Abs JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1976 of 2199

INSTALLATION

NOTE: Sunroof glass must be set in place and

attached as close as possible to flush with the roof

surface. For wind noise reasons, care must be

taken to ensure that the glass is not remounted

either a) Overflush to the roof surface at the front

edge of the glass, or b) Underflush to the roof sur-

face at the rear edge of the glass.

(1) Position glass panel in to opening.

(2) Start the four attaching screws.

(3) Tighten screws.

(4) Verify sunroof operation and alignment. Check

fit and adjust as necessary. (Refer to 23 - BODY/

SUNROOF/GLASS PANEL - ADJUSTMENTS - FIT)

ADJUSTMENTS

ADJUSTMENTS - FIT

(1) Move the sunshade rearward to the open posi-

tion.

(2) Move the sunroof glass panel to the fully closed

position.

(3) Loosen the forward screws on each side enough

to make the front adjustment.

(4) Adjust the front of the sunroof glass panel 1

mm (1/32 inch) below the top surface of the roof

panel.

(5) Tighten the front two screws.

(6) Loosen the rear screws on each side enough to

make the rear adjustment.

(7) Adjust the rear of the sunroof glass panel 1

mm (1/32 inch) above the top surface of the roof

panel.

(8) Tighten the rear two screws.

(9) Check for proper fit. If not OK, repeat glass

panel adjustment.

ADJUSTMENT - TIMING

NOTE: A gage comes with the new motor.

(1) If the glass panel was not in the fully closed

position, when the motor was removed, the sunroof

glass panel needs to be timed, before the new motor

is installed.

(2) Remove sunroof glass panel.

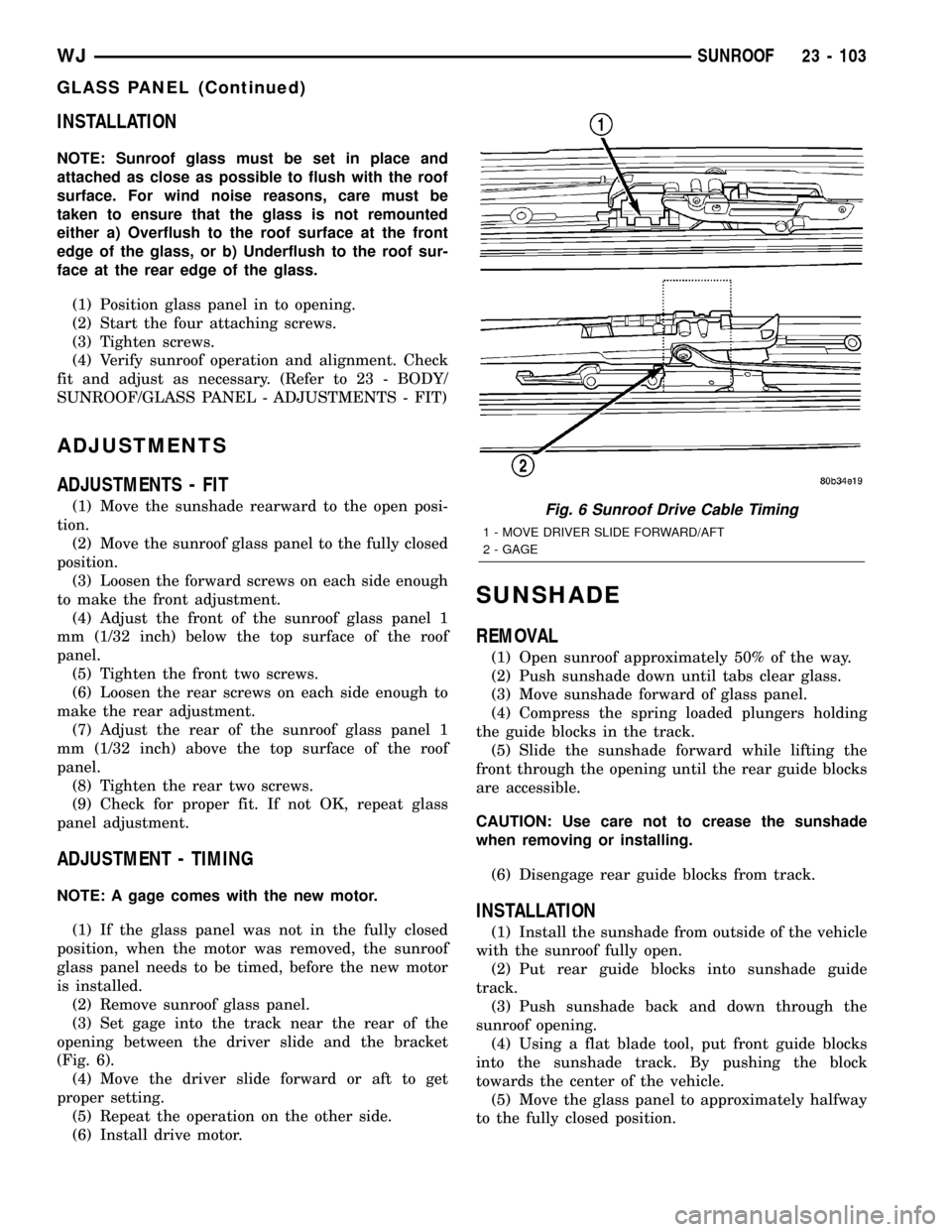

(3) Set gage into the track near the rear of the

opening between the driver slide and the bracket

(Fig. 6).

(4) Move the driver slide forward or aft to get

proper setting.

(5) Repeat the operation on the other side.

(6) Install drive motor.

SUNSHADE

REMOVAL

(1) Open sunroof approximately 50% of the way.

(2) Push sunshade down until tabs clear glass.

(3) Move sunshade forward of glass panel.

(4) Compress the spring loaded plungers holding

the guide blocks in the track.

(5) Slide the sunshade forward while lifting the

front through the opening until the rear guide blocks

are accessible.

CAUTION: Use care not to crease the sunshade

when removing or installing.

(6) Disengage rear guide blocks from track.

INSTALLATION

(1) Install the sunshade from outside of the vehicle

with the sunroof fully open.

(2) Put rear guide blocks into sunshade guide

track.

(3) Push sunshade back and down through the

sunroof opening.

(4) Using a flat blade tool, put front guide blocks

into the sunshade track. By pushing the block

towards the center of the vehicle.

(5) Move the glass panel to approximately halfway

to the fully closed position.

Fig. 6 Sunroof Drive Cable Timing

1 - MOVE DRIVER SLIDE FORWARD/AFT

2 - GAGE

WJSUNROOF 23 - 103

GLASS PANEL (Continued)

Page 2079 of 2199

OPERATION

OPERATION - HEATER AND AIR CONDITIONER

Outside fresh air enters the vehicle through the

cowl top opening at the base of the windshield, and

passes through a plenum chamber to the HVAC sys-

tem blower housing. Air flow velocity can then be

adjusted with the blower motor speed selector switch

on the a/c heater control panel. The air intake open-

ings must be kept free of snow, ice, leaves, and other

obstructions for the HVAC system to receive a suffi-

cient volume of outside air.

It is also important to keep the air intake openings

clear of debris because leaf particles and other debris

that is small enough to pass through the cowl ple-

num screen can accumulate within the HVAC hous-

ing. The closed, warm, damp and dark environment

created within the HVAC housing is ideal for the

growth of certain molds, mildews and other fungi.

Any accumulation of decaying plant matter provides

an additional food source for fungal spores, which

enter the housing with the fresh air. Excess debris,

as well as objectionable odors created by decaying

plant matter and growing fungi can be discharged

into the passenger compartment during HVAC sys-

tem operation.

Both the manual and AZC heater and air condi-

tioner are blend-air type systems. In a blend-air sys-

tem, a blend door controls the amount of

unconditioned air (or cooled air from the evaporator)

that is allowed to flow through, or around, the heater

core. A temperature control knob on the a/c heater

control panel determines the discharge air tempera-

ture by energizing the blend door actuator, which

operates the blend door. This allows an almost imme-

diate control of the output air temperature of the sys-

tem. The AZC system will have separate blend doors

and temperature controls for each front seat occu-

pant.

The mode control knob on the a/c heater control

panel is used to direct the conditioned air to the

selected system outlets. On manual temperature con-

trol systems, the mode control knob switches engine

vacuum to control the mode doors, which are oper-

ated by vacuum actuators. On AZC systems, the

mode control knob switches electrical current to con-

trol the mode doors, which are operated by electronic

actuators.

The outside air intake can be shut off on manual

temperature control systems by selecting the Recircu-

lation Mode with the mode control knob. The outside

air intake can be shut off on Automatic Zone Control

(AZC) type system by pushing the Recirculation

Mode button. This will operate the recirculation door

that closes off the outside fresh air intake and recir-

culates the air that is already inside the vehicle.The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a ther-

mal expansion valve to meter refrigerant flow to the

evaporator coil. To maintain minimum evaporator

temperature and prevent evaporator freezing, the

system utilizes an evaporator thermister probe with

the appropriate operating logic located in the body

control module (BCM).

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The high pressure service port is located on the liq-

uid line near the receiver/drier. The low pressure ser-

vice port is located on the suction line near the

evaporator at the rear of the engine compartment.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low specific humidity air. The evaporator, located

in the HVAC housing on the dash panel below the

instrument panel, is cooled to temperatures near the

freezing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the tempera-

ture of the air delivered to the interior of the vehicle. It

is important to understand the effect that humidity has

on the performance of the air conditioning system.

When humidity is high, the evaporator has to perform a

double duty. It must lower the air temperature, and it

must lower the temperature of the moisture in the air

that condenses on the evaporator fins. Condensing the

moisture in the air transfers heat energy into the evap-

orator fins and tubing. This reduces the amount of heat

the evaporator can absorb from the air. High humidity

greatly reduces the ability of the evaporator to lower

the temperature of the air.

24 - 2 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2102 of 2199

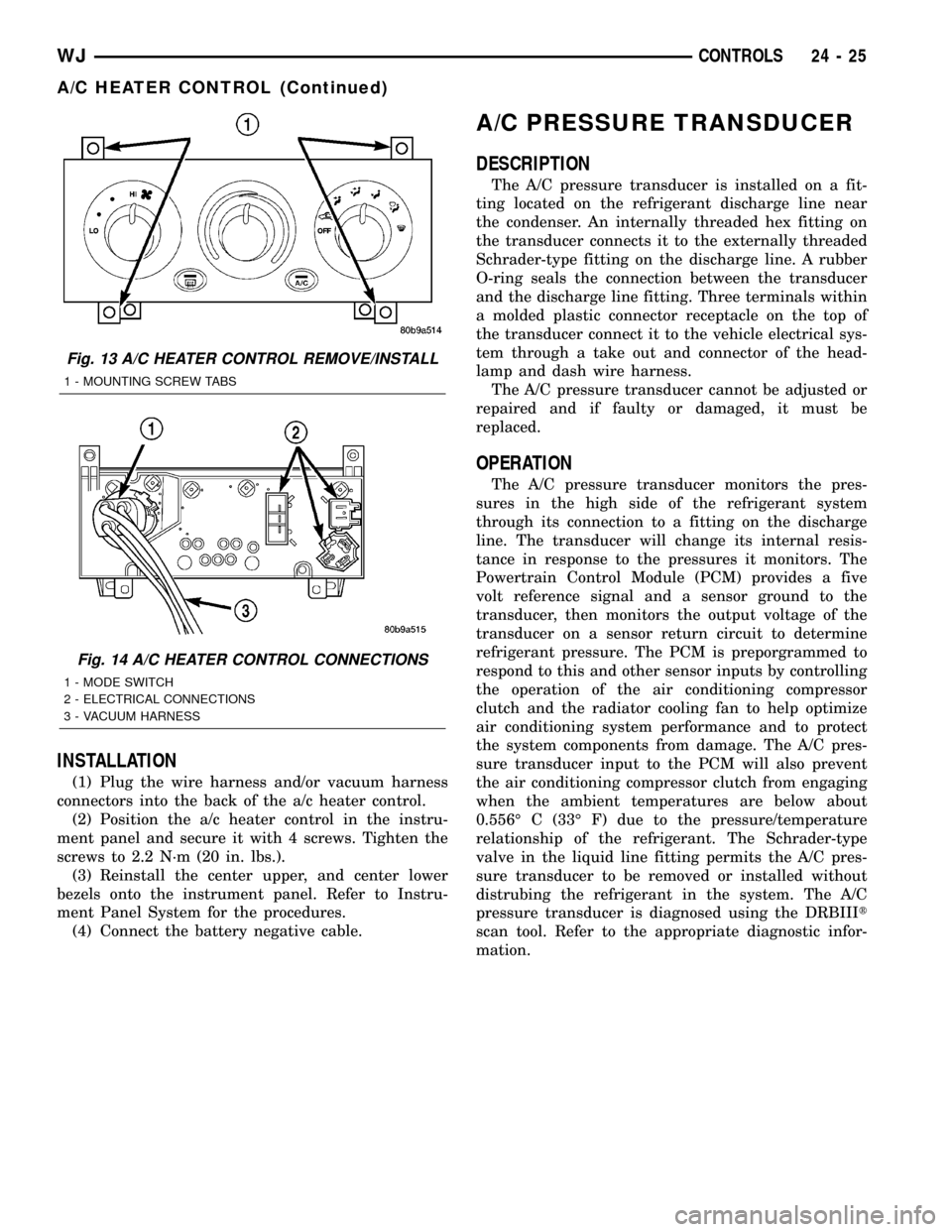

INSTALLATION

(1) Plug the wire harness and/or vacuum harness

connectors into the back of the a/c heater control.

(2) Position the a/c heater control in the instru-

ment panel and secure it with 4 screws. Tighten the

screws to 2.2 N´m (20 in. lbs.).

(3) Reinstall the center upper, and center lower

bezels onto the instrument panel. Refer to Instru-

ment Panel System for the procedures.

(4) Connect the battery negative cable.

A/C PRESSURE TRANSDUCER

DESCRIPTION

The A/C pressure transducer is installed on a fit-

ting located on the refrigerant discharge line near

the condenser. An internally threaded hex fitting on

the transducer connects it to the externally threaded

Schrader-type fitting on the discharge line. A rubber

O-ring seals the connection between the transducer

and the discharge line fitting. Three terminals within

a molded plastic connector receptacle on the top of

the transducer connect it to the vehicle electrical sys-

tem through a take out and connector of the head-

lamp and dash wire harness.

The A/C pressure transducer cannot be adjusted or

repaired and if faulty or damaged, it must be

replaced.

OPERATION

The A/C pressure transducer monitors the pres-

sures in the high side of the refrigerant system

through its connection to a fitting on the discharge

line. The transducer will change its internal resis-

tance in response to the pressures it monitors. The

Powertrain Control Module (PCM) provides a five

volt reference signal and a sensor ground to the

transducer, then monitors the output voltage of the

transducer on a sensor return circuit to determine

refrigerant pressure. The PCM is preporgrammed to

respond to this and other sensor inputs by controlling

the operation of the air conditioning compressor

clutch and the radiator cooling fan to help optimize

air conditioning system performance and to protect

the system components from damage. The A/C pres-

sure transducer input to the PCM will also prevent

the air conditioning compressor clutch from engaging

when the ambient temperatures are below about

0.556É C (33É F) due to the pressure/temperature

relationship of the refrigerant. The Schrader-type

valve in the liquid line fitting permits the A/C pres-

sure transducer to be removed or installed without

distrubing the refrigerant in the system. The A/C

pressure transducer is diagnosed using the DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

Fig. 13 A/C HEATER CONTROL REMOVE/INSTALL

1 - MOUNTING SCREW TABS

Fig. 14 A/C HEATER CONTROL CONNECTIONS

1 - MODE SWITCH

2 - ELECTRICAL CONNECTIONS

3 - VACUUM HARNESS

WJCONTROLS 24 - 25

A/C HEATER CONTROL (Continued)

Page 2116 of 2199

INSTALLATION

(1) Install the defroster duct on the HVAC unit

housing.

(2) Install the three screws that secure the

defroster duct to the HVAC unit housing. Tighten the

mounting screws to 2.2 N´m (20 in. lbs.).

(3) Install the instrument panel assembly in the

vehicle(Refer to 23 - BODY/INSTRUMENT PANEL -

INSTALLATION).

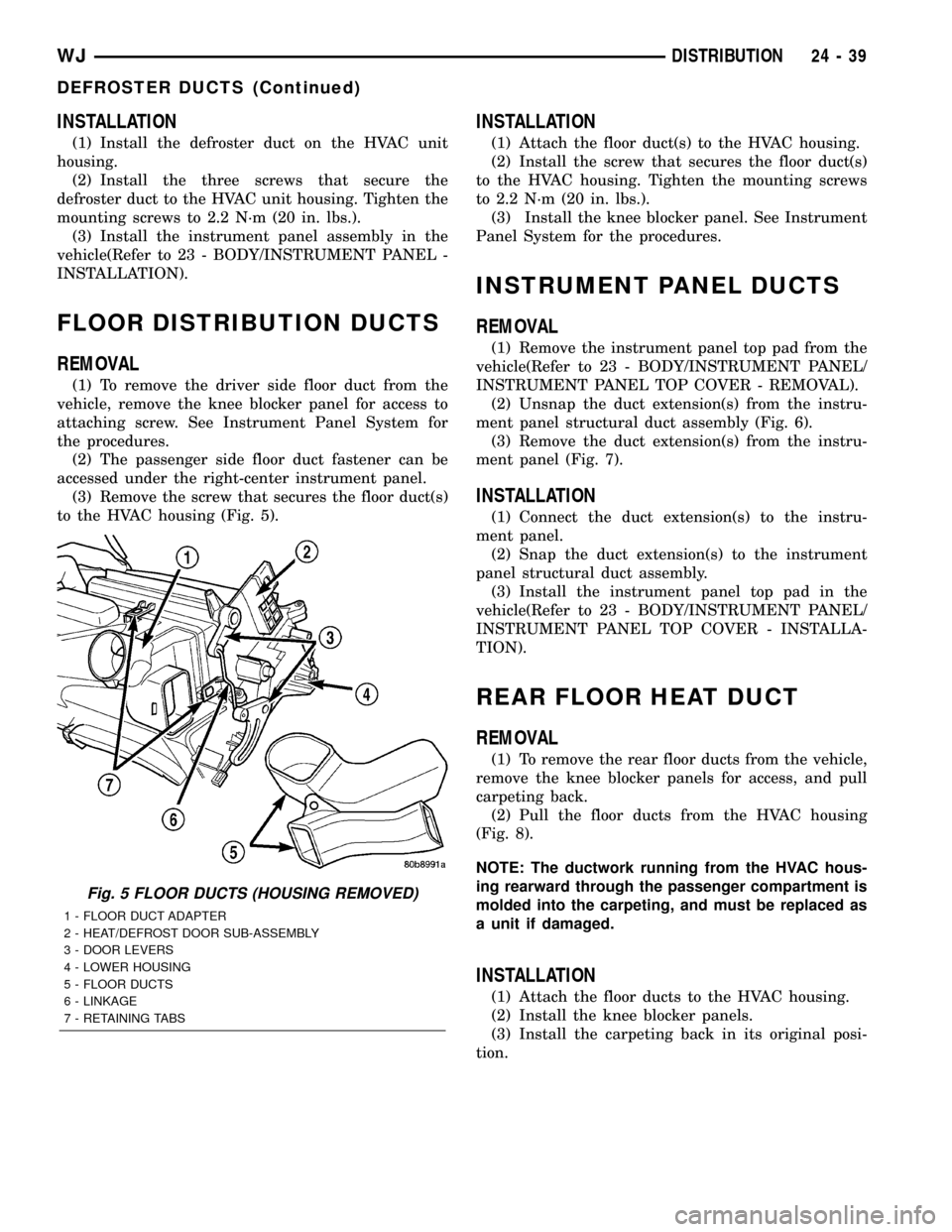

FLOOR DISTRIBUTION DUCTS

REMOVAL

(1) To remove the driver side floor duct from the

vehicle, remove the knee blocker panel for access to

attaching screw. See Instrument Panel System for

the procedures.

(2) The passenger side floor duct fastener can be

accessed under the right-center instrument panel.

(3) Remove the screw that secures the floor duct(s)

to the HVAC housing (Fig. 5).

INSTALLATION

(1) Attach the floor duct(s) to the HVAC housing.

(2) Install the screw that secures the floor duct(s)

to the HVAC housing. Tighten the mounting screws

to 2.2 N´m (20 in. lbs.).

(3) Install the knee blocker panel. See Instrument

Panel System for the procedures.

INSTRUMENT PANEL DUCTS

REMOVAL

(1) Remove the instrument panel top pad from the

vehicle(Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - REMOVAL).

(2) Unsnap the duct extension(s) from the instru-

ment panel structural duct assembly (Fig. 6).

(3) Remove the duct extension(s) from the instru-

ment panel (Fig. 7).

INSTALLATION

(1) Connect the duct extension(s) to the instru-

ment panel.

(2) Snap the duct extension(s) to the instrument

panel structural duct assembly.

(3) Install the instrument panel top pad in the

vehicle(Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - INSTALLA-

TION).

REAR FLOOR HEAT DUCT

REMOVAL

(1) To remove the rear floor ducts from the vehicle,

remove the knee blocker panels for access, and pull

carpeting back.

(2) Pull the floor ducts from the HVAC housing

(Fig. 8).

NOTE: The ductwork running from the HVAC hous-

ing rearward through the passenger compartment is

molded into the carpeting, and must be replaced as

a unit if damaged.

INSTALLATION

(1) Attach the floor ducts to the HVAC housing.

(2) Install the knee blocker panels.

(3) Install the carpeting back in its original posi-

tion.

Fig. 5 FLOOR DUCTS (HOUSING REMOVED)

1 - FLOOR DUCT ADAPTER

2 - HEAT/DEFROST DOOR SUB-ASSEMBLY

3 - DOOR LEVERS

4 - LOWER HOUSING

5 - FLOOR DUCTS

6 - LINKAGE

7 - RETAINING TABS

WJDISTRIBUTION 24 - 39

DEFROSTER DUCTS (Continued)

Page 2123 of 2199

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(13) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

(14) Install the instrument panel in the vehicle(Re-

fer to 23 - BODY/INSTRUMENT PANEL - INSTAL-

LATION).

(15) Connect the battery negative cable.

(16) Start the engine and check for proper opera-

tion of the heating and air conditioning systems.

BLEND DOOR

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove and disassemble the HVAC housing.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - DISASSEMBLY)

(2) Remove evaporator from lower case to ease

access to plastic door shaft bushing.

(3) Pinch the retention tabs holding the blend door

pivot shaft to the case. The 3 plastic tabs, located on

the inside of the case, are part of the shaft retainer.

(4) Remove door(s).

INSTALLATION

(1) Install the blend door(s) by snapping the pivot

shaft into the HVAC case.

(2) Install the evaporator in the lower case.

(3) Reassemble the HVAC housing and install in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

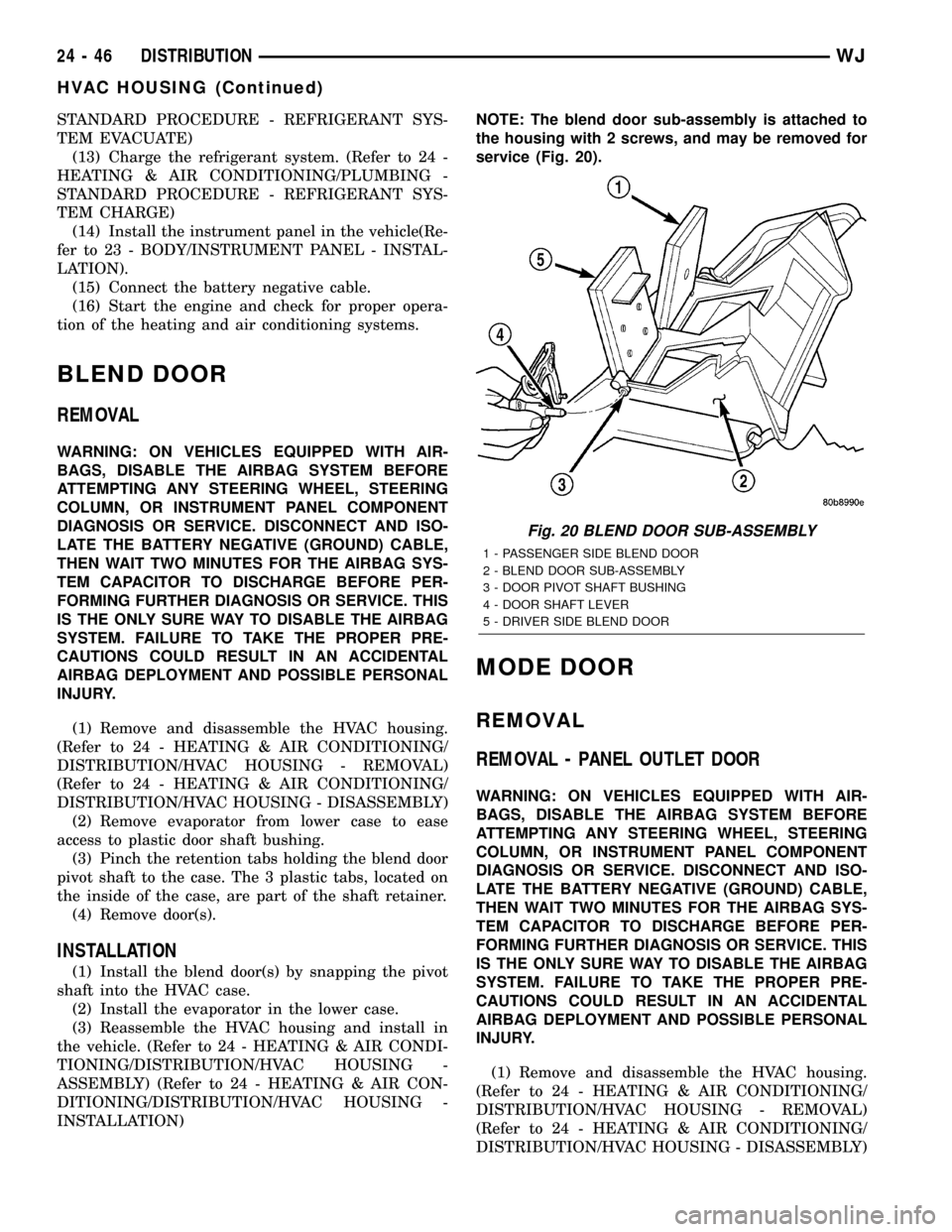

INSTALLATION)NOTE: The blend door sub-assembly is attached to

the housing with 2 screws, and may be removed for

service (Fig. 20).

MODE DOOR

REMOVAL

REMOVAL - PANEL OUTLET DOOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove and disassemble the HVAC housing.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - DISASSEMBLY)

Fig. 20 BLEND DOOR SUB-ASSEMBLY

1 - PASSENGER SIDE BLEND DOOR

2 - BLEND DOOR SUB-ASSEMBLY

3 - DOOR PIVOT SHAFT BUSHING

4 - DOOR SHAFT LEVER

5 - DRIVER SIDE BLEND DOOR

24 - 46 DISTRIBUTIONWJ

HVAC HOUSING (Continued)

Page 2124 of 2199

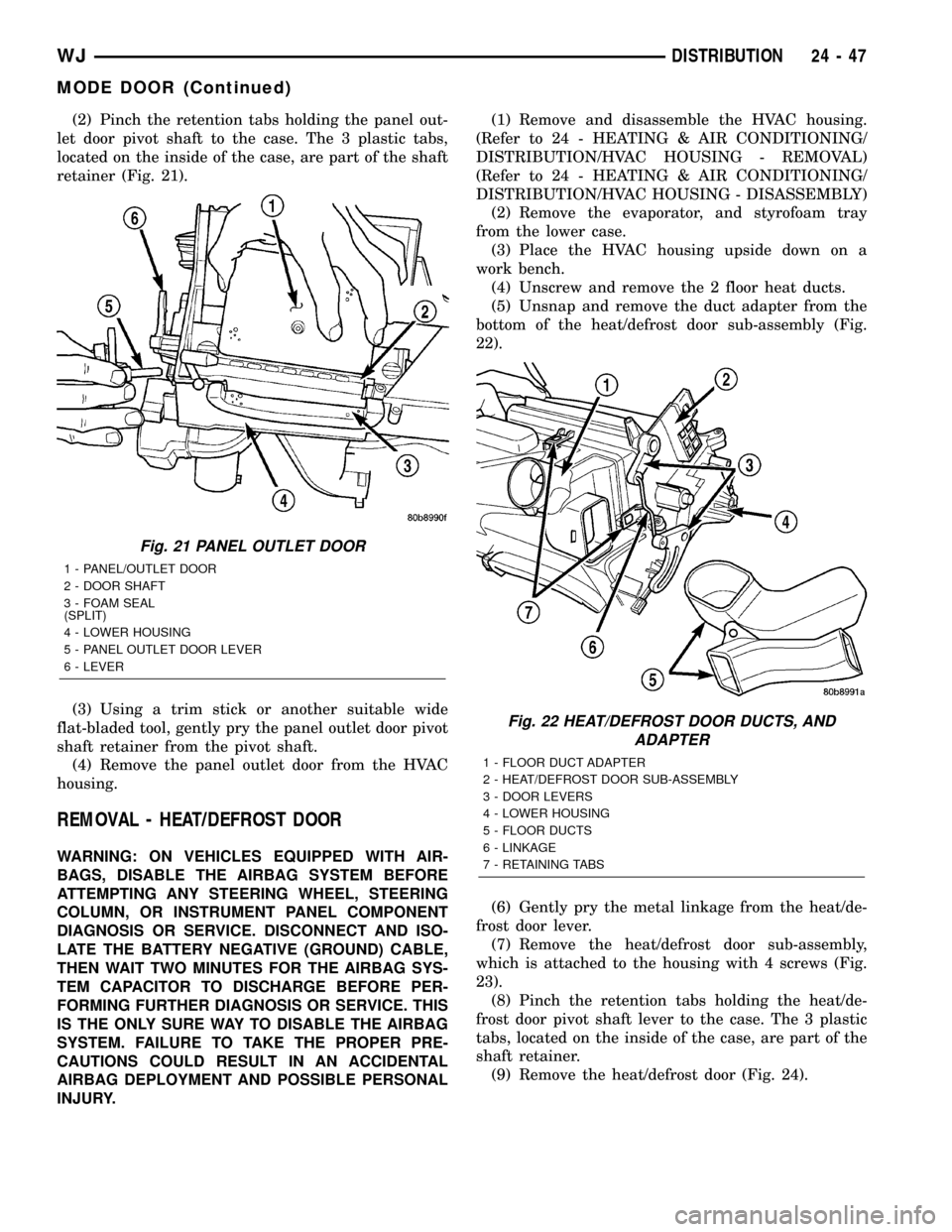

(2) Pinch the retention tabs holding the panel out-

let door pivot shaft to the case. The 3 plastic tabs,

located on the inside of the case, are part of the shaft

retainer (Fig. 21).

(3) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the panel outlet door pivot

shaft retainer from the pivot shaft.

(4) Remove the panel outlet door from the HVAC

housing.

REMOVAL - HEAT/DEFROST DOOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Remove and disassemble the HVAC housing.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - DISASSEMBLY)

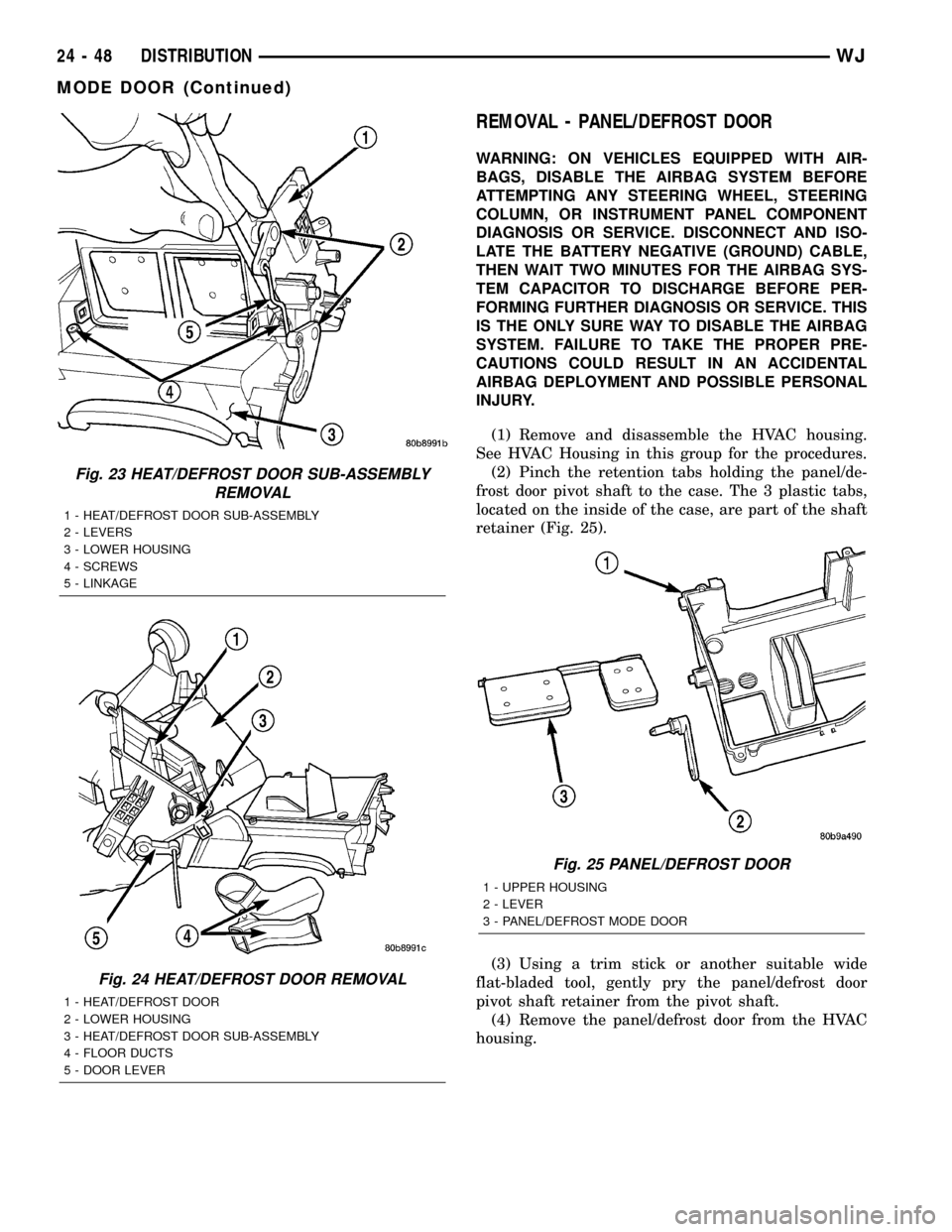

(2) Remove the evaporator, and styrofoam tray

from the lower case.

(3) Place the HVAC housing upside down on a

work bench.

(4) Unscrew and remove the 2 floor heat ducts.

(5) Unsnap and remove the duct adapter from the

bottom of the heat/defrost door sub-assembly (Fig.

22).

(6) Gently pry the metal linkage from the heat/de-

frost door lever.

(7) Remove the heat/defrost door sub-assembly,

which is attached to the housing with 4 screws (Fig.

23).

(8) Pinch the retention tabs holding the heat/de-

frost door pivot shaft lever to the case. The 3 plastic

tabs, located on the inside of the case, are part of the

shaft retainer.

(9) Remove the heat/defrost door (Fig. 24).

Fig. 21 PANEL OUTLET DOOR

1 - PANEL/OUTLET DOOR

2 - DOOR SHAFT

3 - FOAM SEAL

(SPLIT)

4 - LOWER HOUSING

5 - PANEL OUTLET DOOR LEVER

6 - LEVER

Fig. 22 HEAT/DEFROST DOOR DUCTS, AND

ADAPTER

1 - FLOOR DUCT ADAPTER

2 - HEAT/DEFROST DOOR SUB-ASSEMBLY

3 - DOOR LEVERS

4 - LOWER HOUSING

5 - FLOOR DUCTS

6 - LINKAGE

7 - RETAINING TABS

WJDISTRIBUTION 24 - 47

MODE DOOR (Continued)

Page 2125 of 2199

REMOVAL - PANEL/DEFROST DOOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

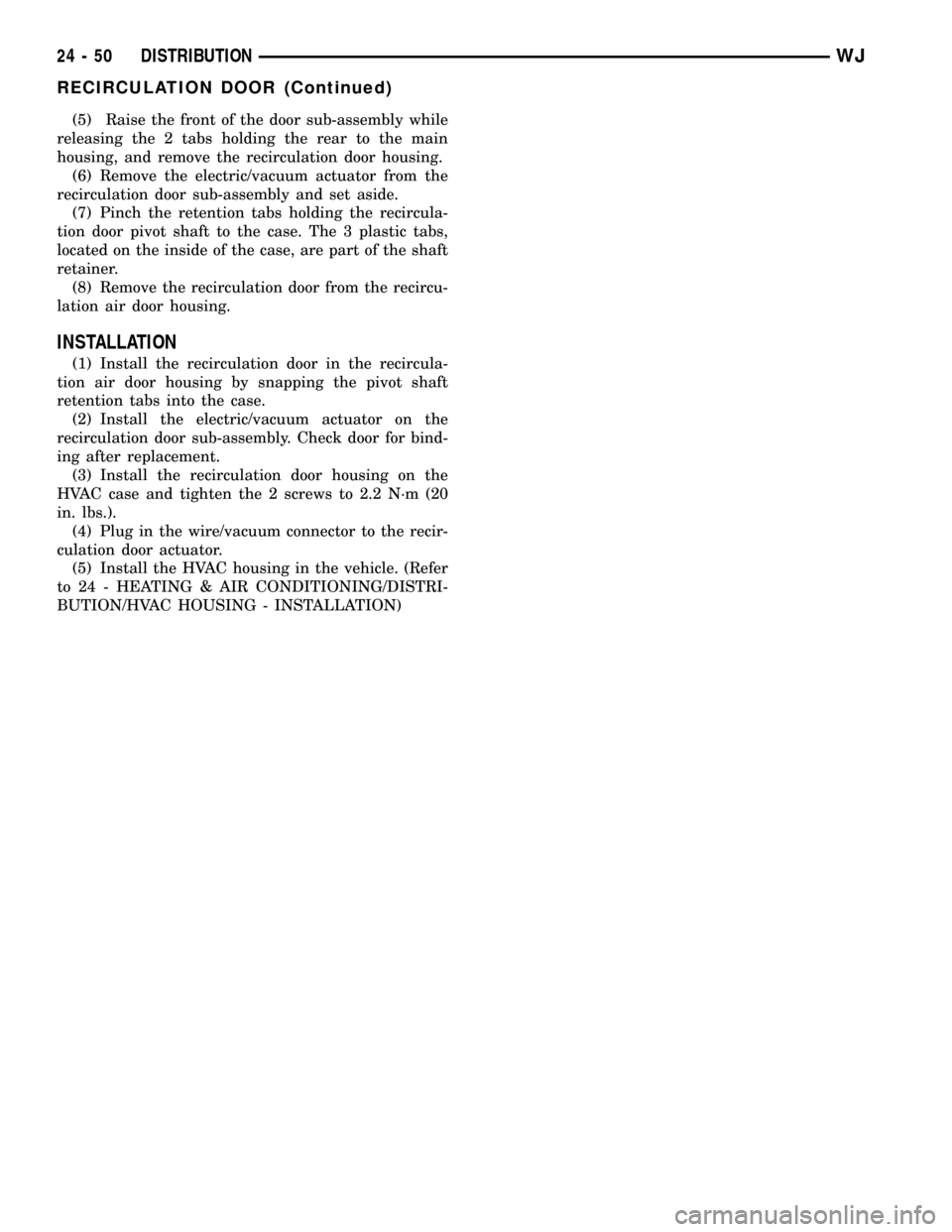

(1) Remove and disassemble the HVAC housing.

See HVAC Housing in this group for the procedures.

(2) Pinch the retention tabs holding the panel/de-

frost door pivot shaft to the case. The 3 plastic tabs,

located on the inside of the case, are part of the shaft

retainer (Fig. 25).

(3) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the panel/defrost door

pivot shaft retainer from the pivot shaft.

(4) Remove the panel/defrost door from the HVAC

housing.

Fig. 23 HEAT/DEFROST DOOR SUB-ASSEMBLY

REMOVAL

1 - HEAT/DEFROST DOOR SUB-ASSEMBLY

2 - LEVERS

3 - LOWER HOUSING

4 - SCREWS

5 - LINKAGE

Fig. 24 HEAT/DEFROST DOOR REMOVAL

1 - HEAT/DEFROST DOOR

2 - LOWER HOUSING

3 - HEAT/DEFROST DOOR SUB-ASSEMBLY

4 - FLOOR DUCTS

5 - DOOR LEVER

Fig. 25 PANEL/DEFROST DOOR

1 - UPPER HOUSING

2 - LEVER

3 - PANEL/DEFROST MODE DOOR

24 - 48 DISTRIBUTIONWJ

MODE DOOR (Continued)

Page 2127 of 2199

(5) Raise the front of the door sub-assembly while

releasing the 2 tabs holding the rear to the main

housing, and remove the recirculation door housing.

(6) Remove the electric/vacuum actuator from the

recirculation door sub-assembly and set aside.

(7) Pinch the retention tabs holding the recircula-

tion door pivot shaft to the case. The 3 plastic tabs,

located on the inside of the case, are part of the shaft

retainer.

(8) Remove the recirculation door from the recircu-

lation air door housing.

INSTALLATION

(1) Install the recirculation door in the recircula-

tion air door housing by snapping the pivot shaft

retention tabs into the case.

(2) Install the electric/vacuum actuator on the

recirculation door sub-assembly. Check door for bind-

ing after replacement.

(3) Install the recirculation door housing on the

HVAC case and tighten the 2 screws to 2.2 N´m (20

in. lbs.).

(4) Plug in the wire/vacuum connector to the recir-

culation door actuator.

(5) Install the HVAC housing in the vehicle. (Refer

to 24 - HEATING & AIR CONDITIONING/DISTRI-

BUTION/HVAC HOUSING - INSTALLATION)

24 - 50 DISTRIBUTIONWJ

RECIRCULATION DOOR (Continued)

Page 2130 of 2199

CAUTION

CAUTION

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with the service equipment being used.

Never add R-12 to a refrigerant system designed to

use R-134a. Damage to the system will result.

R-12 refrigerant oil must not be mixed with R-134a

refrigerant oil. They are not compatible.

Do not use R-12 equipment or parts on the R-134a

system. Damage to the system will result.

Do not overcharge the refrigerant system. This will

cause excessive compressor head pressure and

can cause noise and system failure.

Recover the refrigerant before opening any fitting

or connection. Open the fittings with caution, even

after the system has been discharged. Never open

or loosen a connection before recovering the refrig-

erant.

The refrigerant system must always be evacuated

before charging.

Do not open the refrigerant system or uncap a

replacement component until you are ready to ser-

vice the system. This will prevent contamination in

the system.

Before disconnecting a component, clean the out-

side of the fittings thoroughly to prevent contami-

nation from entering the refrigerant system.

Immediately after disconnecting a component from

the refrigerant system, seal the open fittings with a

cap or plug.

Before connecting an open refrigerant fitting,

always install a new seal or gasket. Coat the fitting

and seal with clean refrigerant oil before connect-

ing.

Do not remove the sealing caps from a replacement

component until it is to be installed.

When installing a refrigerant line, avoid sharp

bends that may restrict refrigerant flow. Position the

refrigerant lines away from exhaust system compo-

nents or any sharp edges, which may damage the

line.

Tighten refrigerant fittings only to the specified

torque. The aluminum fittings used in the refriger-

ant system will not tolerate overtightening.

When disconnecting a refrigerant fitting, use a

wrench on both halves of the fitting. This will pre-

vent twisting of the refrigerant lines or tubes.

Refrigerant oil will absorb moisture from the atmo-

sphere if left uncapped. Do not open a container of

refrigerant oil until you are ready to use it. Replace

the cap on the oil container immediately after using.

Store refrigerant oil only in a clean, airtight, and

moisture-free container.Keep service tools and the work area clean. Con-

tamination of the refrigerant system through care-

less work habits must be avoided.REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS

Kinks or sharp bends in the refrigerant plumbing

will reduce the capacity of the entire system. High

pressures are produced in the system when it is oper-

ating. Extreme care must be exercised to make sure

that all refrigerant system connections are pressure

tight.

A good rule for the flexible hose refrigerant lines is

to keep the radius of all bends at least ten times the

diameter of the hose. Sharp bends will reduce the

flow of refrigerant. The flexible hose lines should be

routed so they are at least 80 millimeters (3 inches)

from the exhaust manifold. It is a good practice to

inspect all flexible refrigerant system hose lines at

least once a year to make sure they are in good con-

dition and properly routed.

There are two types of refrigerant fittings:

²All fittings with O-rings need to be coated with

refrigerant oil before installation. Use only O-rings

that are the correct size and approved for use with

R-134a refrigerant. Failure to do so may result in a

leak.

²Unified plumbing connections with gaskets can-

not be serviced with O-rings. The gaskets are not

reusable and new gaskets do not require lubrication

before installing.

Using the proper tools when making a refrigerant

plumbing connection is very important. Improper

tools or improper use of the tools can damage the

refrigerant fittings. Always use two wrenches when

loosening or tightening tube fittings. Use one wrench

to hold one side of the connection stationary, while

loosening or tightening the other side of the connec-

tion with a second wrench.

The refrigerant must be recovered completely from

the system before opening any fitting or connection.

Open the fittings with caution, even after the refrig-

erant has been recovered. If any pressure is noticed

as a fitting is loosened, tighten the fitting and

recover the refrigerant from the system again.

Do not discharge refrigerant into the atmosphere.

Use an R-134a refrigerant recovery/recycling device

that meets SAE Standard J2210.

The refrigerant system will remain chemically sta-

ble as long as pure, moisture-free R-134a refrigerant

and refrigerant oil is used. Dirt, moisture, or air can

upset this chemical stability. Operational troubles or

serious damage can occur if foreign material is

present in the refrigerant system.

When it is necessary to open the refrigerant sys-

tem, have everything needed to service the system

WJPLUMBING 24 - 53

PLUMBING (Continued)

Page 2139 of 2199

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

(9) Connect the negative battery cable.

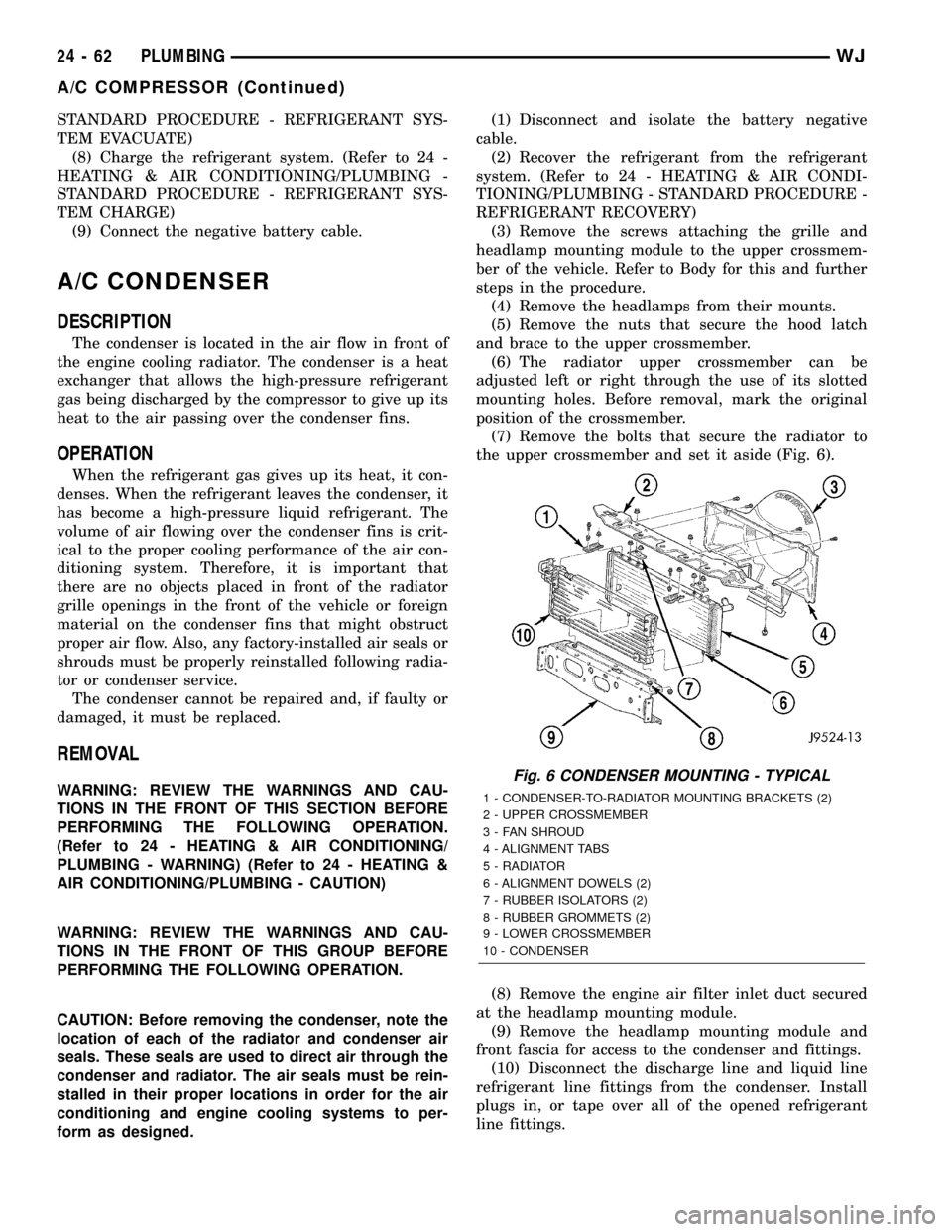

A/C CONDENSER

DESCRIPTION

The condenser is located in the air flow in front of

the engine cooling radiator. The condenser is a heat

exchanger that allows the high-pressure refrigerant

gas being discharged by the compressor to give up its

heat to the air passing over the condenser fins.

OPERATION

When the refrigerant gas gives up its heat, it con-

denses. When the refrigerant leaves the condenser, it

has become a high-pressure liquid refrigerant. The

volume of air flowing over the condenser fins is crit-

ical to the proper cooling performance of the air con-

ditioning system. Therefore, it is important that

there are no objects placed in front of the radiator

grille openings in the front of the vehicle or foreign

material on the condenser fins that might obstruct

proper air flow. Also, any factory-installed air seals or

shrouds must be properly reinstalled following radia-

tor or condenser service.

The condenser cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS GROUP BEFORE

PERFORMING THE FOLLOWING OPERATION.

CAUTION: Before removing the condenser, note the

location of each of the radiator and condenser air

seals. These seals are used to direct air through the

condenser and radiator. The air seals must be rein-

stalled in their proper locations in order for the air

conditioning and engine cooling systems to per-

form as designed.(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Remove the screws attaching the grille and

headlamp mounting module to the upper crossmem-

ber of the vehicle. Refer to Body for this and further

steps in the procedure.

(4) Remove the headlamps from their mounts.

(5) Remove the nuts that secure the hood latch

and brace to the upper crossmember.

(6) The radiator upper crossmember can be

adjusted left or right through the use of its slotted

mounting holes. Before removal, mark the original

position of the crossmember.

(7) Remove the bolts that secure the radiator to

the upper crossmember and set it aside (Fig. 6).

(8) Remove the engine air filter inlet duct secured

at the headlamp mounting module.

(9) Remove the headlamp mounting module and

front fascia for access to the condenser and fittings.

(10) Disconnect the discharge line and liquid line

refrigerant line fittings from the condenser. Install

plugs in, or tape over all of the opened refrigerant

line fittings.Fig. 6 CONDENSER MOUNTING - TYPICAL

1 - CONDENSER-TO-RADIATOR MOUNTING BRACKETS (2)

2 - UPPER CROSSMEMBER

3 - FAN SHROUD

4 - ALIGNMENT TABS

5 - RADIATOR

6 - ALIGNMENT DOWELS (2)

7 - RUBBER ISOLATORS (2)

8 - RUBBER GROMMETS (2)

9 - LOWER CROSSMEMBER

10 - CONDENSER

24 - 62 PLUMBINGWJ

A/C COMPRESSOR (Continued)