light JEEP COMPASS 2015 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2015, Model line: COMPASS, Model: JEEP COMPASS 2015 1.GPages: 132, PDF Size: 21.94 MB

Page 86 of 132

- Malfunction Indicator Light (MIL)

Certain conditions, such as a loose or missing gas cap, poor fuel quality, etc., may

illuminate the MIL after engine start. The vehicle should be serviced if the light stays

on through several typical driving cycles. In most situations, the vehicle will drive

normally and not require towing.

If the MIL flashes when the engine is running, serious conditions may exist that could

lead to immediate loss of power or severe catalytic converter damage. We recommend

you do not operate the vehicle. Have the vehicle serviced immediately.

-ElectronicStabilityControl(ESC)Activation/MalfunctionIndicatorLight

If the “ESC Activation/Malfunction Indicator Light” comes on continuously with the

engine running, a malfunction has been detected in the ESC system. If this light

remains on after several ignition cycles, and the vehicle has been driven several miles

(kilometers) at speeds greater than 30 mph (48 km/h), we recommend you do not

operate the vehicle. Have the vehicle serviced immediately.

The “ESC Activation/Malfunction Indicator Light” starts to flash as soon as the tires

lose traction and the ESC system becomes active. If the light begins to flash during

acceleration, ease up on the accelerator and apply as little throttle as possible. Be

sure to adapt your speed and driving to the prevailing road conditions. The light also

flashes when TCS is active. To improve the vehicle's traction when starting off in deep

snow, sand or gravel, it may be desirable to switch the ESC system to Partial Off mode

by momentarily pressing the ESC Offswitch.

INSTRUMENT CLUSTER INDICATOR LIGHTS

- Turn Signal Indicator

The arrows will flash with the exterior turn signals when the turn signal lever is

operated. A tone will chime, and a EVIC message will appear if either turn signal is

left on for more than 1 mile (1.6 km).

NOTE:

If either indicator flashes at a rapid rate, check for a defective outside light bulb.

- High Beam Indicator

Indicates that headlights are on high beam.

WHAT TO DO IN EMERGENCIES

84

Page 87 of 132

- Front Fog Light Indicator

This indicator will illuminate when the front fog lights are on.

- Vehicle Security Light

This light will flash rapidly for approximately 15 seconds when the vehicle theft

alarm is arming. The light will flash at a slower speed continuously after the alarm is

set. The security light will also come on for about three seconds when the ignition is

first turned on.

– 4WD Indicator

This light indicates the vehicle is in 4-wheel drive (4WD) mode.

- Electronic Stability Control (ESC) OFF Indicator Light

This light indicates the Electronic Stability Control (ESC) is off.

— Cruise Indicator

This indicator shows that the Electronic Speed Control System is ON.

- Hill Descent Control Indicator — If Equipped

This indicator will illuminate when Hill Descent Control (HDC) has been selected

using the Hill Descent Control Switch.

Oil Change Indicator

Message

If an “oil change” message (shown as CHANgE OIL) appears and a single chime

sounds, it is time for your next required oil change.

Resetting The Light After Servicing

1. Turn the ignition switch to the ON/RUN position (do not start engine).

2. Fully depress the accelerator pedal three times within 10 seconds.

3. Turn the ignition switch to the OFF/LOCK position.

WHAT TO DO IN EMERGENCIES

85

Page 89 of 132

AUTOMATIC TRANSMISSION OVERHEATING

During sustained high speed driving or trailer towing up long grades on hot days, the

automatic transmission oil may become too hot.

When the transmission overheat warning lightturns on, you will experience

reduced performance until the automatic transmission cools down. Once the trans-

mission has cooled down and the light turns off, you may continue to drive normally.

If the high speed is maintained, the overheating will continue to occur.

If the overheating continues, it may become necessary to stop the vehicle and run the

engine at idle with the transmission in NEUTRAL until the light turns off.

JACKING AND TIRE CHANGING

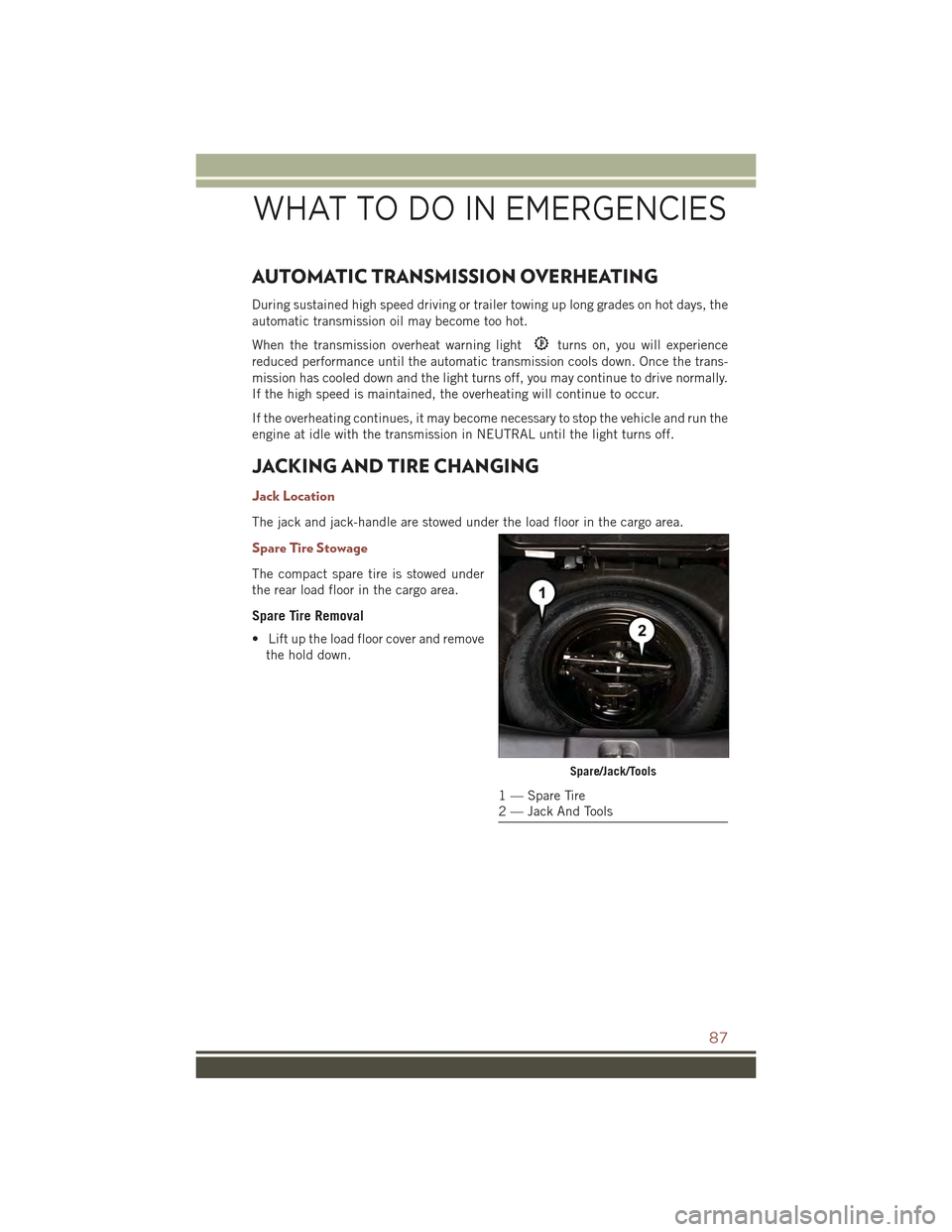

Jack Location

The jack and jack-handle are stowed under the load floor in the cargo area.

Spare Tire Stowage

The compact spare tire is stowed under

the rear load floor in the cargo area.

Spare Tire Removal

• Lift up the load floor cover and remove

the hold down.

Spare/Jack/Tools

1 — Spare Tire2 — Jack And Tools

WHAT TO DO IN EMERGENCIES

87

Page 92 of 132

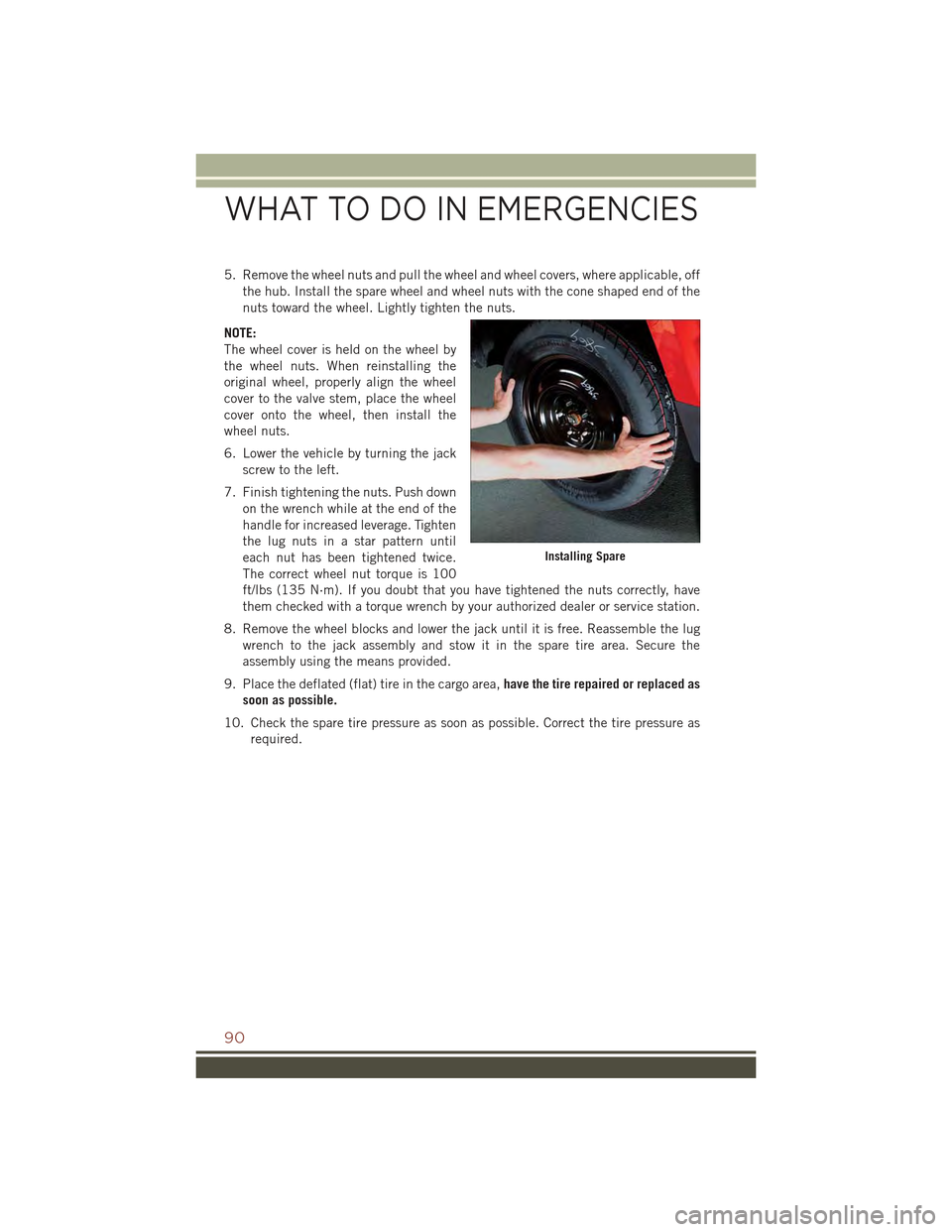

5. Remove the wheel nuts and pull the wheel and wheel covers, where applicable, off

the hub. Install the spare wheel and wheel nuts with the cone shaped end of the

nuts toward the wheel. Lightly tighten the nuts.

NOTE:

The wheel cover is held on the wheel by

the wheel nuts. When reinstalling the

original wheel, properly align the wheel

cover to the valve stem, place the wheel

cover onto the wheel, then install the

wheel nuts.

6. Lower the vehicle by turning the jack

screw to the left.

7. Finish tightening the nuts. Push down

on the wrench while at the end of the

handle for increased leverage. Tighten

the lug nuts in a star pattern until

each nut has been tightened twice.

The correct wheel nut torque is 100

ft/lbs (135 N·m). If you doubt that you have tightened the nuts correctly, have

them checked with a torque wrench by your authorized dealer or service station.

8. Remove the wheel blocks and lower the jack until it is free. Reassemble the lug

wrench to the jack assembly and stow it in the spare tire area. Secure the

assembly using the means provided.

9. Place the deflated (flat) tire in the cargo area,have the tire repaired or replaced as

soon as possible.

10. Check the spare tire pressure as soon as possible. Correct the tire pressure as

required.

Installing Spare

WHAT TO DO IN EMERGENCIES

90

Page 93 of 132

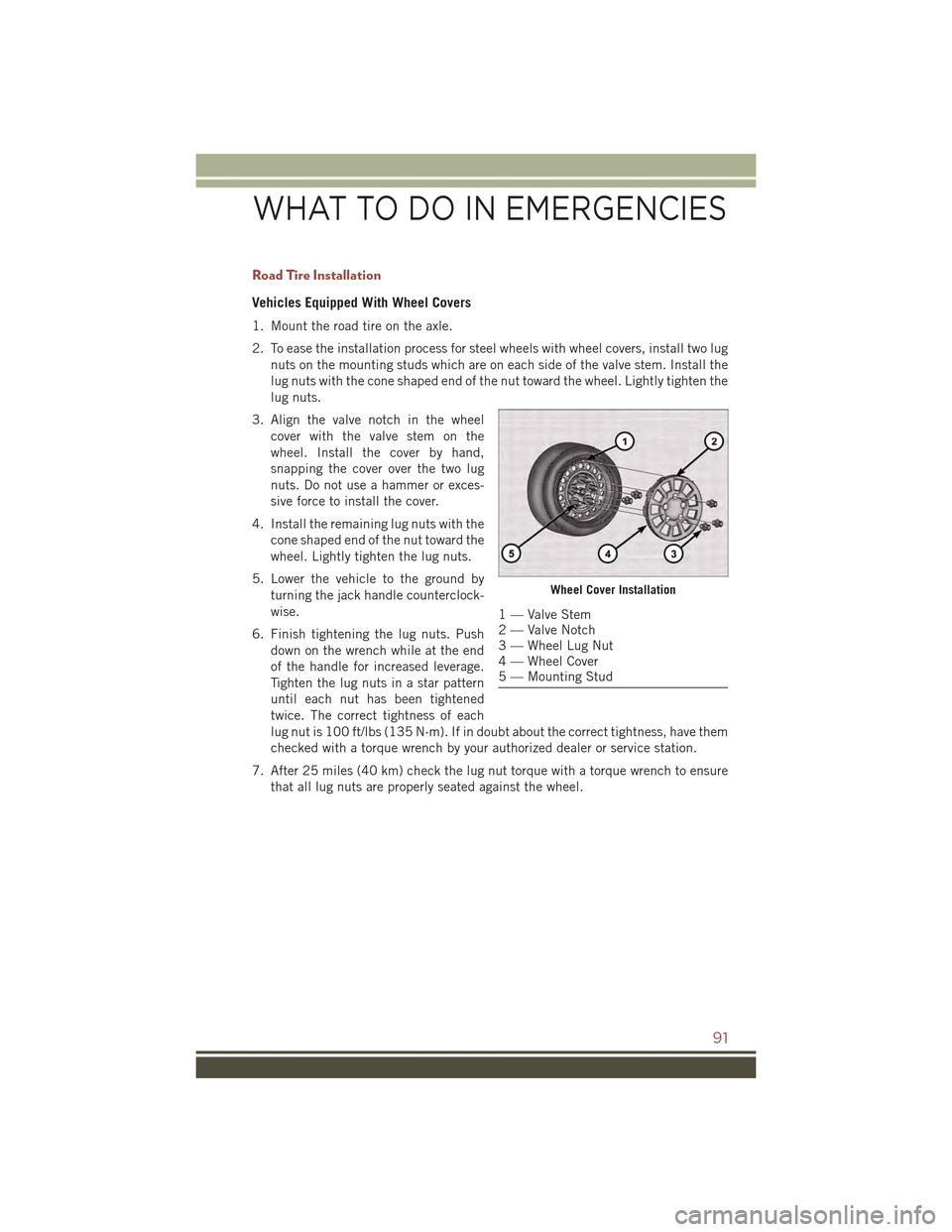

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug

nuts on the mounting studs which are on each side of the valve stem. Install the

lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the

lug nuts.

3. Align the valve notch in the wheel

cover with the valve stem on the

wheel. Install the cover by hand,

snapping the cover over the two lug

nuts. Do not use a hammer or exces-

sive force to install the cover.

4. Install the remaining lug nuts with the

cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

5. Lower the vehicle to the ground by

turning the jack handle counterclock-

wise.

6. Finish tightening the lug nuts. Push

down on the wrench while at the end

of the handle for increased leverage.

Tighten the lug nuts in a star pattern

until each nut has been tightened

twice. The correct tightness of each

lug nut is 100 ft/lbs (135 N·m). If in doubt about the correct tightness, have them

checked with a torque wrench by your authorized dealer or service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure

that all lug nuts are properly seated against the wheel.

Wheel Cover Installation

1 — Valve Stem2 — Valve Notch3 — Wheel Lug Nut4 — Wheel Cover5 — Mounting Stud

WHAT TO DO IN EMERGENCIES

91

Page 94 of 132

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the

handle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct tightness of each lug nut is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure

that all lug nuts are properly seated against the wheel.

CAUTION!

• Do not attempt to raise the vehicle by jacking on locations other than those

indicated in the Jacking Instructions for this vehicle.

• Be sure to mount the spare tire with the valve stem facing outward. The vehicle

could be damaged if the spare tire is mounted incorrectly.

WHAT TO DO IN EMERGENCIES

92

Page 110 of 132

MAINTENANCE PROCEDURES

For information on the maintenance procedures for your vehicle, please refer to

“Maintenance Procedures” in “Maintaining Your Vehicle” in your Owner’s Manual or

applicable supplement on the DVD for further details.

MAINTENANCE SCHEDULE

Your vehicle is equipped with an automatic oil change indicator system. The oil

change indicator system will remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change indicator message will

illuminate. This means that service is required for your vehicle. Operating conditions

such as frequent short-trips, trailer tow, extremely hot or cold ambient temperatures

will influence when the “Change Oil” or “Oil Change Required” message is dis-

played. Severe Operating Conditions can cause the change oil message to illuminate

as early as 3,500 miles (5,600 km) since last reset. Have your vehicle serviced as

soon as possible, within the next 500 miles (805 km).

On Electronic Vehicle Information Center (EVIC) equipped vehicles, “Oil Change

Required” will be displayed in the EVIC and a single chime will sound, indicating that

an oil change is necessary.

On Non-EVIC equipped vehicles, “Change Oil” will flash in the instrument cluster

odometer and a single chime will sound, indicating that an oil change is necessary.

Your authorized dealer will reset the oil change indicator message after completing

the scheduled oil change. If a scheduled oil change is performed by someone other

than your authorized dealer, the message can be reset by referring to the steps

described under “Instrument Cluster Warning Lights” in “What To Do In Emergen-

cies” in this guide or “Instrument Cluster Descriptions” or “Electronic Vehicle

Information Center (EVIC)” in “Understanding Your Instrument Panel” in the

Owner’s Manual on your DVD for further information.

NOTE:

Under no circumstances should oil change intervals exceed 10,000 miles

(16,000 km) or twelve months, whichever comes first.

MAINTAINING YOUR VEHICLE

108

Page 111 of 132

Severe Duty All Models

Change Engine Oil at 4000 miles (6,500 km) if the vehicle is operated in a dusty and

off road environment. This type of vehicle use is considered Severe Duty.

Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual wear or damage

• Check the fluid levels of the coolant reservoir, brake master cylinder, power

steering and fill as needed

• Check function of all interior and exterior lights

Required Maintenance Intervals.

Refer to the maintenance schedules on the following page for the required mainte-

nance intervals.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

•Change oil and filter.

• Rotate the tires.Rotate at the first sign of irregular wear, even if it occurs before the oil

indicator system turns on.

•Inspect battery and clean and tighten terminals as required.

•Inspect brake pads, shoes, rotors, drums, hoses and park brake.

•Inspect engine cooling system protection and hoses.

•Inspect exhaust system.

•Inspect engine air cleaner if using in dusty or off-road conditions.

MAINTAINING YOUR VEHICLE

109

Page 115 of 132

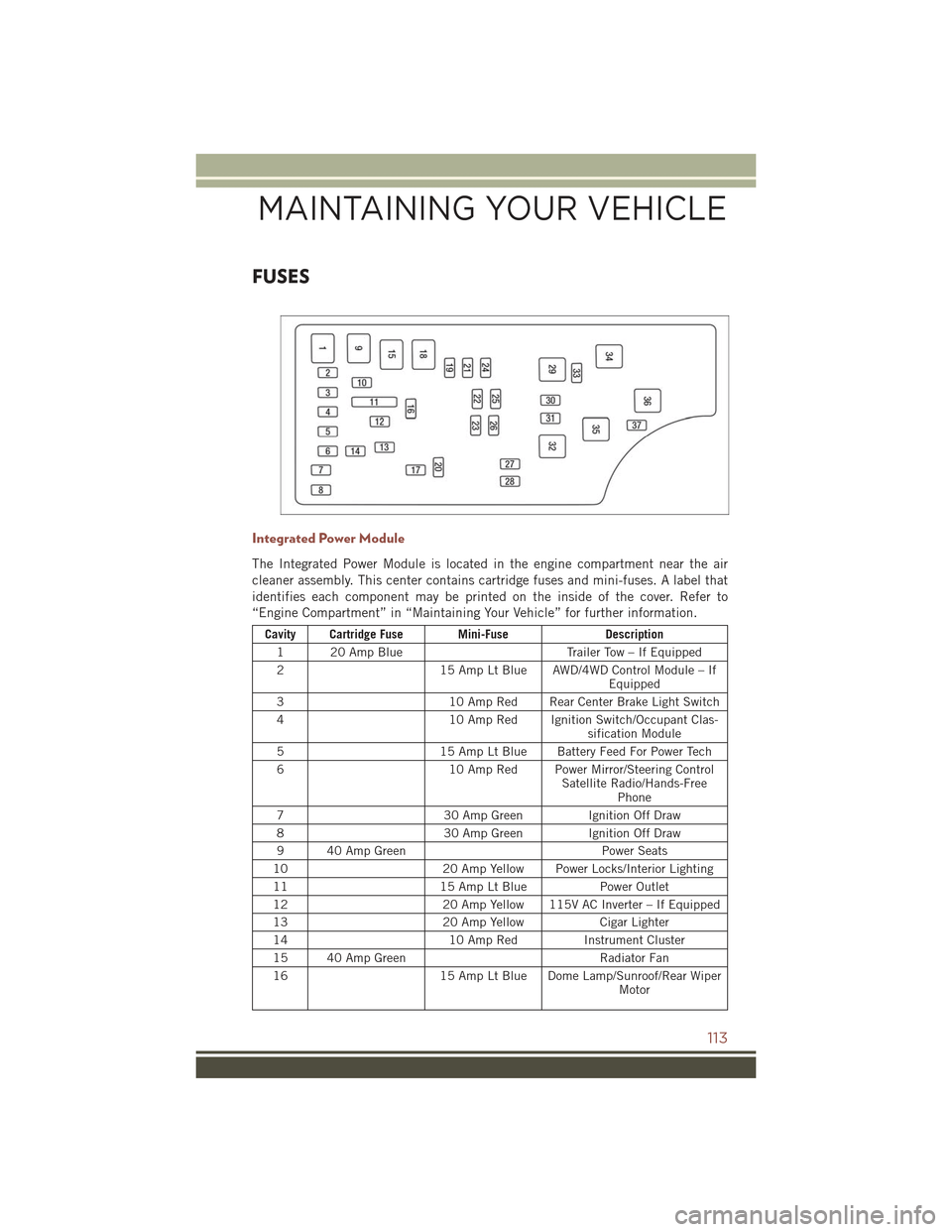

FUSES

Integrated Power Module

The Integrated Power Module is located in the engine compartment near the air

cleaner assembly. This center contains cartridge fuses and mini-fuses. A label that

identifies each component may be printed on the inside of the cover. Refer to

“Engine Compartment” in “Maintaining Your Vehicle” for further information.

Cavity Cartridge Fuse Mini-FuseDescription

120AmpBlueTr a i l e r To w – I f E q u i p p e d

215 Amp Lt Blue AWD/4WD Control Module – IfEquipped

310 Amp Red Rear Center Brake Light Switch

410 Amp Red Ignition Switch/Occupant Clas-sification Module

515 Amp Lt Blue Battery Feed For Power Tech

610 Amp Red Power Mirror/Steering ControlSatellite Radio/Hands-FreePhone

730 Amp GreenIgnition Off Draw

830 Amp GreenIgnition Off Draw

940AmpGreenPower Seats

1020 Amp Yellow Power Locks/Interior Lighting

1115 Amp Lt BluePower Outlet

1220 Amp Yellow 115V AC Inverter – If Equipped

1320 Amp YellowCigar Lighter

1410 Amp RedInstrument Cluster

15 40 Amp GreenRadiator Fan

1615 Amp Lt Blue Dome Lamp/Sunroof/Rear WiperMotor

MAINTAINING YOUR VEHICLE

113

Page 120 of 132

EXTERIOR BULBS

LIGHT BULBS – ExteriorBulb Number

Low Beam HeadlampH11

Premium Low Beam HeadlampHIR2

High Beam Headlamp9005

Premium High Beam HeadlampHIR2

Daytime Running Light (DRL)3157K

Front Park/Turn Signal7444NA

Front Side Marker Lamp194

Front Fog LampH11LL

Center High Mounted Stop Lamp (CHMSL) LED Assembly(Serviced at Authorized Dealer)

Rear Tail/Stop LampLED Assembly(Serviced at Authorized Dealer)

Rear Turn Lamp7440NA (WY21W) Amber

Backup Lamp7440 (W21W) Crystal

License LampW5W

MAINTAINING YOUR VEHICLE

118