seat adjustment JEEP DJ 1953 Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 333 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

P h.

Install

the tube seats, flat side toward the check

valve,

and press in with tube nuts or the master

cylinder

brake pipe tube nuts.

BLEEDING

a.

Before the master cylinder is installed on the

car,

the unit must be bled.

b.

Support the cylinder assembly in a vise and

fill

both fluid reservoirs with approved brake fluid,

e.

Loosely install a plug in each

outlet

of the

cylinder.

Depress the push rod several times until

air

bubbles cease to appear in the brake fluid.

d.

Tighten the plugs and attempt to depress the piston. The piston travel should be restricted after

all

air is expelled.

e.

Install

the master cylinder on the car and bleed

the hydraulic lines at the wheel cylinder. Refer to

Par.

P-7.

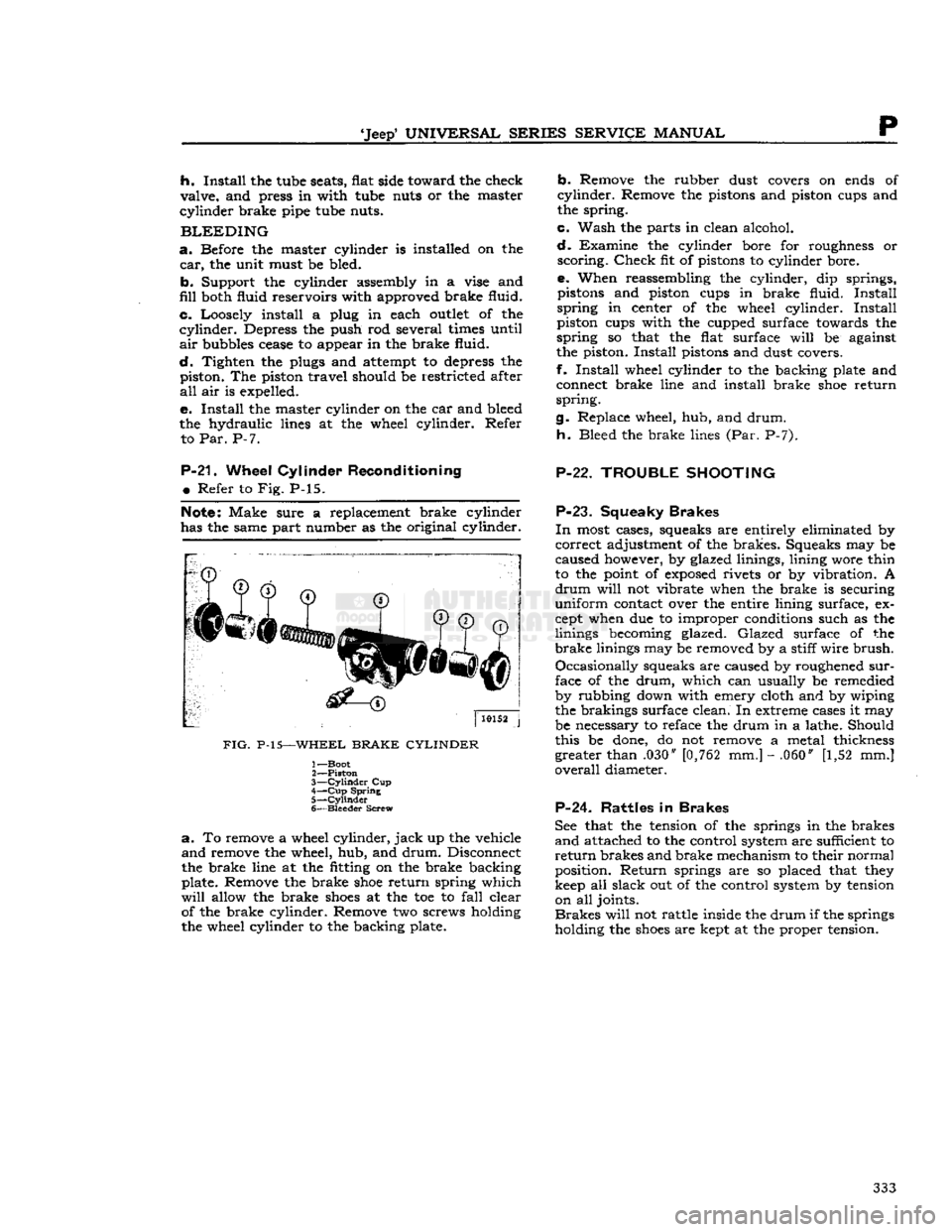

P-21.

Wheel

Cylinder

Reconditioning

•

Refer to Fig. P-15.

Note:

Make sure a replacement brake cylinder

has the same part number as the original cylinder.

FIG.

P-15—WHEEL

BRAKE CYLINDER

1— Boot

2—

Piston

3—

Cylinder

Cup

4—

Cup

Spring

5—

Cylinder

6—

Bleeder

Screw

a.

To remove a wheel cylinder,

jack

up the vehicle

and

remove the wheel, hub, and

drum.

Disconnect

the brake line at the fitting on the brake backing

plate. Remove the brake

shoe

return spring which

will

allow the brake

shoes

at the toe to

fall

clear of the brake cylinder. Remove two screws holding

the wheel cylinder to the backing plate.

b.

Remove the rubber dust covers on ends of

cylinder.

Remove the pistons and piston cups and

the spring.

c.

Wash the parts in clean alcohol.

d.

Examine the cylinder bore for roughness or

scoring.

Check

fit of pistons to cylinder bore.

e. When reassembling the cylinder, dip springs, pistons and piston cups in brake fluid.

Install

spring

in center of the wheel cylinder.

Install

piston cups with the cupped surface towards the

spring

so that the flat surface

will

be against

the piston.

Install

pistons and dust covers.

f.

Install

wheel cylinder to the backing plate and connect brake line and install brake

shoe

return

spring.

g. Replace wheel, hub, and

drum.

h.

Bleed the brake lines (Par. P-7).

P-22. TROUBLE

SHOOTING

P-23.

Squeaky

Brakes

In

most cases, squeaks are entirely eliminated by

correct

adjustment of the brakes. Squeaks may be

caused however, by glazed linings, lining wore thin

to the point of

exposed

rivets or by vibration. A

drum

will

not vibrate when the brake is securing

uniform

contact over the entire lining surface, ex

cept when due to improper conditions such as the

linings becoming glazed.

Glazed

surface of the

brake

linings may be removed by a stiff

wire

brush.

Occasionally

squeaks are caused by roughened

sur

face of the

drum,

which can usually be remedied

by rubbing down with emery cloth and by wiping

the brakings surface clean. In extreme cases it may

be necessary to reface the drum in a lathe. Should

this be done, do not remove a metal thickness greater than .030" [0,762 mm.] - .060" [1,52 mm.]

overall

diameter.

P-24. Rattles

in

Brakes

See that the tension of the springs in the brakes

and

attached to the control system are sufficient to

return

brakes and brake mechanism to their normal

position.

Return

springs are so placed that they

keep all slack out of the control system by tension on all joints.

Brakes

will

not rattle inside the

drum

if the springs

holding the

shoes

are kept at the proper tension. 333

Page 337 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

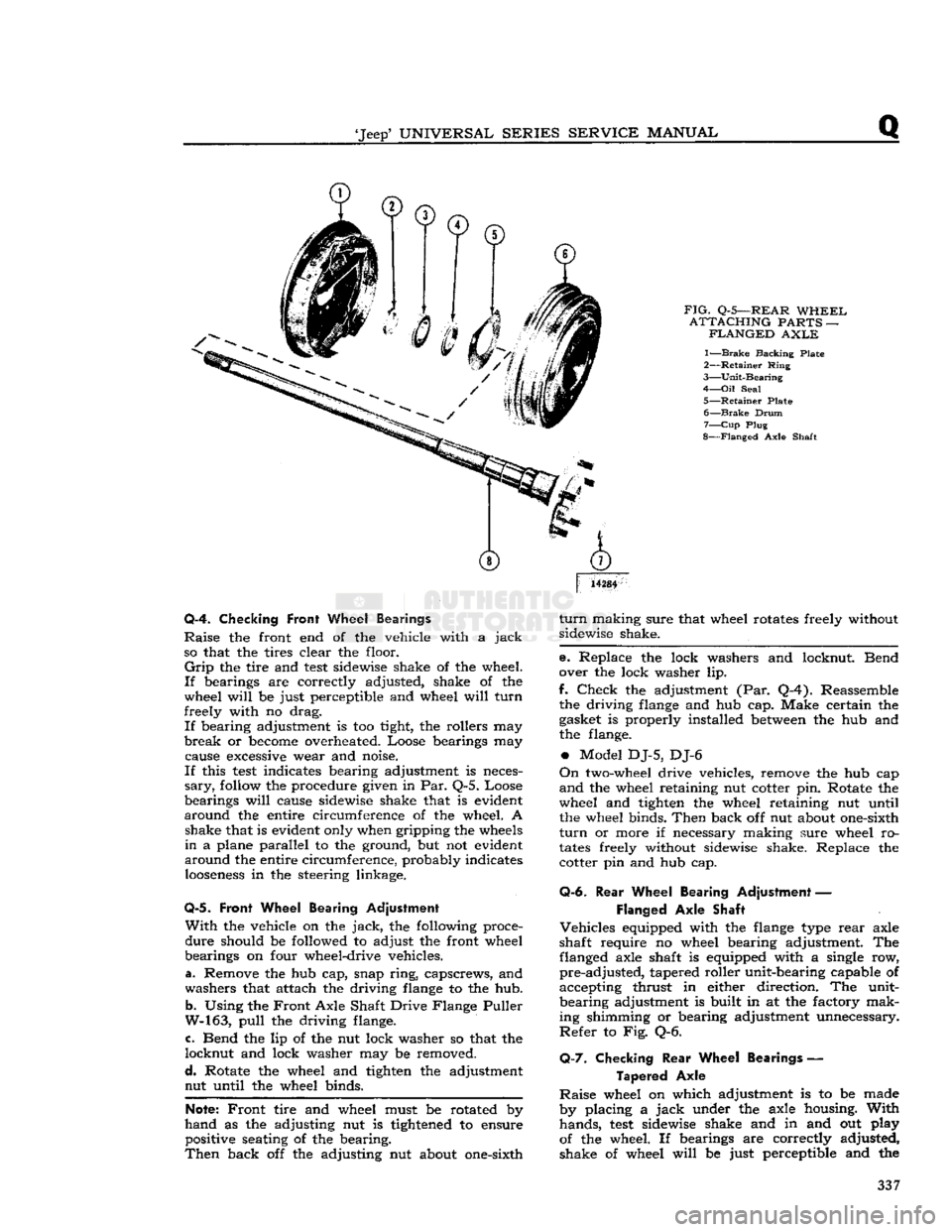

FIG.

Q-5—REAR

WHEEL

ATTACHING

PARTS —

FLANGED

AXLE

1—

Brake

Backing Plate

2—

Retainer

Ring

3—

Unit-Bearing

4—

Oil

Seal

5—

Retainer

Plate 6—

Brake

Drum

7—

Cup

Plug

8—

Flanged

Axle Shaft

14284

Q-4. Checking

Front

Wheel Bearings

Raise

the front end of the vehicle with a

jack

so that the tires clear the floor.

Grip

the tire and

test

sidewise shake of the wheel.

If

bearings are correctly adjusted, shake of the

wheel

will

be just perceptible and wheel

will

turn

freely with no drag.

If

bearing adjustment is too tight, the rollers may

break

or

become

overheated. Loose bearings may cause

excessive

wear and noise.

If

this

test

indicates bearing adjustment is neces

sary,

follow

the procedure given in Par. Q-5. Loose

bearings

will

cause sidewise shake that is evident

around

the entire circumference of the wheel. A shake that is evident only when gripping the

wheels

in

a plane parallel to the ground, but not evident

around

the entire circumference, probably indicates

looseness

in the steering linkage.

Q-5.

Front Wheel Bearing Adjustment

With

the vehicle on the

jack,

the following proce

dure

should be followed to adjust the front wheel

bearings on four wheel-drive vehicles.

a. Remove the hub cap, snap

ring,

capscrews, and

washers that attach the driving

flange

to the hub.

b.

Using the

Front

Axle Shaft Drive Flange Puller

W-163,

pull

the driving flange.

c. Bend the lip of the nut lock washer so that the

locknut

and lock washer may be removed.

d.

Rotate the wheel and tighten the adjustment nut until the wheel binds.

Note:

Front

tire and wheel must be rotated by

hand

as the adjusting nut is

tightened

to ensure positive seating of the bearing.

Then

back off the adjusting nut about one-sixth

turn

making sure that wheel rotates freely without

sidewise shake.

e. Replace the lock washers and locknut. Bend

over the lock washer lip.

f.

Check

the adjustment (Par. Q-4). Reassemble the driving

flange

and hub cap. Make certain the

gasket is properly installed

between

the hub and

the flange.

•

Model DJ-5, DJ-6

On

two-wheel drive vehicles, remove the hub cap

and

the wheel retaining nut cotter pin. Rotate the

wheel and tighten the wheel retaining nut until the wheel binds.

Then

back off nut about one-sixth

turn

or more if necessary making sure wheel ro

tates

freely without sidewise shake. Replace the cotter pin and hub cap.

Q-6.

Rear

Wheel Bearing Adjustment —

Flanged

Axle Shaft

Vehicles

equipped with the

flange

type

rear

axle

shaft require no wheel bearing adjustment. The flanged axle shaft is equipped with a single row,

pre-adjusted,

tapered roller unit-bearing capable of

accepting thrust in either direction. The unit-

bearing

adjustment is built in at the factory mak

ing shimming or bearing adjustment unnecessary.

Refer

to Fig. Q-6.

Q-7.

Checking

Rear

Wheel Bearings —

Tapered

Axle

Raise

wheel on which adjustment is to be made

by placing a

jack

under the axle housing.

With

hands,

test

sidewise shake and in and out play

of the wheel. If bearings are correctly adjusted,

shake of wheel

will

be just perceptible and the 337

Page 351 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

T

BODY

Contents

SUBJECT

PAR.

Brake

and

Clutch

Pedal Pads T-7

Canvas

Tops T-5

Care

of

Fabric

Tops. : T-6

Front

Seat Adjustment. . . T-8

Passenger Seat Safety

Catch

. .T-9

Windshield

T-2, T-3

Windshield

Glass and Weatherstrip T-4

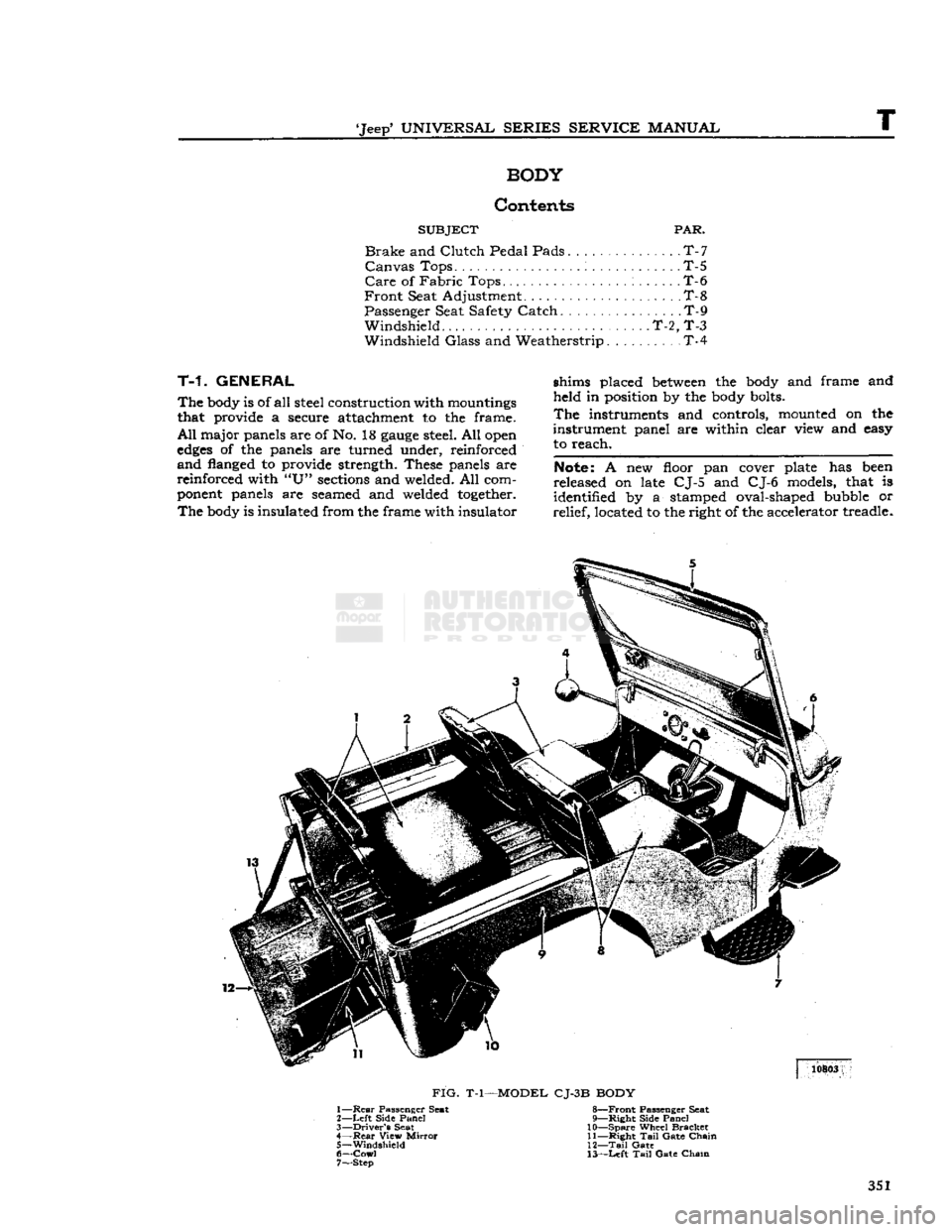

T-1.

GENERAL

The

body

is of

all

steel construction with mountings

that provide a secure attachment to the frame.

All

major panels are of No. 18

gauge

steel. All

open

edges

of the panels are turned under, reinforced

and

flanged to provide strength. These panels are reinforced with

"U"

sections

and welded. All com

ponent

panels are seamed and welded

together.

The

body

is insulated from the frame with insulator shims placed

between

the

body

and frame and

held in position by the

body

bolts.

The

instruments and controls, mounted on the

instrument panel are within clear view and easy

to reach.

Note:

A new floor pan cover plate has

been

released on late CJ-5 and CJ-6 models, that is

identified by a stamped oval-shaped bubble or

relief, located to the right of the accelerator treadle.

FIG.

T-l—MODEL CJ-3B BODY

1—

Rear

Passenger Seat 8—Front Passenger Seat

2—

Left

Side

Panel

9—Right Side

Panel

3—

Driver's

Seat 10—Spare Wheel

Bracket

4—

Rear

View

Mirror

11—Right

Tail

Gate

Chain

5—

Windshield

12—Tail

Gate

6—

Cowl

13—Left

Tail

Gate

Chain

7— Step

351

Page 355 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

T

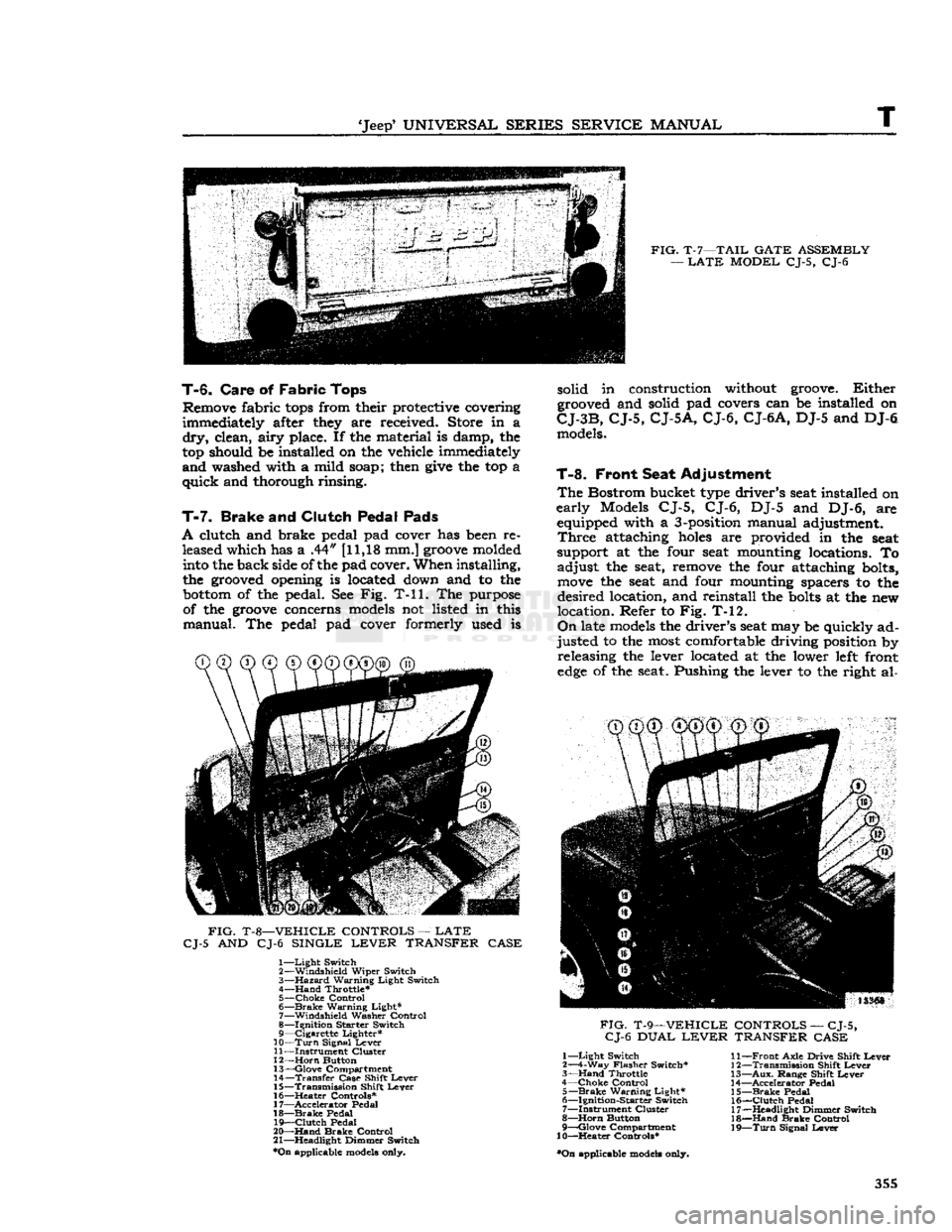

FIG.

T-7—TAIL

GATE

ASSEMBLY

—

LATE

MODEL

CJ-5, CJ-6

T-6.

Care

of

Fabric

Tops

Remove fabric

tops

from their protective covering

immediately after they are received. Store in a

dry,

clean,

airy

place. If the material is damp, the

top should be installed on the vehicle immediately

and

washed with a mild soap; then

give

the top a

quick

and thorough rinsing.

T-7.

Brake

and

Clutch Pedal Pads

A

clutch and brake pedal pad cover has been re leased which has a .44" [11,18 mm.]

groove

molded into the back side of the pad cover. When installing,

the grooved opening is located down and to the

bottom

of the pedal. See Fig. T-ll. The purpose of the

groove

concerns models not listed in this

manual.

The pedal pad cover formerly used is

FIG.

T-8—VEHICLE

CONTROLS

—

LATE

CJ-5

AND CJ-6

SINGLE

LEVER

TRANSFER

CASE

1—

Light

Switch

2—

Windshield

Wiper

Switch

3—

Hazard

Warning

Light

Switch

4—

Hand

Throttle*

5—

Choke

Control

6—

Brake

Warning

Light*

7—

Windshield

Washer

Control

8—

Ignition

Starter

Switch

9—

Cigarette

Lighter*

10—

Turn

Signal

Lever

11—

Instrument

Cluster

12—

Horn

Button

13—

Glove

Compartment

14—

Transfer

Case

Shift

Lever

15—

Transmission

Shift

Lever

16—

^Heater

Controls*

17—

Accelerator

Pedal

18—

Brake

Pedal

19—

Clutch

Pedal

20—

Hand

Brake

Control

21—

Headlight

Dimmer

Switch

*On

applicable models only. solid in construction without groove.

Either

grooved and solid pad covers can be installed on

CJ-3B,

CJ-5,

CJ-5A,

CJ-6,

CJ-6A,

DJ-5 and DJ-6 models.

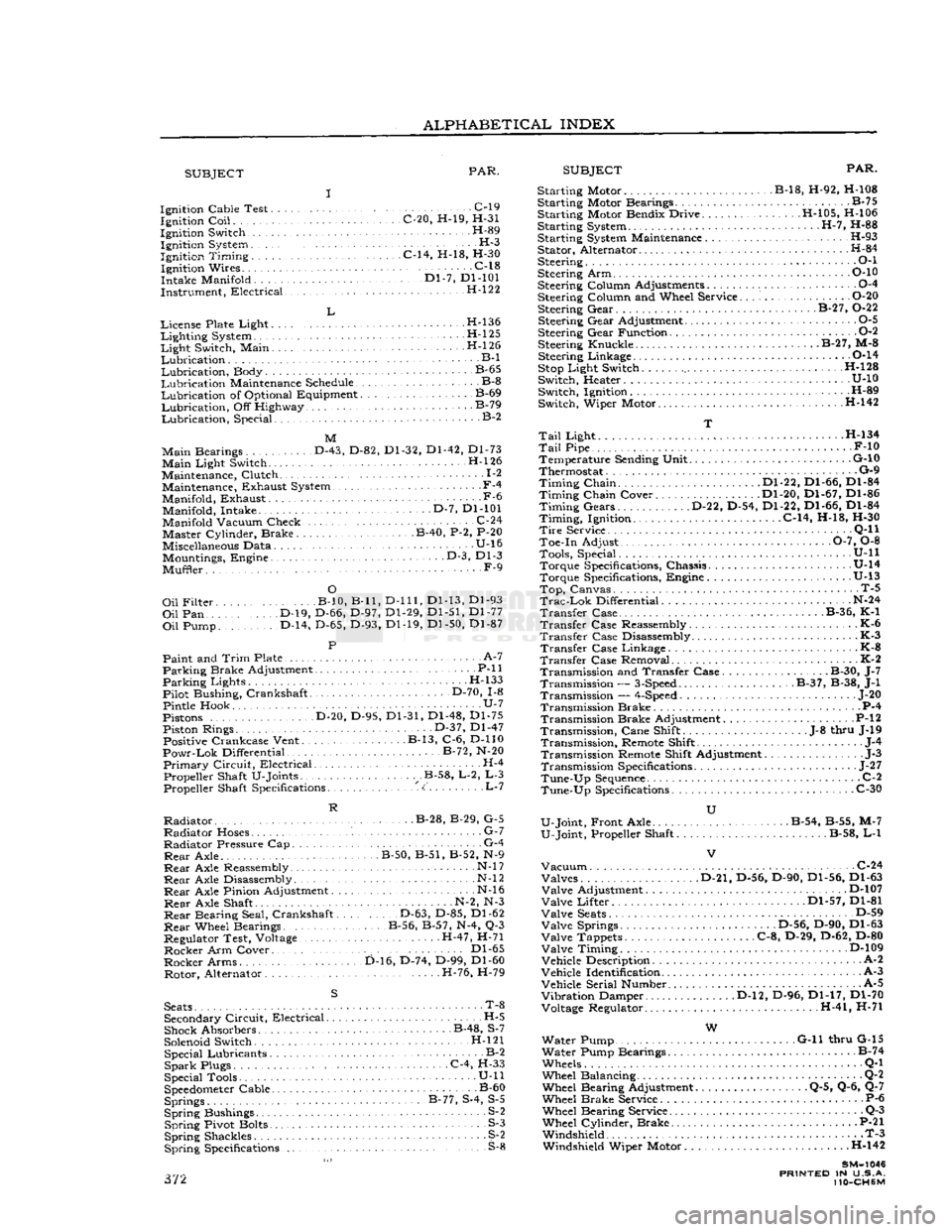

T-8.

Front Seat Adjustment

The

Bostrom bucket type driver's seat installed on

early

Models CJ-5, CJ-6, DJ-5 and DJ-6, are equipped with a 3-position manual adjustment.

Three

attaching

holes

are provided in the seat

support at the four seat mounting locations. To

adjust

the seat, remove the four attaching bolts,

move

the seat and four mounting spacers to the

desired

location, and reinstall the

bolts

at the new

location. Refer to Fig. T-12.

On

late models the driver's seat may be quickly ad

justed

to the most comfortable driving position by releasing the lever located at the lower left front

edge

of the seat. Pushing the lever to the right al-

CD CD®

®@©"®^

FIG.

T-9—VEHICLE

CONTROLS

—

CJ-5,

CJ-6

DUAL

LEVER

TRANSFER

CASE

1—

Light

Switch

2—4-Way

Flasher

Switch*

3—

Hand

Throttle

4—

Choke

Control

5—

Brake

Warning

Light*

6—

Ignition-Starter

Switch

7—

Instrument

Cluster

8—

Horn

Button

9—

Qlove

Compartment

10—Heater

Controls*

•On

applicable models only.

11—

Front

Axle

Drive

Shift

Lever

12—

Transmission

Shift

Lever

13—

Aux.

Range

Shift

Lever

14—

Accelerator

Pedal

15—

Brake

Pedal

16—

Clutch

Pedal

17—

Headlight

Dimmer

Switch

18—

Hand

Brake

Control

19—

Turn

Signal

Lever

355

Page 356 of 376

T

BODY

lows

the seat to be

moved forward

or

rearward.

Re

positioning

the

lever

to the

left

will

lock

the seat

in

the

desired position.

T-9.

Passenger

Seat

Safety

Catch

Thejfront

passenger seat on

late model vehicles

is

provided

with

a

safety

catch, located

at the

left

rear

base of the seat. To

tilt

the seat

forward,

first

release

the

catch

by

pulling

upwards

on the

catch lever. 11213

.

FIG.

T-ll—CLUTCH

AND

BRAKE PEDAL

PAD

FIG.

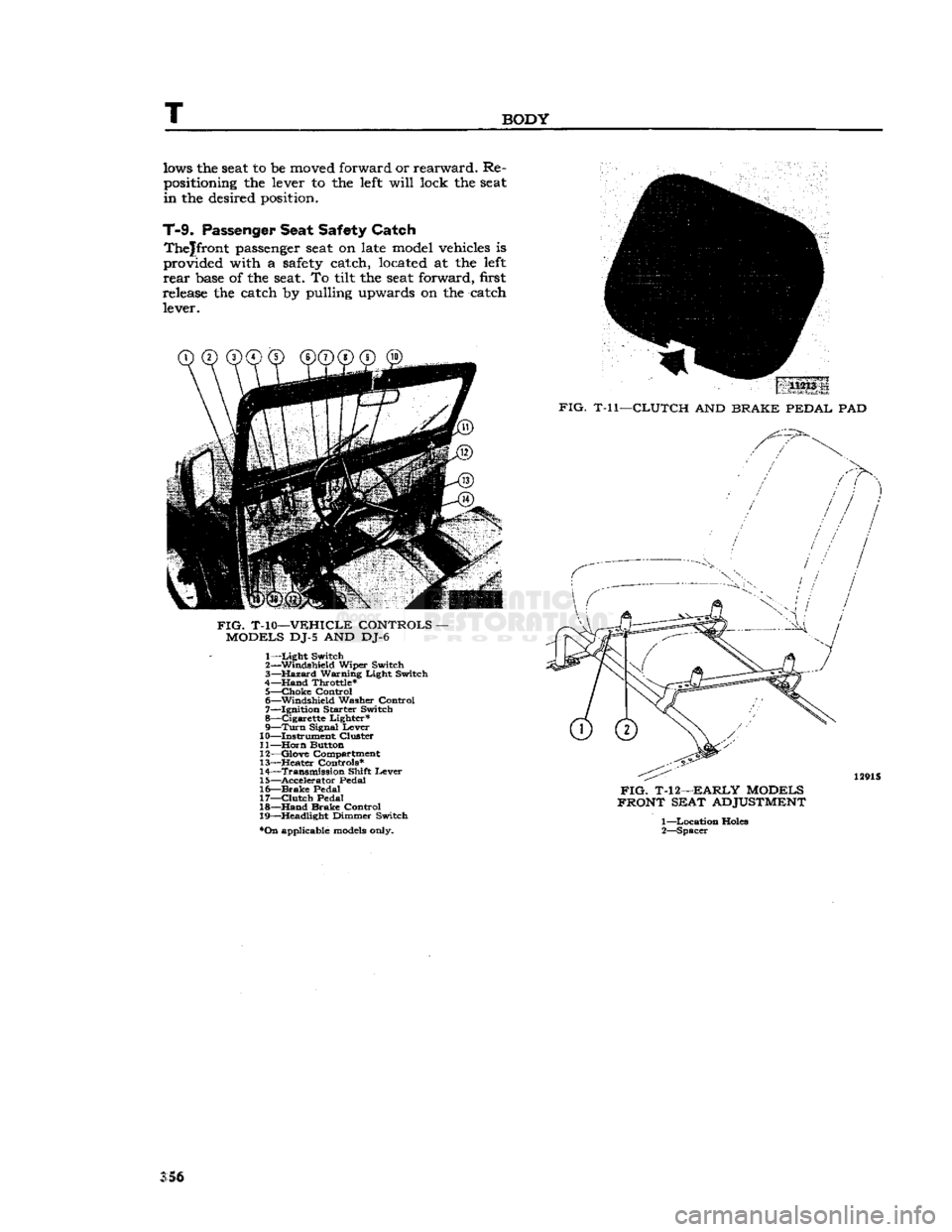

T-10—VEHICLE CONTROLS

-

MODELS

DJ-5 AND DJ-6 1—

Light

Switch

2— Windshield Wiper Switch

3—

Hazard

Warning Light Switch

4—Hand Throttle*

5—

choke

Control

6— Windshield

Washer

Control

7— Ignition

Starter

Switch

8— Cigarette Lighter* 9—

Turn

Signal Lever

10— Instrument Cluster

11—

Horn

Button

12— Glove Compartment

13—

Heater

Controls*

14— Transmission Shift Lever

15— Accelerator

Pedal

16—

Brake

Pedal

17—

Clutch

Pedal

18—

Hand

Brake Control

19— Headlight Dimmer Switch

*On

applicable

models

only.

FIG.

T-12—EARLY MODELS

FRONT SEAT

ADJUSTMENT

1—

Location Holes

2— Spacer

S5§

Page 372 of 376

ALPHABETICAL

INDEX

SUBJECT

PAR.

SUBJECT

PAR.

Ignition Cable Test C-l9 Ignition

Coil

C-20, H-19, H-31

Ignition Switch H-89 Ignition System H-3

Ignition

Timing

C-14, H-18, H-30 Ignition Wires C-18

Intake Manifold '." Dl-7, Dl-101

Instrument, Electrical H-122

L

License Plate Light H-l36

Lighting

System H-l25

Light

Switch, Main . H-l 26

Lubrication

B-l

Lubrication,

Body B-65

Lubrication

Maintenance Schedule B-8

Lubrication

of Optional Equipment B-69

Lubrication,

Off Highway B-79

Lubrication,

Special. B-2

M

Main

Bearings D-43, D-82, Dl-32, Dl-42, Dl-73

Main

Light Switch. H-l26

Maintenance, Clutch 1-2 Maintenance, Exhaust System.,

-

F-4

Manifold, Exhaust -F-6 Manifold, Intake D-7, Dl-101

Manifold Vacuum Check. .C-24 Master Cylinder, Brake B-40, P-2, P-20

Miscellaneous Data U-16 Mountings, Engine • • •

-

D-3, Dl-3

Muffler. F-9

O

Oil

Filter B-10, B-ll,

D-lll,

Dl-13, Dl-93

Oil

Pan D-19, D-66, D-97, Dl-29, Dl-51, Dl-77

Oil

Pump. D-14, D-65, D-93, Dl-19, Dl-50, Dl-87

P

Paint and

Trim

Plate • • A-7

Parking

Brake Adjustment P-ll

Parking

Lights H-133

Pilot Bushing, Crankshaft D-70, 1-8

Pintle Hook U-7

Pistons D-20, D-95, Dl-31, Dl-48, Dl-75 Piston Rings. • • •

•

D-37, Dl-47 Positive Crankcase Vent. B-13, C-6, D-110

Powr-Lok

Differential B-72, N-20

Primary

Circuit,

Electrical H-4 Propeller Shaft U-Joints .B-58, L-2, L-3 Propeller Shaft Specifications <:' L-7

R

Radiator

B-28, B-29, G-5

Radiator

Hoses. G-7

Radiator

Pressure Cap G-4

Rear

Axle. B-50, B-51, B-52, N-9

Rear

Axle Reassembly • N-l

7

Rear

Axle Disassembly N-l

2

Rear

Axle Pinion Adjustment N-l6

Rear

Axle Shaft N-2, N-3

Rear

Bearing Seal, Crankshaft D-63, D-85, Dl-62

Rear

Wheel Bearings B-56, B-57, N-4, Q-3

Regulator Test, Voltage H-47, H-71

Rocker

Arm Cover.. . Dl-65

Rocker

Arms D-16, D-74, D-99, Dl-60 Rotor, Alternator H-76, H-79

S

Seats

• T-8 Secondary

Circuit,

Electrical H-5

Shock Absorbers B-48, S-7

Solenoid Switch. H-l21 Special Lubricants B-2

Spark

Plugs C-4, H-33

Special Tools • U-ll

Speedometer

Cable B-60 Springs B-77, S-4, S-5

Spring

Bushings S-2

Spring

Pivot Bolts S-3

Spring

Shackles S^2

Spring

Specifications S-8 372 Starting Motor B-18, H-92, H-108

Starting Motor Bearings B-75

Starting Motor Bendix Drive H-105, H-106

Starting System H-7, H-88

Starting System Maintenance H-93 Stator, Alternator H-84

Steering • • •

•

O-l

Steering Arm P-10

Steering Column Adjustments 0-4

Steering Column and Wheel Service O-20 Steering Gear. . B-27, 0-22

Steering Gear Adjustment 0-5

Steering Gear Function 0-2

Steering Knuckle. B-27, M-8 Steering Linkage 0-14

Stop

Light Switch H-128

Switch, Heater U-10 Switch, Ignition H-89

Switch, Wiper Motor H-142

T

Tail

Light . H-134

Tail

Pipe F-10 Temperature Sending Unit G-10

Thermostat G-9

Timing

Chain Dl-22, Dl-66, Dl-84

Timing

Chain Cover Dl-20, Dl-67, Dl-86

Timing

Gears D-22, D-54, Dl-22, Dl-66, Dl-84

Timing,

Ignition. C-14, H-18, H-30

Tire

Service . •

•

Q-l

1

Toe-in Adjust 0-7, 0-8 Tools, Special. . .

........

U-ll Torque Specifications, Chassis U-14

Torque Specifications, Engine .U-13

Top,

Canvas. T-5

Trac-Lok

Differential N-24

Transfer

Case B-36, K-1

Transfer

Case Reassembly K-6

Transfer

Case Disassembly K-3

Transfer

Case Linkage - K-8

Transfer

Case Removal K-2 Transmission and Transfer Case. B-30, J-7 Transmission —

3-Speed

B-37, B-38, J-l

Transmission —

4-Speed

... J-20

Transmission Brake P-4 Transmission Brake Adjustment P-l

2

Transmission,

Cane Shift .J-8 thru J-19

Transmission,

Remote Shift J-4

Transmission Remote Shift Adjustment J-3

Transmission Specifications

-

J-27

Tune-Up

Sequence

C-2

Tune-Up

Specifications C-30

U

U-Joint, Front Axle . . B-54, B-55, M-7

U-Joint, Propeller Shaft B-58, L-l

Vacuum

C-24 Valves D-21, D-56, D-90, Dl-56, Dl-63

Valve

Adjustment D-107

Valve

Lifter Dl-57, Dl-81

Valve

Seats

D-59

Valve

Springs .D-56, D-90, Dl-63

Valve

Tappets C-8, D-29, D-62, D-80

Valve

Timing D-109

Vehicle Description A-2

Vehicle Identification A-3

Vehicle Serial Number. A-5

Vibration

Damper D-l2, D-96, Dl-17, Dl-70 Voltage Regulator. H-41, H-71

W

Water Pump G-ll thru G-15

Water Pump Bearings B-74

Wheels Q-l

Wheel Balancing Q-2 Wheel Bearing Adjustment Q-5, Q-6, Q-7

Wheel Brake Service P-6 Wheel Bearing Service Q-3

Wheel Cylinder, Brake P-21 Windshield T-3 Windshield Wiper Motor . .H-142

SM-1046

PRINTED

IN U.S.A.

110-CH6M