timing belt JEEP DJ 1953 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: DJ, Model: JEEP DJ 1953Pages: 376, PDF Size: 19.96 MB

Page 168 of 376

G

COOLING SYSTEM

12761

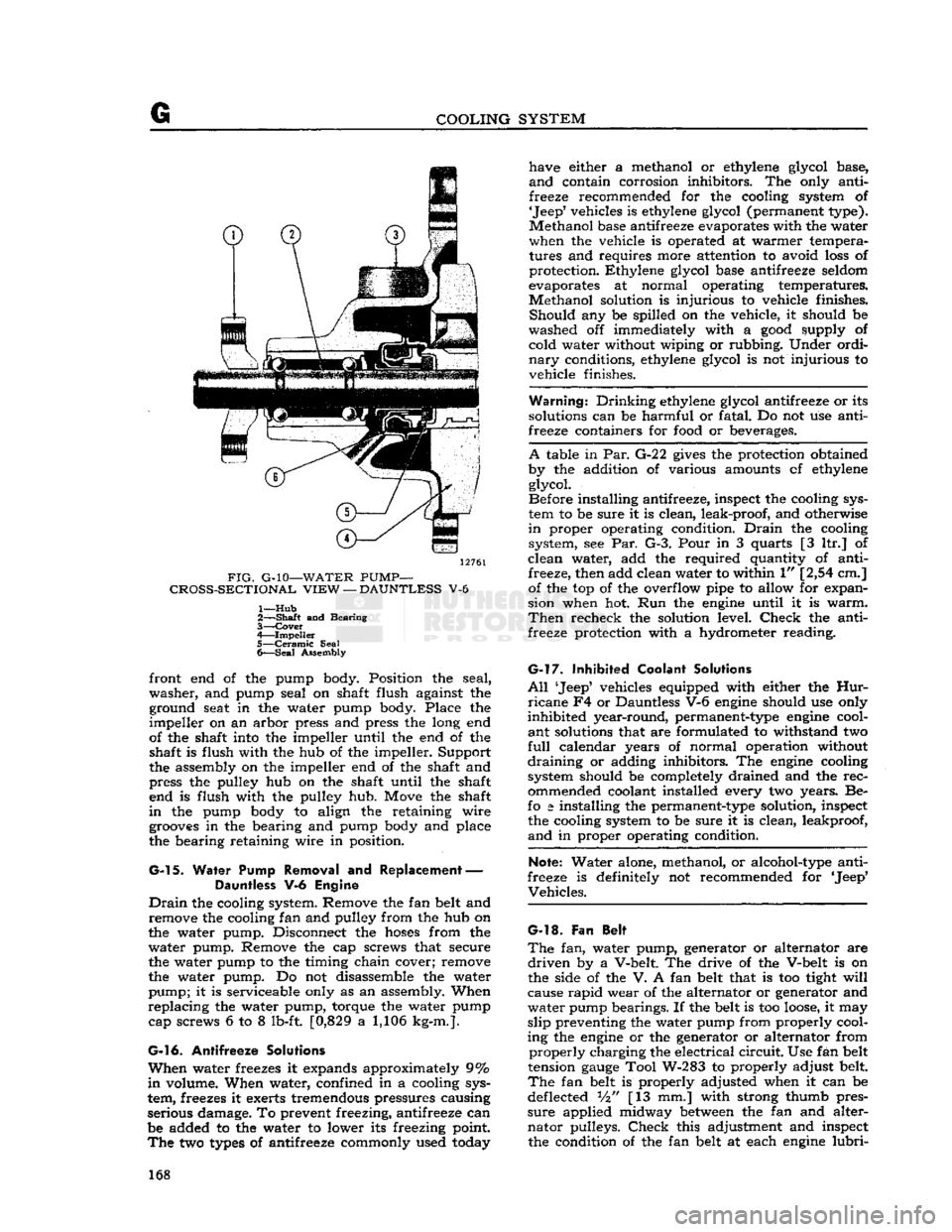

FIG.

G-10—WATER

PUMP—

CROSS-SECTIONAL

VIEW

—

DAUNTLESS

V-6

1—

Hub

2—

—Shaft

and Bearing

3—

Cover

4—

Impeller

5—

Ceramic

Seal

6—

Seal

Assembly front end of the pump body. Position the seal,

washer,

and pump seal on shaft flush against the ground seat in the water pump body. Place the

impeller

on an arbor press and press the long end

of the shaft into the impeller until the end of the shaft is flush with the hub of the impeller. Support

the assembly on the impeller end of the shaft and

press the pulley hub on the shaft until the shaft end is flush with the pulley hub. Move the shaft

in

the pump body to align the retaining wire

grooves

in the bearing and pump body and place

the bearing retaining wire in position.

G-l

5. Water Pump Removal and Replacement — Dauntless V-6 Engine

Drain

the cooling system. Remove the fan belt and remove the cooling fan and pulley from the hub on

the water pump. Disconnect the

hoses

from the

water

pump. Remove the cap screws that secure

the water pump to the timing chain cover; remove

the water pump. Do not disassemble the water

pump;

it is serviceable only as an assembly. When

replacing

the water pump, torque the water pump cap screws 6 to 8 lb-ft. [0,829 a 1,106 kg-m.].

G-16.

Antifreeze Solutions

When

water freezes it expands approximately 9%

in

volume. When water, confined in a cooling sys

tem, freezes it exerts tremendous pressures causing

serious damage. To prevent freezing, antifreeze can

be added to the water to lower its freezing point.

The

two

types

of antifreeze commonly used today have either a methanol or ethylene glycol base,

and

contain corrosion inhibitors. The only anti

freeze recommended for the cooling system of

'Jeep'

vehicles is ethylene glycol (permanent type).

Methanol

base antifreeze evaporates with the water

when the vehicle is operated at warmer tempera

tures and requires more attention to avoid

loss

of

protection. Ethylene glycol base antifreeze seldom

evaporates at normal operating temperatures.

Methanol

solution is injurious to vehicle finishes.

Should

any be spilled on the vehicle, it should be

washed off immediately with a

good

supply of cold water without wiping or rubbing. Under ordi

nary

conditions, ethylene glycol is not injurious to

vehicle finishes.

Warning.*

Drinking

ethylene glycol antifreeze or its

solutions can be harmful or fatal. Do not use anti

freeze containers for

food

or beverages.

A

table in Par.

G-2

2

gives

the protection obtained

by the addition of various amounts cf ethylene glycol.

Before installing antifreeze, inspect the cooling sys

tem to be sure it is clean, leak-proof, and otherwise

in

proper operating condition.

Drain

the cooling system, see Par. G-3. Pour in 3 quarts [3 ltr.] of

clean

water, add the required quantity of anti freeze, then add clean water to within 1" [2,54 cm.] of the top of the overflow pipe to allow for expan

sion when hot. Run the

engine

until it is

warm.

Then

recheck the solution level.

Check

the anti

freeze protection with a hydrometer reading.

G-l7.

Inhibited Coolant Solutions

All

'Jeep5 vehicles equipped with either the

Hur

ricane

F4 or Dauntless V-6

engine

should use only

inhibited

year-round, permanent-type

engine

cool

ant

solutions that are formulated to withstand two

full

calendar years of normal operation without

draining

or adding inhibitors. The

engine

cooling

system should be completely drained and the

rec

ommended coolant installed every two years. Be-

fo

a

installing the permanent-type solution, inspect the cooling system to be sure it is clean, leakproof,

and

in proper operating condition.

Note:

Water alone, methanol, or alcohol-type anti

freeze is definitely not recommended for 'Jeep*

Vehicles.

G-l8.

Fan Belt

The

fan, water pump, generator or alternator are

driven

by a V-belt. The drive of the V-belt is on

the side of the V. A fan belt that is too tight

will

cause

rapid

wear of the alternator or generator and

water

pump bearings. If the belt is too

loose,

it may

slip

preventing the water pump from properly cool

ing the

engine

or the generator or alternator from

properly

charging the electrical

circuit.

Use fan belt

tension

gauge

Tool W-283 to properly adjust belt.

The

fan belt is properly adjusted when it can be

deflected Vi" [13 mm.] with strong thumb pres

sure

applied midway

between

the fan and alter

nator

pulleys.

Check

this adjustment and inspect the condition of the fan belt at each

engine

lubri-

168

Page 170 of 376

G

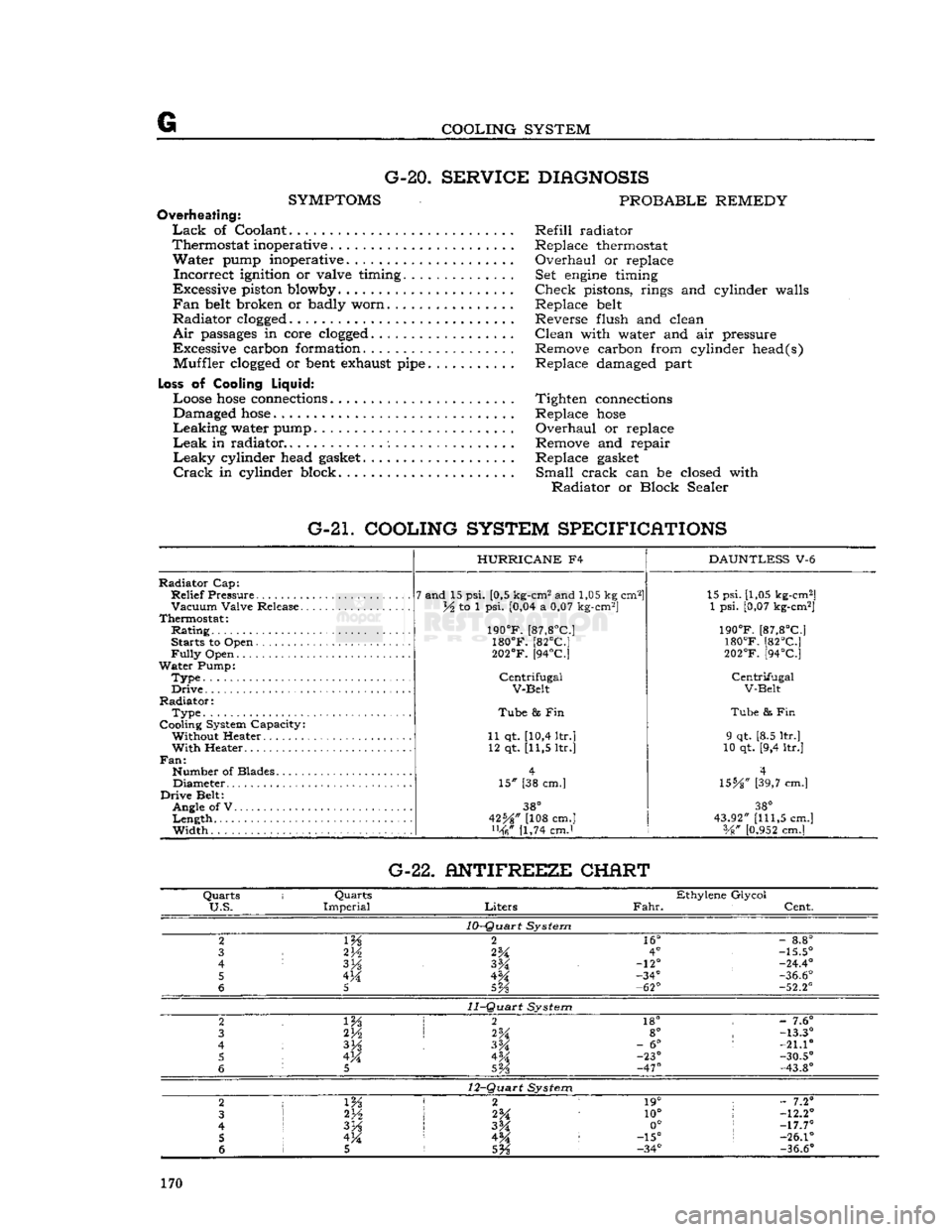

COOLING SYSTEM G-20.

SERVICE DIAGNOSIS

SYMPTOMS

PROBABLE REMEDY

Overheating:

Lack

of Coolant Refill radiator

Thermostat inoperative . Replace thermostat

Water

pump inoperative. Overhaul or replace

Incorrect

ignition or valve timing. Set

engine

timing

Excessive piston blowby Check pistons, rings and cylinder walls

Fan

belt

broken or badly worn Replace

belt

Radiator

clogged

Reverse flush and clean

Air

passages

in core

clogged

Clean with water and air pressure

Excessive carbon formation. Remove carbon from cylinder head(s) Muffler

clogged

or

bent

exhaust

pipe

Replace damaged part

Loss

of Cooling

Liquid:

Loose

hose

connections

Tighten

connections

Damaged

hose

Replace

hose

Leaking

water pump Overhaul or replace

Leak

in radiator Remove and repair

Leaky

cylinder head

gasket

Replace

gasket

Crack

in cylinder block. Small crack can be closed with

Radiator

or Block Sealer

G-21. COOLING SYSTEM SPECIFICATIONS

Radiator

Cap:

Relief

Pressure

Vacuum

Valve Release.

Thermostat:

Rating

Starts to Open

Fully

Open

Water

Pump:

Type.

Drive

Radiator:

Type

Cooling System Capacity: Without Heater

With

Heater..

Fan:

Number of Blades Diameter

Drive

Belt: Angle of V

Length

Width

HURRICANE

F4

7 and 15 psi. [0,5 kg-cm2 and 1,05 kg cm2]

lA to 1 psi. [0,04 a 0,07 kg-cm2]

190°F.

[87,8°C]

180°F.

[82°C]

202°F.

[94°C]

Centrifugal

V-Belt

Tube

8s Fin

11 qt. [10,4 ltr.] 12 qt. [11,5 ltr.]

15" [38 cm.]

38°

42%" [108 cm.] [1,74 cmJ

DAUNTLESS

V-6 15 psi. [1,05 kg-cm2]

1 psi. [0,07 kg-cm2]

190°F.

[87,8°C]

180°F.

[82°C]

202°F.

[94°C]

Centrifugal

V-Belt

Tube

& Fin

9 qt. [8.5 ltr.]

10 qt. [9,4 ltr.]

4

\SbA"

[39,7 cm.]

38°

43.92"

[111,5

cm.] Vg"

[0.952

cm.] G-22. ANTIFREEZE CHERT

Quarts

i

Quarts

Ethylene Glycol

U.S.

Imperial

Liters

Fahr.

Cent.

10-Quart

System

2

m

2

16°

-

8.8°

3

2V2

2%

4°

-15.5°

4

3H

-12°

-24.4°

5 4M -34°

-36.6°

6

5

5Vs

-62°

-52.2°

11-Quart

System

2 2

18° -

7.6°

3 2H

2%

8°

-13.3°

4

3%

-

6°

:

-21.10

5 4M 4M -23°

-30.5°

6

5

SVs

-47°

-43.8°

12-Quart

System

2

1 m 2 1

19° ;

- 7.2°

3

2*A

10°

!

-12.2°

4

I

3H

3M 0°

;

-17.7°

5 !

4M 4^ :

-15°

s

-26.1°

6 1 5

5%

-34°

-36.6°

170

Page 360 of 376

u

MISCELLANEOUS

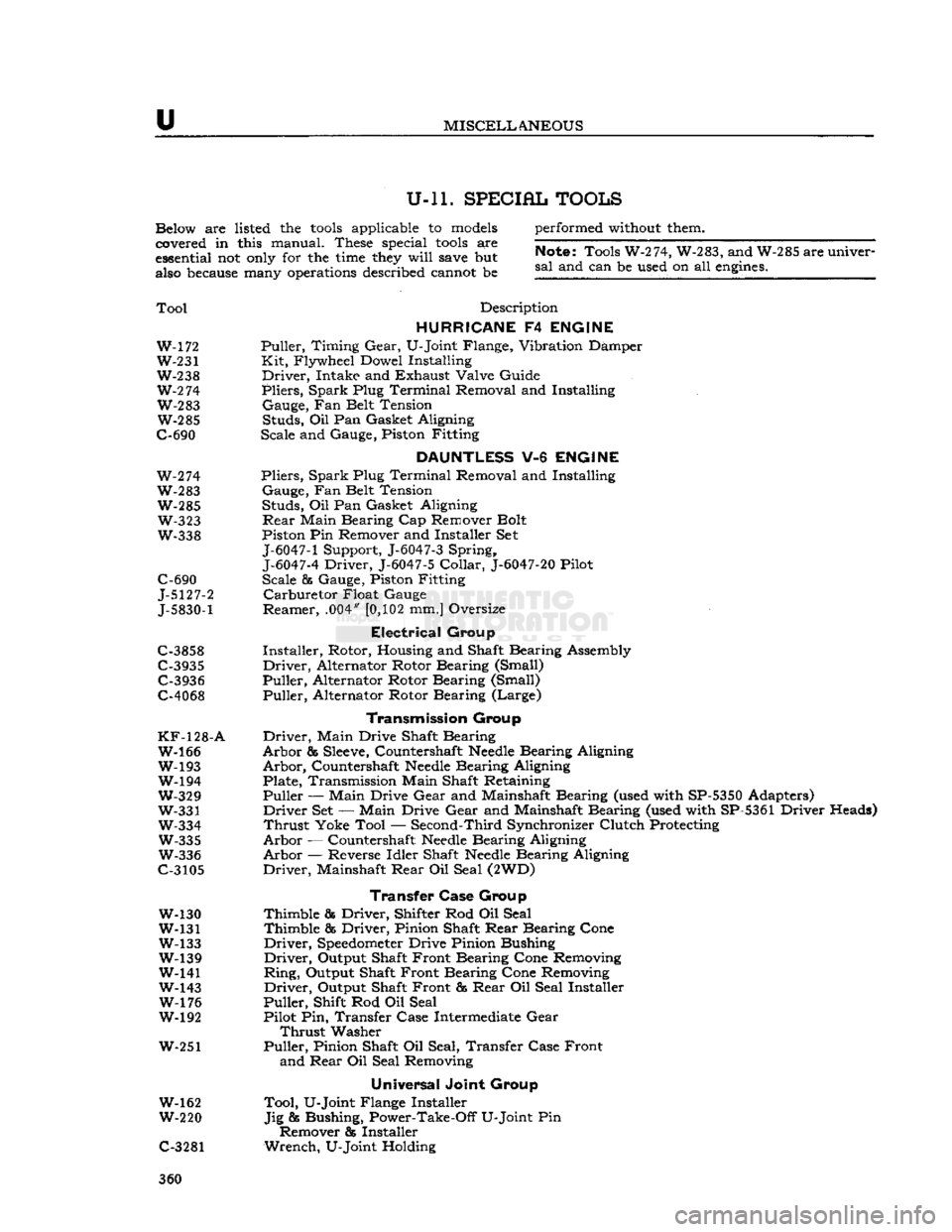

U-ll. SPECIAL TOOLS

Below are listed the

tools

applicable to

models

covered in this manual. These special

tools

are

essential not

only

for the

time

they

will

save

but

also

because

many

operations

described cannot be performed

without

them.

Note;

Tools W-274, W-283, and W-285 are univer

sal

and can be used on all

engines.

Tool

Description

HURRICANE

F4

ENGINE

W-172 Puller, Timing

Gear,

U-Joint Flange, Vibration Damper W-231 Kit, Flywheel Dowel Installing

W-238 Driver, Intake and Exhaust Valve Guide

W-2

74 Pliers, Spark Plug Terminal Removal and Installing W-283 Gauge, Fan Belt Tension W-285 Studs, Oil Pan Gasket Aligning

C-690 Scale and Gauge, Piston Fitting

DAUNTLESS

V-6

ENGINE

W-274 Pliers, Spark Plug Terminal Removal and Installing

W-283 Gauge, Fan Belt Tension W-285 Studs, Oil Pan Gasket Aligning W-323

Rear

Main Bearing Cap Remover Bolt

W-338 Piston Pin Remover and Installer Set

J-6047-1

Support, J-6047-3 Spring,

J-6047-4

Driver, J-6047-5

Collar,

J-6047-20

Pilot

C-690 Scale & Gauge, Piston Fitting

J-5127-2 Carburetor Float Gauge

J-5830-1

Reamer, .004"

[0,102

mm.] Oversize

Electrical

Group

C-3858 Installer, Rotor, Housing and Shaft Bearing Assembly

C-3935 Driver, Alternator Rotor Bearing (Small) C-3936 Puller, Alternator Rotor Bearing (Small)

C-4068 Puller, Alternator Rotor Bearing (Large)

Transmission

Group

KF-128-A

Driver, Main Drive Shaft Bearing W-166 Arbor &

Sleeve,

Countershaft

Needle

Bearing Aligning

W-193 Arbor, Countershaft

Needle

Bearing Aligning W-194 Plate, Transmission Main Shaft Retaining

W-329 Puller — Main Drive

Gear

and Mainshaft Bearing (used with SP-5350 Adapters)

W-331 Driver Set — Main Drive

Gear

and Mainshaft Bearing (used with SP-5361 Driver Heads)

W-334 Thrust Yoke Tool — Second-Third Synchronizer Clutch Protecting W-335 Arbor — Countershaft

Needle

Bearing Aligning

W-336 Arbor — Reverse Idler Shaft

Needle

Bearing Aligning

C-3105 Driver, Mainshaft

Rear

Oil Seal (2WD)

Transfer Case

Group

W-130 Thimble & Driver, Shifter Rod Oil Seal

W-131 Thimble & Driver, Pinion Shaft

Rear

Bearing Cone

W-133 Driver,

Speedometer

Drive Pinion Bushing W-139 Driver, Output Shaft Front Bearing Cone Removing

W-141 Ring, Output Shaft Front Bearing Cone Removing

W-143 Driver, Output Shaft Front &

Rear

Oil Seal Installer W-176 Puller, Shift Rod Oil Seal

W-192 Pilot Pin, Transfer Case Intermediate

Gear

Thrust

Washer

W-251 Puller, Pinion Shaft Oil Seal, Transfer Case Front and

Rear

Oil Seal Removing

Universal

Joint Group

W-162 Tool, U-Joint Flange Installer

W-220 Jig & Bushing, Power-Take-Off U-Joint Pin Remover & Installer

C-3281 Wrench, U-Joint Holding 360