seat adjustment JEEP DJ 1953 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 232 of 376

CLUTCH

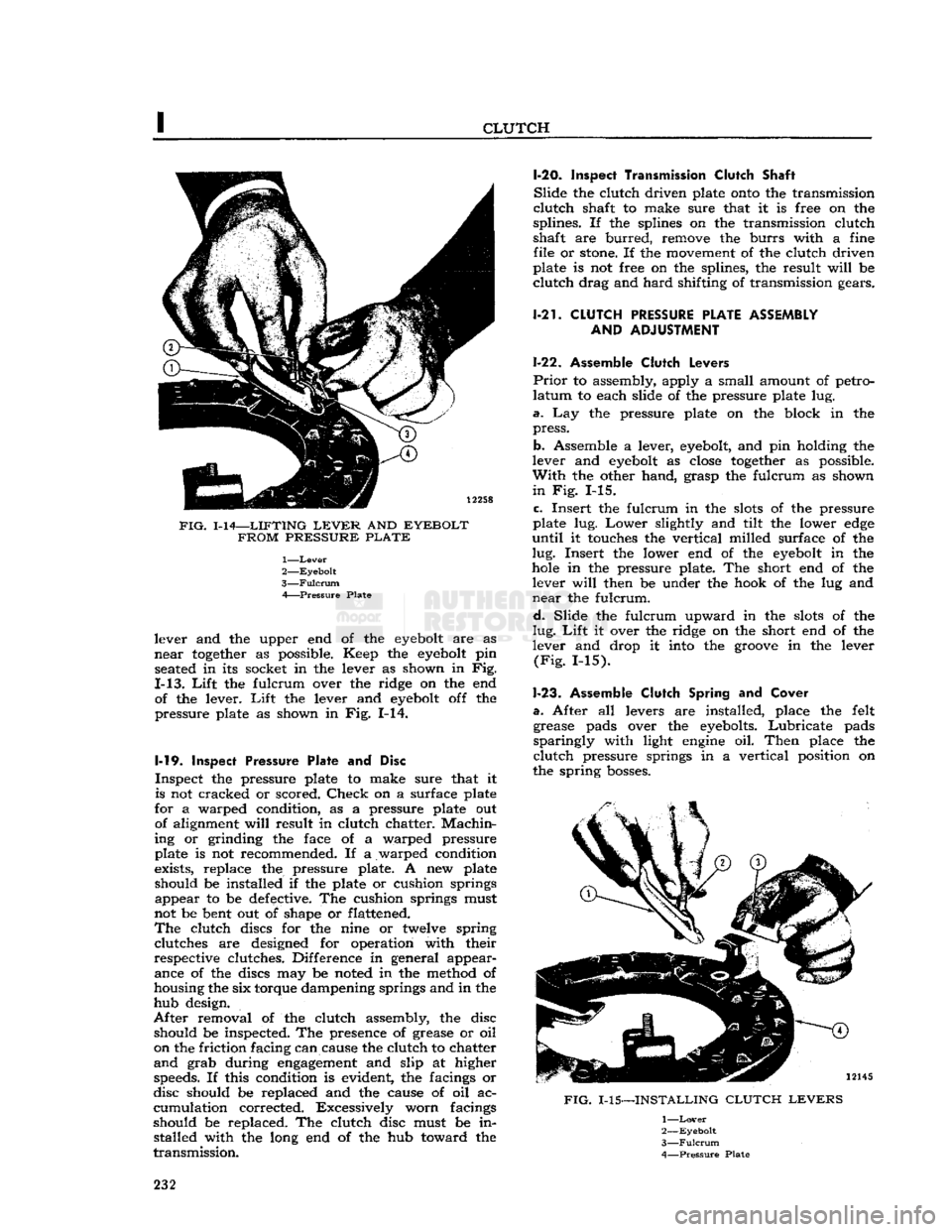

FIG.

1-14—LIFTING

LEVER

AND

EYEBOLT FROM PRESSURE PLATE

1—

Lever

2—

Eyebolt

3—

Fulcrum

A Pressure Plate

lever and the upper end of the

eyebolt

are as

near

together

as possible. Keep the

eyebolt

pin seated in its socket in the lever as shown in Fig.

1-13.

Lift

the fulcrum over the ridge on the end of the lever.

Lift

the lever and

eyebolt

off the

pressure plate as shown in Fig. 1-14.

1-19.

Inspect

Pressure Plate and Disc

Inspect the pressure plate to make sure that it is not cracked or scored.

Check

on a surface plate

for a warped condition, as a pressure plate out of alignment

will

result in clutch chatter.

Machin

ing or grinding the face of a warped pressure

plate is not recommended. If a warped condition

exists, replace the pressure plate. A new plate

should be installed if the plate or cushion springs appear to be defective. The cushion springs must

not be bent out of shape or flattened.

The

clutch discs for the nine or twelve spring clutches are designed for operation with their

respective clutches. Difference in general appear ance of the discs may be noted in the method of

housing the six torque dampening springs and in the

hub design.

After

removal of the clutch assembly, the disc should be inspected. The presence of grease or oil

on the friction facing can cause the clutch to chatter

and

grab during

engagement

and slip at higher speeds. If this condition is evident, the facings or

disc should be replaced and the cause of oil ac

cumulation corrected. Excessively worn facings

should be replaced. The clutch disc must be in stalled with the long end of the hub toward the

transmission.

1-20.

Inspect Transmission Clutch

Shaft

Slide

the clutch driven plate

onto

the transmission

clutch

shaft to make sure that it is free on the

splines. If the splines on the transmission clutch

shaft are

burred,

remove the

burrs

with a fine file or

stone.

If the movement of the clutch driven

plate is not free on the splines, the result

will

be

clutch

drag and

hard

shifting of transmission gears.

1-21.

CLUTCH

PRESSURE

PLATE ASSEMBLY AND

ADJUSTMENT

1-22. Assemble

Clutch

Levers

Prior

to assembly, apply a small amount of petro

latum

to each slide of the pressure plate lug.

a.

Lay the pressure plate on the block in the

press.

b. Assemble a lever,

eyebolt,

and pin holding the

lever and

eyebolt

as

close

together

as possible.

With

the other hand, grasp the fulcrum as shown

in

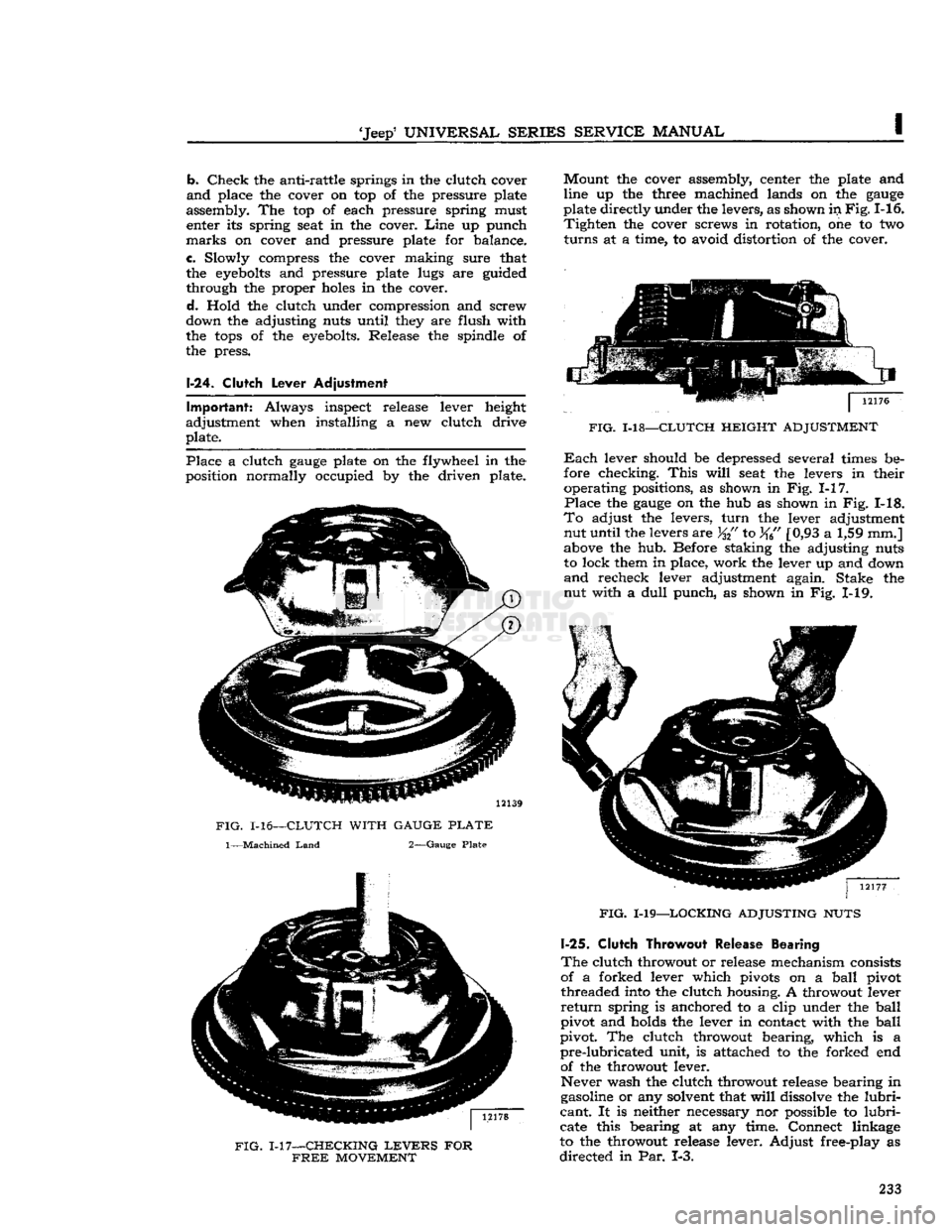

Fig. 1-15.

c.

Insert the fulcrum in the

slots

of the pressure

plate lug.

Lower

slightly and tilt the lower

edge

until

it touches the vertical milled surface of the

lug.

Insert the lower end of the

eyebolt

in the

hole

in the pressure plate. The short end of the lever

will

then be under the hook of the lug and

near

the fulcrum.

d.

Slide the fulcrum upward in the

slots

of the

lug.

Lift

it over the ridge on the short end of the

lever and drop it into the

groove

in the lever

(Fig.

1-15).

1-23.

Assemble

Clutch

Spring and

Cover

a.

After all levers are installed, place the felt grease pads over the eyebolts.

Lubricate

pads

sparingly

with light

engine

oil.

Then

place the

clutch

pressure springs in a vertical position on

the spring

bosses.

FIG.

1-15—INSTALLING

CLUTCH LEVERS

1—

Lover

2—

Eyebolt

3—

Fulcrum

4—

Pressure

Plate

232

Page 233 of 376

'Jeep*

UNIVERSAL SERIES

SERVICE

MANUAL

b.

Check

the anti-rattle springs in the clutch cover

and

place the cover on top of the pressure plate

assembly. The top of each pressure spring must enter its spring seat in the cover.

Line

up punch

marks

on cover and pressure plate for balance.

c.

Slowly compress the cover making sure that

the

eyebolts

and pressure plate lugs are guided through the proper

holes

in the cover.

d.

Hold the clutch under compression and screw

down the adjusting nuts until they are flush with

the

tops

of the eyebolts. Release the spindle of

the press.

1-24.

Clutch

Lever Adjustment

Important:

Always inspect release lever height

adjustment when installing a new clutch drive

plate.

Place

a clutch

gauge

plate on the flywheel in the

position normally occupied by the driven plate.

FIG.

1-16—CLUTCH WITH GAUGE

PLATE

1—Machined

Land

2—Gauge Plate

FIG.

1-17—CHECKING

LEVERS

FOR

FREE

MOVEMENT

Mount

the cover assembly, center the plate and

line up the three machined lands on the

gauge

plate directly under the levers, as shown in

Fig.

1-16.

Tighten

the cover screws in rotation, one to two

turns

at a time, to avoid distortion of the cover.

FIG.

1-18—CLUTCH HEIGHT ADJUSTMENT

Each

lever should be depressed several times be

fore checking.

This

will

seat the levers in their operating positions, as shown in Fig. 1-17.

Place

the

gauge

on the hub as shown in Fig. 1-18.

To

adjust the levers,

turn

the lever adjustment nut until the levers are

%{'

to %6" [0,93 a 1,59 mm.]

above the hub. Before staking the adjusting nuts

to lock them in place, work the lever up and down

and

recheck lever adjustment again. Stake the nut with a

dull

punch, as shown in Fig. 1-19.

FIG.

1-19—LOCKING ADJUSTING NUTS

1-25.

Clutch Throwout

Release Bearing

The

clutch throwout or release mechanism consists

of a forked lever which pivots on a

ball

pivot threaded into the clutch housing. A throwout lever

return

spring is anchored to a clip under the

ball

pivot and holds the lever in contact with the

ball

pivot. The clutch throwout bearing, which is a

pre-lubricated

unit, is attached to the forked end of the throwout lever.

Never wash the clutch throwout release bearing in

gasoline or any solvent that

will

dissolve the

lubri

cant.

It is neither necessary nor possible to

lubri

cate this bearing at any time. Connect linkage

to the throwout release lever. Adjust free-play as

directed

in Par. 1-3. 233

Page 235 of 376

![JEEP DJ 1953 Owners Manual

Jeep

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

sta JEEP DJ 1953 Owners Manual

Jeep

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

sta](/img/16/57041/w960_57041-234.png)

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

stamped thereon.

c.

From

flat bar stock at least Vfe" [3 mm.] thick,

make a

gauge

as shown in Fig. 1-22. Harden, grind

to size, and stamp sizes on the

gauge.

1-27.

Clutch Installation

a.

Very

sparingly, apply wheel bearing lubricant

to inner surface of pilot bushing in crankshaft.

Caution:

If

excessive

lubricant is applied to pilot bushing, it

will

run out on face of flywheel when

hot and

ruin

the driven plate facings.

b. Make sure that splines in the driven plate hub

are

clean; apply a light coat of lubricant to splines

of hub and transmission drive gear shaft. Slide plate over gear shaft several times; remove plate

from shaft and wipe off

excess

lubricant.

Caution:

Driven plate facings must be kept clean

and

dry.

c.

Fill

groove

in throwout bearing collar with wheel bearing lubricant. See Fig. 1-23. Make sure

that front bearing retainer of transmission is clean;

apply a light coat of wheel bearing lubricant. Slide

throwout bearing over bearing retainer several times. Remove bearing from retainer and wipe off

excess

lubricant.

12736

FIG.

1-23—LUBRICATION

POINTS

—

CLUTCH

THROWOUT

BEARING

COLLAR

1—Coat

This

Groove 2—Pack

This

Recess

d.

Clean

and apply wheel bearing lubricant to ball

stud in flywheel housing and to the

seat

in clutch

fork.

e.

If disassembled, install pressure plate in the cover assembly, lining up the

groove

on its

edge

with the

groove

on the

edge

of the cover.

Install

pressure plate retracting springs, and the three

drive

strap-to-pressure plate

bolts

and lock washers.

Torque

bolts

11 lb-ft. [1,51 kg-m.].

Note:

The diaphragm

type

clutch assembly is fac

tory calibrated and requires no adjustment

before

installation. Refer to Par. 1-14 to adjust Borg and

Beck

coil spring

type

clutch assembly.

f.

Install

the pressure plate and driven plate on

flywheel. Support both assemblies with a spare

main

drive gear.

Note:

Be certain that

mark

on clutch cover is

aligned with the

mark

made on the flywheel during

clutch removal.

g.

Install

clutch attaching

bolts

and tighten alter nately so that clutch is drawn squarely

into

position

on flywheel.

Each

bolt

must be

tightened

one turn at a time to avoid bending the clutch cover flange.

Torque

bolts

30 to 40 lb-ft. [4,1 a 5,5 kg-m.].

h.

Lubricate

the ball stud and clutch fork with

wheel bearing lubricant and install clutch fork.

Note:

Be certain that fork retaining spring is

tight

on pivot ball stud.

i.

Install

flywheel housing on

engine

cylinder

block.

Caution:

Be certain that dowel pins are installed

in

cylinder block.

j.

Lubricate

the recess on the inside of the throw-

out bearing collar. Be careful not to use too much

lubricant.

See Fig. 1-23.

Caution:

Make certain that the lips of the spring

retainer (attached to the clutch fork) are in

groove

of the bearing. See Fig. 1-24.

k.

Install

throwout bearing assembly and connect

clutch linkage.

I.

Install

transmission as described in Section J. m. Adjust clutch for %"

[19,05

mm.] free travel,

see

Par.

1-3. 235

Page 270 of 376

K

TRANSFER

CASE

FIG.

K-3—UNIVERSAL JOINT FLANGE

PULLER

1—

U-Joint

Flange

Puller

W-172

2—

V-Joint

Flange Holding

Wrench

C-3281

FIG.

K-4—TRANSFER CASE SHIFT LINKAGE

CJ-5A,

CJ-6A

1—Linkage

Adjustment

loosen

the gear and remove the gear. When separat

ing the two housings, use care that the transmission

main

shaft bearing, which bears in both housings,

remains

in the transmission case.

K-3.

Transfer

Case

Disassembly

•

Refer to Fig. K-1, K-2.

To

remove the gears and bearings from the trans

fer

case on the bench, the following procedure is

recommended.

a.

Remove output shaft nuts and washers using

Yoke

Holding

Wrench,

C-3281. Remove

rear

out

put shaft companion flange with brake drum (if

FIG.

K-5—BEARING CONE REMOVING WEDGE

1— Wedge W-139

2—

Cone

and

Roller

so equipped) and front output shaft yoke, using

Tool

W-172.

b.

Remove cover bolts, lockwashers, and

bottom

cover.

c.

Remove the lockplate screw, lockwasher, and

lock

plate.

d.

Use a brass punch to drive out intermediate shaft to the

rear

of the case. Do not

lose

the thrust

washers located at each end of the gear shaft.

e. Remove the intermediate gear, two thrust

washers,

needle

bearings, and spacers,

thru

the

bottom

of the case.

f. Remove the

poppet

plugs, springs, and balls on both sides of front bearing cap. Shift front wheel

shift lever to

engaged

position (shaft forward).

g. Remove the screws, lockwashers, holding the front bearing cap. Remove the cap as an assembly

including

the clutch shaft, bearing, clutch gear,

fork,

and shift rod. Use care not to

lose

the inter

lock

which floats

between

the shift rods.

h.

Remove the screws, lockwashers holding the

brake

backing plate assembly (if so equipped)

and

rear

output cap with

speedometer

gear as

sembly. Remove entire unit as an assembly.

i.

Use a rawhide hammer to drive against the front

end of output shaft to drive the

rear

bearing cup

from

the case. Use Tool W-139, as shown in Fig.

K-5,

to

wedge

front bearing

cone

and roller as

sembly from its seat on the shaft. Place Tool

W-141,

Fig. K-6, on the output shaft

between

the

front bearing and output shaft gear. Use a rawhide

hammer

to drive against the

rear

end of the output shaft to remove front bearing cup from the case.

Loosen

snap ring and slide it forward on the shaft.

Drive

the shaft

thru

the

rear

of the case. As the shaft is removed, gears, snap

ring,

and thrust washer

will

remain in the case and can be removed from 270

Page 278 of 376

M

FRONT

AXLE

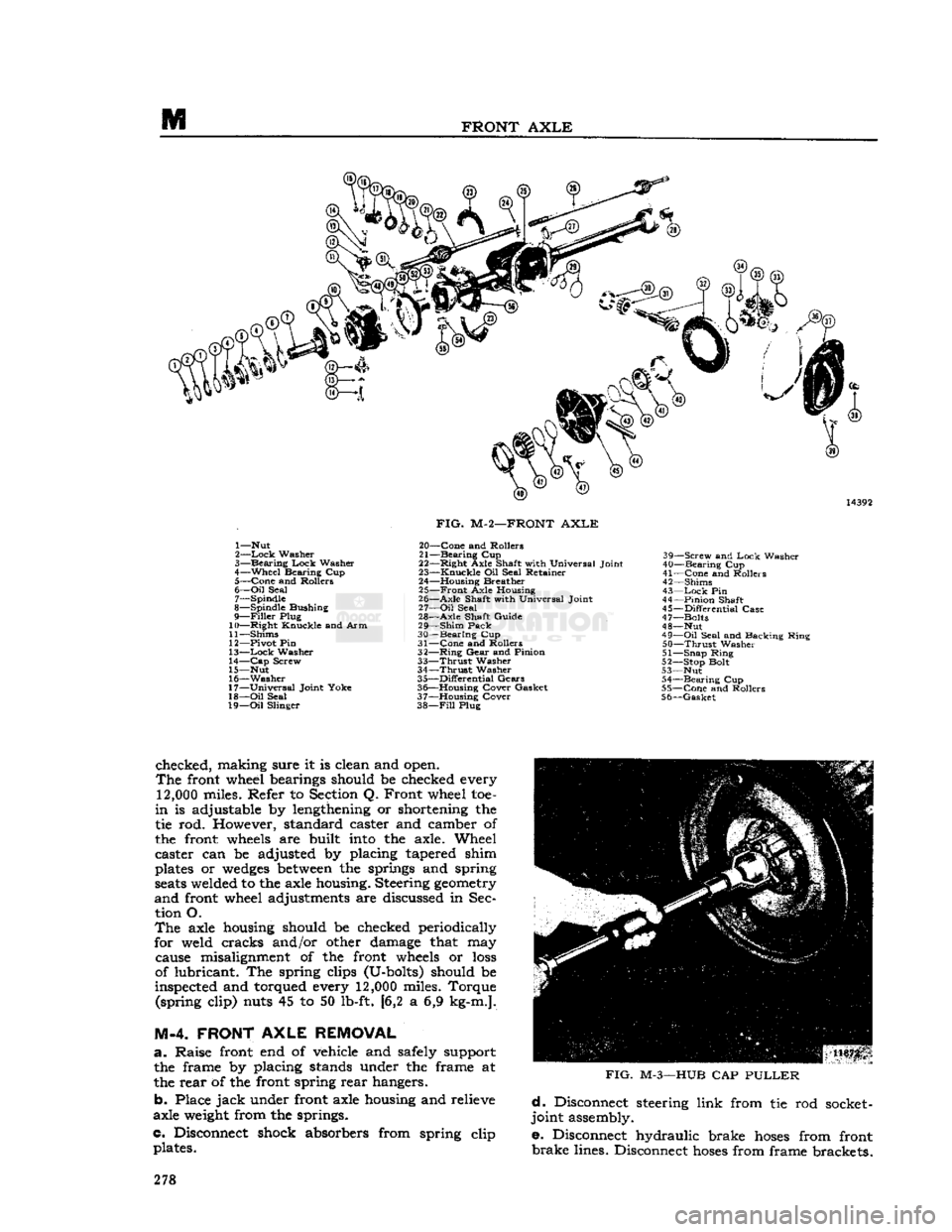

1— Nut

2—

Lock

Washer

3—

Bearing

Lock

Washer

4—

Wheel

Bearing Cup 5—

Cone

and Rollers

6—

Oil

Seal 7— Spindle

8— Spindle Bushing

9—

Filler

Plug

10—

Right

Knuckle and Arm

11— Shims

12— Pivot Pin

13—

Lock

Washer

14—

Cap

Screw

15— Nut

16—

Washer

17—

Universal

Joint Yoke

18—

Oil

Seal

19—

Oil

Slinger

FIG.

M-2—FRONT

AXLE

20—

Cone

and Rollers

21—

Bearing

Cup

22—

Right

Axle Shaft with Universal Joint

23—

Knuckle

Oil Seal Retainer

24— Housing Breather 25—

Front

Axle Housing

26—

Axle

Shaft with Universal Joint

27—

Oil

Seal

28—

Axle

Shaft Guide

29—

Shim

Pack

30—

Bearing

Cup

31—

Cone

and Rollers

32—

Ring

Gear

and Pinion

33—

Thrust

Washer

34—

Thrust

Washer

35—

Differential

Gears

36— Housing Cover Gasket

37— Housing Cover

38—

Fill

Plug 39—

Screw

and

Lock

Washer

40—

Bearing

Cup

41—

Cone

and Rollers

42— Shims

43—

Lock

Pin

44—

Pinion

Shaft

45—

Differential

Case

47— Bolts

48— Nut

49—

Oil

Seal and Backing Ring

50—

Thrust

Washer

51— Snap Ring

52— Stop Bolt

53— Nut 54—

Bearing

Cup

55—

Cone

and Rollers

56—

Gasket

checked, making sure it is clean and open.

The

front wheel bearings should be checked every

12,000

miles. Refer to Section Q. Front wheel toe-

in

is adjustable by lengthening or shortening the

tie rod. However, standard caster and camber of

the front

wheels

are built

into

the axle. Wheel

caster can be adjusted by placing tapered shim

plates or

wedges

between

the springs and spring

seats

welded to the axle housing. Steering

geometry

and

front wheel adjustments are discussed in Sec tion O.

The

axle housing should be checked periodically

for weld cracks and/or other damage that may cause misalignment of the front

wheels

or

loss

of lubricant. The spring clips (U-bolts) should be

inspected and torqued every

12,000

miles. Torque (spring clip) nuts 45 to 50 lb-ft. [6,2 a 6,9 kg-m.].

M-4. FRONT

AXLE

REMOVAL

a.

Raise front end of vehicle

arid

safely support the frame by placing stands under the frame at

the rear of the front spring rear hangers.

b. Place

jack

under front axle housing and relieve

axle

weight

from the springs.

c. Disconnect shock absorbers from spring clip plates.

FIG.

M-3—HUB

CAP

PULLER

d.

Disconnect steering link from tie rod socket-

joint assembly.

e. Disconnect hydraulic brake

hoses

from front

brake

lines. Disconnect

hoses

from frame brackets. 278

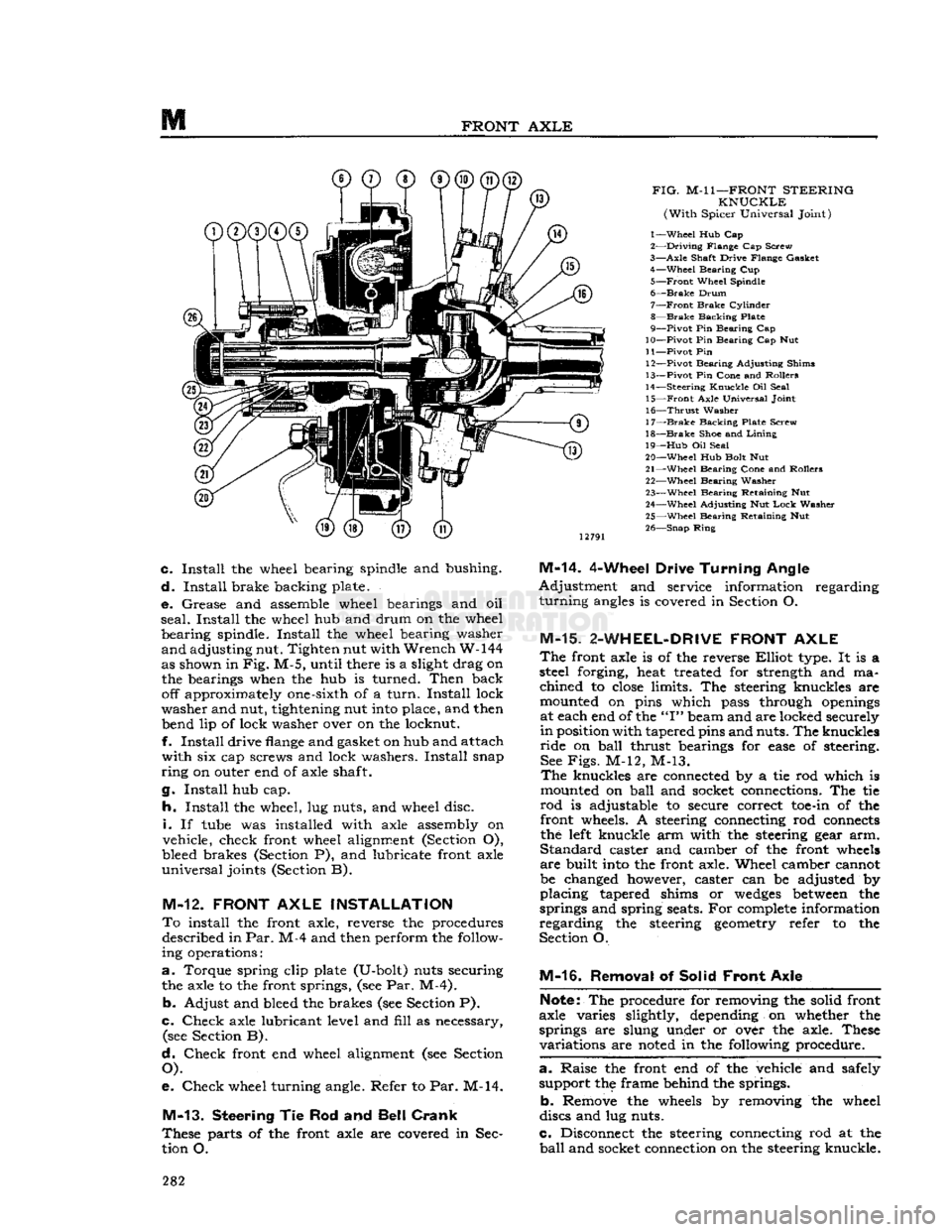

Page 282 of 376

FRONT

AXLE

FIG.

M-l

1—FRONT

STEERING

KNUCKLE

(With

Spicer Universal Joint)

1—

Wheel

Hub Cap

2—

Driving

Flange Cap Screw

3—

Axle

Shaft Drive Flange Gasket 4—

Wheel

Bearing Cup

5—

Front

Wheel Spindle

6—

Brake

Drum

7—

Front

Brake

Cylinder

8—

Brake

Backing Plate

9—

Pivot

Pin Bearing Cap

10—

Pivot

Pin Bearing Cap Nut

11—

Pivot

Pin 12—

Pivot

Bearing Adjusting Shims

13—

Pivot

Pin Cone and Rollers

14—

Steering

Knuckle

Oil Seal 15—

Front

Axle Universal Joint

16—

Thrust

Washer

17—

Brake

Backing Plate Screw

18—

Brake

Shoe and

Lining

19—

Hub

Oil Seal

20—

Wheel

Hub Bolt Nut

21—

Wheel

Bearing Cone and Rollers 22—

Wheel

Bearing Washer

23—

Wheel

Bearing Retaining Nut

24—

Wheel

Adjusting Nut

Lock

Washer

25—

Wheel

Bearing Retaining Nut

26—

Snap

Ring

c.

Install

the wheel bearing spindle and bushing.

d.

Install

brake backing plate.

e.

Grease and assemble wheel bearings and oil

seal.

Install

the wheel hub and drum on the wheel

bearing

spindle.

Install

the wheel bearing washer

and

adjusting nut. Tighten nut with

Wrench

W-144

as shown in

Fig.

M-5, until there is a slight drag on the bearings when the hub is turned.

Then

back off approximately one-sixth of a

turn.

Install

lock

washer

and nut, tightening nut

into

place, and then bend lip of lock washer over on the locknut.

f.

Install

drive

flange

and gasket on hub and attach

with

six cap screws and lock washers.

Install

snap

ring

on outer end of axle shaft.

g.

Install

hub cap.

h.

Install

the wheel, lug nuts, and wheel disc.

i.

If

tube

was installed with axle assembly on

vehicle, check front wheel alignment (Section O),

bleed brakes (Section P), and lubricate front axle

universal

joints (Section B).

M-12.

FRONT

AXLE

INSTALLATION

To

install the front axle, reverse the procedures described in

Par.

M-4 and then perform the follow

ing operations:

a.

Torque spring clip plate (U-bolt) nuts securing the axle to the front springs, (see Par. M-4).

b.

Adjust and bleed the brakes (see Section P).

c.

Check

axle lubricant level and

fill

as necessary, (see Section B).

d.

Check

front end wheel alignment (see Section

O).

e.

Check

wheel turning angle. Refer to Par. M-14.

M-13.

Steering

Tie Rod and

Bell Crank

These

parts of the front axle are covered in Sec

tion O.

M-14.

4-Wheel Drive

Turning

Angle

Adjustment

and service information regarding

turning

angles

is covered in Section O.

M-15.

2-WHEEL-DRIVE

FRONT

AXLE

The

front axle is of the reverse

Elliot

type. It is a

steel forging, heat treated for strength and ma

chined

to

close

limits. The steering knuckles are

mounted on pins which pass through

openings

at each end of the

"I"

beam and are locked securely

in

position with tapered pins and nuts. The knuckles

ride

on

ball

thrust bearings for

ease

of steering. See

Figs.

M-12, M-13.

The

knuckles are connected by a tie rod which is

mounted on

ball

and socket connections. The tie

rod

is adjustable to secure correct

toe-in

of the front wheels. A steering connecting rod

connects

the

left

knuckle arm with the steering gear arm.

Standard

caster and camber of the front

wheels

are

built

into

the front axle. Wheel camber cannot

be changed however, caster can be adjusted by

placing

tapered shims or

wedges

between

the

springs and spring seats. For

complete

information

regarding

the steering

geometry

refer to the

Section O.

M-16.

Removal of Solid

Front

Axle

Note:

The procedure for removing the solid front

axle varies slightly, depending on whether the

springs are slung under or over the axle. These

variations

are

noted

in the following procedure.

a. -

Raise the front end of the vehicle and safely support the frame behind the springs.

b.

Remove the

wheels

by removing the wheel

discs and lug nuts.

c.

Disconnect the steering connecting rod at the

ball

and socket connection on the steering knuckle. 282

Page 297 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

N

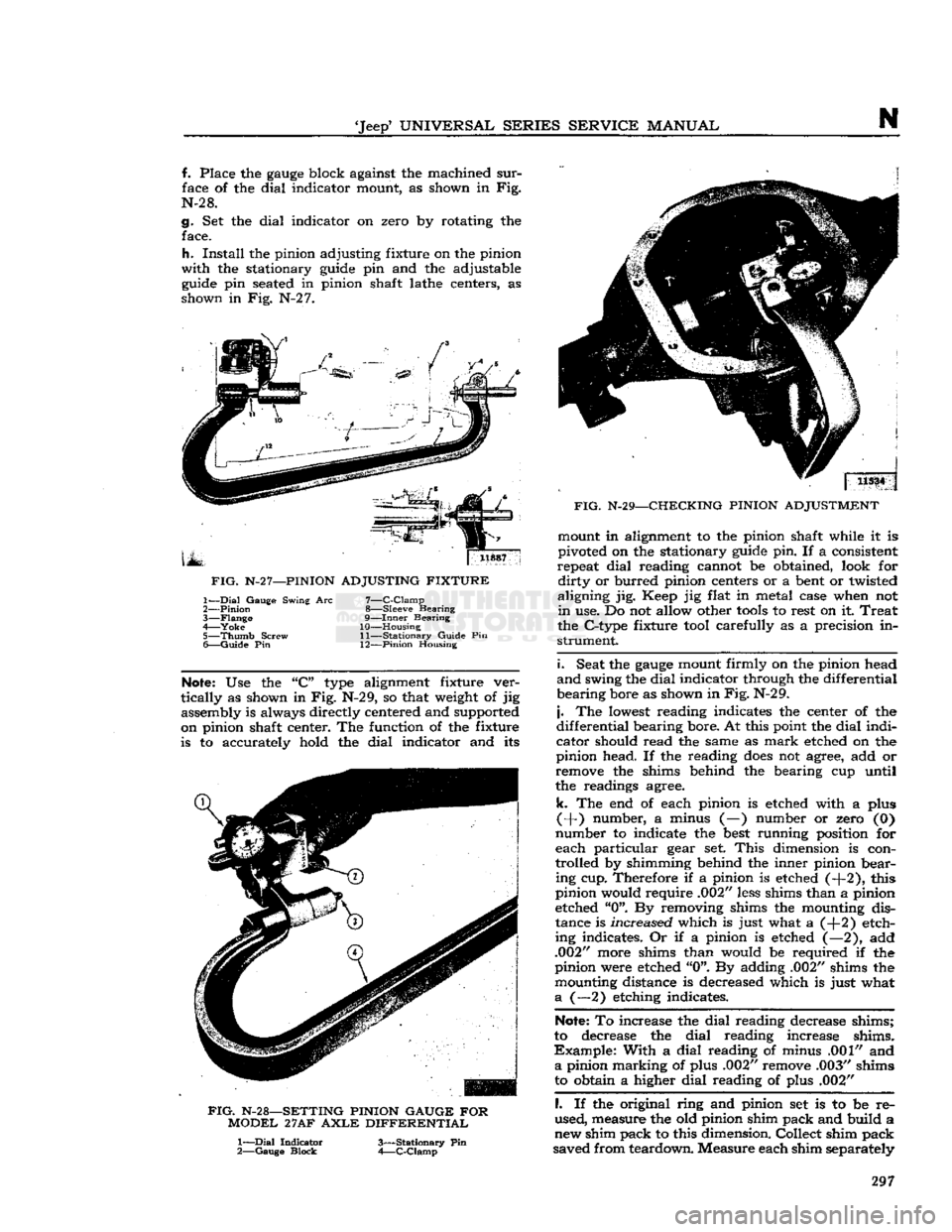

f. Place the

gauge

block against the machined

sur

face of the dial indicator mount, as shown in Fig.

N-2 8.

g. Set the dial indicator on zero by rotating the face.

h.

Install

the pinion adjusting fixture on the pinion

with

the stationary

guide

pin and the adjustable

guide

pin

seated

in pinion shaft lathe centers, as

shown in Fig. N-2 7.

FIG.

N-2

7—PINION

ADJUSTING FIXTURE

7—

C-Clamp

8— Sleeve Bearing

9—

Inner

Bearing

10— Housing 11—

Stationary

Guide Pin

1—

Dial

Gauge Swing Arc

2—

Pinion

3—

Flange

4—

Yoke

5—

Thumb

Screw

6—

Guide

Pin 12—Pinion Housing

Note:

Use the "C"

type

alignment fixture ver

tically

as shown in Fig. N-29, so that

weight

of jig assembly is always directly centered and supported

on pinion shaft center. The function of the fixture is to accurately hold the dial indicator and its

FIG.

N-28—SETTING

PINION

GAUGE FOR

MODEL

27AF

AXLE

DIFFERENTIAL

1—

Dial

Indicator

2—

Gauge

Block

3—

Stationary

Pin

4—

C-Clamp

j

11534 j

FIG.

N-29—CHECKING

PINION

ADJUSTMENT mount in alignment to the pinion shaft while it is

pivoted on the stationary

guide

pin. If a consistent

repeat dial reading cannot be obtained, look for

dirty

or burred pinion centers or a

bent

or twisted

aligning jig. Keep jig flat in metal case when not

in

use. Do not allow other

tools

to rest on it

Treat

the C-type fixture

tool

carefully as a precision in

strument.

i.

Seat the

gauge

mount firmly on the pinion head

and

swing the dial indicator through the differential

bearing bore as shown in

Fig.

N-29.

j.

The

lowest

reading indicates the center of the

differential bearing bore. At this point the dial indi

cator should read the same as

mark

etched on the

pinion head. If the reading

does

not agree, add or

remove the shims behind the bearing cup until

the readings agree.

k.

The end of each pinion is etched with a plus

(+) number, a minus (—) number or zero (0)

number to indicate the

best

running position for

each particular gear set.

This

dimension is con

trolled by shimming behind the inner pinion bear ing cup. Therefore if a pinion is etched (-f-2), this

pinion would require .002"

less

shims than a pinion

etched "0". By removing shims the mounting dis

tance is increased which is just what a (+2) etch

ing indicates. Or if a pinion is etched (—2), add

.002" more shims than would be required if the

pinion were etched "0". By adding .002" shims the mounting distance is decreased which is just what

a

(—2) etching indicates.

Note:

To increase the dial reading decrease shims;

to decrease the dial reading increase shims.

Example:

With a dial reading of minus .001" and

a

pinion marking of plus .002" remove .003" shims

to obtain a higher dial reading of plus .002"

I.

If the original ring and pinion set is to be re

used, measure the old pinion shim pack and build a

new shim pack to this dimension. Collect shim pack

saved from teardown. Measure each shim separately 297

Page 314 of 376

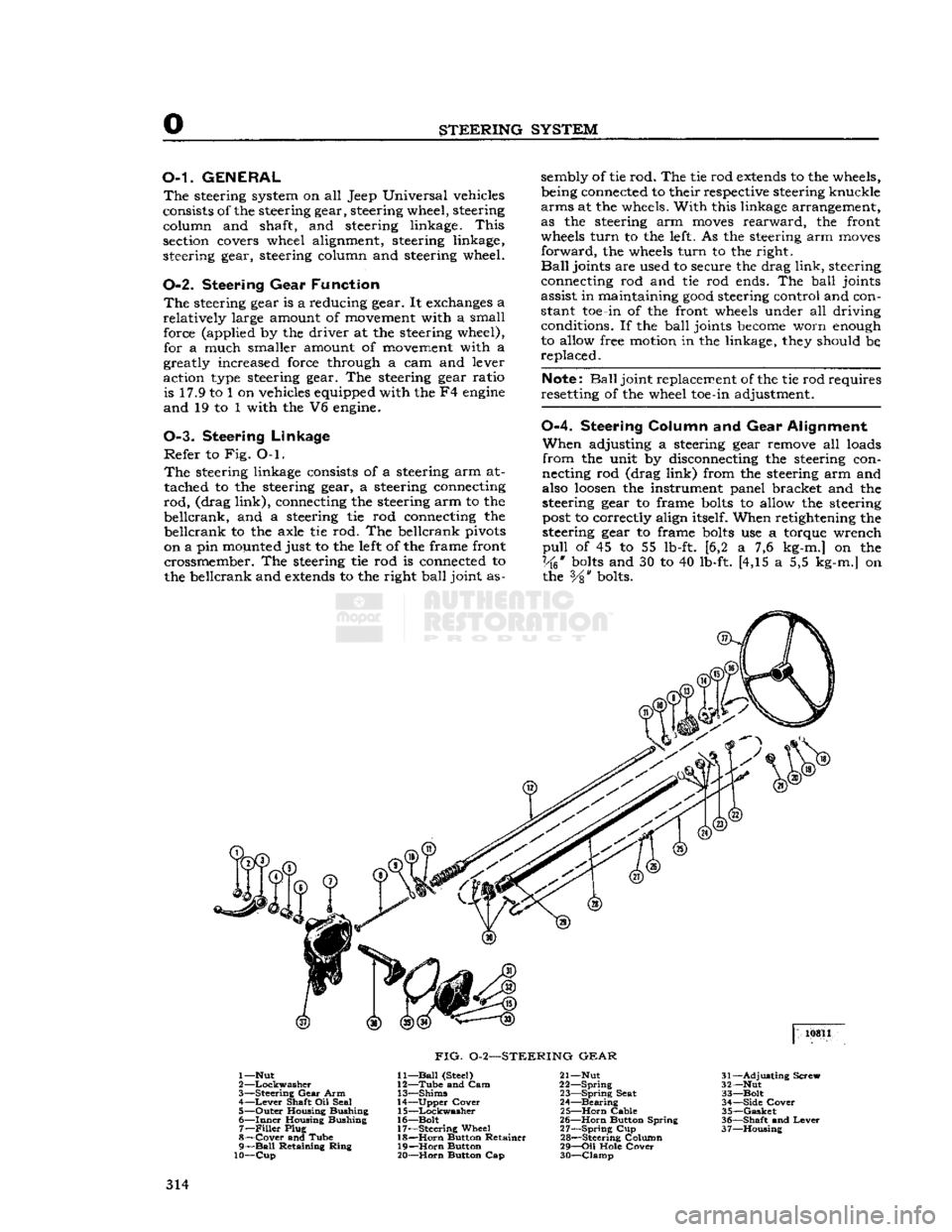

STEERING

SYSTEM

O-L

GENERAL

The

steering system on all Jeep Universal vehicles

consists of the steering gear, steering wheel, steering column and shaft, and steering linkage.

This

section covers wheel alignment, steering linkage,

steering gear, steering column and steering wheel.

0-2. Steering

Gear

Function

The

steering gear is a reducing gear. It exchanges a

relatively

large amount of movement with a small force (applied by the driver at the steering wheel), for a much smaller amount of movement with a

greatly increased force through a cam and lever

action type steering gear. The steering gear ratio is 17.9 to 1 on vehicles equipped with the F4

engine

and

19 to 1 with the V6 engine.

0-3. Steering

Linkage

Refer

to Fig. O-l.

The

steering linkage consists of a steering arm at

tached to the steering gear, a steering connecting

rod,

(drag

link),

connecting the steering arm to the

beilcrank,

and a steering tie rod connecting the

beilcrank

to the axle tie rod. The beilcrank pivots

on a pin mounted just to the left of the frame front crossmember. The steering tie rod is connected to

the beilcrank and

extends

to the right

ball

joint as sembly of tie rod. The tie rod

extends

to the wheels,

being connected to their respective steering knuckle

arms

at the wheels.

With

this linkage arrangement,

as the steering arm

moves

rearward,

the front

wheels

turn

to the left. As the steering arm

moves

forward,

the wheels

turn

to the right.

Ball

joints are used to secure the drag

link,

steering

connecting rod and tie rod ends. The

ball

joints

assist in maintaining

good

steering control and con

stant toe-in of the front wheels under all driving conditions. If the

ball

joints

become

worn enough

to allow free motion in the linkage, they should be,

replaced.

Note:

Ball

joint replacement of the tie rod requires

resetting of the wheel toe-in adjustment.

0-4.

Steering

Column

and Gear

Alignment

When

adjusting a steering gear remove all loads

from

the unit by disconnecting the steering con

necting rod (drag

link)

from the steering arm and

also

loosen

the instrument panel bracket and the

steering gear to frame

bolts

to allow the steering

post

to correctly align itself. When retightening the

steering gear to frame

bolts

use a torque wrench

pull

of 45 to 55 lb-ft. [6,2 a 7,6 kg-m.] on the

Vk*

bolts

and 30 to 40 lb-ft. [4,15 a 5,5 kg-m.] on the

Vs"

bolts. 10811

FIG.

0-2—STEERING

GEAR

1—Nut

2

—Lockwasher

3—

Steering

Gear

Arm 4—

Lever

Shaft Oil Seal

5—

Outer

Housing Bushing

6—

Inner

Housing Bushing 7—

Filler

Plug

8—

Cover

and Tube

9—

Ball

Retaining

Ring

10—Cup

11—

Ball

(Steel)

12—

Tube

and Cam

13—

Shims

14—

Upper

Cover

15—

Lockwasher

16—

Bolt

17—

Steering

Wheel 18—

Horn

Button Retainer

19—

Horn

Button

20—

Horn

Button Cap 21— Nut

22—

Spring

23—

Spring

Seat

24—

Bearing

25—

Horn

Cable

26—

Horn

Button Spring

27—

Spring

Cup

28—

Steering Column

29—

Oil

Hole

Cover

30—

Clamp

31—

Adjusting

Screw

32— Nut

33—

Bolt

34—

Side

Cover

35—

Gasket

36—

Shaft

and

Lever

37—

Housing

314

Page 318 of 376

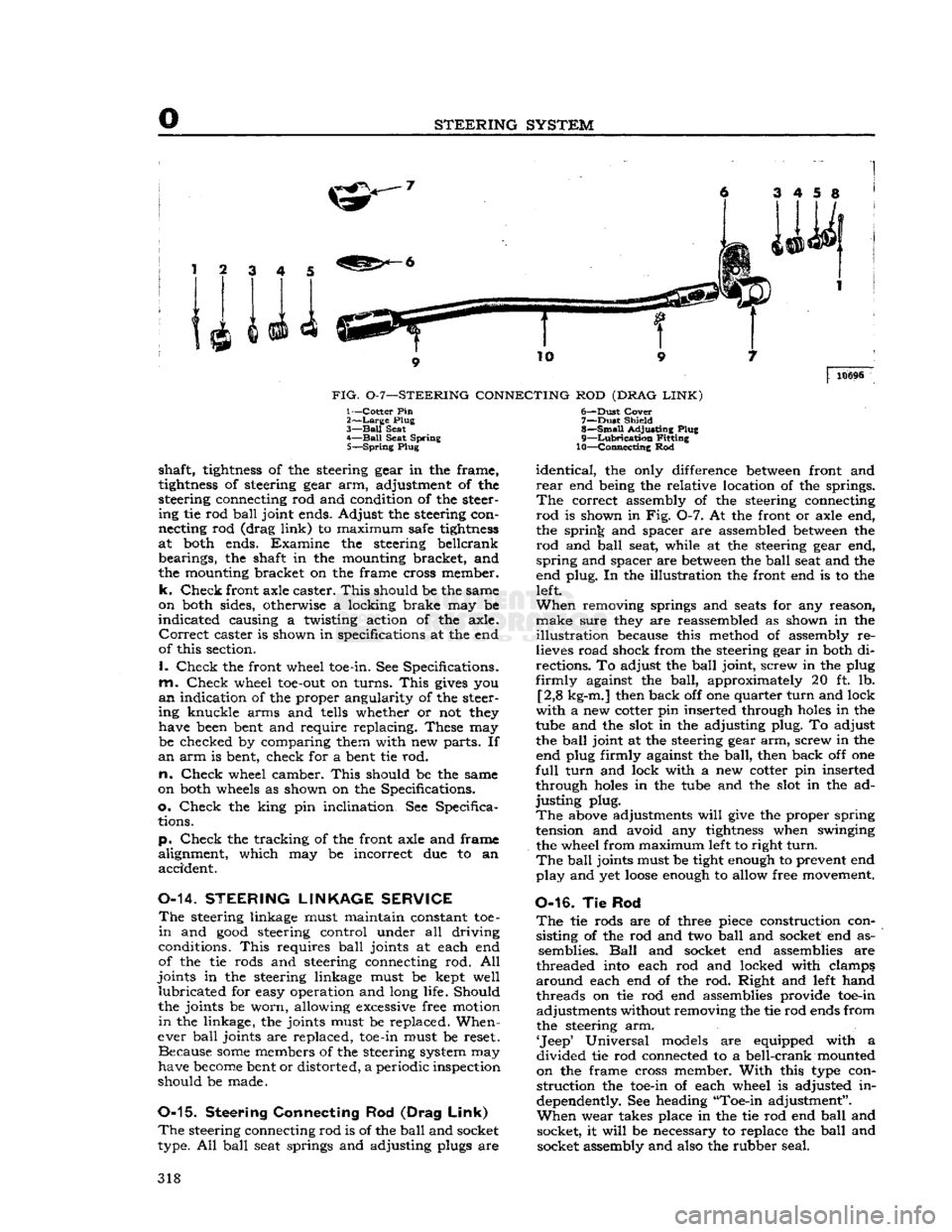

o

STEERING

SYSTEM

10

FIG.

0-7—STEERING

CONNECTING

ROD

(DRAG

LINK)

10696

1—Cotter Pin

2>—Large

Plug

3—

Ball

Seat

4—

Ball

Seat Spring 5—

Spring

Plug

shaft,

tightness

of the steering gear in the frame,

tightness

of steering gear arm, adjustment of the

steering connecting rod and condition of the steer ing tie rod

ball

joint ends. Adjust the steering con

necting rod (drag

link)

to maximum safe

tightness

at both ends. Examine the steering beilcrank bearings, the shaft in the mounting bracket, and

the mounting bracket on the frame cross member,

k.

Check

front axle caster.

This

should be the same

on both sides, otherwise a locking brake may be

indicated

causing a twisting action of the axle.

Correct

caster is shown in specifications at the end

of this section.

I.

Check

the front wheel toe-in. See Specifications,

m.

Check

wheel

toe-out

on turns.

This

gives

you

an

indication of the proper angularity of the steer

ing knuckle arms and tells whether or not they have been bent and require replacing. These may be checked by comparing them with new parts. If

an

arm is bent, check for a bent tie rod.

n.

Check

wheel camber.

This

should be the same

on both wheels as shown on the Specifications,

o.

Check

the king pin inclination. See Specifica tions.

p.

Check

the tracking of the front axle and frame

alignment, which may be incorrect due to an accident.

0-14.

STEERING

LINKAGE

SERVICE

The

steering linkage must maintain constant toe-

in

and

good

steering control under all driving

conditions.

This

requires

ball

joints at each end

of the tie rods and steering connecting rod. All

joints in the steering linkage must be kept well

lubricated

for easy operation and long life. Should

the joints be worn, allowing excessive free motion

in

the linkage, the joints must be replaced. When

ever

ball

joints are replaced, toe-in must be reset. Because

some

members of the steering system may

have

become

bent or distorted, a periodic inspection

should be made.

0-15.

Steering Connecting

Rod

(Drag

Link)

The

steering connecting rod is of the

ball

and socket

type. All

ball

seat springs and adjusting plugs are 6—

-Dust

Cover

7—

Dust

Shield

8—

Small

Adjusting Plug

9—

Lubrication

Fitting

10—Connecting Rod

identical,

the only difference

between

front and

rear

end being the relative location of the springs.

The

correct assembly of the steering connecting

rod

is shown in Fig. 0-7. At the front or axle end,

the spring and spacer are assembled

between

the

rod

and

ball

seat, while at the steering gear end,

spring

and spacer are

between

the

ball

seat and the

end plug. In the illustration the front end is to the left.

When

removing springs and

seats

for any reason,

make

sure they are reassembled as shown in the

illustration

because this method of assembly re

lieves road shock from the steering gear in both di

rections. To adjust the

ball

joint, screw in the plug

firmly

against the

ball,

approximately 20 ft. lb. [2,8 kg-m.] then back off one quarter

turn

and lock

with

a new cotter pin inserted through

holes

in the

tube and the slot in the adjusting plug. To adjust the

ball

joint at the steering gear arm, screw in the end plug firmly against the

ball,

then back off one

full

turn

and lock with a new cotter pin inserted

through

holes

in the tube and the slot in the ad

justing

plug.

The

above adjustments

will

give

the proper spring

tension and avoid any

tightness

when swinging

the wheel from maximum left to right

turn.

The

ball

joints must be tight enough to prevent end

play

and yet

loose

enough to allow free movement.

0-16. Tie Rod

The

tie rods are of three piece construction consisting of the rod and two

ball

and socket end as semblies.

Ball

and socket end assemblies are

threaded into each rod and locked with clamps,

around

each end of the rod. Right and left hand threads on tie rod end assemblies provide toe-in adjustments without removing the tie rod ends from

the steering arm.

'Jeep'

Universal models are equipped with a

divided

tie rod connected to a bell-crank mounted

on the frame cross member.

With

this type con

struction

the toe-in of each wheel is adjusted in

dependently. See heading "Toe-in adjustment".

When

wear takes place in the tie rod end

ball

and socket, it

will

be necessary to replace the

ball

and socket assembly and also the rubber seal. 318

Page 331 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

P

f. On vehicles without a transmission brake hold

the brake

shoes

in their relative position and

engage

the parking brake cable

into

the parking

brake

lever.

g. On vehicles without a transmission brake in

stall

the parking brake strut and spring

between

the parking brake lever and the primary

shoe.

h.

Place the brake

shoes

on the backing plate and

install

the retainer pins, springs and retainers.

i.

Install the anchor pin plate.

j.

Install the lever and

sleeve

on the primary

shoe

then install the secondary return spring, then the

primary

return spring.

Important:

A

"L"

or "R" is located on the hex

agon

side of the lever crank for identification. The

lever crank marked "R" applies to the primary

shoe

on the

left

rear brake assembly. The lever

crank

marked

"L"

applies to the primary

shoe

on

the right rear brake assembly.

k. Place the upper linkage rod in the

groove

of the

anchor pin and

engage

the hook of the link rod

into

the adjusting lever.

I.

Install the brake drum. Install the wheel and

tire

assembly.

m. Adjust the brakes as described

below.

P-19.

Brake

Shoe

Initial

Adjustment —

a.

Should wheel brake units have

been

disassem bled for any reason, an initial adjustment

MUST

be made

before

drum installation.

b.

When the brake parts have

been

installed in

their correct position, initially adjust the adjusting

screw assemblies to a point where approximately Y% [9,53 mm.] of threads are

exposed

between

the

star

wheel and star wheel nut.

Note:

Following the initial adjustment and final

assembly, check brake pedal height to ensure

brake

operation. Then drive the car in reverse and

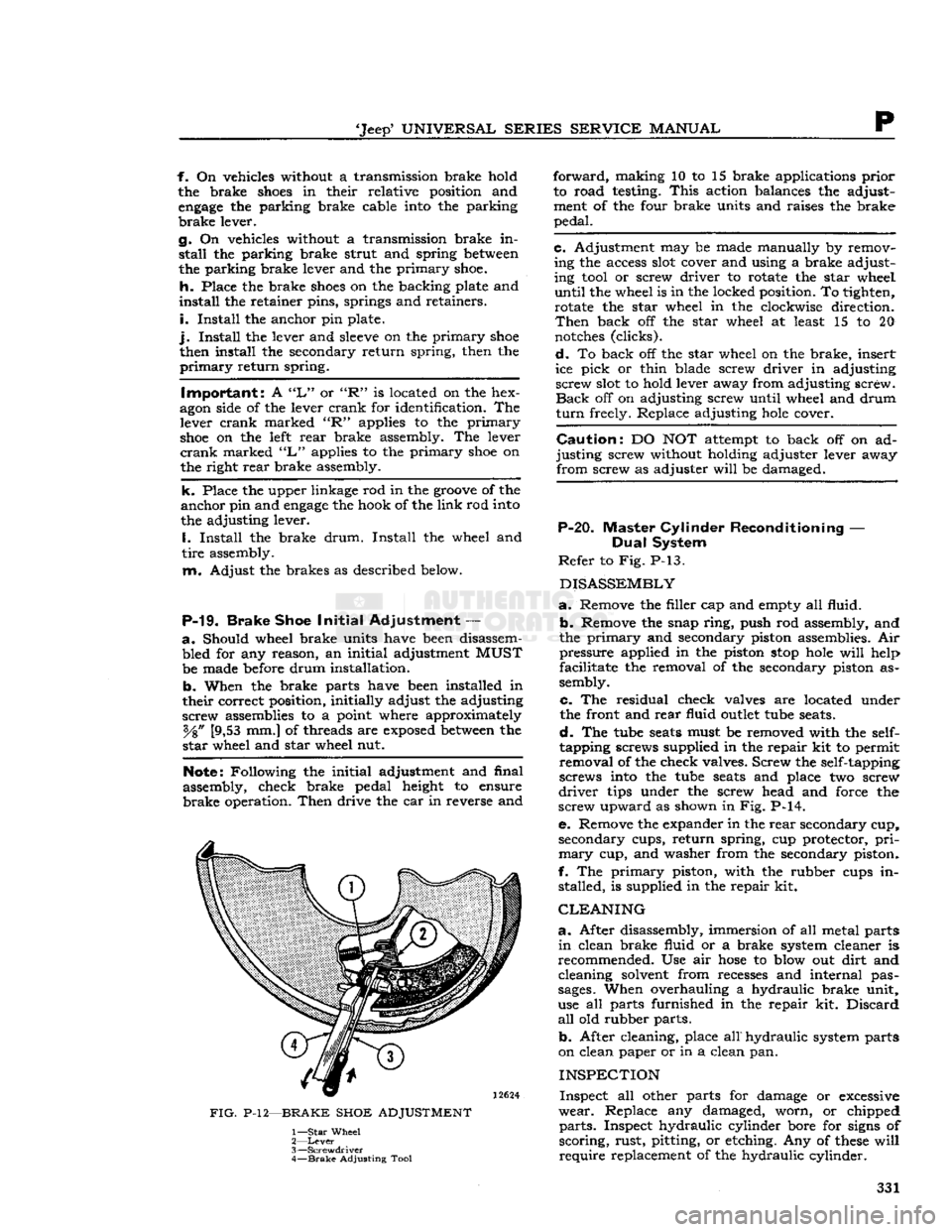

FIG.

P-12—BRAKE SHOE ADJUSTMENT

1—

Star

Wheel

2—

Lever

3—

Screwdriver

4—

Brake

Adjusting Tool

forward,

making 10 to 15 brake applications prior

to road testing.

This

action balances the adjust

ment of the four brake units and raises the brake

pedal.

c. Adjustment may be made manually by removing the access

slot

cover and using a brake adjust

ing

tool

or screw driver to rotate the star wheel

until

the wheel is in the locked position. To tighten, rotate the star wheel in the clockwise direction.

Then

back off the star wheel at least 15 to 20

notches

(clicks).

d.

To back off the star wheel on the brake, insert

ice pick or thin blade screw driver in adjusting screw

slot

to hold lever away from adjusting screw.

Back

off on adjusting screw until wheel and drum

turn

freely. Replace adjusting

hole

cover.

Caution:

DO NOT attempt to back off on ad

justing screw without holding adjuster lever away from screw as adjuster

will

be damaged.

P-20. Master Cylinder Reconditioning —

Dual

System

Refer

to Fig. P-13.

DISASSEMBLY

a.

Remove the filler cap and empty all fluid.

b.

Remove the snap ring, push rod assembly, and

the primary and secondary piston assemblies. Air pressure applied in the piston

stop

hole

will

help

facilitate the removal of the secondary piston as

sembly.

c. The residual check valves are located under

the front and rear fluid

outlet

tube

seats.

d.

The

tube

seats

must be removed with the

self-

tapping screws supplied in the repair kit to permit removal of the check valves. Screw the self-tapping

screws

into

the

tube

seats

and place two screw

driver

tips under the screw head and force the

screw upward as shown in Fig. P-14.

e. Remove the expander in the rear secondary cup, secondary cups, return spring, cup protector,

pri

mary

cup, and washer from the secondary piston.

f. The primary piston, with the rubber cups in stalled, is supplied in the repair kit.

CLEANING

a.

After disassembly, immersion of all metal parts

in

clean brake fluid or a brake system cleaner is

recommended. Use air

hose

to blow out dirt and cleaning solvent from recesses and internal pas

sages.

When overhauling a hydraulic brake unit,

use all parts furnished in the repair kit. Discard

all

old rubber parts.

b.

After cleaning, place

all"

hydraulic

system parts

on clean paper or in a clean pan.

INSPECTION

Inspect all other parts for damage or

excessive

wear.

Replace any damaged, worn, or chipped

parts.

Inspect hydraulic cylinder bore for

signs

of

scoring, rust, pitting, or etching. Any of

these

will

require

replacement of the hydraulic cylinder. 331