Speed sensor JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1584 of 2199

(8) Engine starts must be possible with shifter

lever in PARK or NEUTRAL gate positions only.

Engine starts must not be possible in any other gate

positions other than PARK or NEUTRAL.

(9) With shifter lever handle push-button not

depressed and lever detent in:

²PARK position- apply forward force on center of

handle and remove pressure. Engine start must be

possible.

²PARK position- apply rearward force on center

of handle and remove pressure. Engine start must be

possible.

²NEUTRAL position- engine start must be possi-

ble.

²NEUTRAL position, engine running and brakes

applied- Apply forward force on center of shift han-

dle. Transmission should not be able to shift into

REVERSE detent.

ELECTRONIC GOVERNOR

DESCRIPTION

Governor pressure is controlled electronically. Com-

ponents used for governor pressure control include:

²Governor body

²Valve body transfer plate

²Governor pressure solenoid valve

²Governor pressure sensor

²Fluid temperature thermistor

²Throttle position sensor (TPS)

²Transmission speed sensor

²Powertrain control module (PCM)

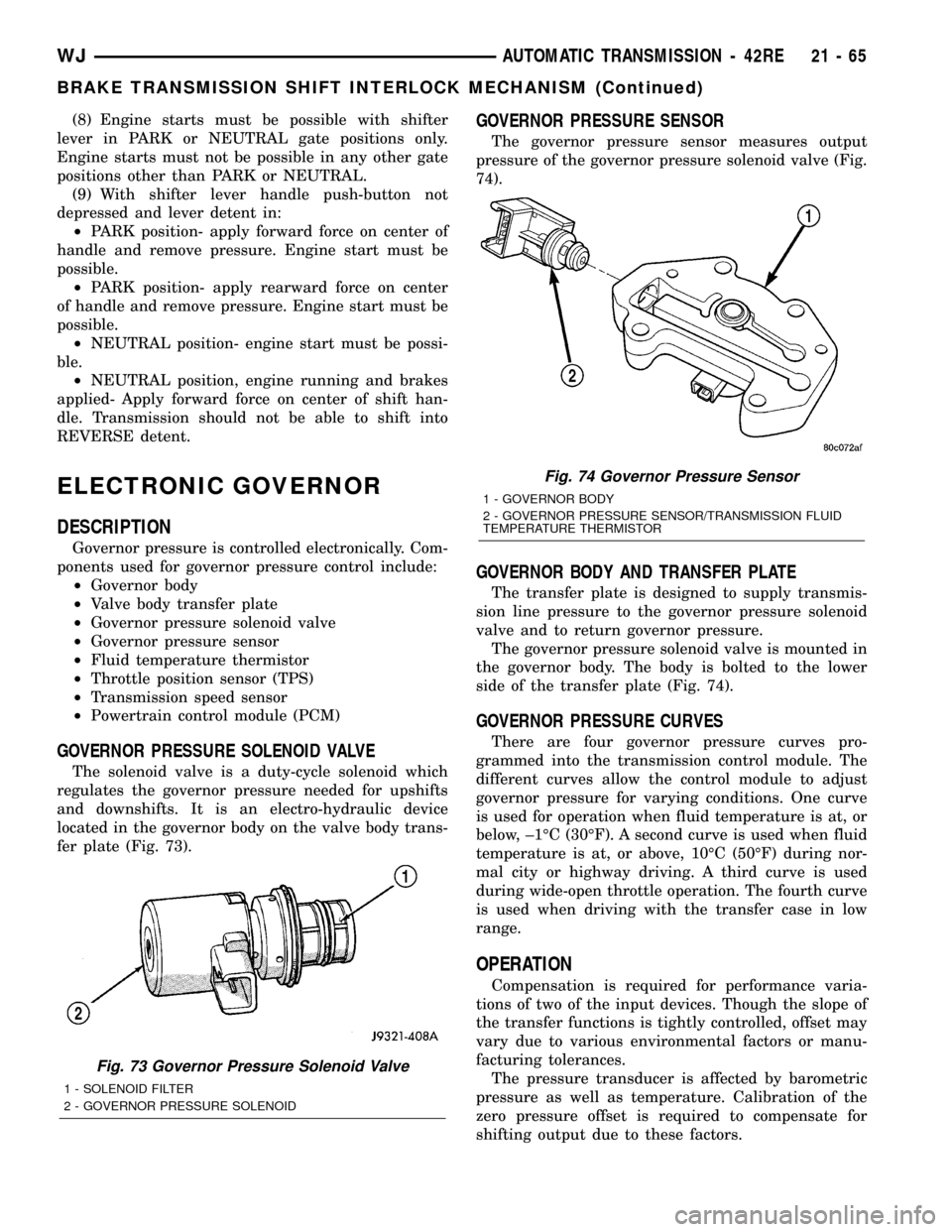

GOVERNOR PRESSURE SOLENOID VALVE

The solenoid valve is a duty-cycle solenoid which

regulates the governor pressure needed for upshifts

and downshifts. It is an electro-hydraulic device

located in the governor body on the valve body trans-

fer plate (Fig. 73).

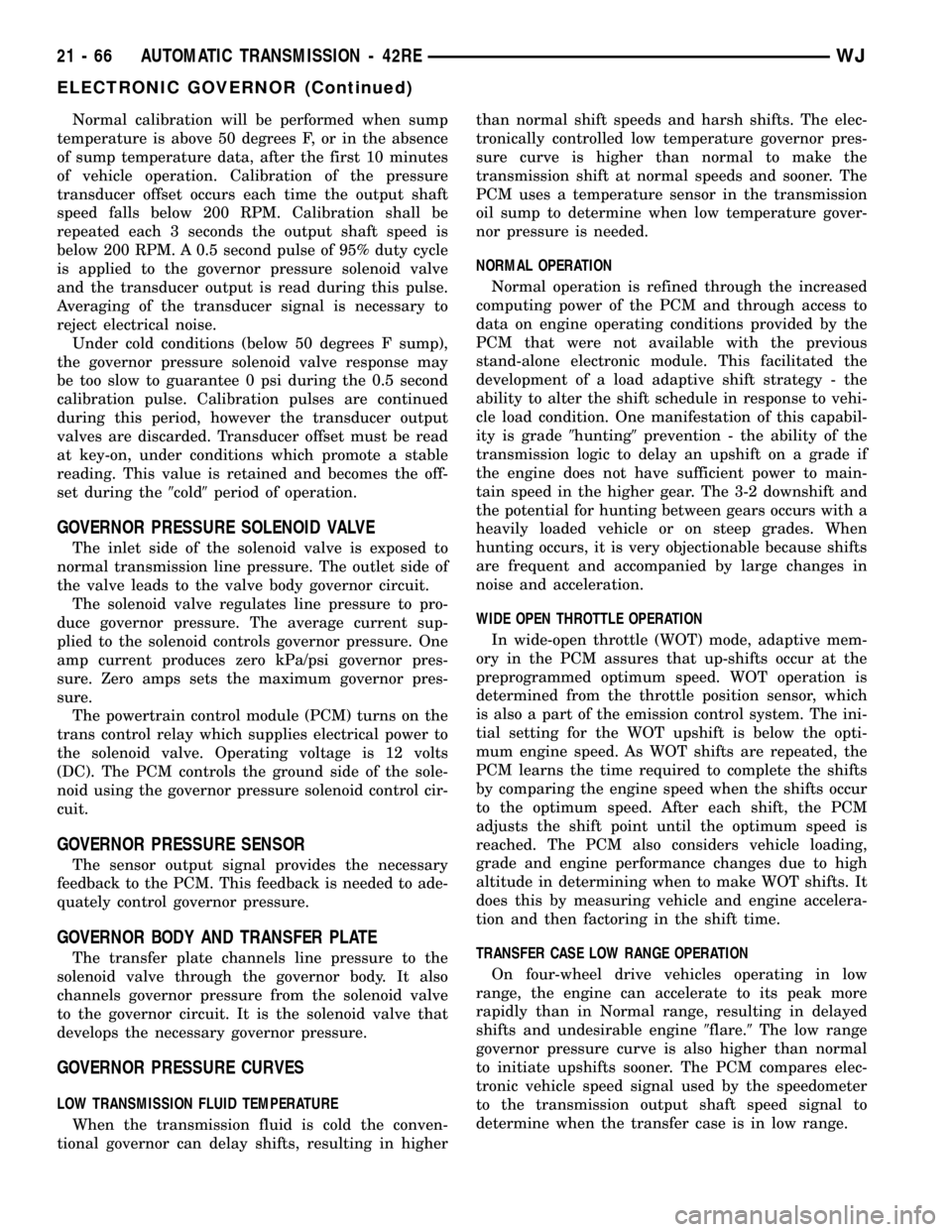

GOVERNOR PRESSURE SENSOR

The governor pressure sensor measures output

pressure of the governor pressure solenoid valve (Fig.

74).

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate is designed to supply transmis-

sion line pressure to the governor pressure solenoid

valve and to return governor pressure.

The governor pressure solenoid valve is mounted in

the governor body. The body is bolted to the lower

side of the transfer plate (Fig. 74).

GOVERNOR PRESSURE CURVES

There are four governor pressure curves pro-

grammed into the transmission control module. The

different curves allow the control module to adjust

governor pressure for varying conditions. One curve

is used for operation when fluid temperature is at, or

below, ±1ÉC (30ÉF). A second curve is used when fluid

temperature is at, or above, 10ÉC (50ÉF) during nor-

mal city or highway driving. A third curve is used

during wide-open throttle operation. The fourth curve

is used when driving with the transfer case in low

range.

OPERATION

Compensation is required for performance varia-

tions of two of the input devices. Though the slope of

the transfer functions is tightly controlled, offset may

vary due to various environmental factors or manu-

facturing tolerances.

The pressure transducer is affected by barometric

pressure as well as temperature. Calibration of the

zero pressure offset is required to compensate for

shifting output due to these factors.

Fig. 73 Governor Pressure Solenoid Valve

1 - SOLENOID FILTER

2 - GOVERNOR PRESSURE SOLENOID

Fig. 74 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

WJAUTOMATIC TRANSMISSION - 42RE 21 - 65

BRAKE TRANSMISSION SHIFT INTERLOCK MECHANISM (Continued)

Page 1585 of 2199

Normal calibration will be performed when sump

temperature is above 50 degrees F, or in the absence

of sump temperature data, after the first 10 minutes

of vehicle operation. Calibration of the pressure

transducer offset occurs each time the output shaft

speed falls below 200 RPM. Calibration shall be

repeated each 3 seconds the output shaft speed is

below 200 RPM. A 0.5 second pulse of 95% duty cycle

is applied to the governor pressure solenoid valve

and the transducer output is read during this pulse.

Averaging of the transducer signal is necessary to

reject electrical noise.

Under cold conditions (below 50 degrees F sump),

the governor pressure solenoid valve response may

be too slow to guarantee 0 psi during the 0.5 second

calibration pulse. Calibration pulses are continued

during this period, however the transducer output

valves are discarded. Transducer offset must be read

at key-on, under conditions which promote a stable

reading. This value is retained and becomes the off-

set during the9cold9period of operation.

GOVERNOR PRESSURE SOLENOID VALVE

The inlet side of the solenoid valve is exposed to

normal transmission line pressure. The outlet side of

the valve leads to the valve body governor circuit.

The solenoid valve regulates line pressure to pro-

duce governor pressure. The average current sup-

plied to the solenoid controls governor pressure. One

amp current produces zero kPa/psi governor pres-

sure. Zero amps sets the maximum governor pres-

sure.

The powertrain control module (PCM) turns on the

trans control relay which supplies electrical power to

the solenoid valve. Operating voltage is 12 volts

(DC). The PCM controls the ground side of the sole-

noid using the governor pressure solenoid control cir-

cuit.

GOVERNOR PRESSURE SENSOR

The sensor output signal provides the necessary

feedback to the PCM. This feedback is needed to ade-

quately control governor pressure.

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate channels line pressure to the

solenoid valve through the governor body. It also

channels governor pressure from the solenoid valve

to the governor circuit. It is the solenoid valve that

develops the necessary governor pressure.

GOVERNOR PRESSURE CURVES

LOW TRANSMISSION FLUID TEMPERATURE

When the transmission fluid is cold the conven-

tional governor can delay shifts, resulting in higherthan normal shift speeds and harsh shifts. The elec-

tronically controlled low temperature governor pres-

sure curve is higher than normal to make the

transmission shift at normal speeds and sooner. The

PCM uses a temperature sensor in the transmission

oil sump to determine when low temperature gover-

nor pressure is needed.

NORMAL OPERATION

Normal operation is refined through the increased

computing power of the PCM and through access to

data on engine operating conditions provided by the

PCM that were not available with the previous

stand-alone electronic module. This facilitated the

development of a load adaptive shift strategy - the

ability to alter the shift schedule in response to vehi-

cle load condition. One manifestation of this capabil-

ity is grade9hunting9prevention - the ability of the

transmission logic to delay an upshift on a grade if

the engine does not have sufficient power to main-

tain speed in the higher gear. The 3-2 downshift and

the potential for hunting between gears occurs with a

heavily loaded vehicle or on steep grades. When

hunting occurs, it is very objectionable because shifts

are frequent and accompanied by large changes in

noise and acceleration.

WIDE OPEN THROTTLE OPERATION

In wide-open throttle (WOT) mode, adaptive mem-

ory in the PCM assures that up-shifts occur at the

preprogrammed optimum speed. WOT operation is

determined from the throttle position sensor, which

is also a part of the emission control system. The ini-

tial setting for the WOT upshift is below the opti-

mum engine speed. As WOT shifts are repeated, the

PCM learns the time required to complete the shifts

by comparing the engine speed when the shifts occur

to the optimum speed. After each shift, the PCM

adjusts the shift point until the optimum speed is

reached. The PCM also considers vehicle loading,

grade and engine performance changes due to high

altitude in determining when to make WOT shifts. It

does this by measuring vehicle and engine accelera-

tion and then factoring in the shift time.

TRANSFER CASE LOW RANGE OPERATION

On four-wheel drive vehicles operating in low

range, the engine can accelerate to its peak more

rapidly than in Normal range, resulting in delayed

shifts and undesirable engine9flare.9The low range

governor pressure curve is also higher than normal

to initiate upshifts sooner. The PCM compares elec-

tronic vehicle speed signal used by the speedometer

to the transmission output shaft speed signal to

determine when the transfer case is in low range.

21 - 66 AUTOMATIC TRANSMISSION - 42REWJ

ELECTRONIC GOVERNOR (Continued)

Page 1607 of 2199

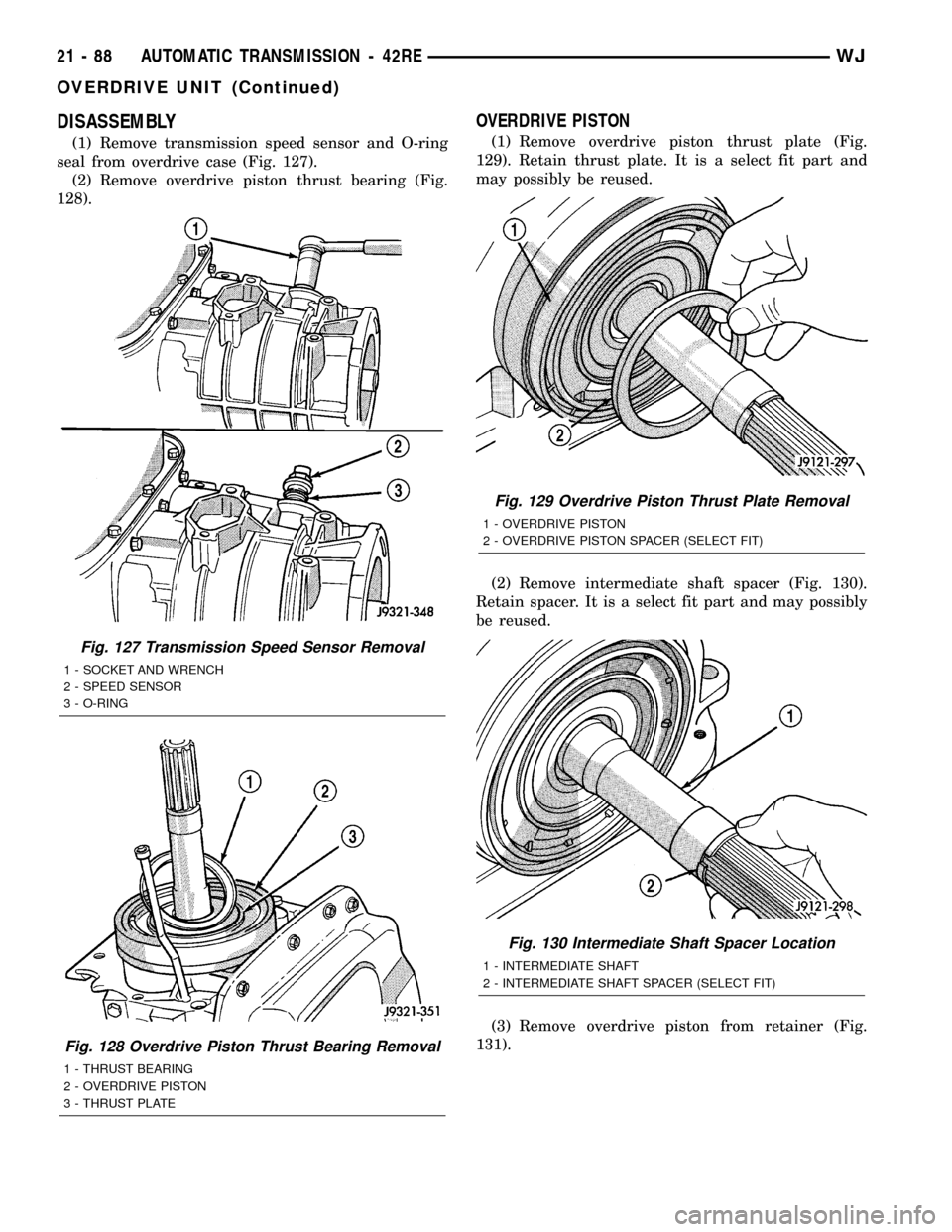

DISASSEMBLY

(1) Remove transmission speed sensor and O-ring

seal from overdrive case (Fig. 127).

(2) Remove overdrive piston thrust bearing (Fig.

128).

OVERDRIVE PISTON

(1) Remove overdrive piston thrust plate (Fig.

129). Retain thrust plate. It is a select fit part and

may possibly be reused.

(2) Remove intermediate shaft spacer (Fig. 130).

Retain spacer. It is a select fit part and may possibly

be reused.

(3) Remove overdrive piston from retainer (Fig.

131).

Fig. 127 Transmission Speed Sensor Removal

1 - SOCKET AND WRENCH

2 - SPEED SENSOR

3 - O-RING

Fig. 128 Overdrive Piston Thrust Bearing Removal

1 - THRUST BEARING

2 - OVERDRIVE PISTON

3 - THRUST PLATE

Fig. 129 Overdrive Piston Thrust Plate Removal

1 - OVERDRIVE PISTON

2 - OVERDRIVE PISTON SPACER (SELECT FIT)

Fig. 130 Intermediate Shaft Spacer Location

1 - INTERMEDIATE SHAFT

2 - INTERMEDIATE SHAFT SPACER (SELECT FIT)

21 - 88 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1623 of 2199

(3) Leave Alignment Tool 6227-2 in place. Tool will

keep planetary and clutch hub splines in alignment

until overdrive unit is ready for installation on trans-

mission.

(4) Transmission speed sensor can be installed at

this time if desired. However, it is recommended that

sensor not be installed until after overdrive unit is

secured to transmission.

OVERDRIVE PISTON

(1) Install new seals on over drive piston.

(2) Stand transmission case upright on bellhous-

ing.

(3) Position Guide Ring 8114-1 on outer edge of

overdrive piston retainer.

(4) Position Seal Guide 8114-2 on inner edge of

overdrive piston retainer.

(5) Install overdrive piston in overdrive piston

retainer by: aligning locating lugs on overdrive piston

to the two mating holes in retainer.

(a) Aligning locating lugs on overdrive piston to

the two mating holes in retainer.(b) Lubricate overdrive piston seals with Mopart

Door Ease, or equivalent.

(c) Install piston over Seal Guide 8114-2 and

inside Guide Ring 8114-1.

(d) Push overdrive piston into position in

retainer.

(e) Verify that the locating lugs entered the lug

bores in the retainer.

(6) Install intermediate shaft spacer on intermedi-

ate shaft.

(7) Install overdrive piston thrust plate on over-

drive piston.

(8) Install overdrive piston thrust bearing on over-

drive piston.

(9) Install transmission speed sensor and O-ring

seal in overdrive case (Fig. 127).

INSTALLATION

(1) Be sure overdrive unit Alignment Tool 6227-2

is fully seated before moving unit. If tool is not

seated and gear splines rotate out of alignment, over-

drive unit will have to be disassembled in order to

realign splines.

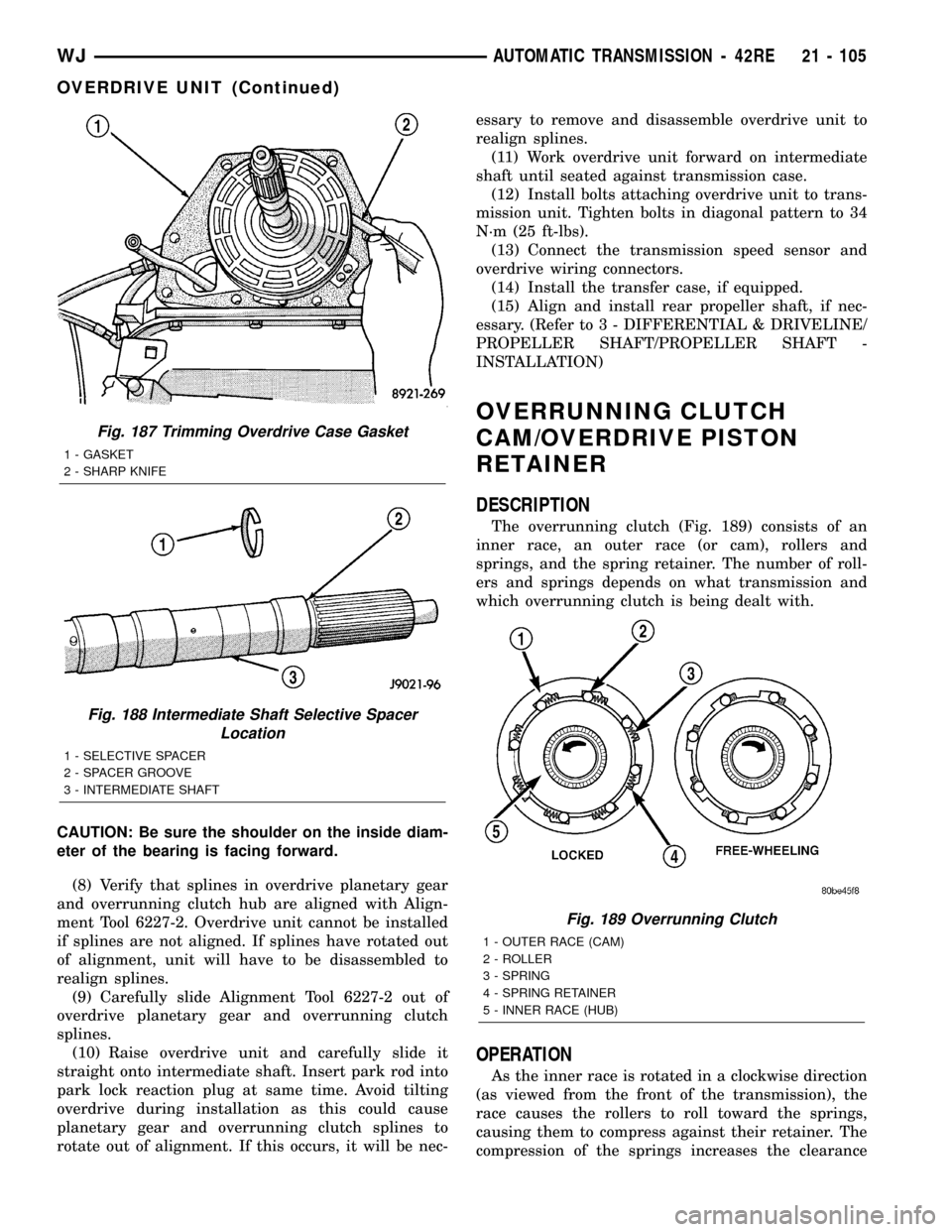

(2) If overdrive piston retainer was not removed

during service and original case gasket is no longer

reusable, prepare new gasket by trimming it.

(3) Cut out old case gasket around piston retainer

with razor knife (Fig. 187).

(4) Use old gasket as template and trim new gas-

ket to fit.

(5) Position new gasket over piston retainer and

on transmission case. Use petroleum jelly to hold

gasket in place if necessary. Do not use any type of

sealer to secure gasket. Use petroleum jelly only.

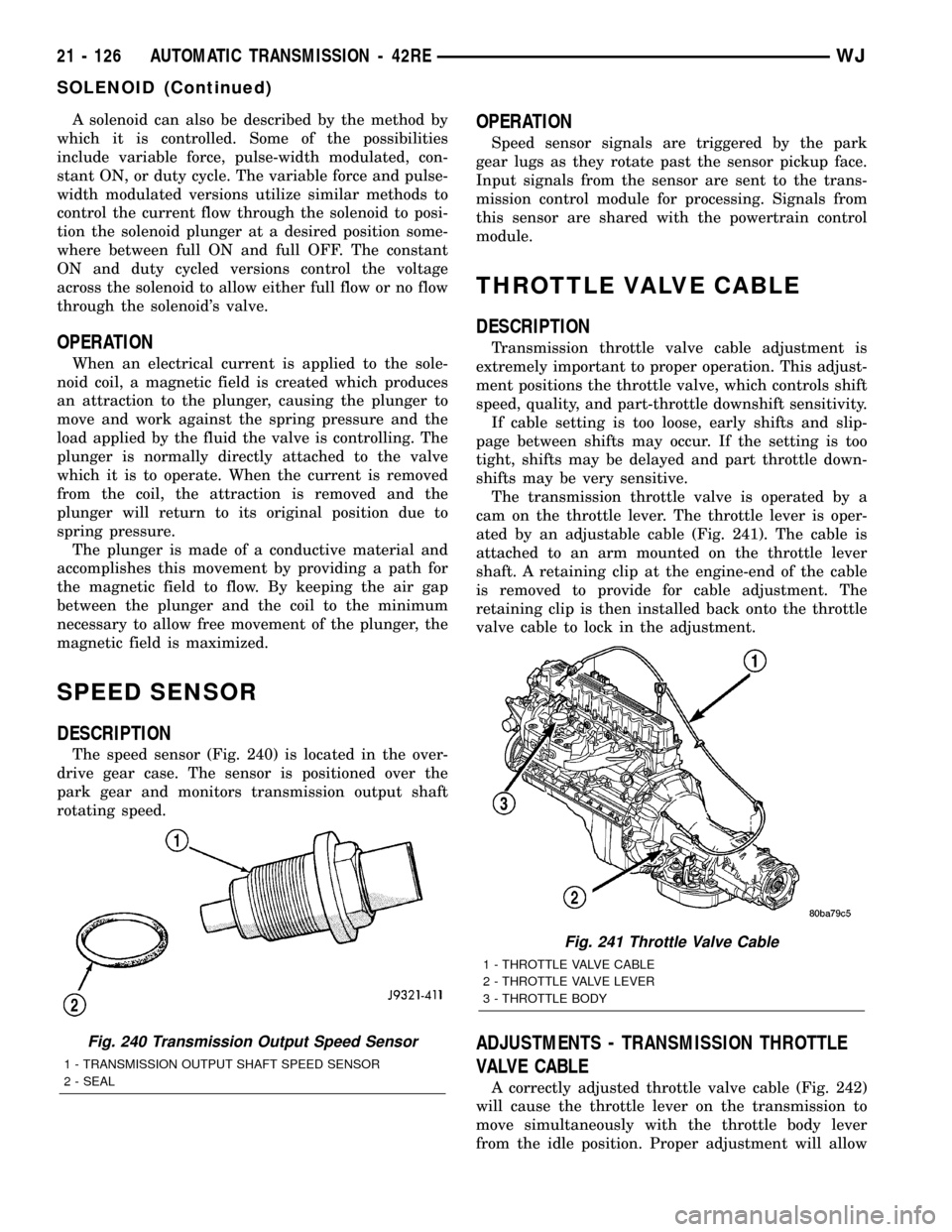

(6) Install selective spacer on intermediate shaft, if

removed. Spacer goes in groove just rearward of

shaft rear splines (Fig. 188).

(7) Install thrust bearing in overdrive unit sliding

hub. Use petroleum jelly to hold bearing in position.

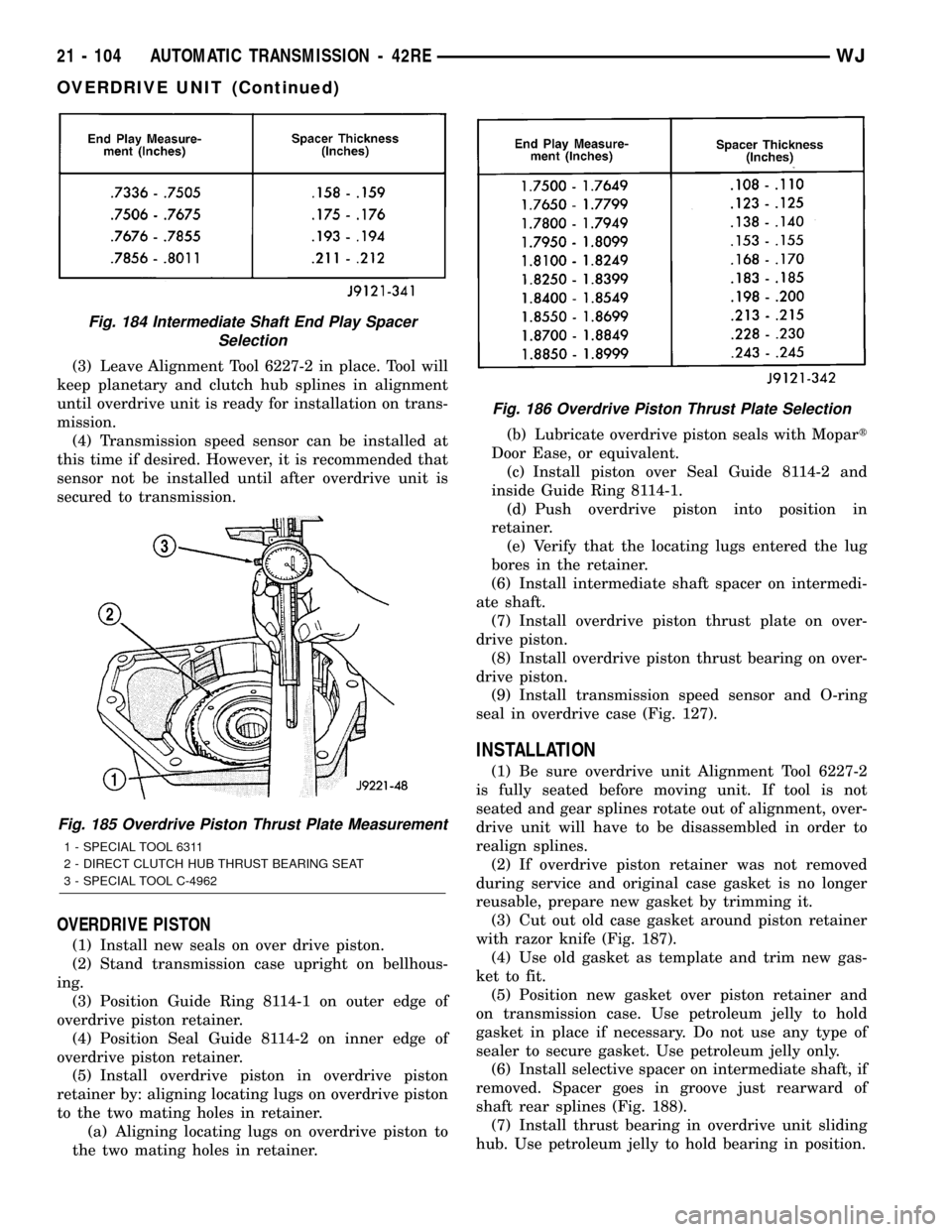

Fig. 184 Intermediate Shaft End Play Spacer

Selection

Fig. 185 Overdrive Piston Thrust Plate Measurement

1 - SPECIAL TOOL 6311

2 - DIRECT CLUTCH HUB THRUST BEARING SEAT

3 - SPECIAL TOOL C-4962

Fig. 186 Overdrive Piston Thrust Plate Selection

21 - 104 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1624 of 2199

CAUTION: Be sure the shoulder on the inside diam-

eter of the bearing is facing forward.

(8) Verify that splines in overdrive planetary gear

and overrunning clutch hub are aligned with Align-

ment Tool 6227-2. Overdrive unit cannot be installed

if splines are not aligned. If splines have rotated out

of alignment, unit will have to be disassembled to

realign splines.

(9) Carefully slide Alignment Tool 6227-2 out of

overdrive planetary gear and overrunning clutch

splines.

(10) Raise overdrive unit and carefully slide it

straight onto intermediate shaft. Insert park rod into

park lock reaction plug at same time. Avoid tilting

overdrive during installation as this could cause

planetary gear and overrunning clutch splines to

rotate out of alignment. If this occurs, it will be nec-essary to remove and disassemble overdrive unit to

realign splines.

(11) Work overdrive unit forward on intermediate

shaft until seated against transmission case.

(12) Install bolts attaching overdrive unit to trans-

mission unit. Tighten bolts in diagonal pattern to 34

N´m (25 ft-lbs).

(13) Connect the transmission speed sensor and

overdrive wiring connectors.

(14) Install the transfer case, if equipped.

(15) Align and install rear propeller shaft, if nec-

essary. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT -

INSTALLATION)

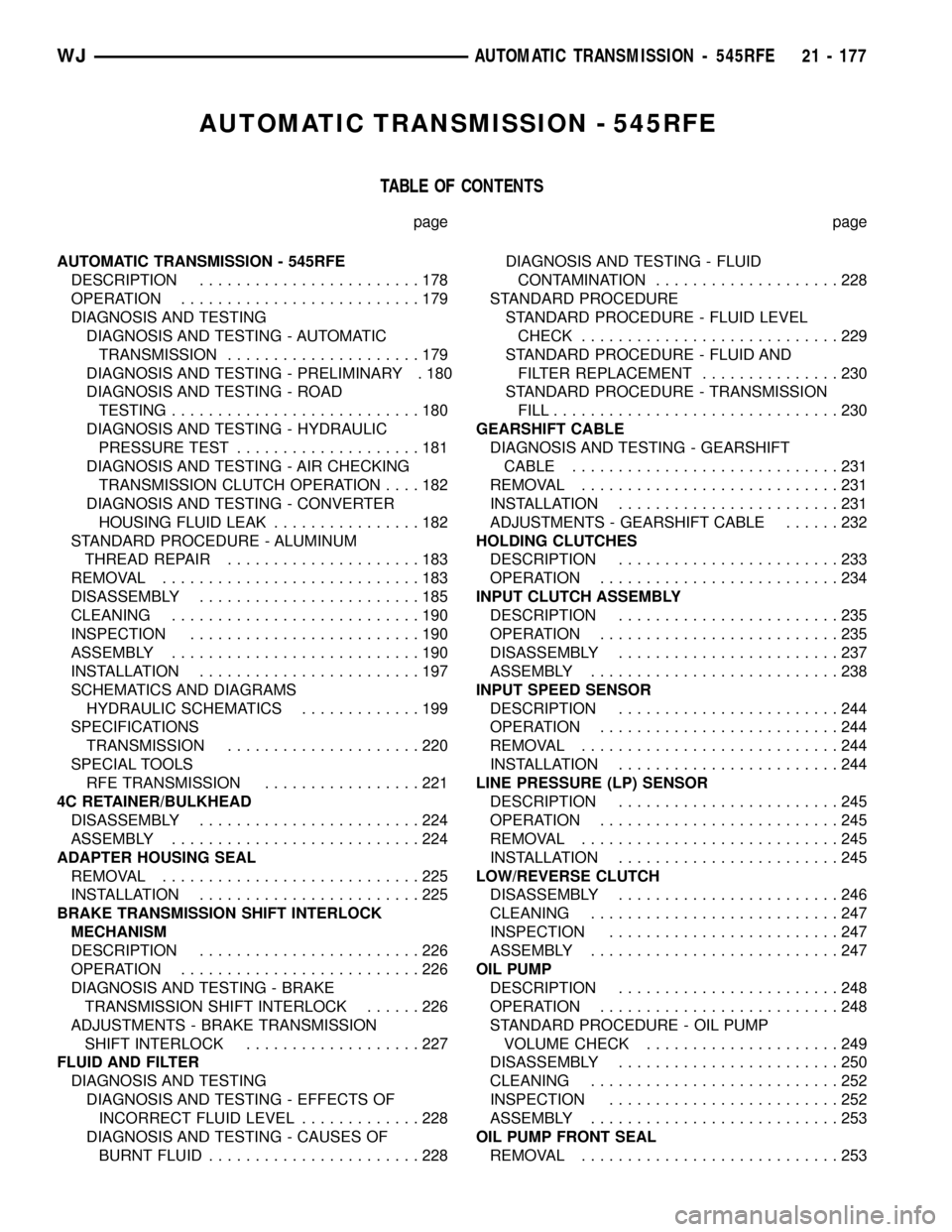

OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER

DESCRIPTION

The overrunning clutch (Fig. 189) consists of an

inner race, an outer race (or cam), rollers and

springs, and the spring retainer. The number of roll-

ers and springs depends on what transmission and

which overrunning clutch is being dealt with.

OPERATION

As the inner race is rotated in a clockwise direction

(as viewed from the front of the transmission), the

race causes the rollers to roll toward the springs,

causing them to compress against their retainer. The

compression of the springs increases the clearance

Fig. 187 Trimming Overdrive Case Gasket

1 - GASKET

2 - SHARP KNIFE

Fig. 188 Intermediate Shaft Selective Spacer

Location

1 - SELECTIVE SPACER

2 - SPACER GROOVE

3 - INTERMEDIATE SHAFT

Fig. 189 Overrunning Clutch

1 - OUTER RACE (CAM)

2 - ROLLER

3 - SPRING

4 - SPRING RETAINER

5 - INNER RACE (HUB)

WJAUTOMATIC TRANSMISSION - 42RE 21 - 105

OVERDRIVE UNIT (Continued)

Page 1645 of 2199

A solenoid can also be described by the method by

which it is controlled. Some of the possibilities

include variable force, pulse-width modulated, con-

stant ON, or duty cycle. The variable force and pulse-

width modulated versions utilize similar methods to

control the current flow through the solenoid to posi-

tion the solenoid plunger at a desired position some-

where between full ON and full OFF. The constant

ON and duty cycled versions control the voltage

across the solenoid to allow either full flow or no flow

through the solenoid's valve.

OPERATION

When an electrical current is applied to the sole-

noid coil, a magnetic field is created which produces

an attraction to the plunger, causing the plunger to

move and work against the spring pressure and the

load applied by the fluid the valve is controlling. The

plunger is normally directly attached to the valve

which it is to operate. When the current is removed

from the coil, the attraction is removed and the

plunger will return to its original position due to

spring pressure.

The plunger is made of a conductive material and

accomplishes this movement by providing a path for

the magnetic field to flow. By keeping the air gap

between the plunger and the coil to the minimum

necessary to allow free movement of the plunger, the

magnetic field is maximized.

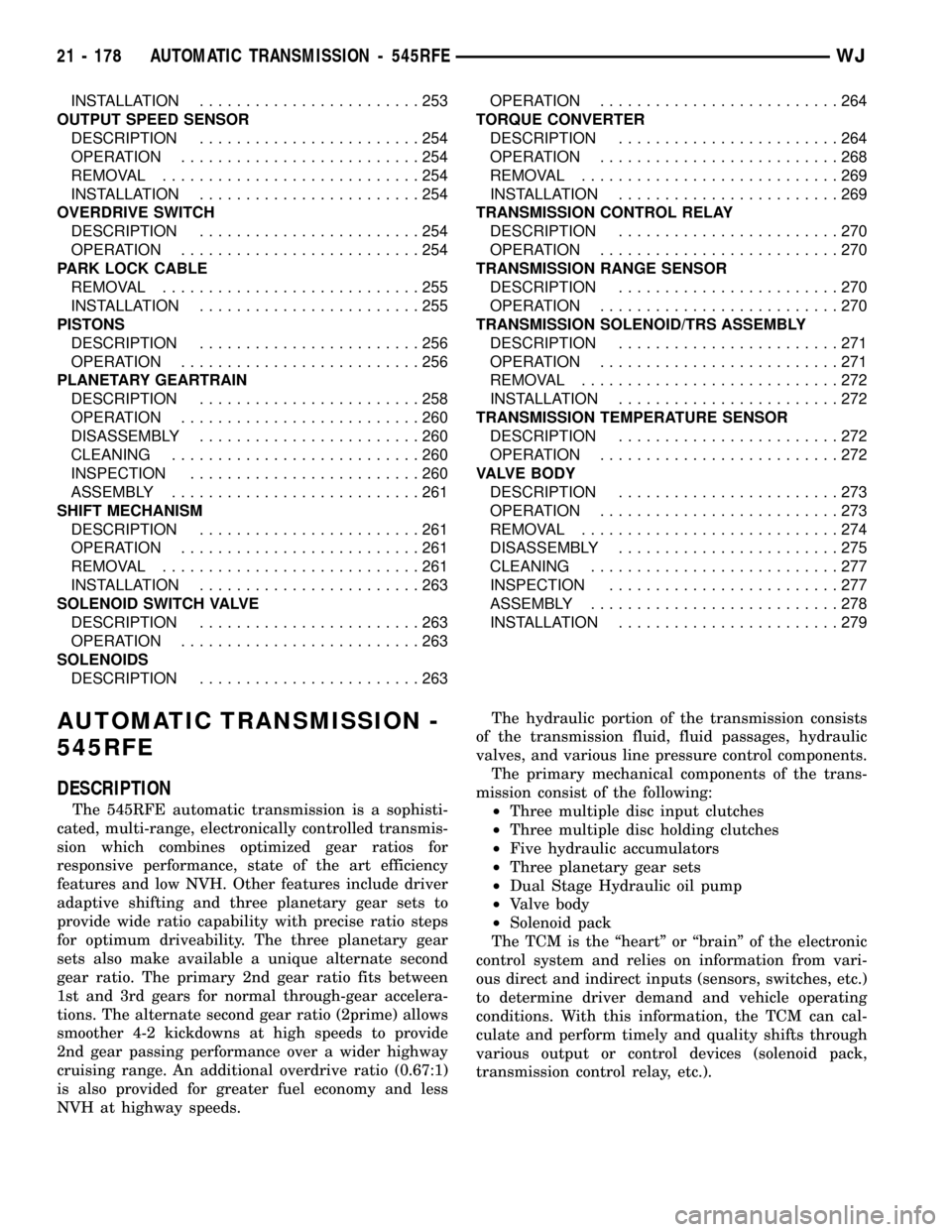

SPEED SENSOR

DESCRIPTION

The speed sensor (Fig. 240) is located in the over-

drive gear case. The sensor is positioned over the

park gear and monitors transmission output shaft

rotating speed.

OPERATION

Speed sensor signals are triggered by the park

gear lugs as they rotate past the sensor pickup face.

Input signals from the sensor are sent to the trans-

mission control module for processing. Signals from

this sensor are shared with the powertrain control

module.

THROTTLE VALVE CABLE

DESCRIPTION

Transmission throttle valve cable adjustment is

extremely important to proper operation. This adjust-

ment positions the throttle valve, which controls shift

speed, quality, and part-throttle downshift sensitivity.

If cable setting is too loose, early shifts and slip-

page between shifts may occur. If the setting is too

tight, shifts may be delayed and part throttle down-

shifts may be very sensitive.

The transmission throttle valve is operated by a

cam on the throttle lever. The throttle lever is oper-

ated by an adjustable cable (Fig. 241). The cable is

attached to an arm mounted on the throttle lever

shaft. A retaining clip at the engine-end of the cable

is removed to provide for cable adjustment. The

retaining clip is then installed back onto the throttle

valve cable to lock in the adjustment.

ADJUSTMENTS - TRANSMISSION THROTTLE

VALVE CABLE

A correctly adjusted throttle valve cable (Fig. 242)

will cause the throttle lever on the transmission to

move simultaneously with the throttle body lever

from the idle position. Proper adjustment will allow

Fig. 240 Transmission Output Speed Sensor

1 - TRANSMISSION OUTPUT SHAFT SPEED SENSOR

2 - SEAL

Fig. 241 Throttle Valve Cable

1 - THROTTLE VALVE CABLE

2 - THROTTLE VALVE LEVER

3 - THROTTLE BODY

21 - 126 AUTOMATIC TRANSMISSION - 42REWJ

SOLENOID (Continued)

Page 1696 of 2199

AUTOMATIC TRANSMISSION - 545RFE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 545RFE

DESCRIPTION........................178

OPERATION..........................179

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION.....................179

DIAGNOSIS AND TESTING - PRELIMINARY . 180

DIAGNOSIS AND TESTING - ROAD

TESTING...........................180

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST....................181

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION....182

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK................182

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR.....................183

REMOVAL............................183

DISASSEMBLY........................185

CLEANING...........................190

INSPECTION.........................190

ASSEMBLY...........................190

INSTALLATION........................197

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS.............199

SPECIFICATIONS

TRANSMISSION.....................220

SPECIAL TOOLS

RFE TRANSMISSION.................221

4C RETAINER/BULKHEAD

DISASSEMBLY........................224

ASSEMBLY...........................224

ADAPTER HOUSING SEAL

REMOVAL............................225

INSTALLATION........................225

BRAKE TRANSMISSION SHIFT INTERLOCK

MECHANISM

DESCRIPTION........................226

OPERATION..........................226

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK......226

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK...................227

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL.............228

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID.......................228DIAGNOSIS AND TESTING - FLUID

CONTAMINATION....................228

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK............................229

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT...............230

STANDARD PROCEDURE - TRANSMISSION

FILL...............................230

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE.............................231

REMOVAL............................231

INSTALLATION........................231

ADJUSTMENTS - GEARSHIFT CABLE......232

HOLDING CLUTCHES

DESCRIPTION........................233

OPERATION..........................234

INPUT CLUTCH ASSEMBLY

DESCRIPTION........................235

OPERATION..........................235

DISASSEMBLY........................237

ASSEMBLY...........................238

INPUT SPEED SENSOR

DESCRIPTION........................244

OPERATION..........................244

REMOVAL............................244

INSTALLATION........................244

LINE PRESSURE (LP) SENSOR

DESCRIPTION........................245

OPERATION..........................245

REMOVAL............................245

INSTALLATION........................245

LOW/REVERSE CLUTCH

DISASSEMBLY........................246

CLEANING...........................247

INSPECTION.........................247

ASSEMBLY...........................247

OIL PUMP

DESCRIPTION........................248

OPERATION..........................248

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................249

DISASSEMBLY........................250

CLEANING...........................252

INSPECTION.........................252

ASSEMBLY...........................253

OIL PUMP FRONT SEAL

REMOVAL............................253

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 177

Page 1697 of 2199

INSTALLATION........................253

OUTPUT SPEED SENSOR

DESCRIPTION........................254

OPERATION..........................254

REMOVAL............................254

INSTALLATION........................254

OVERDRIVE SWITCH

DESCRIPTION........................254

OPERATION..........................254

PARK LOCK CABLE

REMOVAL............................255

INSTALLATION........................255

PISTONS

DESCRIPTION........................256

OPERATION..........................256

PLANETARY GEARTRAIN

DESCRIPTION........................258

OPERATION..........................260

DISASSEMBLY........................260

CLEANING...........................260

INSPECTION.........................260

ASSEMBLY...........................261

SHIFT MECHANISM

DESCRIPTION........................261

OPERATION..........................261

REMOVAL............................261

INSTALLATION........................263

SOLENOID SWITCH VALVE

DESCRIPTION........................263

OPERATION..........................263

SOLENOIDS

DESCRIPTION........................263OPERATION..........................264

TORQUE CONVERTER

DESCRIPTION........................264

OPERATION..........................268

REMOVAL............................269

INSTALLATION........................269

TRANSMISSION CONTROL RELAY

DESCRIPTION........................270

OPERATION..........................270

TRANSMISSION RANGE SENSOR

DESCRIPTION........................270

OPERATION..........................270

TRANSMISSION SOLENOID/TRS ASSEMBLY

DESCRIPTION........................271

OPERATION..........................271

REMOVAL............................272

INSTALLATION........................272

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................272

OPERATION..........................272

VALVE BODY

DESCRIPTION........................273

OPERATION..........................273

REMOVAL............................274

DISASSEMBLY........................275

CLEANING...........................277

INSPECTION.........................277

ASSEMBLY...........................278

INSTALLATION........................279

AUTOMATIC TRANSMISSION -

545RFE

DESCRIPTION

The 545RFE automatic transmission is a sophisti-

cated, multi-range, electronically controlled transmis-

sion which combines optimized gear ratios for

responsive performance, state of the art efficiency

features and low NVH. Other features include driver

adaptive shifting and three planetary gear sets to

provide wide ratio capability with precise ratio steps

for optimum driveability. The three planetary gear

sets also make available a unique alternate second

gear ratio. The primary 2nd gear ratio fits between

1st and 3rd gears for normal through-gear accelera-

tions. The alternate second gear ratio (2prime) allows

smoother 4-2 kickdowns at high speeds to provide

2nd gear passing performance over a wider highway

cruising range. An additional overdrive ratio (0.67:1)

is also provided for greater fuel economy and less

NVH at highway speeds.The hydraulic portion of the transmission consists

of the transmission fluid, fluid passages, hydraulic

valves, and various line pressure control components.

The primary mechanical components of the trans-

mission consist of the following:

²Three multiple disc input clutches

²Three multiple disc holding clutches

²Five hydraulic accumulators

²Three planetary gear sets

²Dual Stage Hydraulic oil pump

²Valve body

²Solenoid pack

The TCM is the ªheartº or ªbrainº of the electronic

control system and relies on information from vari-

ous direct and indirect inputs (sensors, switches, etc.)

to determine driver demand and vehicle operating

conditions. With this information, the TCM can cal-

culate and perform timely and quality shifts through

various output or control devices (solenoid pack,

transmission control relay, etc.).

21 - 178 AUTOMATIC TRANSMISSION - 545RFEWJ

Page 1698 of 2199

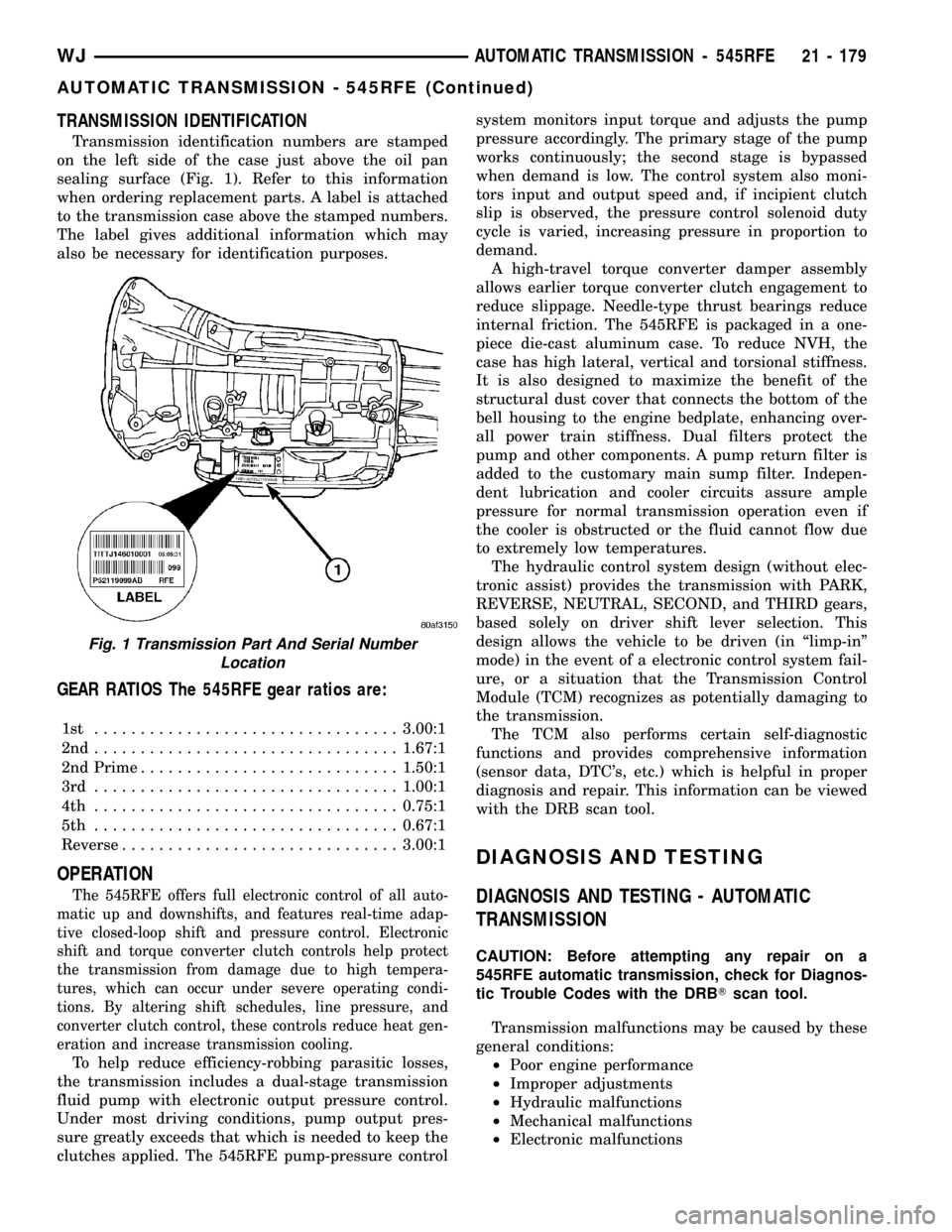

TRANSMISSION IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan

sealing surface (Fig. 1). Refer to this information

when ordering replacement parts. A label is attached

to the transmission case above the stamped numbers.

The label gives additional information which may

also be necessary for identification purposes.

GEAR RATIOS The 545RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime............................1.50:1

3rd .................................1.00:1

4th .................................0.75:1

5th .................................0.67:1

Reverse..............................3.00:1

OPERATION

The 545RFE offers full electronic control of all auto-

matic up and downshifts, and features real-time adap-

tive closed-loop shift and pressure control. Electronic

shift and torque converter clutch controls help protect

the transmission from damage due to high tempera-

tures, which can occur under severe operating condi-

tions. By altering shift schedules, line pressure, and

converter clutch control, these controls reduce heat gen-

eration and increase transmission cooling.

To help reduce efficiency-robbing parasitic losses,

the transmission includes a dual-stage transmission

fluid pump with electronic output pressure control.

Under most driving conditions, pump output pres-

sure greatly exceeds that which is needed to keep the

clutches applied. The 545RFE pump-pressure controlsystem monitors input torque and adjusts the pump

pressure accordingly. The primary stage of the pump

works continuously; the second stage is bypassed

when demand is low. The control system also moni-

tors input and output speed and, if incipient clutch

slip is observed, the pressure control solenoid duty

cycle is varied, increasing pressure in proportion to

demand.

A high-travel torque converter damper assembly

allows earlier torque converter clutch engagement to

reduce slippage. Needle-type thrust bearings reduce

internal friction. The 545RFE is packaged in a one-

piece die-cast aluminum case. To reduce NVH, the

case has high lateral, vertical and torsional stiffness.

It is also designed to maximize the benefit of the

structural dust cover that connects the bottom of the

bell housing to the engine bedplate, enhancing over-

all power train stiffness. Dual filters protect the

pump and other components. A pump return filter is

added to the customary main sump filter. Indepen-

dent lubrication and cooler circuits assure ample

pressure for normal transmission operation even if

the cooler is obstructed or the fluid cannot flow due

to extremely low temperatures.

The hydraulic control system design (without elec-

tronic assist) provides the transmission with PARK,

REVERSE, NEUTRAL, SECOND, and THIRD gears,

based solely on driver shift lever selection. This

design allows the vehicle to be driven (in ªlimp-inº

mode) in the event of a electronic control system fail-

ure, or a situation that the Transmission Control

Module (TCM) recognizes as potentially damaging to

the transmission.

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRB scan tool.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

CAUTION: Before attempting any repair on a

545RFE automatic transmission, check for Diagnos-

tic Trouble Codes with the DRBTscan tool.

Transmission malfunctions may be caused by these

general conditions:

²Poor engine performance

²Improper adjustments

²Hydraulic malfunctions

²Mechanical malfunctions

²Electronic malfunctions

Fig. 1 Transmission Part And Serial Number

Location

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 179

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1702 of 2199

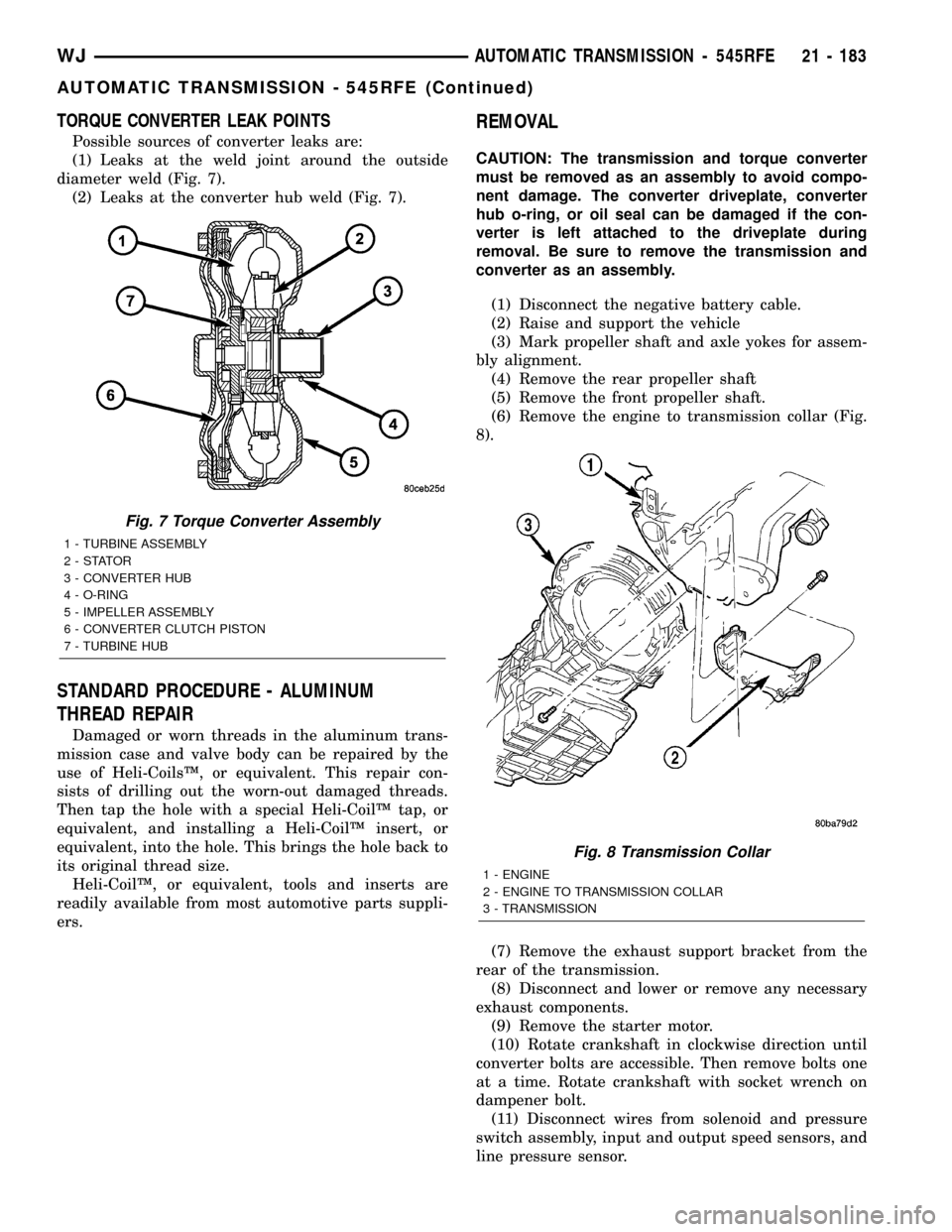

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

(1) Leaks at the weld joint around the outside

diameter weld (Fig. 7).

(2) Leaks at the converter hub weld (Fig. 7).

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

REMOVAL

CAUTION: The transmission and torque converter

must be removed as an assembly to avoid compo-

nent damage. The converter driveplate, converter

hub o-ring, or oil seal can be damaged if the con-

verter is left attached to the driveplate during

removal. Be sure to remove the transmission and

converter as an assembly.

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle

(3) Mark propeller shaft and axle yokes for assem-

bly alignment.

(4) Remove the rear propeller shaft

(5) Remove the front propeller shaft.

(6) Remove the engine to transmission collar (Fig.

8).

(7) Remove the exhaust support bracket from the

rear of the transmission.

(8) Disconnect and lower or remove any necessary

exhaust components.

(9) Remove the starter motor.

(10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(11) Disconnect wires from solenoid and pressure

switch assembly, input and output speed sensors, and

line pressure sensor.

Fig. 7 Torque Converter Assembly

1 - TURBINE ASSEMBLY

2-STATOR

3 - CONVERTER HUB

4 - O-RING

5 - IMPELLER ASSEMBLY

6 - CONVERTER CLUTCH PISTON

7 - TURBINE HUB

Fig. 8 Transmission Collar

1 - ENGINE

2 - ENGINE TO TRANSMISSION COLLAR

3 - TRANSMISSION

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 183

AUTOMATIC TRANSMISSION - 545RFE (Continued)