamber above the diaphragm is full of fuel

which

has been admitted through intake passage.

When

the throttle is opened, vacuum drops in the

chamber and the diaphragm is initially forced

upward

by the spring on the diaphragm shaft.

The

upward motion is picked up by accelerator

|

13347

FIG.

E-12—ACCELERATING

PUMP

SYSTEM

1—

Pump

Fuel

Passage

6—Intake

Passage

2—

Discharge

Pump Jet 7—Diaphragm

3—

Pump

Check

Valve

Ball

8—Vacuum Chamber 4—

Bail

Check

Weight

9—Vacuum

Restriction

Jet

5—

Pump

Lifter

Arm 10—Vacuum Bleed Passage

E-20.

Accelerating Pump Maintenance

If

engine

acceleration is unsatisfactory, remove the

pump diaphragm and check the diaphragm for wear

or

damage. Then remove the pump check retainer

ring

located directly above the pump check weight

and

pump ball check. Pump ball check must seat

properly

as a leak

will

cause poor acceleration performance. Inspect and replace all worn or

damaged parts.

Clean

and blow out all passages

with

compressed air.

Note

that when testing the pump for discharge volume with the carburetor

off the engine, only half of the maximum pump capacity

will

be discharged. When the

engine

is

operating, vacuum controls the balance of dis charge. 116