lock JEEP COMPASS 2023 Manual Online

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: COMPASS, Model: JEEP COMPASS 2023Pages: 344, PDF Size: 18.8 MB

Page 244 of 344

242SAFETY

(Continued)

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven

wear patterns. Check for stones, nails, glass, or

other objects lodged in the tread or sidewall.

Inspect the tread for cuts and cracks. Inspect

sidewalls for cuts, cracks, and bulges. Check the

lug nut/bolt torque for tightness. Check the tires

(including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel or

brake fluid leaks are suspected, the cause should

be located and corrected immediately.

ONLY use the driver’s side floor mat on the

driver’s side floor area. To check for interfer -

ence, with the vehicle properly parked with the

engine off, fully depress the accelerator, the

brake, and the clutch pedal (if present) to

check for interference. If your floor mat inter -

feres with the operation of any pedal, or is not

secure to the floor, remove the floor mat from

the vehicle and place the floor mat in your

trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

ALWAYS make sure objects cannot fall or slide

into the driver’s side floor area when the

vehicle is moving. Objects can become

trapped under accelerator, brake, or clutch

pedals and could cause a loss of vehicle

control.

WARNING!

NEVER place any objects under the floor mat

(e.g., towels, keys, etc.). These objects could

change the position of the floor mat and may

cause interference with the accelerator,

brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to

the floor and check the floor mat fasteners are

secure to the vehicle carpet. Fully depress

each pedal to check for interference with the

accelerator, brake, or clutch pedals then

re-install the floor mats.

It is recommended to only use mild soap and

water to clean your floor mats. After cleaning,

always check your floor mat has been properly

installed and is secured to your vehicle using

the floor mat fasteners by lightly pulling mat.

WARNING!

22_MP_OM_EN_USC_t.book Page 242

Page 250 of 344

248IN CASE OF EMERGENCY

PREPARATIONS FOR JACKING

1. Park the vehicle on a firm level surface as far

from the edge of the roadway as possible.

Avoid icy or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake.

4. Place the ignition in the OFF position. 5. Block both the front and rear of the wheel

diagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.

Wheel Blocked

NOTE:Passengers should not remain in the vehicle when

the vehicle is being lifted or raised.

JACK LOCATION/SPARE TIRE STOWAGE

If equipped, the jack and tools are located in the

rear storage compartment, below the spare tire.

NOTE:Items may vary depending on the trim level.

Jack And Tools Location

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

1 — Jack

2 — Alignment Pin

3 — Emergency Funnel

4 — Wheel Bolt Wrench

5 — Screwdriver

22_MP_OM_EN_USC_t.book Page 248

Page 251 of 344

IN CASE OF EMERGENCY249

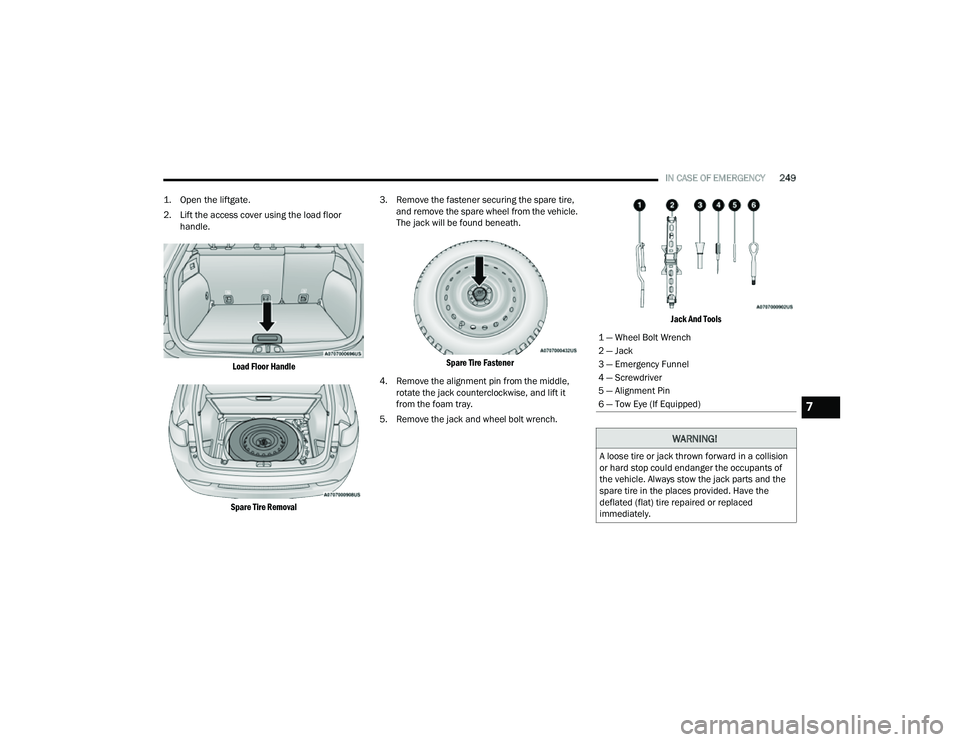

1. Open the liftgate.

2. Lift the access cover using the load floor handle.

Load Floor Handle

Spare Tire Removal

3. Remove the fastener securing the spare tire,

and remove the spare wheel from the vehicle.

The jack will be found beneath.

Spare Tire Fastener

4. Remove the alignment pin from the middle, rotate the jack counterclockwise, and lift it

from the foam tray.

5. Remove the jack and wheel bolt wrench.

Jack And Tools

1 — Wheel Bolt Wrench

2 — Jack

3 — Emergency Funnel

4 — Screwdriver

5 — Alignment Pin

6 — Tow Eye (If Equipped)

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

7

22_MP_OM_EN_USC_t.book Page 249

Page 252 of 344

250IN CASE OF EMERGENCY

(Continued)

JACKING INSTRUCTIONS

Jack Warning Label

1. Remove the spare tire, jack, and wheel bolt wrench.

2. If equipped with aluminum wheels where the center cap covers the wheel bolts, use the

wheel bolt wrench to pry the center cap off

carefully before raising the vehicle. 3. Before raising the vehicle, use the wheel bolt

wrench to loosen, but not remove, the wheel

bolts on the wheel with the flat tire. Turn the

wheel bolts counterclockwise one turn while

the wheel is still on the ground.

NOTE:Placement for the front and rear jack locations are

critical. See below images for proper jacking loca -

tions.

Jacking Locations

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before

raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the wheel

to be raised.

Never start or run the engine with the vehicle

on a jack.

Do not let anyone sit in the vehicle when it is

on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

To ensure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with

the valve stem facing the ground.

WARNING!

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the

Jacking Instructions for this vehicle.

22_MP_OM_EN_USC_t.book Page 250

Page 253 of 344

IN CASE OF EMERGENCY251

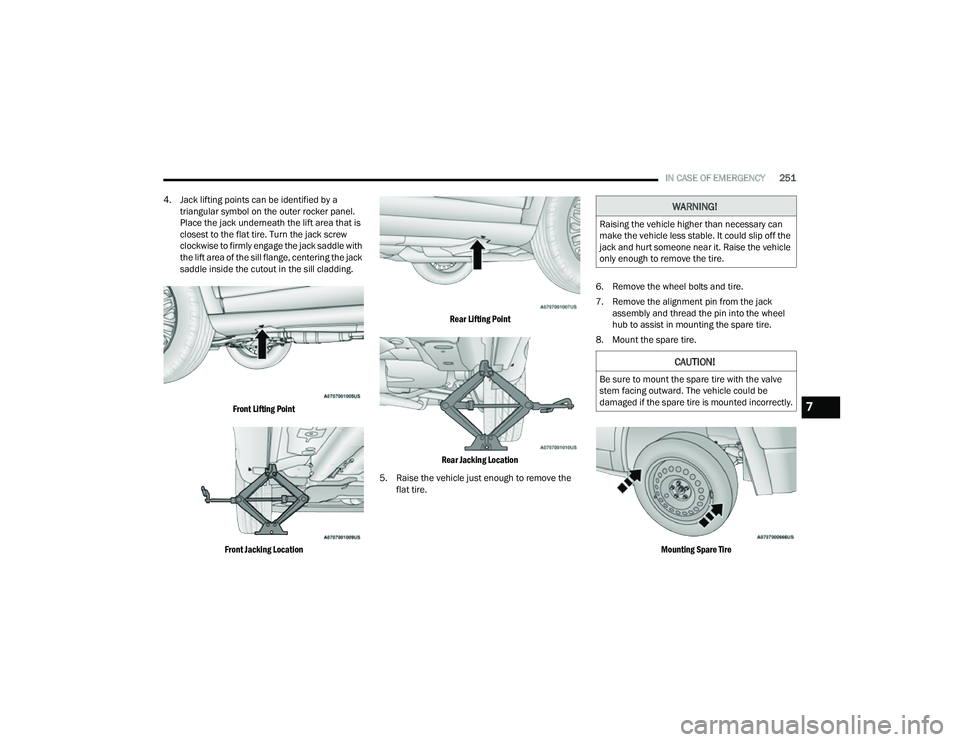

4. Jack lifting points can be identified by a triangular symbol on the outer rocker panel.

Place the jack underneath the lift area that is

closest to the flat tire. Turn the jack screw

clockwise to firmly engage the jack saddle with

the lift area of the sill flange, centering the jack

saddle inside the cutout in the sill cladding.

Front Lifting Point

Front Jacking Location Rear Lifting Point

Rear Jacking Location

5. Raise the vehicle just enough to remove the flat tire. 6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack

assembly and thread the pin into the wheel

hub to assist in mounting the spare tire.

8. Mount the spare tire.

Mounting Spare Tire

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted incorrectly.

7

22_MP_OM_EN_USC_t.book Page 251

Page 254 of 344

252IN CASE OF EMERGENCY

NOTE:

For vehicles equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

For additional warnings, cautions, and infor -

mation about the spare tire, its use, and

operation Ú page 298.

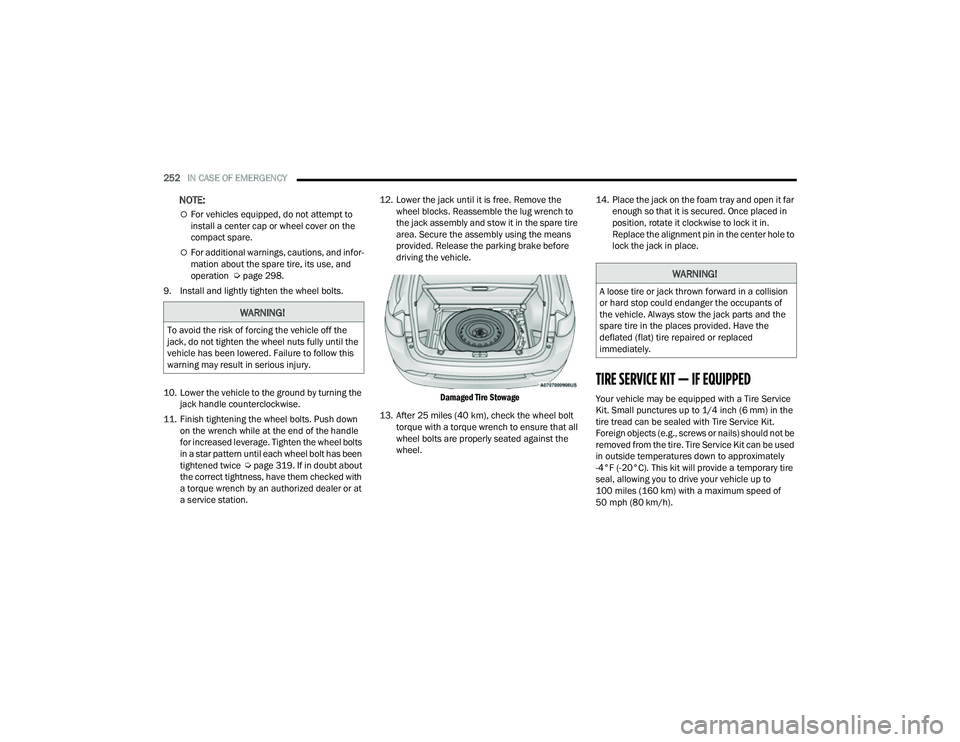

9. Install and lightly tighten the wheel bolts.

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the wheel bolts

in a star pattern until each wheel bolt has been

tightened twice Úpage 319. If in doubt about

the correct tightness, have them checked with

a torque wrench by an authorized dealer or at

a service station. 12. Lower the jack until it is free. Remove the

wheel blocks. Reassemble the lug wrench to

the jack assembly and stow it in the spare tire

area. Secure the assembly using the means

provided. Release the parking brake before

driving the vehicle.

Damaged Tire Stowage

13. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to ensure that all

wheel bolts are properly seated against the

wheel. 14. Place the jack on the foam tray and open it far

enough so that it is secured. Once placed in

position, rotate it clockwise to lock it in.

Replace the alignment pin in the center hole to

lock the jack in place.

TIRE SERVICE KIT — IF EQUIPPED

Your vehicle may be equipped with a Tire Service

Kit. Small punctures up to 1/4 inch (6 mm) in the

tire tread can be sealed with Tire Service Kit.

Foreign objects (e.g., screws or nails) should not be

removed from the tire. Tire Service Kit can be used

in outside temperatures down to approximately

-4°F (-20°C). This kit will provide a temporary tire

seal, allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of

50 mph (80 km/h).

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

22_MP_OM_EN_USC_t.book Page 252

Page 264 of 344

262IN CASE OF EMERGENCY

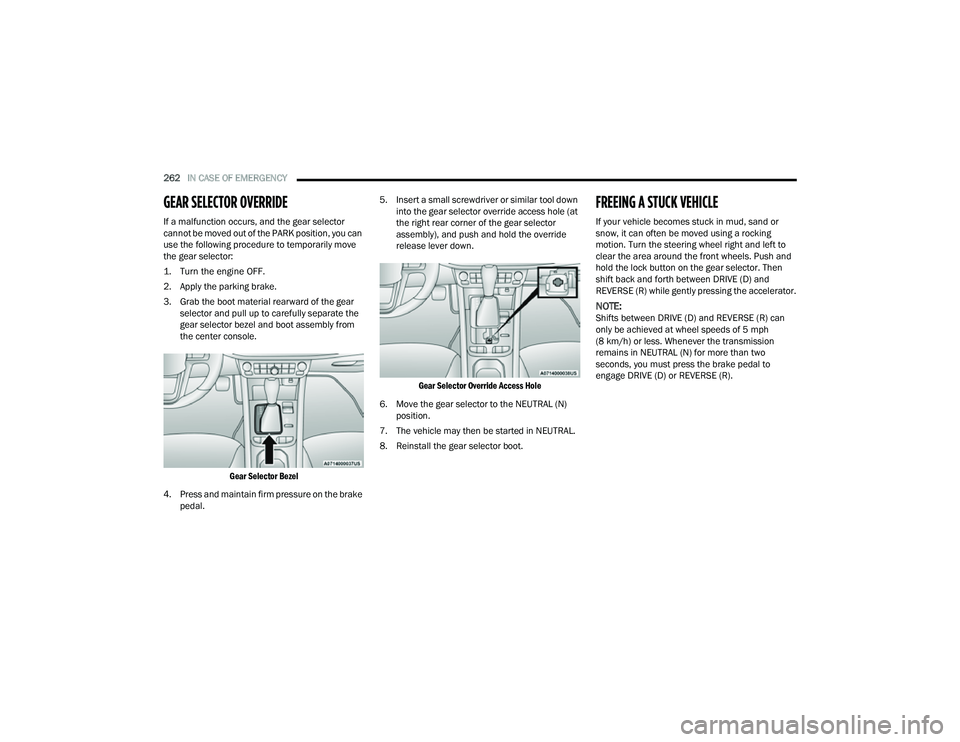

GEAR SELECTOR OVERRIDE

If a malfunction occurs, and the gear selector

cannot be moved out of the PARK position, you can

use the following procedure to temporarily move

the gear selector:

1. Turn the engine OFF.

2. Apply the parking brake.

3. Grab the boot material rearward of the gear

selector and pull up to carefully separate the

gear selector bezel and boot assembly from

the center console.

Gear Selector Bezel

4. Press and maintain firm pressure on the brake pedal. 5. Insert a small screwdriver or similar tool down

into the gear selector override access hole (at

the right rear corner of the gear selector

assembly), and push and hold the override

release lever down.

Gear Selector Override Access Hole

6. Move the gear selector to the NEUTRAL (N) position.

7. The vehicle may then be started in NEUTRAL.

8. Reinstall the gear selector boot.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. Push and

hold the lock button on the gear selector. Then

shift back and forth between DRIVE (D) and

REVERSE (R) while gently pressing the accelerator.

NOTE:Shifts between DRIVE (D) and REVERSE (R) can

only be achieved at wheel speeds of 5 mph

(8 km/h) or less. Whenever the transmission

remains in NEUTRAL (N) for more than two

seconds, you must press the brake pedal to

engage DRIVE (D) or REVERSE (R).

22_MP_OM_EN_USC_t.book Page 262

Page 277 of 344

SERVICING AND MAINTENANCE275

Refrigerant Recovery And Recycling

R-134a — If Equipped

R-134a Air Conditioning Refrigerant is a Hydrofluo -

rocarbon (HFC) that is an ozone-friendly

substance. It is recommended that air conditioning

service be performed by an authorized dealer or

other service facilities using recovery and recycling

equipment.

NOTE:Use only the manufacturer approved A/C system

PAG compressor oil and refrigerants.

Refrigerant Recovery And Recycling

R-1234yf — If Equipped

R-1234yf Air Conditioning Refrigerant is a

Hydrofluoroolefin (HFO) that is endorsed by the

Environmental Protection Agency and is an

ozone-friendly substance with a low

global-warming potential. It is recommended that

air conditioning service be performed by an

authorized dealer using recovery and recycling

equipment.

NOTE:Use only the manufacturer approved A/C system

PAG compressor oil, and refrigerants.

Cabin Air Filter

See an authorized dealer for service.

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points and

rollers, liftgate, tailgate, decklid, sliding doors and

hood hinges, should be lubricated periodically with

a lithium-based grease, such as Mopar® Spray

White Lube to ensure quiet, easy operation and to

protect against rust and wear. Prior to the

application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit;

after lubricating, excess oil and grease should be

removed. Particular attention should also be given

to hood latching components to ensure proper

function. When performing other underhood

services, the hood latch, release mechanism and

safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and Spring.

Apply a small amount of a high quality lubricant,

such as Mopar® Lock Cylinder Lubricant directly

into the lock cylinder.

WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield and rear window periodically with a

sponge or soft cloth and a mild nonabrasive

cleaner. This will remove accumulations of salt,

waxes, or road film, and help reduce streaking and

smearing.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry windshield

or rear window.

Avoid using the wiper blades to remove frost or ice

from the windshield or rear window. Make sure

that they are not frozen to the glass before turning

them on to avoid damaging the blade. Keep the

wiper blade out of contact with petroleum products

such as engine oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending

on geographical area and frequency of use. If chat -

tering, marks, water lines or wet spots are present,

clean the wiper blades or replace as necessary.8

22_MP_OM_EN_USC_t.book Page 275

Page 278 of 344

276SERVICING AND MAINTENANCE

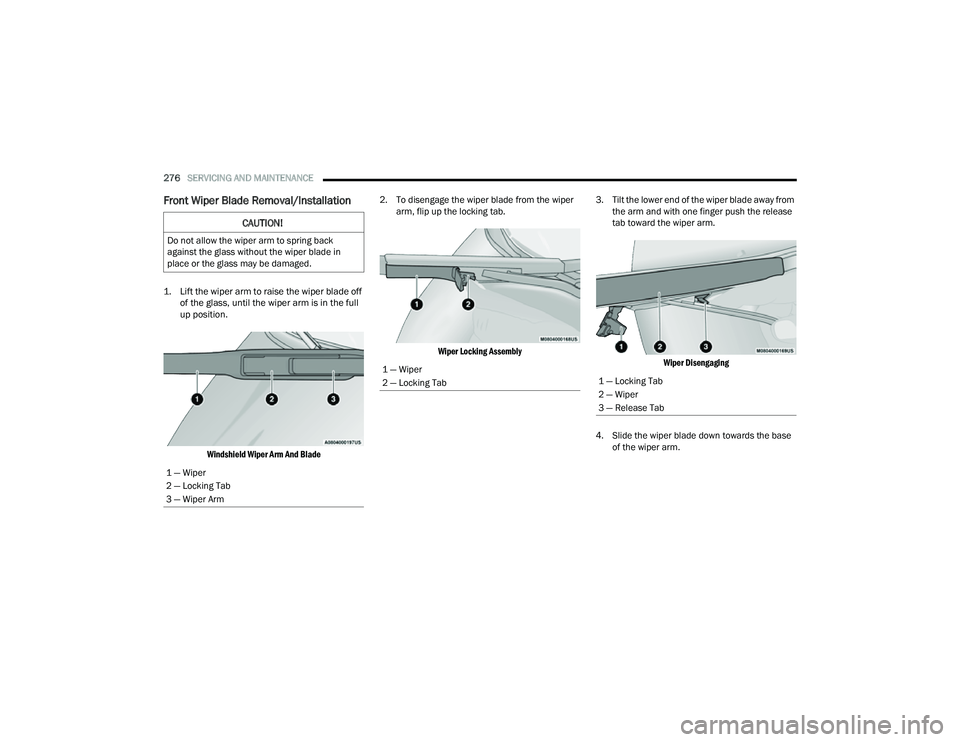

Front Wiper Blade Removal/Installation

1. Lift the wiper arm to raise the wiper blade off

of the glass, until the wiper arm is in the full

up position.

Windshield Wiper Arm And Blade

2. To disengage the wiper blade from the wiper

arm, flip up the locking tab.

Wiper Locking Assembly

3. Tilt the lower end of the wiper blade away from

the arm and with one finger push the release

tab toward the wiper arm.

Wiper Disengaging

4. Slide the wiper blade down towards the base of the wiper arm.

CAUTION!

Do not allow the wiper arm to spring back

against the glass without the wiper blade in

place or the glass may be damaged.

1 — Wiper

2 — Locking Tab

3 — Wiper Arm

1 — Wiper

2 — Locking Tab1 — Locking Tab

2 — Wiper

3 — Release Tab

22_MP_OM_EN_USC_t.book Page 276

Page 279 of 344

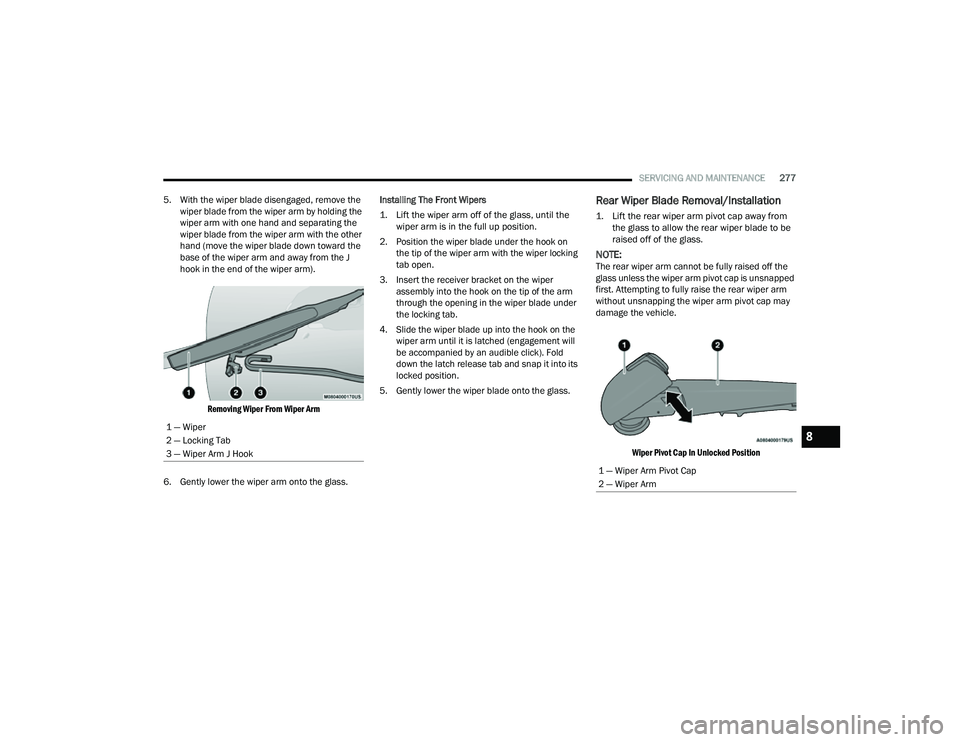

SERVICING AND MAINTENANCE277

5. With the wiper blade disengaged, remove the wiper blade from the wiper arm by holding the

wiper arm with one hand and separating the

wiper blade from the wiper arm with the other

hand (move the wiper blade down toward the

base of the wiper arm and away from the J

hook in the end of the wiper arm).

Removing Wiper From Wiper Arm

6. Gently lower the wiper arm onto the glass. Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the

wiper arm is in the full up position.

2. Position the wiper blade under the hook on the tip of the wiper arm with the wiper locking

tab open.

3. Insert the receiver bracket on the wiper assembly into the hook on the tip of the arm

through the opening in the wiper blade under

the locking tab.

4. Slide the wiper blade up into the hook on the wiper arm until it is latched (engagement will

be accompanied by an audible click). Fold

down the latch release tab and snap it into its

locked position.

5. Gently lower the wiper blade onto the glass.

Rear Wiper Blade Removal/Installation

1. Lift the rear wiper arm pivot cap away from the glass to allow the rear wiper blade to be

raised off of the glass.

NOTE:The rear wiper arm cannot be fully raised off the

glass unless the wiper arm pivot cap is unsnapped

first. Attempting to fully raise the rear wiper arm

without unsnapping the wiper arm pivot cap may

damage the vehicle.

Wiper Pivot Cap In Unlocked Position

1 — Wiper

2 — Locking Tab

3 — Wiper Arm J Hook

1 — Wiper Arm Pivot Cap

2 — Wiper Arm

8

22_MP_OM_EN_USC_t.book Page 277