wheel alignment JEEP COMPASS 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: COMPASS, Model: JEEP COMPASS 2023Pages: 344, PDF Size: 18.8 MB

Page 250 of 344

248IN CASE OF EMERGENCY

PREPARATIONS FOR JACKING

1. Park the vehicle on a firm level surface as far

from the edge of the roadway as possible.

Avoid icy or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake.

4. Place the ignition in the OFF position. 5. Block both the front and rear of the wheel

diagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.

Wheel Blocked

NOTE:Passengers should not remain in the vehicle when

the vehicle is being lifted or raised.

JACK LOCATION/SPARE TIRE STOWAGE

If equipped, the jack and tools are located in the

rear storage compartment, below the spare tire.

NOTE:Items may vary depending on the trim level.

Jack And Tools Location

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

1 — Jack

2 — Alignment Pin

3 — Emergency Funnel

4 — Wheel Bolt Wrench

5 — Screwdriver

22_MP_OM_EN_USC_t.book Page 248

Page 251 of 344

IN CASE OF EMERGENCY249

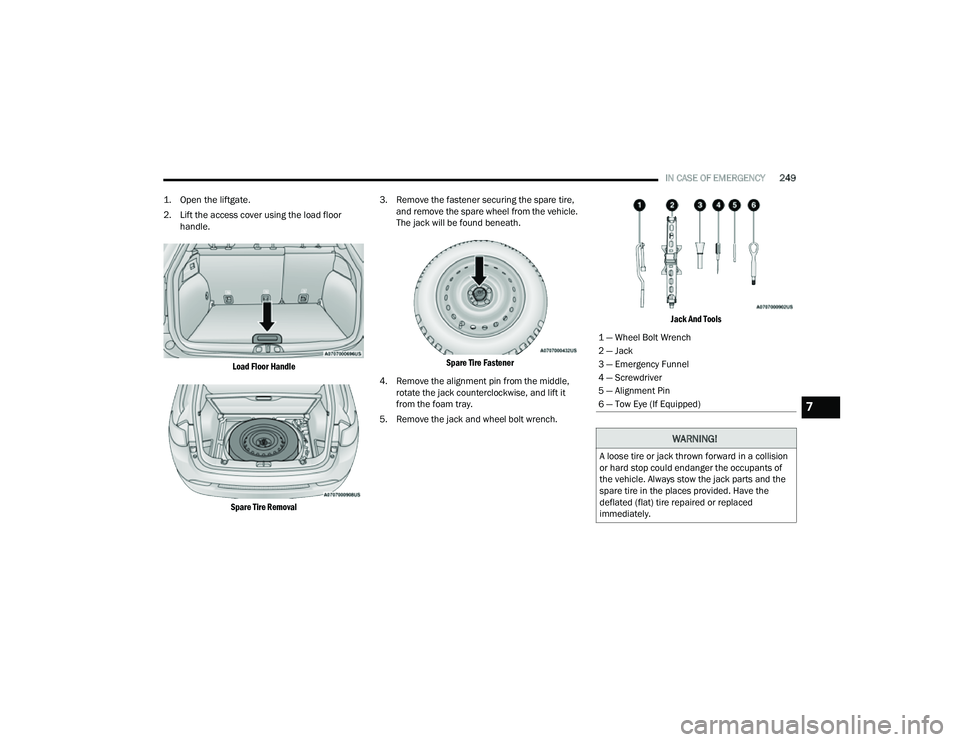

1. Open the liftgate.

2. Lift the access cover using the load floor handle.

Load Floor Handle

Spare Tire Removal

3. Remove the fastener securing the spare tire,

and remove the spare wheel from the vehicle.

The jack will be found beneath.

Spare Tire Fastener

4. Remove the alignment pin from the middle, rotate the jack counterclockwise, and lift it

from the foam tray.

5. Remove the jack and wheel bolt wrench.

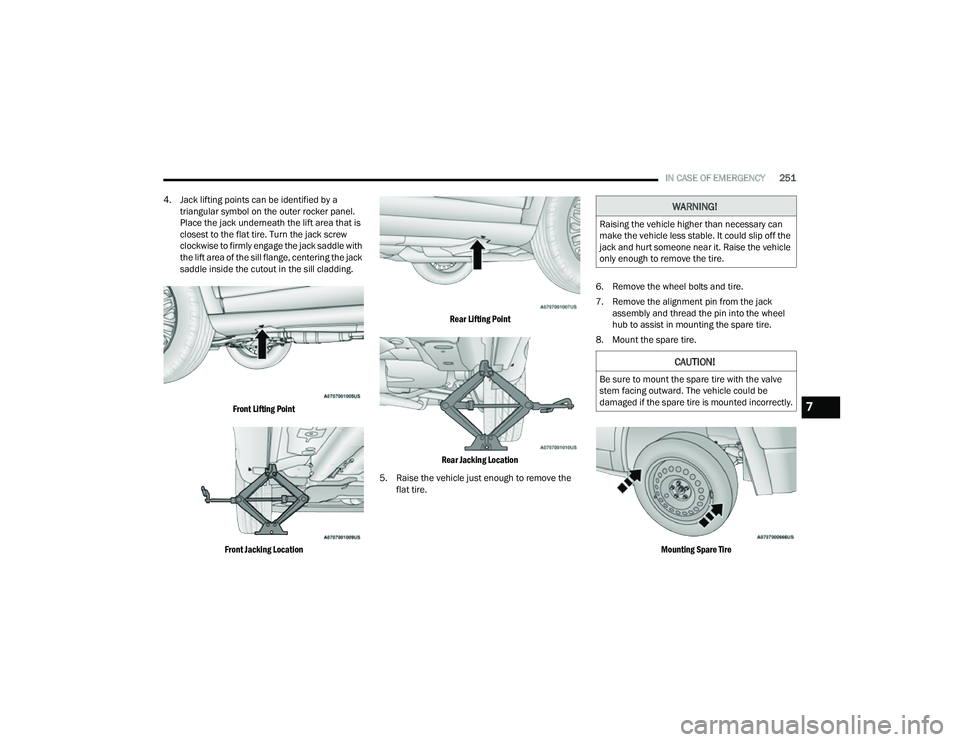

Jack And Tools

1 — Wheel Bolt Wrench

2 — Jack

3 — Emergency Funnel

4 — Screwdriver

5 — Alignment Pin

6 — Tow Eye (If Equipped)

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

7

22_MP_OM_EN_USC_t.book Page 249

Page 253 of 344

IN CASE OF EMERGENCY251

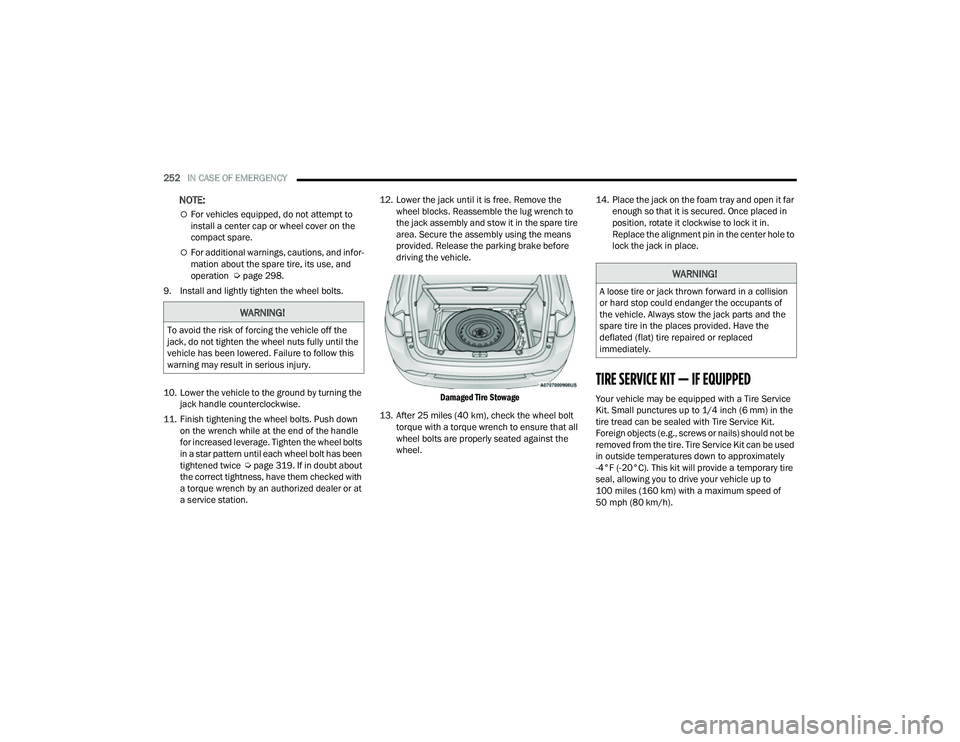

4. Jack lifting points can be identified by a triangular symbol on the outer rocker panel.

Place the jack underneath the lift area that is

closest to the flat tire. Turn the jack screw

clockwise to firmly engage the jack saddle with

the lift area of the sill flange, centering the jack

saddle inside the cutout in the sill cladding.

Front Lifting Point

Front Jacking Location Rear Lifting Point

Rear Jacking Location

5. Raise the vehicle just enough to remove the flat tire. 6. Remove the wheel bolts and tire.

7. Remove the alignment pin from the jack

assembly and thread the pin into the wheel

hub to assist in mounting the spare tire.

8. Mount the spare tire.

Mounting Spare Tire

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted incorrectly.

7

22_MP_OM_EN_USC_t.book Page 251

Page 254 of 344

252IN CASE OF EMERGENCY

NOTE:

For vehicles equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

For additional warnings, cautions, and infor -

mation about the spare tire, its use, and

operation Ú page 298.

9. Install and lightly tighten the wheel bolts.

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the wheel bolts

in a star pattern until each wheel bolt has been

tightened twice Úpage 319. If in doubt about

the correct tightness, have them checked with

a torque wrench by an authorized dealer or at

a service station. 12. Lower the jack until it is free. Remove the

wheel blocks. Reassemble the lug wrench to

the jack assembly and stow it in the spare tire

area. Secure the assembly using the means

provided. Release the parking brake before

driving the vehicle.

Damaged Tire Stowage

13. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to ensure that all

wheel bolts are properly seated against the

wheel. 14. Place the jack on the foam tray and open it far

enough so that it is secured. Once placed in

position, rotate it clockwise to lock it in.

Replace the alignment pin in the center hole to

lock the jack in place.

TIRE SERVICE KIT — IF EQUIPPED

Your vehicle may be equipped with a Tire Service

Kit. Small punctures up to 1/4 inch (6 mm) in the

tire tread can be sealed with Tire Service Kit.

Foreign objects (e.g., screws or nails) should not be

removed from the tire. Tire Service Kit can be used

in outside temperatures down to approximately

-4°F (-20°C). This kit will provide a temporary tire

seal, allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of

50 mph (80 km/h).

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

22_MP_OM_EN_USC_t.book Page 252