light JEEP COMPASS 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2018, Model line: COMPASS, Model: JEEP COMPASS 2018Pages: 348, PDF Size: 6.03 MB

Page 191 of 348

NOTE:

We advise referring to an authorized dealer.

WARNING!

Carry out the operation of replacing lamps

only with the engine off. Also make sure

that the engine is cold, to avoid the danger

of burns.

Turn Signal Light/Position Lights/Daytime Run-

ning Lights

To replace the bulbs proceed as follows:

1. Turn the front wheels completely.

2. Remove the wheel liner.

3. Remove the electrical connectors.

4. For the DRL bulb, grip the bulb at the top

and bottom locking tabs and squeeze to

and remove the bulb.

5. To replace the DRL bulb gently push bulb

towards housing. Be sure to hear both the

top and bottom locking tabs “CLICK” to

ensure the bulb is properly seated.6. For the turn signal bulb, rotate in a coun-

terclockwise direction and remove the

bulb and bulb socket. Pull the bulb axially

to remove it from the socket.

7. Install the bulb and sockets and rotate

them clockwise making sure that it is

properly locked.

8. Reconnect the electrical connectors.

9. Reinstall the wheel liner.

NOTE:

We advise referring to an authorized dealer.

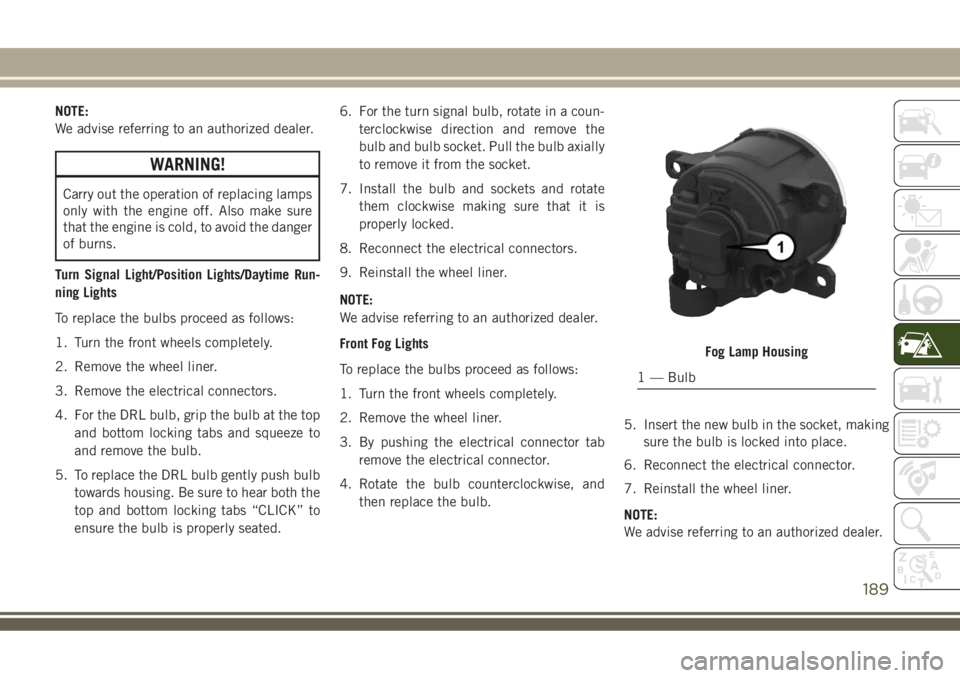

Front Fog Lights

To replace the bulbs proceed as follows:

1. Turn the front wheels completely.

2. Remove the wheel liner.

3. By pushing the electrical connector tab

remove the electrical connector.

4. Rotate the bulb counterclockwise, and

then replace the bulb.5. Insert the new bulb in the socket, making

sure the bulb is locked into place.

6. Reconnect the electrical connector.

7. Reinstall the wheel liner.

NOTE:

We advise referring to an authorized dealer.

Fog Lamp Housing

1 — Bulb

189

Page 192 of 348

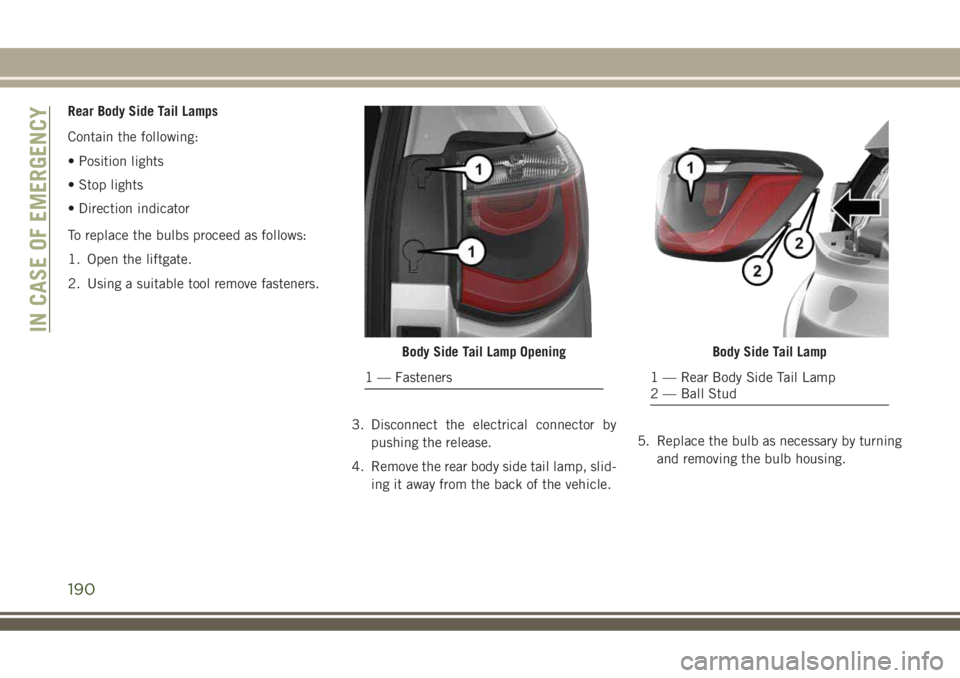

Rear Body Side Tail Lamps

Contain the following:

• Position lights

• Stop lights

• Direction indicator

To replace the bulbs proceed as follows:

1. Open the liftgate.

2. Using a suitable tool remove fasteners.

3. Disconnect the electrical connector by

pushing the release.

4. Remove the rear body side tail lamp, slid-

ing it away from the back of the vehicle.5. Replace the bulb as necessary by turning

and removing the bulb housing.

Body Side Tail Lamp Opening

1 — Fasteners

Body Side Tail Lamp

1 — Rear Body Side Tail Lamp

2 — Ball Stud

IN CASE OF EMERGENCY

190

Page 194 of 348

Reverse Lamps

1. Open the liftgate.

2. Using a suitable tool remove the access

panel for body side lamps, remove lift gate

access cover for lift gate lamps.

3. Disconnect the electrical connector by

pushing the release.

4. Remove bulb and replace making sure it

is properly locked.

5. Reconnect the electrical connector.

6. Reinstall the access panels making sure

they are locked in correctly.

7. Finally close the tailgate.

3rd Stop Lamp

The CHMSL is LED. For their replacement,

see an authorized dealer.

License Plate Lights

The license plate light is LED. For their

replacement, see an authorized dealer.FUSES

WARNING!

• When replacing a blown fuse, always use

an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Do not place a fuse inside a

circuit breaker cavity or vice versa. Fail-

ure to use proper fuses may result in

serious personal injury, fire and/or prop-

erty damage.

• Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

WARNING!

tem), power unit systems (engine sys-

tem, transmission system) or steering

system blows, contact an authorized

dealer.

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check

the fuse element inside the blade fuse for a

break/melt.

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery dis-

charge.

Fuse Location

The fuses are grouped into controllers lo-

cated in the engine compartment.

IN CASE OF EMERGENCY

192

Page 196 of 348

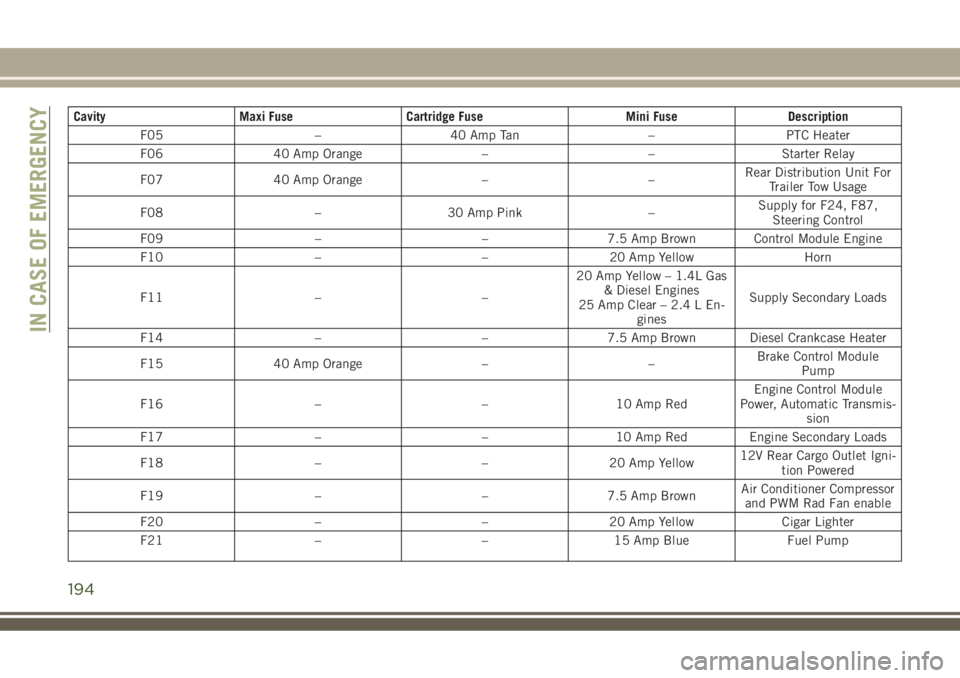

Cavity Maxi Fuse Cartridge Fuse Mini Fuse Description

F05 – 40 Amp Tan – PTC Heater

F06 40 Amp Orange – – Starter Relay

F07 40 Amp Orange – –Rear Distribution Unit For

Trailer Tow Usage

F08 – 30 Amp Pink –Supply for F24, F87,

Steering Control

F09 – – 7.5 Amp Brown Control Module Engine

F10 – – 20 Amp Yellow Horn

F11 – –20 Amp Yellow – 1.4L Gas

& Diesel Engines

25 Amp Clear – 2.4 L En-

ginesSupply Secondary Loads

F14 – – 7.5 Amp Brown Diesel Crankcase Heater

F15 40 Amp Orange – –Brake Control Module

Pump

F16 – – 10 Amp RedEngine Control Module

Power, Automatic Transmis-

sion

F17 – – 10 Amp Red Engine Secondary Loads

F18 – – 20 Amp Yellow12V Rear Cargo Outlet Igni-

tion Powered

F19 – – 7.5 Amp BrownAir Conditioner Compressor

and PWM Rad Fan enable

F20 – – 20 Amp Yellow Cigar Lighter

F21 – – 15 Amp Blue Fuel Pump

IN CASE OF EMERGENCY

194

Page 199 of 348

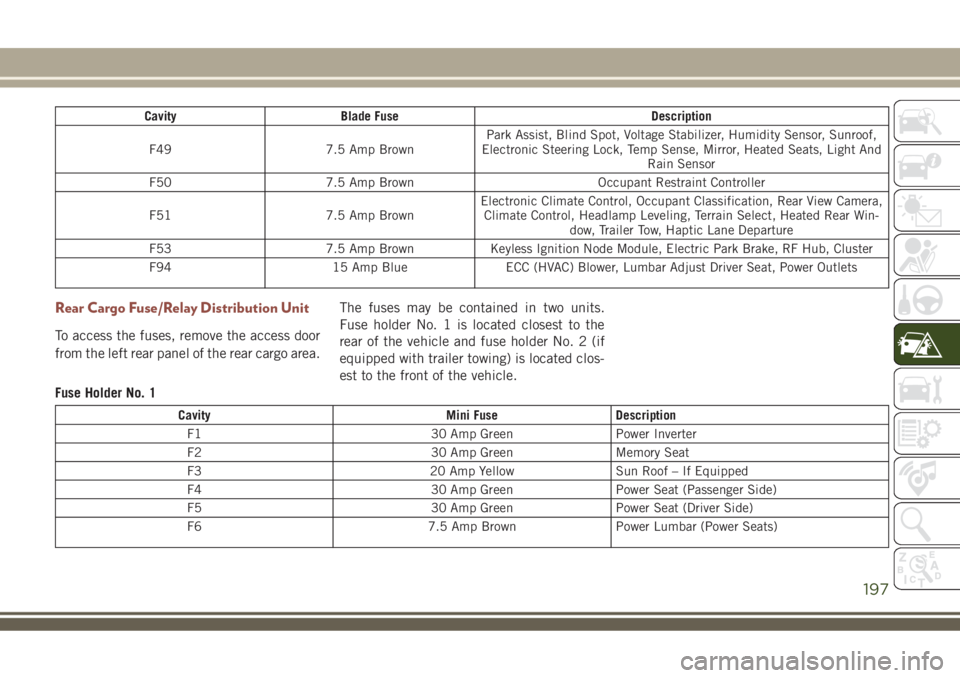

Cavity Blade Fuse Description

F49 7.5 Amp BrownPark Assist, Blind Spot, Voltage Stabilizer, Humidity Sensor, Sunroof,

Electronic Steering Lock, Temp Sense, Mirror, Heated Seats, Light And

Rain Sensor

F50 7.5 Amp Brown Occupant Restraint Controller

F51 7.5 Amp BrownElectronic Climate Control, Occupant Classification, Rear View Camera,

Climate Control, Headlamp Leveling, Terrain Select, Heated Rear Win-

dow, Trailer Tow, Haptic Lane Departure

F53 7.5 Amp Brown Keyless Ignition Node Module, Electric Park Brake, RF Hub, Cluster

F94 15 Amp Blue ECC (HVAC) Blower, Lumbar Adjust Driver Seat, Power Outlets

Rear Cargo Fuse/Relay Distribution Unit

To access the fuses, remove the access door

from the left rear panel of the rear cargo area.The fuses may be contained in two units.

Fuse holder No. 1 is located closest to the

rear of the vehicle and fuse holder No. 2 (if

equipped with trailer towing) is located clos-

est to the front of the vehicle.

Fuse Holder No. 1

Cavity Mini Fuse Description

F1 30 Amp Green Power Inverter

F2 30 Amp Green Memory Seat

F3 20 Amp Yellow Sun Roof – If Equipped

F4 30 Amp Green Power Seat (Passenger Side)

F5 30 Amp Green Power Seat (Driver Side)

F6 7.5 Amp Brown Power Lumbar (Power Seats)

197

Page 200 of 348

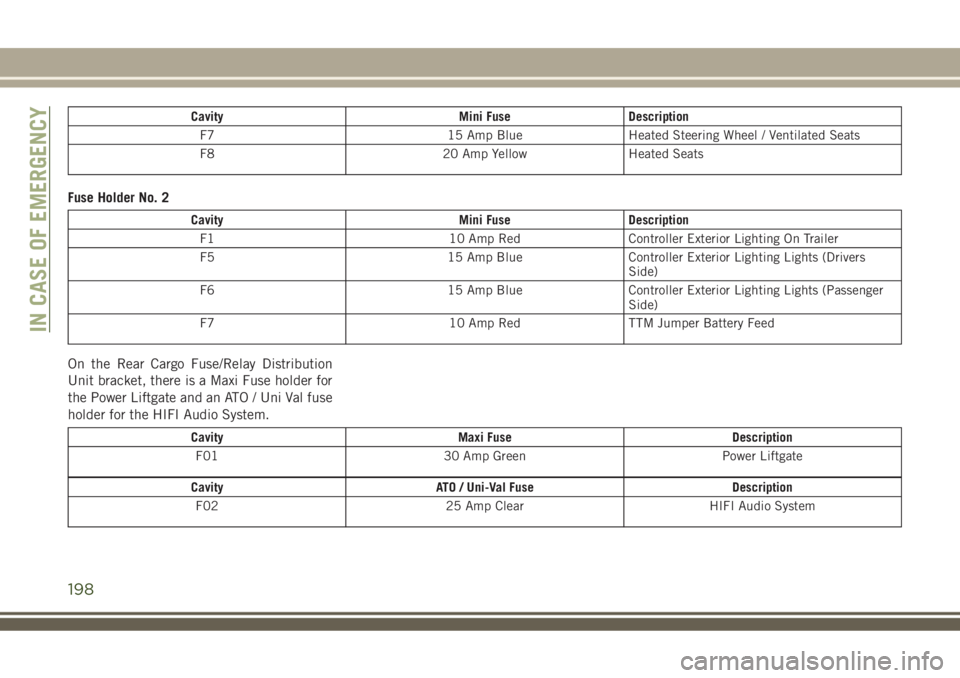

Cavity Mini Fuse Description

F7 15 Amp Blue Heated Steering Wheel / Ventilated Seats

F8 20 Amp Yellow Heated Seats

Fuse Holder No. 2

Cavity Mini Fuse Description

F1 10 Amp Red Controller Exterior Lighting On Trailer

F5 15 Amp Blue Controller Exterior Lighting Lights (Drivers

Side)

F6 15 Amp Blue Controller Exterior Lighting Lights (Passenger

Side)

F7 10 Amp Red TTM Jumper Battery Feed

On the Rear Cargo Fuse/Relay Distribution

Unit bracket, there is a Maxi Fuse holder for

the Power Liftgate and an ATO / Uni Val fuse

holder for the HIFI Audio System.

Cavity Maxi Fuse Description

F01 30 Amp Green Power Liftgate

Cavity ATO / Uni-Val Fuse Description

F02 25 Amp Clear HIFI Audio System

IN CASE OF EMERGENCY

198

Page 205 of 348

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack

assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

8. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.NOTE:

• For vehicles equipped, do not attempt

to install a center cap or wheel cover on

the compact spare.

• Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires—

General Information” in “Servicing And

Maintenance” in the Owner's Manual

for additional warnings, cautions, and

information about the spare tire, its

use, and operation.

9. Install and lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

10. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push

down on the wrench while at the end ofthe handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica-

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

them checked with a torque wrench by

your authorized dealer or at a service

station.

12. Place the jack on the foam tray and open

it far enough so that it is secured. Once

placed in position, rotate it clockwise to

lock it in. Replace the alignment pin in

the center hole to lock the jack in place.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

203

Page 206 of 348

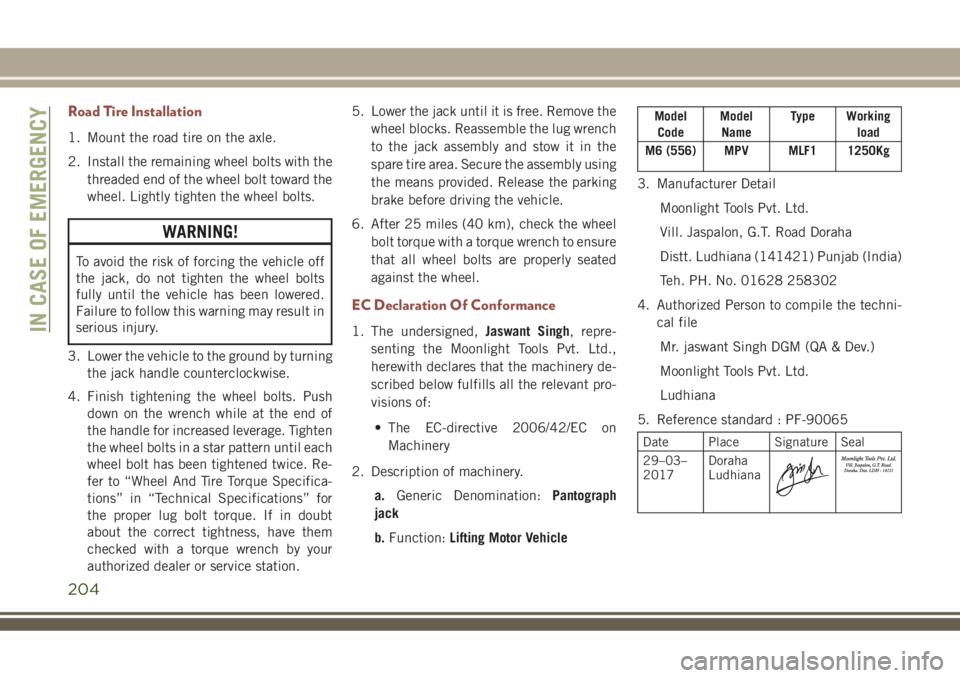

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the

threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage. Tighten

the wheel bolts in a star pattern until each

wheel bolt has been tightened twice. Re-

fer to “Wheel And Tire Torque Specifica-

tions” in “Technical Specifications” for

the proper lug bolt torque. If in doubt

about the correct tightness, have them

checked with a torque wrench by your

authorized dealer or service station.5. Lower the jack until it is free. Remove the

wheel blocks. Reassemble the lug wrench

to the jack assembly and stow it in the

spare tire area. Secure the assembly using

the means provided. Release the parking

brake before driving the vehicle.

6. After 25 miles (40 km), check the wheel

bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

EC Declaration Of Conformance

1. The undersigned,Jaswant Singh, repre-

senting the Moonlight Tools Pvt. Ltd.,

herewith declares that the machinery de-

scribed below fulfills all the relevant pro-

visions of:

• The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a.Generic Denomination:Pantograph

jack

b.Function:Lifting Motor Vehicle

Model

CodeModel

NameType Working

load

M6 (556) MPV MLF1 1250Kg

3. Manufacturer Detail

Moonlight Tools Pvt. Ltd.

Vill. Jaspalon, G.T. Road Doraha

Distt. Ludhiana (141421) Punjab (India)

Teh. PH. No. 01628 258302

4. Authorized Person to compile the techni-

cal file

Mr. jaswant Singh DGM (QA & Dev.)

Moonlight Tools Pvt. Ltd.

Ludhiana

5. Reference standard : PF-90065

Date Place Signature Seal

29–03–

2017Doraha

Ludhiana

IN CASE OF EMERGENCY

204

Page 213 of 348

4. Have the tire inspected and repaired or

replaced at the earliest opportunity at

your authorized dealer or tire service

center.

5. Remove the Speed Limit sticker from the

steering wheel after the tire has been

repaired.

6. Replace the Sealant Bottle at your autho-

rized dealer as soon as possible. Refer to

“Sealant Bottle Replacement”.

NOTE:

When having the tire serviced, advise the

authorized dealer or service center that the

tire has been sealed using the Tire Service

Kit.

Sealant Bottle Replacement:

1. Unwrap the power cord.

2. Unwrap the hose.

3. Remove the bottle cover.

4. Rotate the bottle up beyond vertical to

release.

5. Pull the bottle away from the Compressor.NOTE:

• For sealant bottle installation, follow these

steps reverse order.

• Replacement sealant bottles are available

at authorized service centers.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so

please follow the procedures in this section

carefully.

NOTE:

When using a portable battery booster pack,

follow the manufacturer’s operating instruc-

tions and precautions.

WARNING!

Do not attempt jump starting if the battery

is frozen. It could rupture or explode and

cause personal injury.

CAUTION!

Do not use a portable battery booster pack

or any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

Preparations For Jump Start

The battery in your vehicle is located in the

front of the engine compartment, behind the

left headlight assembly.

NOTE:

The positive battery post is covered with a

protective cap. Lift up on the cap to gain

access to the post.

211

Page 224 of 348

SCHEDULED SERVICING

1.4L Gasoline Engine

The scheduled services listed in this manual

must be done at the times or mileages speci-

fied to protect your vehicle warranty and

ensure the best vehicle performance and re-

liability. More frequent maintenance may be

needed for vehicles in severe operating con-

ditions, such as dusty areas and very short

trip driving. Inspection and service should

also be done anytime a malfunction is sus-

pected.

• Change your engine oil more often if you

drive your vehicle off-road for an extended

period of time.

• Under no circumstances should oil change

intervals exceed 7,500 miles (12,000 km)

or 12 months, whichever comes first.Once A Month Or Before A Long Trip

• Check engine oil level.

• Check windshield washer fluid level.

• Check tire pressure and look for unusual

wear or damage. Rotate tires at the first

sign of irregular wear, even if it occurs

before the oil indicator system turns on.

• Check the fluid levels of the coolant reser-

voir and brake master cylinder, fill as

needed.

• Check function of all interior and exterior

lights.

At Each Oil Change

• Change oil and filter.

• Rotate the tires.Rotate at the first sign of

irregular wear, even if it occurs before the oil

indicator system turns on.

• Inspect battery and clean and tighten ter-

minals as required.• Inspect brake pads, shoes, rotors, drums,

hoses and park brake.

• Inspect engine cooling system protection

and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty

or off-road conditions.

Refer to the “Maintenance Plan” on the fol-

lowing page for the required maintenance

intervals.

CAUTION!

Failure to perform the required mainte-

nance items may result in damage to the

vehicle.

SERVICING AND MAINTENANCE

222