ECU JEEP COMPASS 2023 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: COMPASS, Model: JEEP COMPASS 2023Pages: 344, PDF Size: 18.8 MB

Page 243 of 344

SAFETY241

(Continued)

SAFETY CHECKS YOU SHOULD MAKE

I

NSIDE THE VEHICLE

Seat Belts

Inspect the seat belt system periodically, checking

for cuts, frays, and loose parts. Damaged parts

must be replaced immediately. Do not

disassemble or modify the system.

If your vehicle is involved in a collision, or if you

have questions regarding the seat belt or retractor

conditions, take your vehicle to an authorized FCA

dealer or authorized FCA Certified Collision Care

Program facility for inspection.

Air Bag Warning Light

The Air Bag Warning Light will turn on for

four to eight seconds as a bulb check

when the ignition switch is first placed in

the ON/RUN position. If the light is either

not on during starting, stays on, or turns on while

driving, have the system inspected at an

authorized dealer as soon as possible. After the

bulb check, this light will illuminate with a single

chime when a fault with the Air Bag System has

been detected. It will stay on until the fault is

removed. If the light comes on intermittently or

remains on while driving, have an authorized

dealer service the vehicle immediately

Ú page 204.

Defroster

Check operation by selecting the defrost mode and

place the blower control on high speed. You should

be able to feel the air directed against the

windshield. See an authorized dealer for service if

your defroster is inoperable.

Floor Mat Safety Information

Always use floor mats designed to fit your vehicle.

Only use a floor mat that does not interfere with the

operation of the accelerator, brake or clutch

pedals. Only use a floor mat that is securely

attached using the floor mat fasteners so it cannot

slip out of position and interfere with the

accelerator, brake or clutch pedals or impair safe

operation of your vehicle in other ways.

WARNING!

An improperly attached, damaged, folded, or

stacked floor mat, or damaged floor mat

fasteners may cause your floor mat to interfere

with the accelerator, brake, or clutch pedals and

cause a loss of vehicle control. To prevent

SERIOUS INJURY or DEATH:

ALWAYS securely attach your floor

mat using the floor mat fasteners.

DO NOT install your floor mat upside

down or turn your floor mat over.

Lightly pull to confirm mat is secured using the

floor mat fasteners on a regular basis.

ALWAYS REMOVE THE EXISTING

FLOOR MAT FROM THE VEHICLE

before installing any other floor mat.

NEVER install or stack an additional

floor mat on top of an existing floor mat.

ONLY install floor mats designed to fit your

vehicle. NEVER install a floor mat that cannot

be properly attached and secured to your

vehicle. If a floor mat needs to be replaced,

only use a FCA approved floor mat for the

specific make, model, and year of your

vehicle.

6

22_MP_OM_EN_USC_t.book Page 241

Page 244 of 344

242SAFETY

(Continued)

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven

wear patterns. Check for stones, nails, glass, or

other objects lodged in the tread or sidewall.

Inspect the tread for cuts and cracks. Inspect

sidewalls for cuts, cracks, and bulges. Check the

lug nut/bolt torque for tightness. Check the tires

(including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel or

brake fluid leaks are suspected, the cause should

be located and corrected immediately.

ONLY use the driver’s side floor mat on the

driver’s side floor area. To check for interfer -

ence, with the vehicle properly parked with the

engine off, fully depress the accelerator, the

brake, and the clutch pedal (if present) to

check for interference. If your floor mat inter -

feres with the operation of any pedal, or is not

secure to the floor, remove the floor mat from

the vehicle and place the floor mat in your

trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

ALWAYS make sure objects cannot fall or slide

into the driver’s side floor area when the

vehicle is moving. Objects can become

trapped under accelerator, brake, or clutch

pedals and could cause a loss of vehicle

control.

WARNING!

NEVER place any objects under the floor mat

(e.g., towels, keys, etc.). These objects could

change the position of the floor mat and may

cause interference with the accelerator,

brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to

the floor and check the floor mat fasteners are

secure to the vehicle carpet. Fully depress

each pedal to check for interference with the

accelerator, brake, or clutch pedals then

re-install the floor mats.

It is recommended to only use mild soap and

water to clean your floor mats. After cleaning,

always check your floor mat has been properly

installed and is secured to your vehicle using

the floor mat fasteners by lightly pulling mat.

WARNING!

22_MP_OM_EN_USC_t.book Page 242

Page 251 of 344

IN CASE OF EMERGENCY249

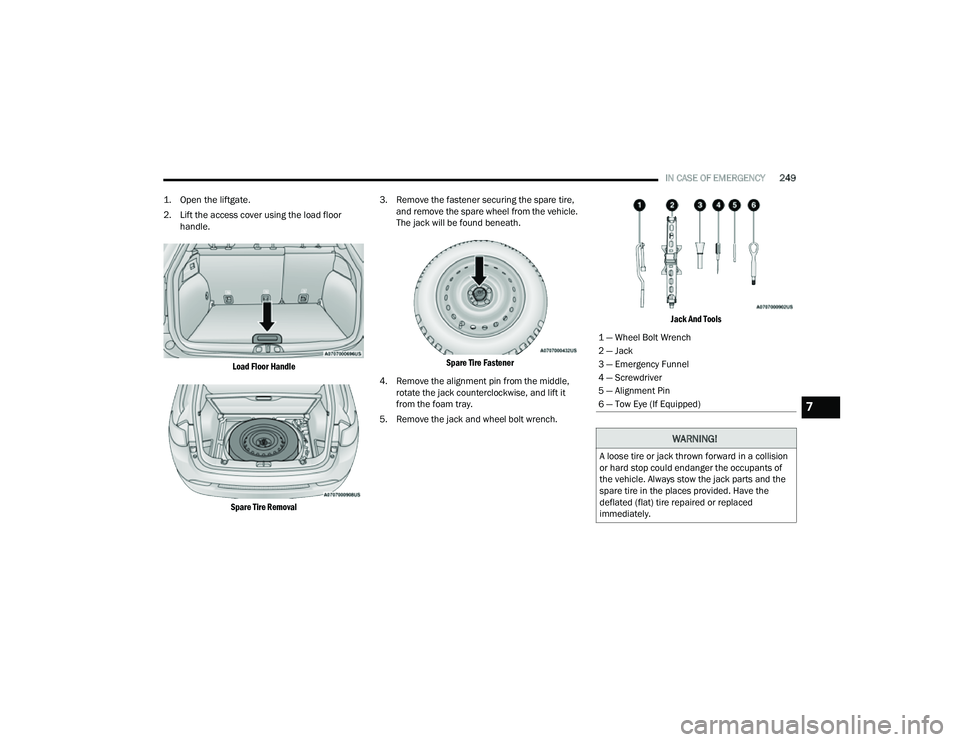

1. Open the liftgate.

2. Lift the access cover using the load floor handle.

Load Floor Handle

Spare Tire Removal

3. Remove the fastener securing the spare tire,

and remove the spare wheel from the vehicle.

The jack will be found beneath.

Spare Tire Fastener

4. Remove the alignment pin from the middle, rotate the jack counterclockwise, and lift it

from the foam tray.

5. Remove the jack and wheel bolt wrench.

Jack And Tools

1 — Wheel Bolt Wrench

2 — Jack

3 — Emergency Funnel

4 — Screwdriver

5 — Alignment Pin

6 — Tow Eye (If Equipped)

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

7

22_MP_OM_EN_USC_t.book Page 249

Page 252 of 344

250IN CASE OF EMERGENCY

(Continued)

JACKING INSTRUCTIONS

Jack Warning Label

1. Remove the spare tire, jack, and wheel bolt wrench.

2. If equipped with aluminum wheels where the center cap covers the wheel bolts, use the

wheel bolt wrench to pry the center cap off

carefully before raising the vehicle. 3. Before raising the vehicle, use the wheel bolt

wrench to loosen, but not remove, the wheel

bolts on the wheel with the flat tire. Turn the

wheel bolts counterclockwise one turn while

the wheel is still on the ground.

NOTE:Placement for the front and rear jack locations are

critical. See below images for proper jacking loca -

tions.

Jacking Locations

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before

raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the wheel

to be raised.

Never start or run the engine with the vehicle

on a jack.

Do not let anyone sit in the vehicle when it is

on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

To ensure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with

the valve stem facing the ground.

WARNING!

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the

Jacking Instructions for this vehicle.

22_MP_OM_EN_USC_t.book Page 250

Page 254 of 344

252IN CASE OF EMERGENCY

NOTE:

For vehicles equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

For additional warnings, cautions, and infor -

mation about the spare tire, its use, and

operation Ú page 298.

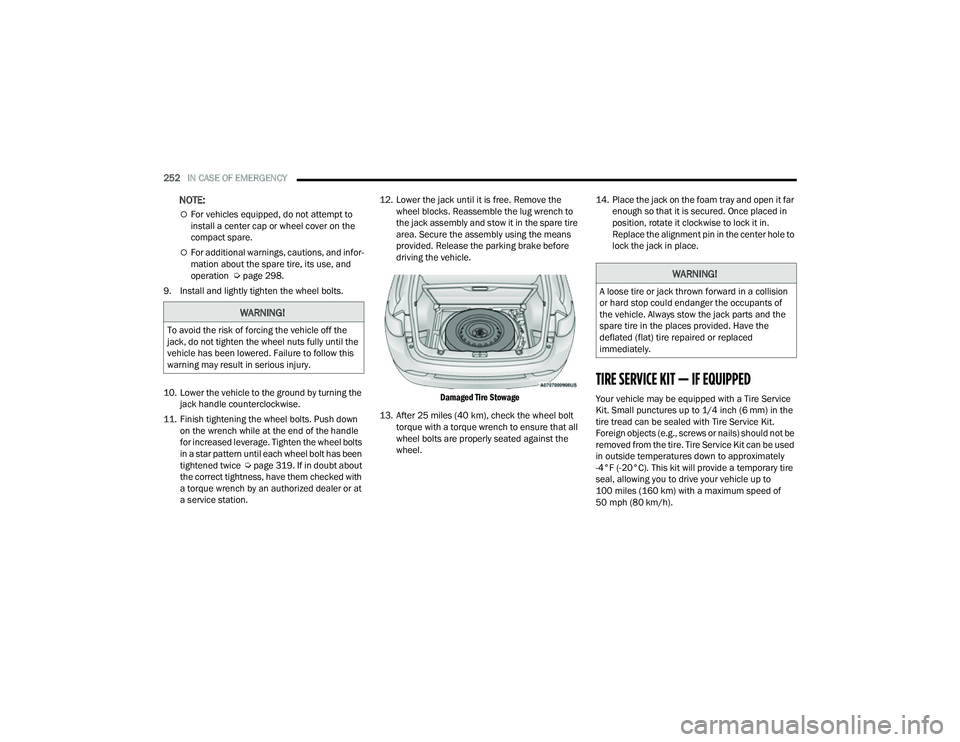

9. Install and lightly tighten the wheel bolts.

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the wheel bolts

in a star pattern until each wheel bolt has been

tightened twice Úpage 319. If in doubt about

the correct tightness, have them checked with

a torque wrench by an authorized dealer or at

a service station. 12. Lower the jack until it is free. Remove the

wheel blocks. Reassemble the lug wrench to

the jack assembly and stow it in the spare tire

area. Secure the assembly using the means

provided. Release the parking brake before

driving the vehicle.

Damaged Tire Stowage

13. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to ensure that all

wheel bolts are properly seated against the

wheel. 14. Place the jack on the foam tray and open it far

enough so that it is secured. Once placed in

position, rotate it clockwise to lock it in.

Replace the alignment pin in the center hole to

lock the jack in place.

TIRE SERVICE KIT — IF EQUIPPED

Your vehicle may be equipped with a Tire Service

Kit. Small punctures up to 1/4 inch (6 mm) in the

tire tread can be sealed with Tire Service Kit.

Foreign objects (e.g., screws or nails) should not be

removed from the tire. Tire Service Kit can be used

in outside temperatures down to approximately

-4°F (-20°C). This kit will provide a temporary tire

seal, allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of

50 mph (80 km/h).

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

22_MP_OM_EN_USC_t.book Page 252

Page 266 of 344

264IN CASE OF EMERGENCY

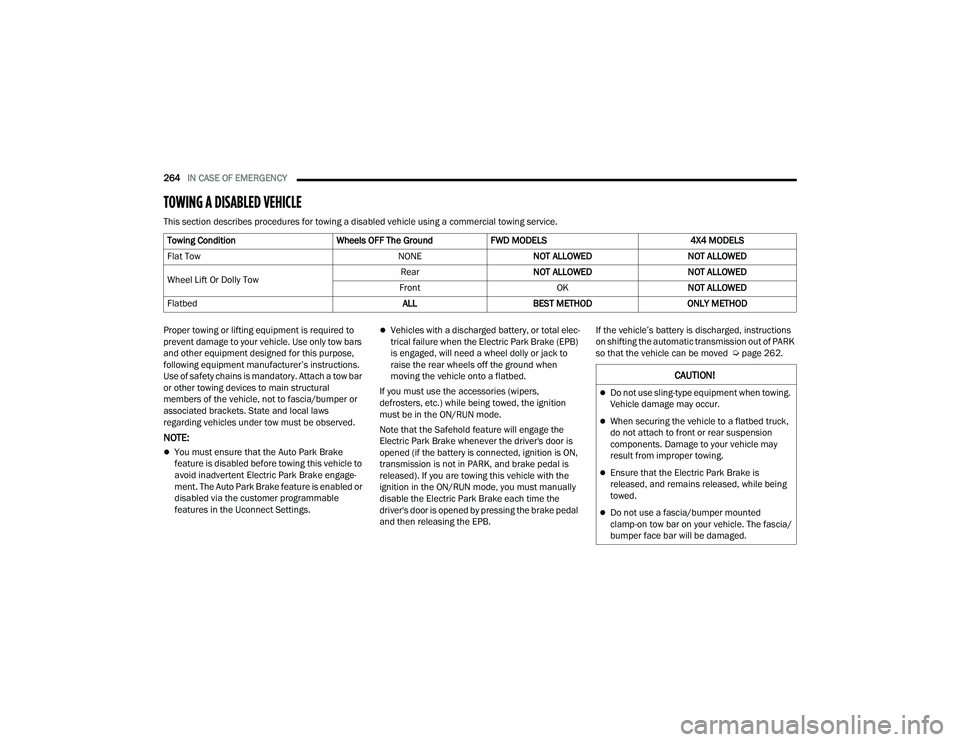

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing service.

Proper towing or lifting equipment is required to

prevent damage to your vehicle. Use only tow bars

and other equipment designed for this purpose,

following equipment manufacturer’s instructions.

Use of safety chains is mandatory. Attach a tow bar

or other towing devices to main structural

members of the vehicle, not to fascia/bumper or

associated brackets. State and local laws

regarding vehicles under tow must be observed.

NOTE:

You must ensure that the Auto Park Brake

feature is disabled before towing this vehicle to

avoid inadvertent Electric Park Brake engage -

ment. The Auto Park Brake feature is enabled or

disabled via the customer programmable

features in the Uconnect Settings.

Vehicles with a discharged battery, or total elec -

trical failure when the Electric Park Brake (EPB)

is engaged, will need a wheel dolly or jack to

raise the rear wheels off the ground when

moving the vehicle onto a flatbed.

If you must use the accessories (wipers,

defrosters, etc.) while being towed, the ignition

must be in the ON/RUN mode.

Note that the Safehold feature will engage the

Electric Park Brake whenever the driver's door is

opened (if the battery is connected, ignition is ON,

transmission is not in PARK, and brake pedal is

released). If you are towing this vehicle with the

ignition in the ON/RUN mode, you must manually

disable the Electric Park Brake each time the

driver's door is opened by pressing the brake pedal

and then releasing the EPB. If the vehicle’s battery is discharged, instructions

on shifting the automatic transmission out of PARK

so that the vehicle can be moved Ú

page 262.

Towing Condition

Wheels OFF The GroundFWD MODELS 4X4 MODELS

Flat Tow NONENOT ALLOWED NOT ALLOWED

Wheel Lift Or Dolly Tow Rear

NOT ALLOWED NOT ALLOWED

Front OKNOT ALLOWED

Flatbed ALLBEST METHOD ONLY METHOD

CAUTION!

Do not use sling-type equipment when towing.

Vehicle damage may occur.

When securing the vehicle to a flatbed truck,

do not attach to front or rear suspension

components. Damage to your vehicle may

result from improper towing.

Ensure that the Electric Park Brake is

released, and remains released, while being

towed.

Do not use a fascia/bumper mounted

clamp-on tow bar on your vehicle. The fascia/

bumper face bar will be damaged.

22_MP_OM_EN_USC_t.book Page 264

Page 284 of 344

282SERVICING AND MAINTENANCE

(Continued)

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator

and in the coolant expansion bottle. If engine

coolant needs to be added, the contents of the

coolant expansion bottle must also be protected

against freezing.

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro-

sion protection of your engine which contains

aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces -

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically. For the proper maintenance intervals

Ú page 268.

Brake Master Cylinder

The fluid in the master cylinder should be checked

when performing under hood services or

immediately if the Brake Warning Light is

illuminated.

Be sure to clean the top of the master cylinder area

before removing the cap. If necessary, add fluid to

bring the fluid level up to the requirements

described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be

checked when pads are replaced. However, low

fluid level may be caused by a leak and a checkup

may be needed. Use only the manufacturer recommended brake

fluid Ú

page 324.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting or

riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear,

and possible brake damage. You would not have

your full braking capacity in an emergency.

WARNING!

Use only the manufacturer recommended

brake fluid Úpage 324. Using the wrong type

of brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in a open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure.

This could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

22_MP_OM_EN_USC_t.book Page 282

Page 290 of 344

288SERVICING AND MAINTENANCE

F37 – ––

F38 –10 Amp Red ECM / TCM / AGSM / DCSM / STM

F39 – ––

F40 – ––

F41 – ––

F42 –20 Amp Yellow Cargo Power Outlet – Ignition power

F43 – –Cargo Power Outlet (Can be replaced with 20 Amp fuse in F42 direct battery power)

F44 – ––

F45 – ––

F46 –30 Amp Tan Drivetrain Control Module (DTCM) AWD Power

F47 –30 Amp Tan Front Windshield Defrost*

F48 – ––

F49 –15 Amp Blue Transmission Control Module (TCM)

F50 –5 Amp Tan Drive Train Control Module (DTCM) ECU Power

F51 –20 Amp Yellow NOX SNSR Feed (Diesel Engine)

F52 –5 Amp Tan Automatic Gearbox Shifter Module (AGSM) (Diesel & Gas)

F53 – ––

F54 – ––

F55 – ––

F56 – ––

Cavity Cartridge Fuse Mini Fuse Description

* If Equipped

22_MP_OM_EN_USC_t.book Page 288

Page 292 of 344

290SERVICING AND MAINTENANCE

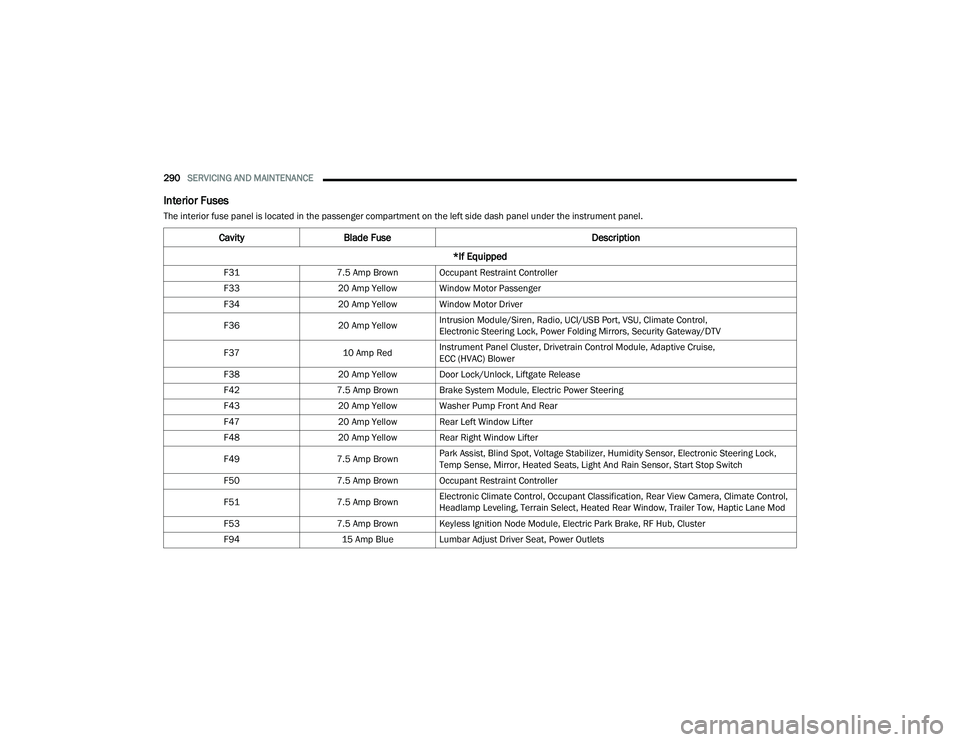

Interior Fuses

The interior fuse panel is located in the passenger compartment on the left side dash panel under the instrument panel.

CavityBlade Fuse Description

*If Equipped

F31 7.5 Amp Brown Occupant Restraint Controller

F33 20 Amp Yellow Window Motor Passenger

F34 20 Amp Yellow Window Motor Driver

F36 20 Amp YellowIntrusion Module/Siren, Radio, UCI/USB Port, VSU, Climate Control,

Electronic Steering Lock, Power Folding Mirrors, Security Gateway/DTV

F37 10 Amp RedInstrument Panel Cluster, Drivetrain Control Module, Adaptive Cruise,

ECC (HVAC) Blower

F38 20 Amp Yellow Door Lock/Unlock, Liftgate Release

F42 7.5 Amp Brown Brake System Module, Electric Power Steering

F43 20 Amp Yellow Washer Pump Front And Rear

F47 20 Amp Yellow Rear Left Window Lifter

F48 20 Amp Yellow Rear Right Window Lifter

F49 7.5 Amp BrownPark Assist, Blind Spot, Voltage Stabilizer, Humidity Sensor, Electronic Steering Lock,

Temp Sense, Mirror, Heated Seats, Light And Rain Sensor, Start Stop Switch

F50 7.5 Amp Brown Occupant Restraint Controller

F51 7.5 Amp BrownElectronic Climate Control, Occupant Classification, Rear View Camera, Climate Control,

Headlamp Leveling, Terrain Select, Heated Rear Window, Trailer Tow, Haptic Lane Mod

F53 7.5 Amp Brown Keyless Ignition Node Module, Electric Park Brake, RF Hub, Cluster

F94 15 Amp Blue Lumbar Adjust Driver Seat, Power Outlets

22_MP_OM_EN_USC_t.book Page 290

Page 331 of 344

329

INDEX

A

Active Lane Management System................. 145Adaptive Cruise Control (ACC)........................ 116Adding Engine Coolant (Antifreeze)............... 280Additives, Fuel............................................... 322Air Bag........................................................... 214Air Bag Operation...................................... 215Air Bag Warning Light...................... 213, 216Driver Knee Air Bag................................... 219Enhanced Accident Response......... 224, 266Event Data Recorder (EDR)....................... 266Front Air Bag............................................. 216If Deployment Occurs................................ 223Knee Impact Bolsters................................ 219Maintaining Your Air Bag System.............. 227Maintenance............................................. 227Redundant Air Bag Warning Light.............214Side Air Bags............................................. 220Transporting Pets...................................... 240Air Bag Light........................................ 213, 241Air Cleaner, Engine

(Engine Air Cleaner Filter).............................. 274Air Conditioner Maintenance......................... 274Air Conditioner Refrigerant.................. 274, 275Air Conditioner System.................................. 274Air Conditioning Filter............................. 57, 275

Air Conditioning, Operating Tips....................... 56Air Filter........................................................ 274Air PressureTires......................................................... 306AlarmArm The System.......................................... 21Disarm The System..................................... 22Security Alarm...................................... 21, 92Alarm SystemSecurity Alarm............................................. 21Alterations/ModificationsVehicle......................................................... 10Antifreeze (Engine Coolant)................. 280, 323Disposal................................................... 281Anti-Lock Brake System (ABS)...................... 187Anti-Lock Warning Light................................... 92Arming SystemSecurity Alarm............................................. 21Assist, Hill Start............................................. 193Audio Systems (Radio).................................. 164Auto Down Power Windows............................. 62Auto Hold...................................................... 105Automatic Dimming Mirror............................... 37Automatic Door Locks...................................... 25Automatic Headlights....................................... 45Automatic High Beams.................................... 45

Automatic Temperature Control (ATC)..............56Automatic Transaxle..................................... 106Automatic Transmission................................ 107Adding Fluid..................................... 283, 324Fluid And Filter Change............................. 283Fluid Change............................................. 283Fluid Level Check...................................... 283Fluid Type........................................ 283, 324Special Additives...................................... 283Automatic Transmission Limp Home Mode......25Auxiliary Electrical Outlet (Power Outlet)..........59Axle Fluid....................................................... 324Axle Lubrication............................................ 324

B

Battery................................................... 90, 272Charging System Light.................................90Keyless Key Fob Replacement....................15Battery Saver Feature......................................88Belts, Seat.................................................... 241Blind Spot Monitoring................................... 194Body Mechanism Lubrication........................ 275B-Pillar Location............................................ 303Brake Assist System..................................... 188Brake Control System, Electronic.................. 188Brake Fluid.................................................... 324

11

22_MP_OM_EN_USC_t.book Page 329