intake JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 2158 of 2199

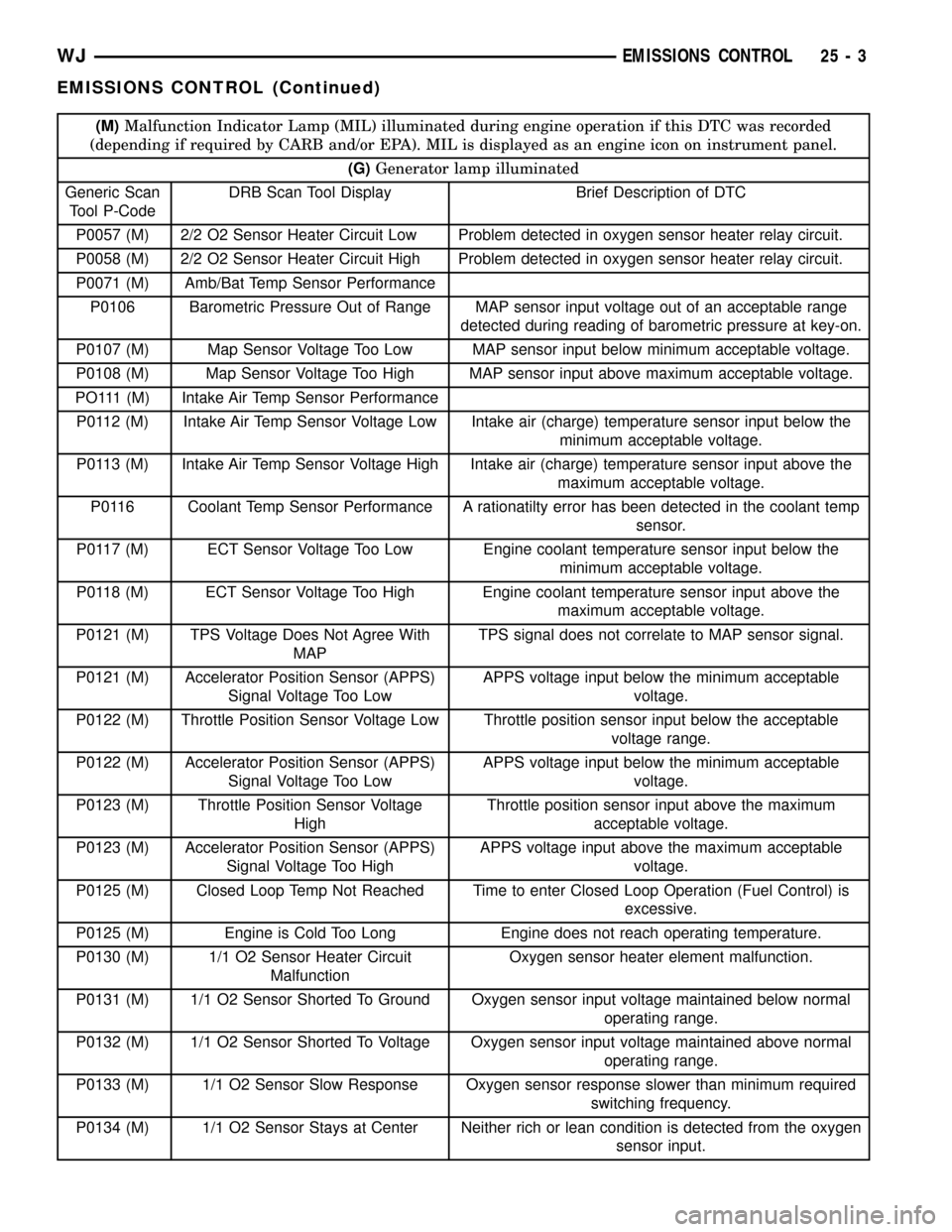

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0057 (M) 2/2 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0058 (M) 2/2 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0071 (M) Amb/Bat Temp Sensor Performance

P0106 Barometric Pressure Out of Range MAP sensor input voltage out of an acceptable range

detected during reading of barometric pressure at key-on.

P0107 (M) Map Sensor Voltage Too Low MAP sensor input below minimum acceptable voltage.

P0108 (M) Map Sensor Voltage Too High MAP sensor input above maximum acceptable voltage.

PO111 (M) Intake Air Temp Sensor Performance

P0112 (M) Intake Air Temp Sensor Voltage Low Intake air (charge) temperature sensor input below the

minimum acceptable voltage.

P0113 (M) Intake Air Temp Sensor Voltage High Intake air (charge) temperature sensor input above the

maximum acceptable voltage.

P0116 Coolant Temp Sensor Performance A rationatilty error has been detected in the coolant temp

sensor.

P0117 (M) ECT Sensor Voltage Too Low Engine coolant temperature sensor input below the

minimum acceptable voltage.

P0118 (M) ECT Sensor Voltage Too High Engine coolant temperature sensor input above the

maximum acceptable voltage.

P0121 (M) TPS Voltage Does Not Agree With

MAPTPS signal does not correlate to MAP sensor signal.

P0121 (M) Accelerator Position Sensor (APPS)

Signal Voltage Too LowAPPS voltage input below the minimum acceptable

voltage.

P0122 (M) Throttle Position Sensor Voltage Low Throttle position sensor input below the acceptable

voltage range.

P0122 (M) Accelerator Position Sensor (APPS)

Signal Voltage Too LowAPPS voltage input below the minimum acceptable

voltage.

P0123 (M) Throttle Position Sensor Voltage

HighThrottle position sensor input above the maximum

acceptable voltage.

P0123 (M) Accelerator Position Sensor (APPS)

Signal Voltage Too HighAPPS voltage input above the maximum acceptable

voltage.

P0125 (M) Closed Loop Temp Not Reached Time to enter Closed Loop Operation (Fuel Control) is

excessive.

P0125 (M) Engine is Cold Too Long Engine does not reach operating temperature.

P0130 (M) 1/1 O2 Sensor Heater Circuit

MalfunctionOxygen sensor heater element malfunction.

P0131 (M) 1/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0132 (M) 1/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0133 (M) 1/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0134 (M) 1/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor input.

WJEMISSIONS CONTROL 25 - 3

EMISSIONS CONTROL (Continued)

Page 2162 of 2199

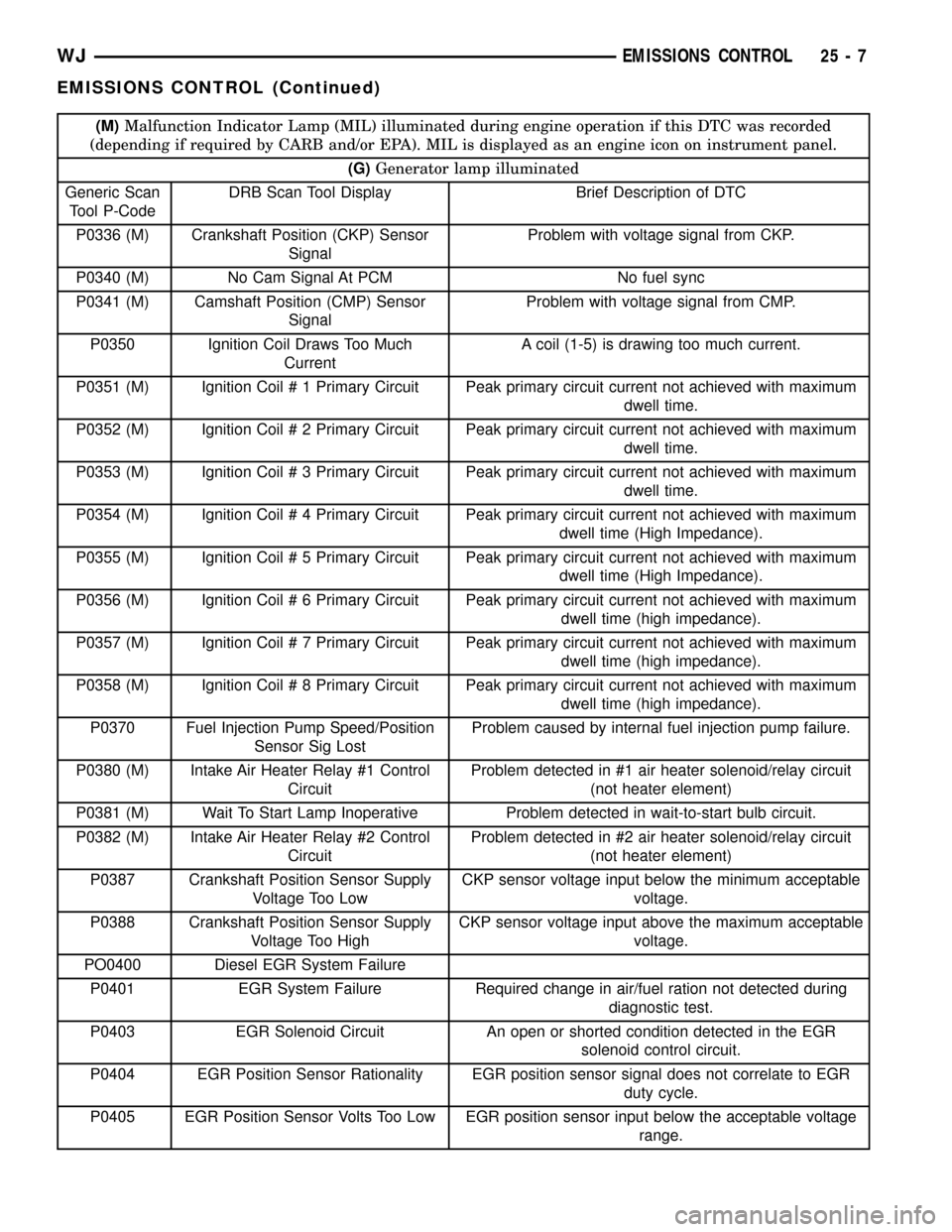

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0336 (M) Crankshaft Position (CKP) Sensor

SignalProblem with voltage signal from CKP.

P0340 (M) No Cam Signal At PCM No fuel sync

P0341 (M) Camshaft Position (CMP) Sensor

SignalProblem with voltage signal from CMP.

P0350 Ignition Coil Draws Too Much

CurrentA coil (1-5) is drawing too much current.

P0351 (M) Ignition Coil # 1 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0352 (M) Ignition Coil # 2 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0353 (M) Ignition Coil # 3 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0354 (M) Ignition Coil # 4 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0355 (M) Ignition Coil # 5 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0356 (M) Ignition Coil # 6 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0357 (M) Ignition Coil # 7 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0358 (M) Ignition Coil # 8 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0370 Fuel Injection Pump Speed/Position

Sensor Sig LostProblem caused by internal fuel injection pump failure.

P0380 (M) Intake Air Heater Relay #1 Control

CircuitProblem detected in #1 air heater solenoid/relay circuit

(not heater element)

P0381 (M) Wait To Start Lamp Inoperative Problem detected in wait-to-start bulb circuit.

P0382 (M) Intake Air Heater Relay #2 Control

CircuitProblem detected in #2 air heater solenoid/relay circuit

(not heater element)

P0387 Crankshaft Position Sensor Supply

Voltage Too LowCKP sensor voltage input below the minimum acceptable

voltage.

P0388 Crankshaft Position Sensor Supply

Voltage Too HighCKP sensor voltage input above the maximum acceptable

voltage.

PO0400 Diesel EGR System Failure

P0401 EGR System Failure Required change in air/fuel ration not detected during

diagnostic test.

P0403 EGR Solenoid Circuit An open or shorted condition detected in the EGR

solenoid control circuit.

P0404 EGR Position Sensor Rationality EGR position sensor signal does not correlate to EGR

duty cycle.

P0405 EGR Position Sensor Volts Too Low EGR position sensor input below the acceptable voltage

range.

WJEMISSIONS CONTROL 25 - 7

EMISSIONS CONTROL (Continued)

Page 2166 of 2199

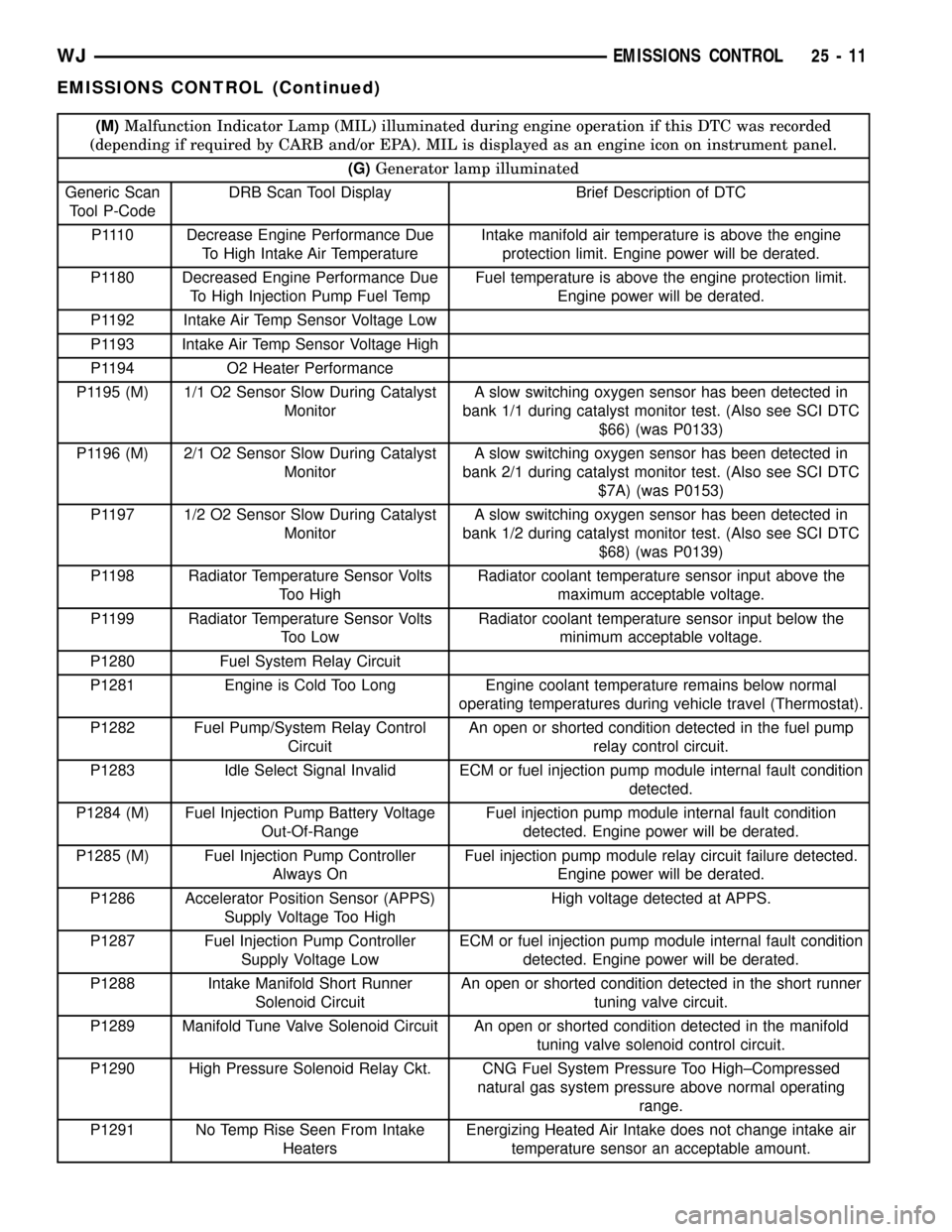

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1110 Decrease Engine Performance Due

To High Intake Air TemperatureIntake manifold air temperature is above the engine

protection limit. Engine power will be derated.

P1180 Decreased Engine Performance Due

To High Injection Pump Fuel TempFuel temperature is above the engine protection limit.

Engine power will be derated.

P1192 Intake Air Temp Sensor Voltage Low

P1193 Intake Air Temp Sensor Voltage High

P1194 O2 Heater Performance

P1195 (M) 1/1 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 1/1 during catalyst monitor test. (Also see SCI DTC

$66) (was P0133)

P1196 (M) 2/1 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 2/1 during catalyst monitor test. (Also see SCI DTC

$7A) (was P0153)

P1197 1/2 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 1/2 during catalyst monitor test. (Also see SCI DTC

$68) (was P0139)

P1198 Radiator Temperature Sensor Volts

Too HighRadiator coolant temperature sensor input above the

maximum acceptable voltage.

P1199 Radiator Temperature Sensor Volts

Too LowRadiator coolant temperature sensor input below the

minimum acceptable voltage.

P1280 Fuel System Relay Circuit

P1281 Engine is Cold Too Long Engine coolant temperature remains below normal

operating temperatures during vehicle travel (Thermostat).

P1282 Fuel Pump/System Relay Control

CircuitAn open or shorted condition detected in the fuel pump

relay control circuit.

P1283 Idle Select Signal Invalid ECM or fuel injection pump module internal fault condition

detected.

P1284 (M) Fuel Injection Pump Battery Voltage

Out-Of-RangeFuel injection pump module internal fault condition

detected. Engine power will be derated.

P1285 (M) Fuel Injection Pump Controller

Always OnFuel injection pump module relay circuit failure detected.

Engine power will be derated.

P1286 Accelerator Position Sensor (APPS)

Supply Voltage Too HighHigh voltage detected at APPS.

P1287 Fuel Injection Pump Controller

Supply Voltage LowECM or fuel injection pump module internal fault condition

detected. Engine power will be derated.

P1288 Intake Manifold Short Runner

Solenoid CircuitAn open or shorted condition detected in the short runner

tuning valve circuit.

P1289 Manifold Tune Valve Solenoid Circuit An open or shorted condition detected in the manifold

tuning valve solenoid control circuit.

P1290 High Pressure Solenoid Relay Ckt. CNG Fuel System Pressure Too High±Compressed

natural gas system pressure above normal operating

range.

P1291 No Temp Rise Seen From Intake

HeatersEnergizing Heated Air Intake does not change intake air

temperature sensor an acceptable amount.

WJEMISSIONS CONTROL 25 - 11

EMISSIONS CONTROL (Continued)

Page 2167 of 2199

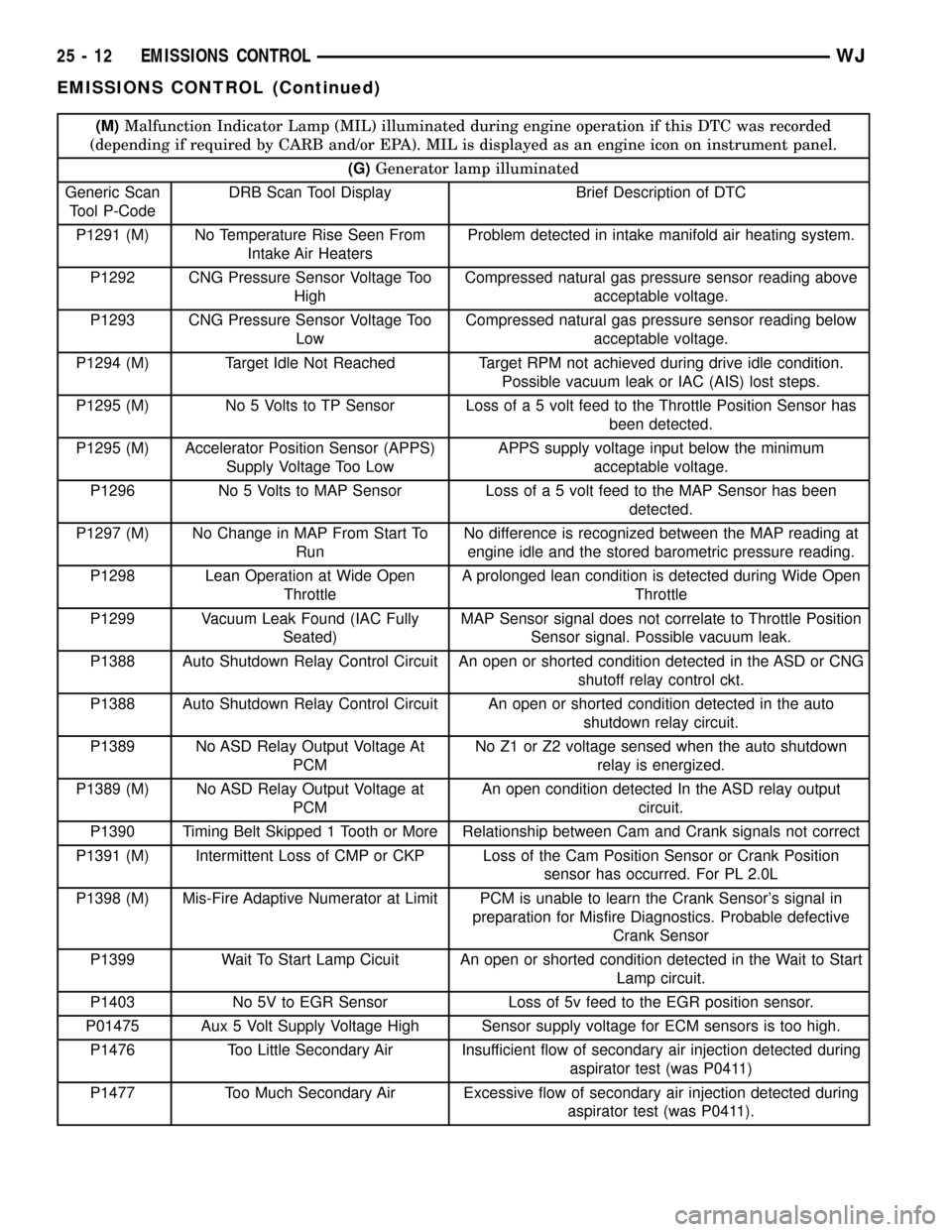

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1291 (M) No Temperature Rise Seen From

Intake Air HeatersProblem detected in intake manifold air heating system.

P1292 CNG Pressure Sensor Voltage Too

HighCompressed natural gas pressure sensor reading above

acceptable voltage.

P1293 CNG Pressure Sensor Voltage Too

LowCompressed natural gas pressure sensor reading below

acceptable voltage.

P1294 (M) Target Idle Not Reached Target RPM not achieved during drive idle condition.

Possible vacuum leak or IAC (AIS) lost steps.

P1295 (M) No 5 Volts to TP Sensor Loss of a 5 volt feed to the Throttle Position Sensor has

been detected.

P1295 (M) Accelerator Position Sensor (APPS)

Supply Voltage Too LowAPPS supply voltage input below the minimum

acceptable voltage.

P1296 No 5 Volts to MAP Sensor Loss of a 5 volt feed to the MAP Sensor has been

detected.

P1297 (M) No Change in MAP From Start To

RunNo difference is recognized between the MAP reading at

engine idle and the stored barometric pressure reading.

P1298 Lean Operation at Wide Open

ThrottleA prolonged lean condition is detected during Wide Open

Throttle

P1299 Vacuum Leak Found (IAC Fully

Seated)MAP Sensor signal does not correlate to Throttle Position

Sensor signal. Possible vacuum leak.

P1388 Auto Shutdown Relay Control Circuit An open or shorted condition detected in the ASD or CNG

shutoff relay control ckt.

P1388 Auto Shutdown Relay Control Circuit An open or shorted condition detected in the auto

shutdown relay circuit.

P1389 No ASD Relay Output Voltage At

PCMNo Z1 or Z2 voltage sensed when the auto shutdown

relay is energized.

P1389 (M) No ASD Relay Output Voltage at

PCMAn open condition detected In the ASD relay output

circuit.

P1390 Timing Belt Skipped 1 Tooth or More Relationship between Cam and Crank signals not correct

P1391 (M) Intermittent Loss of CMP or CKP Loss of the Cam Position Sensor or Crank Position

sensor has occurred. For PL 2.0L

P1398 (M) Mis-Fire Adaptive Numerator at Limit PCM is unable to learn the Crank Sensor's signal in

preparation for Misfire Diagnostics. Probable defective

Crank Sensor

P1399 Wait To Start Lamp Cicuit An open or shorted condition detected in the Wait to Start

Lamp circuit.

P1403 No 5V to EGR Sensor Loss of 5v feed to the EGR position sensor.

P01475 Aux 5 Volt Supply Voltage High Sensor supply voltage for ECM sensors is too high.

P1476 Too Little Secondary Air Insufficient flow of secondary air injection detected during

aspirator test (was P0411)

P1477 Too Much Secondary Air Excessive flow of secondary air injection detected during

aspirator test (was P0411).

25 - 12 EMISSIONS CONTROLWJ

EMISSIONS CONTROL (Continued)

Page 2179 of 2199

EVAPORATIVE EMISSIONS

TABLE OF CONTENTS

page page

EVAPORATIVE EMISSIONS

DESCRIPTION

DESCRIPTION - EVAPORATION CONTROL

SYSTEM............................24

DESCRIPTION - CCV SYSTEM...........25

DESCRIPTION - PCV SYSTEM...........25

OPERATION

OPERATION - 4.0L CCV SYSTEM.........26

OPERATION - 4.7L PCV SYSTEM.........26

SPECIFICATIONS

TORQUE - EVAPORATION SYSTEM.......27

CCV HOSE

DIAGNOSIS AND TESTING - CCV SYSTEM -

4.0L................................28

REMOVAL - FIXED ORIFICE FITTING........28

INSTALLATION - FIXED ORIFICE FITTING....29

EVAP/PURGE SOLENOID

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................29

INSTALLATION.........................29

FUEL FILLER CAP

DESCRIPTION.........................29

OPERATION...........................29REMOVAL.............................29

LEAK DETECTION PUMP

DESCRIPTION.........................30

OPERATION...........................31

DIAGNOSIS AND TESTING - ENABLING

CONDITIONS TO RUN EVAP LEAK

DETECTION TEST.....................32

REMOVAL.............................35

INSTALLATION.........................35

ORVR

DESCRIPTION.........................37

OPERATION...........................37

P C V VA LV E

DIAGNOSIS AND TESTING - PCV VALVE/PCV

SYSTEM - 4.7L.......................37

REMOVAL - PCV VALVE - 4.7L.............39

INSTALLATION - PCV VALVE - 4.7L.........39

VACUUM LINES

DESCRIPTION.........................39

VAPOR CANISTER

DESCRIPTION.........................39

OPERATION...........................39

REMOVAL.............................40

INSTALLATION.........................40

EVAPORATIVE EMISSIONS

DESCRIPTION

DESCRIPTION - EVAPORATION CONTROL

SYSTEM

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When

fuel evaporates in the fuel tank, the vapors pass

through the control valve, through the fuel manage-

ment valve, and through vent hoses and tubes to a

charcoal filled evaporative canister. The canister tem-

porarily holds the vapors. The Powertrain Control

Module (PCM) allows intake manifold vacuum todraw vapors into the combustion chambers during

certain operating conditions.

Gas powered engines use a duty cycle purge sys-

tem. The PCM controls vapor flow by operating the

duty cycle EVAP purge solenoid. Refer to Duty Cycle

EVAP Canister Purge Solenoid.

When equipped with certain emissions packages, a

Leak Detection Pump (LDP) will be used as part of

the evaporative system for OBD II requirements.

Also refer to Leak Detection Pump.

Vehicles powered with gasoline engines are also

equipped with ORVR (On-Board Refueling Vapor

Recovery). Refer to ORVR for additional information.

25 - 24 EVAPORATIVE EMISSIONSWJ

Page 2181 of 2199

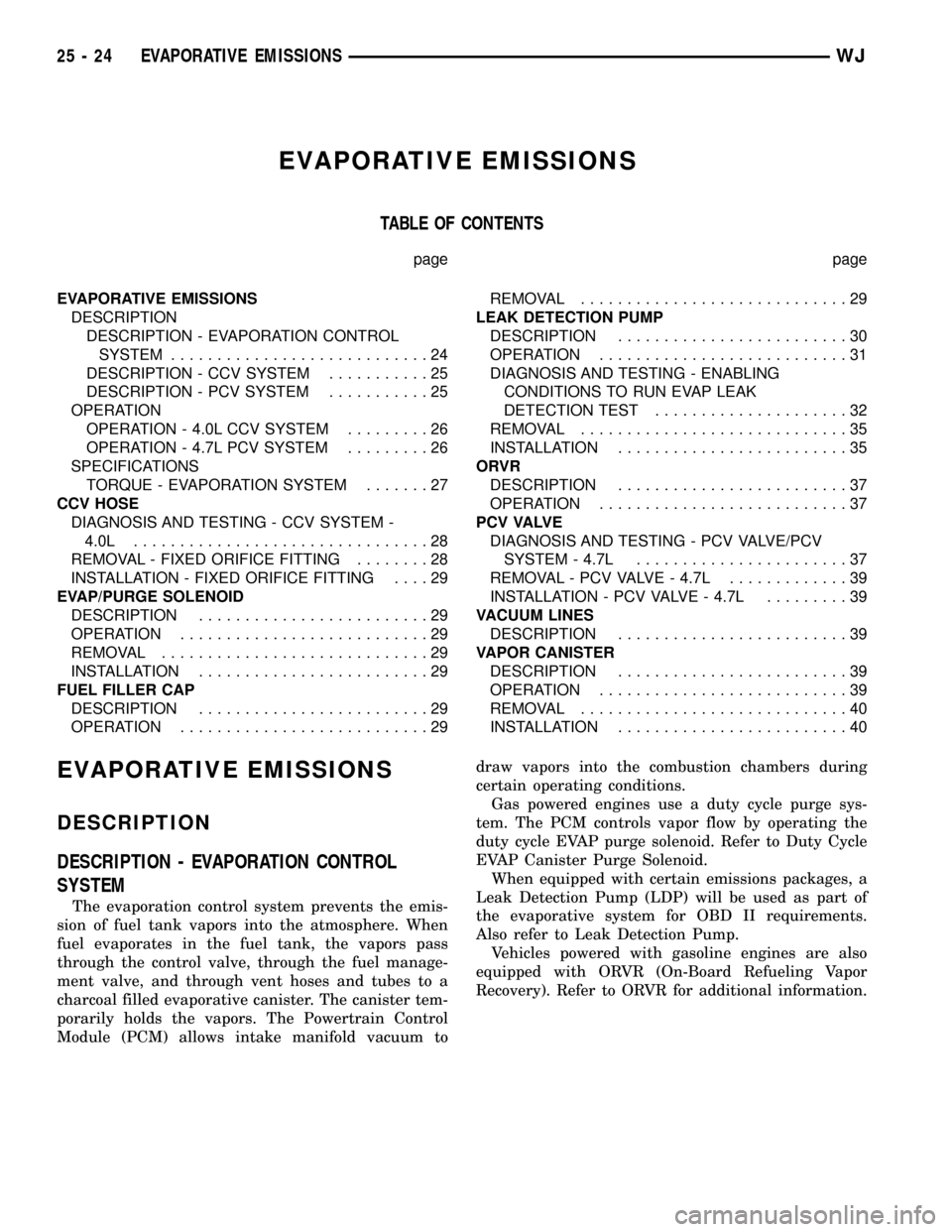

²a PCV valve mounted to the oil filler housing

(Fig. 3). The PCV valve is sealed to the oil filler

housing with an o-ring.

²the air cleaner housing

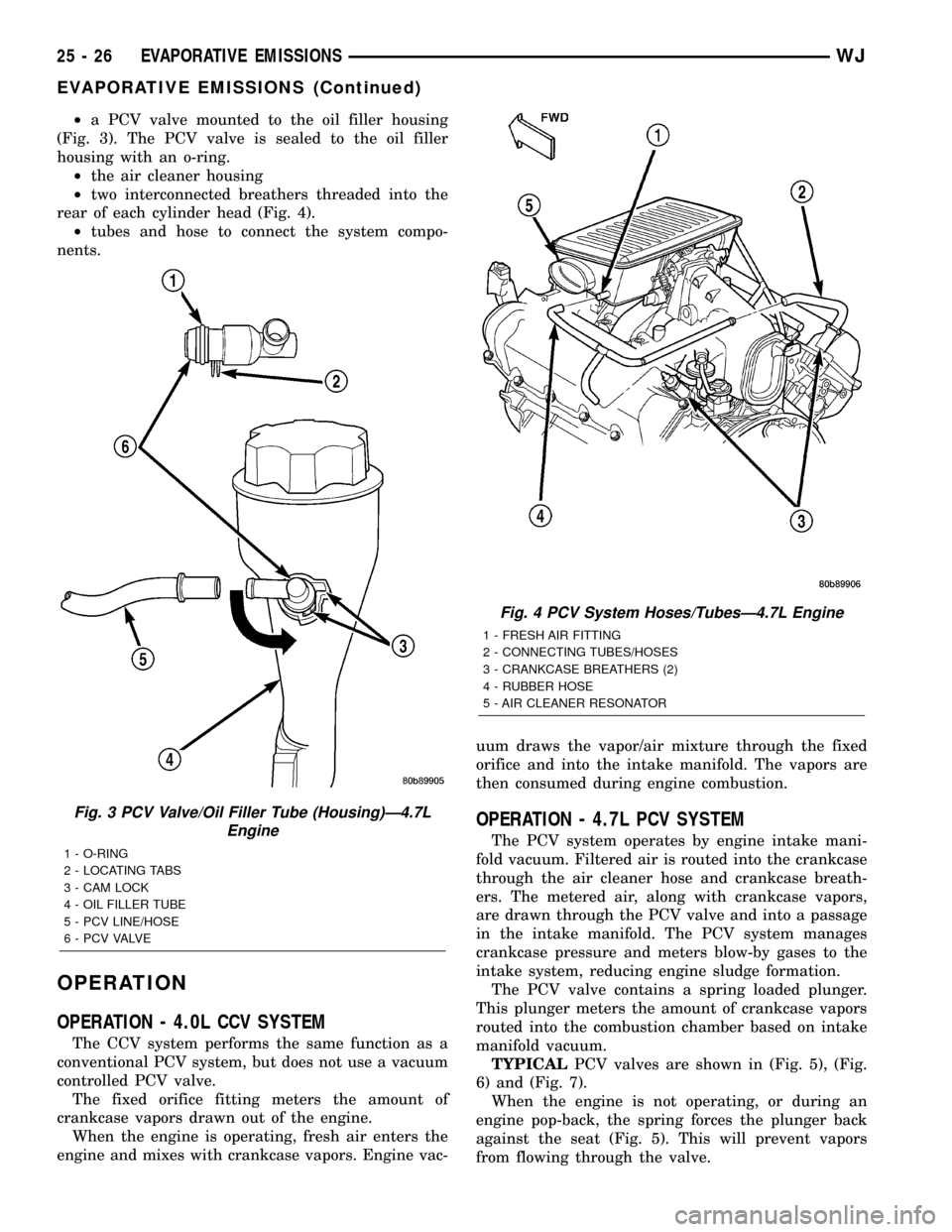

²two interconnected breathers threaded into the

rear of each cylinder head (Fig. 4).

²tubes and hose to connect the system compo-

nents.

OPERATION

OPERATION - 4.0L CCV SYSTEM

The CCV system performs the same function as a

conventional PCV system, but does not use a vacuum

controlled PCV valve.

The fixed orifice fitting meters the amount of

crankcase vapors drawn out of the engine.

When the engine is operating, fresh air enters the

engine and mixes with crankcase vapors. Engine vac-uum draws the vapor/air mixture through the fixed

orifice and into the intake manifold. The vapors are

then consumed during engine combustion.

OPERATION - 4.7L PCV SYSTEM

The PCV system operates by engine intake mani-

fold vacuum. Filtered air is routed into the crankcase

through the air cleaner hose and crankcase breath-

ers. The metered air, along with crankcase vapors,

are drawn through the PCV valve and into a passage

in the intake manifold. The PCV system manages

crankcase pressure and meters blow-by gases to the

intake system, reducing engine sludge formation.

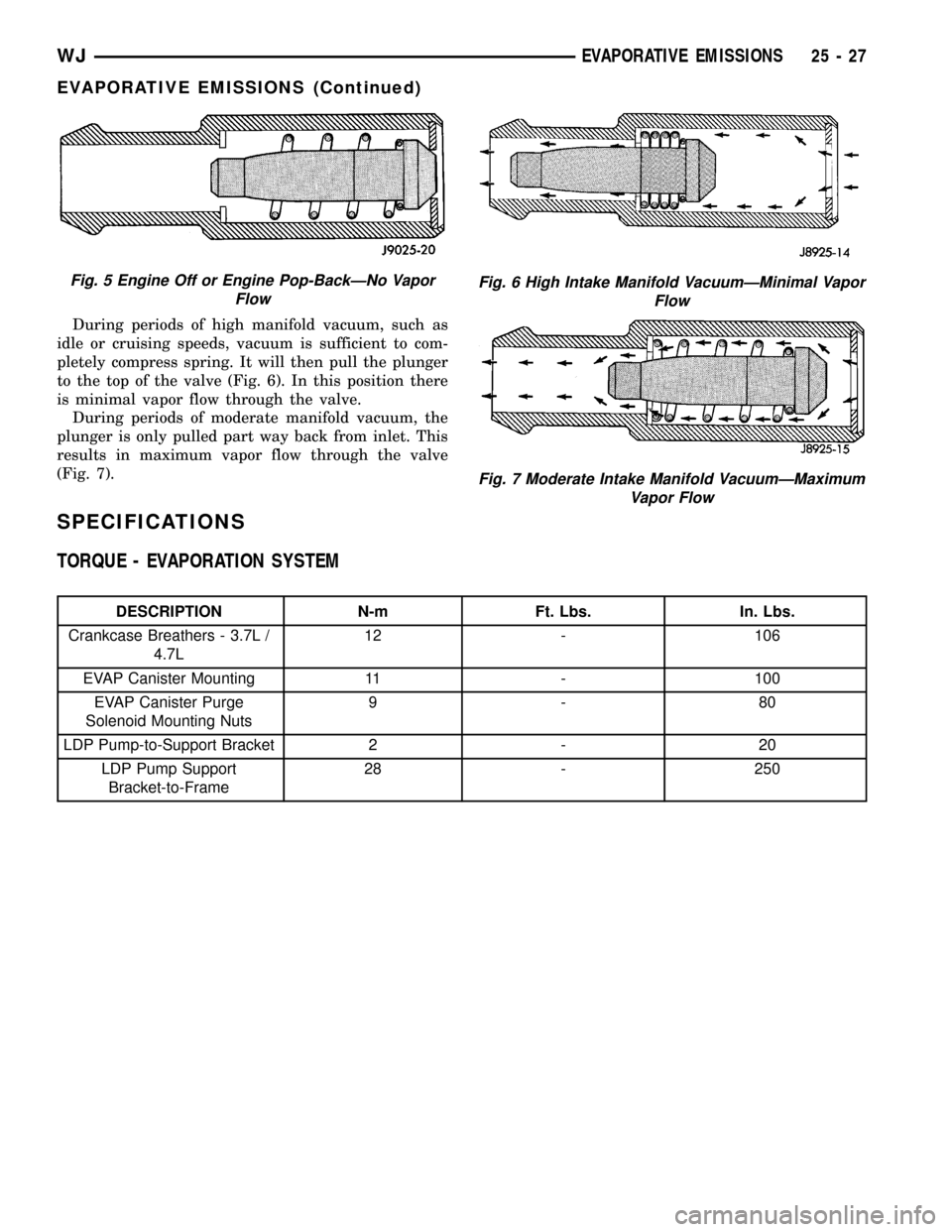

The PCV valve contains a spring loaded plunger.

This plunger meters the amount of crankcase vapors

routed into the combustion chamber based on intake

manifold vacuum.

TYPICALPCV valves are shown in (Fig. 5), (Fig.

6) and (Fig. 7).

When the engine is not operating, or during an

engine pop-back, the spring forces the plunger back

against the seat (Fig. 5). This will prevent vapors

from flowing through the valve.

Fig. 3 PCV Valve/Oil Filler Tube (Housing)Ð4.7L

Engine

1 - O-RING

2 - LOCATING TABS

3 - CAM LOCK

4 - OIL FILLER TUBE

5 - PCV LINE/HOSE

6 - P C V VA LV E

Fig. 4 PCV System Hoses/TubesÐ4.7L Engine

1 - FRESH AIR FITTING

2 - CONNECTING TUBES/HOSES

3 - CRANKCASE BREATHERS (2)

4 - RUBBER HOSE

5 - AIR CLEANER RESONATOR

25 - 26 EVAPORATIVE EMISSIONSWJ

EVAPORATIVE EMISSIONS (Continued)

Page 2182 of 2199

During periods of high manifold vacuum, such as

idle or cruising speeds, vacuum is sufficient to com-

pletely compress spring. It will then pull the plunger

to the top of the valve (Fig. 6). In this position there

is minimal vapor flow through the valve.

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve

(Fig. 7).

SPECIFICATIONS

TORQUE - EVAPORATION SYSTEM

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Crankcase Breathers - 3.7L /

4.7L12 - 106

EVAP Canister Mounting 11 - 100

EVAP Canister Purge

Solenoid Mounting Nuts9- 80

LDP Pump-to-Support Bracket 2 - 20

LDP Pump Support

Bracket-to-Frame28 - 250

Fig. 5 Engine Off or Engine Pop-BackÐNo Vapor

FlowFig. 6 High Intake Manifold VacuumÐMinimal Vapor

Flow

Fig. 7 Moderate Intake Manifold VacuumÐMaximum

Vapor Flow

WJEVAPORATIVE EMISSIONS 25 - 27

EVAPORATIVE EMISSIONS (Continued)

Page 2183 of 2199

CCV HOSE

DIAGNOSIS AND TESTING - CCV SYSTEM -

4.0L

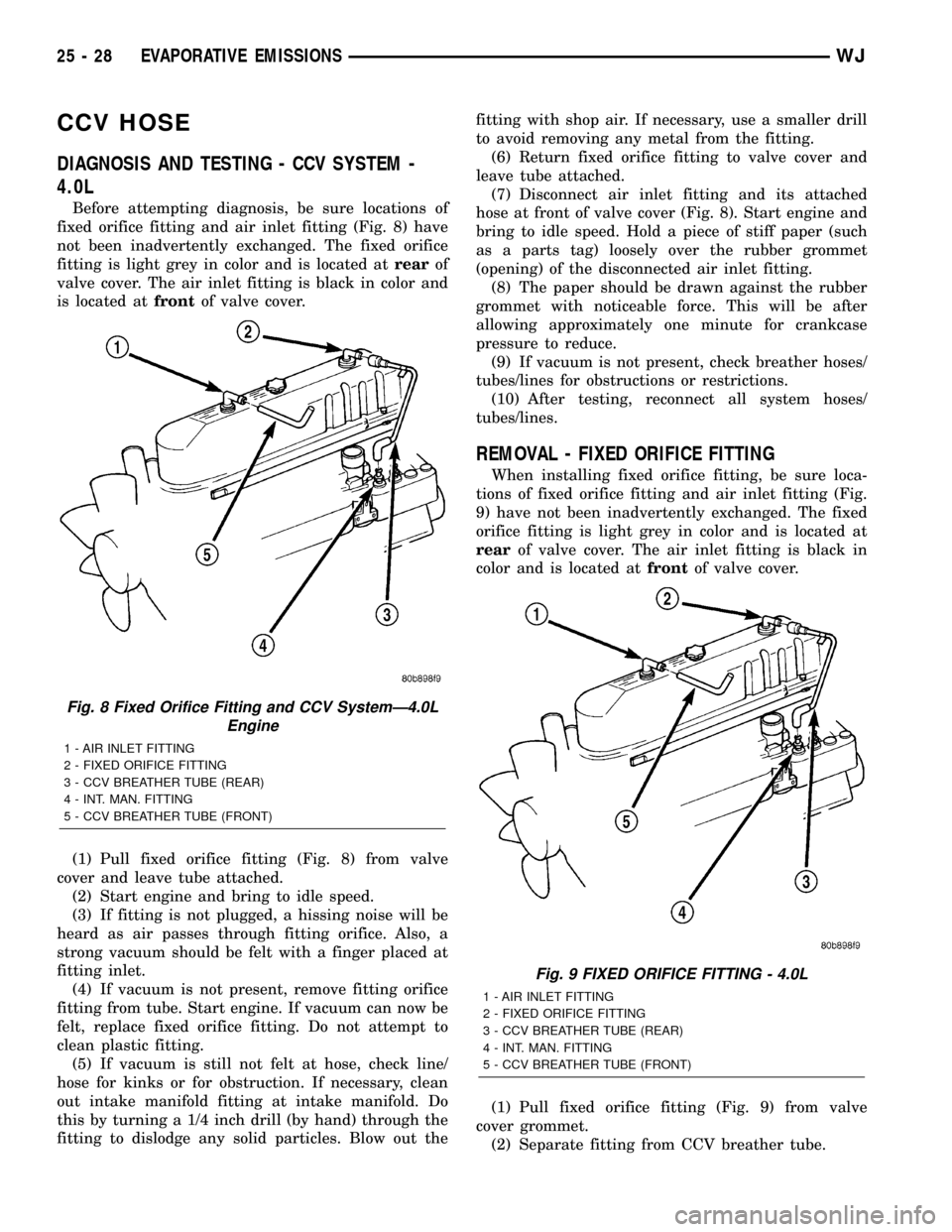

Before attempting diagnosis, be sure locations of

fixed orifice fitting and air inlet fitting (Fig. 8) have

not been inadvertently exchanged. The fixed orifice

fitting is light grey in color and is located atrearof

valve cover. The air inlet fitting is black in color and

is located atfrontof valve cover.

(1) Pull fixed orifice fitting (Fig. 8) from valve

cover and leave tube attached.

(2) Start engine and bring to idle speed.

(3) If fitting is not plugged, a hissing noise will be

heard as air passes through fitting orifice. Also, a

strong vacuum should be felt with a finger placed at

fitting inlet.

(4) If vacuum is not present, remove fitting orifice

fitting from tube. Start engine. If vacuum can now be

felt, replace fixed orifice fitting. Do not attempt to

clean plastic fitting.

(5) If vacuum is still not felt at hose, check line/

hose for kinks or for obstruction. If necessary, clean

out intake manifold fitting at intake manifold. Do

this by turning a 1/4 inch drill (by hand) through the

fitting to dislodge any solid particles. Blow out thefitting with shop air. If necessary, use a smaller drill

to avoid removing any metal from the fitting.

(6) Return fixed orifice fitting to valve cover and

leave tube attached.

(7) Disconnect air inlet fitting and its attached

hose at front of valve cover (Fig. 8). Start engine and

bring to idle speed. Hold a piece of stiff paper (such

as a parts tag) loosely over the rubber grommet

(opening) of the disconnected air inlet fitting.

(8) The paper should be drawn against the rubber

grommet with noticeable force. This will be after

allowing approximately one minute for crankcase

pressure to reduce.

(9) If vacuum is not present, check breather hoses/

tubes/lines for obstructions or restrictions.

(10) After testing, reconnect all system hoses/

tubes/lines.

REMOVAL - FIXED ORIFICE FITTING

When installing fixed orifice fitting, be sure loca-

tions of fixed orifice fitting and air inlet fitting (Fig.

9) have not been inadvertently exchanged. The fixed

orifice fitting is light grey in color and is located at

rearof valve cover. The air inlet fitting is black in

color and is located atfrontof valve cover.

(1) Pull fixed orifice fitting (Fig. 9) from valve

cover grommet.

(2) Separate fitting from CCV breather tube.

Fig. 8 Fixed Orifice Fitting and CCV SystemÐ4.0L

Engine

1 - AIR INLET FITTING

2 - FIXED ORIFICE FITTING

3 - CCV BREATHER TUBE (REAR)

4 - INT. MAN. FITTING

5 - CCV BREATHER TUBE (FRONT)

Fig. 9 FIXED ORIFICE FITTING - 4.0L

1 - AIR INLET FITTING

2 - FIXED ORIFICE FITTING

3 - CCV BREATHER TUBE (REAR)

4 - INT. MAN. FITTING

5 - CCV BREATHER TUBE (FRONT)

25 - 28 EVAPORATIVE EMISSIONSWJ

Page 2184 of 2199

INSTALLATION - FIXED ORIFICE FITTING

When installing fixed orifice fitting, be sure loca-

tions of fixed orifice fitting and air inlet fitting (Fig.

9) have not been inadvertently exchanged. The fixed

orifice fitting is light grey in color and is located at

rearof valve cover. The air inlet fitting is black in

color and is located atfrontof valve cover.

(1) Connect fitting to CCV breather tube.

(2) Return fixed orifice fitting to valve cover grom-

met.

EVAP/PURGE SOLENOID

DESCRIPTION

The duty cycle EVAP canister purge solenoid (DCP)

regulates the rate of vapor flow from the EVAP can-

ister to the intake manifold. The Powertrain Control

Module (PCM) operates the solenoid.

OPERATION

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged. The

PCM de-energizes the solenoid during open loop oper-

ation.

The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM cycles

(energizes and de-energizes) the solenoid 5 or 10

times per second, depending upon operating condi-

tions. The PCM varies the vapor flow rate by chang-

ing solenoid pulse width. Pulse width is the amount

of time that the solenoid is energized. The PCM

adjusts solenoid pulse width based on engine operat-

ing condition.

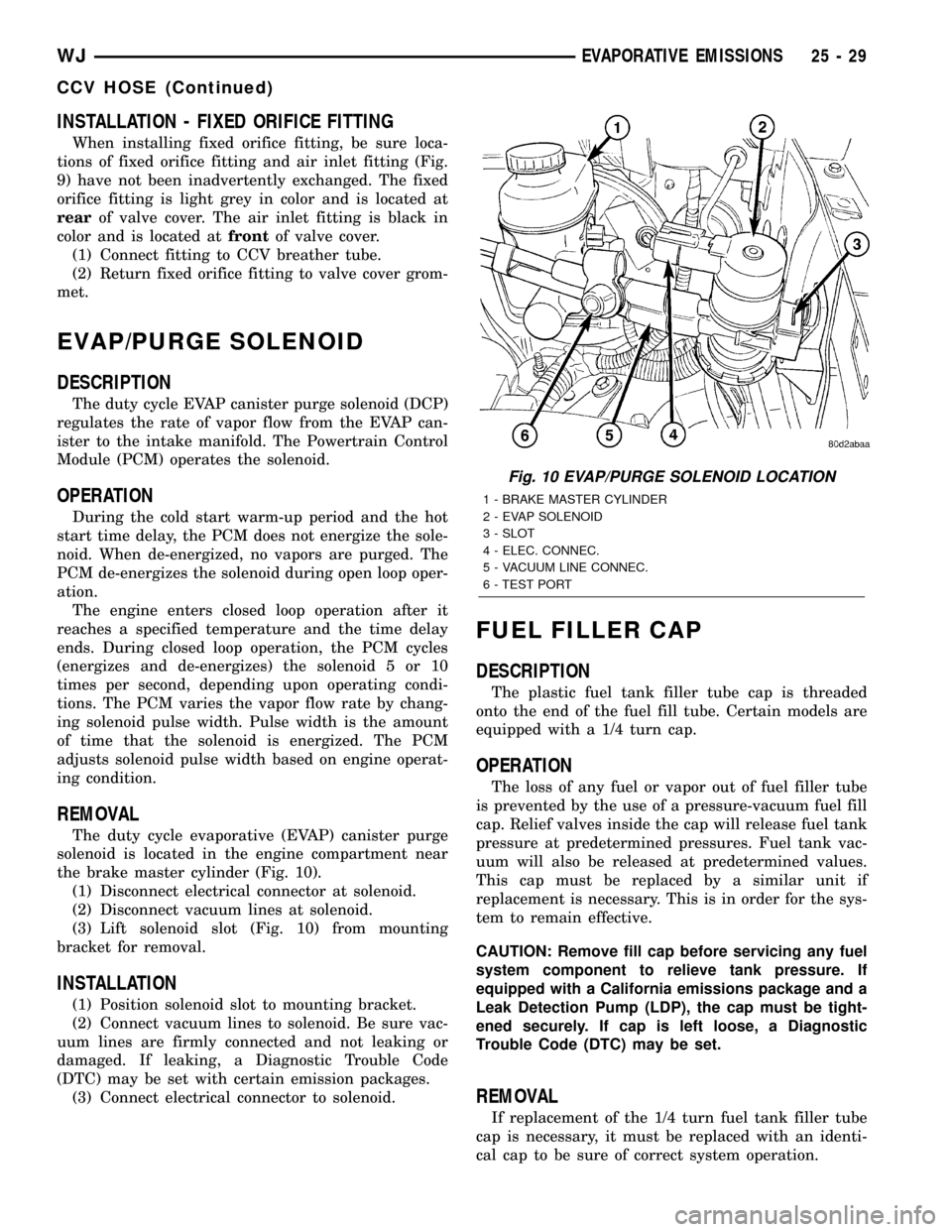

REMOVAL

The duty cycle evaporative (EVAP) canister purge

solenoid is located in the engine compartment near

the brake master cylinder (Fig. 10).

(1) Disconnect electrical connector at solenoid.

(2) Disconnect vacuum lines at solenoid.

(3) Lift solenoid slot (Fig. 10) from mounting

bracket for removal.

INSTALLATION

(1) Position solenoid slot to mounting bracket.

(2) Connect vacuum lines to solenoid. Be sure vac-

uum lines are firmly connected and not leaking or

damaged. If leaking, a Diagnostic Trouble Code

(DTC) may be set with certain emission packages.

(3) Connect electrical connector to solenoid.

FUEL FILLER CAP

DESCRIPTION

The plastic fuel tank filler tube cap is threaded

onto the end of the fuel fill tube. Certain models are

equipped with a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube

is prevented by the use of a pressure-vacuum fuel fill

cap. Relief valves inside the cap will release fuel tank

pressure at predetermined pressures. Fuel tank vac-

uum will also be released at predetermined values.

This cap must be replaced by a similar unit if

replacement is necessary. This is in order for the sys-

tem to remain effective.

CAUTION: Remove fill cap before servicing any fuel

system component to relieve tank pressure. If

equipped with a California emissions package and a

Leak Detection Pump (LDP), the cap must be tight-

ened securely. If cap is left loose, a Diagnostic

Trouble Code (DTC) may be set.

REMOVAL

If replacement of the 1/4 turn fuel tank filler tube

cap is necessary, it must be replaced with an identi-

cal cap to be sure of correct system operation.

Fig. 10 EVAP/PURGE SOLENOID LOCATION

1 - BRAKE MASTER CYLINDER

2 - EVAP SOLENOID

3 - SLOT

4 - ELEC. CONNEC.

5 - VACUUM LINE CONNEC.

6 - TEST PORT

WJEVAPORATIVE EMISSIONS 25 - 29

CCV HOSE (Continued)

Page 2185 of 2199

CAUTION: Remove the fuel tank filler tube cap to

relieve fuel tank pressure. The cap must be

removed prior to disconnecting any fuel system

component or before draining the fuel tank.

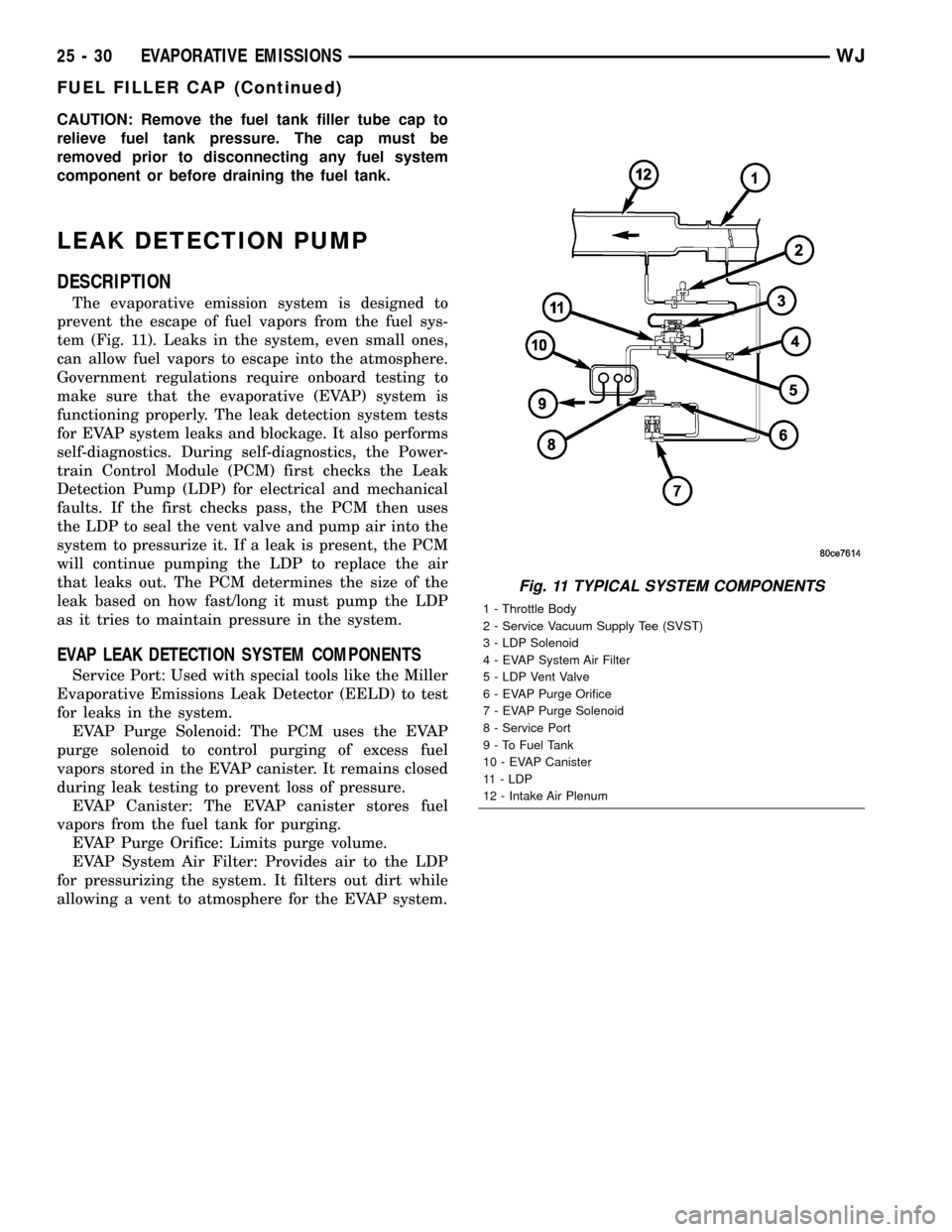

LEAK DETECTION PUMP

DESCRIPTION

The evaporative emission system is designed to

prevent the escape of fuel vapors from the fuel sys-

tem (Fig. 11). Leaks in the system, even small ones,

can allow fuel vapors to escape into the atmosphere.

Government regulations require onboard testing to

make sure that the evaporative (EVAP) system is

functioning properly. The leak detection system tests

for EVAP system leaks and blockage. It also performs

self-diagnostics. During self-diagnostics, the Power-

train Control Module (PCM) first checks the Leak

Detection Pump (LDP) for electrical and mechanical

faults. If the first checks pass, the PCM then uses

the LDP to seal the vent valve and pump air into the

system to pressurize it. If a leak is present, the PCM

will continue pumping the LDP to replace the air

that leaks out. The PCM determines the size of the

leak based on how fast/long it must pump the LDP

as it tries to maintain pressure in the system.

EVAP LEAK DETECTION SYSTEM COMPONENTS

Service Port: Used with special tools like the Miller

Evaporative Emissions Leak Detector (EELD) to test

for leaks in the system.

EVAP Purge Solenoid: The PCM uses the EVAP

purge solenoid to control purging of excess fuel

vapors stored in the EVAP canister. It remains closed

during leak testing to prevent loss of pressure.

EVAP Canister: The EVAP canister stores fuel

vapors from the fuel tank for purging.

EVAP Purge Orifice: Limits purge volume.

EVAP System Air Filter: Provides air to the LDP

for pressurizing the system. It filters out dirt while

allowing a vent to atmosphere for the EVAP system.

Fig. 11 TYPICAL SYSTEM COMPONENTS

1 - Throttle Body

2 - Service Vacuum Supply Tee (SVST)

3 - LDP Solenoid

4 - EVAP System Air Filter

5 - LDP Vent Valve

6 - EVAP Purge Orifice

7 - EVAP Purge Solenoid

8 - Service Port

9 - To Fuel Tank

10 - EVAP Canister

11 - LDP

12 - Intake Air Plenum

25 - 30 EVAPORATIVE EMISSIONSWJ

FUEL FILLER CAP (Continued)