warning light JEEP COMPASS 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: COMPASS, Model: JEEP COMPASS 2019Pages: 362, PDF Size: 6.23 MB

Page 167 of 362

ADAPTIVE CRUISE

CONTROL (ACC) —

IF EQUIPPEDACC will allow you to keep cruise control

engaged in light to moderate traffic condi-

tions without the constant need to reset your

cruise control. ACC utilizes a radar sensor

and a forward facing camera designed to

detect a vehicle directly ahead of you.

NOTE:

• If the sensor does not detect a vehicle

ahead of you, ACC will maintain a fixed set

speed.

• If the ACC sensor detects a vehicle ahead,

ACC will apply limited braking or accelera-

tion (not to exceed the original set speed)

automatically to maintain a preset follow-

ing distance, while matching the speed of

the vehicle ahead.

To Activate/Deactivate

Push and release the Adaptive Cruise Control

(ACC) on/off button. The ACC menu in the

instrument cluster display will read “ACC

Ready.”To turn the system off, push and release the

Adaptive Cruise Control (ACC) on/off button

again. At this time, the system will turn off

and the instrument cluster display will read

“Adaptive Cruise Control (ACC) Off.”

WARNING!

Leaving the Adaptive Cruise Control (ACC)

system on when not in use is dangerous.

You could accidentally set the system or

cause it to go faster than you want. You

could lose control and have a collision.

Always leave the system off when you are

not using it.

To Set A Desired ACC Speed

When the vehicle reaches the speed desired,

push the SET(+)button or the SET(-)button

and release. The instrument cluster display

will show the set speed.

If the system is set when the vehicle speed is

below 19 mph (30 km/h), the set speed shall

be defaulted to 19 mph (30 km/h). If the

system is set when the vehicle speed is above

19 mph (30 km/h), the set speed shall be the

current speed of the vehicle.

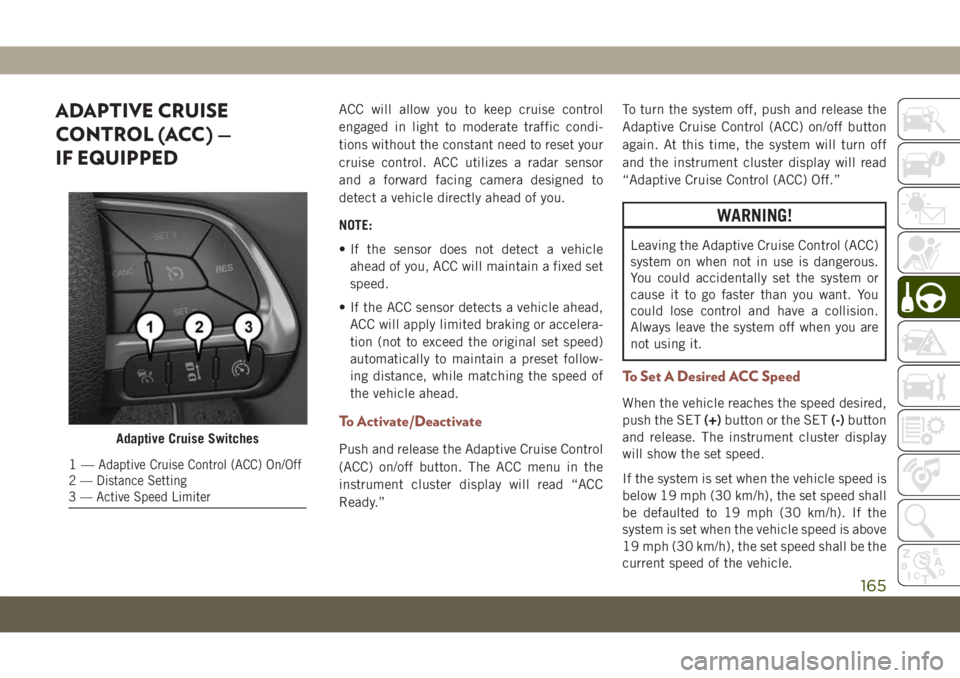

Adaptive Cruise Switches

1—Adaptive Cruise Control (ACC) On/Off

2 — Distance Setting

3 — Active Speed Limiter

165

Page 183 of 362

7. Remove the fuel nozzle and close the fuel

door.

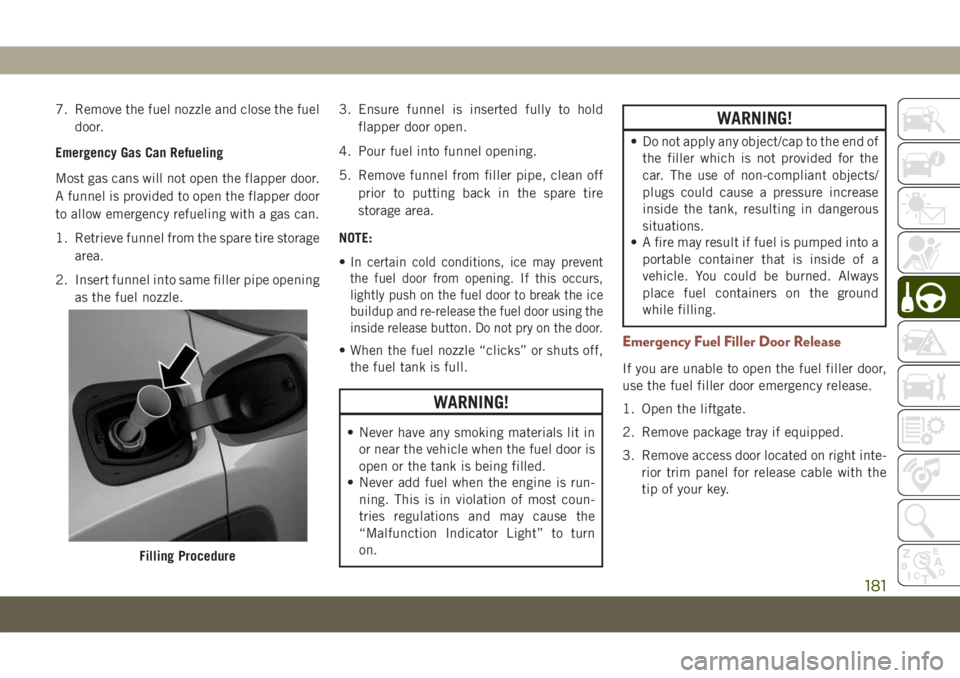

Emergency Gas Can Refueling

Most gas cans will not open the flapper door.

A funnel is provided to open the flapper door

to allow emergency refueling with a gas can.

1. Retrieve funnel from the spare tire storage

area.

2. Insert funnel into same filler pipe opening

as the fuel nozzle.3. Ensure funnel is inserted fully to hold

flapper door open.

4. Pour fuel into funnel opening.

5. Remove funnel from filler pipe, clean off

prior to putting back in the spare tire

storage area.

NOTE:

•

In certain cold conditions, ice may prevent

the fuel door from opening. If this occurs,

lightly push on the fuel door to break the ice

buildup and re-release the fuel door using the

inside release button. Do not pry on the door.

• When the fuel nozzle “clicks” or shuts off,

the fuel tank is full.

WARNING!

• Never have any smoking materials lit in

or near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most coun-

tries regulations and may cause the

“Malfunction Indicator Light” to turn

on.

WARNING!

• Do not apply any object/cap to the end of

the filler which is not provided for the

car. The use of non-compliant objects/

plugs could cause a pressure increase

inside the tank, resulting in dangerous

situations.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

Emergency Fuel Filler Door Release

If you are unable to open the fuel filler door,

use the fuel filler door emergency release.

1. Open the liftgate.

2. Remove package tray if equipped.

3. Remove access door located on right inte-

rior trim panel for release cable with the

tip of your key.

Filling Procedure

181

Page 186 of 362

Emergency Gas Can Refueling

Most gas cans will not open the flapper door.

A funnel is provided to open the flapper door

to allow emergency refueling with a gas can.

1. Retrieve funnel from the rear cargo area.

2. Insert funnel into same filler pipe opening

as the fuel nozzle.

3. Ensure funnel is inserted fully to hold

flapper door open.

4. Pour fuel into funnel opening.

5. Remove funnel from filler pipe, clean off

prior to putting back in the spare tire

storage area.

NOTE:

• When the fuel nozzle “clicks” or shuts off,

the fuel tank is full.WARNING!

• Never have any smoking materials lit in

or near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most coun-

tries regulations and may cause the

“Malfunction Indicator Light” to turn

on.

• Do not apply any object/cap to the end of

the filler which is not provided for the

car. The use of non-compliant objects/

plugs could cause a pressure increase

inside the tank, resulting in dangerous

situations.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

Adblue (UREA) — If Equipped

The vehicle is equipped with an UREA injec-

tion system and Selective Catalytic Reduc-

tion to meet emission standards. These two

systems ensure compliance with the diesel

emissions requirements; at the same, they

ensure fuel-efficiency, handling, torque and

power. For messages and system warnings,

refer to the "Warning Lights And Messages" in

the "Getting To Know Your Instrument Panel"

section. AdBlue (UREA) is a very stable prod-

uct with a long shelf life. Stored at tempera-

tures LOWER than 90 °F (32 °C), it has a

shelf life of at least one year. For more infor-

mation on the AdBlue liquid type, see the

“Fluids and lubricants” in the “Technical

specifications” section. The vehicle is

equipped with an automatic AdBlue heating

system when the engine starts allowing the

system to work correctly at temperatures

lower than 12 °F (-11 °C).

NOTE:

AdBlue freezes at temperatures lower than

12 °F (-11 °C).

STARTING AND OPERATING

184

Page 188 of 362

Proceed as follows:

• Insert the AdBlue (UREA) nozzle in the

filler, start refilling and stop refilling at the

first shut-off (the shut-off indicates that the

AdBlue (UREA) tank is full). Do not pro-

ceed with the refilling, to prevent spillage

of AdBlue (UREA).

• Extract the nozzle.

Refilling With Containers

Proceed as follows:

• Check the expiration date.

• Read the advice for use on the label before

pouring the content of the bottle into the

AdBlue (UREA) tank.

• If systems which cannot be screwed in (e.g.

tanks) are used for refilling, after the indi-

cation appears on the instrument panel

display refer to “Warning lights And Mes-

sages" in the “Getting To Know Your Instru-

ment Panel” for further information, fill the

AdBlue (UREA) tank with no more than

2 Gallons (8 liters).• If containers which can be screwed to the

filler are used, the reservoir is full when the

AdBlue (UREA) level in the container stops

pouring out. Do not proceed further.

Operations After Refilling

Proceed as follows:

• Fit the cap back on the AdBlue (UREA)

filler by turning it clockwise and screwing it

completely.

• Cycle the ignition to RUN (it is not neces-

sary to start the engine).

• Wait for the indication on the instrument

panel to switch off before moving the car.

The indication may stay on for a few sec-

onds to approximately half a minute. If the

engine is started and the car is moved, the

indication will remain on for longer. This

will not compromise engine operation.

• If the AdBlue (UREA) was topped up when

the tank was empty, wait for 2 minutes

before starting the engine.NOTE:

• If AdBlue (UREA) is spilled out of the filler

neck, clean up well the area and proceed to

filling up again. If the liquid crystallizes,

eliminate it with a sponge and warm water.

• DO NOT EXCEED THE MAXIMUM LEVEL:

this could cause damage to the reservoir.

AdBlue (UREA) freezes at under 12° F

(-11° C). Although the system is designed

to operate below the freezing point of the

UREA, it is advisable not to fill the tank

beyond the maximum level because if the

UREA freezes the system can be damaged.

Follow the instructions in this section.

• If the AdBlue (UREA) is spilled on painted

surfaces or aluminium, immediately clean

the area with water and use absorbent ma-

terial to collect the fluid that has been

spilled on the ground.

•

Do not try to start the engine if AdBlue

(UREA) was accidentally added to the diesel

fuel tank, this can result in serious engine

damage, contact an authorized dealer.

•Do not add additives or other fluids to AdBlue

(UREA), doing so could damage the system.

STARTING AND OPERATING

186

Page 189 of 362

• The use of non-conforming or degraded

AdBlue (UREA) may lead to indications

appearing on the instrument panel display

refer to “Warning Lights And Messages" in

the “Getting To Know Your Instrument

Panel” for further information.

• Never pour AdBlue (UREA) into another

container: it could be contaminated.

• If the AdBlue (UREA) runs out, see refer to

“Warning Lights And Messages" in the

“Getting To Know Your Instrument Panel”

for further information to continue using

the car normally.

TRAILER TOWING

Common Towing Definitions

The following trailer towing related defini-

tions will assist you in understanding the

following information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of

your vehicle. This includes driver, passen-

gers, cargo and tongue weight.

The total load must be limited so that you do

not exceed the GVWR. Refer to “Vehicle

Loading/Vehicle Certification Label” in “Start-

ing And Operating” for further information.

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the

weight of all cargo, consumables and equip-

ment (permanent or temporary) loaded in or

on the trailer in its "loaded and ready for

operation" condition.

The recommended way to measure GTW is to

put your fully loaded trailer on a vehicle

scale. The entire weight of the trailer must be

supported by the scale.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the

front and rear axles. Distribute the load over

the front and rear axles evenly. Make sure

that you do not exceed either front or rear

GAWR. Refer to “Vehicle Loading/Vehicle

Certification Label” in “Starting And Operat-

ing” for further information.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating

is exceeded. You could lose control of the

vehicle and have a collision.

Tongue Weight (TW)

The tongue weight is the downward force

exerted on the hitch ball by the trailer. You

must consider this as part of the load on your

vehicle.

Trailer Frontal Area

The frontal area is the maximum height mul-

tiplied by the maximum width of the front of

a trailer.

187

Page 195 of 362

HAZARD WARNING

FLASHERS

The Hazard Warning flasher switch is located

in the lower center area of the instrument

panel.

Push the switch to turn on the

Hazard Warning flasher. When the

switch is activated, all directional

turn signals will flash on and off to

warn oncoming traffic of an emergency. Push

the switch a second time to turn off the

Hazard Warning flashers.This is an emergency warning system and it

should not be used when the vehicle is in

motion. Use it when your vehicle is disabled

and it is creating a safety hazard for other

motorists.

When you must leave the vehicle to seek

assistance, the Hazard Warning flashers will

continue to operate even though the ignition

is placed in the OFF position.

NOTE:

With extended use, the Hazard Warning

flashers may wear down your battery.

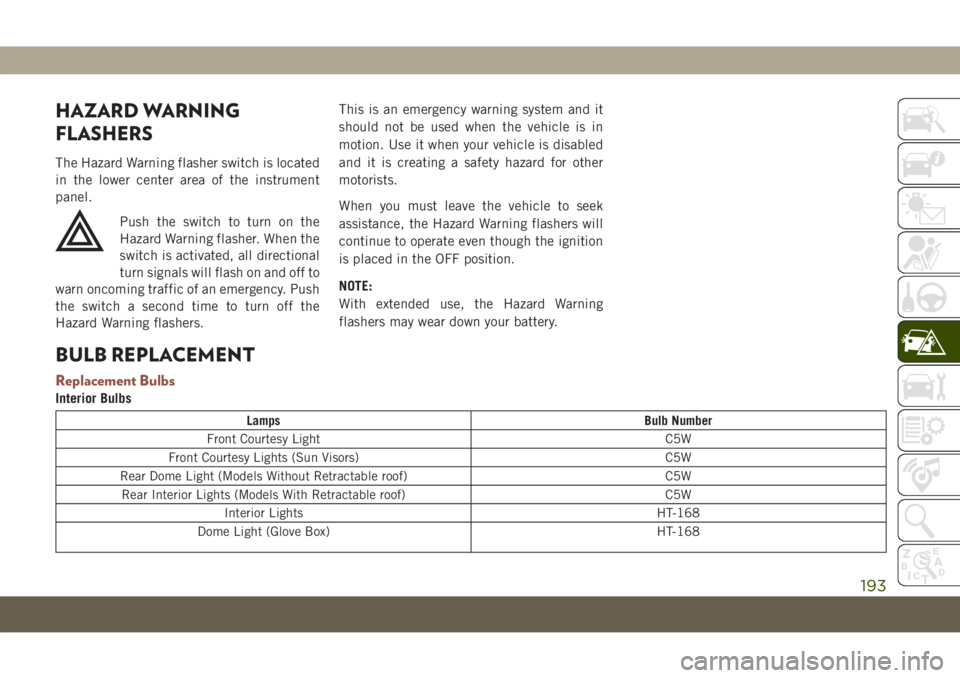

BULB REPLACEMENT

Replacement Bulbs

Interior Bulbs

Lamps Bulb Number

Front Courtesy Light C5W

Front Courtesy Lights (Sun Visors) C5W

Rear Dome Light (Models Without Retractable roof) C5W

Rear Interior Lights (Models With Retractable roof) C5W

Interior Lights HT-168

Dome Light (Glove Box) HT-168

193

Page 198 of 362

NOTE:

We advise referring to an authorized dealer.

WARNING!

Carry out the operation of replacing lamps

only with the engine off. Also make sure

that the engine is cold, to avoid the danger

of burns.

Turn Signal Light/Position Lights/

Daytime Running Lights

To replace the bulbs proceed as follows:

1. Turn the front wheels completely.

2. Remove the wheel liner.

3. Remove the electrical connectors.

4. For the DRL bulb, grip the bulb at the top

and bottom locking tabs and squeeze to

and remove the bulb.

5. To replace the DRL bulb gently push bulb

towards housing. Be sure to hear both the

top and bottom locking tabs “CLICK” to

ensure the bulb is properly seated.6. For the turn signal bulb, rotate in a coun-

terclockwise direction and remove the

bulb and bulb socket. Pull the bulb axially

to remove it from the socket.

7. Install the bulb and sockets and rotate

them clockwise making sure that it is

properly locked.

8. Reconnect the electrical connectors.

9. Reinstall the wheel liner.

NOTE:

We advise referring to an authorized dealer.

Front Fog Lights

To replace the bulbs proceed as follows:

1. Turn the front wheels completely.

2. Remove the wheel liner.

3. By pushing the electrical connector tab

remove the electrical connector.

4. Rotate the bulb counterclockwise, and

then replace the bulb.5. Insert the new bulb in the socket, making

sure the bulb is locked into place.

6. Reconnect the electrical connector.

7. Reinstall the wheel liner.

NOTE:

We advise referring to an authorized dealer.

Fog Lamp Housing

1 — Bulb

IN CASE OF EMERGENCY

196

Page 201 of 362

Rear Fog Lamps

We advise referring to an authorized dealer

for service.

NOTE:

We advise referring to an authorized dealer.

Reverse Lamps

We advise referring to an authorized dealer

for service.

3rd Stop Lamp

The CHMSL is LED. For their replacement,

see an authorized dealer.

License Plate Lights

The license plate light is LED. For their re-

placement, see an authorized dealer.WARNING!

• Before proceeding with the replacement

of the lamp wait until the exhaust pipes

are cool: DANGER OF BURNS!

• Modifications or repair of the electrical

system performed incorrectly and with-

out taking into account the technical

characteristics can cause malfunctions

with the risk of fire.

• Halogen lamps contain gas under pres-

sure, in the event of breakage be careful

of the projection of fragments of glass.

• Halogen lamps must be handled by

touching only the metallic part. If the

transparent bulb is in contact with the

fingers, reduces the intensity of the

emitted light and you can also affect the

life of the lamp. In case of accidental

contact, rub the bulb with a cloth damp-

ened with alcohol and allow to dry.

NOTE:

It is recommended to have your bulbs re-

placed by an authorized dealer.

FUSES

WARNING!

• When replacing a blown fuse, always use

an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Do not place a fuse inside a

circuit breaker cavity or vice versa. Fail-

ure to use proper fuses may result in

serious personal injury, fire and/or prop-

erty damage.

• Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

•

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system, trans-

mission system) or steering system blows,

contact an authorized dealer.

199

Page 214 of 362

5. Raise the vehicle just enough to remove

the flat tire.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack

assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

8. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.NOTE:

• For vehicles equipped, do not attempt

to install a center cap or wheel cover on

the compact spare.

• Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires—

General Information” in “Servicing And

Maintenance” in the Owner's Manual

for additional warnings, cautions, and

information about the spare tire, its

use, and operation.

9. Install and lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

10. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.11. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Wheel And Tire Torque

Specifications” in “Technical Specifica-

tions” for the proper lug bolt torque. If in

doubt about the correct tightness, have

them checked with a torque wrench by

an authorized dealer or at a service

station.

12. Place the jack on the foam tray and open

it far enough so that it is secured. Once

placed in position, rotate it clockwise to

lock it in. Replace the alignment pin in

the center hole to lock the jack in place.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

IN CASE OF EMERGENCY

212

Page 215 of 362

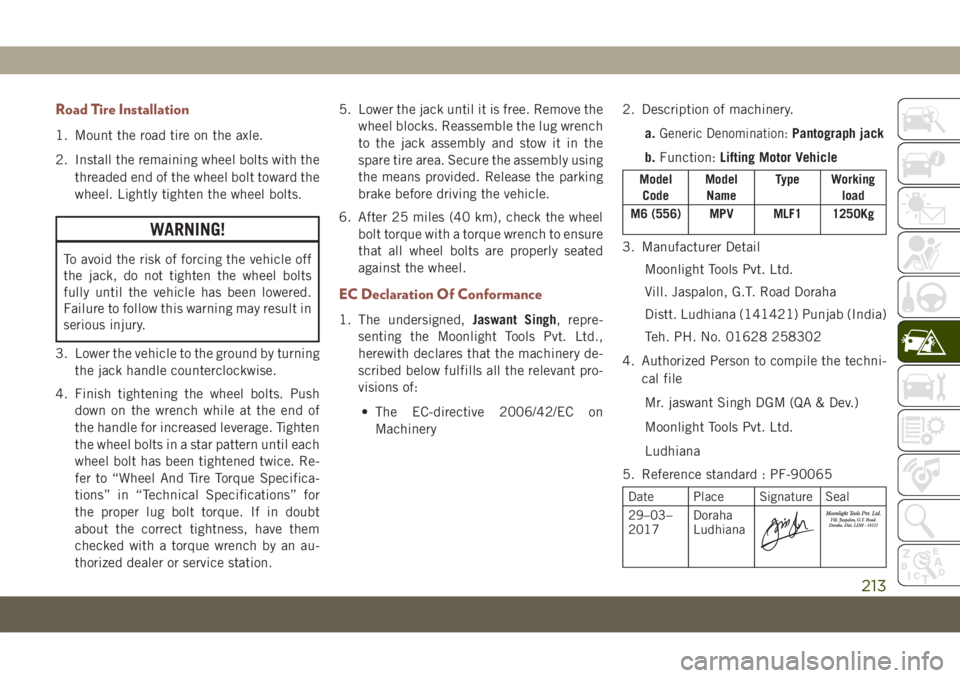

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the

threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel bolts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage. Tighten

the wheel bolts in a star pattern until each

wheel bolt has been tightened twice. Re-

fer to “Wheel And Tire Torque Specifica-

tions” in “Technical Specifications” for

the proper lug bolt torque. If in doubt

about the correct tightness, have them

checked with a torque wrench by an au-

thorized dealer or service station.5. Lower the jack until it is free. Remove the

wheel blocks. Reassemble the lug wrench

to the jack assembly and stow it in the

spare tire area. Secure the assembly using

the means provided. Release the parking

brake before driving the vehicle.

6. After 25 miles (40 km), check the wheel

bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

EC Declaration Of Conformance

1. The undersigned,Jaswant Singh, repre-

senting the Moonlight Tools Pvt. Ltd.,

herewith declares that the machinery de-

scribed below fulfills all the relevant pro-

visions of:

• The EC-directive 2006/42/EC on

Machinery2. Description of machinery.

a.

Generic Denomination:Pantograph jack

b.Function:Lifting Motor Vehicle

Model

CodeModel

NameType Working

load

M6 (556) MPV MLF1 1250Kg

3. Manufacturer Detail

Moonlight Tools Pvt. Ltd.

Vill. Jaspalon, G.T. Road Doraha

Distt. Ludhiana (141421) Punjab (India)

Teh. PH. No. 01628 258302

4. Authorized Person to compile the techni-

cal file

Mr. jaswant Singh DGM (QA & Dev.)

Moonlight Tools Pvt. Ltd.

Ludhiana

5. Reference standard : PF-90065

Date Place Signature Seal

29–03–

2017Doraha

Ludhiana

213