water pump JEEP CJ 1953 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 78 of 376

01

DAUNTLESS

V-6

ENGINE

14358

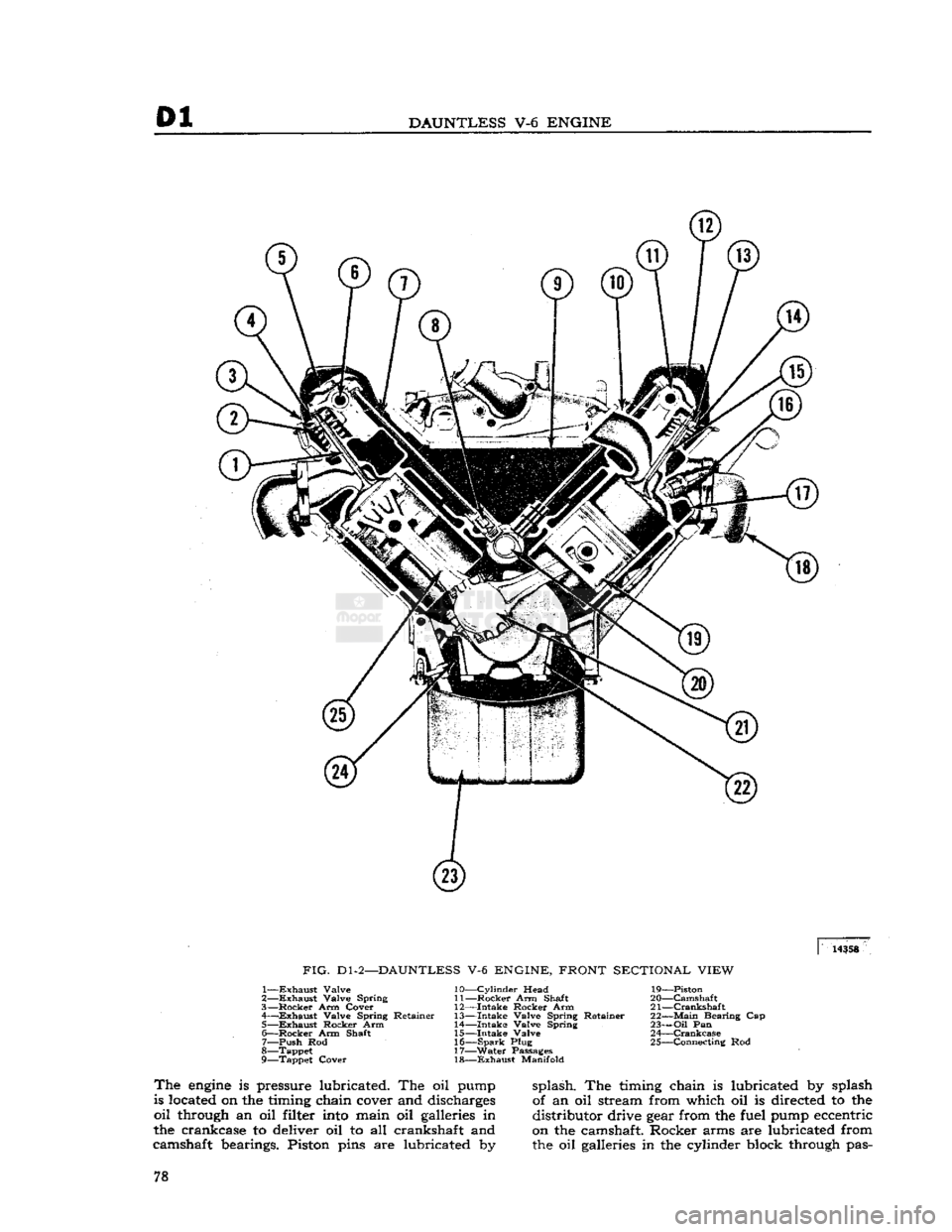

FIG.

Dl-2—DAUNTLESS

V-6

ENGINE, FRONT SECTIONAL VIEW

1—

Exhaust

Valve

2—

Exhaust

Valve Spring

3—

Rocker

Arm Cover

4—

—Exhaust

Valve Spring Retainer 5—

Exhaust

Rocker Arm

6—

Rocker

Arm Shaft 7— push Rod

8— Tappet

9— Tappet Cover 10—

Cylinder

Head

11—

Rocker

Arm Shaft

12—

Intake

Rocker Arm

13—

Intake

Valve Spring Retainer

14—

Intake

Valve Spring

15—

Intake

Valve 16—

Spark

Plug

17—

Water

Passages 18—

Exhaust

Manifold 19— Piston

20—

Camshaft

21—

Crankshaft

22—

Main

Bearing Cap

23—

Oil

Pan

24—

Crankcase

25— Connecting Rod

The

engine

is pressure lubricated. The oil pump

is located on the timing chain cover and discharges

oil

through an oil filter

into

main oil galleries in

the crankcase to deliver oil to all crankshaft and

camshaft bearings. Piston pins are lubricated by- splash. The timing chain is lubricated by splash

of an oil stream from which oil is directed to the

distributor drive gear from the fuel pump eccentric

on the camshaft. Rocker arms are lubricated from

the oil galleries in the cylinder block through pas- 78

Page 79 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

Dl

12710

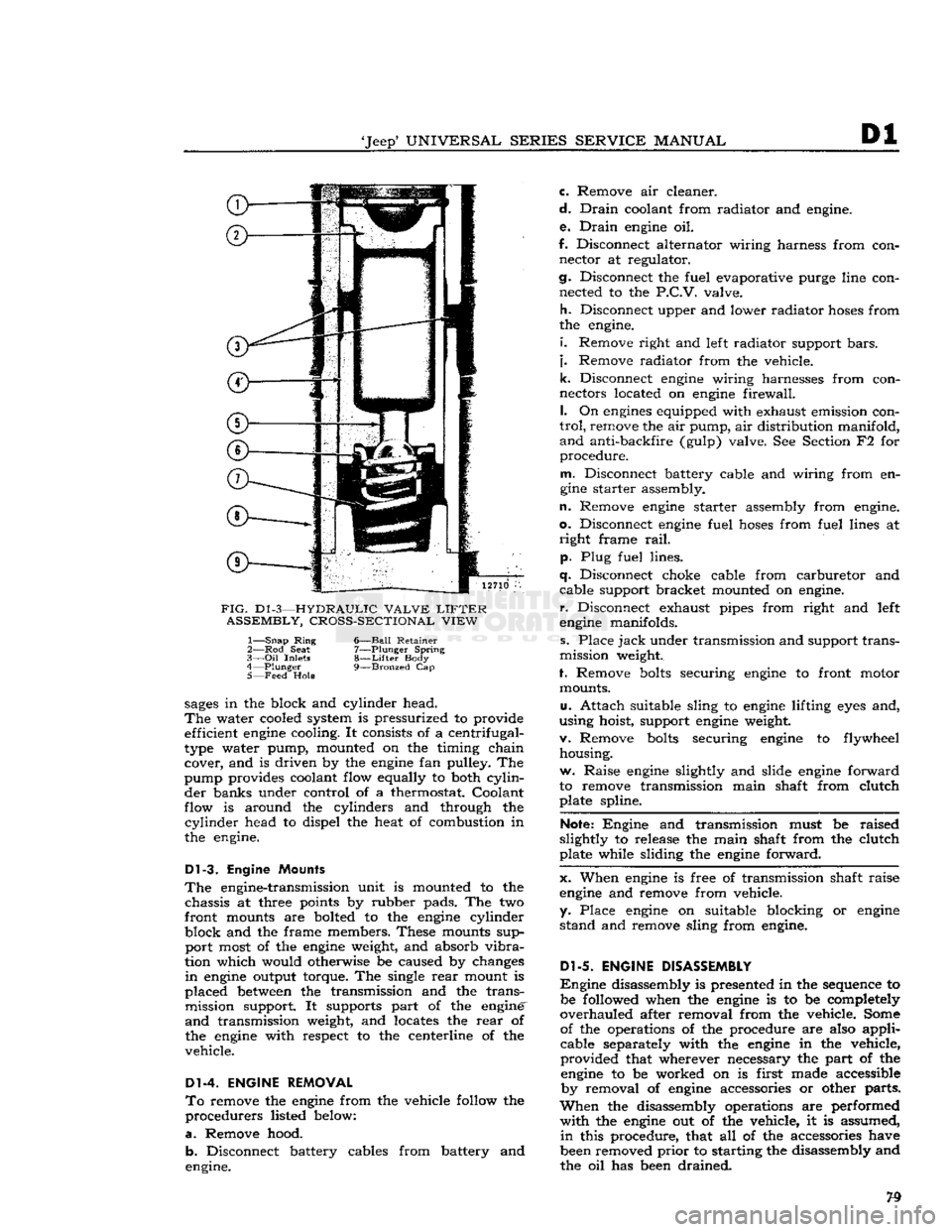

FIG.

D1

-3—HYDRAULIC VALVE

LIFTER

ASSEMBLY, CROSS-SECTIONAL VIEW

1—

Snap

Ring

6—Ball Retainer

2— Rod

Seat

7—Plunger Spring

3—

Oil

Inlets

8—Lifter

Body

4—

Plunger

9—Bronzed

Cap

5— Feed

Hole

sages

in the block and cylinder head.

The

water cooled system is pressurized to provide efficient

engine

cooling. It consists of a centrifugal-

type water pump, mounted on the timing chain cover, and is driven by the

engine

fan pulley. The

pump provides coolant flow equally to both

cylin

der banks under control of a thermostat. Coolant

flow is around the cylinders and through the

cylinder

head to dispel the heat of combustion in

the engine.

Dl-3.

Engine Mounts

The

engine-transmission unit is mounted to the chassis at three points by rubber pads. The two

front mounts are bolted to the

engine

cylinder

block and the frame members. These mounts sup port most of the

engine

weight, and absorb

vibra

tion which would otherwise be caused by changes

in

engine

output torque. The single

rear

mount is

placed

between

the transmission and the trans mission support. It supports part of the engine'

and

transmission weight, and locates the

rear

of

the

engine

with respect to the centerline of the

vehicle.

Dl-4. ENGINE REMOVAL

To

remove the

engine

from the vehicle follow the

procedurers listed below:

a.

Remove hood. b. Disconnect battery cables from battery and

engine. c. Remove air cleaner.

d.

Drain

coolant from radiator and engine.

e.

Drain

engine

oil.

f. Disconnect alternator wiring harness from con nector at regulator.

cj.

Disconnect the fuel evaporative purge line con nected to the

P.C.V.

valve.

h.

Disconnect upper and lower radiator

hoses

from

the engine.

i.

Remove right and left radiator support

bars,

j.

Remove radiator from the vehicle.

k.

Disconnect

engine

wiring harnesses from con

nectors located on

engine

firewall.

I.

On

engines

equipped with exhaust emission con

trol,

remove the air pump, air distribution manifold,

and

anti-backfire (gulp) valve. See Section F2 for

procedure.

m.

Disconnect battery cable and wiring from en

gine

starter assembly.

n.

Remove

engine

starter assembly from engine,

o.

Disconnect

engine

fuel

hoses

from fuel lines at

right

frame

rail,

p. Plug fuel lines.

q.

Disconnect choke cable from carburetor and cable support bracket mounted on engine,

r.

Disconnect exhaust pipes from right and left

engine

manifolds.

s. Place

jack

under transmission and support trans

mission weight.

f. Remove

bolts

securing

engine

to front motor mounts.

u.

Attach suitable sling to

engine

lifting

eyes

and,

using hoist, support

engine

weight.

v. Remove

bolts

securing

engine

to flywheel housing.

w. Raise

engine

slightly and slide

engine

forward

to remove transmission main shaft from clutch plate spline.

Note:

Engine and transmission must be raised

slightly to release the main shaft from the clutch

plate while sliding the

engine

forward.

x. When

engine

is free of transmission shaft raise

engine

and remove from vehicle,

y. Place

engine

on suitable blocking or

engine

stand and remove sling from engine.

Dl-5.

ENGINE DISASSEMBLY

Engine

disassembly is presented in the sequence to be followed when the

engine

is to be completely

overhauled after removal from the vehicle. Some of the operations of the procedure are also applicable separately with the

engine

in the vehicle,

provided that wherever necessary the part of the

engine

to be worked on is first made accessible by removal of

engine

accessories or other parts.

When

the disassembly operations are performed

with

the

engine

out of the vehicle, it is assumed,

in

this procedure, that all of the accessories have

been removed

prior

to starting the disassembly and

the oil has been drained.

Page 80 of 376

Dl

DAUNTLESS

V-6

ENGINE

In

addition to the instructions covering operations

for disassembling the

engine

out of the vehicle, special instructions are given to cover different

operations required when disassembly is

done

with

the

engine

installed.

During

disassembly operations, the

engine

should be mounted in a suitable

engine

repair stand.

Where

practicable, modify or adapt an existing re

pair

stand as necessary to accommodate the

engine.

If

an

engine

repair stand is not used, take care to

perform

disassembly operations in a manner that

will

protect personnel against an accident and the

engine

and its parts against damage.

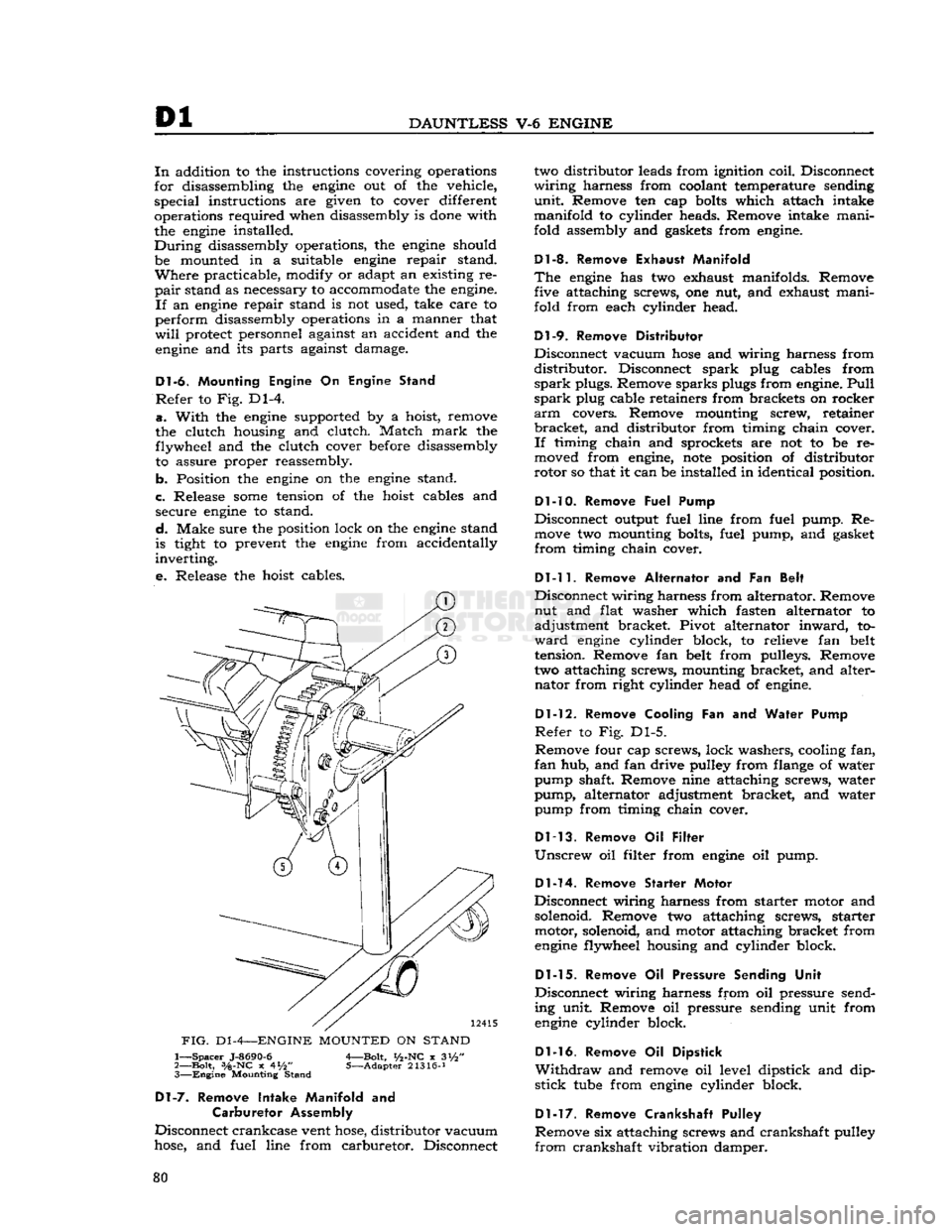

Dl-6.

Mounting Engine

On

Engine Stand

Refer

to Fig. Dl-4.

a.

With

the

engine

supported by a hoist, remove

the clutch housing and clutch. Match

mark

the flywheel and the clutch cover before disassembly to assure proper reassembly.

b. Position the

engine

on the

engine

stand.

c. Release

some

tension of the hoist cables and secure

engine

to stand.

d.

Make sure the position lock on the

engine

stand

is tight to prevent the

engine

from accidentally

inverting.

e.

Release the hoist cables.

FIG.

D1

-4—ENGINE

MOUNTED

ON

STAND

1—

Spacer

J-8690-6

A—Bolt,

i/2-NC

x 3i/2"

2—

Bolt,

3/a-NC

x 4*/2" 5—Adapter 21316-J 3—

Engine

Mounting Stand

Dl-7.

Remove Intake Manifold

and

Carburetor Assembly

Disconnect crankcase vent

hose,

distributor vacuum

hose,

and fuel line from carburetor. Disconnect two distributor leads from ignition coil. Disconnect

wiring

harness from coolant temperature sending

unit.

Remove ten cap

bolts

which attach intake

manifold to cylinder heads. Remove intake mani

fold assembly and gaskets from

engine.

Dl-8. Remove Exhaust Manifold

The

engine

has two exhaust manifolds. Remove five attaching screws, one nut, and exhaust mani

fold from each cylinder head.

Dl-9.

Remove Distributor

Disconnect vacuum

hose

and wiring harness from

distributor.

Disconnect spark plug cables from

spark

plugs. Remove sparks plugs from

engine.

Pull

spark

plug cable retainers from brackets on rocker

arm

covers. Remove mounting screw, retainer

bracket,

and distributor from timing chain cover.

If

timing chain and sprockets are not to be re

moved from

engine,

note

position of distributor

rotor so that it can be installed in identical position.

Dl-10. Remove

Fuel Pump

Disconnect output fuel line from fuel pump. Re

move

two mounting bolts, fuel pump, and gasket

from

timing chain cover.

Dl-11.

Remove Alternator

and Fan

Belt

Disconnect wiring harness from alternator. Remove nut and flat washer which fasten alternator to

adjustment bracket. Pivot alternator

inward,

to

ward

engine

cylinder block, to relieve fan belt

tension. Remove fan belt from pulleys. Remove

two attaching screws, mounting bracket, and alter nator from right cylinder head of

engine.

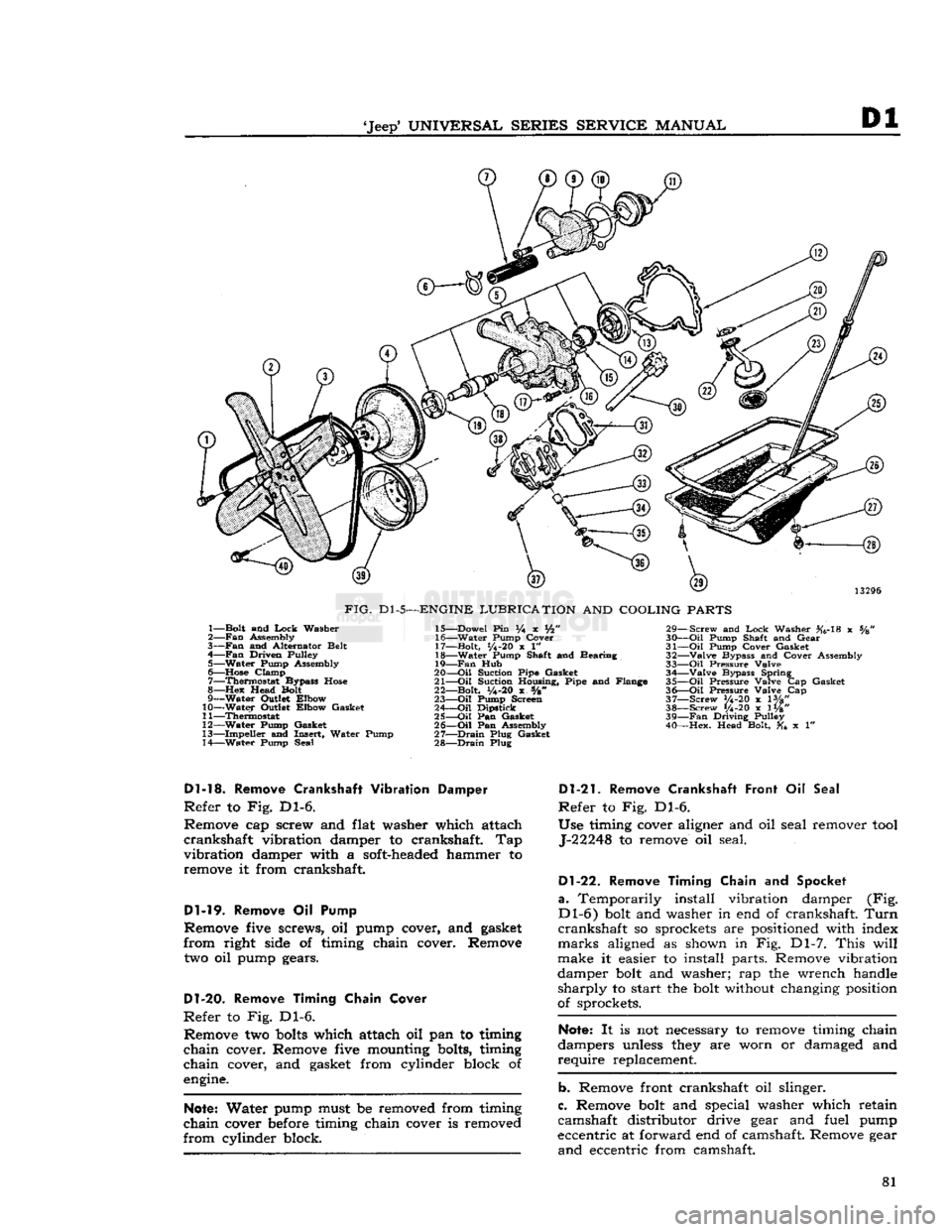

Dl-12.

Remove Cooling

Fan and

Water Pump

Refer

to Fig. Dl-5.

Remove four cap screws, lock washers, cooling fan,

fan

hub, and fan drive pulley from flange of water

pump shaft. Remove nine attaching screws, water

pump, alternator adjustment bracket, and water pump from timing chain cover.

Dl-13.

Remove

Oil

Filter

Unscrew

oil filter from

engine

oil pump.

Dl-14.

Remove Starter Motor

Disconnect wiring harness from starter motor and

solenoid. Remove two attaching screws, starter motor, solenoid, and motor attaching bracket from

engine

flywheel housing and cylinder block.

Dl-15.

Remove

Oil

Pressure Sending Unit

Disconnect wiring harness from oil pressure send

ing unit. Remove oil pressure sending unit from

engine

cylinder block.

Dl-16.

Remove

Oil

Dipstick

Withdraw

and remove oil level dipstick and dip

stick

tube

from

engine

cylinder block.

Dl-17.

Remove Crankshaft Pulley

Remove six attaching screws and crankshaft pulley

from

crankshaft vibration damper. 80

Page 81 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

Dl

13296

FIG.

Dl-5—ENGINE

LUBRICATION

AND

COOLING

PARTS

1— Bolt and

Lock

Washer

2—

Fan

Assembly

3—

Fan

and Alternator Belt

4—

Fan

Driven Pulley 5— Water Pump Assembly

6—

Hose

Clamp 7— Thermostat Bypass

Hose

8—Hex

Head Bolt

9— Water Outlet Elbow

10— Water Outlet Elbow Gasket

11— Thermostat

12— Water Pump Gasket

13— Impeller and Insert, Water Pump

14— Water Pump Seal 15— Dowel Pin % x Vfc"

16— Water Pump Cover

17— Bolt,

1/4-20

x 1"

18— Water Pump Shaft and Bearing

19—

Fan

Hub

20—

-Oil

Suction Pipe Gasket

21—

Oil

Suction Housing, Pipe and Flange

22— Bolt,

y4-20

x s/8"

23—

Oil

Pump Screen

24—

Oil

Dipstick

25—

Oil

Pan Gasket

26—

Oil

Pan Assembly

27—

Drain

Plug Gasket

28—

Drain

Plug 29— Screw and

Lock

Washer #6-18 x %

30—

Oil

Pump Shaft and Gear

31—

Oil

Pump Cover Gasket

32— Valve Bypass and Cover Assembly

33—

Oil

Pressure Valve 34— Valve Bypass Spring

35—

Oil

Pressure Valve Cap Gasket

36—

Oil

Pressure Valve Cap

37— Screw V4-20 x lVg"

38— Screw 1/4-20 x 1W' 39—

Fan

Driving Pulley

40— Hex. Head Bolt, x 1"

Dl-13.

Remove

Crankshaft

Vibration Damper

Refer

to Fig. Dl-6.

Remove cap screw and flat washer which attach

crankshaft

vibration damper to crankshaft. Tap

vibration

damper with a soft-headed hammer to remove it from crankshaft.

Dl-19.

Remove Oil Pump

Remove five screws, oil pump cover, and gasket

from

right side of timing chain cover. Remove

two oil pump gears.

D1-20.

Remove Timing Chain Cover

Refer

to Fig. Dl-6. Remove two

bolts

which attach oil pan to timing

chain

cover. Remove five mounting bolts, timing

chain

cover, and gasket from cylinder block of

engine.

Note:

Water pump must be removed from timing

chain

cover before timing chain cover is removed

from

cylinder block.

Dl-21.

Remove Crankshaft Front

Oil

Seal

Refer

to Fig. Dl-6.

Use timing cover aligner and oil seal remover

tool

J-22248 to remove oil seal.

Dl-22.

Remove Timing Chain

and

Spocket

a.

Temporarily install vibration damper (Fig.

Dl-6)

bolt and washer in end of crankshaft.

Turn

crankshaft

so sprockets are positioned with index

marks

aligned as shown in Fig. Dl-7.

This

will

make it easier to install parts. Remove vibration

damper bolt and washer; rap the wrench handle

sharply

to start the bolt without changing position

of sprockets.

Note:

It is not necessary to remove timing chain

dampers unless they are worn or damaged and

require

replacement.

b. Remove front crankshaft oil slinger.

c. Remove bolt and special washer which retain

camshaft distributor drive gear and fuel pump

eccentric at forward end of camshaft. Remove gear

and

eccentric from camshaft. 81

Page 95 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

Dl

Dl-65.

Rocker Arm Cover Cleaning

and Inspection

a.

Clean

both rocker arm covers with suitable

cleaning solvent and dry thoroughly.

b.

Inspect each rocker arm cover visually for

scratches,

bends, dents, and tears. Replace cover

if

unserviceable.

Dl-66.

Timing Chain

and

Sprocket Inspection

Inspect

the timing chain and both sprockets for

damage or excessive wear. Replace unserviceable

parts.

Dl-67.

Timing Chain Cover Cleaning and Inspection

a.

Clean

the timing chain cover with suitable clean

ing solvent and dry with compressed air.

b.

Inspect the cover visually for breaks,

cracks,

and

other damage.

With

a straightedge, check cylinder

block, water pump, and oil pump faces for bends

and

distortion.

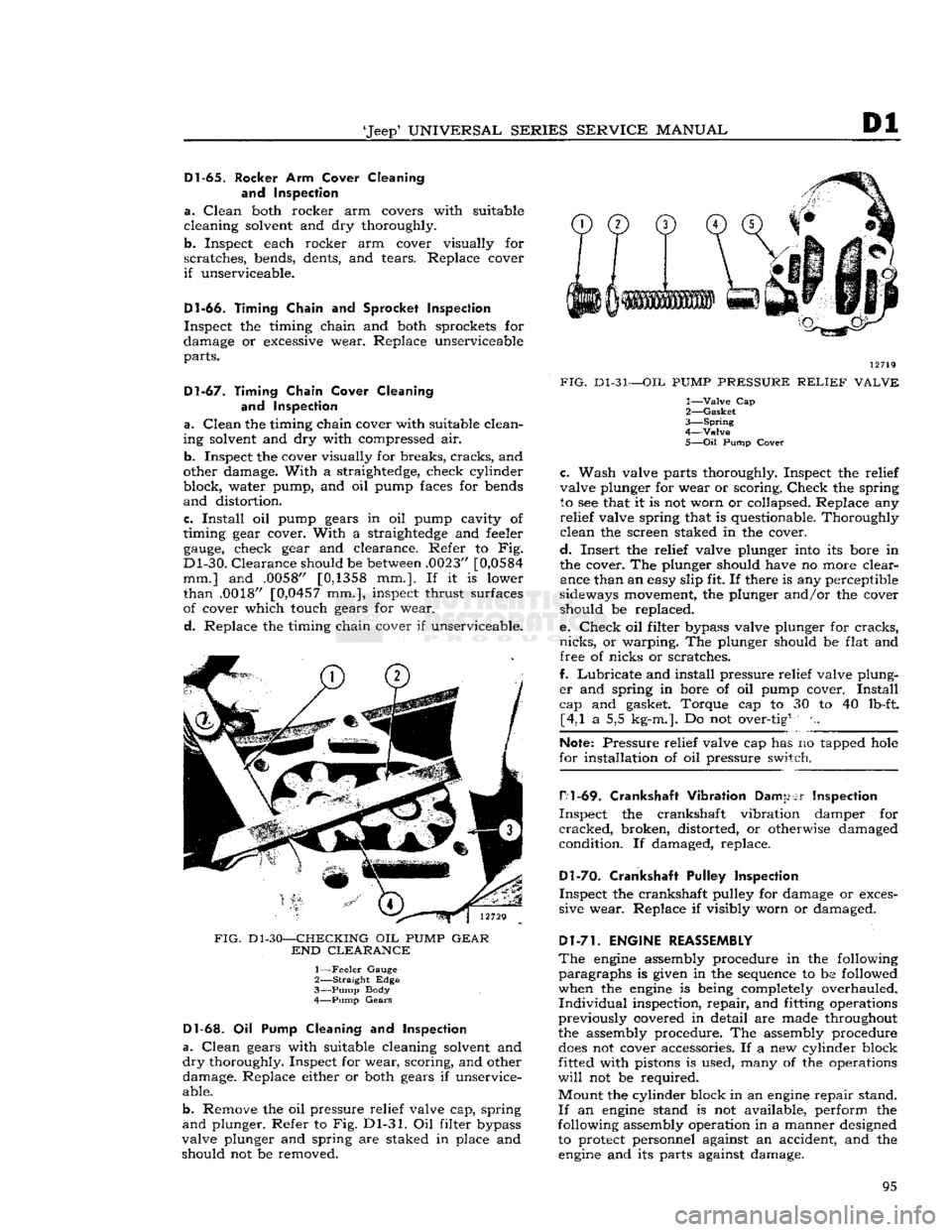

c.

Install

oil pump gears in oil pump cavity of

timing gear cover.

With

a straightedge and feeler

gauge,

check gear and clearance. Refer to Fig.

Dl-30.

Clearance

should be

between

.0023"

[0,0584

mm.] and .0058"

[0,1358

mm.]. If it is lower

than

.0018" [0,0457 mm.], inspect thrust surfaces

of cover which touch gears for wear.

d.

Replace the timing chain cover if unserviceable.

FIG.

Dl-30—CHECKING

OIL

PUMP

GEAR

END

CLEARANCE

1—

Feeler

Gauge

2—

Straight

Edge

3—

Pump

Body

4—

Pump

Gears

Dl-63.

Oil Pump Cleaning and

Inspection

a.

Clean

gears with suitable cleaning solvent and

dry

thoroughly. Inspect for wear, scoring, and other damage. Replace either or both gears if unservice

able.

b.

Remove the oil pressure relief valve cap, spring

and

plunger. Refer to Fig. Dl-31. Oil filter bypass

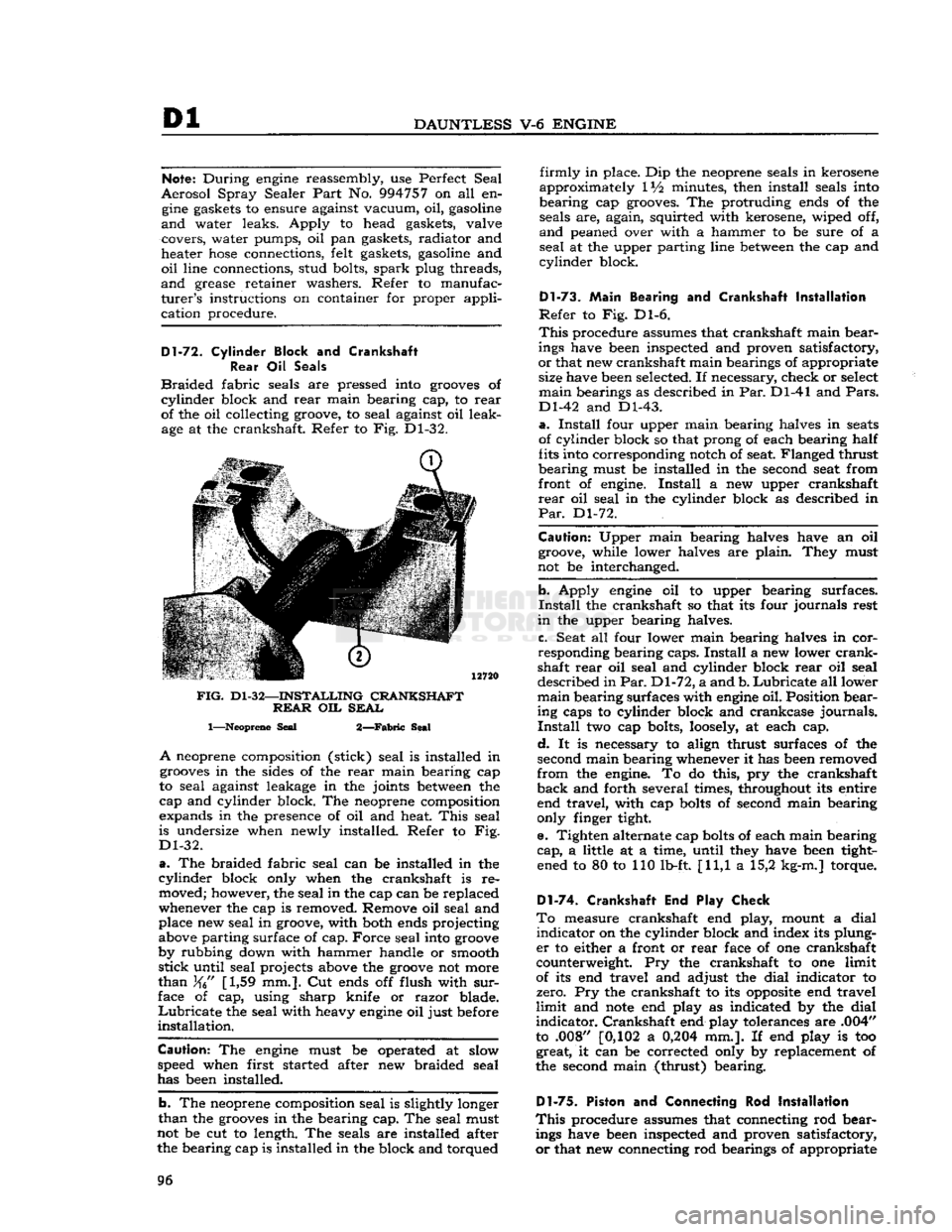

valve plunger and spring are staked in place and should not be removed. 12719

FIG.

Dl-31—OIL

PUMP

PRESSURE

RELIEF

VALVE

1—

Valve

Cap

2—

Gasket

3—

Spring

4—Valve

5—

Oil

Pump

Cover

c.

Wash valve parts thoroughly. Inspect the relief

valve plunger for wear or scoring.

Check

the spring to see that it is not worn or collapsed. Replace any

relief

valve spring that is questionable. Thoroughly

clean

the screen staked in the cover.

d.

Insert the relief valve plunger into its bore in

the cover. The plunger should have no more clear ance than an easy slip fit. If there is any perceptible

sideways movement, the plunger and/or the cover should be replaced.

e.

Check

oil filter bypass valve plunger for

cracks,

nicks,

or warping. The plunger should be flat and free of nicks or scratches.

f.

Lubricate

and install pressure relief valve plung

er

and spring in bore of oil pump cover.

Install

cap and gasket. Torque cap to 30 to 40 lb-ft. [4,1 a 5,5 kg-m.]. Do not over-tig1 n.

Note:

Pressure relief valve cap has no tapped

hole

for installation of oil pressure switch.

H1

-69.

Crankshaft Vibration

Damper

Inspection

Inspect

the crankshaft vibration damper for

cracked,

broken, distorted, or otherwise damaged

condition. If damaged, replace.

Dl-70.

Crankshaft Pulley Inspection

Inspect

the crankshaft pulley for damage or exces

sive wear. Replace if visibly worn or damaged.

Dl-71.

ENGINE REASSEMBLY

The

engine

assembly procedure in the following

paragraphs

is given in the sequence to be followed

when the

engine

is being completely overhauled.

Individual

inspection,

repair,

and fitting operations

previously covered in detail are made throughout

the assembly procedure. The assembly procedure

does

not cover accessories. If a new cylinder block

fitted with pistons is used, many of the operations

will

not be required.

Mount

the cylinder block in an

engine

repair stand.

If

an

engine

stand is not available, perform the

following assembly operation in a manner designed to protect personnel against an accident, and the

engine

and its parts against damage. 95

Page 96 of 376

Dl

DAUNTLESS

V-6

ENGINE

Note:

During

engine

reassembly, use Perfect Seal

Aerosol

Spray Sealer

Part

No.

994757

on all en

gine

gaskets to ensure against vacuum, oil, gasoline

and

water leaks. Apply to head gaskets, valve covers, water pumps, oil pan gaskets, radiator and

heater

hose

connections, felt gaskets, gasoline and

oil

line connections, stud bolts, spark plug threads,

and

grease retainer washers. Refer to manufac

turer's

instructions on container for proper appli

cation procedure.

Dl-72.

Cylinder

Block

and Crankshaft

Rear

Oil Seals

Braided

fabric seals are pressed into

grooves

of

cylinder

block and

rear

main bearing cap, to

rear

of the oil collecting groove, to seal against oil leak age at the crankshaft. Refer to Fig. Dl-32.

FIG.

Dl-32—INSTALLING

CRANKSHAFT REAR

OIL

SEAL

1—Neoprene

Seal

2—Fabric

Seal

A

neoprene composition (stick) seal is installed in

grooves

in the sides of the

rear

main bearing cap

to seal against leakage in the joints

between

the

cap and cylinder block. The neoprene composition

expands in the presence of oil and heat.

This

seal

is undersize when newly installed. Refer to Fig.

Dl-32.

a.

The braided fabric seal can be installed in the

cylinder

block only when the crankshaft is re moved; however, the seal in the cap can be replaced

whenever the cap is removed. Remove oil seal and place new seal in groove, with both ends projecting

above parting surface of cap. Force seal into

groove

by rubbing down with hammer handle or smooth

stick

until seal projects above the

groove

not more

than

[1,59 mm.]. Cut ends off flush with

sur

face of cap, using sharp knife or razor blade.

Lubricate

the seal with heavy

engine

oil just before

installation.

Caution:

The

engine

must be operated at slow

speed when first started after new braided seal

has been installed.

b. The neoprene composition seal is slightly longer

than

the

grooves

in the bearing cap. The seal must

not be cut to length. The seals are installed after the bearing cap is installed in the block and torqued

firmly

in place. Dip the neoprene seals in kerosene

approximately IV2 minutes, then install seals into

bearing cap grooves. The protruding ends of the seals are, again, squirted with kerosene, wiped off,

and

peaned over with a hammer to be sure of a

seal

at the upper parting line

between

the cap and

cylinder

block.

Dl-73.

Main

Bearing and Crankshaft

Installation

Refer

to Fig. Dl-6.

This

procedure assumes that crankshaft main bear

ings have been inspected and proven satisfactory,

or

that new crankshaft main bearings of appropriate size have been selected. If necessary, check or select

main

bearings as described in Par. Dl-41 and

Pars.

Dl-42 and Dl-43.

a.

Install

four upper main bearing halves in

seats

of cylinder block so that prong of each bearing half

fits into corresponding notch of seat. Flanged thrust

bearing must be installed in the second seat from

front of engine.

Install

a new upper crankshaft

rear

oil seal in the cylinder block as described in

Par.

Dl-72.

Caution:

Upper main bearing halves have an oil groove, while lower halves are plain. They must

not be interchanged.

b. Apply

engine

oil to upper bearing surfaces.

Install

the crankshaft so that its four journals rest

in

the upper bearing halves.

c. Seat all four lower main bearing halves in cor

responding bearing caps.

Install

a new lower

crank

shaft

rear

oil seal and cylinder block

rear

oil seal

described in

Par.

Dl-72, a and b.

Lubricate

all lower

main

bearing surfaces with

engine

oil. Position bear ing caps to cylinder block and crankcase journals.

Install

two cap bolts,

loosely,

at each cap.

d.

It is necessary to align thrust surfaces of the

second main bearing whenever it has been removed

from

the engine. To do this, pry the crankshaft

back

and forth several times, throughout its entire end travel, with cap

bolts

of second main bearing

only finger tight.

e. Tighten alternate cap

bolts

of each main bearing

cap,

a little at a time, until they have been tight ened to 80 to 110 lb-ft. [11,1 a 15,2 kg-m.] torque.

D1-74. Crankshaft End Play Check

To

measure crankshaft end play, mount a dial

indicator

on the cylinder block and index its plung

er

to either a front or

rear

face of one crankshaft

counterweight. Pry the crankshaft to one limit

of its end travel and adjust the dial indicator to

zero. Pry the crankshaft to its

opposite

end travel

limit

and

note

end play as indicated by the dial

indicator.

Crankshaft end play tolerances are .004"

to .008" [0,102 a

0,204

mm.]. If end play is too great, it can be corrected only by replacement of

the second main (thrust) bearing.

Dl-75.

Piston and Connecting Rod

Installation

This

procedure assumes that connecting rod bear ings have been inspected and proven satisfactory,

or

that new connecting rod bearings of appropriate 96

Page 101 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

of packing are at top. Drive in a new shedder with

a

suitable punch. Stake the shedder in at least three places to secure it in position. Size the pack-

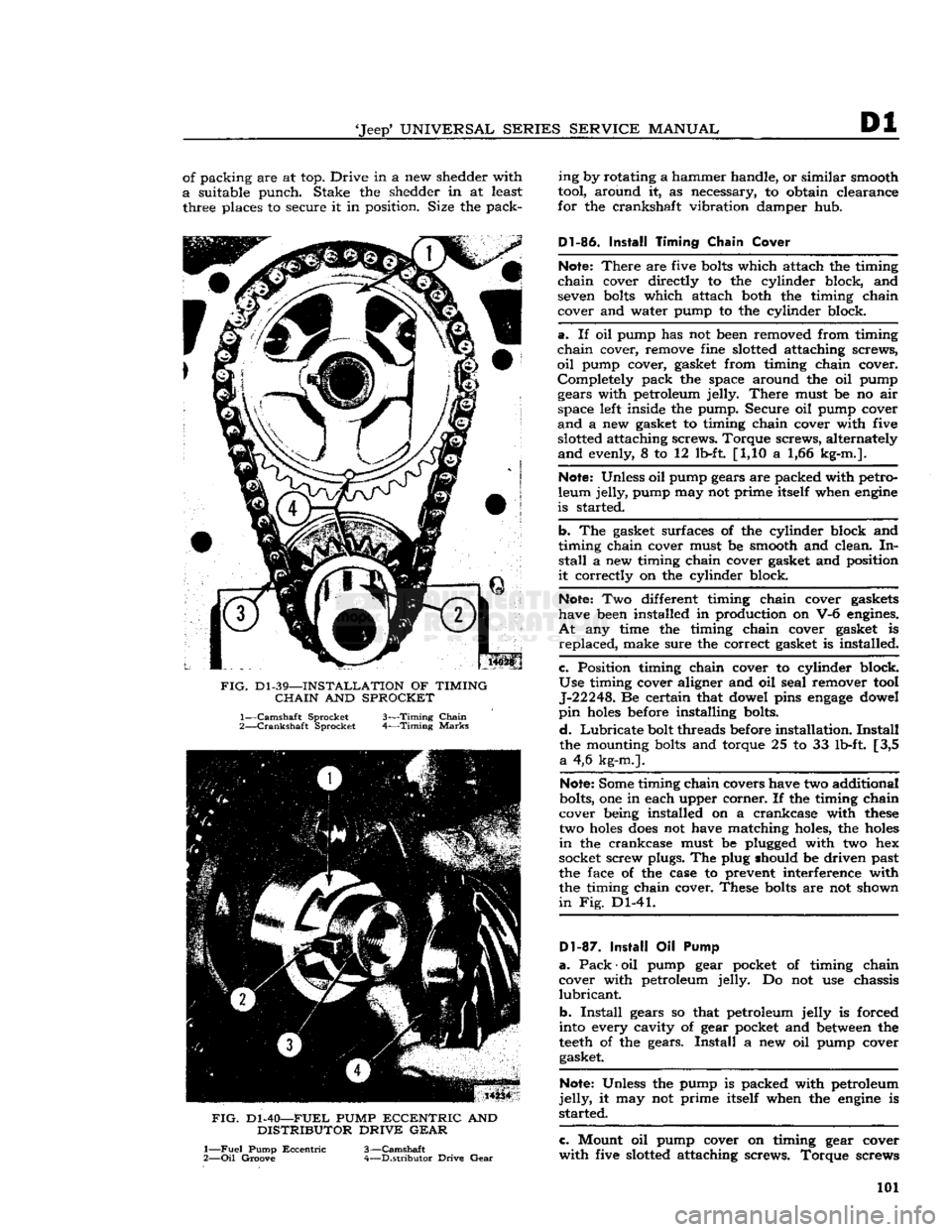

FIG.

Dl-39—INSTALLATION

OF

TIMING

CHAIN

AND

SPROCKET

1—

Camshaft

Sprocket 3—Timing

Chain

2—

Crankshaft

Sprocket 4—Timing

Marks

FIG.

Dl-40—FUEL

PUMP

ECCENTRIC

AND

DISTRIBUTOR

DRIVE GEAR

1—

Fuel

Pump

Eccentric

3—Camshaft

2—

Oil

Groove 4—Distributor Drive

Gear

ing by rotating a hammer handle, or similar smooth

tool, around it, as necessary, to obtain clearance

for the crankshaft vibration damper hub.

Dl-86.

Install

Timing

Chain

Cover

Note:

There

are five

bolts

which attach the timing

chain

cover directly to the cylinder block, and seven

bolts

which attach both the timing chain

cover and water pump to the cylinder block.

a.

If oil pump has not been removed from timing

chain

cover, remove fine slotted attaching screws,

oil

pump cover, gasket from timing chain cover. Completely pack the space around the oil pump gears with petroleum jelly.

There

must be no air

space left inside the pump. Secure oil pump cover

and

a new gasket to timing chain cover with five slotted attaching screws. Torque screws, alternately

and

evenly, 8 to 12 lb-ft [1,10 a 1,66 kg-m.].

Note:

Unless oil pump gears are packed with petro

leum jelly, pump may not prime itself when

engine

is started.

b.

The gasket surfaces of the cylinder block and

timing chain cover must be smooth and clean. In

stall

a new timing chain cover gasket and position

it

correctly on the cylinder block.

Note:

Two different timing chain cover gaskets

have been installed in production on V-6 engines.

At

any time the timing chain cover gasket is

replaced,

make sure the correct gasket is installed.

c.

Position timing chain cover to cylinder block.

Use

timing cover aligner and oil seal remover tool J-22248. Be certain that dowel pins

engage

dowel

pin

holes

before installing bolts.

d.

Lubricate

bolt threads before installation.

Install

the mounting

bolts

and torque 25 to 33 lb-ft. [3,5

a

4,6 kg-m.].

Note:

Some timing chain covers have two additional

bolts, one in each upper corner. If the timing chain

cover being installed on a crankcase with

these

two

holes

does

not have matching holes, the

holes

in

the crankcase must be plugged with two hex

socket screw plugs. The plug should be driven past

the face of the case to prevent interference with the timing chain cover. These

bolts

are not shown

in

Fig. Dl-41.

D1-87.

Install

Oil Pump

a.

Pack

•

oil pump gear pocket of timing chain

cover with petroleum jelly. Do not use chassis

lubricant.

b.

Install

gears so that petroleum jelly is forced

into every cavity of gear pocket and

between

the

teeth

of the gears.

Install

a new oil pump cover gasket.

Note:

Unless the pump is packed with petroleum

jelly,

it may not prime itself when the

engine

is

started.

c.

Mount oil pump cover on timing gear cover

with

five slotted attaching screws. Torque screws 101

Page 102 of 376

![JEEP CJ 1953 Owners Manual

Dl

DAUNTLESS

V-6

ENGINE

FIG.

Dl-41—WATER

PUMP

AND

TIMING CHAIN COVER BOLT LOCATION

Cover

Bolts

alternately and evenly 8 to 12 lb-ft. [1,10 a 1,66

kg-m.].

Dl-88.

Install

Cranksh JEEP CJ 1953 Owners Manual

Dl

DAUNTLESS

V-6

ENGINE

FIG.

Dl-41—WATER

PUMP

AND

TIMING CHAIN COVER BOLT LOCATION

Cover

Bolts

alternately and evenly 8 to 12 lb-ft. [1,10 a 1,66

kg-m.].

Dl-88.

Install

Cranksh](/img/16/57040/w960_57040-101.png)

Dl

DAUNTLESS

V-6

ENGINE

FIG.

Dl-41—WATER

PUMP

AND

TIMING CHAIN COVER BOLT LOCATION

Cover

Bolts

alternately and evenly 8 to 12 lb-ft. [1,10 a 1,66

kg-m.].

Dl-88.

Install

Crankshaft

Vibration

Damper

a.

Lubricate

the vibration damper hub

before

in

stallation to prevent

damage

to the crankshaft

front oil seal during installation and when the

engine

is first started.

b.

Install

the vibration damper on the crankshaft.

Secure it with its attaching flat washer and screw.

Torque

the screw to a minimum of 140 lb-ft.

[19,35

kg-m.].

Dl-89.

Install

Crankshaft Pulley

Secure the crankshaft pulley to the crankshaft

vibration

damper with six screws. Torque screws 18 to 25 lb-ft. [2,5 a 3,4 kg-m.].

Dl-90.

Install

Oil

Level

Dipstick

Insert

oil level dipstick

into

the dipstick tube.

Dl-91.

Install

Oil

Pressure Sending Unit

Install

oil pressure sending unit in cylinder block.

Connect electrical wiring harness to unit.

Dl-92.

Install Starting Motor

Secure starting motor and

solenoid

assembly to

the flywheel housing and cylinder block with two attaching screws. Torque screw, which attaches this

assembly to the flywheel housing, 30 to 40 lb-ft. [4,1 a 5,5 kg-m.]. Torque screw, which attaches

bracket

to cylinder block, 10 to 12 lb-ft. [1,4 a 1,7 kg-m.].

Dl-93.

Install

Oil

Filter

Install

a new oil filter

element

at oil filter nipple,

at

left

side

of timing chain cover. Torque 10 to 15 lb-ft. [1,38 a 2,07 kg-m.].

D1-94. Install Water Pump

Be

certain that mating surfaces of the water pump

and

timing chain cover are clean.

Install

a new

gasket

on the pump flange. Secure the pump and

alternator adjustment bracket to the cover with

nine attaching bolts. Torque

bolts

6 to 8 lb-ft. [0,83 a 1,10 kg-m.]. Refer to Fig. Dl-41.

D1-9S.

Install

Cooling Fan

Secure the cooling fan, fan hub, and fan drive

pulley to the water pump shaft

flange

with four

attaching screws. Torque screws 17 to 23 lb-ft. [2,35 a 3,18 kg-m.].

Dl-96.

Install

Alternator

and Fan

Belt

Mount the alternator and bracket assembly on

right

cylinder head with two attaching screws.

Torque

screws 30 to 40 lb-ft. [4,1 a 5,5 kg-m.].

Fasten

the alternator

loosely

to its adjustment

bracket

with attaching flat washer and nut.

Install

the fan

belt

on its pulleys. Pivot the alternator

outward,

away from cylinder block, to apply fan

belt

tension. Adjust fan

belt

tension to 80 lb. [36,2 kg.];

tighten

alternator-to-adjustment bracket

nut to secure adjustment

setting.

Connect wiring

harness to alternator.

Dl-97.

Install

Fuel Pump

Install

two mounting

bolts

and new

gasket

on

flange

of fuel pump. Secure pump to timing chain cover with screws; torque screws 17 to 23 lb-ft. [2,35 a 3,8 kg-m.]. Connect

output

fuel line to

pump.

Dl-98.

Install Exhaust Manifold

Secure each of two exhaust manifolds to corre

sponding cylinder head with five attaching screws,

and

one nut. Torque screws and nut 15 to 20 lb-ft. [2,07 a 2,8 kg-m.]. See Fig. Dl-42.

Dl-99.

Install Distributor

Insert

distributor drive gear

into

distributor mount-

FIG.

Dl-42—EXHAUST

MANIFOLD INSTALLATION

1—Torque

Bolts—15

to 20

lb-ft.

[2,07 a 2,8

kg-m.]

102

Page 105 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

Dl-104.

SERVICE

DIAGNOSIS

Poor Fuel Economy

Ignition Timing Late or Spark Advance Inoperative

Carburetor

Float Setting Too High

Accelerator Pump Improperly Adjusted

Fuel

Pump Pressure High

Fuel

Line

Leakage

Fuel

Pump Diaphragm Leakage

Cylinder

Compression Low

Valves Do Not Seat Properly

Spark

Plugs

Defective

Spark

Plug Cables

Defective

Ignition

Coil

or Capacitor

Defective

Carburetor

Air Cleaner Dirty

Brakes

Drag

Wheel Alignment Incorrect

Tire

Pressure Incorrect Odometer Inaccurate

Fuel

Tank

Cap Clogged or

Defective

Muffler or Exhaust Pipe Clogged or Bent

Lack

of

Power

Cylinder

Compression Low

Ingitdon Timing Late

Carburetor

or

Fuel

Pump Clogged or

Defective

Fuel

Lines Clogged

Air

Cleaner Restricted

Engine Temperature High Valves Do Not Seat Property

Valve

Timing Late Intake Manifold or Cylinder Head

Gasket Leaks

Muffler or Exhaust Pipe Clogged or Bent

Spark

Plugs Dirty or

Defective

Breaker

Point Gap Incorrect

Breaker

Points

Defective

Ignition

Coil

or Capacitor

Defective

Electrical

Connection Loose

Broken

Valve Spring

Broken

Piston Ring or Piston

Cylinder

Head Gasket

Defective

Distributor Cap Cracked

Low

Compression

Valves Not Seating Properly Piston Rings Seal Poorly

Valve

Spring Weak or Broken

Cylinder

Scored or Worn

Piston Clearance Too Great

Cylinder

Head Gasket Leaks

Burned

Valves and

Seats

Valves Stick or Are Too Loose in Guides

Valve

Timing Incorrect

Valve

Head and Seat Have Excessive Carbon

Engine Overheats

Valve

Spring Weak or Broken

Valve

Lifter Seized or Collapsed

Exhaust

System Clogged

Valves Sticking

Valve

Stem Warped

Valve

Stem Carbonized or Scored

Valve

Stem Clearance Insufficient in Guide

Valve

Spring Weak or Broken

Valve

Spring Distorted

Oil

Contaminated

Overheating

Cooling System Inoperative

Thermostat Inoperative Ignition Timing Incorrect

Valve

Timing Incorrect

Carbon

Accumulation Excessive

Fan

Belt Loose

Muffler or Exhaust Pipe Clogged or Bent

Oil

System Failure

Piston Rings Worn or Scored

Popping,

Spitting,

Detonation

Ignition Timing Incorrect

Carburetion

Improper

Carbon

Deposit

in Combustion

Chambers Excessive

Valves Not Seating Properly

Valve

Spring Broken

Spark

Plug Electrodes Burned

Water or Dirt in

Fuel

Fuel

Line

Clogged

Valve

Timing Incorrect

Excessive

Oil

Consumption

Piston Rings Stuck in Grooves, Weak,

Worn,

Broken, or Incorrectly Fitted

Crankshaft

Main Bearings or

Connecting Rod Bearings Have

Excessive Clearance

Gaskets or Oil Seals

Leak

Cylinder

Bores Worn, Scored,

Out-of-Round or Tapered

Pistons Have Too Great Clearance to Cylinder Bores

Connecting Rods Misaligned High Road Speed

High Temperature

Crankcase

Ventilation System Inoperative

Bearing Failure

Crankshaft

Bearing Journal Rough or Out-of-Round

Oil

Level Low

Oil

Leakage

Oil

Dirty

Oil

Pressure Low or Lacking

(Oil

Pump Failure)

Drilled

Passages

in Crankshaft or

Crankcase

Clogged

Oil

Screen Dirty

Connecting Rod Bent 105

Page 109 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

E

FUEL

SYSTEM

Contents

SUBJECT

PAR.

GENERAL

E-1 Dash

FUEL

EVAPORATIVE EMISSION

?*^r

CONTROL SYSTEM

..E-2

Canister

.E-3 . Demand Valve E-4

Fuel

Tank.

.E-5

Inspection Test. E-8

Sealed Gas Cap. E-7

Servicing

System E-9

Vapor

Separator or Expansion

Tank

E-6

CARBURETOR

—

HURRICANE F4 ENGINE.

. .

......

..... ,. . .E-10 Accelerating Pump System.............. .E-19 Accelerating Pump Maintenance E-20

Carburetor

Reassembly

E-2

2

Carburetor

Disassembly E-21

Choke

System E-17

Dash

Pot Adjustment E-44

Fast

Idle Adjustment E-18

Float

Adjustment E-12

Float

System. E-ll

High-Speed System . .E-15

Idle

Adjustment .E-14

Low-Speed

System . E-13

Metering Rod Adjustment E-16

CARBURETOR

~r

DAUNTLESS V-6 ENGINE

.E-25

Accelerator Pump Adjustment E-41 Accelerator Pump System. . E-30

Air

Horn Body Assembly E-39

Air

Horn Body Removal and Disassembly.

E-33

Carburetor

Cleaning and Inspection E-36

Carburetor

Removal E-32

Choke

System E-31

Curb-Idle

Speed and Mixture Adjustment. .E-42

E-1. GENERAL

The

fuel system of the Jeep Universal vehicle,

whether equipped with a Hurricane F4 or Daunt

less

V-6 Engine,

consists

of the fuel tank, fuel lines, fuel pump, carburetor and

air

cleaner.

Fig. E-1, E-2.

Vehicles equipped with a

Fuel

Evaporative

Emis

sion Control System

also

include a

non-vent

pressure and vacuum

sensitive

gas cap, a liquid

expansion and vapor separator tank, a carbon filled vapor

storage

canister, and a vapor purge line. Service information pertaining to the

Fuel

Evap

orative Emission Control System is outlined in

Par.

E-2 through

E-9.

Refer to Figs. E-3 and E-4.

The

most

important

attention

necessary to the fuel

system is to

keep

it clean and free from water. It should be periodically inspected for leaks.

CAUTION—Whenever

a vehicle is to be stored for

an

extended

period, the fuel system should be com

pletely

drained, the

engine

started and allowed to

run

until the carburetor is emptied.

This

will

avoid

oxidization of the fuel, resulting in the formation of

SUBJECT

PAR.

Pot Adjustment .E-44

nal

Carburetor Adjustments.........E-40

Idle

Adjustment

.

E-43 System . . .E-26

Bowl

Body Assembly E-38

Fuel

Bowl Body Disassembly E-34

Idle

System E-27

Main

Metering System E-28

Power System . E-29

Throttle

Body Assembly .E-37

Throttle

Body Removal, and Disassembly. .E-35

FUEL

PUMP

—

HURRICANE F4 ENGINE.

E-45, 54, 60

Cleaning

and Inspection.............

.E-57,

63 Disassembly E-46, 56, 62

Installation E-59, 65

Reassembly

.E-47,

58, 64

Removal

E-55, 61

Testing.

E-49, 50, 51, 52, 53, 66

Vacuum

Pump E-48

FUEL

PUMP

—

DAUNTLESS V-6 ENGINE

E-67

Removal

E-68

AIR CLEANER

—

CARBURETOR

E-69

ACCELERATOR

LINKAGE

.E-70

FUEL

TANK

AND

LINES

E-71

Float

Unit . .E-76

Fuel

Lines E-77

Fuel

Tank

. . .E-72

Fuel

Tank

Cap E-75

Fuel

Tank

Installation. E-74

Fuel

Tank

Removal E-73

SERVICE

DIAGNOSIS

E-78

SPECIFICATIONS.

E-79

gum in the units of the fuel system. Gum formation

is similar to hard varnish and may cause the fuel

pump valves or the carburetor

float

valve to be

come

stuck or the filter screen blocked. Acetone or commercial fuel system cleaners

will

dissolve

gum formation. In

extreme

cases

it

will

be necessary

to dissassemble and clean the fuel system. In

most

cases, however, a

good

commercial fuel system sol

vent

used in accordance with the manufacturer's

instructions or one pint [0,6 ltr.] of

acetone

placed

in

the fuel tank with

about

one gallon [4,5 ltr.]

of

gasoline

will

dissolve

any

deposits

as it

passes

through the system with the

gasoline.

E-2.

FUEL

EVAPORATIVE EMISSION CONTROL SYSTEM

Description and Operation

•

Refer to Figs. E-3 and E-4.

The

Fuel

Evaporative Emission Control System

is

designed

to reduce fuel vapor emission that 109