torque JEEP COMPASS 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: COMPASS, Model: JEEP COMPASS 2019Pages: 362, PDF Size: 6.23 MB

Page 179 of 362

NOTE:

When operating conditions have been met,

the LaneSense system will monitor if the

driver’s hands are on the steering wheel and

provide an audible and visual warning to the

driver when the driver’s hands are not de-

tected on the steering wheel. The system will

cancel if the driver does not return their

hands to the wheel.

Turning LaneSense On Or Off

The default status of LaneSense

is “Off”.

The LaneSense button is located

on the switch panel below the

Uconnect display.

To turn the LaneSense system on, push the

LaneSense button to turn the system on (LED

turns off). A “Lane Sense On” message is

shown in the instrument cluster display.

To turn the LaneSense system off, push the

LaneSense button once to turn the system off

(LED turns on).NOTE:

The LaneSense system will retain the last

system state on or off from the last ignition

cycle when the ignition is changed to the

ON/RUN position.

LaneSense Warning Message

The LaneSense system will indicate the cur-

rent lane drift condition through the instru-

ment cluster display.

Base Instrument Cluster Display — If

Equipped

When the LaneSense system is on; the lane

lines are gray when both of the lane bound-

aries have not been detected and the Lane-

Sense telltale

is solid white.

Left Lane Departure — Only Left Lane Detected

• When the LaneSense system is on, the

LaneSense telltale

is solid white when

only the left lane marking has been de-

tected and the system is ready to provide

visual warnings in the instrument cluster

display if an unintentional lane departure

occurs.• When the LaneSense system senses the

lane has been approached and is in a lane

departure situation, the left thick lane line

flashes from white to gray, the left thin line

remains solid white and the LaneSense

telltale

changes from solid white to

flashing yellow.

NOTE:

The LaneSense system operates with the

similar behavior for a right lane departure

when only the right lane marking has been

detected.

Left Lane Departure — Both Lanes Detected

• When the LaneSense system is on, the lane

lines turn from gray to white to indicate that

both of the lane markings have been de-

tected. The LaneSense telltale

is solid

green when both lane markings have been

detected and the system is “armed” to

provide visual warnings in the instrument

cluster display and a torque warning in the

steering wheel if an unintentional lane de-

parture occurs.

177

Page 180 of 362

• When the LaneSense system senses a lane

drift situation, the left thick lane line and

the left thin line turn solid white. The

LaneSense telltale

changes from solid

green to solid yellow. At this time torque is

applied to the steering wheel in the oppo-

site direction of the lane boundary.

For example: if approaching the left side of

the lane the steering wheel will turn to the

right.

• When the LaneSense system senses the

lane has been approached and is in a lane

departure situation, the left thick lane line

flashes from white to gray, the left thin line

remains solid white and the LaneSense

telltale

changes from solid yellow to

flashing yellow. At this time torque is ap-

plied to the steering wheel in the opposite

direction of the lane boundary.

For example: if approaching the left side of

the lane the steering wheel will turn to the

right.

NOTE:

The LaneSense system operates with the

similar behavior for a right lane departure.Premium Instrument Cluster Display —

If Equipped

When the LaneSense system is on; the lane

lines are gray when both of the lane bound-

aries have not been detected and the Lane-

Sense telltale

is solid white.

Left Lane Departure — Only Left Lane Detected

• When the LaneSense system is on, the

LaneSense telltale

is solid white when

only the left lane marking has been de-

tected and the system is ready to provide

visual warnings in the instrument cluster

display if an unintentional lane departure

occurs.

• When the LaneSense system senses the

lane has been approached and is in a lane

departure situation, the left thick lane line

flashes yellow, the left thin line remains

solid yellow and the LaneSense telltale

changes from solid white to flashing yellow.

NOTE:

The LaneSense system operates with the

similar behavior for a right lane departure

when only the right lane marking has been

detected.Left Lane Departure — Both Lanes Detected

• When the LaneSense system is on, the lane

lines turn from gray to white to indicate that

both of the lane markings have been de-

tected. The LaneSense telltale

is solid

green when both lane markings have been

detected and the system is “armed” to

provide visual warnings in the instrument

cluster display and a torque warning in the

steering wheel if an unintentional lane de-

parture occurs.

• When the LaneSense system senses a lane

drift situation, the left thick lane line and

left thin line turn solid yellow. The Lane-

Sense telltale

changes from solid green

to solid yellow. At this time torque is ap-

plied to the steering wheel in the opposite

direction of the lane boundary.

For example: if approaching the left side of

the lane the steering wheel will turn to the

right.

• When the LaneSense system senses the

lane has been approached and is in a lane

departure situation, the left thick lane line

flashes yellow and the left thin line remains

solid yellow. The LaneSense telltale

STARTING AND OPERATING

178

Page 181 of 362

stays solid yellow. At this time torque is

applied to the steering wheel in the oppo-

site direction of the lane boundary.

For example: if approaching the left side of

the lane the steering wheel will turn to the

right.

NOTE:

The LaneSense system operates with the

similar behavior for a right lane departure.

Changing LaneSense Status

The LaneSense system has settings to adjust

the intensity of the torque warning (Low/

Medium/High) and the warning zone sensitiv-

ity (Early/Medium/Late) that you can config-

ure through the Uconnect system screen.

Refer to “Uconnect Settings” in “Multime-

dia” in the Owner’s Manual for further de-

tails.NOTE:

• The system will not apply torque to the

steering wheel whenever a safety system

engages (anti-lock brakes, traction control

system, electronic stability control, forward

collision warning, etc.).

• Use of the turn signals and Hazard Warning

flashers also suppresses the warnings.

PARKVIEW REAR BACK UP

CAMERA — IF EQUIPPED

You can see an on-screen image of the rear of

your vehicle whenever the transmission is

shifted into REVERSE. The ParkView Rear

Back-Up Camera image will be displayed on

the Uconnect Display, located on the center

stack of the instrument panel.

If the Uconnect Display appears foggy, clean

the camera lens located on the rear of the

vehicle above the rear license plate

Refer to “ParkView Back-Up Camera” in

“Starting And Operating” in your Owner's

Manual for further information.

WARNING!

Drivers must be careful when backing up

even when using the ParkView Rear Back

Up Camera. Always check carefully behind

your vehicle, and be sure to check for

pedestrians, animals, other vehicles, ob-

structions, or blind spots before backing

up. You are responsible for the safety of

your surroundings and must continue to

pay attention while backing up. Failure to

do so can result in serious injury or death.

CAUTION!

• To avoid vehicle damage, ParkView

should only be used as a parking aid.

The ParkView camera is unable to view

every obstacle or object in your drive

path.

• To avoid vehicle damage, the vehicle

must be driven slowly when using

ParkView to be able to stop in time when

an obstacle is seen. It is recommended

that the driver look frequently over his/

her shoulder when using ParkView.

179

Page 186 of 362

Emergency Gas Can Refueling

Most gas cans will not open the flapper door.

A funnel is provided to open the flapper door

to allow emergency refueling with a gas can.

1. Retrieve funnel from the rear cargo area.

2. Insert funnel into same filler pipe opening

as the fuel nozzle.

3. Ensure funnel is inserted fully to hold

flapper door open.

4. Pour fuel into funnel opening.

5. Remove funnel from filler pipe, clean off

prior to putting back in the spare tire

storage area.

NOTE:

• When the fuel nozzle “clicks” or shuts off,

the fuel tank is full.WARNING!

• Never have any smoking materials lit in

or near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most coun-

tries regulations and may cause the

“Malfunction Indicator Light” to turn

on.

• Do not apply any object/cap to the end of

the filler which is not provided for the

car. The use of non-compliant objects/

plugs could cause a pressure increase

inside the tank, resulting in dangerous

situations.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

Adblue (UREA) — If Equipped

The vehicle is equipped with an UREA injec-

tion system and Selective Catalytic Reduc-

tion to meet emission standards. These two

systems ensure compliance with the diesel

emissions requirements; at the same, they

ensure fuel-efficiency, handling, torque and

power. For messages and system warnings,

refer to the "Warning Lights And Messages" in

the "Getting To Know Your Instrument Panel"

section. AdBlue (UREA) is a very stable prod-

uct with a long shelf life. Stored at tempera-

tures LOWER than 90 °F (32 °C), it has a

shelf life of at least one year. For more infor-

mation on the AdBlue liquid type, see the

“Fluids and lubricants” in the “Technical

specifications” section. The vehicle is

equipped with an automatic AdBlue heating

system when the engine starts allowing the

system to work correctly at temperatures

lower than 12 °F (-11 °C).

NOTE:

AdBlue freezes at temperatures lower than

12 °F (-11 °C).

STARTING AND OPERATING

184

Page 214 of 362

5. Raise the vehicle just enough to remove

the flat tire.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack

assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

8. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.NOTE:

• For vehicles equipped, do not attempt

to install a center cap or wheel cover on

the compact spare.

• Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires—

General Information” in “Servicing And

Maintenance” in the Owner's Manual

for additional warnings, cautions, and

information about the spare tire, its

use, and operation.

9. Install and lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

10. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.11. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica-

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

them checked with a torque wrench by

an authorized dealer or at a service

station.

12. Place the jack on the foam tray and open

it far enough so that it is secured. Once

placed in position, rotate it clockwise to

lock it in. Replace the alignment pin in

the center hole to lock the jack in place.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

IN CASE OF EMERGENCY

212

Page 215 of 362

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the

threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage. Tighten

the wheel bolts in a star pattern until each

wheel bolt has been tightened twice. Re-

fer to “Wheel And Tire Torque Specifica-

tions” in “Technical Specifications” for

the proper lug bolt torque. If in doubt

about the correct tightness, have them

checked with a torque wrench by an au-

thorized dealer or service station.5. Lower the jack until it is free. Remove the

wheel blocks. Reassemble the lug wrench

to the jack assembly and stow it in the

spare tire area. Secure the assembly using

the means provided. Release the parking

brake before driving the vehicle.

6. After 25 miles (40 km), check the wheel

bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

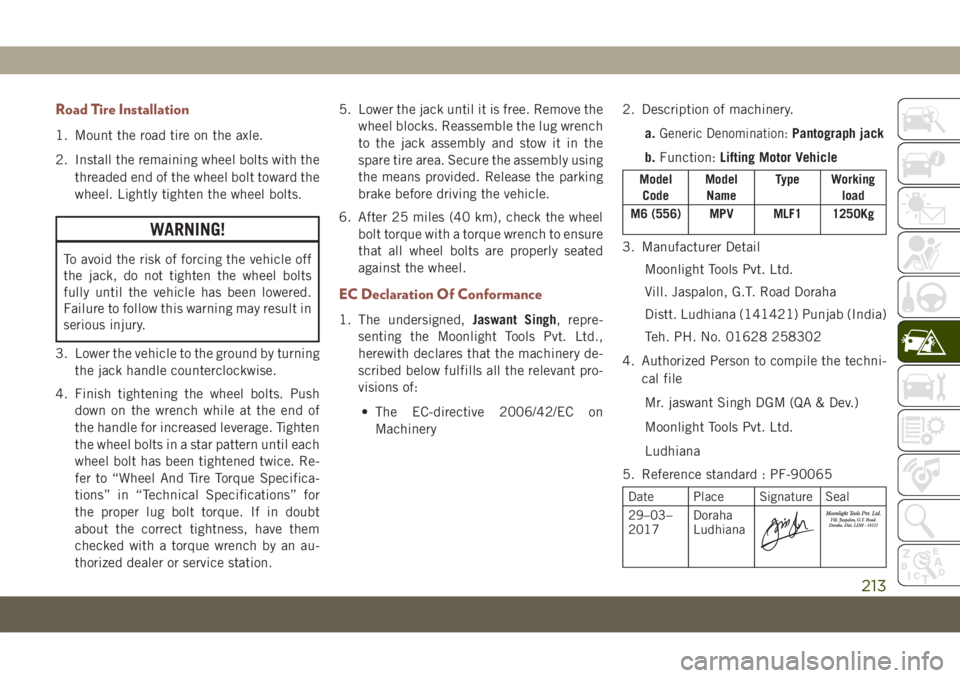

EC Declaration Of Conformance

1. The undersigned,Jaswant Singh, repre-

senting the Moonlight Tools Pvt. Ltd.,

herewith declares that the machinery de-

scribed below fulfills all the relevant pro-

visions of:

• The EC-directive 2006/42/EC on

Machinery2. Description of machinery.

a.

Generic Denomination:Pantograph jack

b.Function:Lifting Motor Vehicle

Model

CodeModel

NameType Working

load

M6 (556) MPV MLF1 1250Kg

3. Manufacturer Detail

Moonlight Tools Pvt. Ltd.

Vill. Jaspalon, G.T. Road Doraha

Distt. Ludhiana (141421) Punjab (India)

Teh. PH. No. 01628 258302

4. Authorized Person to compile the techni-

cal file

Mr. jaswant Singh DGM (QA & Dev.)

Moonlight Tools Pvt. Ltd.

Ludhiana

5. Reference standard : PF-90065

Date Place Signature Seal

29–03–

2017Doraha

Ludhiana

213

Page 251 of 362

WARNING!

• Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot en-

gine parts, causing the brake fluid to

catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should

be taken to avoid its contact with these

surfaces.

• Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This

could result in a collision.

Manual Transmission — If Equipped

Fluid Level Check

Check the fluid level by removing the fill

plug. The fluid level should be between the

bottom of the fill hole and a point not more

than 3/16 inch (4.7 mm) below the bottom of

the hole.

Add fluid, if necessary, to maintain the proper

level.

Please see your authorized dealer for service.

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission perfor-

mance and life. Use only the manufacturer's

specified transmission fluid. Refer to “Fluids

And Lubricants” in “Technical Specifica-

tions” for fluid specifications. It is important

to maintain the transmission fluid at the

correct level using the recommended fluid.

NOTE:

No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder.

Refer to “Fluids And Lubricants” in “Tech-

nical Specifications” for fluid specifica-

tions.

Special Additives

The manufacturer strongly recommends

against using any special additives in the

transmission. Automatic Transmission Fluid

(ATF) is an engineered product and its perfor-

mance may be impaired by supplemental

additives. Therefore, do not add any fluid

additives to the transmission. Avoid using

transmission sealers as they may adversely

affect seals.

CAUTION!

Do not use chemical flushes in your trans-

mission as the chemicals can damage your

transmission components. Such damage

is not covered by the New Vehicle Limited

Warranty.

Fluid Level Check

The fluid level is preset at the factory and

does not require adjustment under normal

operating conditions. Routine fluid level

checks are not required; therefore the trans-

mission has no dipstick. An authorized dealer

can check your transmission fluid level using

special service tools. If you notice fluid leak-

249

Page 266 of 362

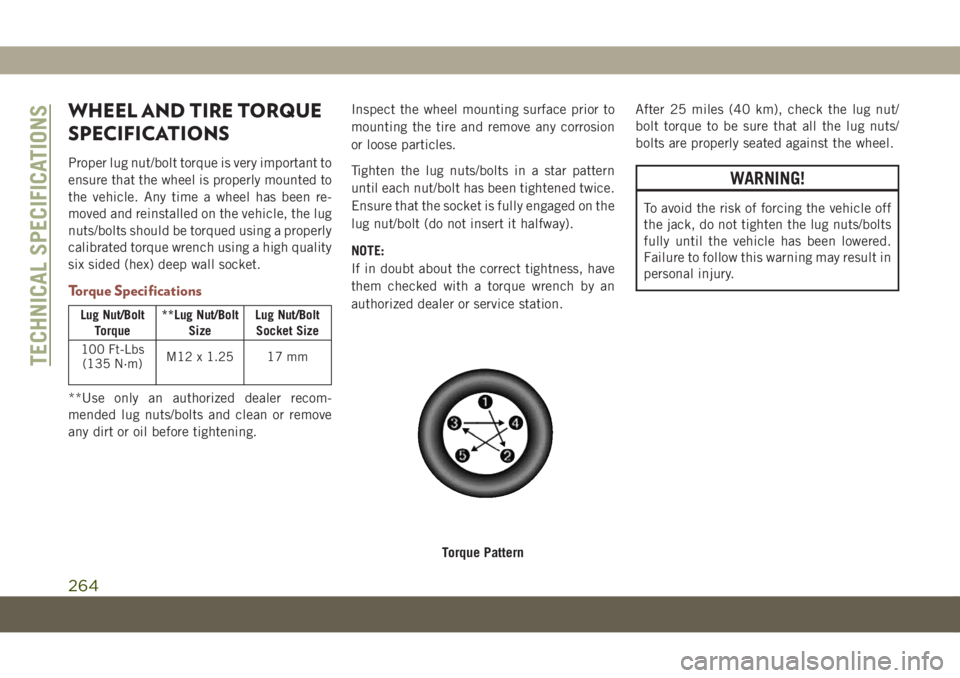

WHEEL AND TIRE TORQUE

SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been re-

moved and reinstalled on the vehicle, the lug

nuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Lug Nut/Bolt

Torque**Lug Nut/Bolt

SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs

(135 N·m)M12 x 1.25 17 mm

**Use only an authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening.Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

or loose particles.

Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it halfway).

NOTE:

If in doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.After 25 miles (40 km), check the lug nut/

bolt torque to be sure that all the lug nuts/

bolts are properly seated against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts/bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

personal injury.

Torque Pattern

TECHNICAL SPECIFICATIONS

264

Page 357 of 362

Telescoping Steering Column........32

Temperature Control, Automatic (ATC) . .47

Text Messages.............286, 321

Tilt Steering Column.............32

Time Delay

Headlight...............33, 35

Tips ......................307

Tires...............140, 250, 256

Aging (Life Of Tires)..........254

Air Pressure...............250

Chains...................257

Changing..............208, 250

Compact Spare.............256

General Information.......250, 256

High Speed................252

Inflation Pressure............251

Jacking...............208, 250

Life Of Tires...............254

Load Capacity..............252

Pressure Monitoring System

(TPMS)................70, 94

Radial...................252

Replacement...............254

Rotation..................258

Safety...................250

Snow Tires................255

Spare Tires............256, 257Spinning.................253

Tread Wear Indicators.........253

Wheel Nut Torque............264

Tire Service Kit...............215

To Open Hood.................53

Tow Hooks

Emergency................228

Towing.....................187

Disabled Vehicle.............226

Guide...................189

Recreational...............191

Weight

...................189

Towing Behind A Motorhome.......191

Towing Eyes.................229

Traction Control................80

Trailer Sway Control (TSC)..........88

Trailer Towing................187

Minimum Requirements........189

Trailer Towing Guide............189

Trailer Weight................189

Transaxle

Automatic................151

Operation.................151

Transmission.................152

Automatic.............152, 249

Maintenance...............249

Manual..................147Transporting Pets..............137

Tread Wear Indicators............253

Turn Signals.............33, 36, 74

Uconnect 3 With 5-Inch Display.....283

Uconnect 4C/4C Nav With

8.4-Inch Display.............296

Uconnect 4 With 7-Inch Display.....288

Uconnect Phone...............313

Making A Call..............320

Pairing..................316

Untwisting Procedure, Seat Belt.....102

USB...................291, 299

Vehicle Identification Number (VIN) . . .263

Vehicle Loading...............252

Vehicle Security Alarm.........18, 19

Vehicle Storage................47

Ventilated Seats................29

Voice Command........319, 320, 323

Voice Recognition

System (VR).........319, 320, 323

Warning Lights (Instrument

Cluster Descriptions)...........68

Warnings And Cautions............4

Warnings, Roll Over

..............2

355