headlights JEEP CJ 1953 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 7 of 376

'Jeep*

UNIVERSAL SERIES

SERVICE

MANUAL

B

LUBRICATION

AND

PERIODIC SERVICES

Contents

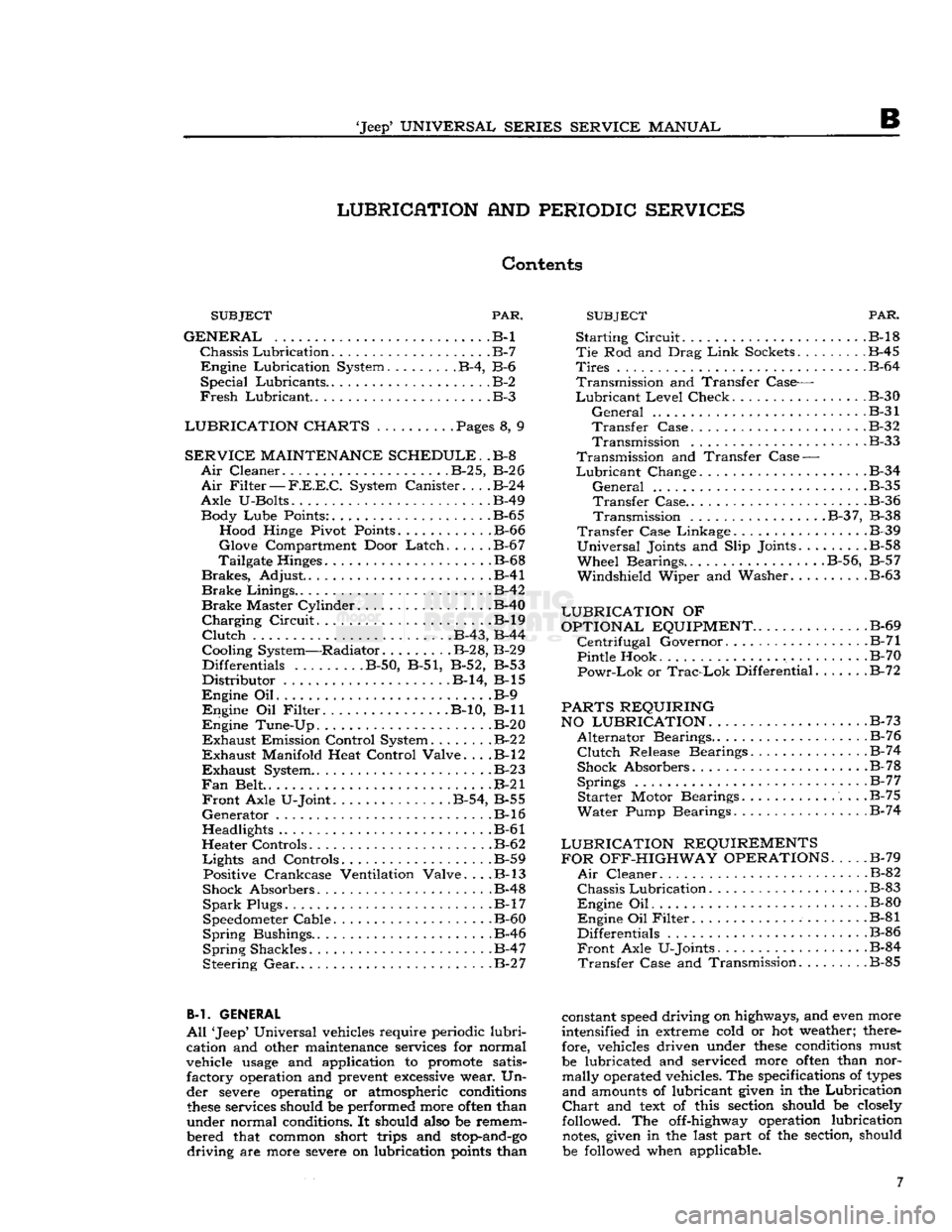

PAR. SUBJECT

PAR.

SUBJECT

GENERAL

.B-l

Chassis

Lubrication

B-7

Engine

Lubrication System B-4, B-6

Special

Lubricants B-2

Fresh

Lubricant.

.B-3

LUBRICATION CHARTS

. Pages 8, 9

SERVICE

MAINTENANCE SCHEDULE.

.B-8

Air

Cleaner

B-2

5,

B-2

6

Air

Filter

—

F.E.E.C.

System Canister

B-2

4

Axle

U-Bolts B-49 Body

Lube

Points: B-65 Hood Hinge Pivot Points B-66

Glove

Compartment Door

Latch

B-6

7

Tailgate Hinges .B-68

Brakes,

Adjust .B-41

Brake

Linings .B-42

Brake

Master Cylinder B-40

Charging

Circuit

B-l9

Clutch

. B-43, B-44

Cooling System—Radiator. B-28, B-29 Differentials

........

.B-50, B-51, B-52, B-53

Distributor

B-14, B-l5

Engine

Oil B-9

Engine

Oil

Filter

B-10, B-ll

Engine

Tune-Up B-20

Exhaust

Emission Control System

B-2

2

Exhaust

Manifold Heat Control Valve. . . .B-l2

Exhaust

System

B-2 3

Fan

Belt . .B-21

Front

Axle U-Joint B-54, B-55

Generator

.B-16

Headlights B-61

Heater Controls B-62

Lights

and Controls B-59 Positive Crankcase Ventilation Valve. . . .B-l3

Shock Absorbers B-48

Spark

Plugs. B-17

Speedometer Cable. .B-60

Spring

Bushings.. . .B-46

Spring

Shackles .B-47

Steering

Gear

B-2 7

B-l. GENERAL

All

'Jeep' Universal vehicles require periodic

lubri

cation and other maintenance services for normal

vehicle

usage

and application to promote satis factory operation and prevent

excessive

wear. Un

der severe operating or atmospheric conditions

these

services should be performed more

often

than

under normal conditions. It should also be remem

bered that common short trips and

stop-and-go

driving

are more severe on lubrication

points

than

Starting

Circuit

B-l8

Tie

Rod and Drag

Link

Sockets

.

B-45

Tires

B-64

Transmission

and Transfer Case—

Lubricant

Level

Check B-30

General

B-31

Transfer

Case B-32

Transmission

.B-33

Transmission

and Transfer

Case

—

Lubricant

Change .B-34

General

.B-35

Transfer

Case B-36

Transmission

B-3

7, B-38

Transfer

Case Linkage B-39

Universal

Joints and Slip Joints.

.......

.B-58

Wheel

Bearings..

.........

. . .B-56, B-57

Windshield

Wiper and Washer B-63

LUBRICATION

OF

OPTIONAL EQUIPMENT

B-69

Centrifugal

Governor. .B-71

Pintle Hook .B-70

Powr-Lok

or

Trac-Lok

Differential B-72

PARTS REQUIRING

NO LUBRICATION.

. . .B-73

Alternator

Bearings. B-76

Clutch

Release Bearings.

.............

.B-74

Shock Absorbers B-78

Springs

B-7

7

Starter

Motor Bearings B-75

Water

Pump Bearings B-74

LUBRICATION REQUIREMENTS FOR OFF-HIGHWAY OPERATIONS

B-79

Air

Cleaner B-82

Chassis

Lubrication

B-83

Engine

Oil B-80

Engine

Oil

Filter

B-81

Differentials .B-86

Front

Axle U-Joints. B-84

Transfer

Case and Transmission .B-85

constant

speed

driving on highways, and even more

intensified in extreme cold or hot weather; there fore, vehicles driven under

these

conditions must

be lubricated and serviced more

often

than nor mally operated vehicles. The specifications of

types

and

amounts of lubricant given in the Lubrication

Chart

and

text

of this section should be closely

followed. The off-highway operation lubrication

notes,

given in the last part of the section, should

be followed when applicable. 7

Page 12 of 376

B

LUBRICATION B-3.

SERVICE

MAINTENANCE

SCHEDULE

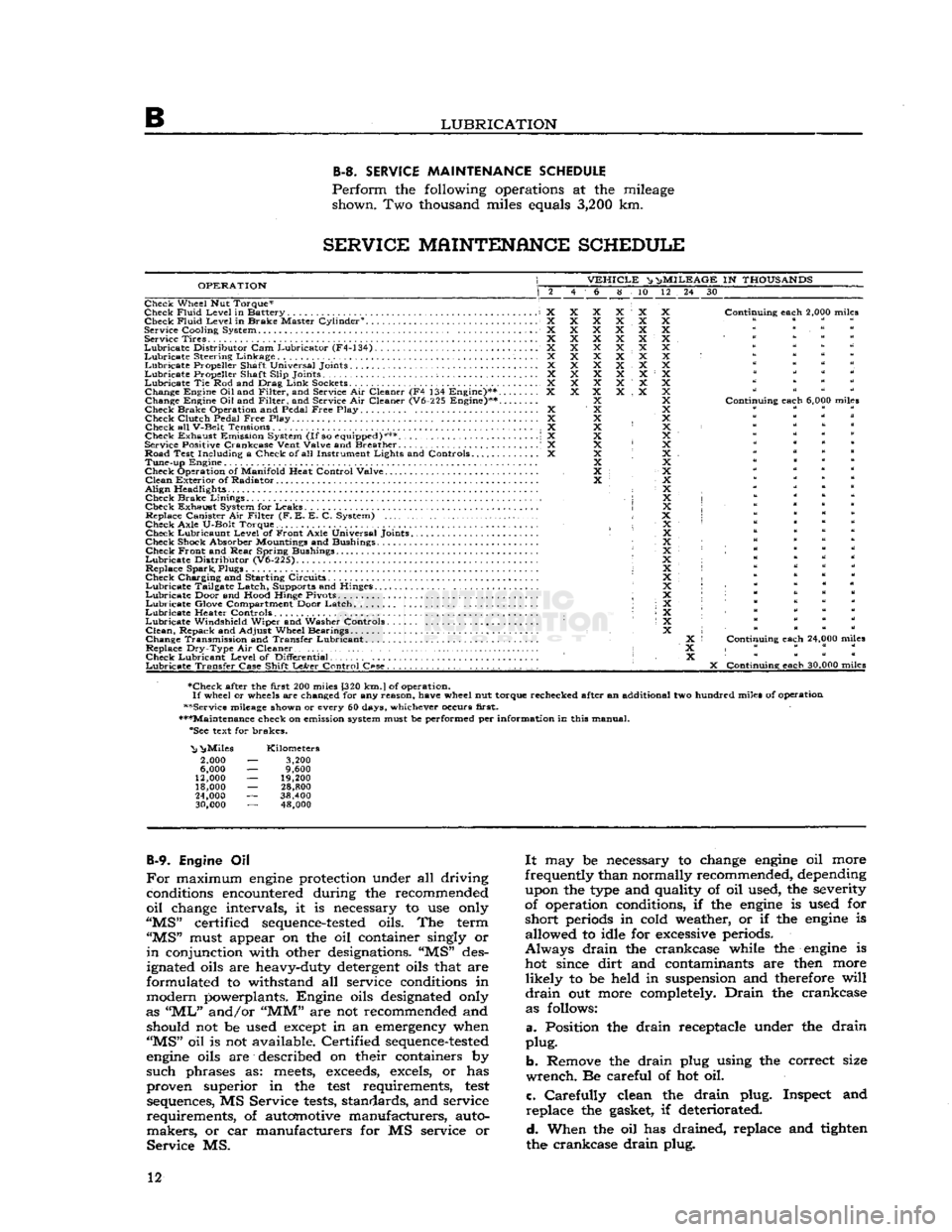

Perform

the following operations at the mileage shown. Two thousand miles equals

3,200

km.

SERVICE

MAINTENANCE

SCHEDULE

OPERATION

VEHICLE

^ n>

MILEAGE

IN

THOUSANDS

6 8 10 12 24 30

Check Wheel Nut Torque*

Check

Fluid

Level

in Battery X Check

Fluid

Level

in Brake Master Cylinder0. X

Service

Cooling

System X Service Tires X

Lubricate

Distributor

Cam Lubricator (F4-134) X

Lubricate

Steering Linkage X

Lubricate

Propeller Shaft Universal Joints X

Lubricate

Propeller Shaft

Slip

Joints ; X

Lubricate

Tie Rod and Drag

Link

Sockets................................... X Change Engine

Oil

and

Filter,

and Service Air Cleaner (F4 134 Engine)** X

Change Engine Oil and

Filter,

and Service Air Cleaner (V6-225 Engine)**....

Check Brake Operation and Pedal

Free

Play X Check

Clutch

Pedal

Free

Play. .... X

Check all

V-Belt

Tensions X

Check Exhaust Emission System

(If

so equipped)*** \ X

Service Positive

Crankcase

Vent

Valve

and Breather . .' X

Road Test

Including

a Check of all Instrument

Lights

and Controls X Tune-up Engine

Check Operation of

Manifold

Heat

Control

Valve

Clean

Exterior of Radiator

Align

Headlights • Check Brake

Linings

,

Check Exhaust System for Leaks Replace Canister Air

Filter

(F. E. E. C. System)

Check

Axle

U-Bolt

Torque. Check Lubricaunt

Level

of Front

Axle

Universal Joints

Check Shock Absorber Mountings and Bushings Check Front and

Rear

Spring Bushings

Lubricate

Distributor

(V6-225).

Replace Spark, Plugs

Check Charging and Starting Circuits

Lubricate

Tailgate Latch, Supports and Hinges.

Lubricate

Door and

Hood

Hinge Pivots ;

Lubricate

Glove Compartment Door Latch

Lubricate

Heater Controls •

Lubricate

Windshield

Wiper and Washer Controls

Clean,

Repack and

Adjust

Wheel Bearings

Change Transmission and Transfer Lubricant. .

Replace

Dry-Type

Air Cleaner • Check Lubricant

Level

of

Differential

Lubricate

Transfer

Case

Shift

LeArer

Control

C«se.

. , . . . . . . . .

Continuing

each

2,000 miles

Continuing

each

6,000 miles

Continuing

each

24,000 miles

X

Continuing

each

30,000 miles

•Check after the

first

200 miles [320

km.

J

of operation.

If

wheel or wheels are changed for any

reason,

have

wheel nut torque rechecked after an additional two hundred miles of operation

••Service mileage shown or every 60 days, whichever occurs

first.

•••Maintenance check on emission system must be performed per

information

in this manual. "See text for brakes.

"Nj

^Miles

2,000

6,000

12,000

18,000

24,000

30,000

Kilometers

3,200

9,600

19,200

28,800

38,400 48,000

B-9.

Engine Oil

For

maximum

engine

protection under all driving conditions encountered during the recommended

oil

change intervals, it is necessary to use only

"MS"

certified

sequence-tested

oils. The term

"MS"

must appear on the oil container singly or

in

conjunction with other designations. "MS" des

ignated oils are heavy-duty detergent oils that are

formulated to withstand all service conditions in

modern powerplants. Engine oils designated only

as

"ML"

and/or

"MM"

are not recommended and should not be used except in an emergency when

"MS"

oil is not available. Certified

sequence-tested

engine

oils are described on their containers by

such

phrases as:

meets,

exceeds,

excels, or has

proven superior in the

test

requirements,

test

sequences, MS Service

tests,

standards, and service

requirements,

of automotive manufacturers, auto

makers,

or car manufacturers for MS service or

Service

MS.

It

may be necessary to change

engine

oil more

frequently than normally recommended, depending upon the type and quality of oil used, the severity

of operation conditions, if the

engine

is used for

short

periods in cold weather, or if the

engine

is allowed to idle for excessive periods.

Always

drain

the crankcase while the

engine

is hot since

dirt

and contaminants are then more

likely

to be held in suspension and therefore

will

drain

out more completely.

Drain

the crankcase as follows:

a.

Position the

drain

receptacle under the

drain

plug.

b.

Remove the

drain

plug using the correct size

wrench.

Be careful of hot oil.

c.

Carefully

clean the

drain

plug. Inspect and

replace

the gasket, if deteriorated.

d.

When the oil has drained, replace and tighten

the crankcase

drain

plug. 12

Page 17 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

B

Reinstall

the axle shafts, and

refill

the housings to

plug level using the universal joint lubricant

specified in

Lubrication

Specifications.

B-56.

Front

Axle Wheel Bearings

To

lubricate the wheel bearings, it is necessary

to remove, clean, repack, and adjust them. When

front wheel hubs and bearings are removed for

lubrication,

they should be thoroughly washed in a

suitable cleaning solvent. The bearings should be

carefully

dried and then given a thorough cleaning

and

inspection. Use a clean brush to remove all

particles

of old lubricant from bearings and hubs.

After

the bearings are cleaned, inspect them for

pitted races and rollers. Also, check the hub oil

seals.

Note:

Wheel bearing lithium base lubricants are

used at the factory for

initial

fill

of

these

bearings.

When

lithium base and sodium base lubricants are

mixed,

the result is a thinned-out mixture that

can

bleed through seals. It is therefore important

that lubricants with the correct base be used when

lubricating

the wheel bearings.

Should

leaks occur at wheel bearing seals, the leaks

may

be caused by a mixture of two

types

of

lubri

cants.

In such cases, the old lubricant should be

completely removed before new lubricant is added.

Wheel

bearings should be thoroughly cleaned,

lubricated

with lithium base and reinstalled.

Repack

the bearing

cones

and rollers with grease

and

reassemble hub in the reverse order of the

disassembly. Test the bearing adjustment as out

lined

in Section Q.

B-57.

Rear

Axle Wheel Bearings

The

Rear

wheel bearings an early models equipped

with

lubrication fittings with a vent opening

through the housings above each fitting should be

lubricated

sparingly, each

2,000

miles

[3.200

km.].

Use

a hand compressor and wheel bearing grease,

forcing

the grease through each lubrication fitting

until

it flows from the vent. Vent should be kept

clear

of obstruction or grease

will

back up into the

brakes.

Do not add grease after it flows from the

vent for it may be forced through the wheel key-

way

onto

the outside of the wheel and possibly

onto

the brake linings.

Rear

wheel bearings that do

not have lubrication fittings should be removed

each

12,000

miles

[19.200

km.] and the bearing

cleaned, inspected and repacked. Refer to proce

dure

in Par. B-56.

Note:

When servicing the Flanged Axle Unit

Bear

ing Assembly, refer to Section N, Par. N-5 for

proper

lubrication procedures.

B-58.

Propeller Shafts

and

Universal Joints

The

propeller shaft slip joints and universals should

be lubricated with a hand compressor grease gun so as to not damage the bearing seals. The units

should be lubricated with a

good

quality grease.

Refer

to the

Lubrication

Chart

for lubrication fre

quency and lubricant type and grade. B-59.

Lights

and

Controls

a.

Check

all interior and exterior lights and light

switches for proper operation, including: parking

lights, headlamps (high beam and low beam),

tail

lights, brake lights, directional lights, and in strument panel lights.

b.

Check

all instrument panel controls and

instru

ments for proper operation.

B-60.

Speedometer Cable

Remove the

speedometer

cable from its housing every

12,000

miles

[19.300

km.].

Clean

it thor

oughly and coat it with a

good

quality light graphite grease.

B-61.

Headlights

Refer

to Section H.

B-62.

Heater Controls

Apply

Lubriplate

130-A to all friction points and

pivot points on the heater controls panel unit as well as the pivot points at the dashpot. Apply

a

few drops of penetrating oil all along the Bowden

cable.

This

oil

will

penetrate into the center wire.

B-63.

Windshield Wiper and

Washer Controls

Lubricate

the friction points and the pivot points

on the windshield wiper transmission and linkage

arms

with a slight amount of

Lubriplate

130-A.

B-64.

Rotate Tires

Refer

to Section Q for the correct method of rotat ing the tires.

B-65.

Body Lube Points

•

Refer to Par. B-66 through B-68.

B-66.

Hood Hinge Pivot Points

Lubricate

the frictional points of the hood hinge

pivot points with a few drops of light-weight

engine

oil.

B-67.

Glove Compartment Door Latch

Sparingly

wipe

Lubriplate

130-A on the

glove

com

partment door latch.

B-68.

Tailgate Hinges

Lubricate

the friction points of the tailgate hinges

with

a few drops of light-weight

engine

oil.

B-69.

LUBRICATION

OF

OPTIONAL EQUIPMENT

B-70.

Pintle Hook

When

lubricating the vehicle, place a few drops of oil on the pintle hook and safety latch pivot pins.

B-7!.

Centrifugal Governor

Check

the oil level in the governor housing at each

vehicle lubrication. Use the same seasonal grade

oil

as is used in the

engine

and change oil at each

engine

oil change. Do not

fill

the housing above

the level indicating plug opening. Keep the vent

in

the filler plug open at all times. 17

Page 174 of 376

H

ELECTRICAL

SYSTEM

the condenser. Replace the condenser. If there is

no jump to full voltage, overhaul or replace the

distributor.

k.

With the points closed, connect the voltmeter

from

a clean, paint-free

post

on the distributor

body to the negative

post

of the battery. The volt

age drop should be practically zero, a hardly

readable deflection on the voltmeter. If the volt meter registers a

voltage

drop, perform the checks

in

steps

1

and m following.

I.

Check

for

voltage

drop in the battery ground

cable.

Clean

the battery

post,

cable terminals, and contact surface on the bellhousing, or on body if

a

noticeable deflection of the voltmeter occurs,

m.

Check

for any

voltage

drop

between

the dis

tributor

body and a clean, paint-free

spot

on the

cylinder

block. If there is any

voltage

drop, remove

the distributor and clean the mounting surfaces of

distributor

body and cylinder block.

H-5.

SECONDARY

CIRCUIT

If

satisfactory ignition is not obtainable with cor

rect

point gap and tension; satisfactory condenser;

sufficient primary voltage; and correctly cleaned, gapped, and installed spark plugs; the secondary

circiut

should be investigated.

a.

Test the coil.

Bring

the coil up to operating

temperature using the coil heat feature of a coil tester, if available. Refer to the coil tester manu

facturer's

instructions for specific hook-ups for

performing the checks given in

steps

b, c, and d following.

b. Connect the positive lead of the tester to the

battery terminal of the coil primary winding.

Con

nect the tester ground lead to the coil tower. Mea

sure

the resistance of the secondary winding. If the

resistance is more than

20,000

ohms, a fault in the

secondary winding is indicated.

c.

Check

for a grounded secondary by touching the tester ground lead to the coil cover. If resistance

is not over

100,000

ohms, the secondary is grounded

to the cover.

d.

If the secondary winding is satisfactory, mea

sure

the primary current draw in accordance with

the instructions of the

test

equipment manu

facturer.

e.

Check

the secondary circuit for leakage. With the coil primary in the circuit with the breaker unit of the tester, connect a long, high-tension

test

lead

to the coil tower.

Check

the secondary circuit for

leakage by performing the checks given in

steps

f. g, h, and i following.

Note:

In the following

tests,

a slight sparking and

meter deflection

will

usually be

seen

just as contact

is made.

This

is caused by capacitance and

does

not

indicate defective insulation.

f.

Check

distributor cap. Remove the coil lead from the cap and touch the

test

lead to the center contact

inside the cap. If the meter reading drops when the contact is touched or if sparking is seen, a leakage

path is present

between

the center contact and one

of the plug towers.

This

leakage path

will

be in the

form

of a

crack

or carbon track in the cap. Discon nect the spark plug wires from the cap one at a

time and

test

each plug contact with the high-

voltage

lead and with all other plug wires con

nected. Any sparking or meter drop indicates that

a

leakage path exists

between

that particular con

tact and an adjacent one. Testing the adjacent contacts

will

determine which pair is at fault,

g-

Check

distributor rotor. Touch the

test

lead to

the spring contact in the center of the distributor

rotor.

Any leakage in the rotor insulation

between

the contact and the shaft

will

cause a drop in the meter reading and usually sparking

will

be seen.

h.

Check

spark plug wires. Disconnect the spark

plug wires from the plugs and

test

the plug terminal of each. The meter reading should not drop below

the open secondary value (value before making contact). If it

does

or if a large spark occurs when

the

test

lead and the plug wire are separated, there

is a break in the insulation on that wire.

i.

Check

the coil tower insulation. Remove the

high-tension

test

lead from the coil tower and touch

the ground lead of the coil tester to several points

around

the base of the tower. Any sparking or deflection of the meter indicates a leakage path in

the tower insulation.

H-6.

Alternator Charging System

All

Jeep

Universal

Series vehicles have, as standard

equipment a 35-amp., 12-volt, negative ground

alternator and a transistorized

voltage

regulator.

For

repairing the alternator, many of its major components are furnished as complete assemblies

including:

complete brush assembly which requires no soldering or unsoldering of leads; two complete

rectifying

diode

assemblies which eliminate the need for removing and replacing individual diodes;

a

complete isolation

diode

assembly; and a rotor assembly complete with shaft,

pole

pieces, field coil,

and

slip rings.

The

transistorized

voltage

regulator is an electronic

switching device. It

senses

the

voltage

appearing at the auxiliary terminal of the alternator and

supplies the necessary field current for maintaining the system

voltage

at the output

terminal.

The out

put current is determined by the battery electrical

load;

such as headlights, heater, etc.

The

transistorized

voltage

regulator is a sealed unit,

has no adjustments, and must be replaced as a

complete unit.

H-7.

Starting System

The

operation of the starter motor is controlled by

the ignition switch. The starter is made up of a

frame,

field coil, armature, and brushes.

The

starter solenoid electrically

closes

the circuit

between

the battery and the starter motor. When the ignition key is turned to its extreme right, the

solenoid is energized and

closes

the battery-to- starter-motor circuit.

Note:

All Jeep Universal Series vehicles have the

starter

solenoid switch secured to the starter motor

assembly. The Hurricane F4 and Dauntless V-6

engine

Prestolite starter drive is of the inertia type

(rexr

continued on

page

176) 174

Page 195 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

H

no soldering or unsoldering of leads; two complete

rectifying

diode assemblies

which

eliminate the need

for removing and replacing individual diodes; a

corpplete isolation diode assembly; and a rotor

assembly complete with shaft,

pole

pieces, field

coil,

and slip rings.

The

transistorized

voltage

regulator is an electronic

switching device. It

senses

the

voltage

appearing

at the auxiliary terminal of the alternator and

supplies the necessary field current for maintaining

the system

voltage

at the output terminal. The

output current is determined by the battery electri

cal

load; such as headlights, heater, etc.

The

transistorized

voltage

regulator is a sealed

unit,

has no adjustments, and must be replaced

as a complete unit.

H-64. ALTERNATOR

PRECAUTIONS

The

following precautions must be observed to

prevent damage to the alternator and regulator.

a.

Never reverse battery connections. Always

check

the battery polarity with a voltmeter before

any

connections are made to be sure that all con

nections correspond to the battery ground polarity of the vehicle.

b.

Booster batteries for starting must be properly

connected. Make sure that the negative cable of

the booster battery is connected to the negative

terminal

of the battery in the vehicle. The positive

cable of the booster battery should be connected

to the positive terminal of the battery in the

vehicle.

c.

Disconnect the battery cables before using a fast charger.

d.

Never use a fast charger as a booster for

starting

the vehicle.

e.

Never disconnect the

voltage

regulator while

the

engine

is running.

f.

Do not ground the alternator output terminal.

g.

Do not operate the alternator on an open

circuit

with

the field energized.

h.

Do not attempt to polarize an alternator.

These

precautions are stated here as an aid to

service

personnel. They are also restated at appro

priate

places in the

text

of this section of the

manual.

H-65. ALTERNATOR

CHARGING

SYSTEM SERVICE

Important:

All alternator

tests

for the 35, 40 and

55 amp alternator are the same, however, there is a

difference

between

the location of the various ter

minals

and field current specifications. The field

current

of the 35 amp alternator should be 1.7 to 2.3 amps, 40 and 55 amp alternators should be 1.8

to 2.4 amps, with

full

battery

voltage

applied to

the filed coil. Disassembly and assembly procedures

are

the same for all three alternators.

Terminal

locations and wire harness color

codes

for the 35,

40 and 55 amp alternator are shown in Fig. H-38.

H-66.

Service Diagnosis

In

diagnosing a suspected malfunction of the

alternator

charging system, consideration must

be given to the complete electrical power plant of the vehicle; including the alternator, regulator,

ignition switch, charge indicator lamp, battery,

and

all associated wiring. If it is suspected that the

alternator

is not fully charging the battery and

fulfilling

the electrical requirements of the electrical

system, several checks should be made before

checking

the alternator itself:

Note:

Whenever service is required in connection

with

an alternator problem, the first

step

should be to verify that the wiring harness hook-up is correct

as indicated in Fig. H-38.

a.

Test the condition of the battery and

state

of

charge

(Par. H-2).

If the battery is not fully charged

and

in

good

condition, use a replacement battery

for making alternator system

tests.

Caution:

Make certain that the negative battery

post

is connected to ground when making the

battery installation. Serious damage to the alter

nator

can result if battery polarity is reversed.

b.

Check

fan belt for proper tension (Par.

C-27).

Caution:

To increase belt tension, apply pressure

to alternator front housing only as permanent damage can result if pressure is applied to

rear

housing.

H-67.

Alternator In Vehicle Tests

The

following

tests

are made with the alternator

in

the vehicle with output and regulator connec

tions maintained to the alternator except as noted

in

Fig. H-27 and H-28. The field plug and

voltage

regulator are disconnected for

these

tests.

The

tests

are given in proper order and detail in the

following paragraphs.

a.

Isolation Diode Test: To determine if the isola

tion diode is open or shorted, refer to Par. H-69.

b.

Alternator Output Test: To isolate the trouble

to the alternator or regulator, refer to Par. H-70.

c.

Alternator

Field

Circuit

Test: To determine the condition of the field

circuit

(brushes and rotor),

refer

to Par. H-73.

d.

Brush

Insulation

and Continuity

Test:

To deter

mine the condition of the

brush,

refer to

Par.

H-75.

e.

Rotor In-Vehicle Test: To determine whether

the rotor coil is open or shorted, refer to

Par.

H-73.

f. Any further

tests

must be conducted with the

alternator

removed and disassembled. When this

is done, the condition of the rotor, the rectifying

and

isolation diodes, and the stator can be further

tested.

A

commercial alternator tester Sun

Electric

Model

VAT-20

or equivalent can be used to make all

necessary

tests

on the alternator system. If a com

mercial

tester is used, follow the recommended

testing procedure outlined by the tester manu

facturer.

If

a commercial tester is not available, follow the

testing procedure as outlined in this manual.

H-68.

Test Equipment

a.

Volt Ampere Tester such as Sun

Electric

Model

VAT-20

or equivalent with meter ranges as shown

in

the following list can be used. 195

Page 212 of 376

H

ELECTRICAL

SYSTEM

H-124. Testing Indicators and Gauges

Two

gauges

(fuel and temperature) and two in dicators (oil pressure and battery charge) that are

located in the instrument cluster are electrically operated.

The

fuel

gauge

is connected by a single wire to a

float-and-slide-rheostat sending unit in the fuel

tank.

The

temperature

gauge

is connected by a single

wire

to a resistance-type sending unit mounted on the engine.

The

battery charge indicator operates when there

is a difference in potential

between

the generator

and

the battery

.The

battery charge indicator lights

when the generator is not charging the battery. The

indicator

light

goes

out when the generator

begins

to charge the battery.

The

oil pressure indicator is connected by a single

wire

to a diaphragm switch located on the engine.

When

engine

oil pressure is low or zero and the

ignition switch is on, the oil pressure indicator

will

light. When

engine

speed is increased slightly above idle speed, raising the oil pressure to approximately 6 psi. [0,2 kg-cm2], the diaphragm switch

will

open the circuit and the indicator light

will

go out.

A

voltage

regulator maintains a constant

voltage

to the

gauges

in normal operation. On early vehicles,

this

voltage

regulator was mounted on the

rear

of

the instrument cluster. On current vehicles, the

voltage

regulator is integral with the fuel

gauge.

Should

trouble

develop

in the

gauges,

first check the regulator (fuel

gauge

on current production vehicle). If the

voltage

to the regulator is below 10 volts system low

gauge

readings

will

result.

Voltage in

excess

of 16 volts

will

not affect

gauge

readings but may result in premature wear of the

regulator contacts. If the

voltage

to the regulator is

within

the above limits, check the electrical con nections to the regulator (or fuel gauge), especially

the ground connection. If the readings of all the

gauges

is too high, or they all read too low, replace

the regulator (or fuel gauge).

If

the temperature

gauge

or heat indicator in the

instrument cluster have failed, the cause may

originate from the jumper bar shorting out against the instrument case.

Check

the jumper bar

between

the temperature

gauge

and heat indicator at the

rear

of the instrument case. On later production vehicles, the jumper bar is covered with an in

sulating

sleeve

to protect it from shorting out

against the instrument case. If the jumper bar

does

not have this

sleeve,

either install one or

wrap

the bar with plastic electrical tape to

half

an

inch [12,7 mm.] from each end. When installing the jumper bar, be sure the curved

segment

is

closest to the fuel

gauge.

Should

only one of the two

gauges

register incor

rectly,

check the lead wire from the

gauge

to the

sending unit for shorts or open connections. Next disconnect the

gauge

from the sending unit, and

connect the

gauge

to a new fuel tank sending unit

which

has been grounded to the vehicle.

If

the

gauge

registers incorrectly when operating the new unit,

replace the

gauge;

if correctly, replace the sending

unit.

Should

a new fuel tank unit not be available for testing, use a 12-volt

test

light in its place. When

the

gauge

is operating correctly, the pointer

will

move

approximately three-quarters across the

dial.

On

some

vehicles, the temperature

gauge

may

register on or

close

to the H (hot)

mark

when

coolant temperature is

190°F.

to

200°F.

[88°C.

a

93°C.].

In such cases, a 25-ohm,

1-watt

resistor

may be installed on the temperature

gauge

which

will

place the pointer just beyond the center

mark

at a coolant temperature of

190°F.

to

200°F.

Install

the resistor

between

the two terminals on the back

of the

gauge.

Insulate the

exposed

leads of the resistor with electrical tape.

If

the oil pressure indicator

does

not indicate cor

rectly,

first check the light bulb. Next check all

connections and lead wires. If, after all possible

defects

are corrected, the indicator light

does

not go on and off properly, then the diaphragm type

switch in the cylinder block should be replaced.

H-12S.

LIGHTING SYSTEM The

wiring of the lighting systems is shown in

the wiring diagrams, which indicate the various units in relation to their positions in the vehicle.

The

wires in the various circuits are of different

colors or are marked by tracers to aid when check

ing individual circuits.

The

lighting circuits of all models are protected by

an

overload circuit breaker mounted on the back of the main light switch and no replaceable fuse is

required.

The

upper and lower headlight beams are con

trolled by a

foot

switch located on the toe board

to the left of the clutch pedal.

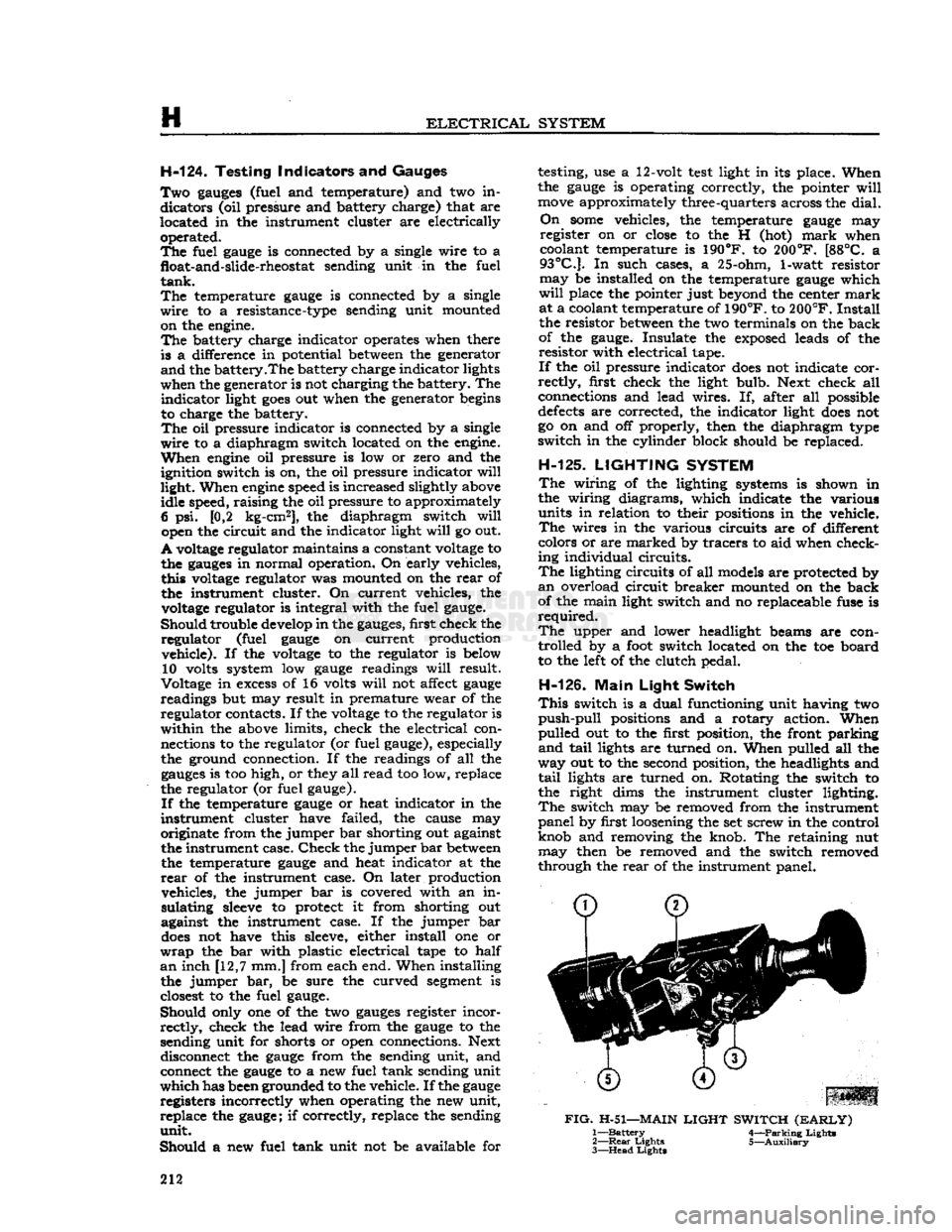

H-126.

Main

Light

Switch

This

switch is a dual functioning unit having two

push-pull

positions and a rotary action. When

pulled out to the first position, the front parking

and

tail

lights are turned on. When pulled all the

way out to the second position, the headlights and

tail

lights are turned on. Rotating the switch to

the right dims the instrument cluster lighting.

The

switch may be removed from the instrument

panel by first loosening the set screw in the control

knob and removing the knob. The retaining nut may then be removed and the switch removed

through the

rear

of the instrument panel.

FIG.

H-51—MAIN

LIGHT

SWITCH

(EARLY)

1—

Battery

4—Parking Lights

2—

Rear

Lights 5—Auxiliary

3—

Head

Lights

212

Page 213 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

H

FIG.

H-52—MAIN

LIGHT SWITCH (LATE)

1—

Circuit

Breaker

2—

Light

Switch

3—

Rear

Lights

4—

Head

Lights

5—

Parking

Lights

The

light switch shown in

Fig.

H-51 was superseded

by the one shown in

Fig.

H-52.

H-127.

Headlight Dimmer Switch To

remove the headlight dimmer switch, first raise

the hood and disconnect the wires attached to the

switch.

Then

remove the two screws that hold the

dimmer

switch to the floor board. Remove the

switch.

Check

the operation of the dimmer switch

with

a

test

light. A

circuit

across two different pairs of contacts (one to headlights, the other to the

high-beam indicator light) should alternately light

the

test

lamp when the switch is operated.

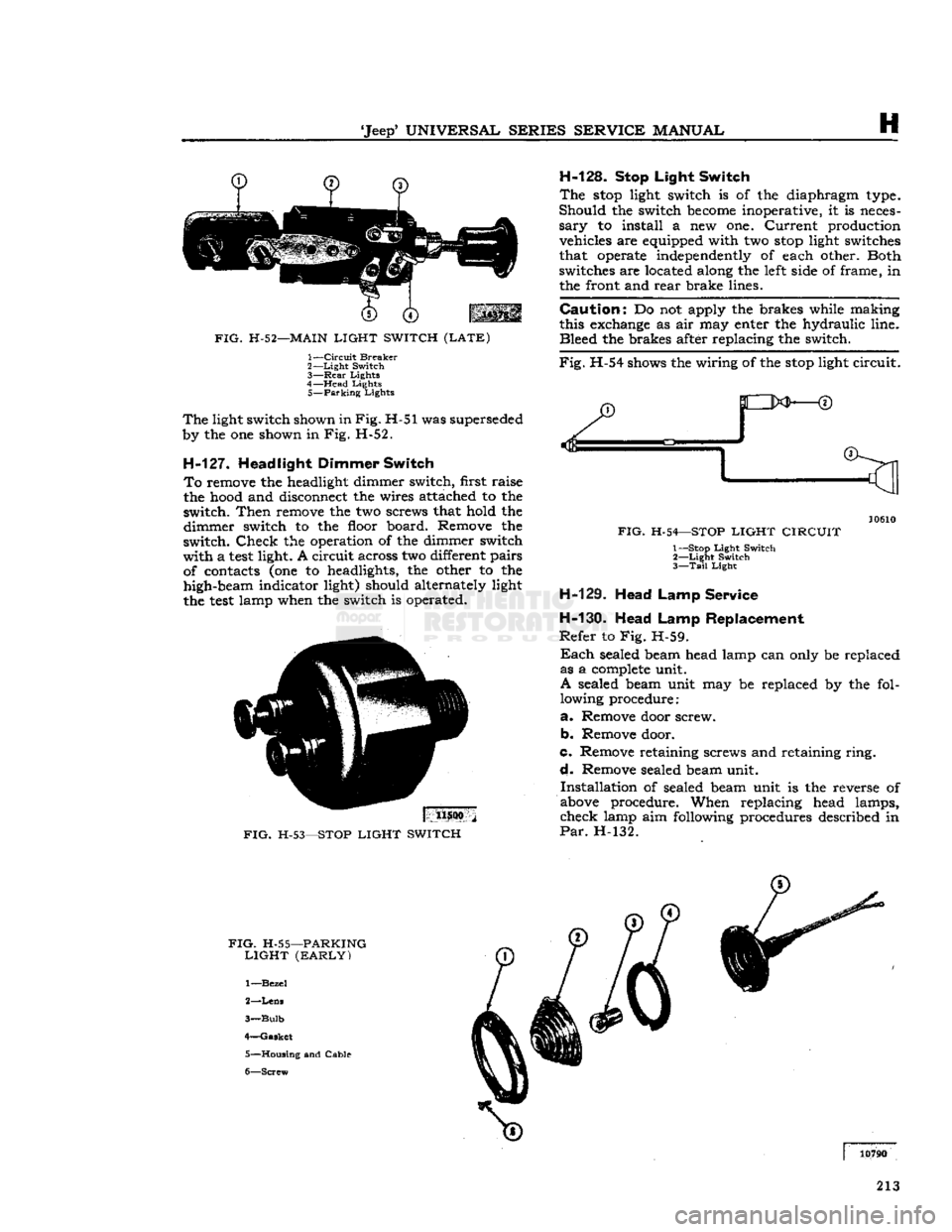

H-128.

Stop Light Switch

The

stop

light switch is of the diaphragm type.

Should

the switch

become

inoperative, it is neces

sary

to install a new one.

Current

production vehicles are equipped with two

stop

light switches

that operate independently of each other. Both

switches are located along the

left

side of frame, in the front and

rear

brake lines.

Caution:

Do not apply the brakes while making

this exchange as air may enter the hydraulic line.

Bleed

the brakes after replacing the switch.

Fig.

H-54 shows the wiring of the

stop

light

circuit.

11500

FIG.

H-53—STOP

LIGHT SWITCH

FIG.

H-54—STOP

LIGHT CIRCUIT

1— Stop

Light

Switch

2—

Light

Switch

3—

Tail

Light

H-129. Head Lamp Service

H-130.

Head Lamp Replacement

Refer

to Fig. H-59.

Each

sealed beam head lamp can only be replaced as a

complete

unit.

A

sealed beam unit may be replaced by the fol lowing procedure:

a.

Remove door screw.

b.

Remove door.

c.

Remove retaining screws and retaining

ring.

d.

Remove sealed beam unit.

Installation

of sealed beam unit is the reverse of

above procedure. When replacing head lamps,

check

lamp aim following procedures described in

Par.

H-132.

FIG.

H-55—PARKING

LIGHT (EARLY)

1—

Bezel

2—

Lens

3—

Bulb

4—

Gasket

5—

Housing

and Cable

6—

Screw

213

Page 215 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

H

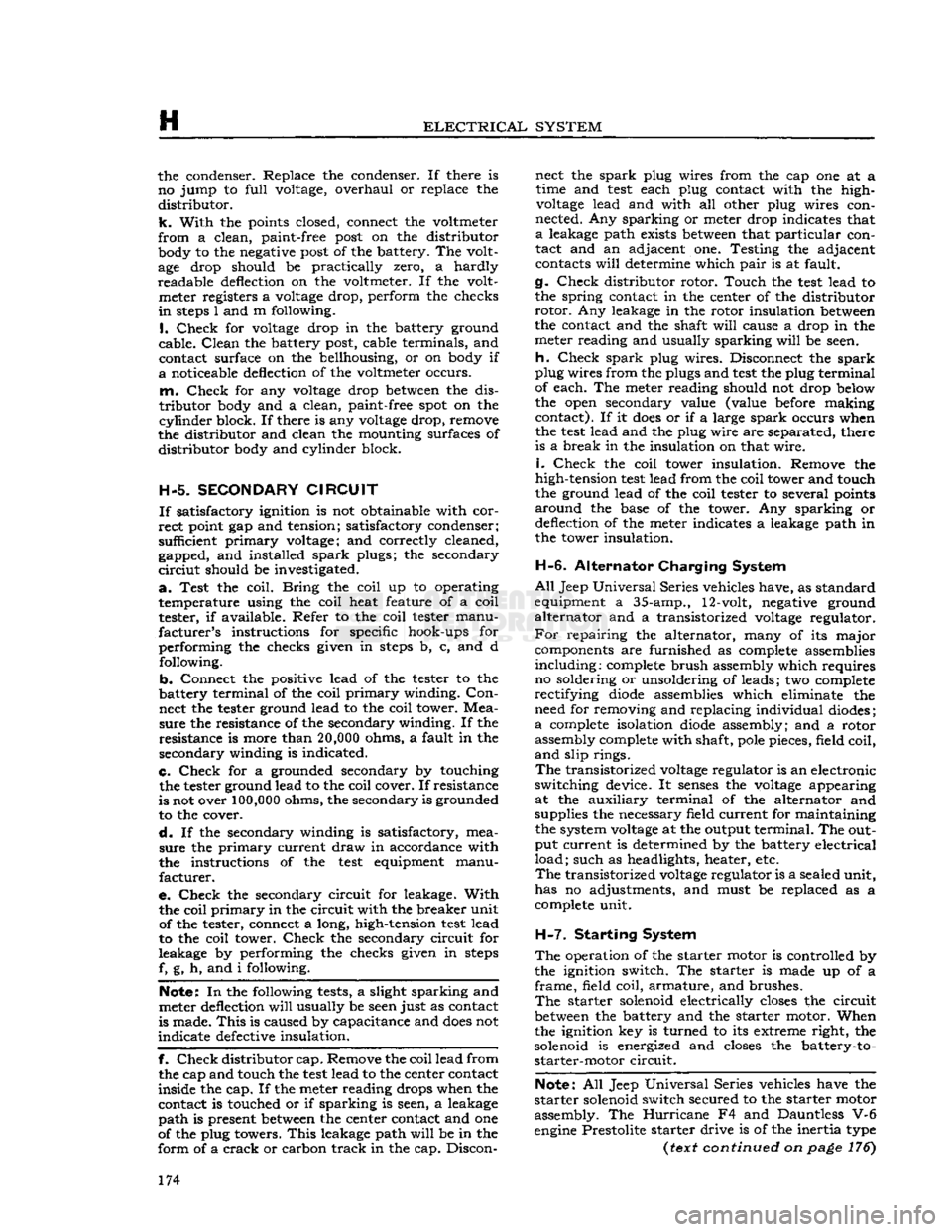

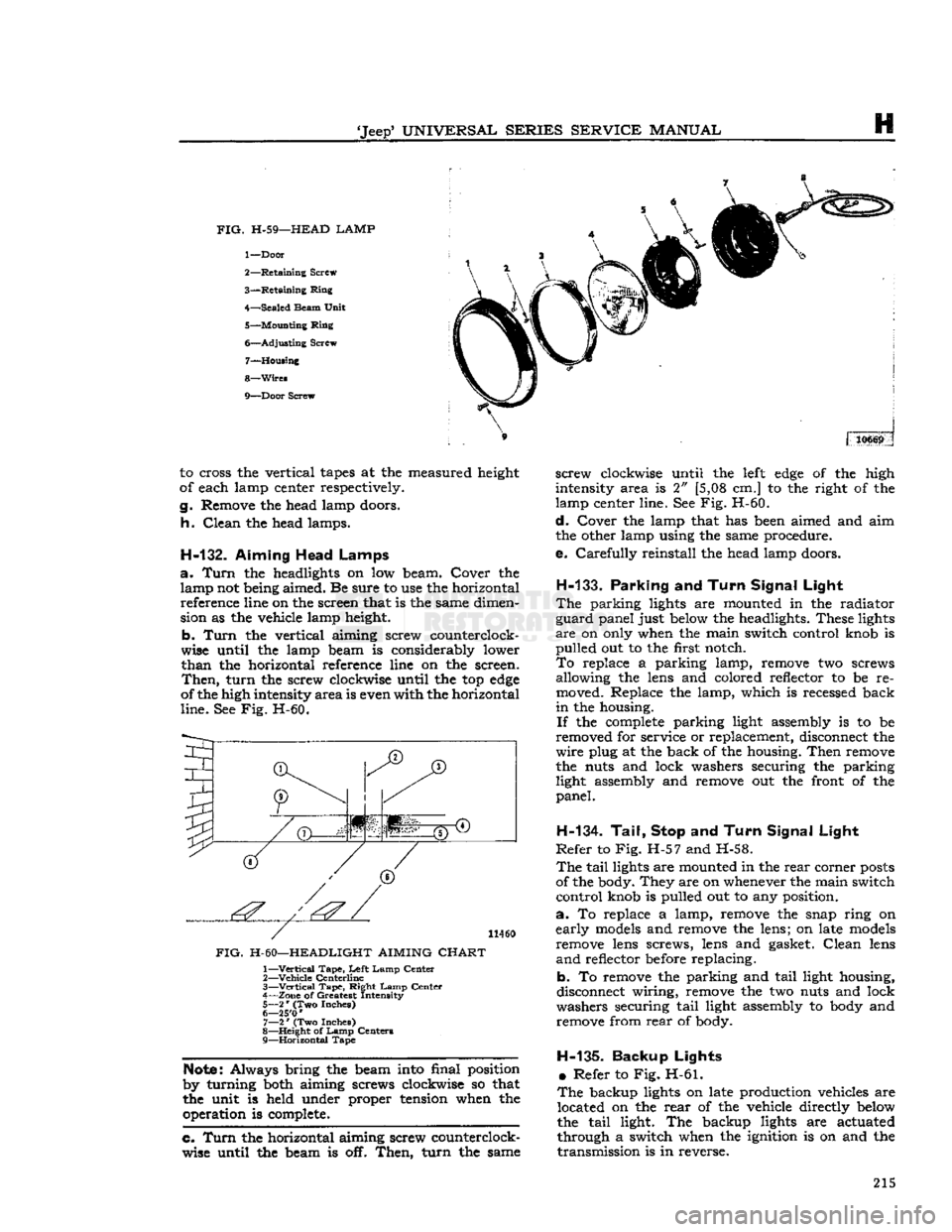

FIG.

H-59—HEAD LAMP

1—

Door

2—

Retaining

Screw

3—

Retaining

Ring

4—

Sealed

Beam

Unit

5—

Mounting

Ring

6—

Adjusting

Screw 7—

Housing

8—

Wires

9—

Door

Screw 310669

to cross the vertical

tapes

at the measured height

of each lamp center respectively.

g.

Remove the head lamp doors.

h.

Clean

the head lamps.

H-132.

Aiming Head Lamps

a.

Turn

the headlights on low beam. Cover the lamp not being aimed. Be sure to use the horizontal reference line on the screen that is the same dimen

sion as the vehicle lamp height.

b.

Turn

the vertical aiming screw counterclock

wise until the lamp beam is considerably lower

than

the horizontal reference line on the screen.

Then,

turn

the screw clockwise until the top

edge

of the high intensity

area

is even with the horizontal

line.

See Fig. H-60.

I

(T)

JT)

1'.'' | '':'

11460

FIG.

H-60—HEADLIGHT AIMING

CHART

1—

Vertical

Tape,

Left

Lamp

Center

2—

Vehicle

Centerline

3—

—Vertical

Tape,

Right

Lamp

Center

4—

Zone

of Greatest Intensity

5—

2

*

(Two Inches)

6— 25'0

'

7—

2

*

(Two Inches)

8—

Height

of

Lamp

Centers

9—

Horizontal

Tape

Note:

Always bring the beam into final position

by turning both aiming screws clockwise so that

the unit is held under proper tension when the operation is complete.

c. Turn

the horizontal aiming screw counterclock

wise until the beam is off.

Then,

turn

the same

screw

clockwise until the

left

edge

of the high

intensity area is 2" [5,08 cm.] to the right of the

lamp center line. See Fig. H-60.

d.

Cover the lamp that has been aimed and aim

the other lamp using the same procedure.

e.

Carefully

reinstall the head lamp doors.

H-133.

Parking

and

Turn Signal Light

The

parking lights are mounted in the radiator

guard

panel just below the headlights. These lights

are

on only when the main switch control knob is

pulled

out to the first notch.

To

replace a parking lamp, remove two screws allowing the lens and colored reflector to be re

moved. Replace the lamp, which is recessed back

in

the housing.

If

the

complete

parking light assembly is to be

removed for service or replacement, disconnect the

wire

plug at the back of the housing.

Then

remove

the nuts and lock washers securing the parking light assembly and remove out the front of the

panel.

H-134. Tail, Stop

and

Turn Signal Light

Refer

to Fig. H-57 and H-58.

The

tail

lights are mounted in the

rear

corner

posts

of the body. They are on whenever the main switch

control

knob is pulled out to any position.

a.

To replace a lamp, remove the snap ring on

early

models

and remove the lens; on late

models

remove lens screws, lens and gasket.

Clean

lens

and

reflector before replacing.

b. To remove the parking and

tail

light housing,

disconnect wiring, remove the two nuts and lock

washers securing

tail

light assembly to body and remove from

rear

of body.

H-135-

Backup Lights •

Refer to Fig. H-61.

The

backup lights on late production vehicles are located on the

rear

of the vehicle directly below

the

tail

light. The backup lights are actuated

through a switch when the ignition is on and the

transmission

is in reverse. 215