transmission JEEP DJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 44 of 376

D

HURRICANE

F4

ENGINE

Note:

Check

the condition of the rubber O-rings.

Defective O-rings could be the major cause of oil

leakage into cylinders. Always discard and replace

all

O-rings removed as only new O-rings should be installed at reassembly.

D-18.

Ream

Cylinder

Bore Ridges

To

prevent breaking the piston lands, the ridge

at the top of each cylinder bore must be removed

first.

To remove this ridge, use a cylinder ridge

reamer,

as shown in Fig. D-3 following the instruc

tions furnished by the reamer manufacturer. Use

care

not to cut below the top of the upper ring

travel

in the bore. Keep each piston top covered

with

an oil-soaked cloth to prevent cuttings from

falling

into the cylinder.

Note:

This

operation should be performed at this

time before the

engine

is rotated for the sequence

steps

following.

D-19.

Remove Oil Pan

Rotate the

engine

to the upside down position.

Remove the screws and lockwashers that attach

the oil pan to the cylinder block. Remove the oil

pan

and gasket.

Discard

the gasket.

D-20.

Remove Piston and Connecting

Rod

Assemblies

Remove the stamped locking nuts from the lower

end of each connecting rod bearing bolt. Remove

the connecting rod nuts. Remove the bearing cap evenly. Push the connecting rod and piston as

sembly out of the cylinder block with the handle end of a hammer until the piston rings are free from

the cylinder bore. Remove the piston and connecting rod assembly

from

the top of the cylinder block. Reassemble the

connecting rod bearing cap with the bearings in

place in the rod from which it was removed. Rotate

the crankshaft and follow the same procedure until

all

the piston and connecting rod assemblies are

removed.

Pistons and connecting rod assemblies may be removed for repair with the

engine

in the vehicle after draining the cooling system, removing the

oil

pan and the cylinder head, and reaming the ridges as previously described.

D-21.

Remove

Timing

Gear

Cover

Remove the bolts, nuts, and lockwashers, that at

tach

the timing gear cover to the engine. Remove

the cover, timing pointer, and cover gasket.

Dis

card

the gasket. Remove the crankshaft oil seal

from

the timing gear cover and discard the seal. Remove the oil slinger and spacer from the

crank

shaft.

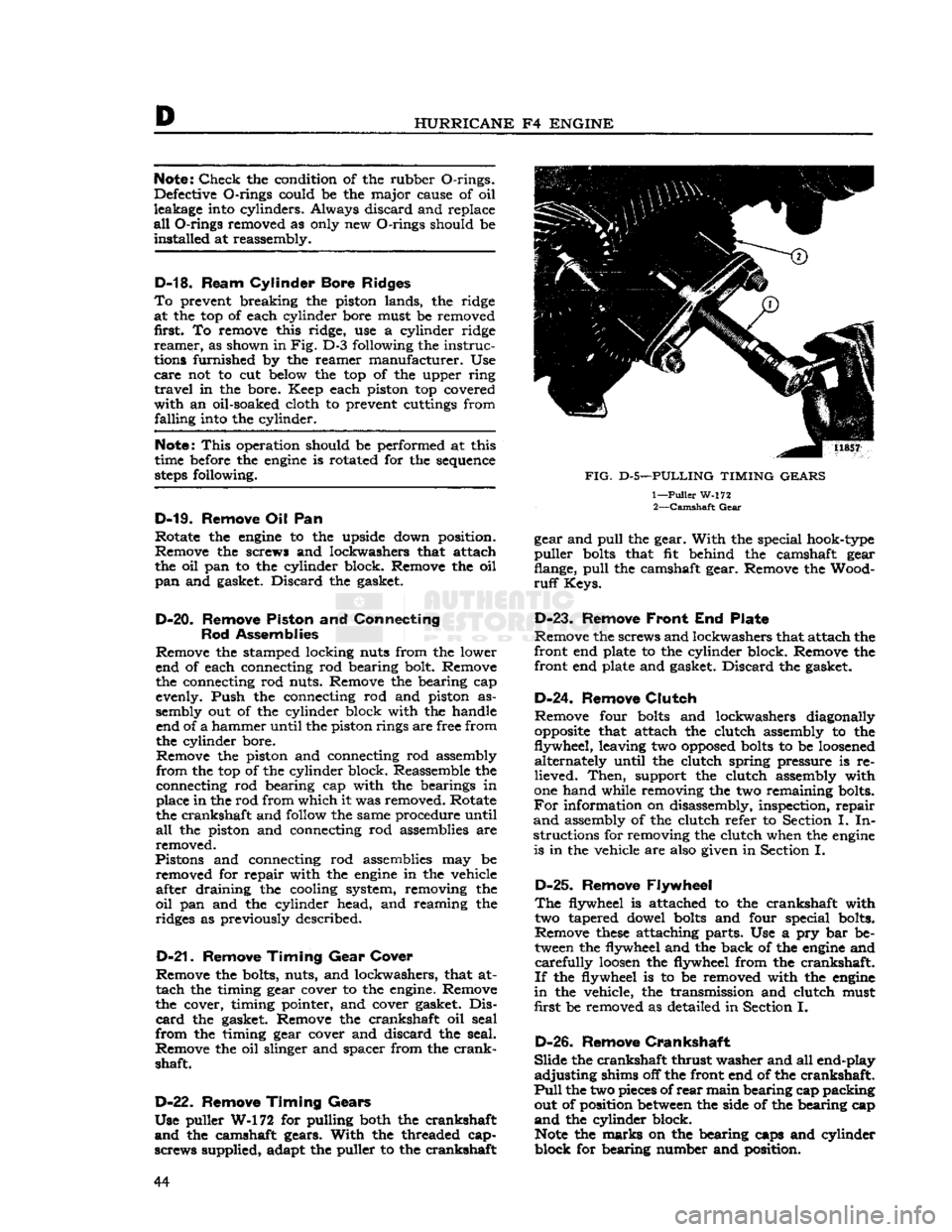

D-22.

Remove

Timing

Gears

Use puller W-172 for pulling both the crankshaft

and

the camshaft gears.

With

the threaded cap-

screws supplied, adapt the puller to the crankshaft

FIG.

D-5—PULLING TIMING GEARS

1—

Puller

W-172 2—

Camshaft

Gear

gear and

pull

the gear.

With

the special hook-type

puller

bolts

that fit behind the camshaft gear

flange,

pull

the camshaft gear. Remove the Wood

ruff

Keys.

D-23.

Remove

Front

End Plate

Remove the screws and lockwashers that attach the

front end plate to the cylinder block. Remove the

front end plate and gasket.

Discard

the gasket.

D-24. Remove

Clutch

Remove four

bolts

and lockwashers diagonally

opposite

that attach the clutch assembly to the

flywheel, leaving two

opposed

bolts

to be

loosened

alternately until the clutch spring pressure is re

lieved.

Then,

support the clutch assembly with

one hand while removing the two remaining bolts.

For

information on disassembly, inspection, repair

and

assembly of the clutch refer to Section I. In

structions for removing the clutch when the

engine

is in the vehicle are also given in Section I.

D-25.

Remove Flywheel

The

flywheel is attached to the crankshaft with two tapered dowel

bolts

and four special bolts.

Remove

these

attaching parts. Use a pry bar be tween the flywheel and the back of the

engine

and

carefully

loosen

the flywheel from the crankshaft.

If

the flywheel is to be removed with the

engine

in

the vehicle, the transmission and clutch must

first be removed as detailed in Section I.

D-26.

Remove

Crankshaft

Slide

the crankshaft thrust washer and all end-play

adjusting

shims off the front end of the crankshaft.

Pull

the two pieces of

rear

main bearing cap packing out of position

between

the side of the bearing cap

and

the cylinder block.

Note

the marks on the bearing caps and cylinder

block for bearing number and position. 44

Page 60 of 376

HURRICANE

F4

ENGINE

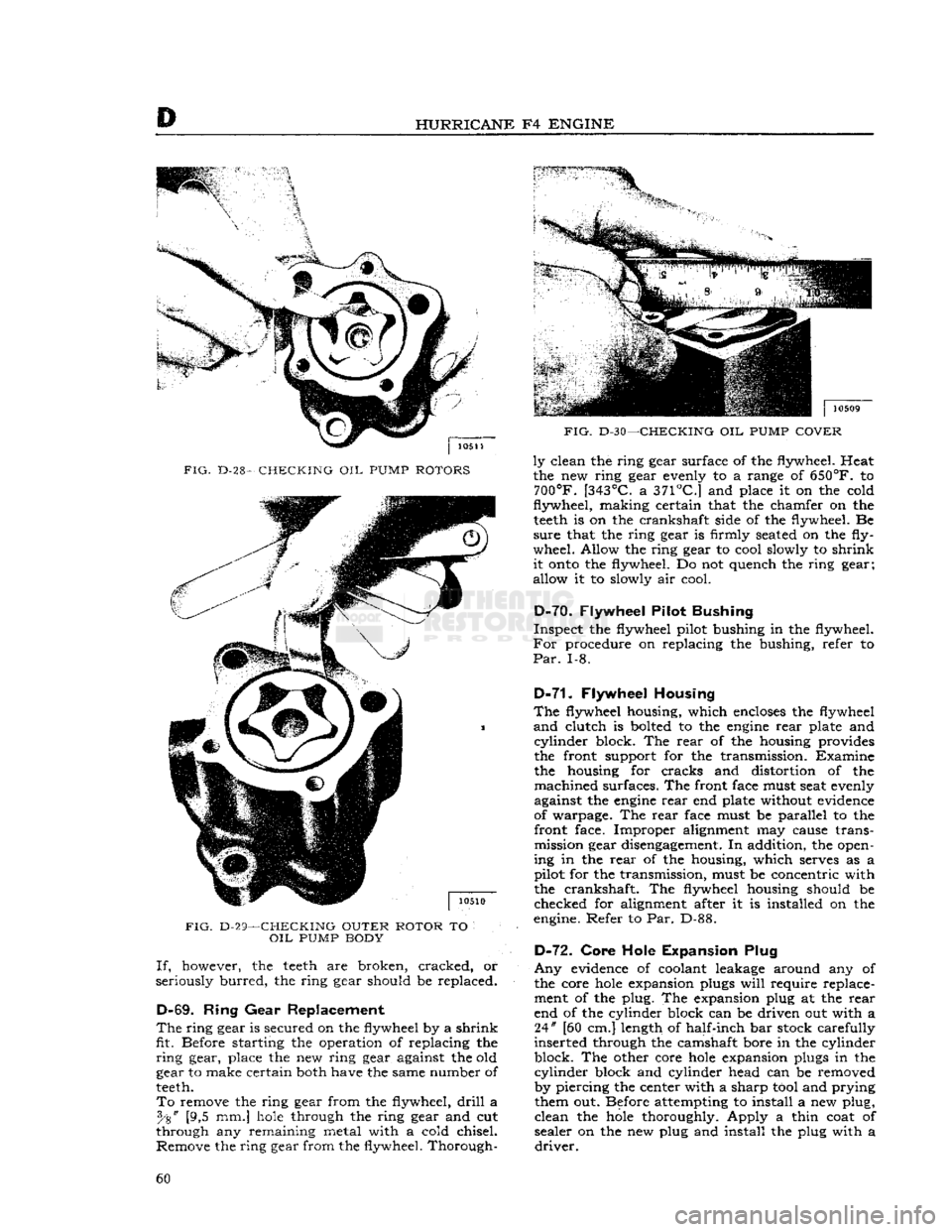

FIG.

D-28-

CHECKING

OIL

PUMP

ROTORS

FIG.

D-29—CHECKING OUTER ROTOR

TO

OIL

PUMP

BODY If,

however, the

teeth

are broken, cracked, or

seriously

burred,

the ring gear should be replaced.

D-69.

Ring

Gear

Replacement

The

ring

gear

is secured on the flywheel by a

shrink

fit. Before starting the operation of replacing the

ring

gear, place the new ring gear against the old

gear to make certain both have the same number of

teeth.

To

remove the ring gear from the flywheel,

drill

a [9,5 mm.]

hole

through the ring gear and cut

through any remaining metal with a cold chisel. Remove the ring gear from the flywheel. Thorough-

FIG.

D-30—CHECKING

OIL

PUMP

COVER

ly

clean the ring gear surface of the flywheel. Heat

the new ring gear evenly to a range of

650°F.

to

700°F.

[343°C.

a

371°C.]

and place it on the cold

flywheel,

making

certain that the chamfer on the

teeth

is on the crankshaft side of the flywheel. Be

sure

that the ring gear is firmly seated on the fly

wheel. Allow the ring gear to cool slowly to

shrink

it

onto

the flywheel. Do not quench the ring gear;

allow it to slowly air cool.

D-7Q.

Flywheel Pilot Bushing

Inspect

the flywheel pilot bushing in the flywheel.

For

procedure on replacing the bushing, refer to

Par.

1-8.

D-71.

Flywheel Housing

The

flywheel housing, which

encloses

the flywheel

and

clutch is bolted to the

engine

rear

plate and

cylinder

block. The

rear

of the housing provides

the front support for the transmission. Examine the housing for cracks and distortion of the

machined

surfaces. The front face must seat evenly

against the

engine

rear

end plate without evidence

of warpage. The

rear

face must be parallel to the front face. Improper alignment may cause transmission gear disengagement. In addition, the open

ing in the

rear

of the housing, which serves as a

pilot for the transmission, must be concentric with the crankshaft. The flywheel housing should be

checked for alignment after it is installed on the

engine. Refer to Par. D-88.

D-72.

Core Hole Expansion Plug

Any

evidence of coolant leakage around any of

the core

hole

expansion plugs

will

require replace ment of the plug. The expansion plug at the

rear

end of the cylinder block can be driven out with a 24" [60 cm.] length of half-inch bar stock carefully

inserted through the camshaft bore in the cylinder

block. The other core

hole

expansion plugs in the

cylinder

block and cylinder head can be removed

by piercing the center with a sharp tool and prying them out. Before attempting to install a new plug,

clean

the

hole

thoroughly. Apply a thin coat of

sealer on the new plug and install the plug with a

driver.

60

Page 68 of 376

D

HURRICANE

F4

ENGINE

D-101.

Install

Manifold

If

manifold studs were removed for replacement,

apply sealer on the stud threads

before

installing

a

new stud.

See Section Fl for exhaust emission controlled

engines.

Make

certain that no foreign objects are inside the manifold and that all

passages

are clear. Place a

new set of manifold

gaskets

in position on the side

of the cylinder block.

Then,

carefully slide the manifold

onto

the studs and against the cylinder block being careful not to damage the gaskets.

Torque

all manifold attaching nuts evenly 29 to

35 lb-ft. [4,0 a 4,8 kg-m.].

D-102.

Install

Oil

Filler

Tube

When

installing the oil filler tube, be sure that the

beveled lower end is away from the crankshaft.

Place a

piece

of

hard

wood

over the top of the

tube

to prevent damage to the cap gasket seat.

D-103.

Install

Water Pump

Make

certain that the mating surfaces of the water pump and the cylinder block are clean and smooth.

Install

the gasket on the

flange

of the pump and

install

the pump in position on the cylinder block.

Torque

the water pump attaching

bolts

alternately

and

evenly 12 to 17 lb-ft. [1,7 a 2,3 kg-m.].

D-104.

Install

Water Outlet Fitting

Install

the thermostat and the water

outlet

fitting.

Torque

the water

outlet

fitting attaching

bolts

20

to 25 lb-ft. [2,8 a 3,4 kg-m.].

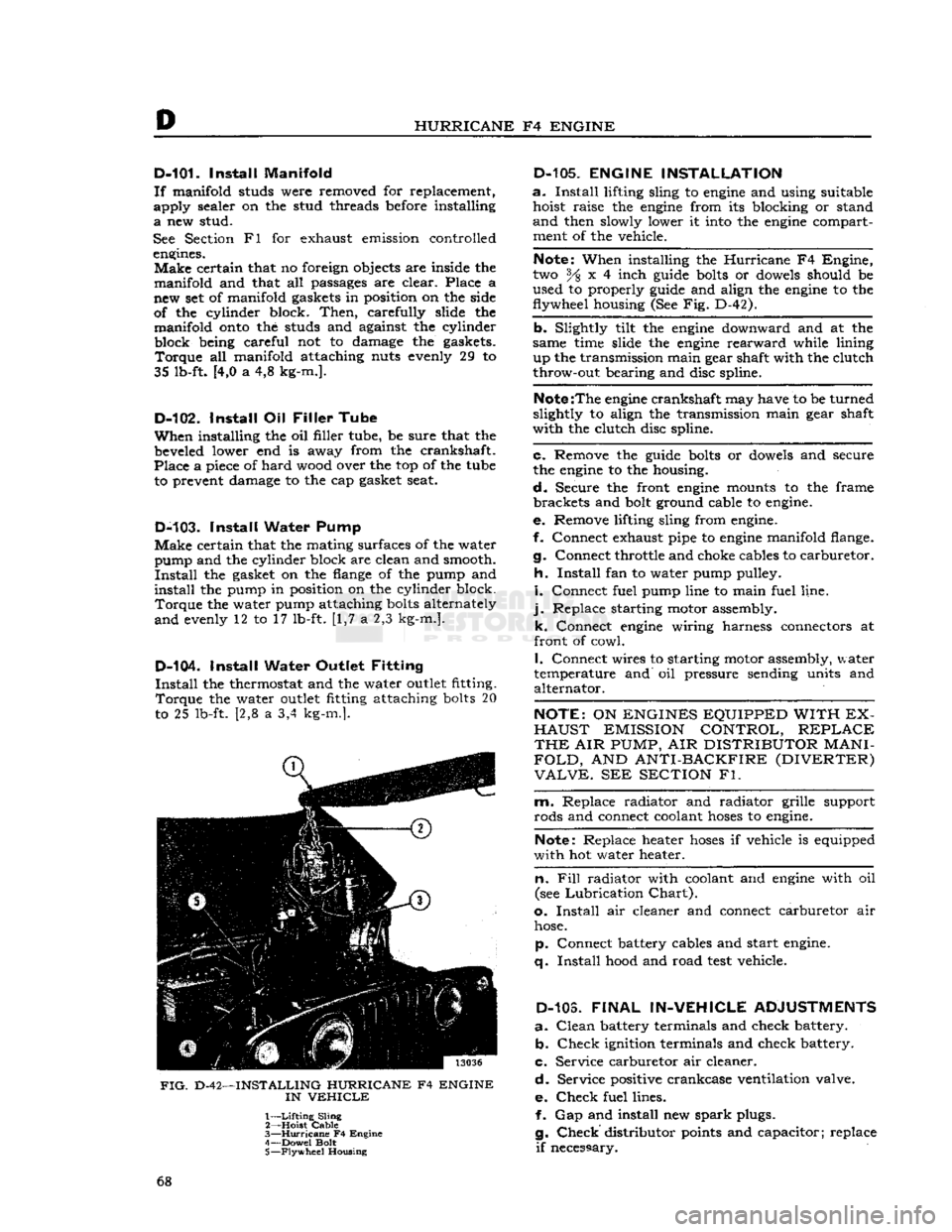

FIG.

D-42—INSTALLING HURRICANE F4 ENGINE

IN

VEHICLE

1—

Lifting

Sling

2— Hoist

Cable

3—

Hurricane

F4 Engine

4— Dowel Bolt

5—

Flywheel

Housing

D-105.

ENGINE INSTALLATION

a.

Install

lifting sling to

engine

and using suitable hoist raise the

engine

from its blocking or stand

and

then slowly lower it

into

the

engine

compartment of the vehicle.

Note:

When installing the

Hurricane

F4 Engine,

two % x 4 inch

guide

bolts

or

dowels

should be

used to properly

guide

and align the

engine

to the

flywheel housing (See Fig. D-42).

b. Slightly tilt the

engine

downward and at the

same time slide the

engine

rearward

while lining up the transmission main gear shaft with the clutch

throw-out bearing and disc spline.

Note

:The

engine

crankshaft may have to be turned

slightly to align the transmission main gear shaft

with the clutch disc spline.

c. Remove the

guide

bolts

or

dowels

and secure

the

engine

to the housing.

d.

Secure the front

engine

mounts to the frame brackets and

bolt

ground cable to

engine.

e. Remove lifting sling from

engine.

f. Connect exhaust pipe to

engine

manifold flange.

g. Connect throttle and choke cables to carburetor.

h.

Install

fan to water pump pulley.

i.

Connect fuel pump line to main fuel line,

j.

Replace starting motor assembly. k. Connect

engine

wiring harness connectors at

front of cowl.

I.

Connect wires to starting motor assembly, water

temperature and oil pressure sending units and alternator.

NOTE:

ON

ENGINES EQUIPPED WITH EX

HAUST

EMISSION CONTROL,

REPLACE

THE

AIR

PUMP,

AIR

DISTRIBUTOR

MANI

FOLD,

AND

ANTI-BACKFIRE (DIVERTER)

VALVE.

SEE

SECTION

Fl.

m. Replace radiator and radiator grille support

rods and connect coolant

hoses

to

engine.

Note:

Replace heater

hoses

if vehicle is equipped

with hot water heater.

n. Fill

radiator with coolant and

engine

with oil

(see

Lubrication

Chart).

o.

Install

air cleaner and connect carburetor air

hose.

p. Connect battery cables and start

engine,

q.

Install

hood

and road

test

vehicle.

D-103.

FINAL

IN-VEHICLE

ADJUSTMENTS

a.

Clean

battery terminals and check battery. b.

Check

ignition terminals and check battery.

c. Service carburetor air cleaner.

d.

Service positive crankcase ventilation valve.

e.

Check

fuel lines. f. Gap and install new

spark

plugs.

g.

Check

distributor

points

and capacitor; replace

if

necessary. 68

Page 79 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

Dl

12710

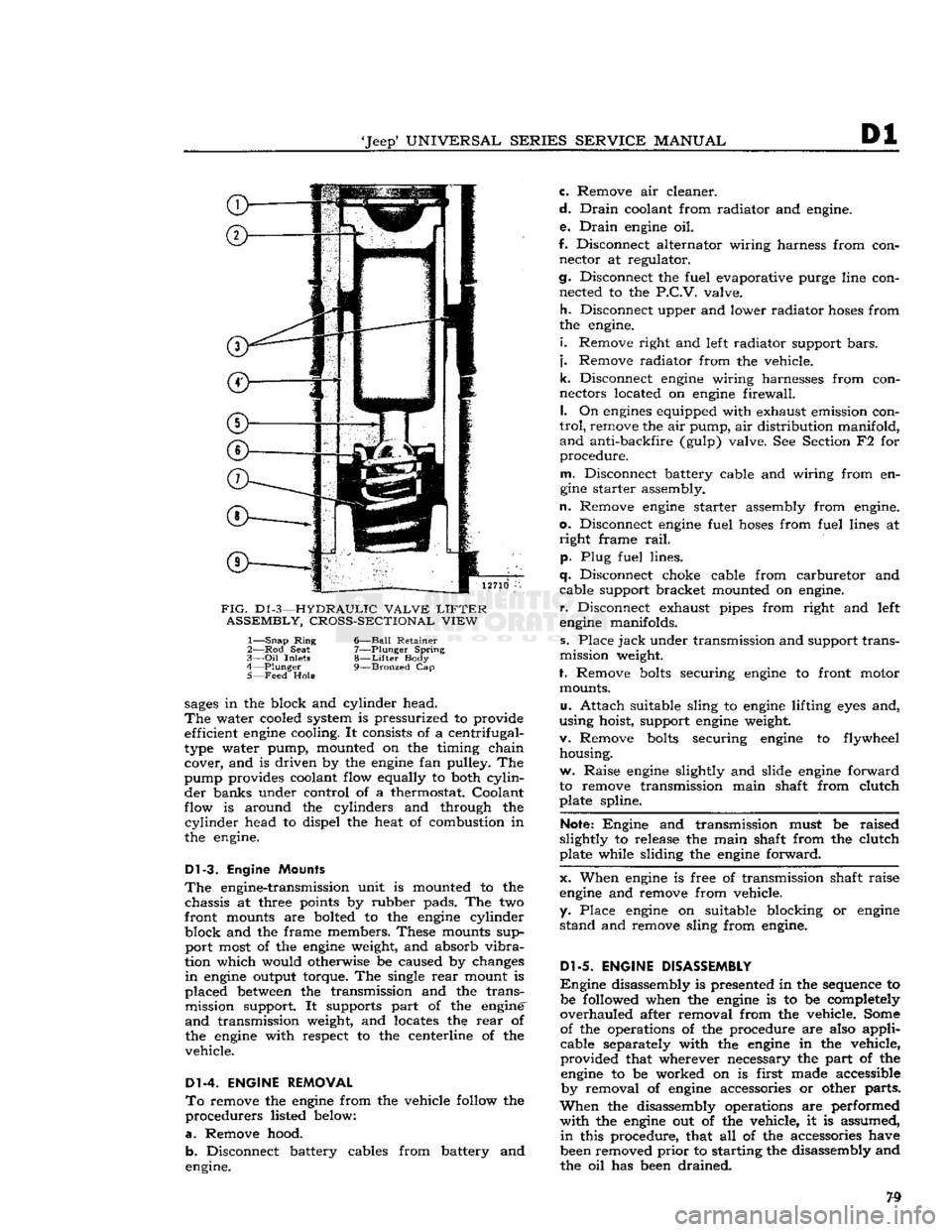

FIG.

D1

-3—HYDRAULIC VALVE

LIFTER

ASSEMBLY, CROSS-SECTIONAL VIEW

1—

Snap

Ring

6—Ball Retainer

2— Rod

Seat

7—Plunger Spring

3—

Oil

Inlets

8—Lifter

Body

4—

Plunger

9—Bronzed

Cap

5— Feed

Hole

sages

in the block and cylinder head.

The

water cooled system is pressurized to provide efficient

engine

cooling. It consists of a centrifugal-

type water pump, mounted on the timing chain cover, and is driven by the

engine

fan pulley. The

pump provides coolant flow equally to both

cylin

der banks under control of a thermostat. Coolant

flow is around the cylinders and through the

cylinder

head to dispel the heat of combustion in

the engine.

Dl-3.

Engine Mounts

The

engine-transmission unit is mounted to the chassis at three points by rubber pads. The two

front mounts are bolted to the

engine

cylinder

block and the frame members. These mounts sup port most of the

engine

weight, and absorb

vibra

tion which would otherwise be caused by changes

in

engine

output torque. The single

rear

mount is

placed

between

the transmission and the trans mission support. It supports part of the engine'

and

transmission weight, and locates the

rear

of

the

engine

with respect to the centerline of the

vehicle.

Dl-4. ENGINE REMOVAL

To

remove the

engine

from the vehicle follow the

procedurers listed below:

a.

Remove hood. b. Disconnect battery cables from battery and

engine. c. Remove air cleaner.

d.

Drain

coolant from radiator and engine.

e.

Drain

engine

oil.

f. Disconnect alternator wiring harness from con nector at regulator.

cj.

Disconnect the fuel evaporative purge line con nected to the

P.C.V.

valve.

h.

Disconnect upper and lower radiator

hoses

from

the engine.

i.

Remove right and left radiator support

bars,

j.

Remove radiator from the vehicle.

k.

Disconnect

engine

wiring harnesses from con

nectors located on

engine

firewall.

I.

On

engines

equipped with exhaust emission con

trol,

remove the air pump, air distribution manifold,

and

anti-backfire (gulp) valve. See Section F2 for

procedure.

m.

Disconnect battery cable and wiring from en

gine

starter assembly.

n.

Remove

engine

starter assembly from engine,

o.

Disconnect

engine

fuel

hoses

from fuel lines at

right

frame

rail,

p. Plug fuel lines.

q.

Disconnect choke cable from carburetor and cable support bracket mounted on engine,

r.

Disconnect exhaust pipes from right and left

engine

manifolds.

s. Place

jack

under transmission and support trans

mission weight.

f. Remove

bolts

securing

engine

to front motor mounts.

u.

Attach suitable sling to

engine

lifting

eyes

and,

using hoist, support

engine

weight.

v. Remove

bolts

securing

engine

to flywheel housing.

w. Raise

engine

slightly and slide

engine

forward

to remove transmission main shaft from clutch plate spline.

Note:

Engine and transmission must be raised

slightly to release the main shaft from the clutch

plate while sliding the

engine

forward.

x. When

engine

is free of transmission shaft raise

engine

and remove from vehicle,

y. Place

engine

on suitable blocking or

engine

stand and remove sling from engine.

Dl-5.

ENGINE DISASSEMBLY

Engine

disassembly is presented in the sequence to be followed when the

engine

is to be completely

overhauled after removal from the vehicle. Some of the operations of the procedure are also applicable separately with the

engine

in the vehicle,

provided that wherever necessary the part of the

engine

to be worked on is first made accessible by removal of

engine

accessories or other parts.

When

the disassembly operations are performed

with

the

engine

out of the vehicle, it is assumed,

in

this procedure, that all of the accessories have

been removed

prior

to starting the disassembly and

the oil has been drained.

Page 90 of 376

DAUNTLESS

V-6

ENGINE

Note:

The rib on

edge

of cap and the conical

boss

on web of connecting rod must be toward

rear

of

engine

in all connecting rod assemblies of left

cyl

inder

bank and toward front of

engine

in all connecting rod assemblies of right cylinder bank.

Dl-50.

Oil

Pump Intake

and

Screen Cleaning

a.

Pry screen from housing and examine for clog

ging due to deposit of sludge or other foreign

material.

b.

Clean

the screen and housing thoroughly in sol

vent; dry with compressed air.

c.

Install

screen in housing.

Dl-51.

Oil Pan Cleaning and Inspection

Inspect

the oil pan for corrosion, dents, leaks, and

other damage. Inspect its mounting flange carefully

for damage or distortion to be certain that it

will

give

a

good

seal.

Dl-52.

Flywheel Cleaning

and

Inspection

Clean

the flywheel with suitable cleaning solvent;

dry

with compressed air. Inspect clutch face for

burned

or scuffed condition and for rivet grooves.

Inspection

for run out or improper mounting is de

scribed

in installation procedure.

Inspect

teeth

of the flywheel

ring

gear for

burrs,

nicks,

and minor distortion. If necessary and pos

sible, use a small emery wheel to remove

burrs

and

reshape teeth. If gear

teeth

are broken,

cracked,

seriously

burred

or deformed, the

ring

gear must be replaced.

Dl-53.

Ring Gear Replacement

a.

Drill

a

hole

between

two

ring

gear teeth; then

split

the gear with a cold chisel. Be careful not to

damage

ring

gear shoulder or seat surfaces of fly

wheel.

b.

Polish several

spots

on the new

ring

gear to be

installed.

With

a hot plate or slowly moving torch,

heat the new

ring

gear until polished

spots

become

blue, about

600°F.

[312°C.].

Caution:

Do not heat the

ring

gear to a temperature

greater than

800°F.

[424°C.].

Excessive heat

will

destroy heat treatment given to

ring

gear during

manufacture.

c.

Quickly

install

ring

gear on flywheel. Chamfered

edge

of

ring

gear must be toward

ring

gear shoulder

of flywheel. Be certain that

ring

gear is seated prop

erly.

Allow

ring

gear to cool slowly, so that it

will

be held tightly in place.

Dl-54.

Flywheel Housing Cleaning and Inspection

Both

flywheel and clutch are enclosed by a fly

wheel housing. Its front surface is bolted to the

engine

cylinder block, and its

rear

surface acts as

front

support to the transmission.

Clean

the fly wheel housing with a suitable cleaning solvent; dry

with

compressed air. Inspect front and

rear

surfaces

for distortion and improper alignment with each

other;

these

planes must be

parallel

to assure

proper

alignment

between

engine

and transmission.

Dl-55.

Camshaft Cleaning

and

Inspection

Clean

both camshaft and camshaft bearing surfaces

with

a suitable cleaning solvent; dry with com

pressed air.

Note:

The steel-backed babbitt-lined camshaft

bearings are pressed into the crankcase.

From

front

to

rear,

each bearing is .030" [0,76 mm.] smaller

in

diameter than the preceding bearing.

From

front

to

rear,

each camshaft

journal

is correspondingly

smaller

in diameter.

The

camshaft bearings must be line reamed to

proper

diameter after being pressed into crankcase.

Since

this operation requires special reaming equip

ment, the original bearings should be retained un

less

they are severly damaged. Slightly scored cam

shaft bearings are satisfactory if the surfaces of camshaft journals are polished, bearings are

polished to remove

burrs,

and

radial

clearance

between

camshaft and bearings is within .0015"

to .004" [0,038 a 0,102 mm.].

Dl-56.

Valve Lifter

and

Push

Rod

Cleaning and Inspection

a.

Examine the cam contact surface at lower end of each valve lifter body. If surface is excessively

worn,

galled, or otherwise damaged, discard the

valve lifter. Also examine the mating camshaft

lobe

for excessive wear or damage.

b.

Disassemble one or two valve lifters, as de

scribed

below, and inspect them for

dirt

or

varnish.

If

they are dirty or have a varnish deposit, clean

and

inspect all twelve valve lifters. Otherwise,

service

only

those

valve lifters which do not operate

properly.

c.

To disassemble each valve lifter, depress the

push

rod seat with a push rod, and remove the

plunger retainer from the valve lifter body with

a

retainer remover. Remove push rod seat and

plunger from valve lifter body. If plunger sticks

in

valve lifter body, place body in large end of

a

plunger remover tool, with plunger downward.

While

holding lifter with thumb, rap the open end

of remover against a block of wood with just enough force to jar the plunger from body. Refer to

Figs.

Dl-20, Dl-22 and Dl-23.

d.

Drain

oil from valve lifter and remove the check

valve retainer,

ball,

valve spring, and plunger

spring.

e. Keep all parts of each valve lifter separated

during

part cleaning and inspection. The valve

lifter

body and plunger are selectively fitted to each other and must not be interchanged with parts

of other valve lifters.

f. Rinse all valve lifter parts in kerosene to remove as much oil as possible.

This

will

reduce contamina

tion of the cleaning solvent. Immerse all parts in cleaning solvent for approximately one hour. The

time required

will

depend on varnish

deposits

and

effectiveness

of the solvent. After the varnish has

dissolved or has

softened

sufficiently to permit re

moval

by wiping, allow parts to

drain.

Varnish

can

then be cleaned from the valve lifter body

with

a

brush.

Rinse the parts in kerosene to dissolve 90

Page 104 of 376

Dl

DAUNTLESS

V-6

ENGINE

e.

Connect electrical wiring harness to coolant

temperature sending unit. Connect two distributor leads to ignition coil. Connect fuel line

between

fuel pump and carburetor, vacuum

hose

between

distributor and carburetor, and crankcase vent

hose

to intake manifold

below

rear

of carburetor.

FIG.

D1-46—-INTAKE

MANIFOLD

INSTALLATION

1—Long Bolt 2—Open Bolt Hole

Dl-102.

ENGINE INSTALLATION

Install

the

engine

in the vehicle in the following

procedure listed

below:

a.

Attach suitable sling to

engine

lifting

eyes

and,

using a hoist, lift the

engine

from blocks or

engine

stand.

b. When

engine

is free of the stand lower it slowly

into

the

engine

compartment of the vehicle.

Note:

The

engine

and transmission must be lined

up to

engage

the main shaft and clutch plate spline

while sliding the

engine

rearward

into

the mounting

position.

c.

Install

and tighten up

bolts

securing

engine

to

flywheel housing.

d.

Install

and tighten front

engine

mounting bolts.

e.

Remove sling from the

engine.

I.

Connect exhaust pipes to right and

left

engine

manifolds.

g. Connect choke cable support bracket to

car

buretor.

h.

Connect

engine

fuel

hoses

and fuel lines at right

frame

rail.

I.

Connect fuel lines.

j.

Mount

engine

starter motor assembly to

engine.

k.

Connect battery cable and wiring to

engine

starter

motor.

I.

Connect

engine

wiring harnesses to connectors

located on

engine

firewall.

Note:

On

engines

equipped with exhaust emission

control, replace the air pump, air distributor mani

fold, and anti-backfire (gulp) valve. See Section F2.

m. Replace radiator, and secure with bolts,

n.

Replace and tighten right and

left

radiator sup

port rods.

0. Connect upper and lower radiator

hoses

to the

engine.

p. Connect alternator wiring harness from connec

tor at regulator,

q.

Replace air cleaner.

r.

Connect battery ground cable from the battery

to the

engine

and the

engine

ground strap,

s.

Replace the hood.

After

the

engine

is installed in the vehicle,

fill

radiator

with coolant and

engine

with oil (Refer to

Lubrication

Section B), then perform an

engine

Tune-up

and road

test

(Refer to Tune-up Sec

tion C).

Dl-103.

FINAL IN-VEHICLE ADJUSTMENTS

a.

Clean

battery terminals and check battery.

b.

Check

ignition wires and connections.

c. Service carburetor air cleaner.

d.

Service positive crankcase ventilation valve.

e.

Check

fuel lines.

f. Gap and install new

spark

plugs.

g.

Check

distributor

points

and capacitor; replace

if

necessary.

h.

Check

ignition (distributor) timing; reset if

necessary. 1.

Check

carburetor adjustments; reset if necessary,

j.

With

engine

fully warmed up, tighten cylinder

head and manifold

bolts

and nuts to specified

torque.

Check

cylinder head

gaskets

and

bolts

for

air

or coolant leaks.

Note:

Tightness of cylinder head

bolts

should be

checked and corrected after 500 miles [800 km.]

of normal operation and again at 1000 miles [1600

km.].

k.

Check

fan belt tension; adjust if necessary.

I.

Check

for and correct any oil leak, fuel leak or

coolant leak. 104

Page 148 of 376

Fl

EXHAUST

EMISSION

CONTROL

SYSTEMS

IMPORTANT

NOTICE

The

Exhaust

Emission Systems covered

in

this publication

meet

State and

Federal

requirements for hydrocarbon and carbon

monoxide

emissions.

To

assure continued proper operation,

these

systems

must

be

inspected

regularly,

parts must be replaced

at

factory-recommended intervals and

engine

tune-up services performed at intervals specified in the

Exhaust

Emission

Con

trol

System Maintenance charts.

For

the

above

reasons,

these

systems

must not, under any circumstances,

be

altered

to anything other than

required

specifications provided in this publication.

Further,

the

Exhaust

Emission

Control

System, or any

of

its components, must

not be physically altered or modified in any respect.

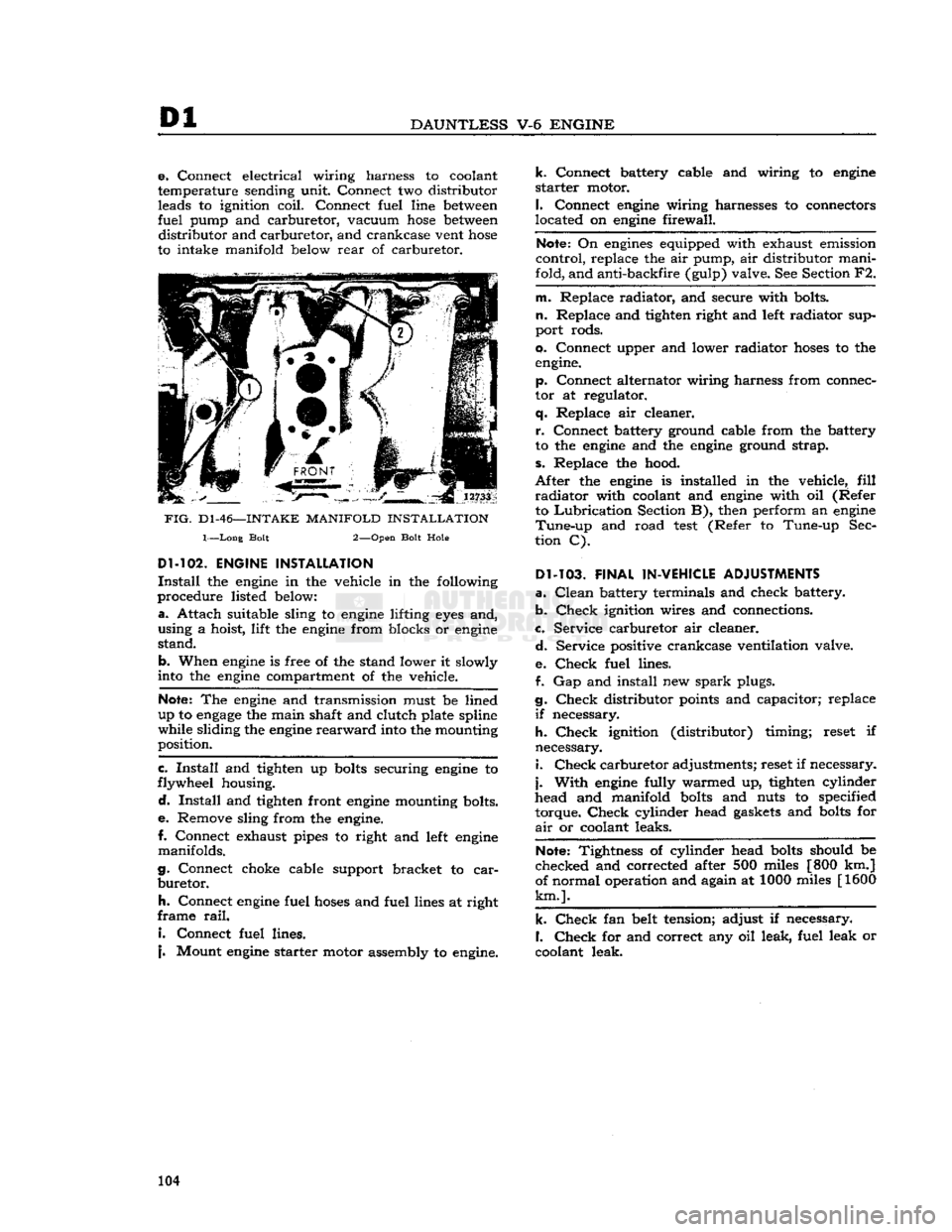

DHTfl

TAG

For

the serviceman's guidance, each vehicle equipped with exhaust emission

control

will

have data

tag

permanently affixed

to the

radiator shroud—-in

example:

VEHICLE

EMISSION

CONTROL

INFORMATION

MODEL

F4-134

C.I.D.

•

ENGINE

AT

NORMAL

OPERATING

TEMPERATURE

•

LIGHTS

AND

ALL

ACCESSORIES OFF

•

IDLE

MIXTURE

. . .

LEAN

BEST

IDLE

•

IGNITION

TIMING

0*

(TDC)

•

SPARK

PLUG

GAP

. . . .030

•

DWELL

...

42* (.020

POINT

GAP)

•

IDLE

SPEED

. . .

700-750 RPM

TRANSMISSION

IN

NEUTRAL

DURING

TUNE

UP

SEE SERVICE MANUAL

FOR

ADDITIONAL INFORMATION

THIS VEHICLE CONFORMS

TO U.S.

DEPT.

OF

H.E.W.

REGULATIONS APPLICABLE

TO

1971 MODEL YEAR NEW MOTOR VEHICLES

Jeep

CORPORATION

14401

Important:

Always refer

to

the data tag when checking or re-adjusting ignition

timing,

idle speed, and idle mixture. 148

Page 159 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

F2

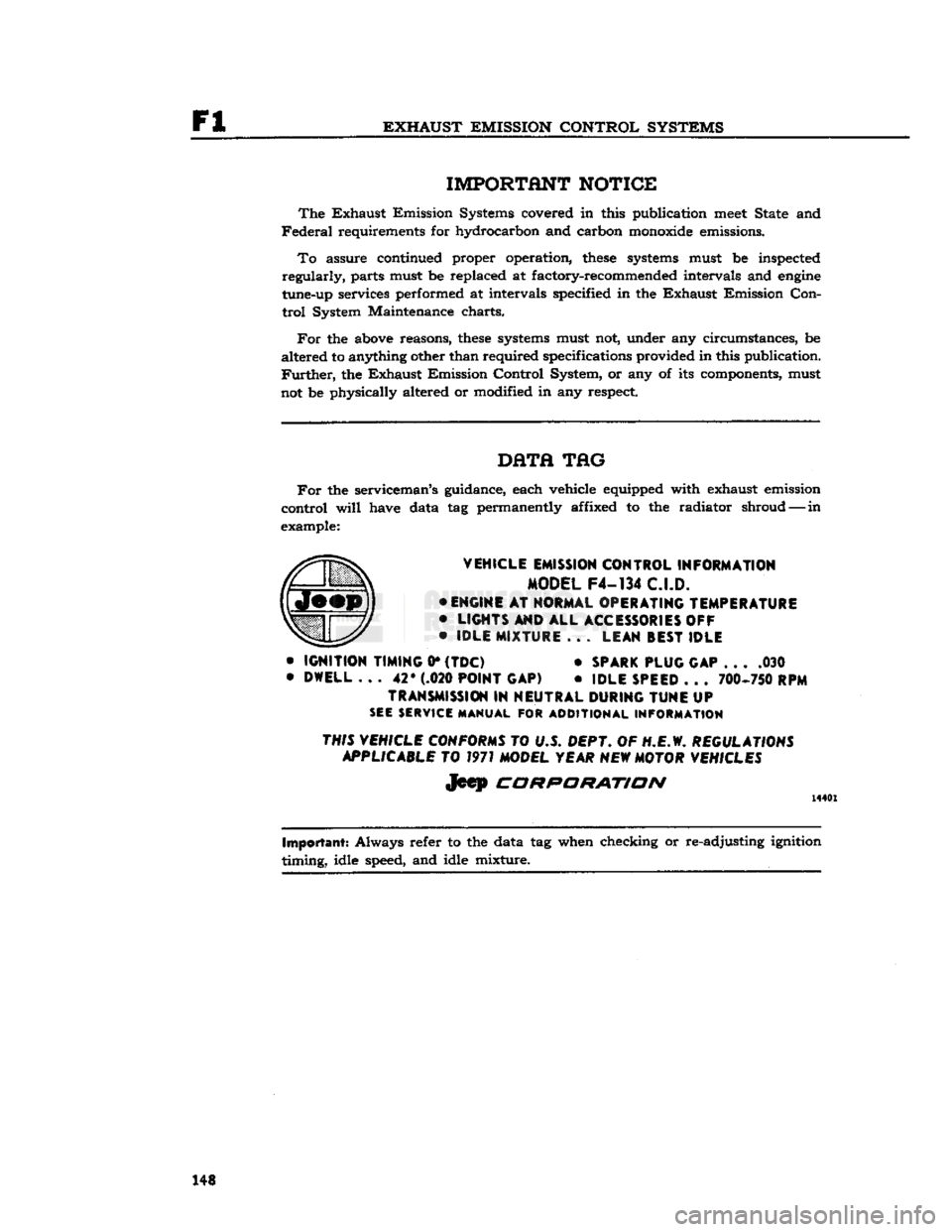

F2-35.

EXHAUST EMISSION CONTOL SYSTEM

DISTRIBUTOR SPECIFICATIONS

Distributor:

Make

Delco-Remy Prestolite Prestolite

Model...

1110376

IAT-4501 or IAT-4502 IAT-4502A

Breaker

Point Gap .016"

[0,406

mm.] .016"

[0,406

mm.] .016"

[0,406

mm.]

Breaker

Arm Tension 19 to 23 oz. [538 a 652 gr.] 17 to 22 oz. [482 a 623 gr.] 17 to 22 oz. [482 a 623 gr.]

Cam

Angle. 29° to 31° 29° + 3° 29° ± 3°

Max.

Auto Advance

(Crankshaft

Degrees). 13° to 15° at 1,950 rpm. 16° (& 1800 rpm. 21° @ 1800 rpm.

26°

@

4200

rpm. (Max.) 32° @

4200

rpm. (Max.)

Max.

Vac. Advance

(Distributor

Degrees) 8° 8° 8°

Condenser Capacity. .18 to .23 mfd. .25 to .28 mfd. .25 to .28 mfd.

Timing:

Crankshaft

5°

(BTC)

@ Idle 5°

(BTC)

© Idle 0°

(TDC)

© Idle

Mark

Location Crankshaft Pulley Crankshaft Pulley Crankshaft Pulley

Firing

Order

1-6-5-4-3-2 1-6-5-4-3-2 1-6-5-4-3-2

F2-36.

SPARK PLUG

GAP

Spark

Plug Gap. .035"

[0,889

mm.]

IMPORTANT

NOTICE

The

Exhaust Emission Systems covered in this publication

meet

State and Federal

requirements for hydrocarbon and carbon

monoxide

emissions.

To

assure continued proper operation,

these

systems

must be inspected regularly,

parts must be replaced at factory-recommended intervals and

engine

tune-up services

performed at intervals specified in the Exhaust Emission Control System Maintenance

charts.

For

the

above

reasons,

these

systems

must not, under any circumstances, be altered

to anything other than required specifications provided in this publication.

Further,

the Exhaust Emission Control System, or any of its components, must not be physi

cally

altered or modified in any respect.

DATA

TAG

For

the serviceman's guidance, each vehicle equipped with exhaust emission control

will

have data tag permanently affixed to the radiator shroud — in example:

VEHICLE EMISSION CONTROL INFORMATION MODEL V6-225 C.I.D.

•

ENGINE

AT

NORMAL OPERATING TEMPERATURE

•

LIGHTS

AND ALL

ACCESSORIES

OFF

•

IDLE MIXTURE

.. .

LEAN BEST IDLE

•

IGNITION TIMING

0*

(TDC)

*

SPARK PLUG

GAP 035

•

DWELL

. . . 30* (.016

POINT

GAP) •

IDLE SPEED

. . .

650- 700

RPM

TRANSMISSION

IN

NEUTRAL DURING TUNE

UP

SEE

SERVICE MANUAL FOR ADDITIONAL INFORMATION

THIS VEHICLE CONFORMS

TO U.S. DEPT. OF H.E.W.

REGULATIONS APPLICABLE

TO

1971

MODEL YEAR

NEW

MOTOR VEHICLES

Jeep

CORPORATION

14400

NOTE:

The

above

tag applies to vehicles equipped with Distributor Model

IAT-4502A.

On

vehicles equipped with Distributor Models

1110376,

IAT-4501 and IAT-4502 the tag is the same

except

that Ignition Timing is 5°

T.D.C.

Always

refer to the data tag when checking or re-adjusting ignition timing, idle speed, and idle mixture.

159

Page 215 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

H

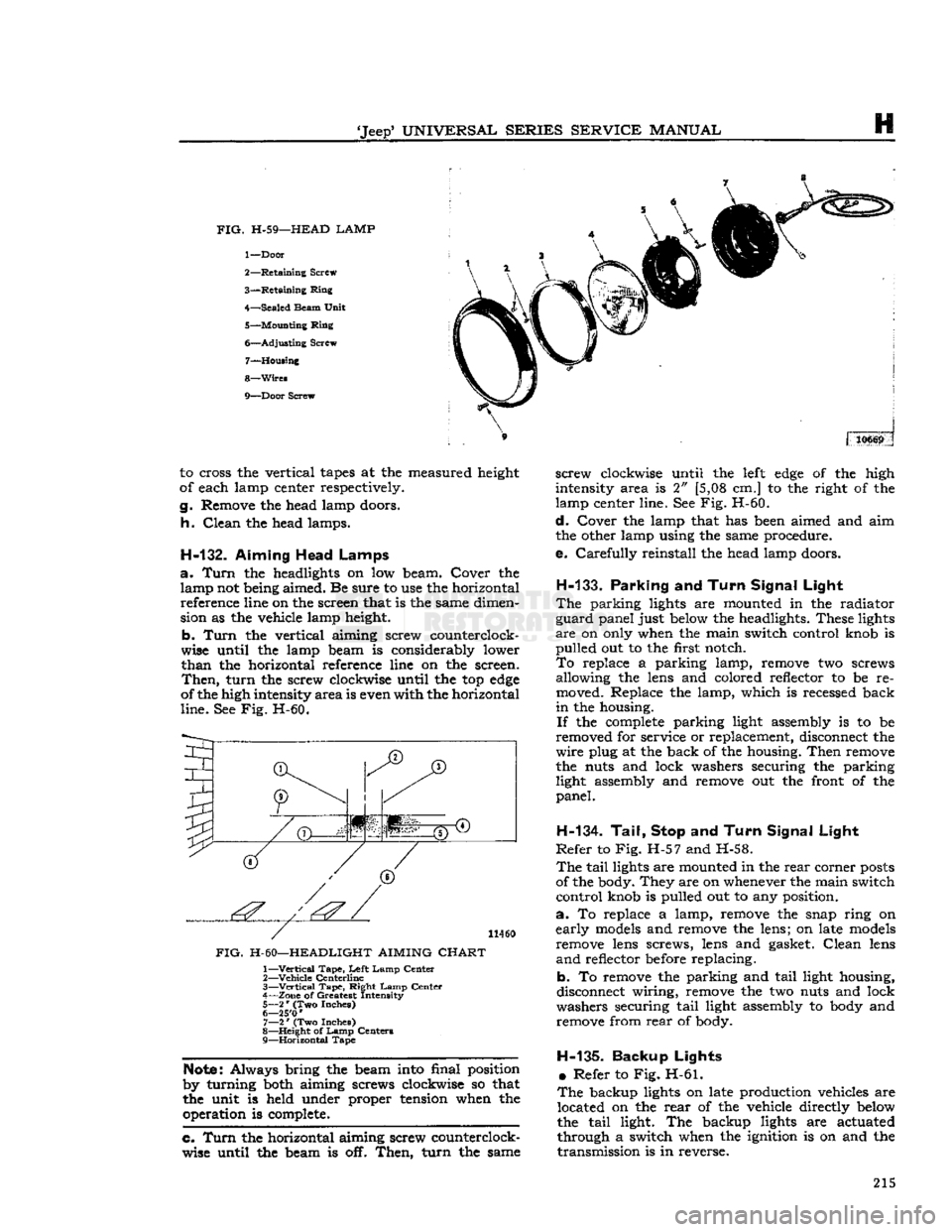

FIG.

H-59—HEAD LAMP

1—

Door

2—

Retaining

Screw

3—

Retaining

Ring

4—

Sealed

Beam

Unit

5—

Mounting

Ring

6—

Adjusting

Screw 7—

Housing

8—

Wires

9—

Door

Screw 310669

to cross the vertical

tapes

at the measured height

of each lamp center respectively.

g.

Remove the head lamp doors.

h.

Clean

the head lamps.

H-132.

Aiming Head Lamps

a.

Turn

the headlights on low beam. Cover the lamp not being aimed. Be sure to use the horizontal reference line on the screen that is the same dimen

sion as the vehicle lamp height.

b.

Turn

the vertical aiming screw counterclock

wise until the lamp beam is considerably lower

than

the horizontal reference line on the screen.

Then,

turn

the screw clockwise until the top

edge

of the high intensity

area

is even with the horizontal

line.

See Fig. H-60.

I

(T)

JT)

1'.'' | '':'

11460

FIG.

H-60—HEADLIGHT AIMING

CHART

1—

Vertical

Tape,

Left

Lamp

Center

2—

Vehicle

Centerline

3—

—Vertical

Tape,

Right

Lamp

Center

4—

Zone

of Greatest Intensity

5—

2

*

(Two Inches)

6— 25'0

'

7—

2

*

(Two Inches)

8—

Height

of

Lamp

Centers

9—

Horizontal

Tape

Note:

Always bring the beam into final position

by turning both aiming screws clockwise so that

the unit is held under proper tension when the operation is complete.

c. Turn

the horizontal aiming screw counterclock

wise until the beam is off.

Then,

turn

the same

screw

clockwise until the

left

edge

of the high

intensity area is 2" [5,08 cm.] to the right of the

lamp center line. See Fig. H-60.

d.

Cover the lamp that has been aimed and aim

the other lamp using the same procedure.

e.

Carefully

reinstall the head lamp doors.

H-133.

Parking

and

Turn Signal Light

The

parking lights are mounted in the radiator

guard

panel just below the headlights. These lights

are

on only when the main switch control knob is

pulled

out to the first notch.

To

replace a parking lamp, remove two screws allowing the lens and colored reflector to be re

moved. Replace the lamp, which is recessed back

in

the housing.

If

the

complete

parking light assembly is to be

removed for service or replacement, disconnect the

wire

plug at the back of the housing.

Then

remove

the nuts and lock washers securing the parking light assembly and remove out the front of the

panel.

H-134. Tail, Stop

and

Turn Signal Light

Refer

to Fig. H-57 and H-58.

The

tail

lights are mounted in the

rear

corner

posts

of the body. They are on whenever the main switch

control

knob is pulled out to any position.

a.

To replace a lamp, remove the snap ring on

early

models

and remove the lens; on late

models

remove lens screws, lens and gasket.

Clean

lens

and

reflector before replacing.

b. To remove the parking and

tail

light housing,

disconnect wiring, remove the two nuts and lock

washers securing

tail

light assembly to body and remove from

rear

of body.

H-135-

Backup Lights •

Refer to Fig. H-61.

The

backup lights on late production vehicles are located on the

rear

of the vehicle directly below

the

tail

light. The backup lights are actuated

through a switch when the ignition is on and the

transmission

is in reverse. 215

Page 216 of 376

ELECTRICAL

SYSTEM

14385

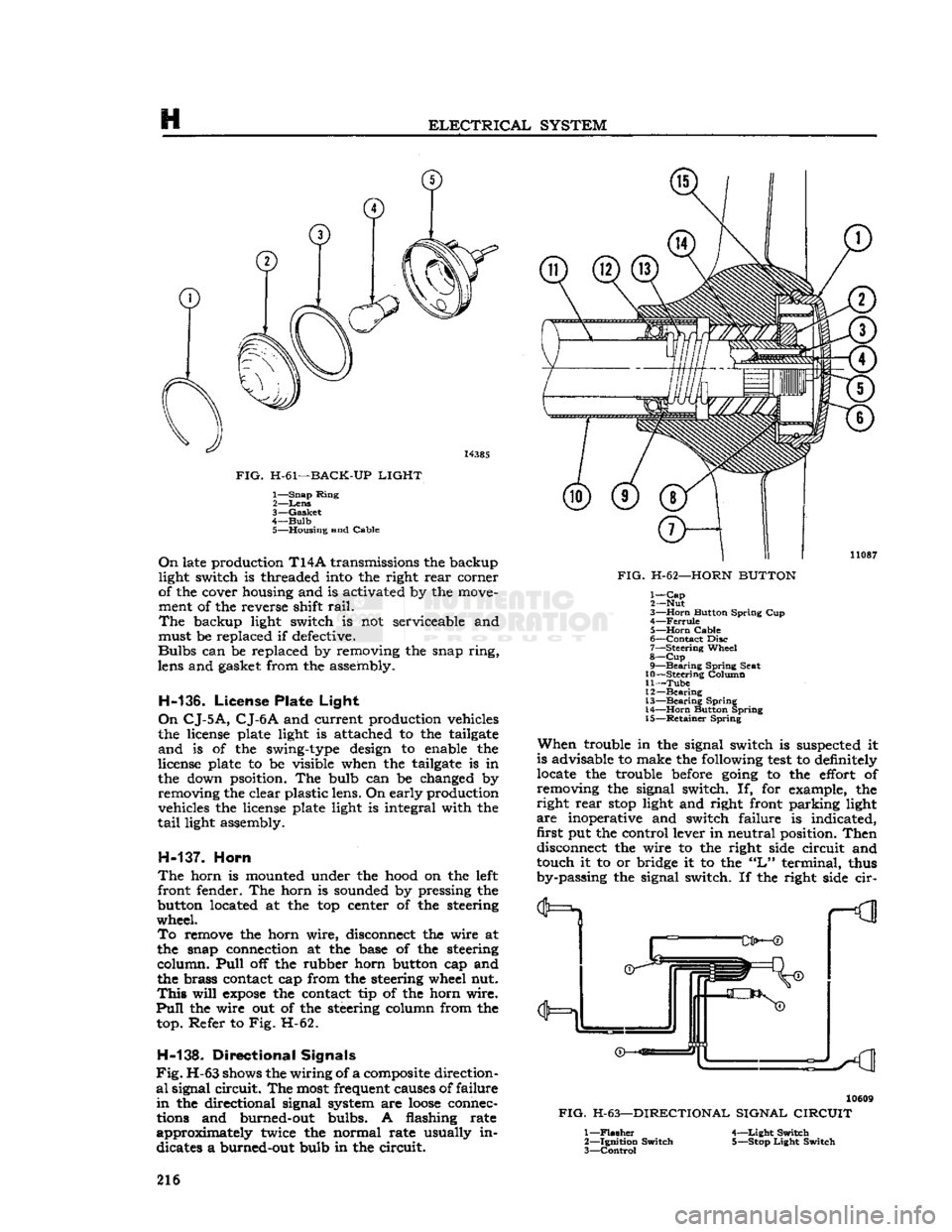

FIG.

H-61—BACK-UP

LIGHT

1—

Snap

Ring

2—

Lens

3—

Gasket

4—

Bulb

5—

Housing

and

Cable

On

late production

T14A

transmissions the backup

light switch is threaded into the right

rear

corner

of the cover housing and is activated by the move

ment of the reverse shift

rail.

The

backup light switch is not serviceable and

must be replaced if defective.

Bulbs

can be replaced by removing the snap

ring,

lens and gasket from the assembly.

H-136.

License Plate

Light

On

CJ-5A,

CJ-6A

and current production vehicles

the license plate light is attached to the tailgate

and

is of the swing-type design to enable the

license plate to be visible when the tailgate is in

the down psoition. The bulb can be changed by

removing

the clear plastic lens. On early production

vehicles the license plate light is integral with the

tail

light assembly.

H-137.

Horn

The

horn is mounted under the hood on the

left

front

fender. The horn is sounded by pressing the

button located at the top center of the steering

wheel.

To

remove the horn wire, disconnect the wire at

the snap connection at the base of the steering

column.

Pull

off the rubber horn button cap and

the brass contact cap from the steering wheel nut.

This

will

expose

the contact tip of the horn wire.

Pull

the wire out of the steering column from the top. Refer to Fig. H-62.

H-13S.

Directional

Signals

Fig.

H-63 shows the

wiring

of a

composite

direction

al

signal

circuit.

The most frequent causes of

failure

in

the directional signal system are

loose

connec

tions and burned-out bulbs. A flashing rate

approximately

twice the normal rate usually in

dicates a burned-out bulb in the

circuit.

11087

FIG.

H-62—HORN

BUTTON 1—

Cap

2— Nut

3—

Horn

Button

Spring

Cup 4—

Ferrule

5—

Horn

Cable

6—

Contact

Disc

7—

Steering

Wheel

8—

Cup

9—

Bearing

Spring

Seat

10—

Steering

Column

11—

Tube

12—

Bearing

13—

Bearing

Spring

14—

Horn

Button

Spring

15—

Retainer

Spring

When

trouble in the signal switch is suspected it

is advisable to make the following

test

to definitely

locate the trouble before

going

to the effort of

removing

the signal switch. If, for example, the

right

rear

stop

light and right front parking light

are

inoperative and switch failure is indicated, first put the control lever in neutral position.

Then

disconnect the wire to the right side

circuit

and

touch it to or bridge it to the

"L"

terminal, thus

by-passing the signal switch. If the right side cir- 10609

FIG.

H-63—DIRECTIONAL SIGNAL

CIRCUIT

1—

Flasher

2—

Ignition

Switch

3—

Control

4—

Light

Switch

5— Stop

Light

Switch

216