tires JEEP GLADIATOR 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: GLADIATOR, Model: JEEP GLADIATOR 2023Pages: 448, PDF Size: 17.37 MB

Page 9 of 448

7

TOWING A DISABLED VEHICLE .......................... 350 Four–Wheel Drive Models ............................ 351

Without The Key Fob ..................................... 351

Emergency Tow Hooks —

If Equipped .................................................... 351

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS) .................................................................. 352

EVENT DATA RECORDER (EDR) ......................... 352

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GASOLINE

ENGINE ................................................................. 353

Maintenance Plan ......................................... 354

SCHEDULED SERVICING — DIESEL ENGINE .... 357

Maintenance Plan — Diesel Fuel Up To

B5 Biodiesel................................................... 358Additional Maintenance — B6 To B20

Biodiesel ........................................................ 361

ENGINE COMPARTMENT .................................... 362

3.6L Gasoline Engine ................................... 3623.0L Diesel Engine ........................................ 363

Checking Oil Level ......................................... 364

Adding Washer Fluid ..................................... 364

Maintenance-Free Battery ............................ 364

Pressure Washing ......................................... 365 VEHICLE MAINTENANCE..................................... 365

Engine Oil ....................................................... 365

Engine Oil Filter ............................................. 366Engine Air Cleaner Filter ............................... 366

Draining Fuel/Water Separator Filter —

Diesel Engine ................................................. 368

Fuel Filter Replacement — Diesel Engine .... 369

Priming If The Engine Has Run Out Of

Fuel — Diesel Engine .................................... 370

Intervention Regeneration Strategy —

Message Process Flow ................................ 371Diesel Exhaust Fluid ..................................... 371

Accessory Drive Belt Inspection ................... 372Air Conditioner Maintenance........................ 372

Body Lubrication ........................................... 374Windshield Wiper Blades.............................. 374Exhaust System ............................................ 376

Cooling System .............................................. 377

Charge Air Cooler — Inter-Cooler

(Diesel Engine) .............................................. 379

Brake System ............................................... 380

Front/Rear Axle Fluid ................................... 380Transfer Case ............................................... 381

Manual Transmission — If Equipped............ 381

Automatic Transmission —

If Equipped .................................................... 381

Fuses ............................................................. 382Bulb Replacement ........................................ 392 TIRES ..................................................................... 395

Tire Safety Information ................................. 395

Tires — General Information ......................... 401

Tire Types....................................................... 405Spare Tires — If Equipped ............................ 406

Wheel And Wheel Trim Care......................... 407

Snow Traction Devices ................................. 408

Tire Rotation Recommendations ................. 409

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES .................... 410

Treadwear...................................................... 410

Traction Grades ............................................. 410Temperature Grades..................................... 410

STORING THE VEHICLE ....................................... 411

BODYWORK .......................................................... 411

Protection From Atmospheric Agents .......... 411

Body And Underbody Maintenance ............. 412

Preserving The Bodywork ............................. 412

INTERIORS ........................................................... 414

Carpet Safety Information ............................ 414

Carpet Removal............................................. 415Seats And Fabric Parts ................................. 416

Plastic And Coated Parts .............................. 417

Leather Surfaces........................................... 417

Glass Surfaces ............................................. 417

23_JT_OM_EN_USC_t.book Page 7

Page 85 of 448

GETTING TO KNOW YOUR VEHICLE83

(Continued)

LOWERING THE SOFT TOP

Use this QR code to access your

digital experience. If the temperature is below 72°F (24°C) and/or

the top has been folded down for a period of time,

the top will appear to have shrunk when you raise

it, making it difficult to put up. This is caused by a

natural contraction of the vinyl or acrylic materials

of the fabric top.

Place the vehicle in a warm area. Pull steadily on

the top fabric. The vinyl will stretch back to its

original size and the top can then be installed. If

the temperature is 41°F (5°C) or below, do not

attempt to put the top down or roll the rear or side

curtains.

WARNING!

Do not drive the vehicle with the rear window

up/removed unless the quarter windows are

also removed. Dangerous exhaust gases

could enter the vehicle causing harm to the

driver and passengers.

The fabric quarter windows and fabric top are

designed only for protection against the

elements. Do not rely on them to contain occu -

pants within the vehicle or to protect against

injury during an accident. Remember, always

wear seat belts.

Make sure hands and fingers are clear of all

pinch points when installing and removing the

soft top. The lift assist mechanism and side

bows may cause serious injury if fingers or

hands get caught in between.

CAUTION!

The soft top is not designed to carry any

additional loads such as roof racks, spare tires,

building, hunting or camping supplies, and/or

luggage, etc. Also, it was not designed as a

structural member of the vehicle and, thus,

cannot properly carry any additional loads other

than environmental (rain, snow, etc.).

CAUTION!

Do not run a fabric top through an automatic

car wash. Window scratches and wax buildup

may result.

Do not lower the top when the temperature is

below 41°F (5°C). Damage to the top may

result.

Do not move your vehicle until the top has been

either fully attached to the windshield frame, or

fully lowered.

Follow the proper steps for cleaning and caring

for your vehicle’s fabric top

Ú

page 413.

Do not use any tools (screwdrivers, etc.) to pry

or force any of the clamps, clips, or retainers

securing the soft top. Do not force or pry the soft

top framework when opening or closing.

Damage to the top may result.

Failure to follow these cautions may cause interior

water damage, stains, or mildew on the top

material:

It is recommended that the top be free of water

prior to opening it. Operating the top, opening a

door or lowering a window while the top is wet

may allow water to drip into the vehicle's interior.

Careless handling and storage of the soft top

may damage the seals, causing water to leak

into the vehicle's interior.

The soft top must be positioned properly to

ensure sealing. Improper installation can cause

water to leak into the vehicle's interior.

CAUTION!

2

23_JT_OM_EN_USC_t.book Page 83

Page 97 of 448

GETTING TO KNOW YOUR VEHICLE95

(Continued)

HARD TOP FRONT PANEL(S) REMOVAL

Use this QR code to access your

digital experience.

CAUTION!

The hard top is not designed to carry any addi -

tional loads, such as after-market roof racks,

spare tires, building materials, hunting or

camping supplies, etc. Ú page 115.

Do not move your vehicle until the top has

been either fully attached to the front header,

sport bar, and body, or fully removed.

Failure to follow these cautions may cause

interior water damage, stains or mildew:

It is recommended that the top be free of

water prior to panel removal. Removing the

top, opening a door, or lowering a window

while the top is wet may allow water to drip

into the vehicle’s interior.

The hard top assembly must be positioned

properly to ensure sealing. Improper installa -

tion can cause water to leak into the vehicle’s

interior.

Careless handling and storage of the remov -

able roof panels may damage the seals,

causing water to leak into the vehicle’s inte -

rior.

The front panel(s) must be positioned properly

to ensure sealing. Improper installation can

cause water to leak into the vehicle’s interior.

CAUTION!

2

23_JT_OM_EN_USC_t.book Page 95

Page 102 of 448

100GETTING TO KNOW YOUR VEHICLE

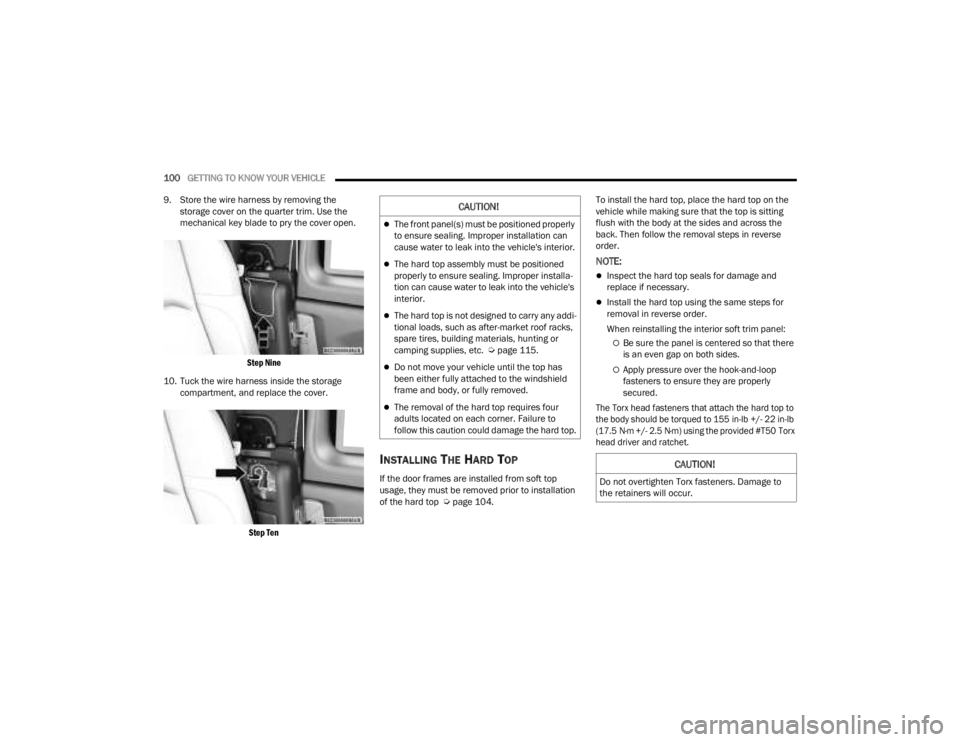

9. Store the wire harness by removing the storage cover on the quarter trim. Use the

mechanical key blade to pry the cover open.

Step Nine

10. Tuck the wire harness inside the storage compartment, and replace the cover.

Step Ten

INSTALLING THE HARD TOP

If the door frames are installed from soft top

usage, they must be removed prior to installation

of the hard top Ú page 104. To install the hard top, place the hard top on the

vehicle while making sure that the top is sitting

flush with the body at the sides and across the

back. Then follow the removal steps in reverse

order.

NOTE:

Inspect the hard top seals for damage and

replace if necessary.

Install the hard top using the same steps for

removal in reverse order.

When reinstalling the interior soft trim panel:

Be sure the panel is centered so that there

is an even gap on both sides.

Apply pressure over the hook-and-loop

fasteners to ensure they are properly

secured.

The Torx head fasteners that attach the hard top to

the body should be torqued to 155 in-lb +/- 22 in-lb

(17.5 N·m +/- 2.5 N·m) using the provided #T50 Torx

head driver and ratchet.

CAUTION!

The front panel(s) must be positioned properly

to ensure sealing. Improper installation can

cause water to leak into the vehicle's interior.

The hard top assembly must be positioned

properly to ensure sealing. Improper installa -

tion can cause water to leak into the vehicle's

interior.

The hard top is not designed to carry any addi -

tional loads, such as after-market roof racks,

spare tires, building materials, hunting or

camping supplies, etc. Ú page 115.

Do not move your vehicle until the top has

been either fully attached to the windshield

frame and body, or fully removed.

The removal of the hard top requires four

adults located on each corner. Failure to

follow this caution could damage the hard top.

CAUTION!

Do not overtighten Torx fasteners. Damage to

the retainers will occur.

23_JT_OM_EN_USC_t.book Page 100

Page 139 of 448

GETTING TO KNOW YOUR INSTRUMENT PANEL137

Service Forward Collision Warning (FCW)

Light — If Equipped

This warning light will illuminate to

indicate a fault in the Forward Collision

Warning System. Contact an authorized

dealer for service Úpage 291.

Service Stop/Start System Warning Light —

If Equipped

This warning light will illuminate when the

Stop/Start system is not functioning

properly and service is required. Contact

an authorized dealer for service.

Sway Bar Fault Warning Light —

If Equipped

This light will illuminate when there is a

fault in the sway bar disconnect system

Úpage 166.

Tire Pressure Monitoring System (TPMS)

Warning Light

The warning light switches on and a

message is displayed to indicate that the

tire pressure is lower than the

recommended value and/or that slow

pressure loss is occurring. In these cases, optimal

tire life and fuel consumption may not be

guaranteed. Should one or more tires be in the condition

previously mentioned, the display will show the

indications corresponding to each tire.

Each tire, including the spare (if provided), should

be checked monthly when cold and inflated to the

inflation pressure recommended by the vehicle

manufacturer on the vehicle placard or tire

inflation pressure label. If your vehicle has tires of

a different size than the size indicated on the

vehicle placard or tire inflation pressure label, you

should determine the proper tire inflation pressure

for those tires.

As an added safety feature, your vehicle has been

equipped with a TPMS that illuminates a low tire

pressure telltale when one or more of your tires is

significantly underinflated. Accordingly, when the

low tire pressure telltale illuminates, you should

stop and check your tires as soon as possible and

inflate them to the proper pressure. Driving on a

significantly underinflated tire causes the tire to

overheat and can lead to tire failure. Underinflation also reduces fuel efficiency and tire tread life, and

may affect the vehicle’s handling and stopping

ability.

Please note that the TPMS is not a substitute for

proper tire maintenance, and it is the driver’s

responsibility to maintain correct tire pressure,

even if underinflation has not reached the level to

trigger illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system

is not operating properly. The TPMS malfunction

indicator is combined with the low tire pressure

telltale. When the system detects a malfunction,

the telltale will flash for approximately one minute

and then remain continuously illuminated. This

sequence will continue upon subsequent vehicle

start-ups as long as the malfunction exists. When

the malfunction indicator is illuminated, the

system may not be able to detect or signal low tire

pressure as intended. TPMS malfunctions may

occur for a variety of reasons, including the

installation of replacement or alternate tires or

wheels on the vehicle that prevent the TPMS from

functioning properly. Always check the TPMS

malfunction telltale after replacing one or more

tires or wheels on your vehicle to ensure that the

replacement or alternate tires and wheels allow

the TPMS to continue to function properly.

WARNING!

Do not continue driving with one or more flat

tires as handling may be compromised. Stop the

vehicle, avoiding sharp braking and steering. If a

tire puncture occurs, repair immediately using

the dedicated tire repair kit and contact an

authorized dealer as soon as possible.

3

23_JT_OM_EN_USC_t.book Page 137

Page 140 of 448

138GETTING TO KNOW YOUR INSTRUMENT PANEL

AdBlue® (UREA) Injection System Failure

Warning Light — If Equipped

This warning light will illuminate along

with a dedicated message on the display

(if equipped) if an unknown fluid not

conforming with acceptable

characteristics is inserted, or if an average

consumption of AdBlue® (UREA) over 50% is

detected. Contact an authorized dealer as soon as

possible. If the problem is not solved, a specific message will

appear on the Instrument Cluster Display

whenever a certain threshold is reached until it will

no longer be possible to start the engine.

When about 125 miles (200 km) are remaining

before the AdBlue® (UREA) tank is empty, a

continuous dedicated message will appear on the

instrument panel, accompanied by a buzzer sound

(if equipped).

YELLOW INDICATOR LIGHTS

4WD Indicator Light — If Equipped

This light alerts the driver that the vehicle

is in the four-wheel drive mode, and the

front and rear driveshafts are

mechanically locked together forcing the

front and rear wheels to rotate at the same speed.

4WD Low Indicator Light — If Equipped

This light alerts the driver that the vehicle

is in the 4WD Low mode. The front and

rear driveshafts are mechanically locked

together forcing the front and rear

wheels to rotate at the same speed. Low range

provides a greater gear reduction ratio to provide

increased torque at the wheels.

4WD Part Time Indicator Light —

If Equipped

This light alerts the driver that the vehicle

is in the four-wheel drive part time mode,

and the front and rear driveshafts are

mechanically locked together forcing the

front and rear wheels to rotate at the same speed.

Axle Locker Fault Indicator Light —

If Equipped

This light indicates when front and/or

rear axle locker fault has been detected.

Rear Axle Lock Indicator Light —

If Equipped

This light indicates when the rear axle

lock has been activated Ú page 161.

Front And Rear Axle Lock Indicator Light —

If Equipped

This light indicates when the front, rear,

or both axles have been locked. The

telltale will display the lock icon on the

front and rear axles to indicate the

current lock status.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures

and warning have been established for the tire

size equipped on your vehicle. Undesirable

system operation or sensor damage may result

when using replacement equipment that is not

of the same size, type, and/or style. Aftermarket

wheels can cause sensor damage. Using

aftermarket tire sealants may cause the Tire

Pressure Monitoring System (TPMS) sensor to

become inoperable. After using an aftermarket

tire sealant it is recommended that you take

your vehicle to an authorized dealer to have your

sensor function checked.

23_JT_OM_EN_USC_t.book Page 138

Page 164 of 448

162STARTING AND OPERATING

4L

Four-Wheel Drive Low Range — This range provides

low speed four-wheel drive. It maximizes torque to

the front driveshaft, forcing the front and rear

wheels to rotate at the same speed. This range

provides additional traction and maximum pulling

power for loose, slippery road surfaces only. Do not

exceed 25 mph (40 km/h).

The transfer case is intended to be driven in the 2H

position for normal street and highway conditions,

such as hard-surfaced roads.

In the event that additional traction is required, the

transfer case 4H and 4L positions can be used to

lock the front and rear driveshafts together, forcing

the front and rear wheels to rotate at the same

speed. The 4H and 4L positions are intended for

loose, slippery road surfaces only and not intended

for normal driving. Driving in the 4H and 4L

positions on hard-surfaced roads will cause

increased tire wear and damage to the driveline

components. For further information on shifting

into 4H or 4L Ú page 162.

The instrument cluster alerts the driver that the

vehicle is in four-wheel drive, and the front and

rear driveshafts are locked together. The light will

illuminate when the transfer case is shifted into

the 4H position.

When operating your vehicle in 4L, the engine

speed will be approximately three times (four times

for Rubicon models) that of the 2H or 4H positions at a given road speed. Take care not to overspeed

the engine.

Proper operation of four-wheel drive vehicles

depends on tires of equal size, type, and

circumference on each wheel. Any difference will

adversely affect shifting and cause damage to the

transfer case.

Because four-wheel drive provides improved

traction, there is a tendency to exceed safe turning

and stopping speeds. Do not go faster than road

conditions permit.

Shifting Procedures

2H TO 4H OR 4H TO 2H

Shifting between 2H and 4H can be made with the

vehicle stopped or in motion. The preferred shifting

speed would be 0 to 45 mph (72 km/h). With the

vehicle in motion, the transfer case will engage/

disengage faster if you momentarily release the

accelerator pedal after completing the shift. Do not

accelerate while shifting the transfer case. Apply a

constant force when shifting the transfer case lever.

NOTE:

Do not attempt to make a shift while only the

front or rear wheels are spinning. The front and

rear driveshaft speeds must be equal for the

shift to take place. Shifting while only the front

or rear wheels are spinning can cause damage

to the transfer case.

Delayed shifts out of four-wheel drive may be

experienced due to uneven tire wear, low or

uneven tire pressures, excessive vehicle

loading, or cold temperatures.

Shifting effort will increase with speed, this is

normal.

During cold weather, you may experience

increased effort in shifting until the transfer case

fluid warms up. This is normal.

4H TO 4L OR 4L TO 4H

With the vehicle rolling at 1 to 3 mph (2 to 5 km/h),

shift an automatic transmission into NEUTRAL (N), or

press the clutch pedal on a manual transmission.

While the vehicle is coasting at 1 to 3 mph (2 to

5 km/h), shift the transfer case lever firmly to the

desired position. Do not pause with the transfer case

in N (Neutral). Once the shift is completed, place the

automatic transmission into DRIVE or release the

clutch pedal on a manual transmission.

NOTE:Shifting into or out of 4L is possible with the vehicle

completely stopped; however, difficulty may occur

due to the mating teeth not being properly aligned.

Several attempts may be required for clutch teeth

alignment and shift completion to occur. The

preferred method is with the vehicle rolling at 1 to

3 mph (2 to 5 km/h). Avoid attempting to engage

or disengage 4L with the vehicle moving faster

than 1 to 3 mph (2 to 5 km/h).

23_JT_OM_EN_USC_t.book Page 162

Page 166 of 448

164STARTING AND OPERATING

For variable driving conditions, the 4H AUTO mode

can be used. In this mode, the front axle is

engaged, but the vehicle's power is sent to the rear

wheels. Four-wheel drive will be automatically

engaged when the vehicle senses a loss of

traction. Because the front axle is engaged, this

mode will result in lower fuel economy than the 2H

mode.

In the event that additional traction is required, the

transfer case 4H and 4L positions can be used to

lock the front and rear driveshafts together, forcing

the front and rear wheels to rotate at the same

speed. The 4H and 4L positions are intended for

loose, slippery road surfaces only and not intended

for normal driving. Driving in the 4H and 4L

positions on hard-surfaced roads will cause

increased tire wear and damage to the driveline

components. For further information on shifting

into 4H or 4L Ú page 164.

The instrument cluster alerts the driver that the

vehicle is in four-wheel drive, and the front and

rear driveshafts are locked together. The light will

illuminate when the transfer case is shifted into

the 4H position.

When operating your vehicle in 4L, the engine

speed will be approximately three times (four times

for Rubicon models) that of the 2H or 4H positions

at a given road speed. Take care not to overspeed

the engine. Proper operation of four-wheel drive vehicles

depends on tires of equal size, type, and

circumference on each wheel. Any difference will

adversely affect shifting and cause damage to the

transfer case.

Because four-wheel drive provides improved

traction, there is a tendency to exceed safe turning

and stopping speeds. Do not go faster than road

conditions permit.

Shifting Procedures

2H TO 4H AUTO OR 4H AUTO TO 2H

Shifting between 2H and 4H AUTO can be made

with the vehicle stopped or in motion. The

preferred shifting speed would be 0 to 45 mph

(72 km/h). With the vehicle in motion, the transfer

case will engage/disengage faster if you

momentarily release the accelerator pedal after

completing the shift. Do not accelerate while

shifting the transfer case. Apply a constant force

when shifting the transfer case lever.

2H/4H AUTO TO 4H PART TIME OR 4H PART

TIME TO 2H/4H AUTO

Shifting between 2H/4H AUTO to 4H PART TIME

can be made with the vehicle stopped or in motion.

The preferred shifting speed would be 0 to 45 mph

(72 km/h). With the vehicle in motion, the transfer

case will engage/disengage faster if you

momentarily release the accelerator pedal after completing the shift. Do not accelerate while

shifting the transfer case. Apply a constant force

when shifting the transfer case lever.

NOTE:

Do not attempt to make a shift while only the

front or rear wheels are spinning. The front and

rear driveshaft speeds must be equal for the

shift to take place. Shifting while only the front

or rear wheels are spinning can cause damage

to the transfer case.

Delayed shifts out of four-wheel drive may be

experienced due to uneven tire wear, low or

uneven tire pressures, excessive vehicle

loading, or cold temperatures.

Shifting effort will increase with speed, this is

normal.

During cold weather, you may experience

increased effort in shifting until the transfer case

fluid warms up. This is normal.

4H PART TIME/4H AUTO TO 4L OR 4L TO 4H

PART TIME/4H AUTO

With the vehicle rolling at 1 to 3 mph (2 to 5 km/h),

shift an automatic transmission into NEUTRAL (N),

or press the clutch pedal on a manual

transmission. While the vehicle is coasting at 1 to

3 mph (2 to 5 km/h), shift the transfer case lever

firmly to the desired position. Do not pause with

the transfer case in N (Neutral). Once the shift is

23_JT_OM_EN_USC_t.book Page 164

Page 198 of 448

196STARTING AND OPERATING

This label contains the month and year of

manufacture, Gross Vehicle Weight Rating

(GVWR), front and rear Gross Axle Weight Rating

(GAWR), and Vehicle Identification Number (VIN). A

Month-Day-Hour (MDH) number is included on this

label and indicates the Month, Day and Hour of

manufacture. The bar code that appears on the

bottom of the label is your VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear Gross Axle

Weight Rating (GAWR). Total load must be limited

so GVWR on front and rear GAWR are not

exceeded.

Payload

The payload of a vehicle is defined as the allowable

load weight a truck can carry, including the weight

of the driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the

front and rear axles. The load must be distributed

in the cargo area so that the GAWR of each axle is

not exceeded.

Each axle GAWR is determined by the components

in the system with the lowest load carrying capacity

(axle, springs, tires or wheels). Heavier axles or

suspension components sometimes specified by purchasers for increased durability does not

necessarily increase the vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire

size listed.

Inflation Pressure

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The

front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

Loading

The actual total weight and the weight of the front

and rear of your vehicle at the ground can best be

determined by weighing it when it is loaded and

ready for operation.

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has not

been exceeded. The weight on the front and rear of

the vehicle should then be determined separately

to be sure that the load is properly distributed over

the front and rear axle. Weighing the vehicle may

show that the GAWR of either the front or rear axles

has been exceeded but the total load is within the

specified GVWR. If so, weight must be shifted from

front to rear or rear to front as appropriate until the

specified weight limitations are met. Store the

heavier items down low and be sure that the

weight is distributed equally. Stow all loose items

securely before driving.

Improper weight distributions can have an adverse

effect on the way your vehicle steers and handles

and the way the brakes operate.

WARNING!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR. If

you do, parts on your vehicle can break, or it can

change the way your vehicle handles. This could

cause you to lose control. Overloading can

shorten the life of your vehicle.

23_JT_OM_EN_USC_t.book Page 196

Page 204 of 448

202STARTING AND OPERATING

(Continued)

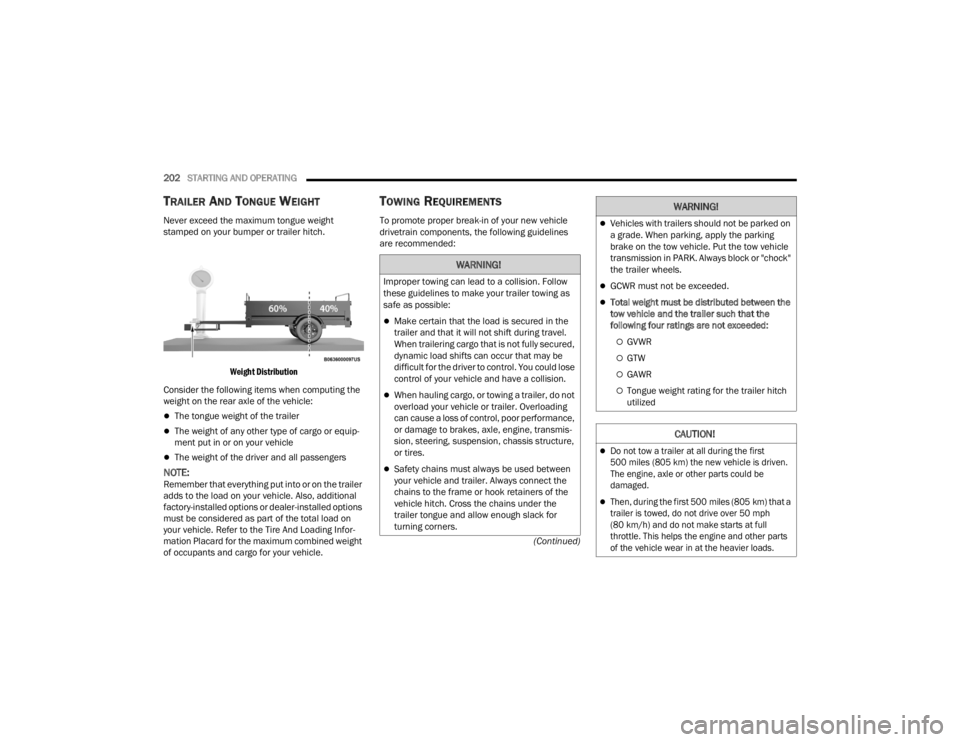

TRAILER AND TONGUE WEIGHT

Never exceed the maximum tongue weight

stamped on your bumper or trailer hitch.

Weight Distribution

Consider the following items when computing the

weight on the rear axle of the vehicle:

The tongue weight of the trailer

The weight of any other type of cargo or equip -

ment put in or on your vehicle

The weight of the driver and all passengers

NOTE:Remember that everything put into or on the trailer

adds to the load on your vehicle. Also, additional

factory-installed options or dealer-installed options

must be considered as part of the total load on

your vehicle. Refer to the Tire And Loading Infor -

mation Placard for the maximum combined weight

of occupants and cargo for your vehicle.

TOWING REQUIREMENTS

To promote proper break-in of your new vehicle

drivetrain components, the following guidelines

are recommended:

WARNING!

Improper towing can lead to a collision. Follow

these guidelines to make your trailer towing as

safe as possible:

Make certain that the load is secured in the

trailer and that it will not shift during travel.

When trailering cargo that is not fully secured,

dynamic load shifts can occur that may be

difficult for the driver to control. You could lose

control of your vehicle and have a collision.

When hauling cargo, or towing a trailer, do not

overload your vehicle or trailer. Overloading

can cause a loss of control, poor performance,

or damage to brakes, axle, engine, transmis -

sion, steering, suspension, chassis structure,

or tires.

Safety chains must always be used between

your vehicle and trailer. Always connect the

chains to the frame or hook retainers of the

vehicle hitch. Cross the chains under the

trailer tongue and allow enough slack for

turning corners.

Vehicles with trailers should not be parked on

a grade. When parking, apply the parking

brake on the tow vehicle. Put the tow vehicle

transmission in PARK. Always block or "chock"

the trailer wheels.

GCWR must not be exceeded.

Total weight must be distributed between the

tow vehicle and the trailer such that the

following four ratings are not exceeded:

GVWR

GTW

GAWR

Tongue weight rating for the trailer hitch

utilized

CAUTION!

Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is driven.

The engine, axle or other parts could be

damaged.

Then, during the first 500 miles (805 km) that a

trailer is towed, do not drive over 50 mph

(80 km/h) and do not make starts at full

throttle. This helps the engine and other parts

of the vehicle wear in at the heavier loads.

WARNING!

23_JT_OM_EN_USC_t.book Page 202