JEEP DJ 1953 Service Manual

Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 131 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

E

possibility of vapor lock by keeping cool fuel from

the tank constantly circulating through the fuel

pump.

Fuel

pump pressure at carburetor (inlet) on Daunt

less

V6-225

engine

should be 3% lbs.

[0,264

kgm-cm2] minimum at idle with the vapor return

hose

squeezed off. With the vapor return

hose

open

pump pressure should be 2j^ lbs. [0,176 kg-cm2]

minimum.

The

Dauntless V-6

engine

is equipped with a sealed

unit,

non-repairable, single-action fuel pump (Fig.

E-33).

Note:

All Dauntless V-6

engines

are equipped with

a

throw-away can-type gasoline filter installed in

the fuel line

between

the fuel pump and the

car

buretor.

This

unit must be replaced every

12,000

miles

[19.200

km.] of vehicle operation.

E-68.

Fuel

Pump Removal

To

remove the fuel pump from the Dauntless V-6

engine, disconnect the fuel inlet, fuel

outlet

and fuel return lines from the pump. Remove the two

fuel pump body attaching cap screws and lock

washers.

Pull

the fuel filter bracket free and remove the pump and gasket. Discard pump and gasket.

Install

new pump in reverse procedure of removal.

E-69.

AIR

CLEANER

Servicing

of the air cleaner is properly taken care of as part of the periodic lubrication and servicing of the vehicle. For this reason, air cleaner servicing

information is given in the Lubrication Section.

Refer

to and follow the instructions given there.

E-70. ACCELERATOR LINKAGE

The

accelerator linkage is properly adjusted when

the vehicle leaves the factory. However, in time

components parts

will

become

worn and require re

adjustment to maintain a smooth even control of

engine

speed. On Models equipped with F4

engines

the adjustment is made at the adjusting block,

Fig.

E-34. Loosen the lock nuts, and adjust the length of the accelerator rod so that when the

car

buretor throttle valve is wide open the accelerator

treadle

will

just strike the toe board. After correct

adjustment is made tighten both lock nuts firmly.

To

adjust the accelerator linkage on V6

engines

loosen

the lock nuts securing the accelerator rod

housing to its securing bracket and adjust the length

of the accelerator rod so that when the carburetor throttle valve is wide open the accelerator treadle

will

just strike the toe board. After correct adjust

ment is made, tighten lock nut firmly, see Fig. E-35 for Dauntless V-6 engine.

E-71. FUEL

TANK

AND

FUEL LINES

The

following paragraphs (E-70 through E-73) describe the removal, installation and services to

be performed when replacing the fuel tank or

servicing

the fuel system.

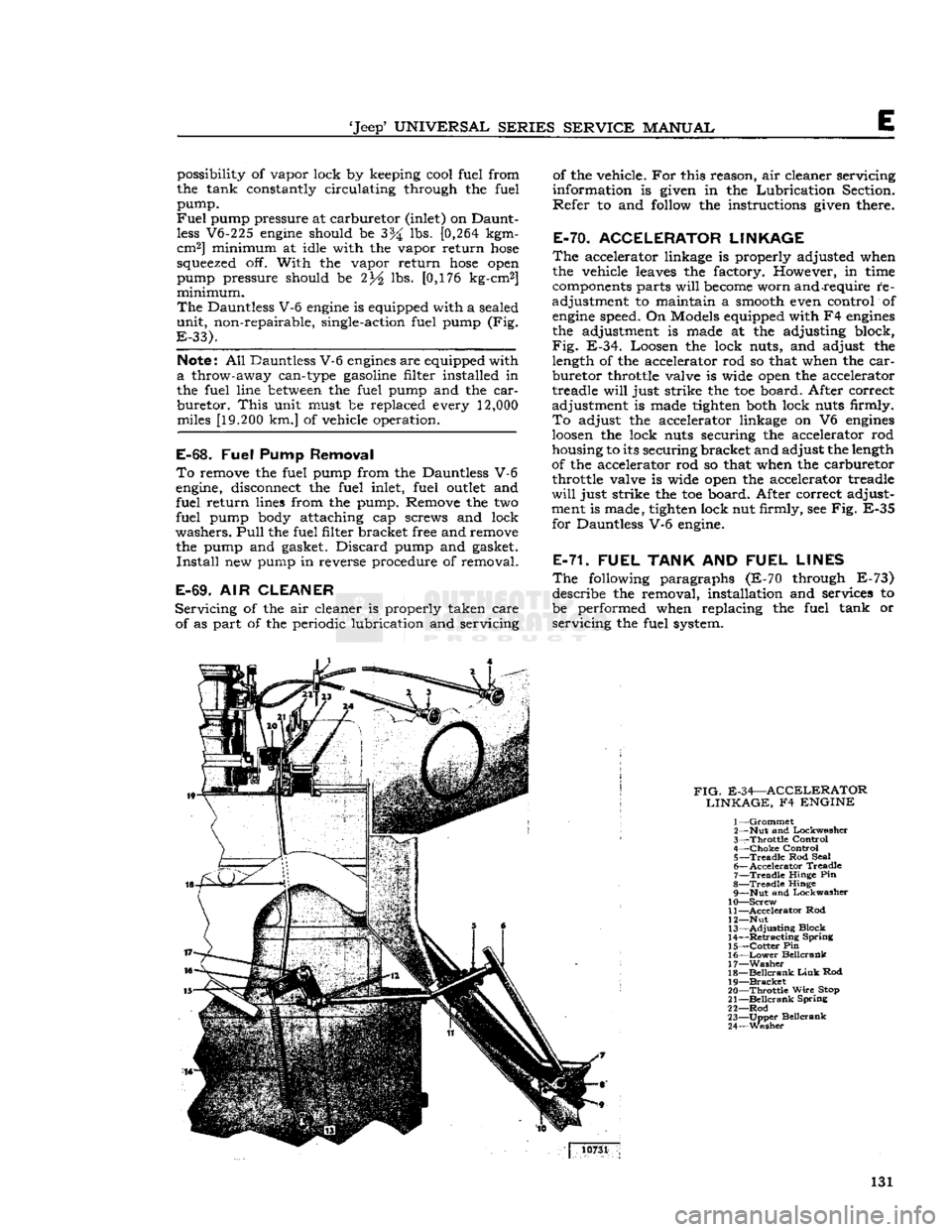

FIG.

E-34—ACCELERATOR LINKAGE,

F4

ENGINE

1—

Grommet

2— Nut and Lockwasher

3—

Throttle

Control

4—

Choke

Control 5—

Treadle

Rod Seal

6—

Accelerator

Treadle

7—

Treadle

Hinge Pin

8—

Treadle

Hinge 9— Nut and Lockwasher

10—

Screw

11—

Accelerator

Rod

12— Nut

13—

Adjusting

Block

14—

Retracting

Spring

15—

Cotter

Pin

16—

Lower

Beilcrank

17—

Washer

18—

Beilcrank

Link

Rod

19—

Bracket

20—

Throttle

Wire

Stop

21—

Beilcrank

Spring

22—

Rod

23—

Upper

Beilcrank

24—

Wesher

10731

131

Page 132 of 376

FUEL

SYSTEM

14417

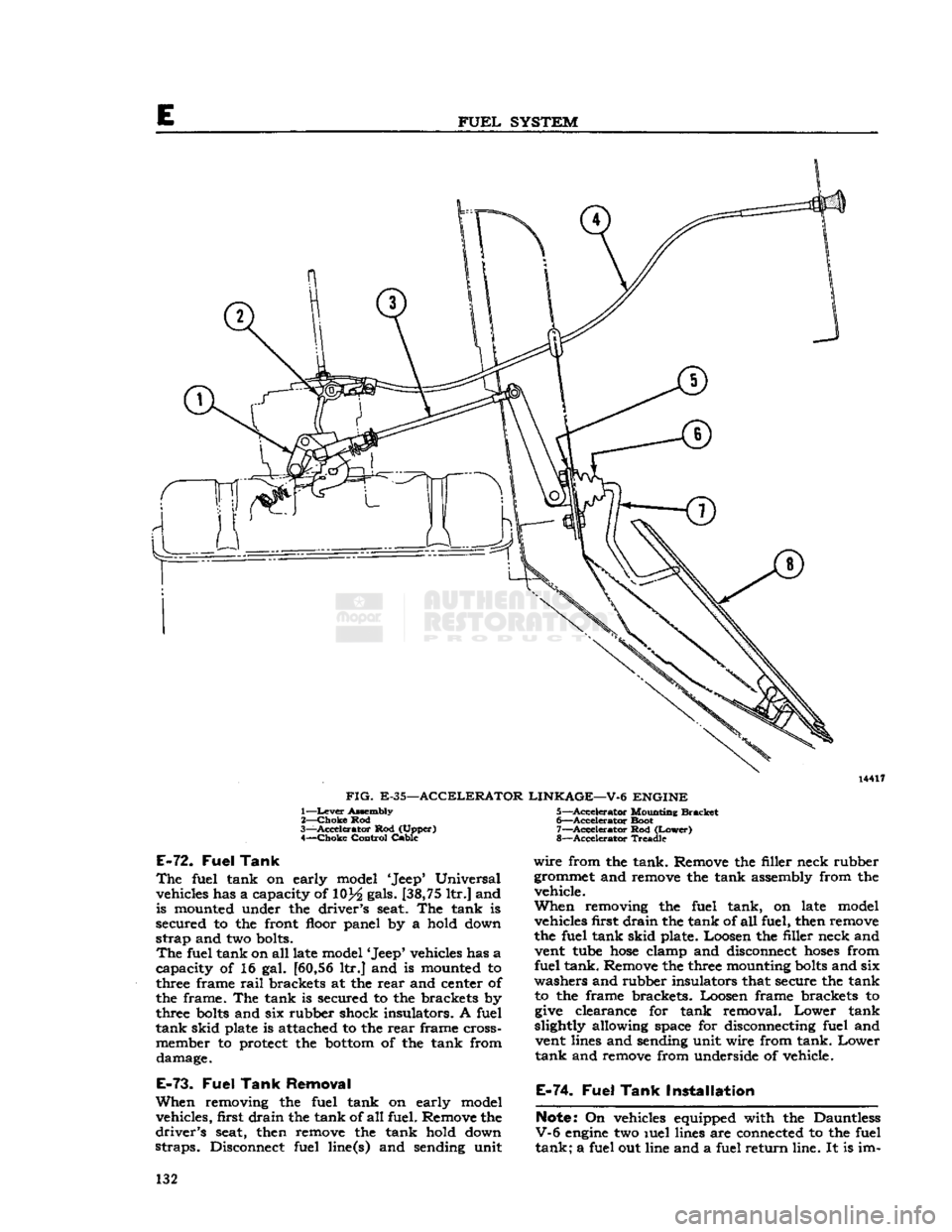

FIG.

E-35—ACCELERATOR LINKAGE—V-6 ENGINE

1— Lever

Assembly

2—

Choke

Rod

3—

-Accelerator

Rod (Upper) 4—

Choke

Control Cable

E-72.

Fuel

Tank

The

fuel tank on early model 'Jeep* Universal vehicles has a capacity of 10}4 gals. [38,75 ltr.] and

is mounted under the driver's seat. The tank is

secured to the front floor panel by a hold down

strap

and two bolts.

The

fuel tank on all late model 'Jeep* vehicles has a

capacity of 16 gal. [60,56 ltr.] and is mounted to

three frame

rail

brackets at the

rear

and center of

the frame. The tank is secured to the brackets by

three

bolts

and six rubber shock insulators. A fuel

tank

skid plate is attached to the

rear

frame cross- member to protect the

bottom

of the tank from damage.

E-73.

Fuel

Tank

Removal

When

removing the fuel tank on early model vehicles, first drain the tank of

all

fuel. Remove the

driver's

seat, then remove the tank hold down

straps.

Disconnect fuel line(s) and sending unit 5—

Accelerator

Mounting Bracket

6—

-Accelerator

Boot

7—

Accelerator

Rod

(Lower)

8—

Accelerator

Treadle

wire

from the tank. Remove the filler neck rubber

grommet and remove the tank assembly from the vehicle.

When

removing the fuel tank, on late model vehicles first

drain

the tank of

all

fuel, then remove

the fuel tank skid plate. Loosen the filler neck and vent tube

hose

clamp and disconnect

hoses

from fuel tank. Remove the three mounting

bolts

and six

washers and rubber insulators that secure the tank to the frame brackets. Loosen frame brackets to

give

clearance for tank removal.

Lower

tank

slightly allowing space for disconnecting fuel and vent lines and sending unit wire from tank.

Lower

tank

and remove from underside of vehicle.

E-74.

Fuel Tank Installation

Note:

On vehicles equipped with the Dauntless

V-6

engine

two luel lines are connected to the fuel

tank;

a fuel out line and a fuel return line. It is im- 132

Page 133 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

E

portant that

these

lines are not accidentally re

versed.

When

installing the fuel tank on late model vehicles, position the tank

between

the frame

rail

to allow space to connect the fuel line(s), vent

hose

and

sending unit wire. After connecting

these

items, align and secure tank to frame brackets.

Position filler

hose

on tank filler neck and tighten

hose

clamp.

Fill

tank with fuel and check for leaks.

When

installing the fuel tank on early model vehicles, reverse the order of removal as given in

Par.

E-73.

E-75.

Fuel

Tank

Cap

A

surge pressure type fuel tank filler cap is used on

all

models.

This

is necessary to prevent fuel leakage

from

the cap vent opening when the vehicle is on a

side slope. Two spring loaded relief valves which

open when venting is required are built into the

cap.

Should the pressure valve

fail

to open, pressure

in

the tank may force fuel by the carburetor inlet

valve causing flooding.

Failure

of the vacuum valve may prevent flow of fuel to the carburetor. Should

the valves

fail

to vent install a new cap.

Note:

Vehicles having a

Fuel

Evaporative

Emis

sion System are equipped with a non-vent sealed gas cap. The sealed cap is designed to allow no

vapors to discharge to the atmosphere. No other type of cap is to be used on vehicles having this

type system.

E-76.

Fuel

Gauge Float Unit

The

fuel tank

gauge

float unit is mounted in the top

of the fuel tank and consists of a housing enclosing

a

rheostat that is actuated by the float arm, and a

float

which

moves

with the fuel level in the tank.

On

V-6 and current production F4

engine

equipped vehicles, the fuel

outlet

pipe is integral with the

float

unit.

The fuel

outlet

pipe has a mesh filter on the inner end.

Note:

Under no circumstances should a fuel tank

gauge

be installed without a mesh filter element.

The

filter,

outlet

pipe, and float unit are locked as

an

assembly to the top of the fuel tank. To remove,

turn

the lock plate that secures the float unit

assembly.

E-77.

Fuel

Lines

Check

lines and connections occasionally for leaks,

and

for severe kinks that might restrict the flow of

fuel. If an excessive amount of

dirt

is found in the

carburetor

or fuel pump, the fuel tank should be

drained

and the fuel lines blown out with com

pressed air.

All

rubber fuel lines and their respective clamps should be checked occasionally to be certain they

are

correctly positioned and not leaking. 133

Page 134 of 376

E

FUEL

SYSTEM

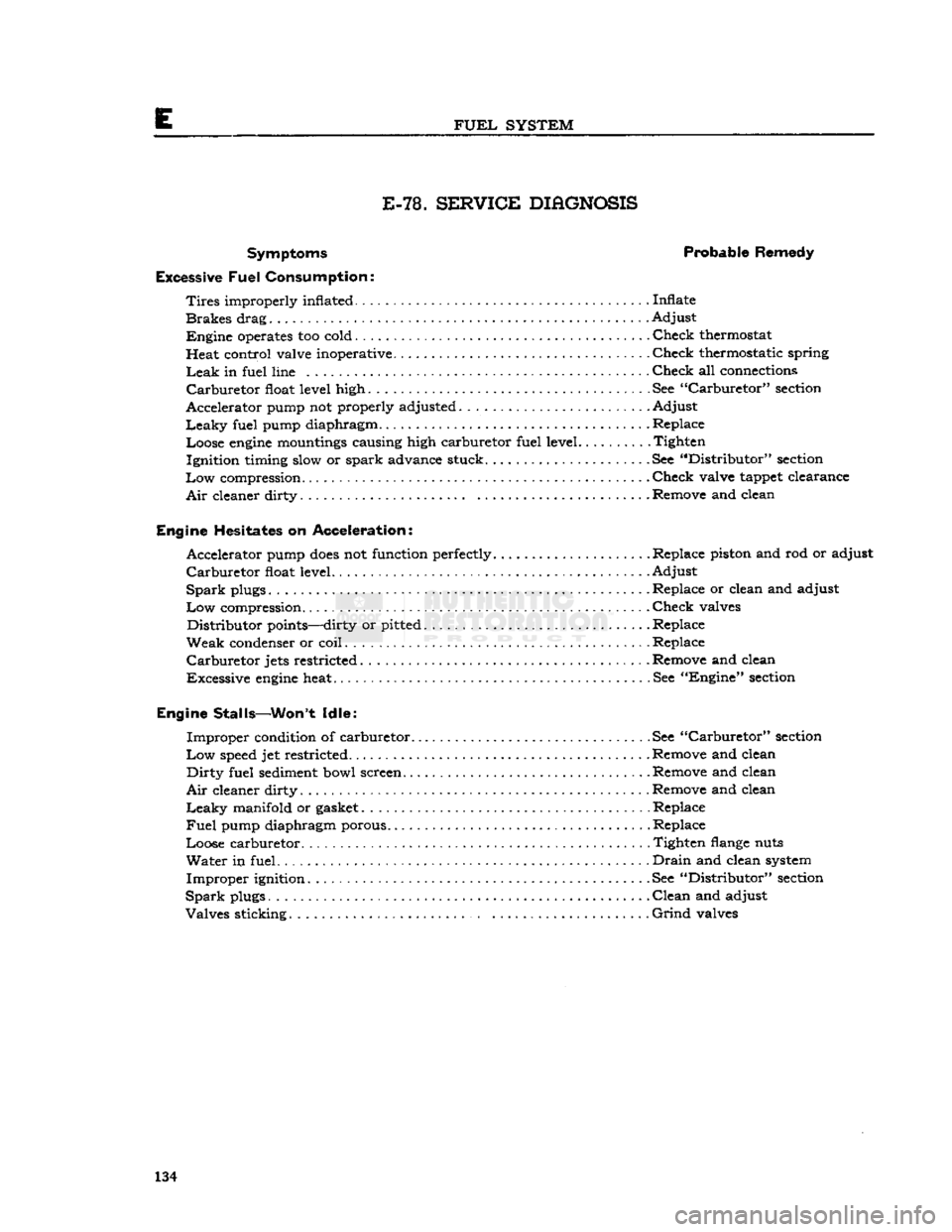

E-78. SERVICE DIHGNOSIS

Symptoms Probable Remedy

Excessive

Fuel

Consumption:

Tires

improperly inflated Inflate

Brakes

drag Adjust

Engine

operates too cold Check thermostat

Heat control valve inoperative Check thermostatic spring

Leak

in fuel line Check all connections

Carburetor

float level high. See

"Carburetor"

section

Accelerator pump not properly adjusted Adjust

Leaky

fuel pump diaphragm Replace

Loose

engine

mountings causing high carburetor fuel level Tighten Ignition timing slow or spark advance stuck See "Distributor" section

Low

compression. Check valve tappet clearance

Air

cleaner dirty

.

Remove and clean

Engine

Hesitates on Acceleration: Accelerator pump

does

not function perfectly.

...................

.Replace piston and rod or adjust

Carburetor

float level. ... .Adjust

Spark

plugs Replace or clean and adjust

Low

compression Check valves

Distributor

points—dirty or pitted Replace

Weak

condenser or coil Replace

Carburetor

jets restricted Remove and clean

Excessive

engine

heat See "Engine" section

Engine

Stalls—Won't Idle:

Improper

condition of carburetor See

"Carburetor"

section

Low

speed

jet restricted Remove and clean

Dirty

fuel sediment bowl screen Remove and clean

Air

cleaner dirty Remove and clean

Leaky

manifold or gasket Replace

Fuel

pump diaphragm porous. Replace

Loose carburetor. Tighten

flange

nuts

Water

in fuel

Drain

and clean system

Improper

ignition. .See "Distributor" section

Spark

plugs Clean and adjust

Valves

sticking.

Grind

valves 134

Page 135 of 376

'Jeep'

UNIVERSAL SERIES

SERVICE

MANUAL

E

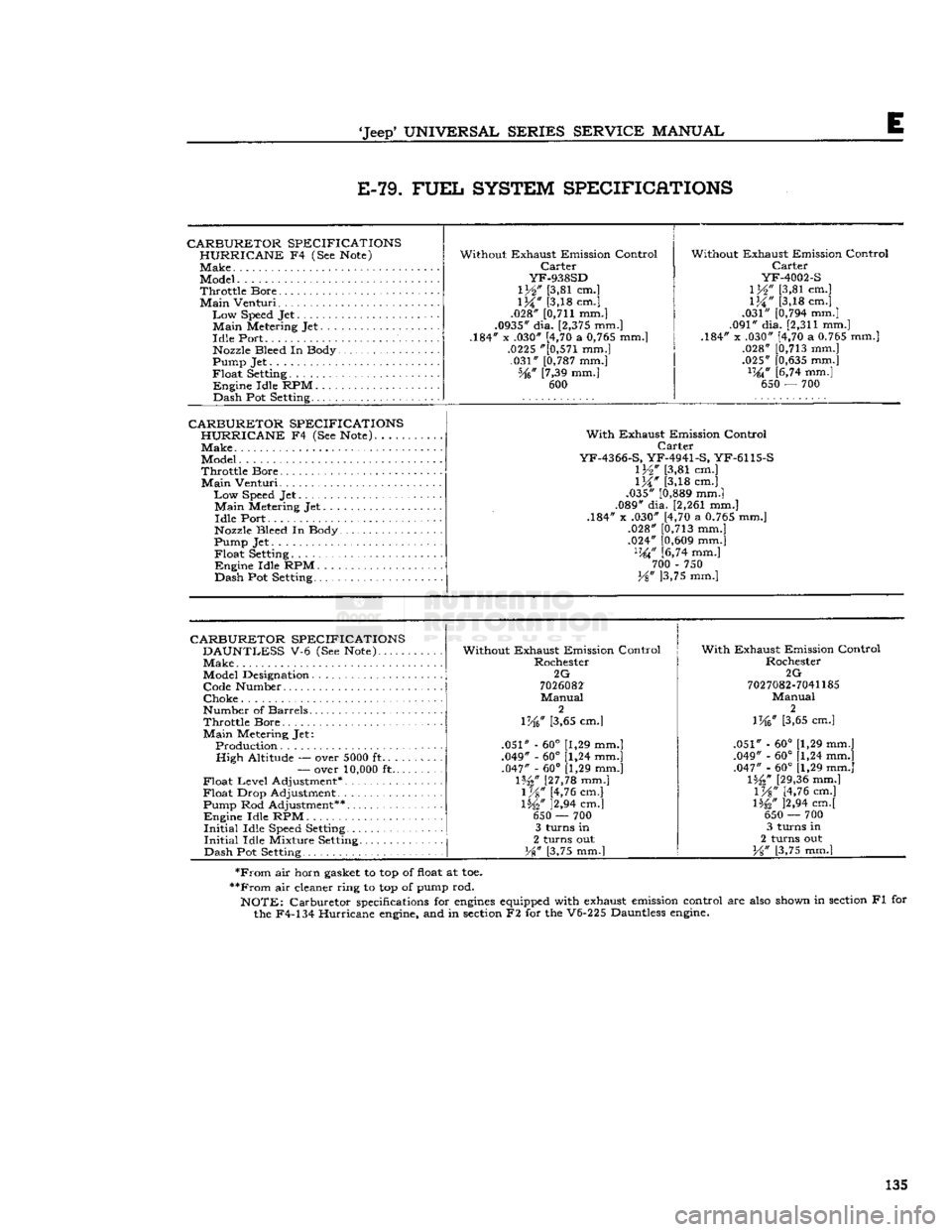

E-79.

FUEL

SYSTEM SPECIFICHTIONS

CARBURETOR SPECIFICATIONS HURRICANE

F4 (See

Note)

Make

Model.

Throttle Bore

Main

Venturi.

Low

Speed

Jet

Main

Metering Jet Idle Port

Nozzle

Bleed In Body

Pump Jet

Float

Setting

Engine Idle RPM Dash Pot

Setting

. ......

CARBURETOR SPECIFICATIONS HURRICANE

F4 (See

Note).

Make Model

Throttle Bore

Main

Venturi

Low

Speed

Jet

Main

Metering Jet Idle Port

Nozzle

Bleed In Body

Pump Jet.

Float

Setting

Engine Idle RPM Dash Pot

Setting

Without Exhaust Emission Control

Carter

YF-938SD

lY2n

[3,81 cm.]

1M"

[3,18 cm.]

.028"

[0,711

mm.]

.0935"

dia.

[2,375

mm.]

.184" x .030" [4,70 a

0,765

mm.]

.0225

"[0,571

mm.] .031"

[0,787

mm.] Vk" [7,39 mm.] 600 Without Exhaust Emission Control

Carter

YF-4002-S

\y%"

[3,81 cm.]

1M"

[3,18 cm.]

.031"

[0,794

mm.]

.091" dia.

[2,311

mm.]

.184" x .030" [4,70 a

0.765

mm.] .028"

[0,713

mm.]

.025"

[0,635

mm.]

lW

[6,74 mm.] 650 — 700

With

Exhaust Emission Control

Carter

YF-4366-S,

YF-4941-S, YF-6115-S IV2" [3,81 cm.]

1M*

[3,18 cm.]

.035"

[0,889

mm.]

.089" dia.

[2,261

mm.]

.184" x .030" [4,70 a

0.765

mm.] .028"

[0,713

mm.]

.024"

[0,609

mm.]

1W

[6,74 mm.] 700 - 750

Y%" ]3,75 mm.]

CARBURETOR SPECIFICATIONS

DAUNTLESS

V-6 (See

Note)

Make

Model

Designation

Code Number

Choke

Number of Barrels

Throttle Bore

Main

Metering Jet: Production . . High Altitude —

over

5000

ft

—

over

10,000

ft... .

Float Level Adjustment*

Float Drop Adjustment Pump Rod Adjustment**

Engine Idle RPM

Initial

Idle

Speed

Setting

Initial

Idle Mixture

Setting.

Dash Pot

Setting

Without Exhaust Emission Control

Rochester

2G

7026082

Manual

2

Wy? [3,65 cm.]

.051" - 60° [1,29 mm.]

.049" - 60° [1,24 mm.] .047" - 60° [1,29 mm.]

Hit"

[27,78

mm.] V/%" [4,76 cm.]

IH2"

J2.94 cm.] 650

-—

700 3 turns in

2 turns out

W [3,75 mm.]

With

Exhaust Emission Control

Rochester

2G

7027082-7041185

Manual

2

[3,65 cm.]

.051" - 60° [1,29 mm.]

.049" - 60° [1,24 mm.] .047" - 60° (1,29 mm.] l%2"

[29,36

mm.] V/£" [4,76 cm.]

\W

]2,94 cm.[ 650 — 700 3 turns in

2 turns out

[3,75 mm.]

*From

air horn

gasket

to top of

float

at toe.

**From

air cleaner ring to top of

pump

rod.

NOTE:

Carburetor

specifications

for

engines

equipped

with

exhaust

emission

control are

also

shown

in

section

Fl for the F4-134 Hurricane

engine,

and in

section

F2 for the V6-225 Dauntless

engine.

135

Page 136 of 376

E

FUEL

SYSTEM E-79.

FUEL

SYSTEM SPECIFICATIONS

(Continued)

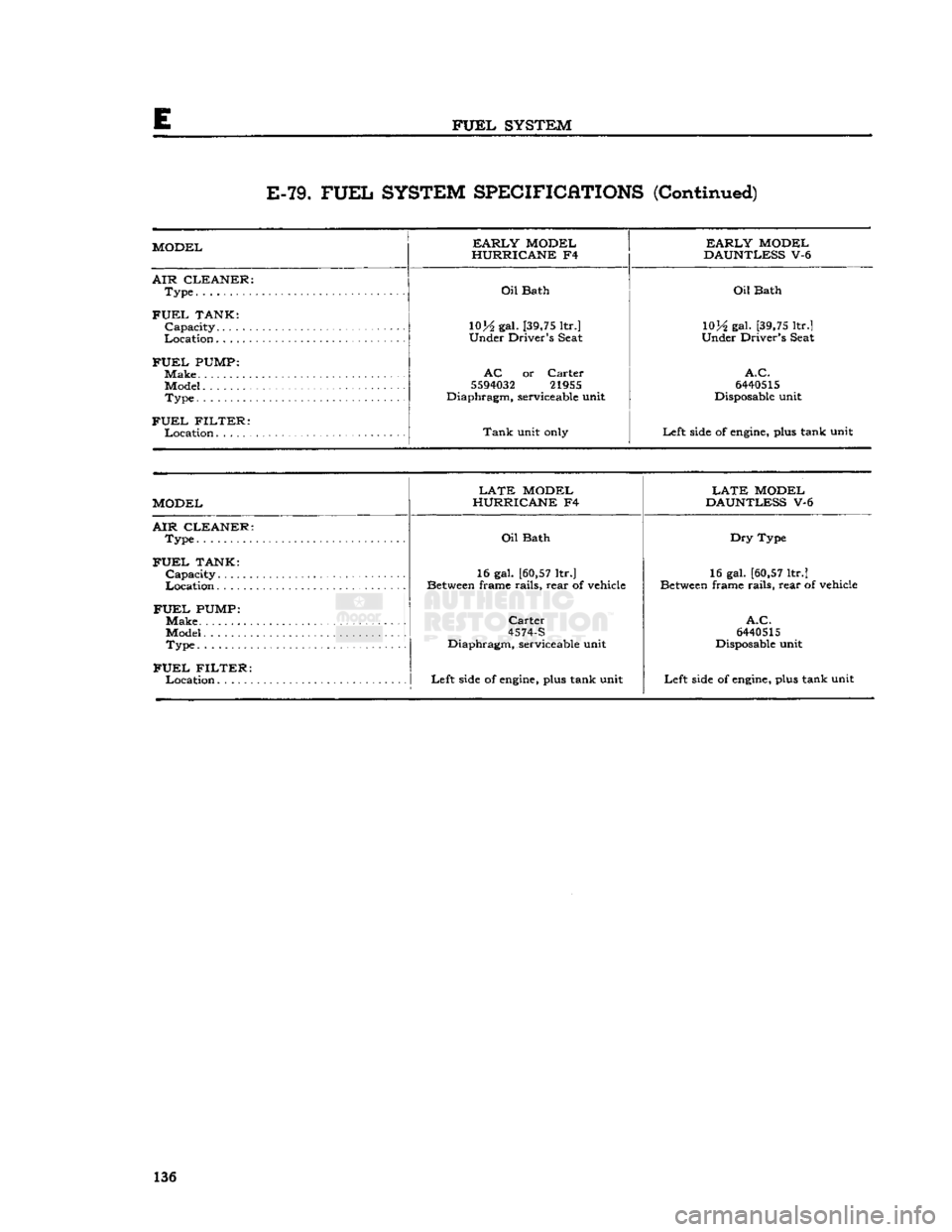

MODEL

EARLY

MODEL

HURRICANE

F4

EARLY

MODEL

DAUNTLESS

V-6

AIR CLEANER:

Type

Oil

Bath

Oil

Bath

FUEL

TANK: 10H

gal. [39,75 ltr.]

10lA

gal. [39,75 ltr.]

Location

Under

Driver's Seat

Under

Driver's Seat

FUEL

PUMP:

AC

or

Carter

A.C.

Model

5594032

21955

6440515

Type..

Diaphragm,

serviceable unit

Disposable unit

FUEL

FILTER:

Tank

unit only

Left

side of engine, plus tank unit

MODEL

LATE

MODEL

HURRICANE

F4

LATE

MODEL

DAUNTLESS

V-6

AIR CLEANER:

Type...

Oil

Bath

Dry

Type

FUEL

TANK:

Capacity

16 gal. [60,57 ltr.]

16 gal. [60,57 ltr.]

Between frame

rails,

rear

of vehicle Between frame

rails,

rear

of vehicle

FUEL

PUMP:

Make.

Carter

A.C.

Model.

. 4574-S

6440515

Type

Diaphragm,

serviceable unit

Disposable unit

FUEL

FILTER:

Left

side of engine, plus tank unit

Left

side of engine, plus tank unit 136

Page 137 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

F EXHAUST SYSTEM

Contents

SUBJECT

PAR.

GENERAL

.F-l Dauntless V-6 Engine Exhaust System....

F-3

Hurricane

F4 Engine Exhaust System....

F-2

MAINTENANCE

REQUIREMENTS

F-4

EXHAUST SYSTEM SERVICING

F-5

SUBJECT

PAR.

Exhaust

Manifold Installation. .F-6

Exhaust

Pipe(s) Replacement F-8

Heat

Control Valve Replacement F-7

Muffler

Replacement F-9

Tail

Pipe Replacement F-10

EXHAUST SYSTEM SPECIFICATIONS.

.

F-11

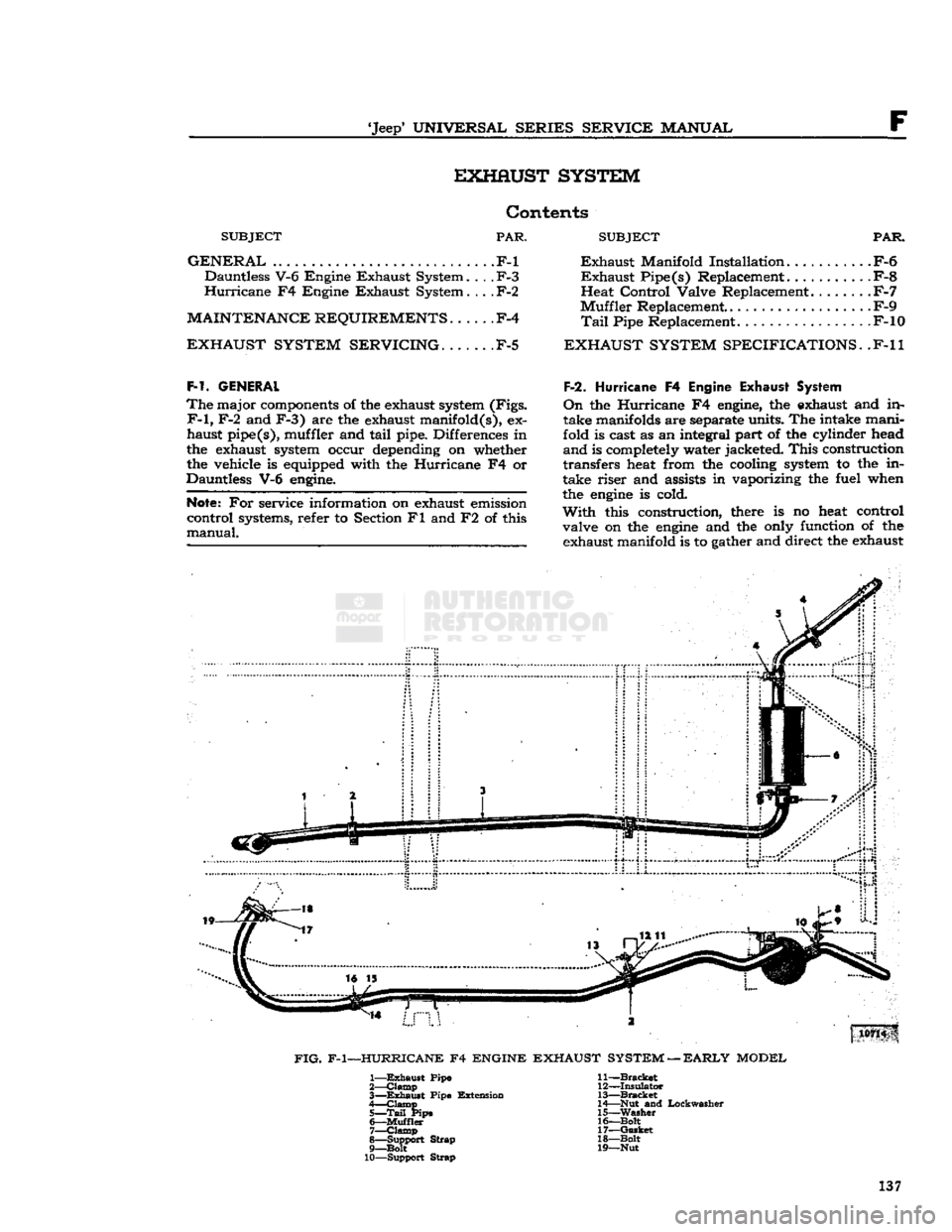

F-L

GENERAL

The

major components of the exhaust system (Figs.

F-l,

F-2 and F-3) are the exhaust manifold(s), ex

haust pipe(s), muffler and tail pipe. Differences in

the exhaust system occur depending on whether the vehicle is equipped with the Hurricane F4 or

Dauntless V-6 engine.

Note:

For service information on exhaust emission

control systems, refer to Section Fl and F2 of this

manual.

F-2. Hurricane

F4 Engine Exhaust System

On

the Hurricane F4 engine, the exhaust and in

take manifolds are separate units. The intake mani

fold is cast as an integral part of the cylinder head

and

is completely water jacketed.

This

construction

transfers

heat from the cooling system to the in

take riser and assists in vaporizing the fuel when

the

engine

is cold.

With

this construction, there is no heat control

valve on the

engine

and the only function of the exhaust manifold is to gather and direct the exhaust

FIG.

F-l—HURRICANE F4 ENGINE EXHAUST

SYSTEM

—

EARLY

MODEL

1—

Exhaust

Pipe

2—

Clamp

3—

Exhaust

Pipe Extension

4—

Clamp

5— Tail

Pipe 6—

Muffler

7—

Clamp

8—

Support

Strap

9—Bolt

10—Support

Strap

11—Bracket

12—

Insulator

13—

Bracket

14—

Nut

and

Lockwasher

15—

Washer

16—Bolt

17—

Gasket

18—

Bolt

19— Nut

137

Page 138 of 376

F

EXHAUST

SYSTEM

12844

FIG.

F-2—DAUNTLESS

V-6

ENGINE

EXHAUST

SYSTEM

—

EARLY

MODEL

1—

Right

Exhaust

Pipe

19—Lockwasher

2—Tall

Pipe 20—Bolt

3—

Bolt

21—Bracket

4—

Bolt

22—Insulator

5—

Muffler

23—Nut 6—

Exhaust

Pipe

Extension

24—Bolt

7—

Crossover

Exhaust

Pipe

25—Clamp

8—

Bracket

26—U-Bolt 9—

Lockwasher

27—Saddle

10—

Nut

28—U-Bolt

11—

Saddle

29—Saddle

12—

Washer

30—Insulator

13—Bolt

31—U-Bolt

14—

Bracket

32—Nut

15—

Reinforcement

3

3—Lockwasher

16—

Nut

34—U-Bolt

17—

Lockwasher

35—Saddle

18—

Nut

gases

into the exhaust pipe.

When

assembling the manifold, to the cylinder

block

(Fig.

F-4)

new gaskets should be installed

and

the nuts drawn up evenly until they are tight

to avoid leakage. Torque manifold nuts to 29-35 lb-ft [4,0 a 4,84 kg-m.].

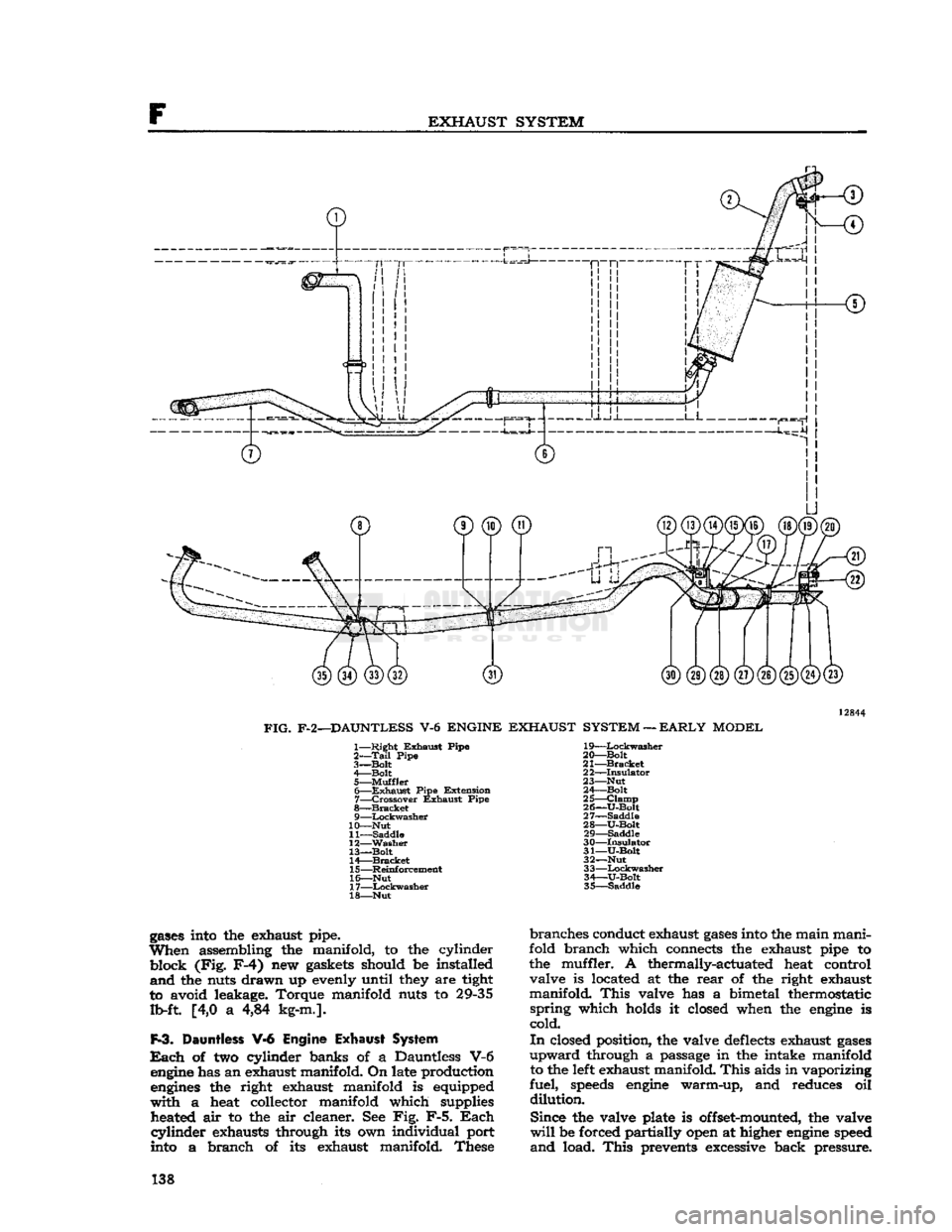

F-3.

Dauntless

¥-6

Engine

Exhaust System

Each

of two cylinder banks of a Dauntless V-6 engine has an exhaust manifold. On late production engines the right exhaust manifold is equipped

with

a heat collector manifold which supplies heated air to the air cleaner. See Fig. F-5.

Each

cylinder

exhausts through its own individual port

into a branch of its exhaust manifold. These

branches

conduct exhaust

gases

into the main mani

fold branch which connects the exhaust pipe to

the muffler. A thermally-actuated heat control valve is located at the

rear

of the right exhaust

manifold.

This

valve has a bimetal thermostatic

spring

which holds it closed when the engine is

cold.

In

closed position, the valve deflects exhaust

gases

upward

through a passage in the intake manifold to the left exhaust manifold.

This

aids in vaporizing

fuel,

speeds

engine warm-up, and reduces oil

dilution.

Since

the valve plate is offset-mounted, the valve

will

be forced partially open at higher engine speed

and

load.

This

prevents excessive back pressure. 138

Page 139 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

©

1

1

©-

IT

T"

I

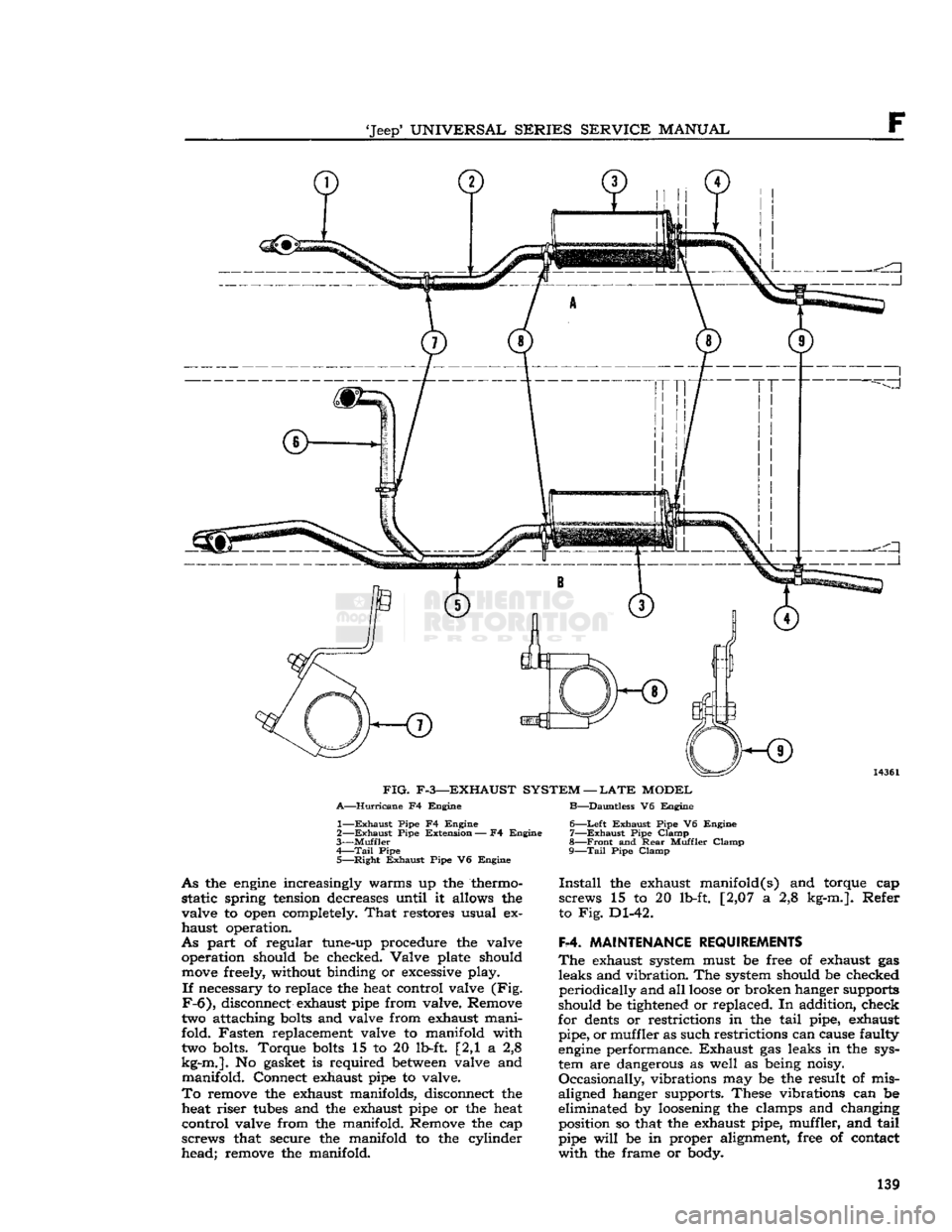

FIG.

F-3—EXHAUST SYSTEM —

LATE

MODEL

A—Hurricane

F4 Engine B—Dauntless V6 Engine

1—

Exhaust

Pipe F4 Engine

2—

Exhaust

Pipe

Extension

— F4 Engine

3—

Muffler

4—

Tail

Pipe

5—

Right

Exhaust

Pipe V6 Engine

As

the

engine

increasingly warms up the thermo static spring tension decreases until it allows the

valve to open completely.

That

restores usual ex haust operation.

As

part of regular tune-up procedure the valve operation should be checked. Valve plate should

move

freely, without binding or excessive play.

If

necessary to replace the heat control valve (Fig.

F-6),

disconnect exhaust pipe from valve. Remove

two attaching

bolts

and valve from exhaust mani

fold. Fasten replacement valve to manifold with two bolts. Torque

bolts

15 to 20 lb-ft [2,1 a 2,8

kg-m.].

No gasket is required

between

valve and manifold. Connect exhaust pipe to valve.

To

remove the exhaust manifolds, disconnect the heat riser

tubes

and the exhaust pipe or the heat

control valve from the manifold. Remove the cap screws that secure the manifold to the cylinder

head; remove the manifold. 6—

Left

Exhaust

Pipe V6 Engine

7—

Exhaust

Pipe

Clamp

8—

Front

and

Rear

Muffler

Clamp

9—

Tail

Pipe

Clamp

Install

the exhaust manifold(s) and torque cap

screws 15 to 20 lb-ft. [2,07 a 2,8 kg-m.]. Refer

to Fig. Dl-42.

F-4.

MAINTENANCE REQUIREMENTS

The

exhaust system must be free of exhaust gas leaks and vibration. The system should be checked periodically and all

loose

or broken hanger supports

should be tightened or replaced. In addition, check

for

dents

or restrictions in the tail pipe, exhaust pipe, or muffler as such restrictions can cause faulty

engine

performance. Exhaust gas leaks in the sys

tem are dangerous as well as being noisy.

Occasionally,

vibrations may be the result of mis

aligned hanger supports. These vibrations can be

eliminated by loosening the clamps and changing position so that the exhaust pipe, muffler, and tail

pipe

will

be in proper alignment, free of contact

with

the frame or body. 139

Page 140 of 376

F

EXHAUST SYSTEM

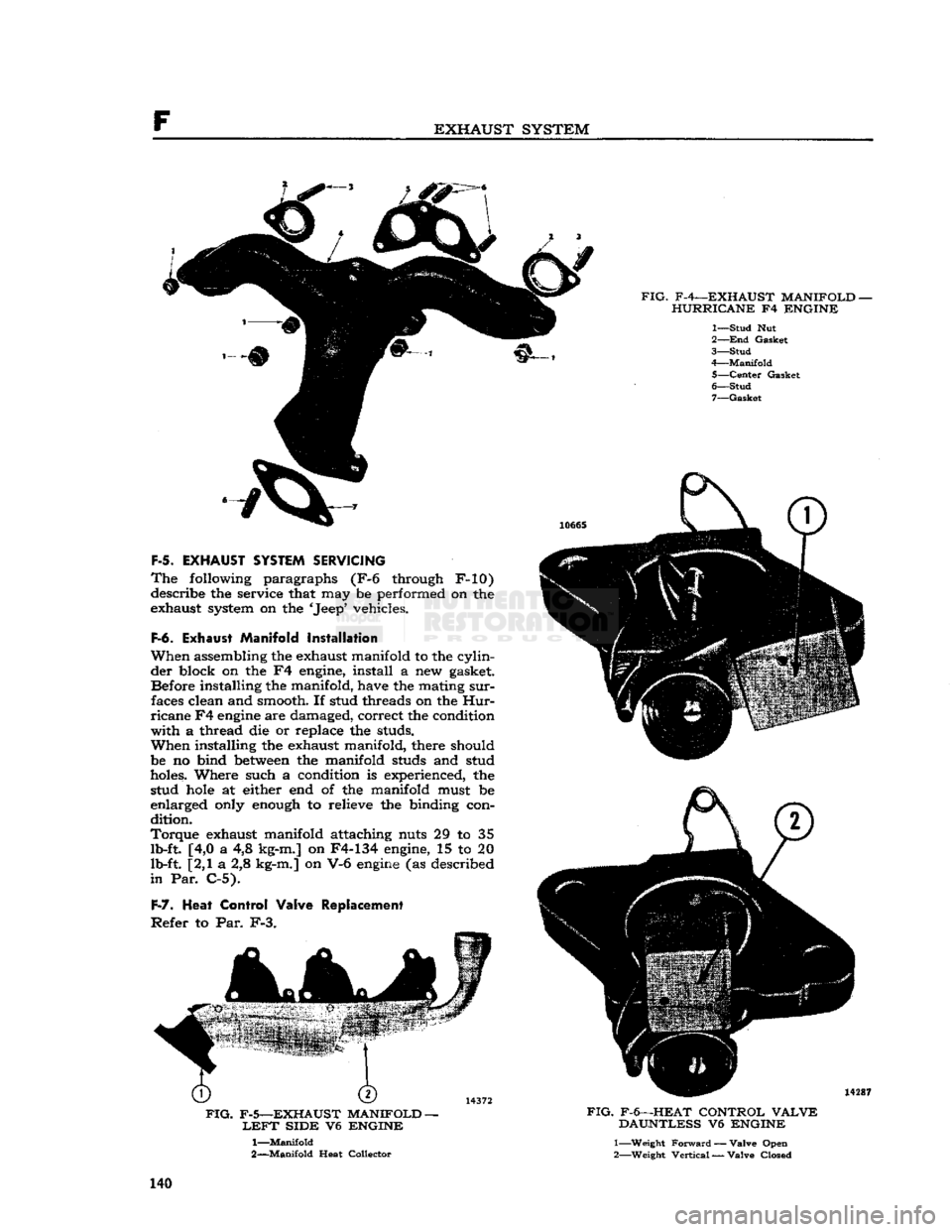

FIG.

F-4—EXHAUST MANIFOLD-HURRICANE

F4

ENGINE

1—

Stud

Nut

2—

End

Gasket

3—

Stud

4—

Manifold

5—

Center

Gasket

6—

Stud

7—

Gasket

F-5.

EXHAUST SYSTEM SERVICING

The

following paragraphs (F-6 through F-10)

describe the service that may be performed on the

exhaust system on the 'Jeep' vehicles.

F-6.

Exhaust Manifold Installation

When

assembling the exhaust manifold to the cylin der block on the F4 engine, install a new gasket. Before installing the manifold, have the mating

sur

faces clean and smooth. If stud threads on the

Hur

ricane

F4

engine

are damaged, correct the condition

with

a thread die or replace the studs.

When

installing the exhaust manifold, there should

be no bind

between

the manifold studs and stud

holes. Where such a condition is experienced, the stud

hole

at either end of the manifold must be

enlarged only enough to relieve the binding con

dition.

Torque

exhaust manifold attaching nuts 29 to 35 lb-ft. [4,0 a 4,8 kg-m.] on F4-134 engine, 15 to 20

lb-ft. [2,1 a 2,8 kg-m.] on V-6

engine

(as described

in

Par. C-5).

F-7.

Heat

Control Valve Replacement

Refer

to Par. F-3.

FIG.

F-5—EXHAUST MANIFOLD

-

LEFT

SIDE

V6

ENGINE

1—

Manifold

2—

Manifold

Heat Collector

J666S

14287

FIG.

F-6—HEAT CONTROL

VALVE

DAUNTLESS

V6

ENGINE

1— Weight

Forward

— Valve Open

2— Weight

Vertical

— Valve Closed 140